Si-HgTe Quantum Dot Visible-Infrared Photodetector

Abstract

:1. Introduction

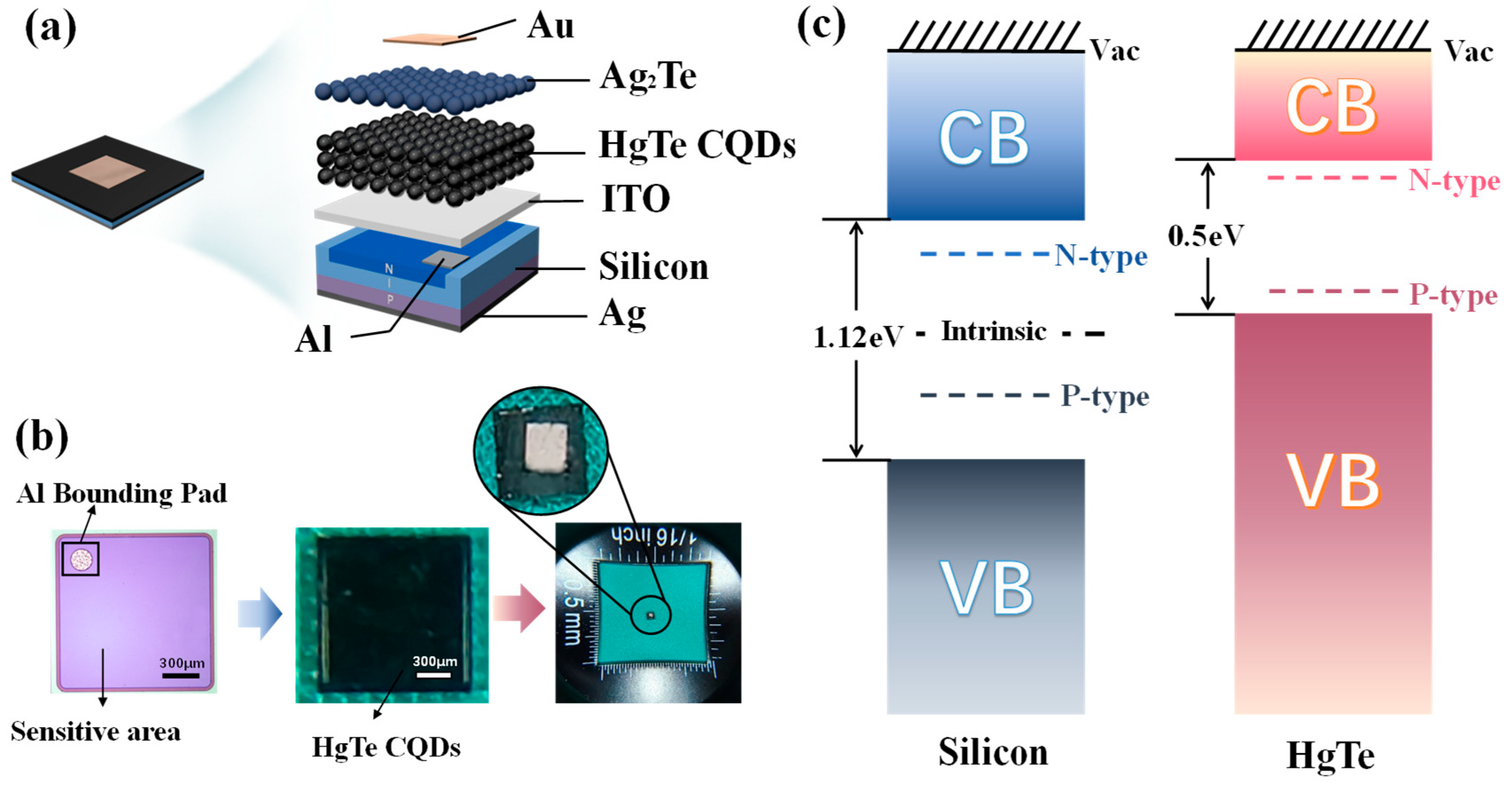

2. Materials and Methods

2.1. Synthesis of HgTe CQDs

2.2. Synthesis of Ag2Te CQDs

2.3. Fabrication of VIS-SWIR Stacked Photodetector

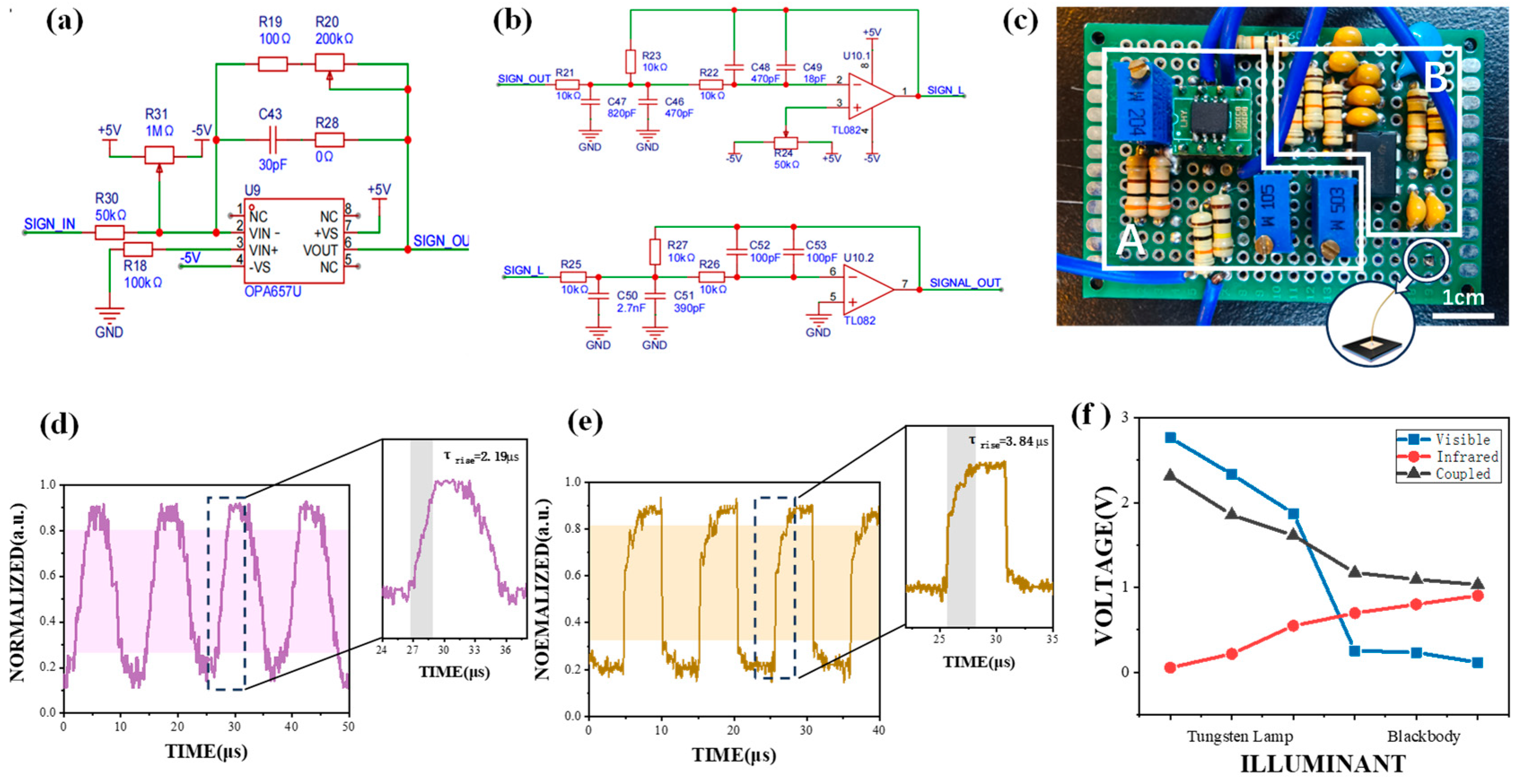

2.4. Design of TIA Circuit

2.5. Characterizations

3. Results and Discussion

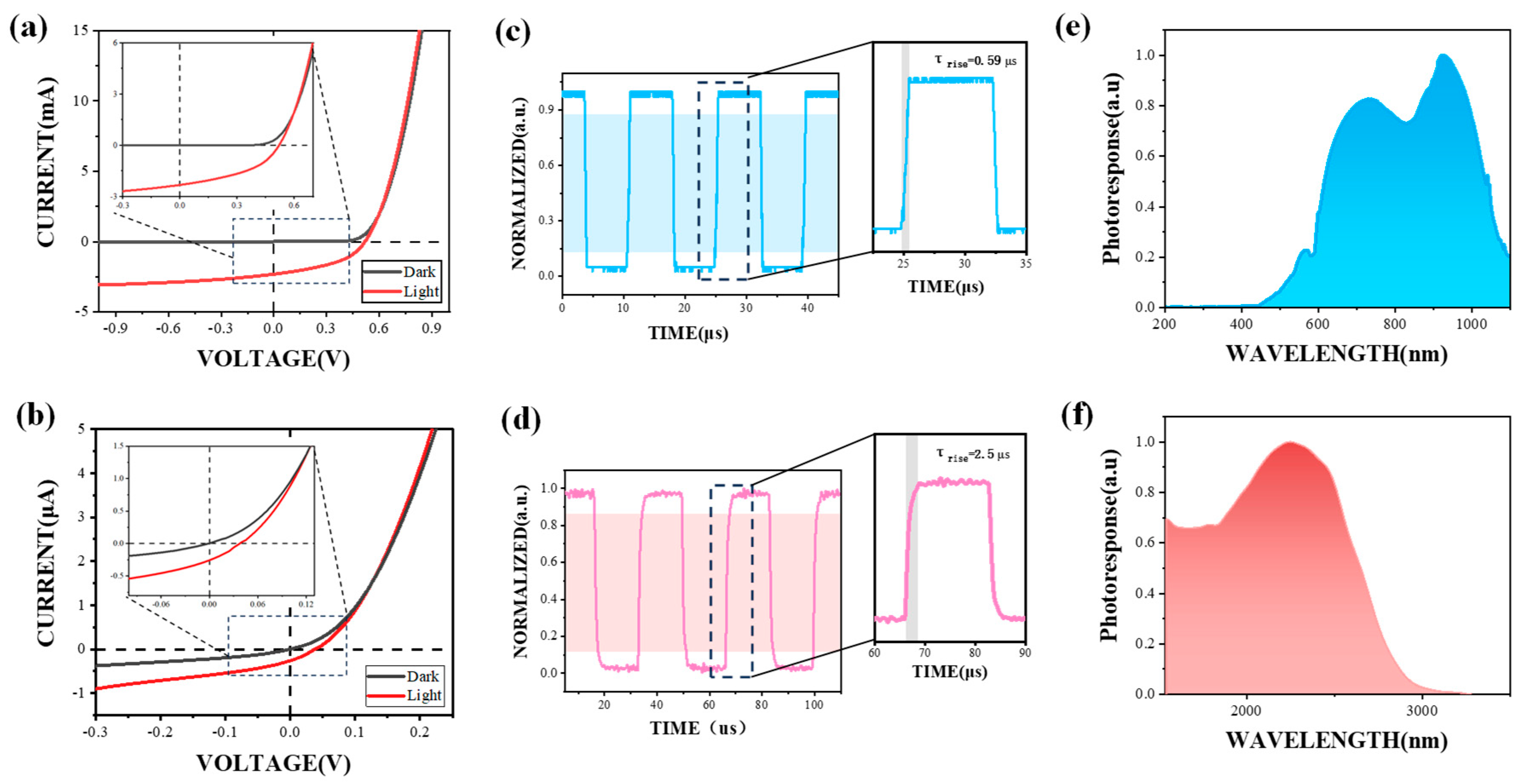

3.1. Characterizations of Single-Band Photodetectors

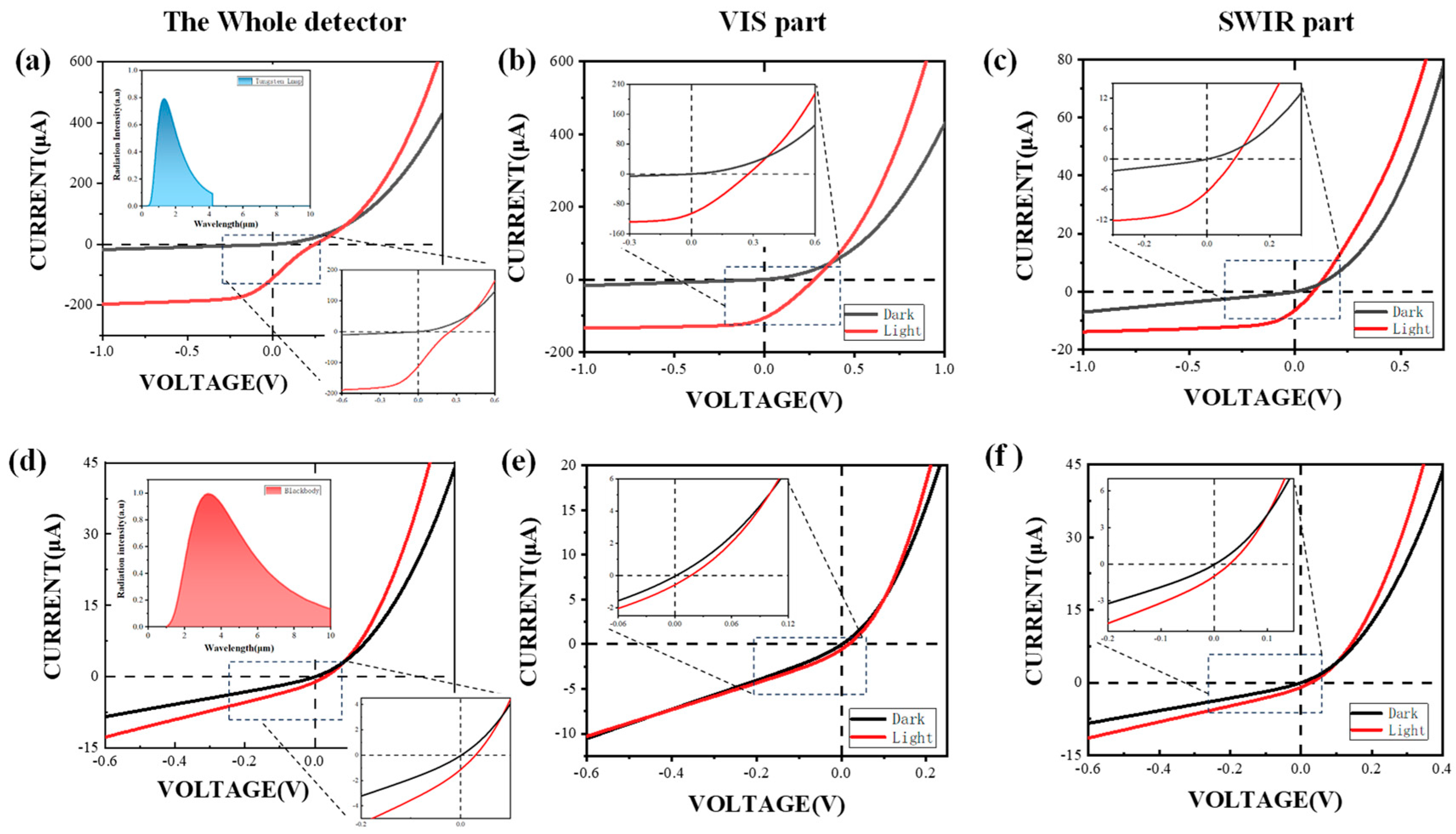

3.2. Characterizations of VIS-SWIR Stacked Photodetectors

3.3. Trans-Impedance Amplifier Circuit

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Meng, L.; Xu, Q.; Zhang, J.; Wang, X. Colloidal Quantum Dot Materials for Next-Generation near-Infrared Optoelectronics. Chem. Commun. 2024, 60, 1072–1088. [Google Scholar] [CrossRef]

- Zeng, L.; Chen, Q.; Zhang, Z.; Wu, D.; Yuan, H.; Li, Y.; Qarony, W.; Lau, S.P.; Luo, L.; Tsang, Y.H. Multilayered PdSe2/Perovskite Schottky Junction for Fast, Self-Powered, Polarization-Sensitive, Broadband Photodetectors, and Image Sensor Application. Adv. Sci. 2019, 6, 1901134. [Google Scholar] [CrossRef]

- Sun, S.; Li, Y.; Chen, F. Innovative CQD Detector for Broadband Multispectral Imaging. Light Sci. Appl. 2024, 13, 308. [Google Scholar] [CrossRef]

- Chen, P.; Wu, Z.; Shi, Y.; Li, C.; Wang, J.; Yang, J.; Dong, X.; Gou, J.; Wang, J.; Jiang, Y. High-performance Silicon-based PbSe-CQDs Infrared Photodetector. J. Mater. Sci. Mater. Electron. 2021, 32, 9452–9462. [Google Scholar] [CrossRef]

- Mauthe, S.; Baumgartner, Y.; Sousa, M.; Ding, Q.; Rossell, M.D.; Schenk, A.; Czornomaz, L.; Moselund, K.E. High-Speed III-V Nanowire Photodetector Monolithically Integrated on Si. Nat. Commun. 2020, 11, 4565. [Google Scholar] [CrossRef] [PubMed]

- Gong, W.; Gao, F.; Bai, J.; Jiang, Y.; Wang, T.; Yan, J.; Li, L. A Design Strategy for Low-Cost Single/Dual-Band Photodetector: Bulk Heterojunction and Interface Engineering. Small 2024, 21, 2403255. [Google Scholar] [CrossRef] [PubMed]

- Wang, B. High-Speed Si-Ge Avalanche Photodiodes. PhotoniX 2022, 3, 8. [Google Scholar] [CrossRef]

- Wang, F.; Wang, Z.; Xu, K.; Wang, F.; Wang, Q.; Huang, Y.; Yin, L.; He, J. Tunable GaTe-MoS2 van Der Waals p–n Junctions with Novel Optoelectronic Performance. Nano Lett. 2015, 15, 7558–7566. [Google Scholar] [CrossRef] [PubMed]

- Elahi, E.; Rabeel, M.; Ahmed, B.; Aziz, J.; Suleman, M.; Khan, M.A.; Rehman, S.; Rehmat, A.; Asim, M.; Rehman, M.A.; et al. Revealing Bipolar Photoresponse in Multiheterostructured WTe2–GaTe/ReSe2–WTe2 P–N Diode by Hybrid 2D Contact Engineering. ACS Appl. Mater. Interfaces 2024, 16, 54367–54376. [Google Scholar] [CrossRef]

- Mohammed, W.F.; Humoody, M.A.; Al-Tikriti, M.N. Simulation of Photogenerated Current of PN Silicon Photodetector Enhanced by Impurity Photovoltaic Effect. Renew. Sustain. Energy Rev. 2013, 26, 408–413. [Google Scholar] [CrossRef]

- Cansizoglu, H.; Ponizovskaya Devine, E.; Gao, Y.; Ghandiparsi, S.; Yamada, T.; Elrefaie, A.F.; Wang, S.-Y.; Islam, M.S. A New Paradigm in High-Speed and High-Efficiency Silicon Photodiodes for Communication—Part I: Enhancing Photon–Material Interactions via Low-Dimensional Structures. IEEE Trans. Electron Devices 2017, 65, 372–381. [Google Scholar] [CrossRef]

- Xue, X.; Luo, Y.; Hao, Q.; Cao, J.; Tang, X.; Liu, Y.; Chen, M. Low Dark-Current Quantum-Dot Infrared Imager. ACS Photonics 2023, 10, 4290–4298. [Google Scholar] [CrossRef]

- Liu, M.; Yazdani, N.; Yarema, M.; Jansen, M.; Wood, V.; Sargent, E.H. Colloidal Quantum Dot Electronics. Nat. Electron. 2021, 4, 548–558. [Google Scholar] [CrossRef]

- Siontas, S.; Li, D.; Wang, H.; Aravind, A.V.P.S.; Zaslavsky, A.; Pacifici, D. High-Performance Germanium Quantum Dot Photodetectors in the Visible and near Infrared. Mater. Sci. Semicond. Process. 2019, 92, 19–27. [Google Scholar] [CrossRef]

- Kuo, M.-H.; Lai, W.-T.; Lee, S.-W.; Chen, Y.-C.; Chang, C.-W.; Chang, W.-H.; Hsu, T.-M.; Li, P.-W. Design of Multifold Ge/Si/Ge Composite Quantum-Dot Heterostructures for Visible to near-Infrared Photodetection. Opt. Lett. 2015, 40, 2401–2404. [Google Scholar] [CrossRef] [PubMed]

- Hwang, A.; Park, M.; Park, Y.; Shim, Y.; Youn, S.; Lee, C.-H.; Jeong, H.B.; Jeong, H.Y.; Chang, J.; Lee, K.; et al. Visible and Infrared Dual-Band Imaging via Ge/MoS2 van Der Waals Heterostructure. Sci. Adv. 2021, 7, eabj2521. [Google Scholar] [CrossRef]

- Sridhar, S.R.; Tailor, N.K.; Satapathi, S.; Kumar, B. Narrow Dual-Band Photodetector Based on Cs2 AgBiBr6 Lead-Free Double Perovskite Single Crystal. IEEE Trans. Electron Devices 2024, 71, 6838–6842. [Google Scholar] [CrossRef]

- Huang, B.; Liu, J.; Han, Z.; Gu, Y.; Yu, D.; Xu, X.; Zou, Y. High-Performance Perovskite Dual-Band Photodetectors for Potential Applications in Visible Light Communication. ACS Appl. Mater. Interfaces 2020, 12, 48765–48772. [Google Scholar] [CrossRef] [PubMed]

- Kim, W.; Seo, Y.; Ahn, D.; Kim, I.S.; Balamurugan, C.; Jung, G.Y.; Kwon, S.; Kim, H.; Pak, Y. Monolithic Perovskite–Silicon Dual-Band Photodetector for Efficient Spectral Light Discrimination. Adv. Sci. 2024, 11, 2308840. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Lin, D.; Xing, J.; Zhao, H.; Wan, H.; Wang, H.; Ji, Z.; Chen, X. Mode-Switching Single-Pixel Imaging via a High-Performance Perovskite-Si Dual-Mode Photodetector. Photonics Res. 2024, 12, 2873–2880. [Google Scholar] [CrossRef]

- Qiu, Y.; Yan, N.; Yao, H.; Chen, M. Plasmon-Enhanced HgTe Colloidal Quantum Dot Infrared Photodetectors. Infrared Phys. Technol. 2023, 135, 104980. [Google Scholar] [CrossRef]

- Xue, X.; Hao, Q.; Chen, M. Very Long Wave Infrared Quantum Dot Photodetector up to 18 μm. Light Sci. Appl. 2024, 13, 89. [Google Scholar] [CrossRef]

- Xia, K.; Gao, X.D.; Fei, G.T.; Xu, S.H.; Liang, Y.F.; Qu, X.X. High-Performance Visible to Mid-Infrared Photodetectors Based on HgTe Colloidal Quantum Dots under Room Temperature. ACS Appl. Mater. Interfaces 2024, 16, 23717–23723. [Google Scholar] [CrossRef]

- Qin, Y.; Guo, T.; Liu, J.; Lin, T.; Wang, J.; Chu, J. Colloidal Quantum Dots in Very-Long-Wave Infrared Detection: Progress, Challenges, and Opportunities. ACS Omega 2023, 8, 19137–19144. [Google Scholar] [CrossRef]

- Hu, Z.; Qin, Y.; Liu, J.; Guo, T.; Wang, J. Postsynthetic Size Focusing via Digestive Ripening in HgTe Quantum Dots. J. Phys. Chem. Lett. 2024, 15, 12636–12642. [Google Scholar] [CrossRef] [PubMed]

- Xue, X.; Chen, M.; Luo, Y.; Qin, T.; Tang, X.; Hao, Q. High-Operating-Temperature Mid-Infrared Photodetectors via Quantum Dot Gradient Homojunction. Light Sci. Appl. 2023, 12, 2. [Google Scholar] [CrossRef]

- Zhao, X.; Yao, H.; Qiu, Y.; Yan, N.; Hao, Q.; Chen, M. Assessing the Potential and Limitations of PbS and HgTe Colloidal Quantum Dot Infrared Detectors for Free Space Optical Communication. Adv. Mater. Technol. 2024, 9, 2400302. [Google Scholar] [CrossRef]

- Geisz, J.F.; France, R.M.; Schulte, K.L.; Steiner, M.A.; Norman, A.G.; Guthrey, H.L.; Young, M.R.; Song, T.; Moriarty, T. Six-Junction III–V Solar Cells with 47.1% Conversion Efficiency under 143 Suns Concentration. Nat. Energy 2020, 5, 326–335. [Google Scholar] [CrossRef]

- Laoufi, A.M.; Dennai, B.; Kadi, O.; Fillali, M. Numerical Modeling of Multi-Junction Solar Cell-Based CIGS with Two Sub-Cells in Parallel Using Silvaco TCAD. Chalcogenide Lett. 2021, 18, 297–301. [Google Scholar] [CrossRef]

- Wang, S.; Xiang, X.; Zhou, C.; Zhai, Y.; Quan, R.; Wang, M.; Hou, F.; Zhang, S.; Dong, R.; Liu, T. Simulation of High SNR Photodetector with L-C Coupling and Transimpedance Amplifier Circuit and Its Verification. Rev. Sci. Instrum. 2017, 88, 013107. [Google Scholar] [CrossRef]

- Lee, G.; Lee, J.; Kang, C. Strong and Sustainable Chemical Bonding of TiO2 on Nylon Surface Using 3-Mercaptopropyltrimethoxysilane (3-MPTMS): Analysis of Antimicrobial and Decomposition Characteristics of Contaminants. J. Coat. Technol. Res. 2019, 16, 1399–1409. [Google Scholar] [CrossRef]

- Kohler, T.; Hejtmann, G.; Henneck, S.; Schubert, M.; Guyenot, M. Sol–gel Encapsulation for Power Electronics Utilizing 3-Glycidyloxypropyltriethoxysilane and 3-Mercaptopropyltrimethoxysilane. J. Sol Gel Sci. Technol. 2022, 103, 832–842. [Google Scholar] [CrossRef]

- Ackerman, M.M.; Chen, M.; Guyot-Sionnest, P. HgTe Colloidal Quantum Dot Photodiodes for Extended Short-Wave Infrared Detection. Appl. Phys. Lett. 2020, 116, 083502. [Google Scholar] [CrossRef]

- Tang, X.; Ackerman, M.M.; Chen, M.; Guyot-Sionnest, P. Dual-Band Infrared Imaging Using Stacked Colloidal Quantum Dot Photodiodes. Nat. Photonics 2019, 13, 277–282. [Google Scholar] [CrossRef]

- Li, S.S. Semiconductor Physical Electronics, 2nd ed.; Springer: New York, NY, USA, 2006; pp. 86–102. ISBN 978-0-387-28893-2. [Google Scholar]

- Liu, E.; Zhu, B.; Luo, J. The Physics of Semiconductor, 7th ed.; Publishing House of Electronics Industry: Beijing, China, 2017; p. 377. ISBN 978-7-121-32007-1. [Google Scholar]

- Chen, M.; Xue, X.; Qin, T.; Wen, C.; Hao, Q.; Tang, X. Universal Homojunction Design for Colloidal Quantum Dot Infrared Photodetectors. Adv. Mater. Technol. 2023, 8, 2300315. [Google Scholar] [CrossRef]

- Chen, M.; Guyot-Sionnest, P. Reversible Electrochemistry of Mercury Chalcogenide Colloidal Quantum Dot Films. ACS Nano 2017, 11, 4165–4173. [Google Scholar] [CrossRef] [PubMed]

- Xu, K.; Xiao, X.; Zhou, W.; Jiang, X.; Wei, Q.; Chen, H.; Deng, Z.; Huang, J.; Chen, B.; Ning, Z. Inverted Si:PbS Colloidal Quantum Dot Heterojunction-Based Infrared Photodetector. ACS Appl. Mater. Interfaces 2020, 12, 15414–15421. [Google Scholar] [CrossRef]

| Photodetectors | Detectivity (Jones) | Response Speed (μs) | Spectral Range (nm) | Data Source |

|---|---|---|---|---|

| Si-HgTe | 1.01 × 1011 (VIS) 2.66 × 1010 (SWIR) | 1.65 | 430–2800 | This work |

| Si-PbS | 1.47 × 1011 | 2.04 | 600–1600 | [39] |

| Perovskite-Si | 5.56 × 1013 | 25 | 400–1100 | [20] |

| Si-Ge | 1.2 × 1011 | 1–2 | 400–1550 | [14] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qian, L.; Zhao, X.; Zhang, K.; Huo, C.; Li, Y.; Yan, N.; Shi, F.; Peng, X.; Chen, M. Si-HgTe Quantum Dot Visible-Infrared Photodetector. Nanomaterials 2025, 15, 262. https://doi.org/10.3390/nano15040262

Qian L, Zhao X, Zhang K, Huo C, Li Y, Yan N, Shi F, Peng X, Chen M. Si-HgTe Quantum Dot Visible-Infrared Photodetector. Nanomaterials. 2025; 15(4):262. https://doi.org/10.3390/nano15040262

Chicago/Turabian StyleQian, Lei, Xue Zhao, Kenan Zhang, Chen Huo, Yongrui Li, Naiquan Yan, Feng Shi, Xing Peng, and Menglu Chen. 2025. "Si-HgTe Quantum Dot Visible-Infrared Photodetector" Nanomaterials 15, no. 4: 262. https://doi.org/10.3390/nano15040262

APA StyleQian, L., Zhao, X., Zhang, K., Huo, C., Li, Y., Yan, N., Shi, F., Peng, X., & Chen, M. (2025). Si-HgTe Quantum Dot Visible-Infrared Photodetector. Nanomaterials, 15(4), 262. https://doi.org/10.3390/nano15040262