In Situ Optical Monitoring and Morphological Evolution of Si Nanowires Grown on Faceted Al2O3(0001) Substrates

Abstract

1. Introduction

2. Experimental Methodology

2.1. Substrate Preparation

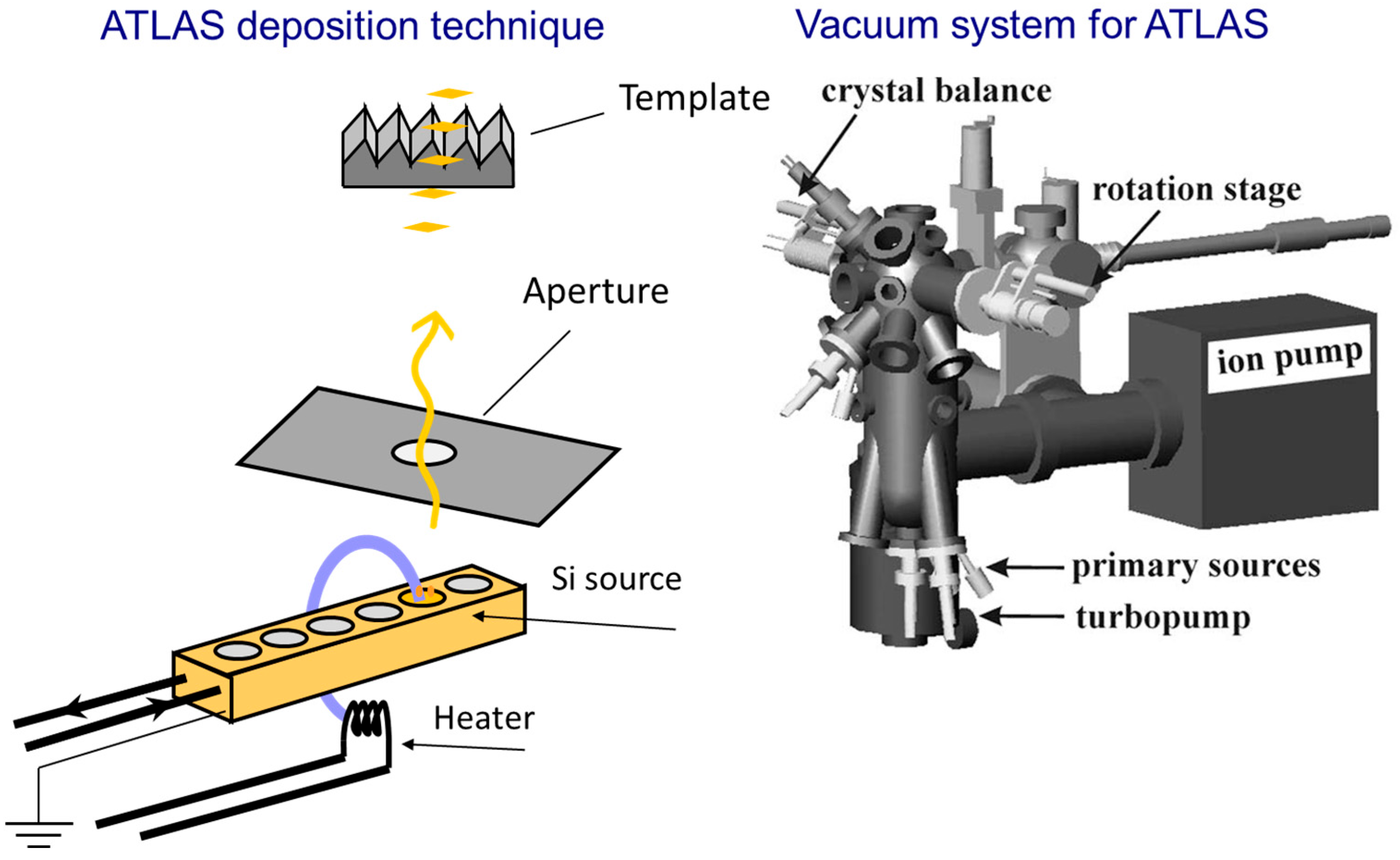

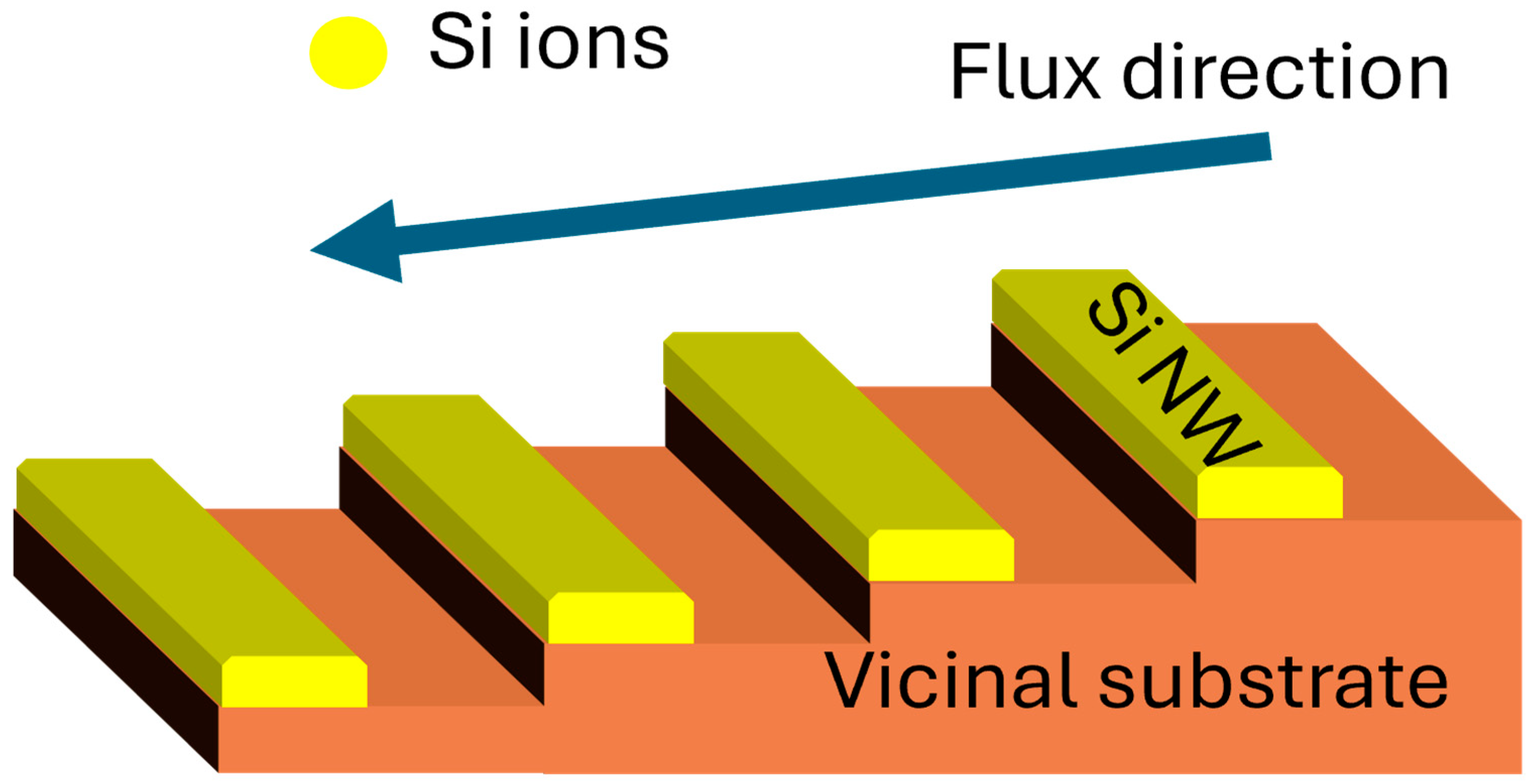

2.2. Si Nanowire Growth via ATLAS

2.3. In Situ Reflectance Anisotropy Spectroscopy (RAS)

2.4. Post-Growth Annealing

3. Results and Discussion

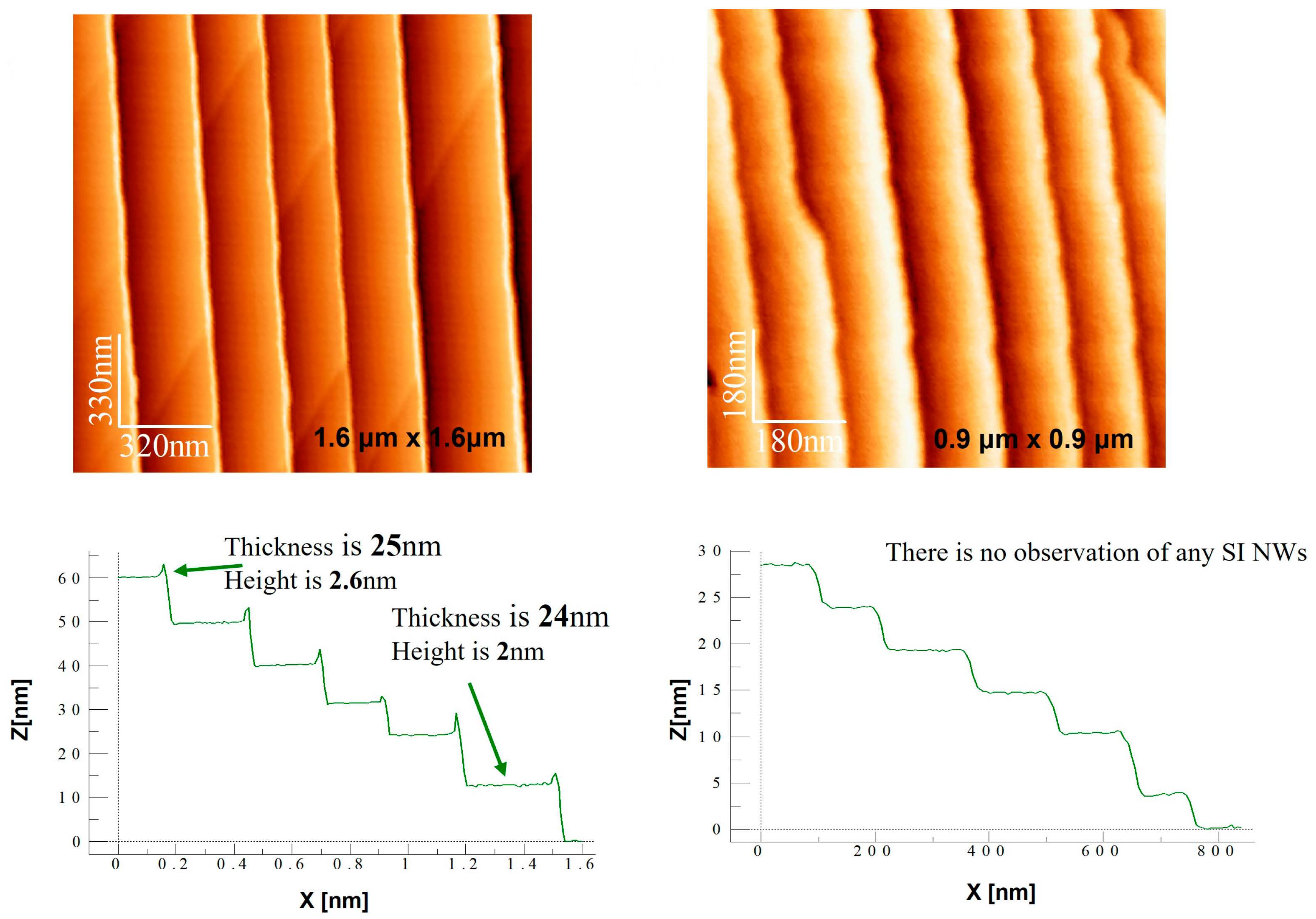

3.1. AFM Characterization

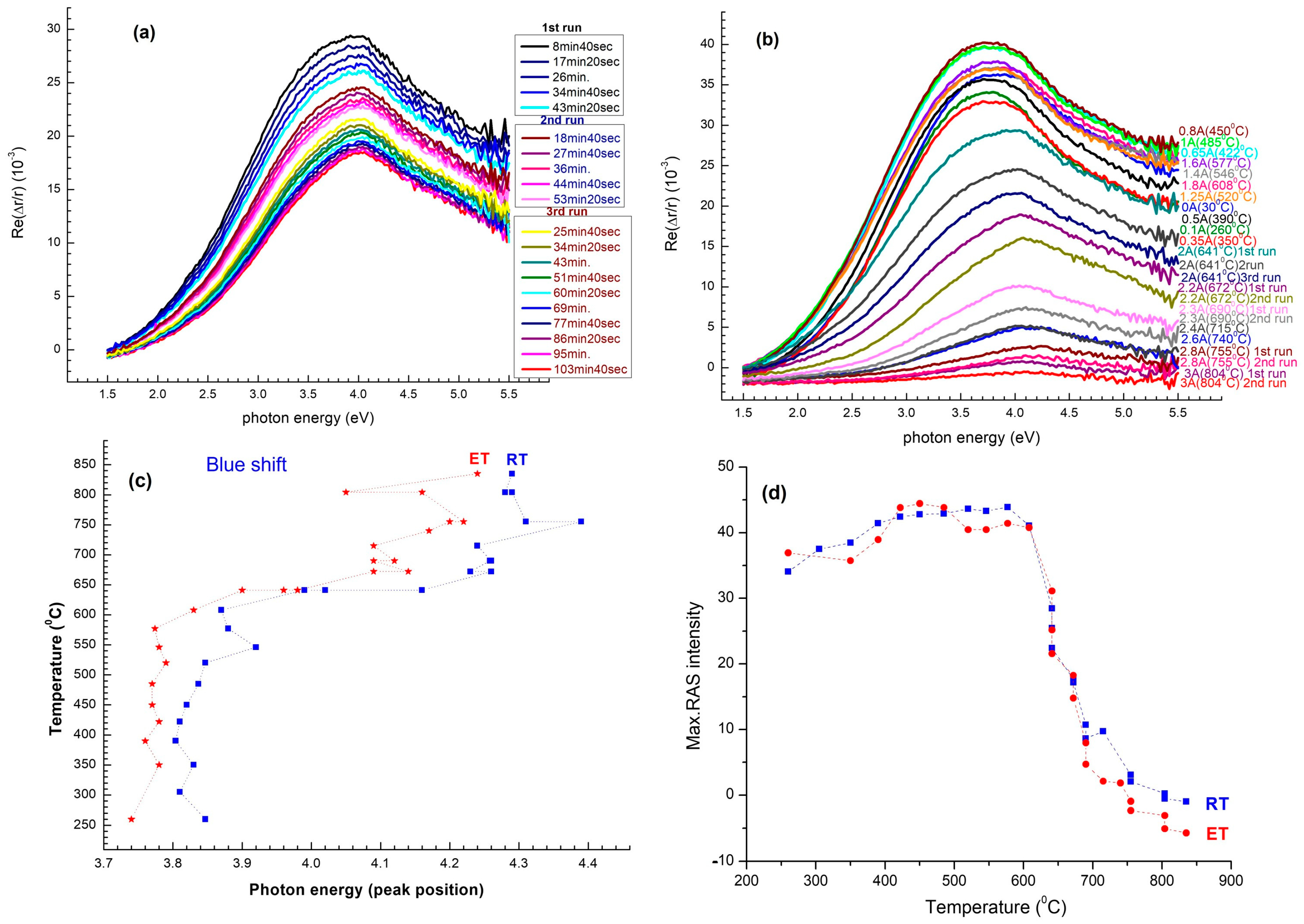

3.2. RAS Analysis During Growth

3.3. RAS Evolution During Annealing

3.4. In Situ RAS at Room Temperature After Each Annealing Step (RT Branch)

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cui, Y.; Lieber, C.M. Functional Nanoscale Electronic Devices Assembled Using Silicon Nanowire Building Blocks. Science 2001, 291, 851–853. [Google Scholar] [CrossRef] [PubMed]

- Lu, W.; Lieber, C.M. Semiconductor Nanowires. Nat. Mater. 2007, 6, 841–850. [Google Scholar] [CrossRef]

- Hochbaum, A.I.; Yang, P. Semiconductor Nanowires for Energy Conversion. Chem. Rev. 2010, 110, 527–546. [Google Scholar] [CrossRef]

- Schmidt, V.; Wittemann, J.V.; Gösele, U. Growth, Thermodynamics, and Electrical Properties of Silicon Nanowires. Chem. Rev. 2010, 110, 361–388. [Google Scholar] [CrossRef] [PubMed]

- Wang, M.; Seo, S.E.; Mirkin, C.A. Epitaxy: Programmable Atom Equivalents versus Atoms. ACS Nano 2023, 17, 6261–6274. [Google Scholar] [CrossRef]

- Das, S.K.; Chettri, B.; Karki, P.; Kunwar, B.; Chettri, P.; Sharma, B. Impact of high-k metal oxide as gate dielectric on the certain electrical properties of silicon nanowire field-effect transistors: A simulation study. Facta Univ.-Ser. Electron. Energetics 2023, 36, 553–565. [Google Scholar] [CrossRef]

- Patolsky, F.; Zheng, G.; Lieber, C.M. Nanowire-Based Biosensors. Proc. Natl. Acad. Sci. USA 2006, 103, 3814–3819. [Google Scholar] [CrossRef]

- Yu, Z.; Fan, S. Optical Absorption Enhancement in Amorphous Silicon Nanowire and Nanocone Arrays. Nano Lett. 2009, 9, 279–282. [Google Scholar] [CrossRef]

- Tian, B.; Zheng, X.; Kempa, T.J.; Fang, Y.; Yu, N.; Yu, G.; Lieber, C.M. Coaxial silicon nanowires as solar cells and nanoelectronic power sources. Nature 2007, 449, 885–889. [Google Scholar] [CrossRef]

- Koo, J.; Xu, X.; Jung, J.; Lee, H.; Kim, S.; Kim, T. Flexible and Wearable Silicon-Nanowire Photodetectors with Broadband Responsivity. Nat. Commun. 2017, 8, 14950. [Google Scholar] [CrossRef]

- Wagner, R.S.; Ellis, W.C. Vapor-Liquid-Solid Mechanism of Single Crystal Growth. Appl. Phys. Lett. 1964, 4, 89–90. [Google Scholar] [CrossRef]

- Morales, A.M.; Lieber, C.M. A Laser Ablation Method for the Synthesis of Crystalline Semiconductor Nanowires. Science (1979) 1998, 279, 208–211. [Google Scholar] [CrossRef]

- Schmidt, V.; Senz, S.; Gösele, U. Diameter-Dependent Growth Direction of Epitaxial Silicon Nanowires. Small 2006, 2, 85–88. [Google Scholar] [CrossRef]

- Mandl, B.; Stangl, J.; Mårtensson, T.; Mikkelsen, A.; Eriksson, J.; Karlsson, L.S.; Seifert, W. Au-free epitaxial growth of InAs nanowires. Nano Lett. 2006, 6, 1817–1821. [Google Scholar] [CrossRef] [PubMed]

- Colombo, C.; Spirkoska, D.; Frimmer, M.; Abstreiter, G.; Morral, A.F.I. Catalyst-Free Silicon Nanowire Arrays on c-Plane Sapphire by Molecular-Beam Epitaxy. Appl. Phys. Lett. 2009, 94, 173108. [Google Scholar] [CrossRef]

- No, Y.-S.; Seo, J.; Jo, M.H. Pattern-Free Epitaxial Growth of Silicon Nanowires. Nano Lett. 2018, 18, 6906–6914. [Google Scholar] [CrossRef]

- Zheng, G.; Patolsky, F.; Cui, Y.; Wang, W.U.; Lieber, C.M. Multiplexed Electrical Detection of Cancer Markers with Nanowire Sensor Arrays. Nat. Biotechnol. 2005, 23, 1294–1301. [Google Scholar] [CrossRef]

- Ren, P.; Wang, Z.; Chen, X.; Wang, Y.; Wu, J.; Du, W.; Zheng, Q.; Ren, X.; Xu, J. Self-Oriented Polycrystalline InP Nanowires Guided by Nanogrooves and Their Near-Infrared Photoresponse. Cryst. Growth Des. 2025, 25, 2456–2464. [Google Scholar] [CrossRef]

- Thune, E.; Boulle, A.; Babonneau, D.; Pailloux, F.; Hamd, W.; Guinebretière, R. Nanostructured sapphire vicinal surfaces as templates for the growth of self-organized oxide nanostructures. Appl. Surf. Sci. 2009, 256, 924–928. [Google Scholar] [CrossRef]

- Cavallini, A.; Carapezzi, S.; Castaldini, A.; Irrera, A. Properties of Si nanowires as a function of their growth conditions. Phys. B Condens. Matter 2014, 439, 41–45. [Google Scholar] [CrossRef]

- Fan, H.J.; Werner, P.; Zacharias, M. Semiconductor Nanowires: From Self-Organization to Patterned Growth. Small 2006, 2, 700–717. [Google Scholar] [CrossRef]

- Aspnes, D.E. Optical Techniques for Surface Analysis. Surf. Sci. 1998, 414, l951–l956. [Google Scholar]

- Santos, P.V.; Koopmans, B.; Esser, N.; Schmidt, W.G.; Bechstedt, F. Optical properties of ordered as layers on InP (110) surfaces. Phys. Rev. Lett. 1996, 77, 759. [Google Scholar] [CrossRef] [PubMed]

- Lyu, J.; Qiao, S.; Yang, L. Anisotropic Heat Conduction of Silicon Nanocube through Strain Gradient Engineering. Nano Lett. 2025, 25, 2988–2995. [Google Scholar] [CrossRef]

- Park, J.M.; Jang, S.C.; Lee, S.M.; Kang, M.H.; Chung, K.B.; Kim, H.S. Oxide thin-film transistors based on i-line stepper process for high PPI displays. J. Inf. Disp. 2023, 24, 103–108. [Google Scholar] [CrossRef]

- Lee, H.; Islam, M.M.; Bae, J.; Jeong, M.; Roy, S.; Lim, T.; Jang, J. A coplanar crystallineInGaO thin film transistor with SiO2 gate insulator on ZrO2 ferroelectric layer: A new ferroelectric TFT structure. Adv. Mater. Technol. 2025, 10, 2401075. [Google Scholar] [CrossRef]

- Naqi, M.; Jang, S.C.; Cho, Y.; Park, J.M.; Oh, J.O.; Rho, H.Y.; Kim, S. Low temperature processed, highly stable CMOS inverter by integrating Zn-ON and tellurium thin-film transistors. J. Inf. Disp. 2023, 24, 199–204. [Google Scholar] [CrossRef]

- Roy, S.; Islam, M.M.; Ali, A.; Saha, J.K.; Lee, H.; Tooshil, A.; Jang, J. High Memory Window, Dual-Gate Amorphous InGaZnO Thin-Film Transistor with Ferroelectric Gate Insulator. Phys. Status Solidi (a) 2025, 222, 2400638. [Google Scholar] [CrossRef]

- Lee, S.M.; Jang, S.C.; Park, J.M.; Park, J.; Choi, N.; Chung, K.B.; Lee, J.W.; Kim, H.S. High-Mobility Tellurium Thin-Film Transistor: Oxygen Scavenger Effect Induced by a Metal-Capping Layer. Nanomaterials 2025, 15, 418. [Google Scholar] [CrossRef] [PubMed]

- Kim, Y.S.; Hong, H.; Hong, T.; Choi, S.H.; Chung, K.B.; Park, J.S. Attaining quantitatively fewer defects in close-packed InGaZnO synthesized using atomic layer deposition. Appl. Surf. Sci. 2024, 664, 160242. [Google Scholar] [CrossRef]

- Min, J.H.; Jang, S.C.; Kim, K.J.; Rim, Y.S.; Kim, H.S. Metal Oxide Semiconductor-Based Negative Capacitance Field-Effect Transistors with a Sub-Threshold Swing of below 30 mV/dec. Mater. Today Electron. 2025, 14, 100178. [Google Scholar] [CrossRef]

- Mantese, L.; Rossow, U.; Aspnes, D.E. Surface-induced optical anisotropy of oxidized, clean, and hydrogenated vicinal Si (001) surfaces. Appl. Surf. Sci. 1996, 107, 35–41. [Google Scholar] [CrossRef]

- Martin, D.S.; Weightman, P. Reflection anisotropy spectroscopy: An optical probe of surfaces and interfaces. Surf. Rev. Lett. 2000, 7, 389–397. [Google Scholar] [CrossRef]

- Spinella, C.; Lombardo, S. Crystallization Kinetics of Amorphous Silicon. J. Appl. Phys. 1998, 84, 5383–5414. [Google Scholar] [CrossRef]

- Hue, D.T.H.; Van Lam, N.; Dinh, V.H.; Nguyen, T.G.; Bui, T.Q.; Van Lich, L. Atomic-level analysis of unusual mechanical and failure behaviors in compositionally graded nanowires: A molecular dynamics study. Vacuum 2024, 225, 113243. [Google Scholar] [CrossRef]

- Knez, M.; Nielsch, K.; Niinistö, L. Synthesis and surface engineering of complex nanostructures by atomic layer deposition. Adv. Mater. 2007, 19, 3425–3438. [Google Scholar] [CrossRef]

- Heurlin, M.; Anttu, N.; Camus, C.; Samuelson, L.; Borgstrom, M.T. In situ characterization of nanowire dimensions and growth dynamics by optical reflectance. Nano Lett. 2015, 15, 3597–3602. [Google Scholar] [CrossRef]

- Su, P.; Zhang, Z.; Luo, L.; Zhang, Z.; Lan, C.; Li, Y.; Xu, S.; Han, X.; Lin, G.; Li, C.; et al. Silicon nanowire array weaved by carbon chains for stretchable lithium–ion battery anode. Small 2024, 20, 2307716. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.; Zhang, X.; Jie, J.; Xie, C.; Zhang, X.; Sun, B.; Wang, Y.; Gao, P. Graphene transparent conductive electrodes for highly efficient silicon nanostructures-based hybrid heterojunction solar cells. J. Phys. Chem. C 2013, 117, 11968–11976. [Google Scholar] [CrossRef]

- Wang, R.; Chen, C.; Zheng, Y.; Wang, H.; Liu, J.W.; Yu, S.H. Structure–property relationship of assembled nanowire materials. Mater. Chem. Front. 2020, 4, 2881–2903. [Google Scholar] [CrossRef]

- Palummo, M.; Witkowski, N.; Pluchery, O.; Del Sole, R.; Borensztein, Y. Reflectance-anisotropy spectroscopy and surface differential reflectance spectra at the Si (100) surface: Combined experimental and theoretical study. Phys. Rev. B Condens. Matter Mater. Phys. 2009, 79, 035327. [Google Scholar] [CrossRef]

- Stutzmann, M. Optical properties of silicon nanostructures. Phys. Status Solidi (b) 1995, 192, 273–286. [Google Scholar] [CrossRef]

- Noffsinger, J.; Kioupakis, E.; Van de Walle, C.G.; Louie, S.G.; Cohen, M.L. Phonon-assisted optical absorption in silicon from first principles. Phys. Rev. Lett. 2012, 108, 167402. [Google Scholar] [CrossRef]

- Zhang, D.; Niu, H.; Li, Y.; Huang, H.M.; Jiang, P.; Li, Y.L. Tuning of electronic and optical properties of a predicted silicon allotrope: Hexagonal silicon h 10-Si. Phys. Rev. B 2021, 104, 125201. [Google Scholar] [CrossRef]

- Kazemi-Zanjani, N.; Kergrene, E.; Liu, L.; Sham, T.K.; Lagugné-Labarthet, F. Tip-enhanced Raman imaging and nano spectroscopy of etched silicon nanowires. Sensors 2013, 13, 12744–12759. [Google Scholar] [CrossRef]

- Cuscunà, M.; Convertino, A.; Mariucci, L.; Fortunato, G.; Felisari, L.; Nicotra, G.; Spinella, C.; Pecora, A.; Martelli, F. Low-temperature, self-catalyzed growth of Si nanowires. Nanotechnology 2010, 21, 255601. [Google Scholar] [CrossRef] [PubMed]

- Wang, B.; Ma, C.; Yu, P.; Govorov, A.O.; Xu, H.; Wang, W.; Besteiro, L.V.; Jing, Z.; Li, P.; Wang, Z. Ultra-broadband nanowire metamaterial absorber. Photonics Res. 2022, 10, 2718–2727. [Google Scholar] [CrossRef]

- Park, I.; Li, Z.; Pisano, A.P.; Williams, R.S. Top-down fabricated silicon nanowire sensors for real-time chemical detection. Nanotechnology 2009, 21, 015501. [Google Scholar] [CrossRef] [PubMed]

- Kohandehghan, A.; Kalisvaart, P.; Cui, K.; Kupsta, M.; Memarzadeh, E.; Mitlin, D. Silicon nanowire lithium-ion battery anodes with ALD deposited TiN coatings demonstrate a major improvement in cycling performance. J. Mater. Chem. A 2013, 1, 12850–12861. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, C.; Wong, A.B.; Resasco, J.; Yang, P. MoS2-wrapped silicon nanowires for photoelectrochemical water reduction. Nano Res. 2015, 8, 281–287. [Google Scholar] [CrossRef]

- Leghrib, R.; Felten, A.; Pireaux, J.; Llobet, E. Gas sensors based on doped-CNT/SnO2 composites for NO2 detection at room temperature. Thin Solid Films 2011, 520, 966–970. [Google Scholar] [CrossRef]

- Syrlybekov, A.; Arca, E.; Verre, R.; O Coileain, C.; Toktarbaiuly, O.; Khalid, A.; Zhang, H.; Shvets, I.V. Induced morphological changes on vicinal MgO (100) subjected to high-temperature annealing: Step formation and surface stability. Surf. Interface Anal. 2015, 47, 969–977. [Google Scholar] [CrossRef]

- Toktarbaiuly, O.; Syrlybekov, A.; Nuraje, N.; Sugurbekova, G.; Shvets, I.V. Surface faceting of vicinal SrTiO3(100). Mater. Today Proc. 2022, 71, 69–77. [Google Scholar] [CrossRef]

- Usov, V.; Stoyanov, S.; Coileain, C.O.; Toktarbaiuly, O.; Shvets, I.V. Antiband instability on vicinal Si(111) under the condition of diffusion-limited sublimation. Phys. Rev. B Condens. Matter Mater. Phys. 2012, 86, 195317. [Google Scholar] [CrossRef]

- Zeybek, O. An Optical Surface Probe by Reflectance Anisotropy Spectroscopy. Hittite J. Sci. Eng. 2019, 6, 147–152. [Google Scholar] [CrossRef]

- Mussabek, G.; Lysenko, V.; Yermukhamed, D.; Sivakov, V.; Timoshenko, V.Y. Thermally induced evolution of the structure and optical properties of silicon nanowires. Results Phys. 2020, 18, 103258. [Google Scholar] [CrossRef]

- Arendse, C.J.; Malgas, G.F.; Muller, T.F.G.; Knoesen, D.; Oliphant, C.J.; Motaung, D.E.; Mwakikunga, B.W. Thermally induced nano-structural and optical changes of nc-Si: H deposited by hot-wire CVD. Nanoscale Res. Lett. 2009, 4, 307. [Google Scholar] [CrossRef]

- Dorofeev, S.G.; Ischenko, A.A.; Kononov, N.N.; Fetisov, G.V. Effect of annealing temperature on the optical properties of nanosilicon produced from silicon monoxide. Curr. Appl. Phys. 2012, 12, 718–725. [Google Scholar] [CrossRef]

- Cen, Z.H.; Chen, T.P.; Ding, L.; Yang, M.; Wong, J.I.; Liu, Z.; Liu, Y.C.; Fung, S. Annealing effect on the optical properties of implanted silicon in a silicon nitride matrix. Appl. Phys. Lett. 2008, 93, 023122. [Google Scholar] [CrossRef]

- Woo, Y.S.; Kang, K.; Jo, M.-H.; Jeon, J.-M.; Kim, M. Solid-phase epitaxy of amorphous Si using single-crystalline Si nanowire seed templates. Appl. Phys. Lett. 2007, 91, 223107. [Google Scholar] [CrossRef]

- Xu, M.; Xue, Z.; Wang, J.; Zhao, Y.; Duan, Y.; Zhu, G.; Roca i Cabarrocas, P. Heteroepitaxial writing of silicon-on-sapphire nanowires. Nano Lett. 2016, 16, 7317–7324. [Google Scholar] [CrossRef]

- Ter-Ovanesyan, E.; Manassen, Y.; Shachal, D. Ordering of amorphous silicon during solid-phase epitaxy studied by scanning tunneling microscopy. Phys. Rev. B 1994, 50, 8020. [Google Scholar] [CrossRef]

- Cheng, Y.; Gan, X.; Liu, Z.; Wang, J.; Xu, J.; Chen, K.; Yu, L. Nanostripe-Confined Catalyst Formation for Uniform Growth of Ultrathin Silicon nanowires. Nanomaterials 2022, 13, 121. [Google Scholar] [CrossRef]

- Rothman, A.; Bukvisova, K.; Itzhak, N.R.; Kaplan-Ashiri, I.; Kossoy, A.E.; Sui, X.; Joselevich, E. Real-time study of surface-guided nanowire growth by in situ scanning electron microscopy. ACS Nano 2022, 16, 18757–18766. [Google Scholar] [CrossRef] [PubMed]

- Dubrovskii, V.G. Modeling catalyst-free growth of III-V nanowires: Empirical and rigorous approaches. Nanomaterials 2023, 13, 1253. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Keller, C.; Dietrich, M.; Olli, P.E.; Gentile, P.; Pouget, S.; Chenevier, P. Porous silicon-nanowire-based electrode for the photoelectrocatalytic production of hydrogen. Sustain. Energy Fuels 2023, 7, 4864–4876. [Google Scholar] [CrossRef]

| Annealing T (°C) | Mean NW Height (nm) | σ (nm) | Areal Coverage (%) | Comments |

|---|---|---|---|---|

| 405 | 10.6 ± 0.8 | 1.9 | 82 | Vertically aligned, uniform diameter |

| 577 | 7.9 ± 1.0 | 2.4 | 71 | Tip thinning and slight coalescence |

| 715 | 2.8 ± 0.7 | 0.9 | 34 | Nanowire stumps: ridge valleys start to flatten |

| 804 | <0.5 | — | <5 | Atomically flat terraces, PSD identical to bare sapphire |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Toktarbaiuly, O.; Zhazitov, M.; Abdullah, M.; Tezekbay, Y.; Kydyrbay, N.; Nuraje, N.; Duisebayev, T. In Situ Optical Monitoring and Morphological Evolution of Si Nanowires Grown on Faceted Al2O3(0001) Substrates. Nanomaterials 2025, 15, 1589. https://doi.org/10.3390/nano15201589

Toktarbaiuly O, Zhazitov M, Abdullah M, Tezekbay Y, Kydyrbay N, Nuraje N, Duisebayev T. In Situ Optical Monitoring and Morphological Evolution of Si Nanowires Grown on Faceted Al2O3(0001) Substrates. Nanomaterials. 2025; 15(20):1589. https://doi.org/10.3390/nano15201589

Chicago/Turabian StyleToktarbaiuly, Olzat, Mergen Zhazitov, Muhammad Abdullah, Yerbolat Tezekbay, Nazerke Kydyrbay, Nurxat Nuraje, and Tolagay Duisebayev. 2025. "In Situ Optical Monitoring and Morphological Evolution of Si Nanowires Grown on Faceted Al2O3(0001) Substrates" Nanomaterials 15, no. 20: 1589. https://doi.org/10.3390/nano15201589

APA StyleToktarbaiuly, O., Zhazitov, M., Abdullah, M., Tezekbay, Y., Kydyrbay, N., Nuraje, N., & Duisebayev, T. (2025). In Situ Optical Monitoring and Morphological Evolution of Si Nanowires Grown on Faceted Al2O3(0001) Substrates. Nanomaterials, 15(20), 1589. https://doi.org/10.3390/nano15201589