An In-Plane Single-Photon Emitter Combining a Triangular Split-Ring Micro-Optical Resonator and a Colloidal Quantum Dot

Abstract

1. Introduction

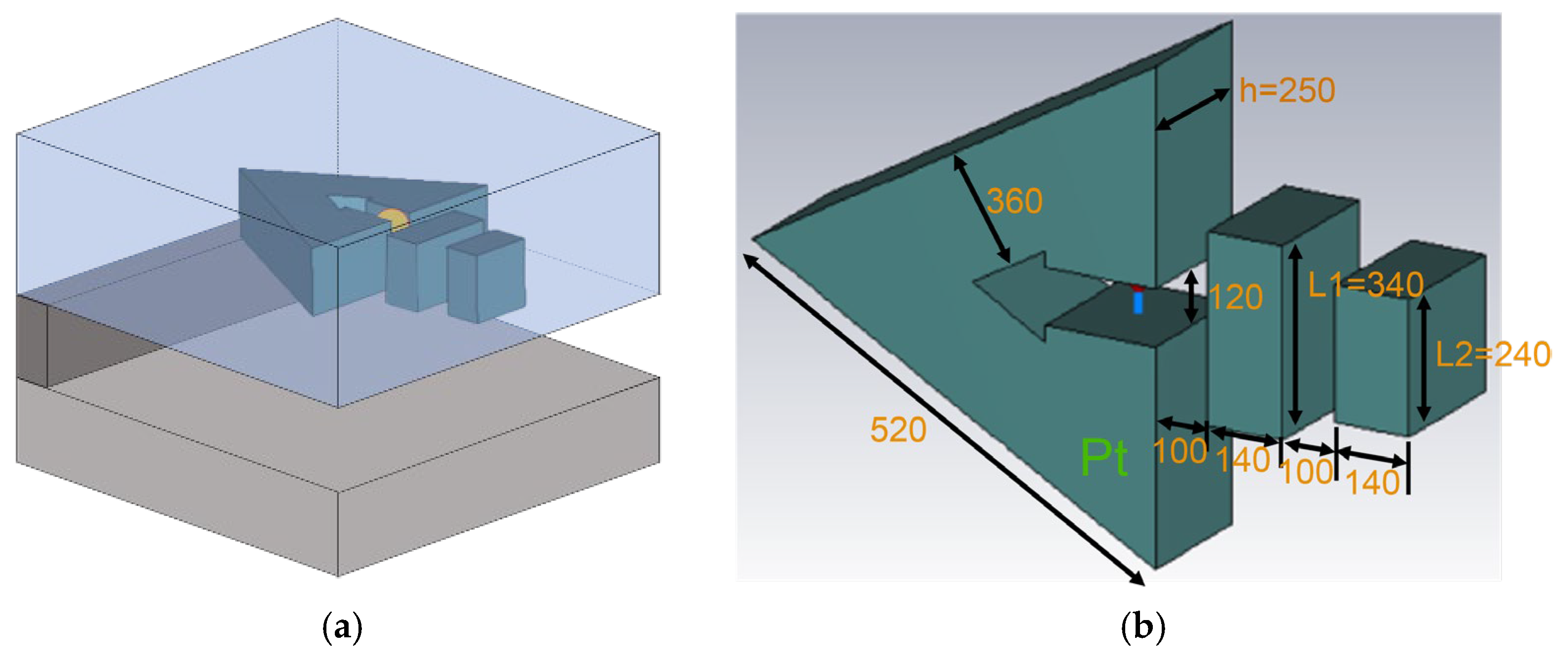

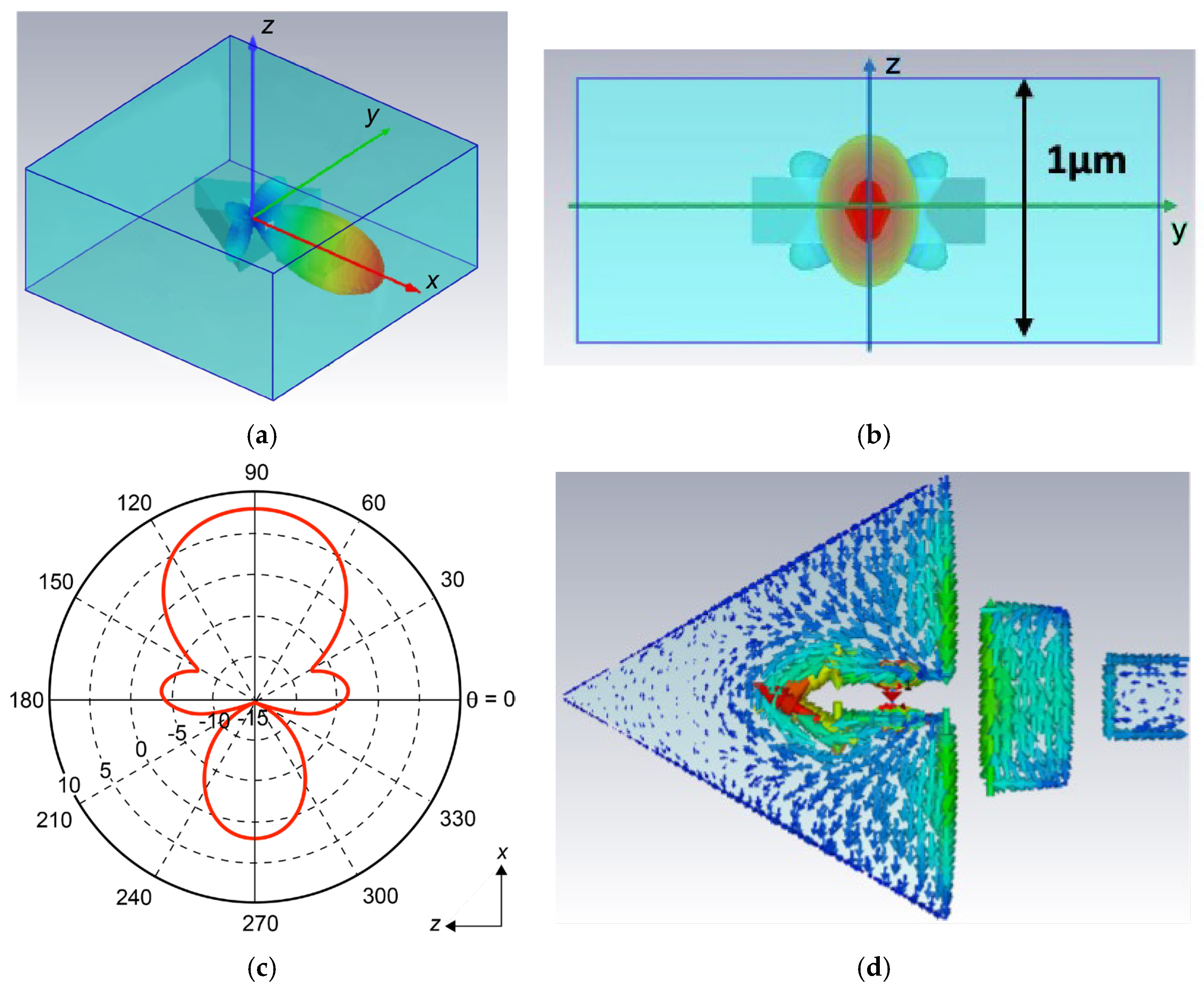

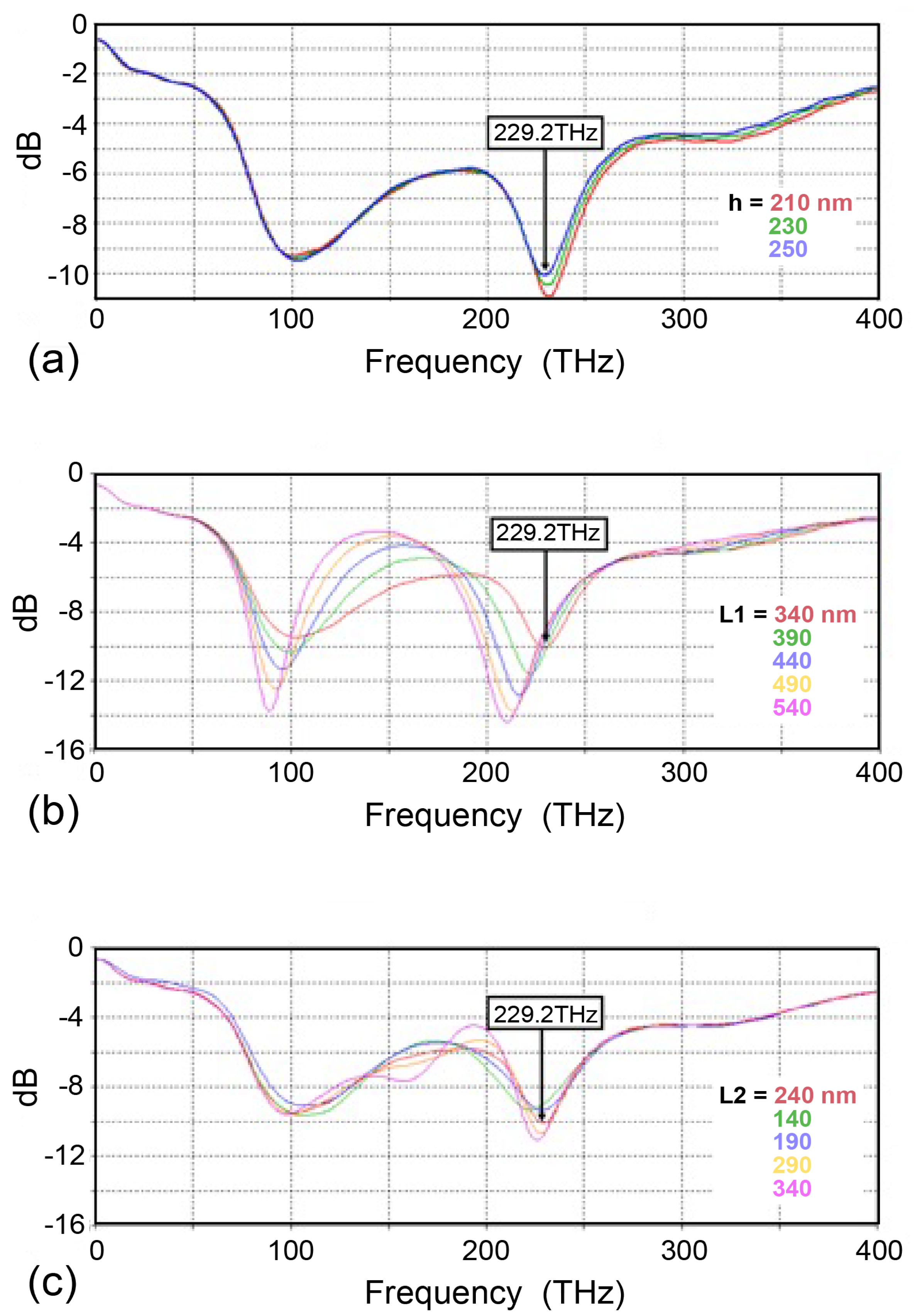

2. Device Structure and Basic Performance

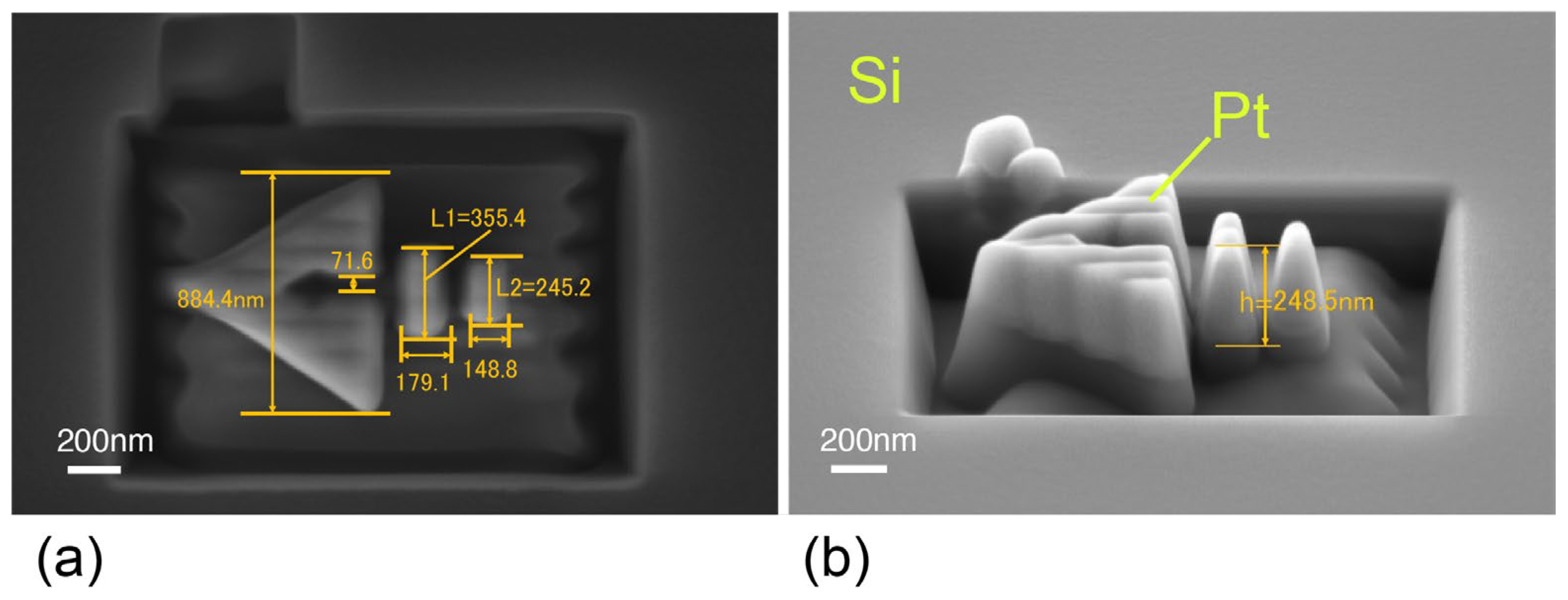

3. Fabrication of SRR and Tolerance of Manufacturing Errors

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lund-Hansen, T.; Stobbe, S.; Julsgaard, B.; Thyrrestrup, H.; Sünner, T.; Kamp, M.; Forchel, A.; Lodahl, P. Experimental Realization of Highly Efficient Broadband Coupling of Single Quantum Dots to a Photonic Crystal Waveguide. Phys. Rev. Lett. 2008, 101, 113903. [Google Scholar] [CrossRef] [PubMed]

- Nomura, M.; Ota, Y.; Kumagai, N.; Iwamoto, S.; Arakawa, Y. Zero-cell photonic crystal nanocavity laser with quantum dot gain. Appl. Phys. Lett. 2010, 97, 191108. [Google Scholar] [CrossRef]

- Nakamura, T.; Asano, T.; Kojima, K.; Kojima, T.; Noda, S. Controlling the emission of quantum dots embedded in photonic crystal nanocavity by manipulating Q-factor and detuning. Phys. Rev. B 2011, 84, 245309. [Google Scholar] [CrossRef]

- Fang, A.; Koschny, T.; Wegener, M.; Soukoulis, C.M. Self-consistent calculation of metamaterials with gain. Phys. Rev. B 2009, 79, 241104. [Google Scholar] [CrossRef]

- Sivan, Y.; Xiao, S.; Chettiar, U.K.; Kildishev, A.V.; Shalaev, V.M. Frequency-domain simulations of a negative-index material with embedded gain. Opt. Express 2009, 17, 24060. [Google Scholar] [CrossRef]

- Meinzer, N.; Ruther, M.; Linden, S.; Soukoulis, C.M.; Khitrova, G.; Hendrickson, J.; Olitzky, J.D.; Gibbs, H.M.; Wegener, M. Arrays of Ag split-ring resonators coupled to InGaAs single-quantum-well gain. Opt. Express 2010, 18, 24140. [Google Scholar] [CrossRef]

- Tanaka, K.; Plum, E.; Ou, J.Y.; Uchino, T.; Zheludev, N.I. Multifold Enhancement of Quantum Dot Luminescence in Plasmonic Metamaterials. Phys. Rev. Lett. 2010, 105, 227403. [Google Scholar] [CrossRef]

- Tanabe, T.; Notomi, M.; Kuramochi, E.; Shinya, A.; Taniyama, H. Trapping and delaying photons for one nanosecond in an ultrasmall high-Q photonic-crystal nanocavity. Nat. Photonics 2006, 1, 49–52. [Google Scholar] [CrossRef]

- Tandaechanurat, A.; Ishida, S.; Aoki, K.; Guimard, D.; Nomura, M.; Iwamoto, S.; Arakawa, Y. Demonstration of high-three-dimensional photonic crystal nanocavity embedding quantum dots. Appl. Phys. Lett. 2009, 94, 171115. [Google Scholar] [CrossRef]

- Lee, K.G.; Chen, X.W.; Eghlidi, H.; Kukura, P.; Lettow, R.; Renn, A.; Sandoghdar, V.; Götzinger, S. A planar dielectric antenna for directional single-photon emission and near-unity collection efficiency. Nat. Photonics 2011, 5, 166–169. [Google Scholar] [CrossRef]

- Curto, A.G.; Taminiau, T.H.; Volpe, G.; Kreuzer, M.P.; Quidant, R.; van Hulst, N.F. Multipolar radiation of quantum emitters with nanowire optical antennas. Nat. Commun. 2013, 4, 1750. [Google Scholar] [CrossRef] [PubMed]

- Vercruysse, D.; Zheng, X.; Sonnefraud, Y.; Verellen, N.; Di Martino, G.; Lagae, L.; Vandenbosch, G.A.E.; Moshchalkov, V.V.; Maier, S.A.; Van Dorpe, P. Directional Fluorescence Emission by Individual V-Antennas Explained by Mode Expansion. ACS Nano 2014, 8, 8232–8241. [Google Scholar] [CrossRef] [PubMed]

- Hoang, T.B.; Akselrod, G.M.; Mikkelsen, M.H. Ultrafast Room-Temperature Single Photon Emission from Quantum Dots Coupled to Plasmonic Nanocavities. Nano Lett. 2016, 16, 270–275. [Google Scholar] [CrossRef] [PubMed]

- Livneh, N.; Harats, M.G.; Istrati, D.; Eisenberg, H.S.; Rapaport, R. Highly Directional Room-Temperature Single Photon Device. Nano Lett. 2016, 16, 2527. [Google Scholar] [CrossRef]

- Tang, J.W.; Xiao, J.; Fang, M.D.; Bao, F.L.; Cao, G.J.; Shen, J.Q.; Evans, J.L.; He, S.L. Selective far-field addressing of coupled quantum dots in a plasmonic nanocavity. Nat. Commun. 2018, 9, 1705. [Google Scholar] [CrossRef]

- Ge, D.D.; Marguet, S.; Issa, A.; Jradi, S.; Nguyen, T.H.; Nahra, M.; Béal, J.; Deturche, R.; Chen, H.S.; Blaize, S.; et al. Hybrid plasmonic nano-emitters with controlled single quantum emitter positioning on the local excitation field. Nat. Commun. 2020, 11, 3414. [Google Scholar] [CrossRef]

- Li, S.; Ai, R.; Chui, K.K.; Fang, Y.; Lai, Y.; Zhuo, X.; Shao, L.; Wang, J.; Lin, H.Q. Routing the Exciton Emissions of WS2 Monolayer with the High-Order Plasmon Modes of Ag Nanorods. Nano Lett. 2023, 23, 4183–4190. [Google Scholar] [CrossRef]

- Huang, X.; Horder, J.; Wong, W.W.; Wang, N.; Bian, Y.; Yamamura, K.; Aharonovich, I.; Jagadish, C.; Tan, H.H. Scalable Bright and Pure Single Photon Sources by Droplet Epitaxy on InP Nanowire Arrays. ACS Nano 2024, 18, 5581–5589. [Google Scholar] [CrossRef]

- Khalid, S.; Laussy, F.P. Perfect single-photon sources. Sci. Rep. 2024, 14, 2684. [Google Scholar] [CrossRef]

- Bendix, P.M.; Jauffred, L.; Norregaard, K.; Oddershede, L.B. Optical Trapping of Nanoparticles and Quantum Dots. IEEE J. Sel. Top. Quantum Electron. 2014, 20, 4800112. [Google Scholar]

- Sugawara, M.; Xuan, Y.; Mitsumori, Y.; Edamatsu, K.; Sadgrove, M. Plasmon-enhanced single photon source directly coupled to an optical fiber. Phys. Rev. Res. 2022, 4, 043146. [Google Scholar] [CrossRef]

- Darbandi, M.; Thomann, R.; Nann, T. Single Quantum Dots in Silica Spheres by Microemulsion Synthesis. Chem. Mater. 2005, 17, 5720–5725. [Google Scholar] [CrossRef]

- Yang, Y.; Jing, L.; Yu, X.; Yan, D.; Gao, M. Coating Aqueous Quantum Dots with Silica via Reverse Microemulsion Method: Toward Size-Controllable and Robust Fluorescent Nanoparticles. Chem. Mater. 2007, 19, 4123–4128. [Google Scholar] [CrossRef]

- Chu, M.; Sun, Y.; Xu, S. Silica-coated quantum dots fluorescent spheres synthesized using a quaternary ‘water-in-oil’ microemulsion system. J. Nanopart. Res. 2008, 10, 613–624. [Google Scholar] [CrossRef]

- Qualtieri, A.; Morello, G.; Spinicelli, P.; Todaro, M.T.; Stomeo, T.; Martiradonna, L.; Giorgi, M.D.; Quelin, X.; Buil, S.; Bramati, A.; et al. Nonclassical emission from single colloidal nanocrystals in a microcavity: A route towards room temperature single photon sources. New J. Phys. 2009, 11, 033025. [Google Scholar] [CrossRef]

- Yang, P.; Ando, M.; Murase, N. Highly Luminescent CdSe/CdxZn1−xS Quantum Dots Coated with Thickness-Controlled SiO2 Shell through Silanization. Langmuir 2011, 27, 9535–9540. [Google Scholar] [CrossRef]

- Mukai, K.; Okumura, I.; Nishizaki, Y.; Yamashita, S.; Niwa, K. Silica coating of PbS quantum dots and their position control using a nanohole on Si substrate. Jpn. J. Appl. Phys. 2018, 57, 04FH01. [Google Scholar] [CrossRef]

- Mukai, K.; Sugimoto, T.; Sugisaki, S.; Ikeda, K.; Watanabe, S. Photon generator combined with silica-coated quantum dot and metamaterial fabricated by the scanning probe microscope lithography. Jpn. J. Appl. Phys. 2020, 59, SGGH06. [Google Scholar] [CrossRef]

- Mukai, K.; Watanabe, S.; Okumura, I.; Sugimoto, T. A photon generating device composed of a quantum dot and a metamaterial element. Jpn. J. Appl. Phys. 2019, 58, SBBI06. [Google Scholar] [CrossRef]

- Mukai, K.; Pribyl, I.; Nakagawa, T.; Uchiyama, K. Polarization-controlled ultrasmall single photon emitter combining a quantum dot and an elliptical split ring metamaterial element. Jpn. J. Appl. Phys. 2024, 63, 02SP37. [Google Scholar] [CrossRef]

- Mukai, K.; Shibata, K.; Nakatsuka, Y.; Ikai, M. All-silicon photon emitter with colloidal PbS quantum dot in tunable microcavity. Phy. E low-Dimens. Syst. Nanostruct. 2018, 103, 417–422. [Google Scholar] [CrossRef]

- Tututuncu, B.; Torpi, H.; Urul, B. A comparative study on different types of metamaterials for A comparative study on different types of metamaterials for enhancement of microstrip patch antenna directivity at the Ku-enhancement of microstrip patch antenna directivity at the Ku-band (12 GHz). Turk. J. Elec. Eng. Comput. Sci. 2018, 26, 1171–1179. [Google Scholar]

- Berka, M.; Rouabhi, A.Y.; Bendaoudi, A.; Mahdjoub, Z. Triangular Split Ring Resonators for X-Band Applications and Operations. J. Nano-Electron. Phys. 2022, 14, 01007. [Google Scholar] [CrossRef]

- Sivasangari, A.; Danasegaran, S.K.; Dhanasekar, S.; Britto, E.C.; Paranthaman, M. Design and Analysis of Triangular Split-Ring Resonator–Based Patch Antenna for High-Speed Terahertz Devices. Braz. J. Phys. 2024, 54, 213. [Google Scholar] [CrossRef]

- Scalari, G.; Maissen, C.; Cibella, S.; Leoni, R.; Faist, J. High quality factor, fully switchable terahertz superconducting metasurface. Appl. Phys. Lett. 2014, 105, 261104. [Google Scholar] [CrossRef]

- Lilley, G.; Messner, M.; Unterrainer, K. Improving the quality factor of the localized surface plasmon resonance. Opt. Mater. Exp. 2015, 5, 246872. [Google Scholar] [CrossRef]

- Tan, T.C.W.; Srivastava, Y.K.; Manjappa, M.; Plum, E.; Singh, R. Lattice induced strong coupling and line narrowing of split resonances in metamaterials. Appl. Phys. Lett. 2018, 112, 201111. [Google Scholar] [CrossRef]

- Yang, X.; Xiao, G.; Lu, Y.; Li, G. Narrow plasmonic surface lattice resonances with preference to asymmetric dielectric environment. Opt. Exp. 2019, 27, 371465. [Google Scholar] [CrossRef]

- Yang, H.; Chen, Y.; Liu, M.; Xiao, G.; Luo, Y.; Liu, H.; Li, J.; Yuan, L. High Q-Factor Hybrid Metamaterial Waveguide Multi-Fano Resonance Sensor in the Visible Wavelength Range. Nanomaterials 2021, 11, 1583. [Google Scholar] [CrossRef]

- Deal, B.E.; Grove, A.S. General Relationship for the Thermal Oxidation of Silicon. J. Appl. Phys. 1965, 36, 3770–3778. [Google Scholar] [CrossRef]

- Mukai, K.; Ikeda, K.; Hatta, R. Improvement of monodispersity and shape symmetry of silica shell for PbS quantum dots by introducing surface silanization and adjusting reverse micelle size. Jpn. J. Appl. Phys. 2022, 61, 015001. [Google Scholar] [CrossRef]

- Mukai, K.; Suzuki, S.; Roppongi, H. Improvement of emission intensity of PbS quantum dots in thick silica shell by initial coating in organic solvent. Jpn. J. Appl. Phys. 2023, 62, 108001. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mukai, K.; Uchiyama, K.; Iwata, K.; Pribyl, I. An In-Plane Single-Photon Emitter Combining a Triangular Split-Ring Micro-Optical Resonator and a Colloidal Quantum Dot. Nanomaterials 2025, 15, 335. https://doi.org/10.3390/nano15050335

Mukai K, Uchiyama K, Iwata K, Pribyl I. An In-Plane Single-Photon Emitter Combining a Triangular Split-Ring Micro-Optical Resonator and a Colloidal Quantum Dot. Nanomaterials. 2025; 15(5):335. https://doi.org/10.3390/nano15050335

Chicago/Turabian StyleMukai, Kohki, Kyosuke Uchiyama, Kohei Iwata, and Issei Pribyl. 2025. "An In-Plane Single-Photon Emitter Combining a Triangular Split-Ring Micro-Optical Resonator and a Colloidal Quantum Dot" Nanomaterials 15, no. 5: 335. https://doi.org/10.3390/nano15050335

APA StyleMukai, K., Uchiyama, K., Iwata, K., & Pribyl, I. (2025). An In-Plane Single-Photon Emitter Combining a Triangular Split-Ring Micro-Optical Resonator and a Colloidal Quantum Dot. Nanomaterials, 15(5), 335. https://doi.org/10.3390/nano15050335