Intelligent Laser Micro/Nano Processing: Research and Advances

Abstract

1. Introduction

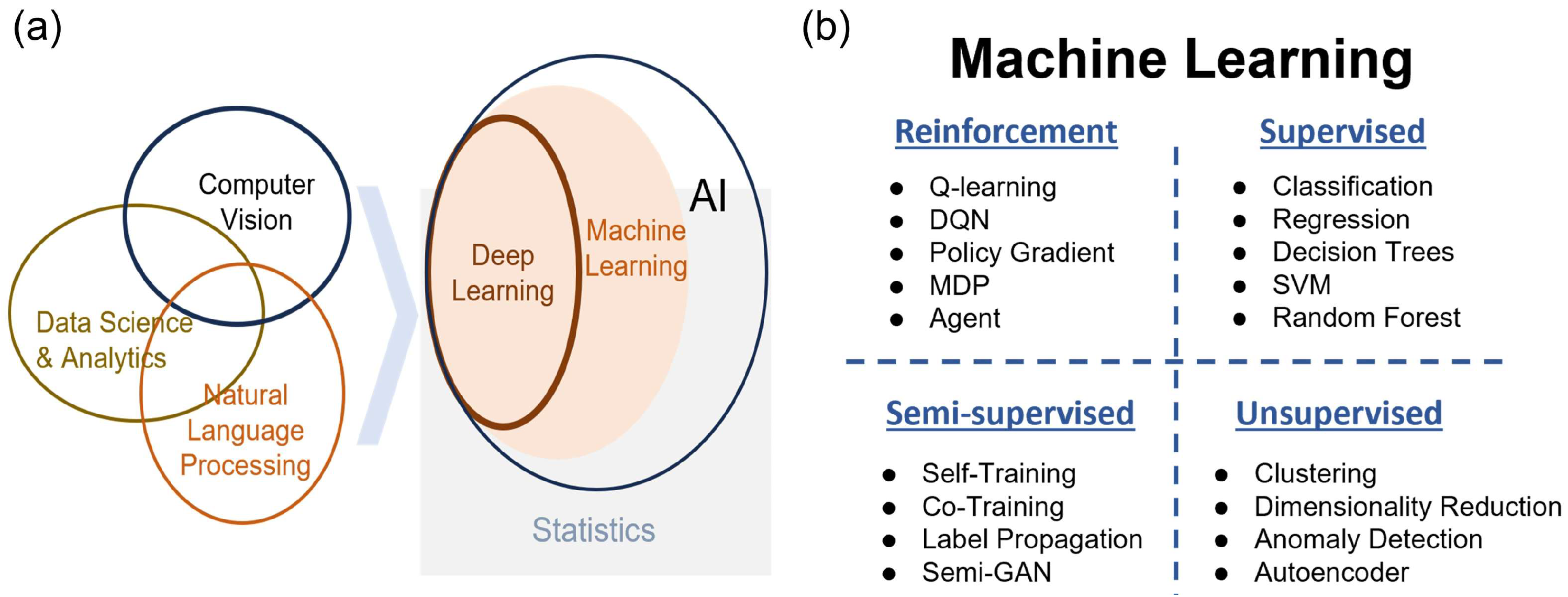

2. Machine Learning-Assisted Modeling Workflow

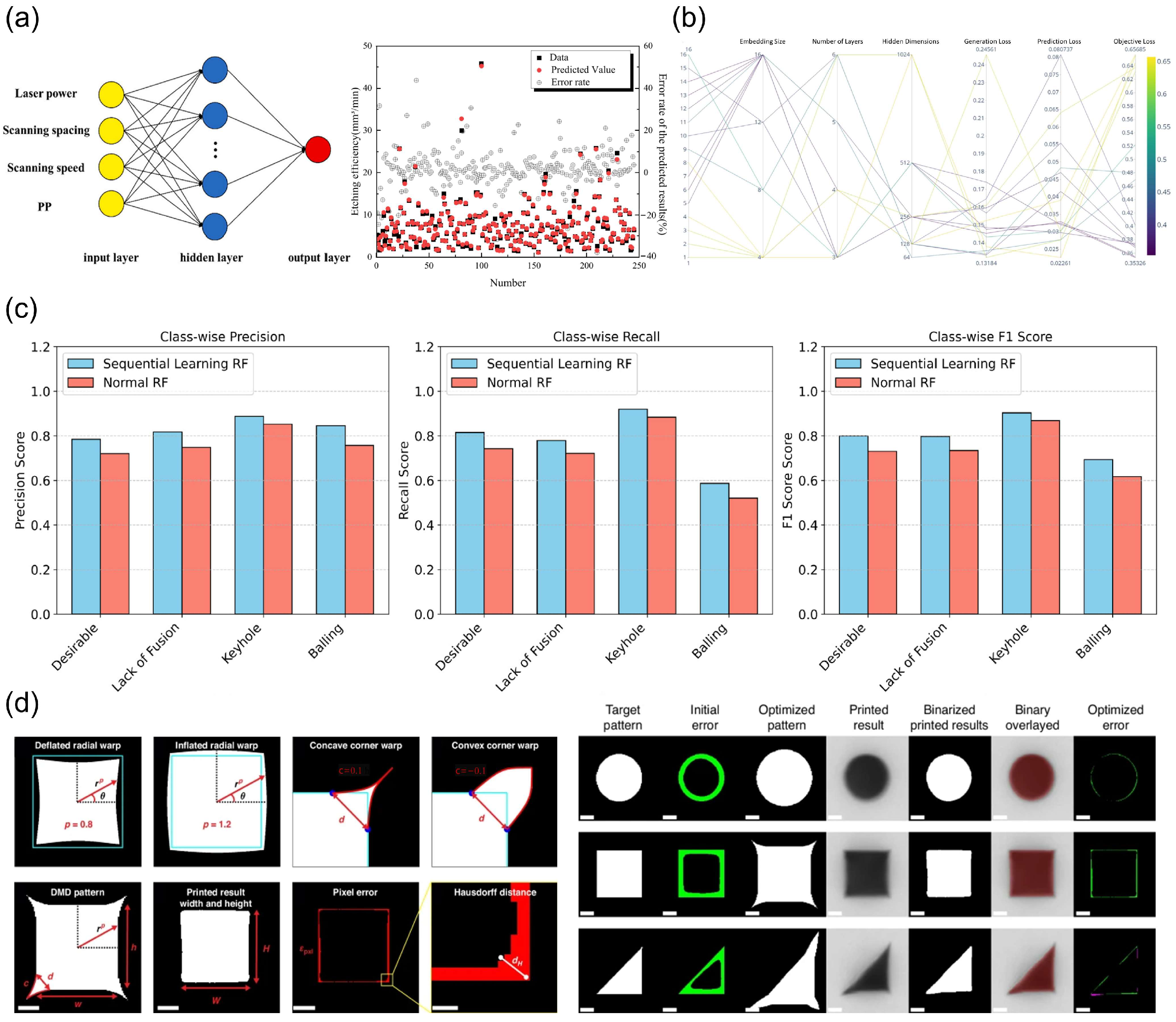

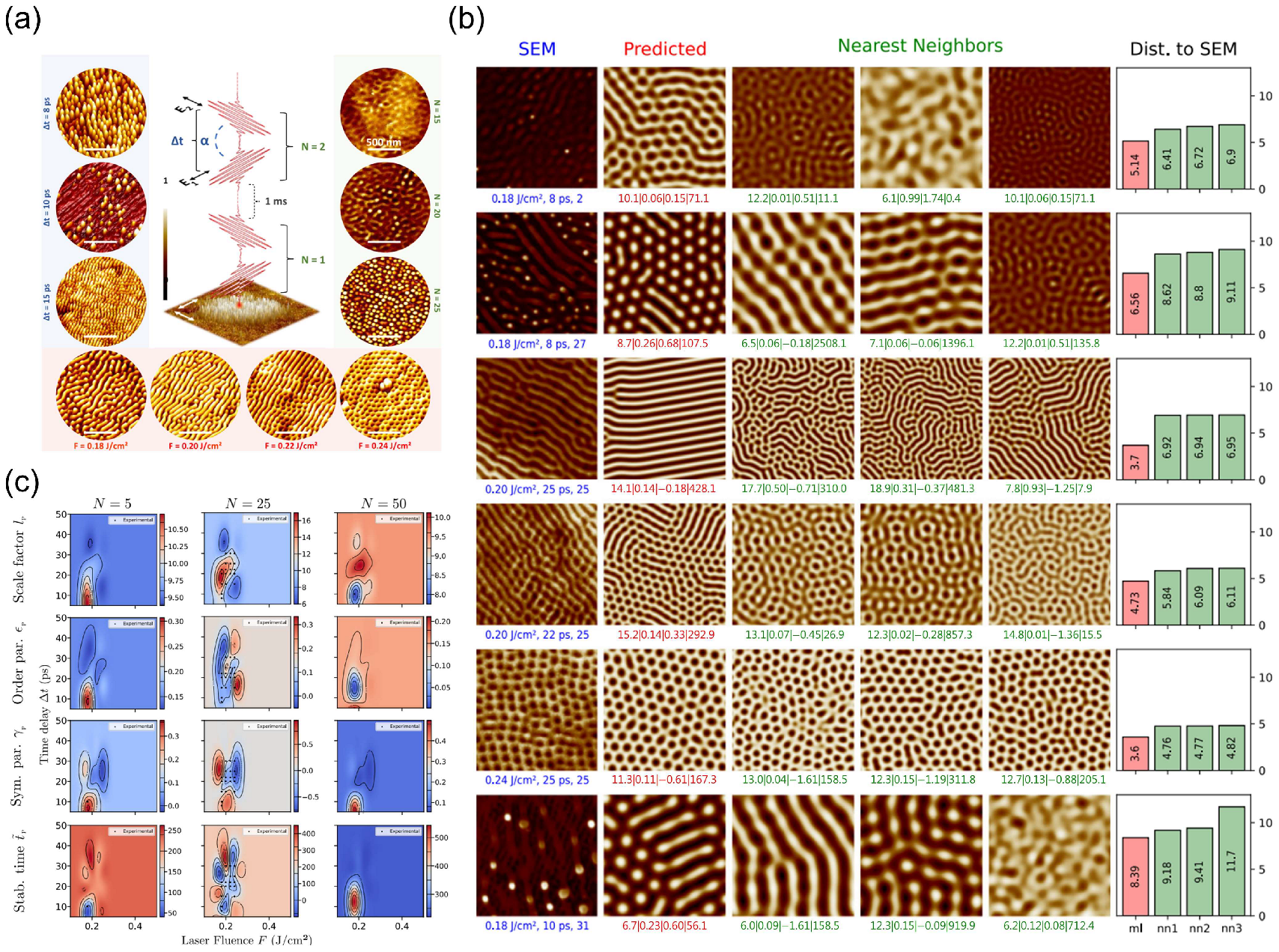

2.1. Data-Driven Modeling

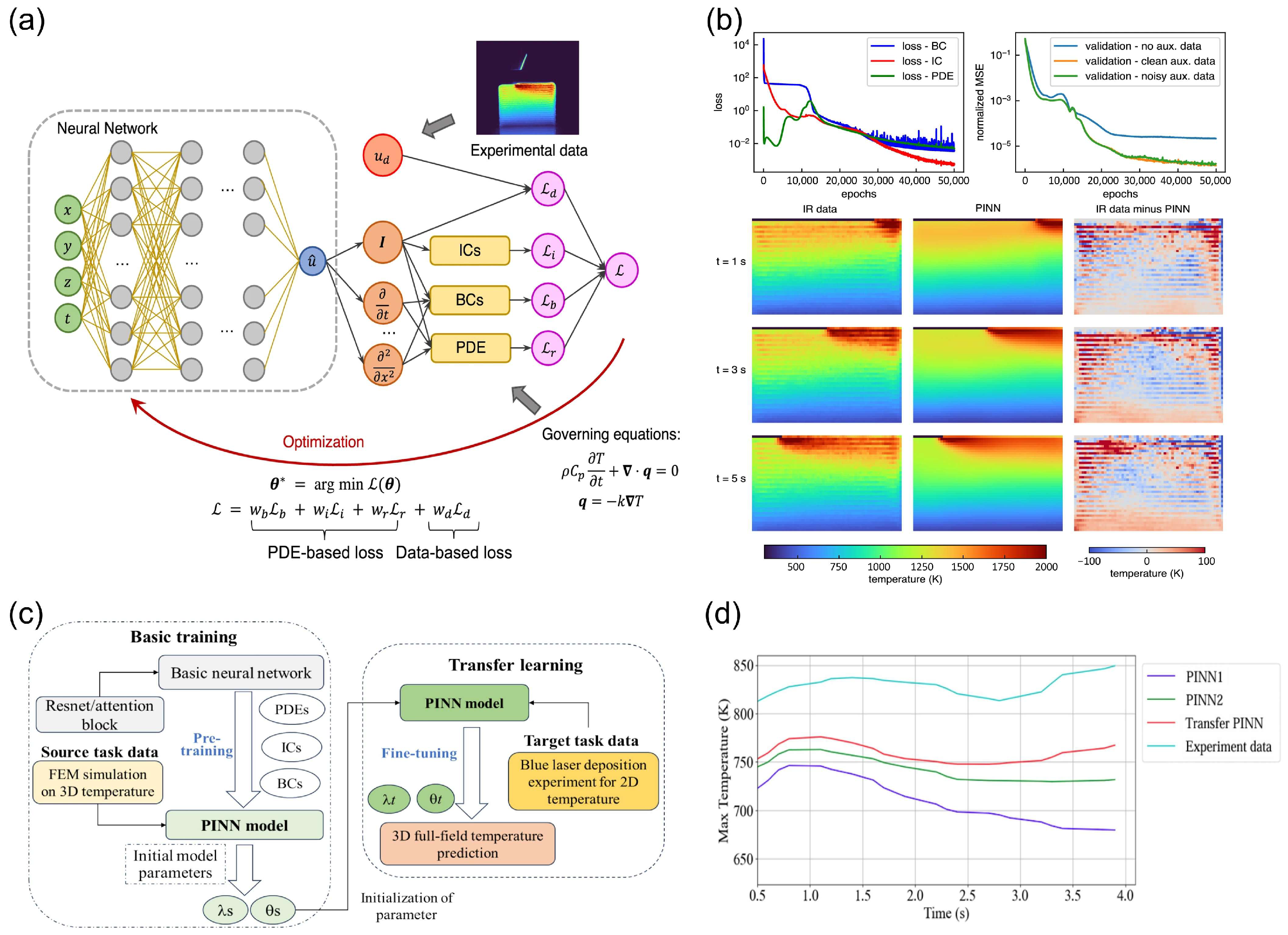

2.2. Physics-Driven Modeling

3. In Situ Monitoring and Feedback Control

3.1. In Situ Monitoring

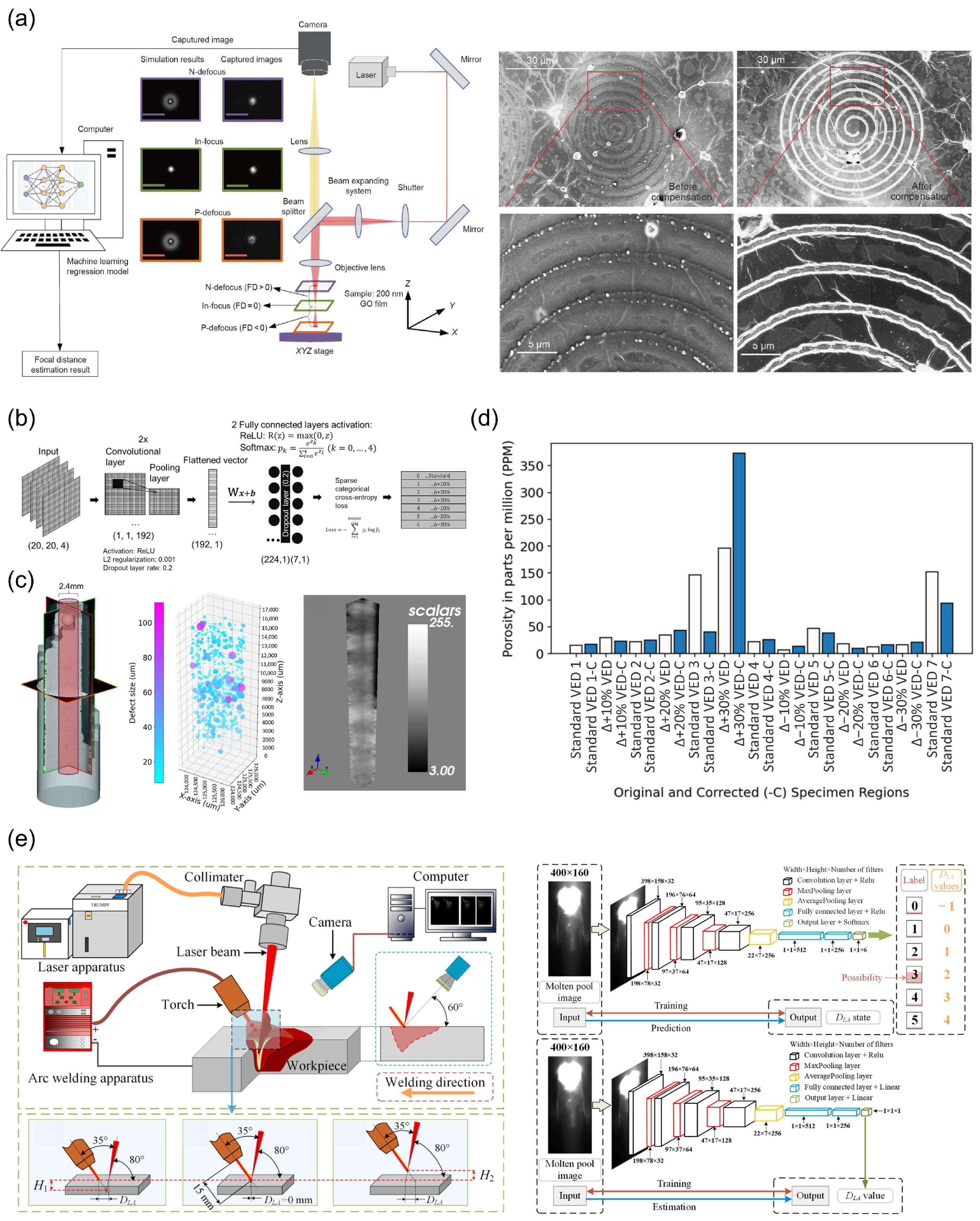

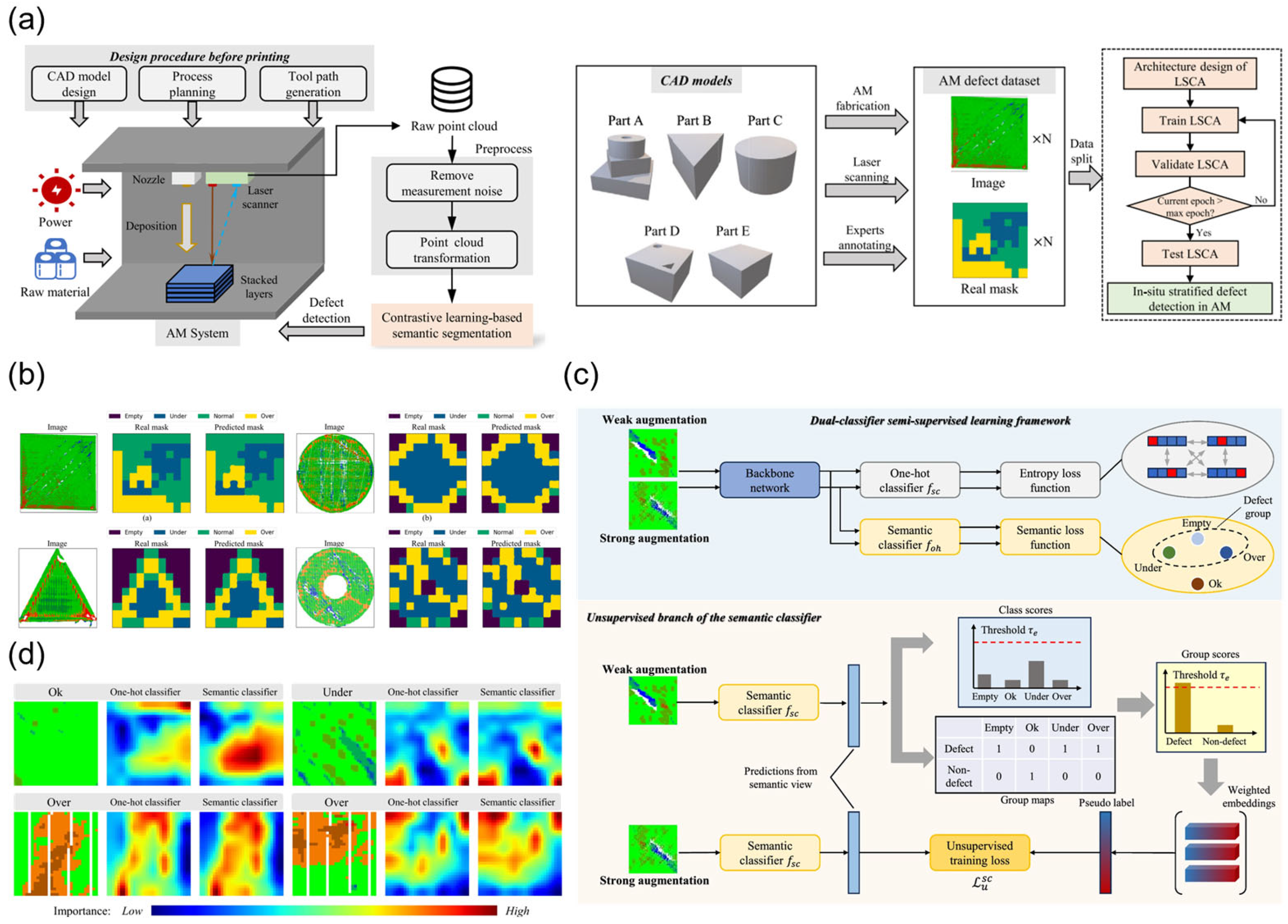

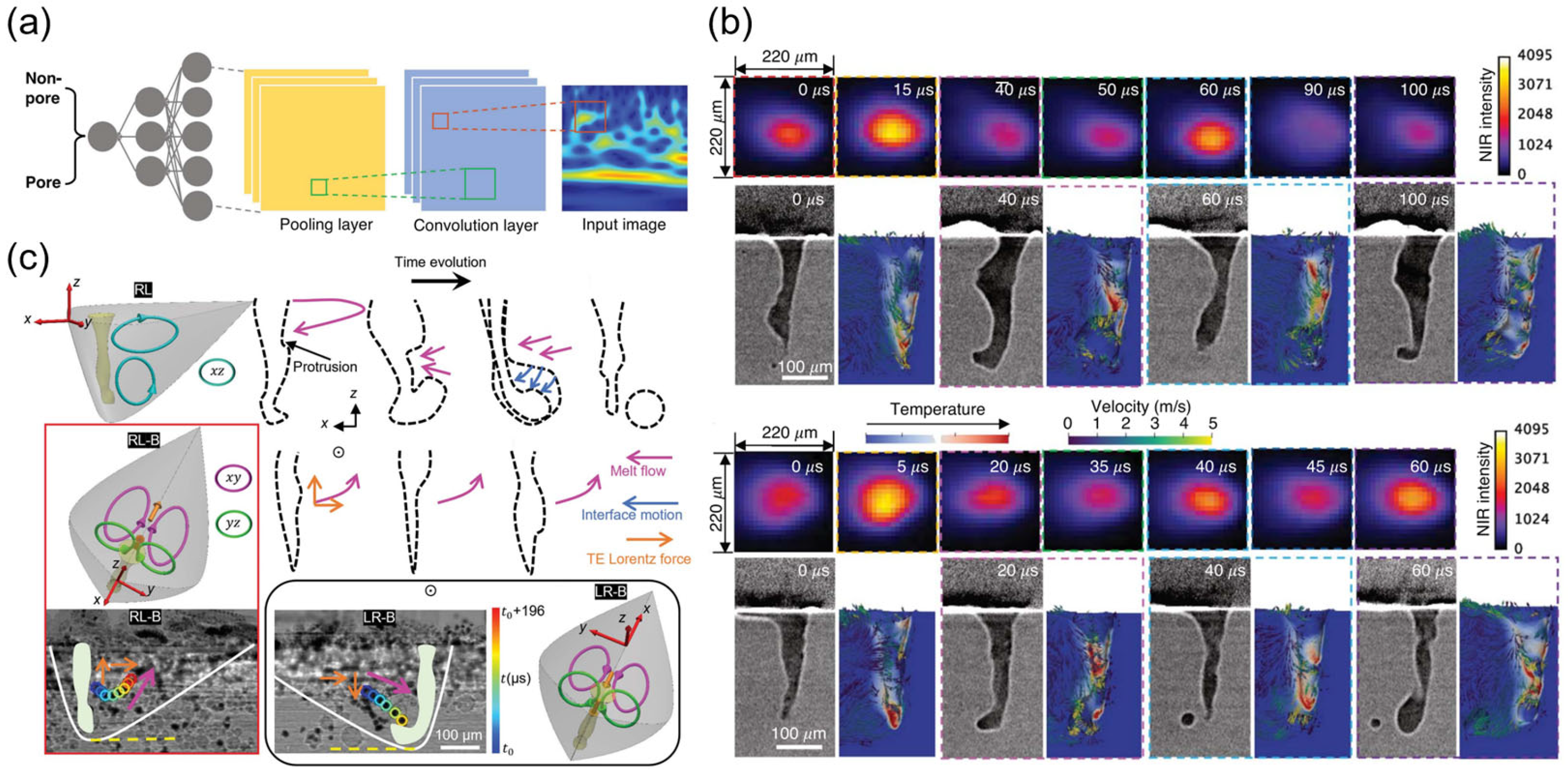

3.1.1. Optical Image-Based Inspection

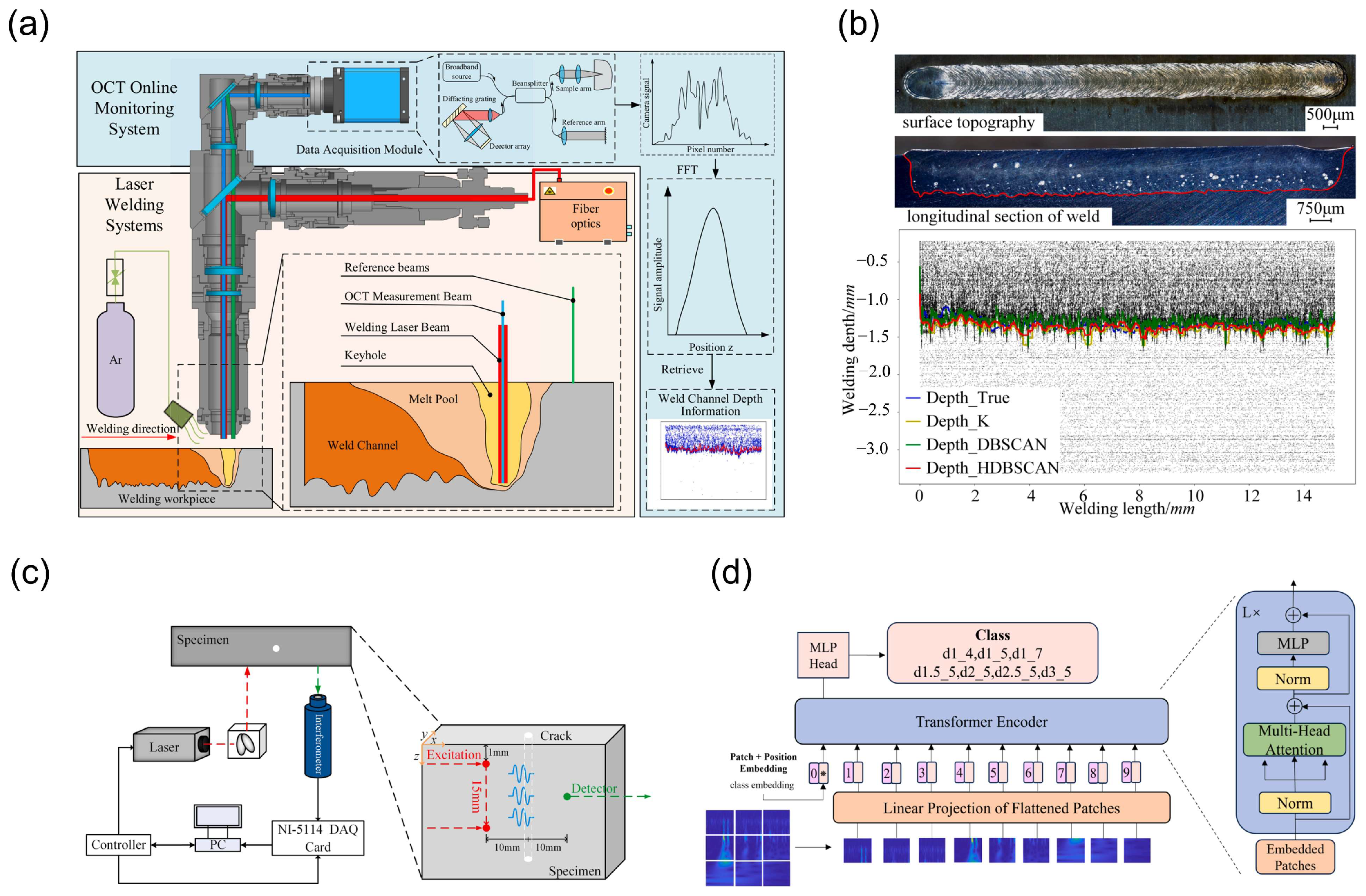

3.1.2. Acoustic Emission Monitoring

3.1.3. Laser Scanning and Interferometry Inspection

3.1.4. Thermal Imaging Monitoring

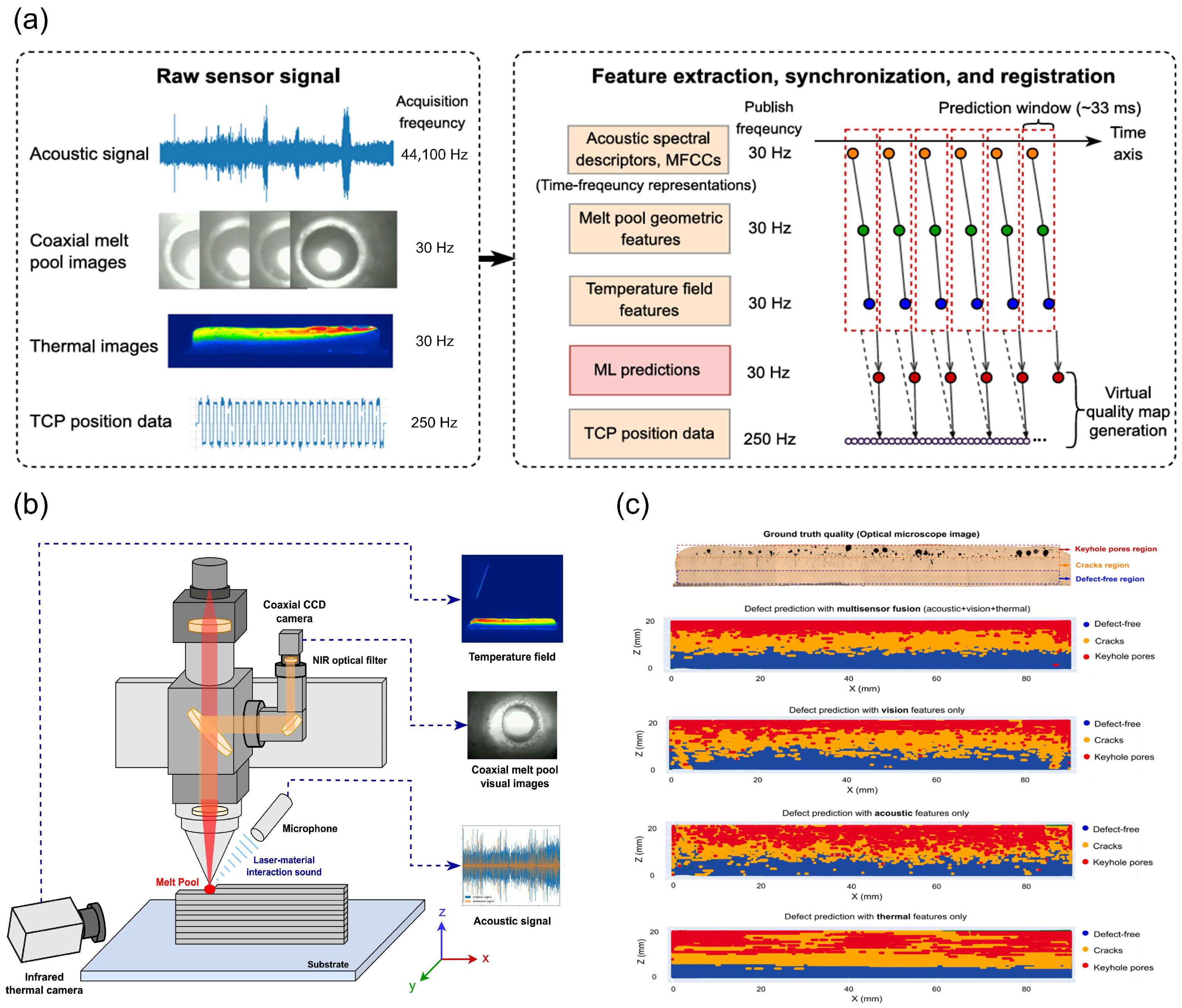

3.1.5. Multi-Modal Fusion Monitoring

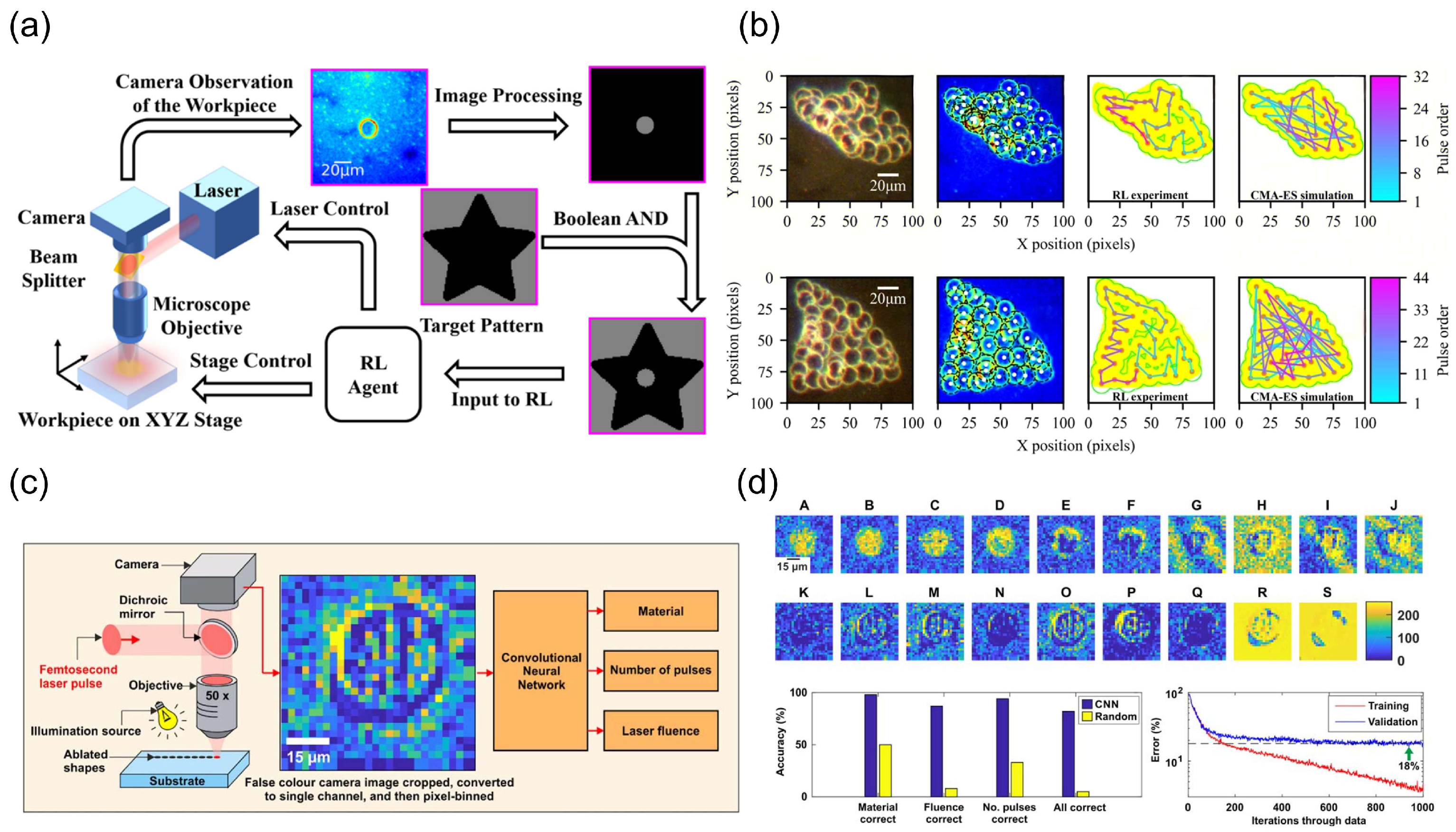

3.2. Feedback Control

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ibrahim, M.S.; Seresht, H.B.; Kum, C.H.; Cho, J.H.; Jin, G.; An, S.H.; Ye, S.; Kim, S.; Wagner, W.R.; Chun, Y. Novel laser-textured grooves extended to the sidewall edges of CoCr surfaces for rapid and selective endothelialization following coronary artery stenting. Biomaterials 2025, 321, 123299. [Google Scholar] [CrossRef]

- Gautam, A.J.; Wairkar, S. 3D-printed bioresorbable vascular stents: Emerging frontiers in personalized cardiac care. Polym. Bull. 2024, 81, 10533–10560. [Google Scholar] [CrossRef]

- Jiang, C.-P.; Masrurotin; Wibisono, A.T.; Macek, W.; Ramezani, M. Enhancing Internal Cooling Channel Design in Inconel 718 Turbine Blades via Laser Powder Bed Fusion: A Comprehensive Review of Surface Topography Enhancements. Int. J. Precis. Eng. Manuf. 2024, 26, 487–511. [Google Scholar] [CrossRef]

- Cai, Z.; Kuang, C.; Yang, H.; Hong, M.; Xu, K. Hybrid Laser Manufacturing and Applications in Flexible Micro-Nano Sensors (Invited). Chin. J. Lasers 2024, 51, 0402403. [Google Scholar] [CrossRef]

- Liu, Y.; Ding, Y.; Liu, Z.; Li, X.; Tian, S.; Fan, L.; Xie, J.; Xu, L.; Lee, J.; Li, J.; et al. Ultrafast laser one-step construction of 3D micro-/nanostructures achieving high-performance zinc metal anodes. PhotoniX 2024, 5, 6. [Google Scholar] [CrossRef]

- Kanishka, K.; Acherjee, B. A systematic review of additive manufacturing-based remanufacturing techniques for component repair and restoration. J. Manuf. Process. 2023, 89, 220–283. [Google Scholar] [CrossRef]

- Park, H.; Park, J.J.; Bui, P.D.; Yoon, H.; Grigoropoulos, C.P.; Lee, D.; Ko, S.H. Laser-Based Selective Material Processing for Next-Generation Additive Manufacturing. Adv. Mater. 2023, 36, e2307586. [Google Scholar] [CrossRef]

- Jia, Y.; Sun, S.; Li, B.; Yao, Z.; Li, C.; Huang, W.; Fang, M. Current research status and prospect of laser wire additive manufacturing technology. Int. J. Adv. Manuf. Technol. 2025, 137, 3229–3255. [Google Scholar] [CrossRef]

- Amsellem, W.; Yazdani Sarvestani, H.; Pankov, V.; Martinez-Rubi, Y.; Gholipour, J.; Ashrafi, B. Deep precision machining of SiC ceramics by picosecond laser ablation. Ceram. Int. 2023, 49, 9592–9606. [Google Scholar] [CrossRef]

- Lin, Z.; Ji, L.; Wang, W. Precision machining of single crystal diamond cutting tool via picosecond laser irradiation. Int. J. Refract. Met. Hard Mater. 2023, 114, 106226. [Google Scholar] [CrossRef]

- Zhang, Y.; Xu, S.; Cui, E.N.; Yu, L.; Wang, Z. Research and Application Progress of Laser-Processing Technology in Diamond Micro-Fabrication. Micromachines 2024, 15, 547. [Google Scholar] [CrossRef] [PubMed]

- Gao, Z.; Deng, T.; Wu, C.; Rong, Y.; Zhang, G.; Huang, Y. Precision cutting of the ABS film by ultraviolet picosecond laser. Opt. Laser Technol. 2025, 191, 113325. [Google Scholar] [CrossRef]

- Zettl, J.; Esen, C.; Hellmann, R. Fundamental Considerations and Analysis of the Energy Distribution in Laser Turning with Ultrashort Laser Pulses. Micromachines 2023, 14, 1838. [Google Scholar] [CrossRef] [PubMed]

- Kozłowska, E.; Grabska-Zielińska, S. Experimental Evaluation of ND: YAG Laser Parameters and Sample Preparation Methods for Texturing Thin AISI 316L Steel Samples. Appl. Sci. 2023, 13, 12352. [Google Scholar] [CrossRef]

- Velayuthaperumal, S.; Radhakrishnan, R. Effect of different laser texture configurations on improving surface wettability and wear characteristics of Ti6Al4V implant material. J. Braz. Soc. Mech. Sci. Eng. 2023, 45, 363. [Google Scholar] [CrossRef]

- Song, D.; Wang, J.; Wu, X.; Gao, L.; Yang, J.; Liu, X.; Luo, Q.; Wang, D.; Wang, Y. Microscopic Processing of Transparent Material with Nanosecond and Ultrafast Lasers. Micromachines 2024, 15, 1101. [Google Scholar] [CrossRef]

- Zhang, H.; Zheng, J.; Cao, G.; Lin, H.; Jia, B. Real-Time Machine Learning-Based Position Recognition in Laser Nanofabrication with Sub-Half-Wavelength Precision. Engineering, 2025; in press. [Google Scholar] [CrossRef]

- Zheng, F.; Xie, L.; Bai, Q.; Zhu, Y.; Yin, M.; Zhang, Y.; Niu, K. Semi-supervised learning for laser directed energy deposition monitoring via co-axial dynamic imaging. Addit. Manuf. 2025, 97, 104628. [Google Scholar] [CrossRef]

- Herberger, C.; Kimmell, J.; Feldhausen, T.; Post, B.; MacDonald, E.; Orlyanchik, V. Multimodal sensor fusion for real-time standoff estimation in directed energy deposition. Addit. Manuf. 2025, 97, 104598. [Google Scholar] [CrossRef]

- Xie, J.; Safdar, M.; Chen, L.; Moon, S.K.; Zhao, Y.F. Audio-visual cross-modality knowledge transfer for machine learning-based in-situ monitoring in laser additive manufacturing. Addit. Manuf. 2025, 101, 104692. [Google Scholar] [CrossRef]

- Kwon, O.; Kim, H.G.; Ham, M.J.; Kim, W.; Kim, G.-H.; Cho, J.-H.; Kim, N.I.; Kim, K. A deep neural network for classification of melt-pool images in metal additive manufacturing. J. Intell. Manuf. 2018, 31, 375–386. [Google Scholar] [CrossRef]

- Xie, Y.; Praeger, M.; Grant-Jacob, J.A.; Eason, R.W.; Mills, B. Motion control for laser machining via reinforcement learning. Opt. Express 2022, 30, 20963–20979. [Google Scholar] [CrossRef] [PubMed]

- Schleier, M.; Esen, C.; Hellmann, R. Vision transformer based cut interruption detection and prediction of laser fusion cutting from monitored melt pool images. J. Laser Appl. 2025, 37, 012033. [Google Scholar] [CrossRef]

- Yang, W.; Qiu, Y.; Liu, W.; Qiu, X.; Bai, Q. Defect prediction in laser powder bed fusion with the combination of simulated melt pool images and thermal images. J. Manuf. Process. 2023, 106, 214–222. [Google Scholar] [CrossRef]

- Ito, K.; Kusano, M.; Demura, M.; Watanabe, M. Detection and location of microdefects during selective laser melting by wireless acoustic emission measurement. Addit. Manuf. 2021, 40, 101915. [Google Scholar] [CrossRef]

- Kargarian, A. Particle energization by high-power laser pulse in a finite-size electron–positron–ion plasma. Laser Phys. 2020, 30, 096002. [Google Scholar] [CrossRef]

- Promoppatum, P.; Yao, S.-C. Analytical evaluation of defect generation for selective laser melting of metals. Int. J. Adv. Manuf. Technol. 2019, 103, 1185–1198. [Google Scholar] [CrossRef]

- Fan, W.; Qian, G.; Wang, Y.; Xu, C.-R.; Chen, Z.; Liu, X.; Li, W.; Liu, X.; Liu, F.; Xu, X.; et al. Deep learning enhanced quantum holography with undetected photons. PhotoniX 2024, 5, 40. [Google Scholar] [CrossRef]

- Lee, W.; Jang, M.A.; Nam, H.S.; Song, J.; Choi, J.; Song, J.W.; Seok, J.Y.; Kim, P.; Kim, J.W.; Yoo, H. Self-supervised denoising of dynamic fluorescence images via temporal gradient-empowered deep learning. PhotoniX 2025, 6, 15. [Google Scholar] [CrossRef]

- Cheng, J.; Liu, R.; Shi, Y.; Hu, M. Inverse prediction of ultrashort pulse nonlinear propagation in optical fibers. Chin. Opt. Lett. 2024, 22, 111902. [Google Scholar] [CrossRef]

- Yu, H.; Lai, S.; Ma, Q.; Jiang, Z.; Pan, D.; Gui, W. Dual feed-forward neural network for predicting complex nonlinear dynamics of mode-locked fiber laser under variable cavity parameters. Chin. Opt. Lett. 2025, 23, 031401. [Google Scholar] [CrossRef]

- Yang, X.; Zhou, J.; Cheng, Z.; Feng, Y. Deep learning prediction of Stokes pulse evolution in ultrafast Raman fiber amplifiers. Chin. Opt. Lett. 2025, 23, 071407. [Google Scholar] [CrossRef]

- Wang, Z.-H.; Weng, T.-T.; Chen, X.-D.; Zhao, L.; Sun, F.-W. SSL Depth: Self-supervised learning enables 16× speedup in confocal microscopy-based 3D surface imaging [Invited]. Chin. Opt. Lett. 2024, 22, 060002. [Google Scholar] [CrossRef]

- Dong, S.; Yang, D.; Wang, Q.; Hu, H.; Sun, J.; Shen, K.; Dong, C.; Liu, H.; Zhu, Z.; Lu, H. Modularized control of broadband surface-enhanced infrared absorption spectroscopy realized in over-coupled metasurfaces. Chin. Opt. Lett. 2025, 23, 053602. [Google Scholar] [CrossRef]

- Xue, C.; Zhang, H.; Cao, H. Multi-agent modelling and analysis of the knowledge learning of a human-machine hybrid intelligent organization with human-machine trust. Syst. Sci. Control Eng. 2024, 12, 2343301. [Google Scholar] [CrossRef]

- Maculotti, G.; Genta, G.; Galetto, M. Optimisation of laser welding of deep drawing steel for automotive applications by Machine Learning: A comparison of different techniques. Qual. Reliab. Eng. Int. 2023, 40, 202–219. [Google Scholar] [CrossRef]

- Nguyen, N.V.; Hum, A.J.W.; Do, T.; Tran, T. Semi-supervised machine learning of optical in-situ monitoring data for anomaly detection in laser powder bed fusion. Virtual Phys. Prototyp. 2022, 18, e2129396. [Google Scholar] [CrossRef]

- Lan, J.; Dong, X. Laser Point Cloud-Image Fusion Technology for Intelligent Driving Vehicles Based on Semi-Supervised Learning Algorithm. IEEE Access 2024, 12, 132664–132676. [Google Scholar] [CrossRef]

- Wang, R.; Cheung, C.F.; Wang, C. Unsupervised Defect Segmentation in Selective Laser Melting. IEEE Trans. Instrum. Meas. 2023, 72, 2520010. [Google Scholar] [CrossRef]

- Xiao, S.; Liu, Z.; Yan, Z.; Wang, M. Grad-MobileNet: A Gradient-Based Unsupervised Learning Method for Laser Welding Surface Defect Classification. Sensors 2023, 23, 4563. [Google Scholar] [CrossRef]

- Vagenas, S.; Al-Saadi, T.; Panoutsos, G. Multi-layer process control in selective laser melting: A reinforcement learning approach. J. Intell. Manuf. 2024, 1–18. [Google Scholar] [CrossRef]

- Tian, W.; Hu, P.; Zhang, C. Optimization framework of laser oscillation welding based on a deep predictive reward reinforcement learning net. J. Intell. Manuf. 2024, 36, 4331–4350. [Google Scholar] [CrossRef]

- Ren, K.; Liu, N.; Zhang, W.; Chew, Y.; Zhang, Y.; Fuh, J.Y.; Bi, G. Laser power planning in directed energy deposition by deep reinforcement learning. Int. J. Adv. Manuf. Technol. 2024, 135, 4683–4694. [Google Scholar] [CrossRef]

- Faizan Mohamed, A.M.; Careri, F.; Khan, R.H.U.; Attallah, M.M.; Stella, L. A novel porosity prediction framework based on reinforcement learning for process parameter optimization in additive manufacturing. Scr. Mater. 2025, 255, 116377. [Google Scholar] [CrossRef]

- Johnson, J.E.; Jamil, I.R.; Pan, L.; Lin, G.; Xu, X. Bayesian optimization with Gaussian-process-based active machine learning for improvement of geometric accuracy in projection multi-photon 3D printing. Light Sci. Appl. 2025, 14, 56. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.; Zhang, X.; Zhou, Y.; Hai, Y.; Wang, B.; Guan, Y. Intelligent femtosecond laser bone drilling via online monitoring and machine learning. J. Manuf. Process. 2024, 117, 224–231. [Google Scholar] [CrossRef]

- Ferreira, J.; Darabi, R.; Sousa, A.; Brueckner, F.; Reis, L.P.; Reis, A.; Tavares, J.M.R.S.; Sousa, J. Gen-JEMA: Enhanced explainability using generative joint embedding multimodal alignment for monitoring directed energy deposition. J. Intell. Manuf. 2025, 1–26. [Google Scholar] [CrossRef]

- Su, J.; Chen, L.; Van Petegem, S.; Jiang, F.; Li, Q.; Luan, J.; Sing, S.L.; Wang, J.; Tan, C. Additive manufacturing metallurgy guided machine learning design of versatile alloys. Mater. Today 2025, 88, 240–250. [Google Scholar] [CrossRef]

- Brandao, E.; Nakhoul, A.; Duffner, S.; Emonet, R.; Garrelie, F.; Habrard, A.; Jacquenet, F.; Pigeon, F.; Sebban, M.; Colombier, J.-P. Learning Complexity to Guide Light-Induced Self-Organized Nanopatterns. Phys. Rev. Lett. 2023, 130, 226201. [Google Scholar] [CrossRef]

- Zhang, Z.; Jia, M.; Wang, L.; Yu, Y.; Yang, Z.; Wang, J.; Wang, Y.; Wang, C.; Lv, Z.; Xu, W. Physical model-guided machine learning for accelerating laser induced plasma micro-machining process optimization. Opt. Laser Technol. 2025, 183, 112402. [Google Scholar] [CrossRef]

- Peng, S.; Yang, S.; Gao, B.; Liu, W.; Wang, F.; Tang, Z. Prediction of 3D temperature field through single 2D temperature data based on transfer learning-based PINN model in laser-based directed energy deposition. J. Manuf. Process. 2025, 138, 140–156. [Google Scholar] [CrossRef]

- Parodo, G.; Sorrentino, L.; Turchetta, S.; Moffa, G. Laser treatment design for CFRP bonding: An innovative approach to reduce process time. Int. J. Adhes. Adhes. 2025, 142, 104075. [Google Scholar] [CrossRef]

- Akmal, J.; Minet-Lallemand, K.; Kuva, J.; Syvänen, T.; Ylander, P.; Puttonen, T.; Björkstrand, R.; Partanen, J.; Nyrhilä, O.; Salmi, M. AI-based defect detection and self-healing in metal additive manufacturing. Virtual Phys. Prototyp. 2025, 20, e2500671. [Google Scholar] [CrossRef]

- Gobert, C.; Reutzel, E.W.; Petrich, J.; Nassar, A.R.; Phoha, S. Application of supervised machine learning for defect detection during metallic powder bed fusion additive manufacturing using high resolution imaging. Addit. Manuf. 2018, 21, 517–528. [Google Scholar] [CrossRef]

- Xie, Y.; Heath, D.J.; Grant-Jacob, J.A.; Mackay, B.S.; McDonnell, M.D.T.; Praeger, M.; Eason, R.W.; Mills, B. Deep learning for the monitoring and process control of femtosecond laser machining. J. Phys. Photonics 2019, 1, 035002. [Google Scholar] [CrossRef]

- Wang, K. Contrastive learning-based semantic segmentation for In-situ stratified defect detection in additive manufacturing. J. Manuf. Syst. 2023, 68, 465–476. [Google Scholar] [CrossRef]

- Mohanavel, V.; Gandhimathi, G.; Bhardwaj, D.; Kavitha, M.; Ramkumar, G.; Ishwarya, M.V.; Ali, M. Deep learning-guided femtosecond laser processing in optical materials and devices for nano fabrication advancements. Opt. Quantum Electron. 2023, 56, 210. [Google Scholar] [CrossRef]

- Tani, S.; Aoyagi, Y.; Kobayashi, Y. Neural-network-assisted in situ processing monitoring by speckle pattern observation. Opt. Express 2020, 28, 26180–26188. [Google Scholar] [CrossRef]

- Ren, Z.; Gao, L.; Clark, S.J.; Fezzaa, K.; Shevchenko, P.; Choi, A.; Everhart, W.; Rollett, A.D.; Chen, L.; Sun, T. Machine learning–aided real-time detection of keyhole pore generation in laser powder bed fusion. Science 2023, 379, 89–94. [Google Scholar] [CrossRef]

- Chen, L.; Bi, G.; Yao, X.; Tan, C.; Su, J.; Ng, N.P.H.; Chew, Y.; Liu, K.; Moon, S.K. Multisensor fusion-based digital twin for localized quality prediction in robotic laser-directed energy deposition. Robot. Comput.-Integr. Manuf. 2023, 84, 102581. [Google Scholar] [CrossRef]

- Chang, Y.-J.; Wang, C.-S.; Hsiao, Y.-H.; Gurajala, S.D.M. Feedback-control based laser micromachining with real-time plasma detection and neural networks. Opt. Laser Technol. 2025, 180, 111500. [Google Scholar] [CrossRef]

- Chen, Z.; Chen, J.; Hong, P.; Zhang, T.; Bao, Y. Data-based thermodynamic model and feedforward-PI control method for laser soldering. Int. J. Adv. Manuf. Technol. 2023, 129, 5249–5260. [Google Scholar] [CrossRef]

- Miyaji, G.; Nagai, D.; Miyoshi, T.; Takada, H.; Yoshitomi, D.; Narazaki, A. Stable fabrication of femtosecond-laser-induced periodic nanostructures on glass using real-time monitoring and active feedback control. Light Adv. Manuf. 2025, 6, 3. [Google Scholar] [CrossRef]

- Kavas, B.; Balta, E.C.; Tucker, M.; Rupenyan, A.; Lygeros, J.; Bambach, M. Layer-to-layer closed-loop feedback control application for inter-layer temperature stabilization in laser powder bed fusion. Addit. Manuf. 2023, 78, 103847. [Google Scholar] [CrossRef]

- van Blitterswijk, R.H.; Botelho, L.A.; Farshidianfar, M.H.; Etman, P.; Khajepour, A. Adaptive thermal model for real-time peak temperature and cooling rate prediction in laser material processing. J. Manuf. Process. 2023, 101, 1301–1317. [Google Scholar] [CrossRef]

- Yu, T.; Zhao, S.; Zhao, J. A mechanism-based optimization strategy with adaptive laser power for laser powder bed fusion. Addit. Manuf. 2024, 92, 104403. [Google Scholar] [CrossRef]

- Hasegawa, S.; Kato, M.; Hayasaki, Y. Holographic ultraviolet nanosecond laser processing using adaptive optics. Appl. Phys. B 2023, 129, 52. [Google Scholar] [CrossRef]

- Yan, Y.; Wu, Z.; Su, X.; You, Z.; Chen, K.; Long, J. Feedback-corrected laser micromachining based on in-situ depth monitoring using laser triangulation. Opt. Lett. 2025, 50, 614–617. [Google Scholar] [CrossRef]

- Chen, H.; Chen, Y.; Shi, D.; Jiang, R.; Guo, Z.; Wang, Y. Complementary differential detection for fast focusing using dual single-pixel detectors. Opt. Lett. 2025, 50, 3285. [Google Scholar] [CrossRef]

- Wittemer, M.; Wudy, K. Robustness investigation of an in-situ absorption measurement system for laser processing. Weld. World 2024, 68, 1461–1472. [Google Scholar] [CrossRef]

- Huang, R.-Y.; Lu, J.-Q.; Cheng, C.-W.; Tsai, M.-C.; Lee, A.-C. Multi-data-driven model-based control to improve the accuracy of overhang structures in laser powder bed fusion. Opt. Laser Technol. 2024, 171, 110398. [Google Scholar] [CrossRef]

- Wang, Y.; Hu, K.; Li, W.; Wang, L. Prediction of melt pool width and layer height for Laser Directed Energy Deposition enabled by physics-driven temporal convolutional network. J. Manuf. Syst. 2023, 69, 1–17. [Google Scholar] [CrossRef]

- McDonnell, M.D.T.; Arnaldo, D.; Pelletier, E.; Grant-Jacob, J.A.; Praeger, M.; Karnakis, D.; Eason, R.W.; Mills, B. Machine learning for multi-dimensional optimisation and predictive visualisation of laser machining. J. Intell. Manuf. 2021, 32, 1471–1483. [Google Scholar] [CrossRef]

- Raihan, A.S.; Harper, A.; Era, I.Z.; Al-Shebeeb, O.; Wuest, T.; Das, S.; Ahmed, I. A data-efficient sequential learning framework for melt pool defect classification in Laser Powder Bed Fusion. J. Manuf. Process. 2025, 145, 201–210. [Google Scholar] [CrossRef]

- Vagheesan, S.; Govindarajalu, J. Hybrid neural network–particle swarm optimization algorithm and neural network–genetic algorithm for the optimization of quality characteristics during CO2 laser cutting of aluminium alloy. J. Braz. Soc. Mech. Sci. Eng. 2019, 41, 328. [Google Scholar] [CrossRef]

- McDonnell, M.D.T.; Grant-Jacob, J.A.; Praeger, M.; Eason, R.W.; Mills, B. Identification of spatial intensity profiles from femtosecond laser machined depth profiles via neural networks. Opt. Express 2021, 29, 36469–36486. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, Z.; Wu, D. Prediction of melt pool temperature in directed energy deposition using machine learning. Addit. Manuf. 2021, 37, 101692. [Google Scholar] [CrossRef]

- Wang, Z.; Ma, Y.; Yuan, B.; Wu, C.; Li, C.; Sun, S. Development of Laser Processing Carbon-Fiber-Reinforced Plastic. Sensors 2023, 23, 3659. [Google Scholar] [CrossRef]

- Zhang, X.; Zhou, L.; Feng, G.; Xi, K.; Algadi, H.; Dong, M. Laser technologies in manufacturing functional materials and applications of machine learning-assisted design and fabrication. Adv. Compos. Hybrid Mater. 2024, 8, 76. [Google Scholar] [CrossRef]

- Luo, Q.; Huang, N.; Bartles, D.L.; Simpson, T.W.; Beese, A.M. Harnessing of in situ processing data to predict mechanical properties of laser powder bed fusion AlSi10Mg. J. Intell. Manuf. 2025, 1–23. [Google Scholar] [CrossRef]

- Vo, C.; Zhou, B.; Yu, X. Optimization of laser processing parameters through automated data acquisition and artificial neural networks. J. Laser Appl. 2021, 33, 042025. [Google Scholar] [CrossRef]

- Liao, S.; Xue, T.; Jeong, J.; Webster, S.; Ehmann, K.; Cao, J. Hybrid thermal modeling of additive manufacturing processes using physics-informed neural networks for temperature prediction and parameter identification. Comput. Mech. 2023, 72, 499–512. [Google Scholar] [CrossRef]

- Velli, M.-C.; Tsibidis, G.D.; Mimidis, A.; Skoulas, E.; Pantazis, Y.; Stratakis, E. Predictive modeling approaches in laser-based material processing. J. Appl. Phys. 2020, 128, 183102. [Google Scholar] [CrossRef]

- Zhang, J.; Jiang, R.; Li, K.; Chen, P.; Bi, S.; Shang, X.; Liu, Z.; Hattrick-Simpers, J.; Simonds, B.J.; Wei, Q.; et al. Accurate and efficient predictions of keyhole dynamics in laser materials processing using machine learning-aided simulations. Int. J. Heat Mass Transf. 2025, 250, 127279. [Google Scholar] [CrossRef]

- Shafaie, M.; Sarparast, M.; Zhang, H. Data-driven investigation of elastoplastic and failure analysis of additively manufactured parts under bending conditions. Eng. Fail. Anal. 2025, 174, 109505. [Google Scholar] [CrossRef]

- Zhu, Q.; Liu, Z.; Yan, J. Machine learning for metal additive manufacturing: Predicting temperature and melt pool fluid dynamics using physics-informed neural networks. Comput. Mech. 2021, 67, 619–635. [Google Scholar] [CrossRef]

- Ye, L.; Xue, H.; Li, Z.; Zhou, Y.; Chen, G.; Xu, F.; Melentiev, R.; Newman, S.; Yu, N. Review of online quality control for laser directed energy deposition (LDED) additive manufacturing. Int. J. Extreme Manuf. 2025, 7, 062005. [Google Scholar] [CrossRef]

- Yildirim, K.; Nagarajan, B.; Tjahjowidodo, T.; Castagne, S. Review of in-situ process monitoring for ultra-short pulse laser micromanufacturing. J. Manuf. Process. 2025, 133, 1126–1159. [Google Scholar] [CrossRef]

- Kononenko, D.Y.; Nikonova, V.; Seleznev, M.; van den Brink, J.; Chernyavsky, D. An in situ crack detection approach in additive manufacturing based on acoustic emission and machine learning. Addit. Manuf. Lett. 2023, 5, 100130. [Google Scholar] [CrossRef]

- Chen, Z.; Wang, D.; Zhang, Y. Microphone signal specialities in laser powder bed fusion: Single-track scan and multi-track scan. J. Mater. Res. Technol. 2023, 24, 1344–1362. [Google Scholar] [CrossRef]

- Pandiyan, V.; Baganis, A.; Axel Richter, R.; Wróbel, R.; Leinenbach, C. Qualify-as-you-go: Sensor fusion of optical and acoustic signatures with contrastive deep learning for multi-material composition monitoring in laser powder bed fusion process. Virtual Phys. Prototyp. 2024, 19, e2356080. [Google Scholar] [CrossRef]

- Imani, F.; Chen, R.; Diewald, E.; Reutzel, E.; Yang, H. Deep Learning of Variant Geometry in Layerwise Imaging Profiles for Additive Manufacturing Quality Control. J. Manuf. Sci. Eng. 2019, 141, 111001. [Google Scholar] [CrossRef]

- Cai, Y.; Li, C.; Chen, H.; Xiong, J. Monitoring of distance between laser beam and arc in laser-arc hybrid welding based on deep learning. Opt. Laser Technol. 2024, 174, 110562. [Google Scholar] [CrossRef]

- Polat, C.; Yapici, G.N.; Elahi, S.; Elahi, P. High-precision laser focus positioning of rough surfaces by deep learning. Opt. Lasers Eng. 2023, 168, 107646. [Google Scholar] [CrossRef]

- Qiu, H.; Jiang, G.; Lin, X. Balling levels detection in laser powder bed fusion using nonlinear genetic algorithm optimized convolutional neural network. Int. J. Adv. Manuf. Technol. 2025, 138, 4275–4291. [Google Scholar] [CrossRef]

- Surovi, N.A.; Soh, G.S. Acoustic feature based geometric defect identification in wire arc additive manufacturing. Virtual Phys. Prototyp. 2023, 18, e2210553. [Google Scholar] [CrossRef]

- Sun, T.; Fan, Z.; Zhao, W.; Sun, X.; Liu, B.; Cui, J.; Mei, X. Hybrid Machine learning and temporal-spatial fusion decision for real-time monitoring of drilling stage in ultrafast laser drilling. Opt. Laser Technol. 2025, 184, 112354. [Google Scholar] [CrossRef]

- Wang, K.; Liu, L.; Xu, C.; Zou, J.; Lin, H.; Fang, N.; Jiang, J. Towards label-free defect detection in additive manufacturing via dual-classifier semi-supervised learning for vision-language models. J. Intell. Manuf. 2025, 1–16. [Google Scholar] [CrossRef]

- Li, K.; Ma, Z.; Fu, P.; Krishnaswamy, S. Quantitative evaluation of surface crack depth with a scanning laser source based on particle swarm optimization-neural network. NDT E Int. 2018, 98, 208–214. [Google Scholar] [CrossRef]

- He, G.; Gao, X.; Li, L.; Gao, P. OCT monitoring data processing method of laser deep penetration welding based on HDBSCAN. Opt. Laser Technol. 2024, 179, 111303. [Google Scholar] [CrossRef]

- Wang, S.; Chen, S.; Wang, H.; Yang, X.; Tang, P.; Chu, J.; Zheng, K. Internal defect detection model based on laser ultrasonic signal decomposition and deep learning. Measurement 2025, 242, 116194. [Google Scholar] [CrossRef]

- Wang, H.; Li, B.; Zhang, S.; Xuan, F. Traditional machine learning and deep learning for predicting melt-pool cross-sectional morphology of laser powder bed fusion additive manufacturing with thermographic monitoring. J. Intell. Manuf. 2024, 36, 2079–2104. [Google Scholar] [CrossRef]

- Bostan, B.; Hinnebusch, S.; Anderson, D.; To, A.C. Accurate detection of local porosity in laser powder bed fusion through deep learning of physics-based in-situ infrared camera signatures. Addit. Manuf. 2025, 101, 104701. [Google Scholar] [CrossRef]

- Fan, X.; Fleming, T.G.; Clark, S.J.; Fezzaa, K.; Getley, A.C.M.; Marussi, S.; Wang, H.; Leung, C.L.A.; Kao, A.; Lee, P.D. Magnetic modulation of keyhole instability during laser welding and additive manufacturing. Science 2025, 387, 864–869. [Google Scholar] [CrossRef]

- Zhao, C.; Sun, J.; Ma, Z.; Yang, Z.; Qiu, X. A multimodal information fusion method for real-time monitoring of glass cutting with laser-induced thermal-crack propagation. Opt. Laser Technol. 2025, 180, 111457. [Google Scholar] [CrossRef]

- Mills, B.; Heath, D.J.; Grant-Jacob, J.A.; Xie, Y.; Eason, R.W. Image-based monitoring of femtosecond laser machining via a neural network. J. Phys. Photonics 2018, 1, 015008. [Google Scholar] [CrossRef]

| Processing Flow | ML Methods | Advantages and Disadvantages | Purpose | Types of Laser Processes | Reference |

|---|---|---|---|---|---|

| Modeling | GPR + BO | Adv: Suitable for low-dimensional nonlinear problems; Disadv: Ignores thermal accumulation effects | Optimize 2D geometric accuracy | Projection multiphoton 3D printing | Johnson et al. [45] |

| ANN/GA/BO | Adv: Reduces trial and error; Disadv: High data/computation cost, poor interpretability | Optimize params for surface/mechanical quality | CFRP laser processing | Zhang et al. [46] | |

| Gen-JEMA (AE/VAE + BO) | Adv: Suitable for multi-modal data prediction; Disadv: VAE underperforms, computational complexity | Melt pool geometry prediction and data generation | LDED | Ferreira et al. [47] | |

| RF + CALPHAD calculations | Adv: Handles high-dimensional data and large number of features; Disadv: Long training and prediction time | Design martensitic steel with tunable strength/ductility | Su et al. [48] | ||

| Deep Convolutional Networks | Adv: Suitable for image prediction; Disadv: Requires extensive training data | Predict nanoscale pattern morphology and feature dimensions | Laser-induced nanoscale patterning | Brandao et al. [49] | |

| SVR + Physics-guided inputs | Adv: Suitable for complex process optimization of small samples with well-defined physical mechanisms; Disadv: Dependency on electron rate equations for intermediate physics | Predict material removal rate and depth | LIPMM | Zhang et al. [50] | |

| Transfer Learning-based PINNs | Adv: Reduces training time via pre-training; Disadv: Adaptive bottlenecks in physical mechanism migration | Predict 3D temperature field | Blue laser deposition | Peng et al. [51] | |

| FEA-guided optimization | Adv: Suitable for multi-physics field coupling parameter optimization problems; Disadv: Computationally demanding for complex geometries | Identify high-stress regions for targeted pretreatment | CFRP laser texturing | Parodo et al. [52] | |

| In situ Monitoring | TNN | Adv: Suitable for multi-dimensional feature extraction; Disadv: Requires high-resolution CMOS imaging | Real-time focal spot positioning | Laser nanofabrication | Zhang et al. [17] |

| CNN | Adv: Suitable for high-precision real-time analysis of images; Disadv: Performance drops in heterogeneous materials | Defect detection | LBPF | Akmal et al. [53] | |

| SVM | Adv: Suitable for classification problems with small sample data; Disadv: Dependent on processing parameters | Classify porosity/incomplete fusion | Gobert et al. [54] | ||

| ViT | Adv: Sub-pixel resolution; Disadv: Computationally intensive affine transformations cause latency | Detect beam translation/rotation and predict thin-film breakthrough | Femtosecond laser machining | Xie et al. [55] | |

| Semi-supervised CAE | Adv: Low training costs; Disadv: Computational burden of image alignment and spatiotemporal alignment | Fuse spatiotemporal melt pool features | LDED | Zheng et al. [18] | |

| LSCA | Adv: Suitable for high-noise, low-contrast, multi-scale scenes imbalance; Disadv: Computational efficiency and real-time bottlenecks | Semantic segmentation of layer defects | Additive manufacturing layer defects | Wang et al. [56] | |

| Feedback Control | RL | Adv: Autonomous error correction, reduces human intervention; Disadv: Training requires virtual environment simulation | Real-time tool path correction and vibration compensation | High-precision laser machining | Xie et al. [22] |

| AlexNet-Guided Framework | Adv: Suitable for parametric co-optimization; Disadv: Real-time bottlenecks with high-resolution inputs | Dynamic optimization of pulse energy and scan speed | Nanoscale laser processing | Mohanavel et al. [57] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.-X.; Gong, W.; Bu, F.-G.; Zhao, X.-J.; Li, S.; Xu, W.-W.; Li, A.-W.; Liu, G.-H.; An, T.; Gao, B.-R. Intelligent Laser Micro/Nano Processing: Research and Advances. Nanomaterials 2025, 15, 1462. https://doi.org/10.3390/nano15191462

Liu Y-X, Gong W, Bu F-G, Zhao X-J, Li S, Xu W-W, Li A-W, Liu G-H, An T, Gao B-R. Intelligent Laser Micro/Nano Processing: Research and Advances. Nanomaterials. 2025; 15(19):1462. https://doi.org/10.3390/nano15191462

Chicago/Turabian StyleLiu, Yu-Xin, Wei Gong, Fan-Gao Bu, Xin-Jing Zhao, Song Li, Wei-Wei Xu, Ai-Wu Li, Guo-Hong Liu, Tao An, and Bing-Rong Gao. 2025. "Intelligent Laser Micro/Nano Processing: Research and Advances" Nanomaterials 15, no. 19: 1462. https://doi.org/10.3390/nano15191462

APA StyleLiu, Y.-X., Gong, W., Bu, F.-G., Zhao, X.-J., Li, S., Xu, W.-W., Li, A.-W., Liu, G.-H., An, T., & Gao, B.-R. (2025). Intelligent Laser Micro/Nano Processing: Research and Advances. Nanomaterials, 15(19), 1462. https://doi.org/10.3390/nano15191462