Antimicrobial Nanotubes: From Synthesis and Promising Antimicrobial Upshots to Unanticipated Toxicities, Strategies to Limit Them, and Regulatory Issues

Abstract

:1. Introduction

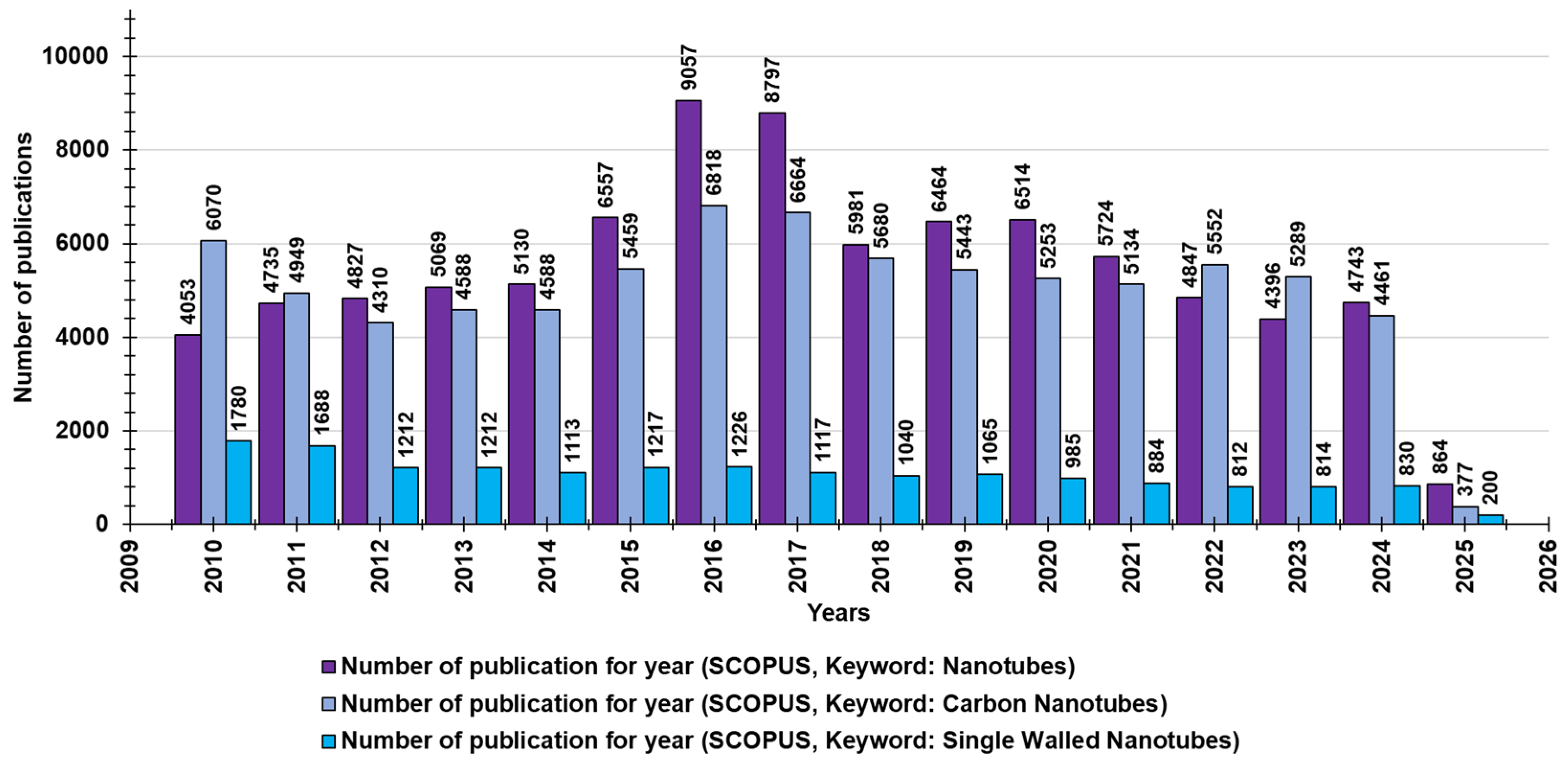

2. Approaching Carbon Nanotubes

2.1. Synthesis of CNTs

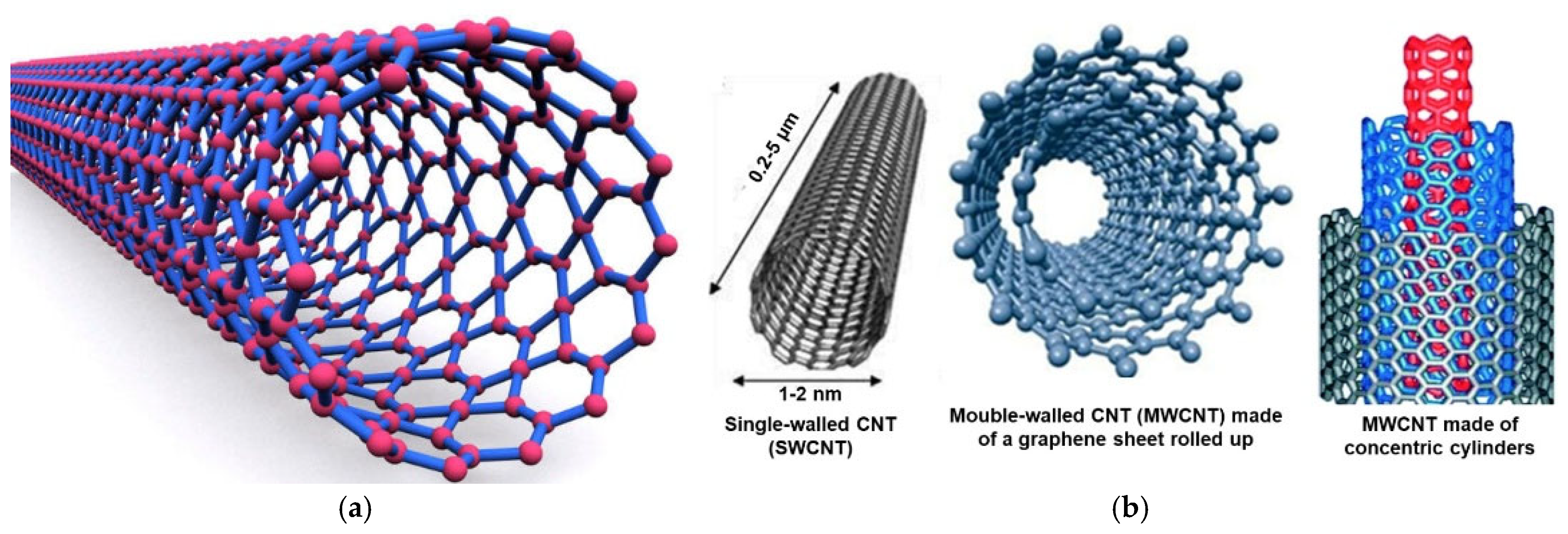

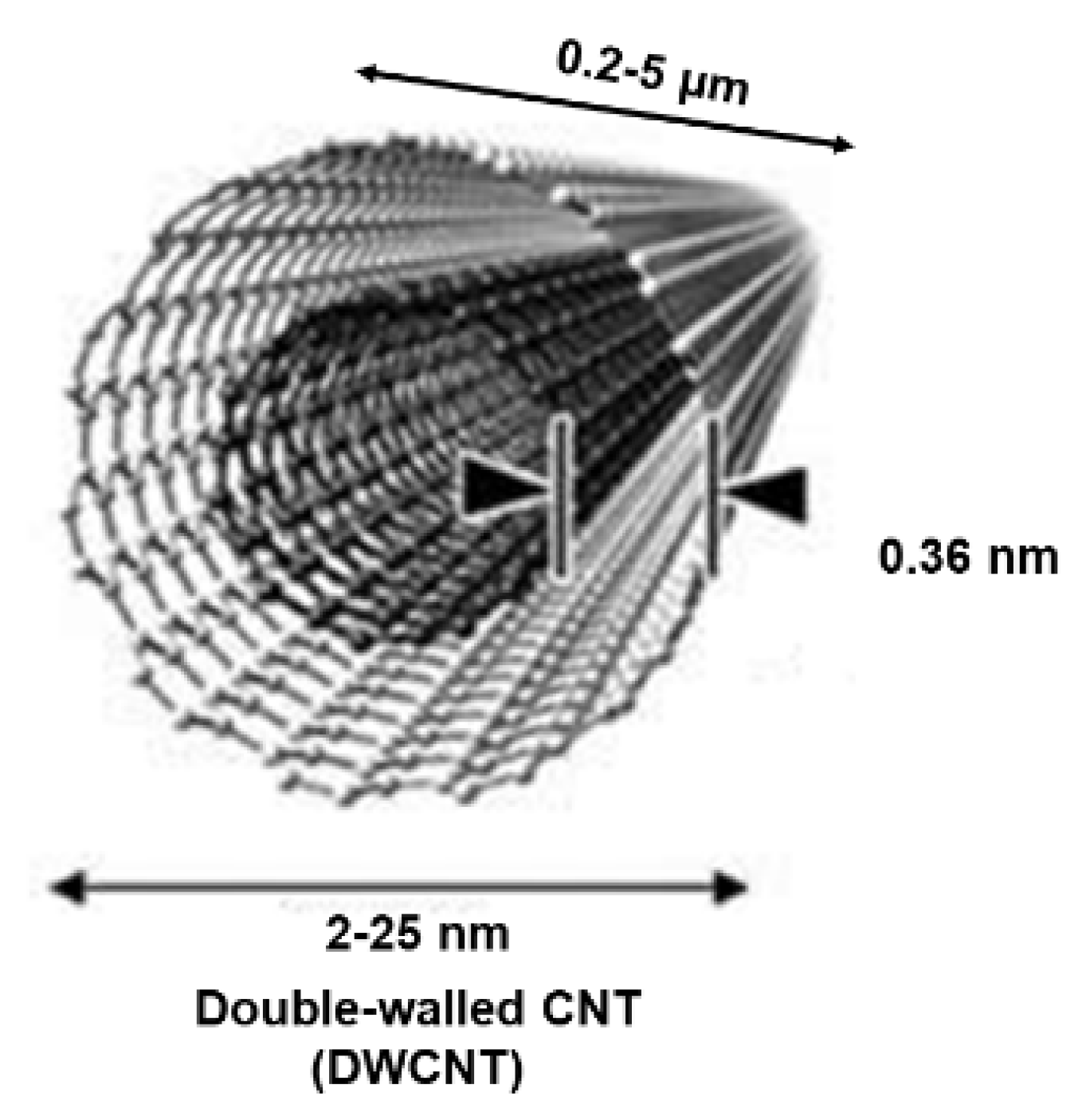

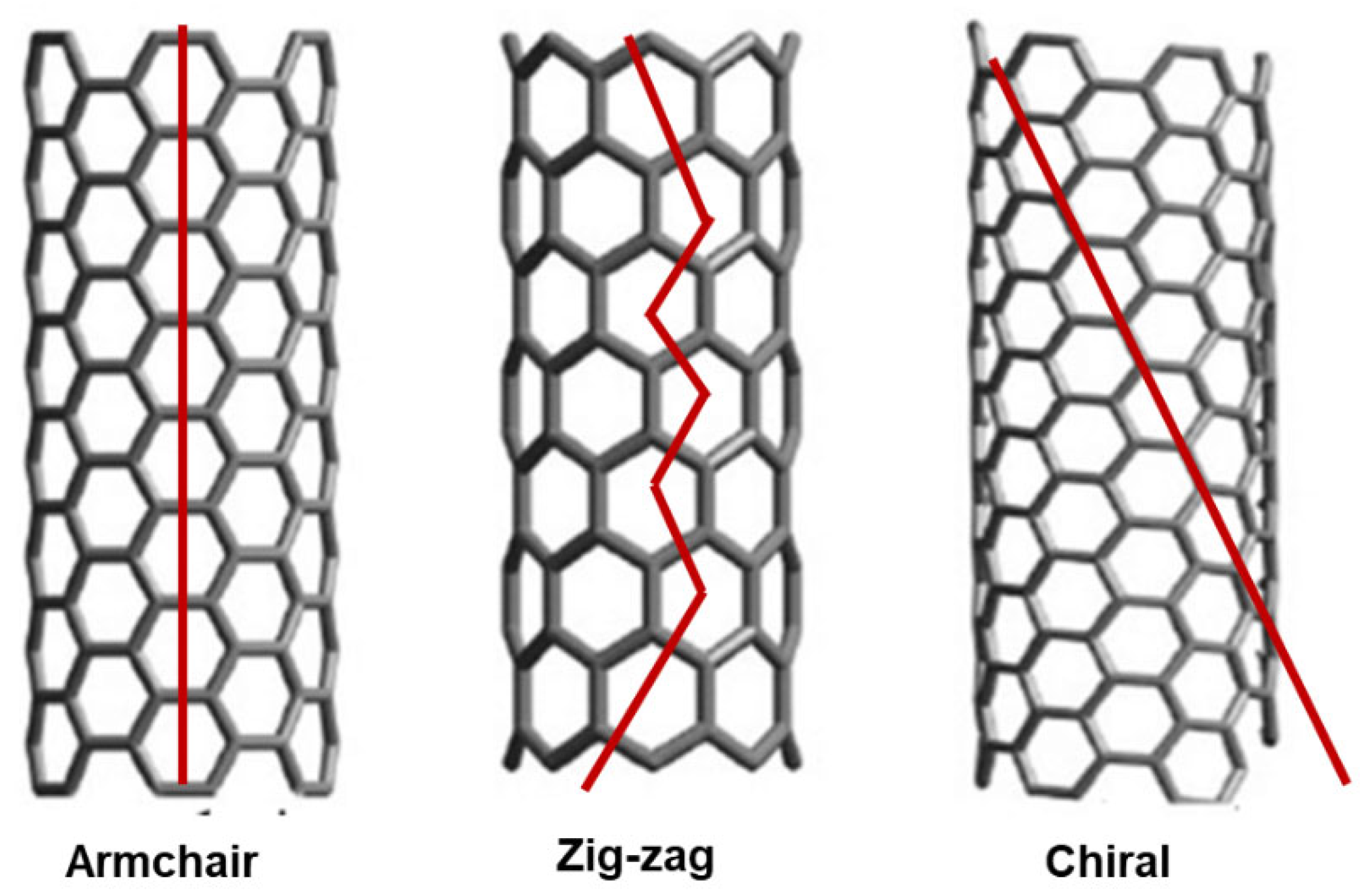

2.2. Architecture and Other Features of CNTs

Relationships Structure/Properties

3. Biomedical Applications of CNTs

3.1. Antimicrobial Properties of Carbon Nanotubes

3.1.1. Mechanisms of Action and Influencing Factors

3.1.2. Most Relevant Case Studies on the Antimicrobial Effects of Non-Modified CNTs

3.1.3. Most Relevant Case Studies on the Antimicrobial Effects of Modified CNTs

Modified SWCNTs

Modified MWCNTs

4. Impediments to the Extensive Application of CNTs: Toxicity Issues

4.1. Introduction to Environmental and Human Safety

Other Hurdles Are Close to Solution

4.2. In Vitro and In Vivo Studies

4.2.1. In Vitro Studies

4.2.2. In Vivo Studies: Pulmonary Toxicity

CNTs Cytotoxic Effects to Other Tissues

5. Possible Strategies to Moderate CNTs’ Toxic Effects: Future Perspective and Preventive Actions

6. Regulatory Considerations

6.1. International Standards Concerning Nanomaterials and CNTs

6.1.1. ISO Standards

6.1.2. ASTM Standards

- E2490 Standard Guide for Measurement of Particle Size Distribution of Nanomaterials in Suspension by Photon Correlation Spectroscopy (PCS);

- E2865 Standard Guide for Measurement of Electrophoretic Mobility and Zeta Potential of Nanosized Biological Materials;

- E2864 Standard Test Method for Measurement of Airborne Metal and Metal Oxide Nanoparticle Surface Area Concentration in Inhalation Exposure Chambers;

- E2524 Standard Test Method for Analysis of Haemolytic Properties of Nanoparticles;

- E2526 Standard Test Method for Evaluation of Cytotoxicity of Nanoparticulate Materials in Porcine Kidney Cells and Human Hepatocarcinoma Cells;

- E2535 Standard Guide for Handling Unbound Engineered Nanoscale Particles in Occupational Settings;

- E3025 Standard Guide for Tiered Approach to Detection and Characterization of Silver Nanomaterials in Textiles;

- E3275-21 Standard Guide for Visualization and Identification of Nanomaterials in Biological and Nonbiological Matrices Using Darkfield Microscopy/Hyperspectral Imaging (DFM/HSI) Analysis;

- E3172-18 Standard Guide for Reporting Production Information and Data for Nano-Objects;

- D8208-19 Standard Practice for Collection of Non-Fibrous Nanoparticles Using a Nanoparticle Respiratory Deposition (NRD) Sampler.

7. Conclusions and Perspectives

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| Key Properties | Potential Uses | Current Hurdles |

|---|---|---|

| Size [61] | Nano-electronics [64] | Electronic heterogeneity [76] |

| Crystallographic defects | ||

| Stone–Wales defects | ||

| Ø < 100 nm Thickness = 1–2 nm Ideally infinite length | Conductors (SWCNTs) Superconductors Semi-conductors 1 Supercapacitors | Not tunable conductivity |

| Electrical and electrochemical properties | Interconnects | ⇩ Controllable orientation |

| ⇧ Electrical conductivity Constant resistively [63] Electrons emission capacity | Chips manufacture [65] Conductivity-enhancing components | ⇩ Organized configuration |

| Thermal Properties | ⇧ Variation in size and density [76] | |

| ⇧ Heat conductivity Expansion | Optics and photonics | |

| Mechanical properties | Light-emitting diodes (LEDs) [66,67] 2 | Export restrictions |

| ⇧ Tensile strength ⇧ Elastic modulus | Photodetectors [68] 2 | |

| Optical Properties | Bolometers [69] 2 | |

| Absorption properties | Optoelectronic memory devices [70] 2 | |

| Photoluminescence (fluorescence) | ||

| Raman spectroscopy properties | ||

| Others | Batteries [71] | Environmental concerns [76] |

| Easily modifiable structure | ||

| Presence of functional groups | Supercapacitors production Ultra-thin flexible batteries Implantable medical devices | |

| Chemical inertness | ||

| Easily optimizable solubility and dispersion | Cleaning up polluted environments | |

| Water filtration Air filters, such as smokestacks [72] | ||

| Others | ||

| Transistors production [73,74] | ||

| Energy production | ||

| Solar cells [75] | ||

| Light weight | Energy Storage | |

| ⇧ Biocompatibility | CNT based fibers and fabrics | |

| Capability of molecules immobilization | CNT based ceramics | |

| Transport of protein, DNA, RNA | ||

| Large surface area | Sources of light | |

| High capability of absorbing chemicals from their surroundings | Entrenched dominance of other material |

| Method | Process Type | Products Purity | Conditions Yields (%) | Advantages | Disadvantages |

|---|---|---|---|---|---|

| Arc discharge (AC) | The carbon in the negative electrode sublimates due to the high discharge temperatures (T) | SWCNTs short tubes Ø = 0.6–1.4 nm MWCNTs short tubes Inner Ø = 1–3 nm Outer Ø = 10 nm Medium purity | Argon/N2 500 torr T ≤ 4000 °C 20–100% | Few structural defects | Length ≤ 50 µm |

| Laser ablation (LA) | Graphite samples are vaporized in a reactor at ⇧ T by a pulsed laser in presence of an inert gas CNTs grow up on the cooler reactor’s surfaces as the vaporized carbon condenses | SWCNTs 5–20 µm Ø = 1–2 nm MWCNTs Low purity | 500–1000 °C at ⇧ energy laser beam 25–1000 °C ≤70% | Controllable Ø by the reaction temperature | ⇧ Expensive than AC, CVD |

| Chemical Vapor Deposition (CVD) | Layered metal catalyst particles are heated in a reactor where a process gas and a carbon-containing gas are bled into | SWCNTs long tubes Ø = 0.6–4 nm MWCNTs long tubes Ø = 10–240 nm Medium-High purity | Low pressure inner gas (argon) 500–1200 °C 60–90% | ⇧ Economic and simple than AD and LA Synthesis at ⇩ temperature and AP ⇧ Yield and purity than AD and LA Versatile in the control of CNTs structure/architecture Suitable for scale up | ⇩ Crystallinity than that by AD and LA Removal of the catalyst support |

| Physical Property | Largest | Smallest | Refs. |

|---|---|---|---|

| Diameter | N.R. | 0.30 nm (MWCNT) 1 0.43 nm (SWCNT) | [148] |

| Length | 0.5 m 2 | Cycloparaphenylenes (2.49 Å) 3 | [149,150] |

| Density | 1.6 g/cm * | N.R. | [151,152] |

| Associations Morphologies | Type of Interaction Arrangement | Possible Products | Applications/Properties | Refs. |

|---|---|---|---|---|

| CNTs/CNTs * | Junctions | Metallic CNTs/semiconducting CNTs | Component of NT-based electronic circuits | [153,154,157] |

| CNTs/GF * | Junctions | Pillared GF (3D-CNTs) | Energy storage Supercapacitors Field emission Transistors High-performance catalysis Photovoltaics Biomedical devices Implants Sensors | [158,159,160,161] |

| 2 CNTs/fullerenes * | Covalent Bond | Fullerene-like nanobuds | Field emitters | [162] |

| CNT/fullerenes * | Entrapment | Carbon peapods (CPPs) | Heating devices Irradiating devices Oscillators | [163,164,165,166] |

| Doughnut shape ** | CNTs twisted into a toroid (Annulus shape) | Nano tori (NTRs) | ⇧ magnetic moment ⇧ stability | [167,168] |

| GF/MWCNTs * | GFs integrated MWCNTs | GFCNTs | ⇧ Surface area 3D-framework ⇧ Total charge capacity per unit of nominal area | [169,170] |

| 1D carbon structures ** | Stacking microstructure of GF layers | Cup-stacked CNTs (CSCNTs) | Semiconductors | [171] |

| Applications | Principle | Detection Target | Year Refs. | |

|---|---|---|---|---|

| Sensors | Electrochemical sensors | Made of AuNPs + MWCNTs Mannan-Os Adducts | Dopamine | 2015 [9] |

| Made of glassy carbon electrodes modified with MWCNTs and CuMPs dispersed in PEIs | Amino acids and glucose | 2016 [10] | ||

| Based on MWCNTs | Clostridium tetani | 2016 [11] | ||

| Based on AgNPs/Bi NPs/MWCNTs nafion modified | Lead and Cadmium | 2020 [12] | ||

| Based on carbon sensor fabricated with coalesced Ru–TiO2 NPs and MWCNTs | Cetrizine | 2019 [13] | ||

| Based on glassy carbon sensor modified with MWCNT in pH 9.0 PBS | Methdilazine | 2019 [14] | ||

| Based on (Ru–TiO2) NPs and MWCNTs | Flufenamic acid (FFA) Mefenamic acid (MFA) | 2019 [15] | ||

| Based on Bi-MWCNT/MCPE at physiological pH | Gallic Acid (GA) | 2020 [16] | ||

| Function | ||||

| Piezoelectric sensors | Based on MWCNTs on PDMS as substrate | N.R. | 2017 [17] | |

| Based on graphene, CNTs and graphene-CNTs composite | N.R. | 2018 [18] | ||

| Based on MWCNT on PDMS as substrate | For developing robotic hands (rehabilitation) Strain-detecting needle for tissue characterization | 2019 [19] | ||

| Based on MWCNTs on thermoplastic urethane as substrate | Sensors integrated into gloves and bandages for assessing specific human functions | 2019 [20] | ||

| Based on MWCNTs on PDMS substrate | To measure pressure directly without the use of deformation materials. | 2019 [21] | ||

| Detection Target | ||||

| Gas sensors | Based on a resonant electromagnetic transducer in microstrip technology | Volatile Organic Compounds (VOCs) | 2019 [22] | |

| Based on dye functionalized matrix anchored onto MWCNTs ammonia | Sulfur dioxide and chlorine | 2018 [23] | ||

| Based on WxOy nano-bricks and MWCNTs | Ammonia gas | 2019 [24] | ||

| Transported Drugs | ||||

| Drug Targeting | Based on MWCNT and pH-responsive gel of chitosan-coated magnetic nanocomposites | Doxorubicin (DOX) to U-87 Glioblastoma cells | 2019 [25] | |

| Based on stimuli-responsive CNTs using Ag nanowires to stimulate the drug release from the core of NTs | Cisplatin | 2017 [26] | ||

| Based on electro-responsive polymer-MWCNT hybrid hydrogel | Sucrose | 2013 [27] | ||

| Based on MWCNTs biodegradable, biocompatible nanocomposite hydrogel | Diclofenac sodium | 2016 [28] | ||

| Cancer diagnosis and treatment | Based on MTX-loaded MWCNTs releasing drugs by enzymatic cleavage | Methotrexate to in vitro breast cells | 2010 [29] | |

| Based on DOX loaded dendrimer modified MWCNTs releasing drugs at low pH | DOX | 2013 [30] | ||

| Based on cationic MWCNTs-NH3þ for direct intertumoral injections | Apoptotic siRNA against polo-like kinase (siPLK1) in calu6 tumor xenografts | 2015 [31] | ||

| Target bacteria/Applications | ||||

| Antibacterial agents | Based on chitosan/MWCNTs nanocomposites | Enterococcus faecalis Staphylococcus epidermidis Escherichia coli | [32,33,34,35,36,37,38] | |

| Based on Fe3O4/SWCNTs | E. coli | 2018 [39] | ||

| Based on Ag–Fe3O4/SWCNTs | N.R. | 2018 [40] | ||

| Based on CDX/Ag/MWCNTs | N.R. | 2014 [41] | ||

| Based on MWCNTs containing carboxylic functions | N.R. | 2015 [42] | ||

| Based on PA/graphene/CNTs | Staphylococcus aureus, E. coli | 2018, 2012 [43,44] | ||

| Based on MWCNTs | Treatment of drinking water through removal and inactivation of viruses and bacteria | 2011 [45] | ||

| Based on MWCNTs functionalized with mono-, di-, and tri-ethanolamine | E. coli, Klebsiella pneumonia Pseudomonas aeruginosa Salmonella typhimurium, Bacillus subtilis S. aureus, Bacillus cereus Streptococcus pneumonia | 2014 [46] | ||

| Based on dispersion SWCNTs/TABM derivative with carboxy groups | E. coli, S. aureus | 2019 [47] | ||

| Target fungi | ||||

| Antifungal agents | Based on chitosan/MWCNTs | Aspergillus niger, Candida trobicalis C. neoformans | 2000 [48] | |

| Based on functionalized CNTs | A. niger, C. albicans, A. fumigatus, Penicillium chrysogenum Saccharomyces cerevisiae, Fusarium culmorum Microsporum canis, Trichophyton mentagrophytes T. rubrum, P. lilacinum | 2013 [49] | ||

| Based on dispersion SWCNTs/TABM derivative with carboxy groups | C. albicans | 2019 [47] | ||

References

- Ifijen, I.H.; Maliki, M.; Omorogbe, S.O.; Ibrahim, S.D. Incorporation of Metallic Nanoparticles Into Alkyd Resin: A Review of Their Coating Performance. In TMS 2022 151st Annual Meeting & Exhibition Supplemental Proceedings; Springer: Cham, Switzerland, 2022; pp. 338–349. [Google Scholar]

- Omorogbe, S.O.; Ikhuoria, E.U.; Ifijen, H.I.; Simo, A.; Aigbodion, A.; Maaza, M. Fabrication of Monodispersed Needle-Sized Hollow Core Polystyrene Microspheres. In TMS 2019 148th Annual Meeting & Exhibition Supplemental Proceedings; Springer: Cham, Switzerland, 2019; pp. 155–164. [Google Scholar]

- Ifijen, H.I.; Ikhuoria, E.U.; Omorogbe, S.O. Correlative Studies on the Fabrication of Poly(Styrene-Methyl-Methacrylate-Acrylic Acid) Colloidal Crystal Films. J. Dispers. Sci. Technol. 2019, 40, 1023–1030. [Google Scholar] [CrossRef]

- Ifijen, I.H.; Ikhuoria, E.U.; Omorogbe, S.O.; Aigbodion, A.I. Ordered Colloidal Crystals Fabrication and Studies on the Properties of Poly (Styrene–Butyl Acrylate–Acrylic Acid) and Polystyrene Latexes. In Nanocomposites VI: Nanoscience and Nanotechnology in Advanced Composites; Springer: Cham, Switzerland, 2019; pp. 125–135. [Google Scholar]

- Ifijen, I.H.; Maliki, M.; Ovonramwen, O.B.; Aigbodion, A.I.; Ikhuoria, E.U. Brilliant Coloured Monochromatic Photonic Crystals Films Generation from Poly (Styrene-Butyl Acrylate-Acrylic Acid) Latex. J. Appl. Sci. Environ. Manag. 2019, 23, 1661. [Google Scholar] [CrossRef]

- Omorogbe, S.O.; Aigbodion, A.I.; Ifijen, H.I.; Simo, A.; Ogbeide-Ihama, N.L.; Ikhuoria, E.U. Low-Temperature Synthesis of Superparamagnetic Fe3O4 Morphologies Tuned Using Oleic Acid as Crystal Growth Modifiers. In TMS 2020 149th Annual Meeting & Exhibition Supplemental Proceedings; Springer: Cham, Switzerland, 2020; pp. 619–631. [Google Scholar]

- Ifijen, I.H.; Ikhuoria, E.U.; Maliki, M.; Otabor, G.O.; Aigbodion, A.I. Nanostructured Materials: A Review on Its Application in Water Treatment. In TMS 2022 151st Annual Meeting & Exhibition Supplemental Proceedings; Springer: Cham, Switzerland, 2022; pp. 1172–1180. [Google Scholar]

- Ifijen, I.H.; Aghedo, O.N.; Odiachi, I.J.; Omorogbe, S.O.; Olu, E.L.; Onuguh, I.C. Nanostructured Graphene Thin Films: A Brief Review of Their Fabrication Techniques and Corrosion Protective Performance. In TMS 2022 151st Annual Meeting & Exhibition Supplemental Proceedings; Springer: Cham, Switzerland, 2022; pp. 366–377. [Google Scholar]

- Ciambelli, P.; La Guardia, G.; Vitale, L. Nanotechnology for Green Materials and Processes. In Studies in Surface Science and Catalysis; Elsevier Science: Amsterdam, The Netherlands, 2020; pp. 97–116. [Google Scholar]

- Omorogbe, S.O.; Aigbodion, A.I.; Ikhuoria, E.U.; Ifijen, I.H. Impact of Varying the Concentration of Tetraethyl-OrthoSilicate on the Average Particle Diameter of Monodisperse Colloidal Silica Spheres. Chem. Sci. J. 2018, 9, 1. [Google Scholar] [CrossRef]

- Ifijen, I.H.; Maliki, M.; Odiachi, I.J.; Aghedo, O.N.; Ohiocheoya, E.B. Review on Solvents Based Alkyd Resins and Water Borne Alkyd Resins: Impacts of Modification on Their Coating Properties. Chem. Afr. 2022, 5, 211–225. [Google Scholar] [CrossRef]

- Ifijen, I.H.; Omonmhenle, S.I. Antimicrobial Properties of Carbon Nanotube: A Succinct Assessment. Biomed. Mater. Devices 2024, 2, 113–120. [Google Scholar] [CrossRef]

- Rathinavel, S.; Priyadharshini, K.; Panda, D. A review on carbon nanotube: An overview of synthesis, properties, functionalization, characterization, and the application. Mater. Sci. Eng. B 2021, 268, 115095. [Google Scholar] [CrossRef]

- Su, Q.; Gan, L.; Liu, J.; Yang, X. Carbon Dots Derived from Pea for Specifically Binding with Cryptococcus Neoformans. Anal. Biochem. 2020, 589, 113476. [Google Scholar] [CrossRef]

- Salari, S.; Jafari, S.M. Application of Nanofluids for Thermal Processing of Food Products. Trends Food Sci. Technol. 2020, 97, 100–113. [Google Scholar] [CrossRef]

- Abd-Elsalam, K.A. Carbon Nanomaterials: 30 Years of Research in Agroecosystems. In Carbon Nanomaterials for Agri-Food and Environmental Applications; Elsevier: Amsterdam, The Netherlands, 2020; pp. 1–18. [Google Scholar]

- Iijima, S. Helical Microtubules of Graphitic Carbon. Nature 1991, 354, 56–58. [Google Scholar] [CrossRef]

- Rahman, M.A.; Abul Barkat, H.; Harwansh, R.K.; Deshmukh, R. Carbon-based Nanomaterials: Carbon Nanotubes, Graphene, and Fullerenes for the Control of Burn Infections and Wound Healing. Curr. Pharm. Biotechnol. 2022, 23, 1483–1496. [Google Scholar] [CrossRef] [PubMed]

- Chong, Y.; Ge, C.; Fang, G.; Wu, R.; Zhang, H.; Chai, Z.; Chen, C.; Yin, J.-J. Light-Enhanced Antibacterial Activity of Graphene Oxide, Mainly via Accelerated Electron Transfer. Environ. Sci. Technol. 2017, 51, 10154–10161. [Google Scholar] [CrossRef] [PubMed]

- Kang, S.; Mauter, M.S.; Elimelech, M. Physicochemical Determinants of Multiwalled Carbon Nanotube Bacterial Cytotoxicity. Environ. Sci. Technol. 2008, 42, 7528–7534. [Google Scholar] [CrossRef]

- Haung, C.-F.; Chan, Y.-H.; Chen, L.-K.; Liu, C.-M.; Huang, W.-C.; Ou, S.-F.; Ou, K.-L.; Wang, D.-Y. Preparation, Characterization, and Properties of Anticoagulation and Antibacterial Films of Carbon-Based Nanowires Fabricated on Surfaces of Ti Implants. J. Electrochem. Soc. 2013, 160, H392–H397. [Google Scholar] [CrossRef]

- Lee, E.-S.; Kim, Y.-O.; Ha, Y.-M.; Lim, D.; Hwang, J.Y.; Kim, J.; Park, M.; Cho, J.W.; Jung, Y.C. Antimicrobial Properties of Lignin-Decorated Thin Multi-Walled Carbon Nanotubes in Poly(Vinyl Alcohol) Nanocomposites. Eur. Polym. J. 2018, 105, 79–84. [Google Scholar] [CrossRef]

- Azizi-Lalabadi, M.; Hashemi, H.; Feng, J.; Jafari, S.M. Carbon Nanomaterials against Pathogens; the Antimicrobial Activity of Carbon Nanotubes, Graphene/Graphene Oxide, Fullerenes, and Their Nanocomposites. Adv. Colloid. Interface Sci. 2020, 284, 102250. [Google Scholar] [CrossRef]

- Oyelami, A.O.; Semple, K.T. Impact of Carbon Nanomaterials on Microbial Activity in Soil. Soil. Biol. Biochem. 2015, 86, 172–180. [Google Scholar] [CrossRef]

- Maleki Dizaj, S.; Mennati, A.; Jafari, S.; Khezri, K.; Adibkia, K. Antimicrobial Activity of Carbon-Based Nanoparticles. Adv. Pharm. Bull. 2015, 5, 19–23. [Google Scholar] [CrossRef]

- Kang, S.; Pinault, M.; Pfefferle, L.D.; Elimelech, M. Single-Walled Carbon Nanotubes Exhibit Strong Antimicrobial Activity. Langmuir 2007, 23, 8670–8673. [Google Scholar] [CrossRef]

- Kang, S.; Herzberg, M.; Rodrigues, D.F.; Elimelech, M. Antibacterial Effects of Carbon Nanotubes: Size Does Matter! Langmuir 2008, 24, 6409–6413. [Google Scholar] [CrossRef]

- Chen, H.; Wang, B.; Gao, D.; Guan, M.; Zheng, L.; Ouyang, H.; Chai, Z.; Zhao, Y.; Feng, W. Broad-Spectrum Antibacterial Activity of Carbon Nanotubes to Human Gut Bacteria. Small 2013, 9, 2735–2746. [Google Scholar] [CrossRef]

- Awasthi, S.; Srivastava, A.; Kumar, D.; Pandey, S.K.; Mubarak, N.M.; Dehghani, M.H.; Ansari, K. An Insight into the Toxicological Impacts of Carbon Nanotubes (CNTs) on Human Health: A Review. Environ. Adv. 2024, 18, 100601. [Google Scholar] [CrossRef]

- Kostarelos, K.; Lacerda, L.; Pastorin, G.; Wu, W.; Wieckowski, S.; Luangsivilay, J.; Godefroy, S.; Pantarotto, D.; Briand, J.P.; Muller, S.; et al. Cellular Uptake of Functionalized Carbon Nanotubes Is Independent of Functional Group and Cell Type. Nat. Nanotechnol. 2007, 2, 108–113. [Google Scholar] [CrossRef] [PubMed]

- Noonan, D.M.; Pagani, A.; Pulze, L.; Bruno, A.; Principi, E.; Congiu, T.; Grimaldi, A.; Bassani, B.; De Flora, S.; Gini, E.; et al. Environmental Impact of Multi-Wall Carbon Nanotubes in a Novel Model of Exposure: Systemic Distribution, Macrophage Accumulation, and Amyloid Deposition. Int. J. Nanomed. 2015, 10, 6133–6145. [Google Scholar] [CrossRef] [PubMed]

- Poland, C.A.; Duffin, R.; Kinloch, I.; Maynard, A.; Wallace, W.A.H.; Seaton, A.; Stone, V.; Brown, S.; MacNee, W.; Donaldson, K. Carbon Nanotubes Introduced into the Abdominal Cavity of Mice Show Asbestos-like Pathogenicity in a Pilot Study. Nat. Nanotechnol. 2008, 3, 423–428. [Google Scholar] [CrossRef]

- Ge, C.; Meng, L.; Xu, L.; Bai, R.; Du, J.; Zhang, L.; Li, Y.; Chang, Y.; Zhao, Y.; Chen, C. Acute Pulmonary and Moderate Cardiovascular Responses of Spontaneously Hypertensive Rats after Exposure to Single-Wall Carbon Nanotubes. Nanotoxicology 2012, 6, 526–542. [Google Scholar] [CrossRef]

- Goerzen, D.; Heller, D.A.; Rachel, A. Meidl Balancing Safety and Innovation: Shaping Responsible Carbon Nanotube Policy; Rice Universities’, Baker Institute for Public Policy: Houston, TX, USA, 2024. [Google Scholar]

- Alfei, S.; Schito, G.C. Nanotubes: Carbon-Based Fibers and Bacterial Nano-Conduits Both Arousing a Global Interest and Conflicting Opinions. Fibers 2022, 10, 75. [Google Scholar] [CrossRef]

- Ebbesen, T.W.; Ajayan, P.M. Large-Scale Synthesis of Carbon Nanotubes. Nature 1992, 358, 220–222. [Google Scholar] [CrossRef]

- Eatemadi, A.; Daraee, H.; Karimkhanloo, H.; Kouhi, M.; Zarghami, N.; Akbarzadeh, A.; Abasi, M.; Hanifehpour, Y.; Joo, S.W. Carbon Nanotubes: Properties, Synthesis, Purification, and Medical Applications. Nanoscale Res. Lett. 2014, 9, 393. [Google Scholar] [CrossRef]

- Guo, T.; Nikolaev, P.; Rinzler, A.G.; Tomanek, D.; Colbert, D.T.; Smalley, R.E. Self-Assembly of Tubular Fullerenes. J. Phys. Chem. 1995, 99, 10694–10697. [Google Scholar] [CrossRef]

- Guo, T.; Nikolaev, P.; Thess, A.; Colbert, D.T.; Smalley, R.E. Catalytic Growth of Single-Walled Nanotubes by Laser Vaporization. Chem. Phys. Lett. 1995, 243, 49–54. [Google Scholar] [CrossRef]

- Kumar, M.; Ando, Y. Chemical Vapor Deposition of Carbon Nanotubes: A Review on Growth Mechanism and Mass Production. J. Nanosci. Nanotechnol. 2010, 10, 3739–3758. [Google Scholar] [CrossRef] [PubMed]

- Neupane, S.; Lastres, M.; Chiarella, M.; Li, W.; Su, Q.; Du, G. Synthesis and Field Emission Properties of Vertically Aligned Carbon Nanotube Arrays on Copper. Carbon 2012, 50, 2641–2650. [Google Scholar] [CrossRef]

- Inami, N.; Mohamed, M.A.; Shikoh, E.; Fujiwara, A. Synthesis-Condition Dependence of Carbon Nanotube Growth by Alcohol Catalytic Chemical Vapor Deposition Method. Sci. Technol. Adv. Mater. 2007, 8, 292–295. [Google Scholar] [CrossRef]

- Ishigami, N.; Ago, H.; Imamoto, K.; Tsuji, M.; Iakoubovskii, K.; Minami, N. Crystal Plane Dependent Growth of Aligned Single-Walled Carbon Nanotubes on Sapphire. J. Am. Chem. Soc. 2008, 130, 9918–9924. [Google Scholar] [CrossRef]

- Naha, S.; Puri, I.K. A Model for Catalytic Growth of Carbon Nanotubes. J. Phys. D Appl. Phys. 2008, 41, 065304. [Google Scholar] [CrossRef]

- Banerjee, S.; Naha, S.; Puri, I.K. Molecular Simulation of the Carbon Nanotube Growth Mode during Catalytic Synthesis. Appl. Phys. Lett. 2008, 92, 233121. [Google Scholar] [CrossRef]

- Eftekhari, A.; Jafarkhani, P.; Moztarzadeh, F. High-Yield Synthesis of Carbon Nanotubes Using a Water-Soluble Catalyst Support in Catalytic Chemical Vapor Deposition. Carbon 2006, 44, 1343–1345. [Google Scholar] [CrossRef]

- Ren, Z.F.; Huang, Z.P.; Xu, J.W.; Wang, J.H.; Bush, P.; Siegal, M.P.; Provencio, P.N. Synthesis of Large Arrays of Well-Aligned Carbon Nanotubes on Glass. Science 1998, 282, 1105–1107. [Google Scholar] [CrossRef]

- Hata, K.; Futaba, D.N.; Mizuno, K.; Namai, T.; Yumura, M.; Iijima, S. Water-Assisted Highly Efficient Synthesis of Impurity-Free Single-Walled Carbon Nanotubes. Science 2004, 306, 1362–1364. [Google Scholar] [CrossRef]

- Futaba, D.N.; Hata, K.; Yamada, T.; Hiraoka, T.; Hayamizu, Y.; Kakudate, Y.; Tanaike, O.; Hatori, H.; Yumura, M.; Iijima, S. Shape-Engineerable and Highly Densely Packed Single-Walled Carbon Nanotubes and Their Application as Super-Capacitor Electrodes. Nat. Mater. 2006, 5, 987–994. [Google Scholar] [CrossRef]

- Smiljanic, O.; Stansfield, B.L.; Dodelet, J.-P.; Serventi, A.; Désilets, S. Gas-Phase Synthesis of SWNT by an Atmospheric Pressure Plasma Jet. Chem. Phys. Lett. 2002, 356, 189–193. [Google Scholar] [CrossRef]

- Kim, K.S.; Cota-Sanchez, G.; Kingston, C.T.; Imris, M.; Simard, B.; Soucy, G. Large-Scale Production of Single-Walled Carbon Nanotubes by Induction Thermal Plasma. J. Phys. D Appl. Phys. 2007, 40, 2375–2387. [Google Scholar] [CrossRef]

- Ren, J.; Li, F.-F.; Lau, J.; González-Urbina, L.; Licht, S. One-Pot Synthesis of Carbon Nanofibers from CO2. Nano Lett. 2015, 15, 6142–6148. [Google Scholar] [CrossRef] [PubMed]

- Service, R.F. Conjuring Chemical Cornucopias out of Thin Air. Science 2015, 349, 1160. [Google Scholar] [CrossRef]

- Yuan, L.; Saito, K.; Pan, C.; Williams, F.A.; Gordon, A.S. Nanotubes from Methane Flames. Chem. Phys. Lett. 2001, 340, 237–241. [Google Scholar] [CrossRef]

- Yuan, L.; Saito, K.; Hu, W.; Chen, Z. Ethylene Flame Synthesis of Well-Aligned Multi-Walled Carbon Nanotubes. Chem. Phys. Lett. 2001, 346, 23–28. [Google Scholar] [CrossRef]

- Duan, H.M.; McKinnon, J.T. Nanoclusters Produced in Flames. J. Phys. Chem. 1994, 98, 12815–12818. [Google Scholar] [CrossRef]

- Murr, L.E.; Bang, J.J.; Esquivel, E.V.; Guerrero, P.A.; Lopez, D.A. Carbon Nanotubes, Nanocrystal Forms, and Complex Nanoparticle Aggregates in Common Fuel-Gas Combustion Sources and the Ambient Air. J. Nanopart. Res. 2004, 6, 241–251. [Google Scholar] [CrossRef]

- Vander Wal, R.L. Fe-Catalyzed Single-Walled Carbon Nanotube Synthesis within a Flame Environment. Combust. Flame 2002, 130, 37–47. [Google Scholar] [CrossRef]

- Saveliev, A.V.; Merchan-Merchan, W.; Kennedy, L.A. Metal Catalyzed Synthesis of Carbon Nanostructures in an Opposed Flow Methane Oxygen Flame. Combust. Flame 2003, 135, 27–33. [Google Scholar] [CrossRef]

- Height, M.J.; Howard, J.B.; Tester, J.W.; Vander Sande, J.B. Flame Synthesis of Single-Walled Carbon Nanotubes. Carbon 2004, 42, 2295–2307. [Google Scholar] [CrossRef]

- Sen, S.; Puri, I.K. Flame Synthesis of Carbon Nanofibres and Nanofibre Composites Containing Encapsulated Metal Particles. Nanotechnology 2004, 15, 264–268. [Google Scholar] [CrossRef]

- Naha, S.; Sen, S.; De, A.K.; Puri, I.K. A Detailed Model for the Flame Synthesis of Carbon Nanotubes and Nanofibers. Proc. Combust. Inst. 2007, 31, 1821–1829. [Google Scholar] [CrossRef]

- Jha, R.; Singh, A.; Sharma, P.K.; Fuloria, N.K. Smart carbon nanotubes for drug delivery system: A comprehensive study. J. Drug Deliv. Sci. Technol. 2020, 58, 101811. [Google Scholar] [CrossRef]

- Monthioux, M.; Kuznetsov, V.L. Who Should Be given the Credit for the Discovery of Carbon Nanotubes? Carbon 2006, 44, 1621–1623. [Google Scholar] [CrossRef]

- Chernozatonskii, L.A. Carbon Nanotube Connectors and Planar Jungle Gyms. Phys. Lett. A 1992, 172, 173–176. [Google Scholar] [CrossRef]

- Menon, M.; Srivastava, D. Carbon Nanotube “T Junctions”: Nanoscale Metal-Semiconductor-Metal Contact Devices. Phys. Rev. Lett. 1997, 79, 4453–4456. [Google Scholar] [CrossRef]

- Ma, K.L.; Yan, X.H.; Guo, Y.D.; Xiao, Y. Electronic Transport Properties of Junctions between Carbon Nanotubes and Graphene Nanoribbons. Eur. Phys. J. B 2011, 83, 487–492. [Google Scholar] [CrossRef]

- Harris, P.J.F.; Suarez-Martinez, I.; Marks, N.A. The Structure of Junctions between Carbon Nanotubes and Graphene Shells. Nanoscale 2016, 8, 18849–18854. [Google Scholar] [CrossRef]

- Lambin, P.; Vigneron, J.P.; Fonseca, A.; Nagy, J.B.; Lucas, A.A. Atomic Structure and Electronic Properties of a Bent Carbon Nanotube. Synth. Met. 1996, 77, 249–252. [Google Scholar] [CrossRef]

- Dimitrakakis, G.K.; Tylianakis, E.; Froudakis, G.E. Pillared Graphene: A New 3-D Network Nanostructure for Enhanced Hydrogen Storage. Nano Lett. 2008, 8, 3166–3170. [Google Scholar] [CrossRef] [PubMed]

- Lalwani, G.; Kwaczala, A.T.; Kanakia, S.; Patel, S.C.; Judex, S.; Sitharaman, B. Fabrication and Characterization of Three-Dimensional Macroscopic All-Carbon Scaffolds. Carbon 2013, 53, 90–100. [Google Scholar] [CrossRef] [PubMed]

- Lalwani, G.; Gopalan, A.; D’Agati, M.; Srinivas Sankaran, J.; Judex, S.; Qin, Y.-X.; Sitharaman, B. Porous Three-Dimensional Carbon Nanotube Scaffolds for Tissue Engineering. J. Biomed. Mater. Res. A 2015, 103, 3212–3225. [Google Scholar] [CrossRef]

- Noyce, S.G.; Vanfleet, R.R.; Craighead, H.G.; Davis, R.C. High Surface-Area Carbon Microcantilevers. Nanoscale Adv. 2019, 1, 1148–1154. [Google Scholar] [CrossRef]

- Yu, M.-F.; Lourie, O.; Dyer, M.J.; Moloni, K.; Kelly, T.F.; Ruoff, R.S. Strength and Breaking Mechanism of Multiwalled Carbon Nanotubes Under Tensile Load. Science 2000, 287, 637–640. [Google Scholar] [CrossRef]

- Peng, B.; Locascio, M.; Zapol, P.; Li, S.; Mielke, S.L.; Schatz, G.C.; Espinosa, H.D. Measurements of Near-Ultimate Strength for Multiwalled Carbon Nanotubes and Irradiation-Induced Crosslinking Improvements. Nat. Nanotechnol. 2008, 3, 626–631. [Google Scholar] [CrossRef]

- Jensen, K.; Mickelson, W.; Kis, A.; Zettl, A. Buckling and Kinking Force Measurements on Individual Multiwalled Carbon Nanotubes. Phys. Rev. B 2007, 76, 195436. [Google Scholar] [CrossRef]

- Mingo, N.; Stewart, D.A.; Broido, D.A.; Srivastava, D. Phonon Transmission through Defects in Carbon Nanotubes from First Principles. Phys. Rev. B 2008, 77, 033418. [Google Scholar] [CrossRef]

- Kumanek, B.; Janas, D. Thermal Conductivity of Carbon Nanotube Networks: A Review. J. Mater. Sci. 2019, 54, 7397–7427. [Google Scholar] [CrossRef]

- Koziol, K.K.; Janas, D.; Brown, E.; Hao, L. Thermal Properties of Continuously Spun Carbon Nanotube Fibres. Phys. E Low. Dimens. Syst. Nanostruct. 2017, 88, 104–108. [Google Scholar] [CrossRef]

- Hong, S.; Myung, S. A Flexible Approach to Mobility. Nat. Nanotechnol. 2007, 2, 207–208. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Li, Q.; Xie, J.; Jin, Z.; Wang, J.; Li, Y.; Jiang, K.; Fan, S. Fabrication of Ultralong and Electrically Uniform Single-Walled Carbon Nanotubes on Clean Substrates. Nano Lett. 2009, 9, 3137–3141. [Google Scholar] [CrossRef] [PubMed]

- Lu, X.; Chen, Z. Curved Pi-Conjugation, Aromaticity, and the Related Chemistry of Small Fullerenes (<C60) and Single-Walled Carbon Nanotubes. Chem. Rev. 2005, 105, 3643–3696. [Google Scholar] [CrossRef] [PubMed]

- Anzar, N.; Hasan, R.; Tyagi, M.; Yadav, N.; Narang, J. Carbon Nanotube—A Review on Synthesis, Properties and Plethora of Applications in the Field of Biomedical Science. Sens. Int. 2020, 1, 100003. [Google Scholar] [CrossRef]

- Khan, M.U.; Reddy, K.R.; Snguanwongchai, T.; Haque, E.; Gomes, V.G. Polymer Brush Synthesis on Surface Modified Carbon Nanotubes via in Situ Emulsion Polymerization. Colloid. Polym. Sci. 2016, 294, 1599–1610. [Google Scholar] [CrossRef]

- Che, J.; Çagin, T.; Goddard, W.A. Thermal Conductivity of Carbon Nanotubes. Nanotechnology 2000, 11, 65–69. [Google Scholar] [CrossRef]

- Smart, S.K.; Cassady, A.I.; Lu, G.Q.; Martin, D.J. The Biocompatibility of Carbon Nanotubes. Carbon 2006, 44, 1034–1047. [Google Scholar] [CrossRef]

- Negri, V.; Pacheco-Torres, J.; Calle, D.; López-Larrubia, P. Carbon Nanotubes in Biomedicine. Top. Curr. Chem. 2020, 378, 15. [Google Scholar] [CrossRef]

- Lamberti, M.; Pedata, P.; Sannolo, N.; Porto, S.; De Rosa, A.; Caraglia, M. Carbon Nanotubes: Properties, Biomedical Applications, Advantages and Risks in Patients and Occupationally-Exposed Workers. Int. J. Immunopathol. Pharmacol. 2015, 28, 4–13. [Google Scholar] [CrossRef]

- Kumar, S.; Rani, R.; Dilbaghi, N.; Tankeshwar, K.; Kim, K.-H. Carbon Nanotubes: A Novel Material for Multifaceted Applications in Human Healthcare. Chem. Soc. Rev. 2017, 46, 158–196. [Google Scholar] [CrossRef]

- Teixeira-Santos, R.; Gomes, M.; Gomes, L.C.; Mergulhão, F.J. Antimicrobial and Anti-Adhesive Properties of Carbon Nanotube-Based Surfaces for Medical Applications: A Systematic Review. iScience 2021, 24, 102001. [Google Scholar] [CrossRef] [PubMed]

- Nagai, H.; Toyokuni, S. Differences and Similarities between Carbon Nanotubes and Asbestos Fibers during Mesothelial Carcinogenesis: Shedding Light on Fiber Entry Mechanism. Cancer Sci. 2012, 103, 1378–1390. [Google Scholar] [CrossRef] [PubMed]

- Aslan, S.; Loebick, C.Z.; Kang, S.; Elimelech, M.; Pfefferle, L.D.; Van Tassel, P.R. Antimicrobial Biomaterials Based on Carbon Nanotubes Dispersed in Poly(Lactic-Co-Glycolic Acid). Nanoscale 2010, 2, 1789. [Google Scholar] [CrossRef] [PubMed]

- Olivi, M.; Zanni, E.; De Bellis, G.; Talora, C.; Sarto, M.S.; Palleschi, C.; Flahaut, E.; Monthioux, M.; Rapino, S.; Uccelletti, D.; et al. Inhibition of Microbial Growth by Carbon Nanotube Networks. Nanoscale 2013, 5, 9023. [Google Scholar] [CrossRef]

- Liu, S.; Ng, A.K.; Xu, R.; Wei, J.; Tan, C.M.; Yang, Y.; Chen, Y. Antibacterial Action of Dispersed Single-Walled Carbon Nanotubes on Escherichia Coli and Bacillus Subtilis Investigated by Atomic Force Microscopy. Nanoscale 2010, 2, 2744. [Google Scholar] [CrossRef]

- Arias, L.R.; Yang, L. Inactivation of Bacterial Pathogens by Carbon Nanotubes in Suspensions. Langmuir 2009, 25, 3003–3012. [Google Scholar] [CrossRef]

- Young, Y.-F.; Lee, H.-J.; Shen, Y.-S.; Tseng, S.-H.; Lee, C.-Y.; Tai, N.-H.; Chang, H.-Y. Toxicity Mechanism of Carbon Nanotubes on Escherichia coli. Mater. Chem. Phys. 2012, 134, 279–286. [Google Scholar] [CrossRef]

- Saleemi, M.A.; Fouladi, M.H.; Yong, P.V.C.; Wong, E.H. Elucidation of Antimicrobial Activity of Non-Covalently Dispersed Carbon Nanotubes. Materials 2020, 13, 1676. [Google Scholar] [CrossRef]

- Vecitis, C.D.; Zodrow, K.R.; Kang, S.; Elimelech, M. Electronic-Structure-Dependent Bacterial Cytotoxicity of Single-Walled Carbon Nanotubes. ACS Nano 2010, 4, 5471–5479. [Google Scholar] [CrossRef]

- Liu, S.; Wei, L.; Hao, L.; Fang, N.; Chang, M.W.; Xu, R.; Yang, Y.; Chen, Y. Sharper and Faster “Nano Darts” Kill More Bacteria: A Study of Antibacterial Activity of Individually Dispersed Pristine Single-Walled Carbon Nanotube. ACS Nano 2009, 3, 3891–3902. [Google Scholar] [CrossRef]

- Rodrigues, D.F.; Elimelech, M. Toxic Effects of Single-Walled Carbon Nanotubes in the Development of E. Coli Biofilm. Environ. Sci. Technol. 2010, 44, 4583–4589. [Google Scholar] [CrossRef] [PubMed]

- Malek, I.; Schaber, C.F.; Heinlein, T.; Schneider, J.J.; Gorb, S.N.; Schmitz, R.A. Vertically Aligned Multi Walled Carbon Nanotubes Prevent Biofilm Formation of Medically Relevant Bacteria. J. Mater. Chem. B 2016, 4, 5228–5235. [Google Scholar] [CrossRef] [PubMed]

- Yick, S.; Mai-Prochnow, A.; Levchenko, I.; Fang, J.; Bull, M.K.; Bradbury, M.; Murphy, A.B.; Ostrikov, K.K. The Effects of Plasma Treatment on Bacterial Biofilm Formation on Vertically-Aligned Carbon Nanotube Arrays. RSC Adv. 2015, 5, 5142–5148. [Google Scholar] [CrossRef]

- Vassallo, J.; Besinis, A.; Boden, R.; Handy, R.D. The Minimum Inhibitory Concentration (MIC) Assay with Escherichia Coli: An Early Tier in the Environmental Hazard Assessment of Nanomaterials? Ecotoxicol. Environ. Saf. 2018, 162, 633–646. [Google Scholar] [CrossRef]

- Hartono, M.R.; Kushmaro, A.; Chen, X.; Marks, R.S. Probing the Toxicity Mechanism of Multiwalled Carbon Nanotubes on Bacteria. Environ. Sci. Pollut. Res. 2018, 25, 5003–5012. [Google Scholar] [CrossRef]

- Zhang, Q.; Nghiem, J.; Silverberg, G.J.; Vecitis, C.D. Semiquantitative Performance and Mechanism Evaluation of Carbon Nanomaterials as Cathode Coatings for Microbial Fouling Reduction. Appl. Environ. Microbiol. 2015, 81, 4744–4755. [Google Scholar] [CrossRef]

- Kim, J.; Shashkov, E.V.; Galanzha, E.I.; Kotagiri, N.; Zharov, V.P. Photothermal Antimicrobial Nanotherapy and Nanodiagnostics with Self-assembling Carbon Nanotube Clusters. Lasers Surg. Med. 2007, 39, 622–634. [Google Scholar] [CrossRef]

- Mohammad, M.R.; Ahmed, D.S.; Mohammed, M.K.A. Synthesis of Ag-Doped TiO2 Nanoparticles Coated with Carbon Nanotubes by the Sol–Gel Method and Their Antibacterial Activities. J. Sol-Gel Sci. Technol. 2019, 90, 498–509. [Google Scholar] [CrossRef]

- Mocan, T.; Matea, C.T.; Pop, T.; Mosteanu, O.; Buzoianu, A.D.; Suciu, S.; Puia, C.; Zdrehus, C.; Iancu, C.; Mocan, L. Carbon Nanotubes as Anti-Bacterial Agents. Cell. Mol. Life Sci. 2017, 74, 3467–3479. [Google Scholar] [CrossRef]

- Huang, Y.-P.; Lin, I.-J.; Chen, C.-C.; Hsu, Y.-C.; Chang, C.-C.; Lee, M.-J. Delivery of Small Interfering RNAs in Human Cervical Cancer Cells by Polyethylenimine-Functionalized Carbon Nanotubes. Nanoscale Res. Lett. 2013, 8, 267. [Google Scholar] [CrossRef]

- Martincic, M.; Tobias, G. Filled Carbon Nanotubes in Biomedical Imaging and Drug Delivery. Expert. Opin. Drug Deliv. 2015, 12, 563–581. [Google Scholar] [CrossRef] [PubMed]

- Zhang, B.; Wang, H.; Shen, S.; She, X.; Shi, W.; Chen, J.; Zhang, Q.; Hu, Y.; Pang, Z.; Jiang, X. Fibrin-Targeting Peptide CREKA-Conjugated Multi-Walled Carbon Nanotubes for Self-Amplified Photothermal Therapy of Tumor. Biomaterials 2016, 79, 46–55. [Google Scholar] [CrossRef] [PubMed]

- Pasquini, L.M.; Hashmi, S.M.; Sommer, T.J.; Elimelech, M.; Zimmerman, J.B. Impact of Surface Functionalization on Bacterial Cytotoxicity of Single-Walled Carbon Nanotubes. Environ. Sci. Technol. 2012, 46, 6297–6305. [Google Scholar] [CrossRef] [PubMed]

- Saleemi, M.A.; Kong, Y.L.; Yong, P.V.C.; Wong, E.H. An Overview of Antimicrobial Properties of Carbon Nanotubes-Based Nanocomposites. Adv. Pharm. Bull. 2022, 12, 449–465. [Google Scholar] [CrossRef]

- Chaudhari, A.A.; Joshi, S.; Vig, K.; Sahu, R.; Dixit, S.; Baganizi, R.; Dennis, V.A.; Singh, S.R.; Pillai, S. A Three-Dimensional Human Skin Model to Evaluate the Inhibition of Staphylococcus aureus by Antimicrobial Peptide-Functionalized Silver Carbon Nanotubes. J. Biomater. Appl. 2019, 33, 924–934. [Google Scholar] [CrossRef]

- Prabhu, S.; Poulose, E.K. Silver Nanoparticles: Mechanism of Antimicrobial Action, Synthesis, Medical Applications, and Toxicity Effects. Int. Nano Lett. 2012, 2, 32. [Google Scholar] [CrossRef]

- Zhu, Z.; Wang, Z.; Li, S.; Yuan, X. Antimicrobial Strategies for Urinary Catheters. J. Biomed. Mater. Res. A 2019, 107, 445–467. [Google Scholar] [CrossRef]

- Chaudhari, A.A.; Ashmore, D.; Nath, S.d.; Kate, K.; Dennis, V.; Singh, S.R.; Owen, D.R.; Palazzo, C.; Arnold, R.D.; Miller, M.E.; et al. A Novel Covalent Approach to Bio-Conjugate Silver Coated Single Walled Carbon Nanotubes with Antimicrobial Peptide. J. Nanobiotechnol. 2016, 14, 58. [Google Scholar] [CrossRef]

- Kumar, A.; Dalal, J.; Dahiya, S.; Punia, R.; Sharma, K.D.; Ohlan, A.; Maan, A.S. In Situ Decoration of Silver Nanoparticles on Single-Walled Carbon Nanotubes by Microwave Irradiation for Enhanced and Durable Anti-Bacterial Finishing on Cotton Fabric. Ceram. Int. 2019, 45, 1011–1019. [Google Scholar] [CrossRef]

- Karumuri, A.K.; Oswal, D.P.; Hostetler, H.A.; Mukhopadhyay, S.M. Silver Nanoparticles Supported on Carbon Nanotube Carpets: Influence of Surface Functionalization. Nanotechnology 2016, 27, 145603. [Google Scholar] [CrossRef]

- Barbinta-Patrascu, M.E.; Ungureanu, C.; Iordache, S.M.; Iordache, A.M.; Bunghez, I.-R.; Ghiurea, M.; Badea, N.; Fierascu, R.-C.; Stamatin, I. Eco-Designed Biohybrids Based on Liposomes, Mint–Nanosilver and Carbon Nanotubes for Antioxidant and Antimicrobial Coating. Mater. Sci. Eng. C 2014, 39, 177–185. [Google Scholar] [CrossRef] [PubMed]

- Chang, Y.-N.; Gong, J.-L.; Zeng, G.-M.; Ou, X.-M.; Song, B.; Guo, M.; Zhang, J.; Liu, H.-Y. Antimicrobial Behavior Comparison and Antimicrobial Mechanism of Silver Coated Carbon Nanocomposites. Process Saf. Environ. Prot. 2016, 102, 596–605. [Google Scholar] [CrossRef]

- Park, S.B.; Steadman, C.S.; Chaudhari, A.A.; Pillai, S.R.; Singh, S.R.; Ryan, P.L.; Willard, S.T.; Feugang, J.M. Proteomic Analysis of Antimicrobial Effects of Pegylated Silver Coated Carbon Nanotubes in Salmonella enterica serovar Typhimurium. J. Nanobiotechnol. 2018, 16, 31. [Google Scholar] [CrossRef] [PubMed]

- Singh, A.; Goswami, A.; Nain, S. Enhanced Antibacterial Activity and Photo-Remediation of Toxic Dyes Using Ag/SWCNT/PPy Based Nanocomposite with Core–Shell Structure. Appl. Nanosci. 2020, 10, 2255–2268. [Google Scholar] [CrossRef]

- Zhu, Y.; Xu, J.; Wang, Y.; Chen, C.; Gu, H.; Chai, Y.; Wang, Y. Silver Nanoparticles-Decorated and Mesoporous Silica Coated Single-Walled Carbon Nanotubes with an Enhanced Antibacterial Activity for Killing Drug-Resistant Bacteria. Nano Res. 2020, 13, 389–400. [Google Scholar] [CrossRef]

- Yun, H.; Kim, J.D.; Choi, H.C.; Lee, C.W. Antibacterial Activity of CNT-Ag and GO-Ag Nanocomposites Against Gram-Negative and Gram-Positive Bacteria. Bull. Korean Chem. Soc. 2013, 34, 3261–3264. [Google Scholar] [CrossRef]

- Leid, J.G.; Ditto, A.J.; Knapp, A.; Shah, P.N.; Wright, B.D.; Blust, R.; Christensen, L.; Clemons, C.B.; Wilber, J.P.; Young, G.W.; et al. In Vitro Antimicrobial Studies of Silver Carbene Complexes: Activity of Free and Nanoparticle Carbene Formulations against Clinical Isolates of Pathogenic Bacteria. J. Antimicrob. Chemother. 2012, 67, 138–148. [Google Scholar] [CrossRef]

- Nepal, D.; Balasubramanian, S.; Simonian, A.L.; Davis, V.A. Strong Antimicrobial Coatings: Single-Walled Carbon Nanotubes Armored with Biopolymers. Nano Lett. 2008, 8, 1896–1901. [Google Scholar] [CrossRef]

- Upadhyayula, V.K.K.; Gadhamshetty, V. Appreciating the Role of Carbon Nanotube Composites in Preventing Biofouling and Promoting Biofilms on Material Surfaces in Environmental Engineering: A Review. Biotechnol. Adv. 2010, 28, 802–816. [Google Scholar] [CrossRef]

- Levashov, P.A.; Sedov, S.A.; Shipovskov, S.; Belogurova, N.G.; Levashov, A.V. Quantitative Turbidimetric Assay of Enzymatic Gram-Negative Bacteria Lysis. Anal. Chem. 2010, 82, 2161–2163. [Google Scholar] [CrossRef]

- Ahmed, F.; Santos, C.M.; Vergara, R.A.M.V.; Tria, M.C.R.; Advincula, R.; Rodrigues, D.F. Antimicrobial Applications of Electroactive PVK-SWNT Nanocomposites. Environ. Sci. Technol. 2012, 46, 1804–1810. [Google Scholar] [CrossRef] [PubMed]

- Aslan, S.; Deneufchatel, M.; Hashmi, S.; Li, N.; Pfefferle, L.D.; Elimelech, M.; Pauthe, E.; Van Tassel, P.R. Carbon Nanotube-Based Antimicrobial Biomaterials Formed via Layer-by-Layer Assembly with Polypeptides. J. Colloid. Interface Sci. 2012, 388, 268–273. [Google Scholar] [CrossRef] [PubMed]

- Goodwin, D.G.; Marsh, K.M.; Sosa, I.B.; Payne, J.B.; Gorham, J.M.; Bouwer, E.J.; Fairbrother, D.H. Interactions of Microorganisms with Polymer Nanocomposite Surfaces Containing Oxidized Carbon Nanotubes. Environ. Sci. Technol. 2015, 49, 5484–5492. [Google Scholar] [CrossRef] [PubMed]

- Sah, U.; Sharma, K.; Chaudhri, N.; Sankar, M.; Gopinath, P. Antimicrobial Photodynamic Therapy: Single-Walled Carbon Nanotube (SWCNT)-Porphyrin Conjugate for Visible Light Mediated Inactivation of Staphylococcus aureus. Colloids Surf. B Biointerfaces 2018, 162, 108–117. [Google Scholar] [CrossRef]

- Tiraferri, A.; Vecitis, C.D.; Elimelech, M. Covalent Binding of Single-Walled Carbon Nanotubes to Polyamide Membranes for Antimicrobial Surface Properties. ACS Appl. Mater. Interfaces 2011, 3, 2869–2877. [Google Scholar] [CrossRef]

- Cajero-Zul, L.R.; López-Dellamary, F.A.; Gómez-Salazar, S.; Vázquez-Lepe, M.; Vera-Graziano, R.; Torres-Vitela, M.R.; Olea-Rodríguez, M.A.; Nuño-Donlucas, S.M. Evaluation of the Resistance to Bacterial Growth of Star-Shaped Poly(ε-Caprolactone)-Co-Poly(Ethylene Glycol) Grafted onto Functionalized Carbon Nanotubes Nanocomposites. J. Biomater. Sci. Polym. Ed. 2019, 30, 163–189. [Google Scholar] [CrossRef]

- Murugan, E.; Vimala, G. Effective Functionalization of Multiwalled Carbon Nanotube with Amphiphilic Poly(Propyleneimine) Dendrimer Carrying Silver Nanoparticles for Better Dispersability and Antimicrobial Activity. J. Colloid. Interface Sci. 2011, 357, 354–365. [Google Scholar] [CrossRef]

- Neelgund, G.M.; Oki, A. Deposition of Silver Nanoparticles on Dendrimer Functionalized Multiwalled Carbon Nanotubes: Synthesis, Characterization and Antimicrobial Activity. J. Nanosci. Nanotechnol. 2011, 11, 3621–3629. [Google Scholar] [CrossRef]

- Neelgund, G.M.; Oki, A.; Luo, Z. Antimicrobial Activity of CdS and Ag2S Quantum Dots Immobilized on Poly(Amidoamine) Grafted Carbon Nanotubes. Colloids Surf. B Biointerfaces 2012, 100, 215–221. [Google Scholar] [CrossRef]

- Ong, L.C.; Tan, Y.F.; Tan, B.S.; Chung, F.F.; Cheong, S.K.; Leong, C.O. Single-walled carbon nanotubes (SWCNTs) inhibit heat shock protein 90 (HSP90) signaling in human lung fibroblasts and keratinocytes. Toxicol. Appl. Pharmacol. 2017, 15, 329:347–357. [Google Scholar] [CrossRef]

- Zardini, H.Z.; Davarpanah, M.; Shanbedi, M.; Amiri, A.; Maghrebi, M.; Ebrahimi, L. Microbial Toxicity of Ethanolamines—Multiwalled Carbon Nanotubes. J. Biomed. Mater. Res. A 2014, 102, 1774–1781. [Google Scholar] [CrossRef] [PubMed]

- Gilbertson, L.M.; Goodwin, D.G.; Taylor, A.D.; Pfefferle, L.; Zimmerman, J.B. Toward Tailored Functional Design of Multi-Walled Carbon Nanotubes (MWNTs): Electrochemical and Antimicrobial Activity Enhancement via Oxidation and Selective Reduction. Environ. Sci. Technol. 2014, 48, 5938–5945. [Google Scholar] [CrossRef] [PubMed]

- Choi, J.; Seo, Y.; Hwang, J.; Kim, J.; Jeong, Y.; Hwang, M. Antibacterial Activity and Cytotoxicity of Multi-Walled Carbon Nanotubes Decorated with Silver Nanoparticles. Int. J. Nanomed. 2014, 9, 4621–4629. [Google Scholar] [CrossRef] [PubMed]

- Jung, J.H.; Hwang, G.B.; Lee, J.E.; Bae, G.N. Preparation of Airborne Ag/CNT Hybrid Nanoparticles Using an Aerosol Process and Their Application to Antimicrobial Air Filtration. Langmuir 2011, 27, 10256–10264. [Google Scholar] [CrossRef]

- Rusen, E.; Mocanu, A.; Nistor, L.C.; Dinescu, A.; Călinescu, I.; Mustăţea, G.; Voicu, Ş.I.; Andronescu, C.; Diacon, A. Design of Antimicrobial Membrane Based on Polymer Colloids/Multiwall Carbon Nanotubes Hybrid Material with Silver Nanoparticles. ACS Appl. Mater. Interfaces 2014, 6, 17384–17393. [Google Scholar] [CrossRef]

- Mohan, R.; Shanmugharaj, A.M.; Sung Hun, R. An Efficient Growth of Silver and Copper Nanoparticles on Multiwalled Carbon Nanotube with Enhanced Antimicrobial Activity. J. Biomed. Mater. Res. B Appl. Biomater. 2011, 96B, 119–126. [Google Scholar] [CrossRef]

- Sui, M.; Zhang, L.; Sheng, L.; Huang, S.; She, L. Synthesis of ZnO Coated Multi-Walled Carbon Nanotubes and Their Antibacterial Activities. Sci. Total Environ. 2013, 452–453, 148–154. [Google Scholar] [CrossRef]

- Karthika, V.; Arumugam, A. Synthesis and Characterization of MWCNT/TiO2/Au Nanocomposite for Photocatalytic and Antimicrobial Activity. IET Nanobiotechnol. 2017, 11, 113–118. [Google Scholar] [CrossRef]

- Kim, S.H.; Kim, D.Y.; Park, J.S.; Park, M.; Park, M.C. Antimicrobial and Antibiofilm Activities of Urinary Catheter Incorporated with ZnO-Carbon Nanotube. ACS Appl. Bio Mater. 2025, 8, 1397–1405. [Google Scholar] [CrossRef]

- Hirschfeld, J.; Akinoglu, E.M.; Wirtz, D.C.; Hoerauf, A.; Bekeredjian-Ding, I.; Jepsen, S.; Haddouti, E.-M.; Limmer, A.; Giersig, M. Long-Term Release of Antibiotics by Carbon Nanotube-Coated Titanium Alloy Surfaces Diminish Biofilm Formation by Staphylococcus Epidermidis. Nanomedicine 2017, 13, 1587–1593. [Google Scholar] [CrossRef]

- Grover, N.; Borkar, I.V.; Dinu, C.Z.; Kane, R.S.; Dordick, J.S. Laccase- and Chloroperoxidase-Nanotube Paint Composites with Bactericidal and Sporicidal Activity. Enzym. Microb. Technol. 2012, 50, 271–279. [Google Scholar] [CrossRef] [PubMed]

- Venkatesan, J.; Jayakumar, R.; Mohandas, A.; Bhatnagar, I.; Kim, S.-K. Antimicrobial Activity of Chitosan-Carbon Nanotube Hydrogels. Materials 2014, 7, 3946–3955. [Google Scholar] [CrossRef] [PubMed]

- Mohamed, N.A.; Al-Harby, N.F.; Almarshed, M.S. Synthesis and Characterization of Novel Trimellitic Anhydride Isothiocyanate-Cross Linked Chitosan Hydrogels Modified with Multi-Walled Carbon Nanotubes for Enhancement of Antimicrobial Activity. Int. J. Biol. Macromol. 2019, 132, 416–428. [Google Scholar] [CrossRef] [PubMed]

- Ding, L.; Wang, H.; Liu, D.; Zeng, X.-A.; Mao, Y. Bacteria Capture and Inactivation with Functionalized Multi-Walled Carbon Nanotubes (MWCNTs). J. Nanosci. Nanotechnol. 2020, 20, 2055–2062. [Google Scholar] [CrossRef]

- Levi-Polyachenko, N.; Young, C.; MacNeill, C.; Braden, A.; Argenta, L.; Reid, S. Eradicating Group A Streptococcus Bacteria and Biofilms Using Functionalised Multi-Wall Carbon Nanotubes. Int. J. Hyperth. 2014, 30, 490–501. [Google Scholar] [CrossRef]

- Bai, Y.; Park, I.S.; Lee, S.J.; Bae, T.S.; Watari, F.; Uo, M.; Lee, M.H. Aqueous Dispersion of Surfactant-Modified Multiwalled Carbon Nanotubes and Their Application as an Antibacterial Agent. Carbon 2011, 49, 3663–3671. [Google Scholar] [CrossRef]

- Khazaee, M.; Ye, D.; Majumder, A.; Baraban, L.; Opitz, J.; Cuniberti, G. Non-Covalent Modified Multi-Walled Carbon Nanotubes: Dispersion Capabilities and Interactions with Bacteria. Biomed. Phys. Eng. Express 2016, 2, 055008. [Google Scholar] [CrossRef]

- Akhavan, O.; Azimirad, R.; Safa, S. Functionalized Carbon Nanotubes in ZnO Thin Films for Photoinactivation of Bacteria. Mater. Chem. Phys. 2011, 130, 598–602. [Google Scholar] [CrossRef]

- Amiri, A.; Zardini, H.Z.; Shanbedi, M.; Maghrebi, M.; Baniadam, M.; Tolueinia, B. Efficient Method for Functionalization of Carbon Nanotubes by Lysine and Improved Antimicrobial Activity and Water-Dispersion. Mater. Lett. 2012, 72, 153–156. [Google Scholar] [CrossRef]

- Hasnain, M.S.; Nayak, A.K. Regulatory Considerations of Carbon Nanotubes. In Carbon Nanotubes for Targeted Drug Delivery; Springer: Cham, Switzerland, 2019; pp. 103–106. [Google Scholar]

- Ma-Hock, L.; Treumann, S.; Strauss, V.; Brill, S.; Luizi, F.; Mertler, M.; Wiench, K.; Gamer, A.O.; van Ravenzwaay, B.; Landsiedel, R. Inhalation Toxicity of Multiwall Carbon Nanotubes in Rats Exposed for 3 Months. Toxicol. Sci. 2009, 112, 468–481. [Google Scholar] [CrossRef]

- Wikipedia. Toxicology of Carbon Nanotubes. Available online: https://en.wikipedia.org/wiki/Toxicology_of_carbon_nanomaterials#:~:text=The%20toxicity%20of%20carbon%20nanotubes%20has%20been%20an,in%20evaluating%20the%20toxicity%20of%20this%20heterogeneous%20material (accessed on 7 March 2025).

- Wang, H.; Wang, J.; Deng, X.; Sun, H.; Shi, Z.; Gu, Z.; Liu, Y.; Zhaoc, Y. Biodistribution of Carbon Single-Wall Carbon Nanotubes in Mice. J. Nanosci. Nanotechnol. 2004, 4, 1019–1024. [Google Scholar] [CrossRef] [PubMed]

- Cheng, J.; Flahaut, E.; Cheng, S.H. Effect of Carbon Nanotubes on Developing Zebrafish (Danio Rerio) Embryos. Environ. Toxicol. Chem. 2007, 26, 708–716. [Google Scholar] [CrossRef] [PubMed]

- Li, J.G.; Li, Q.N.; Xu, J.Y.; Cai, X.Q.; Liu, R.L.; Li, Y.J.; Ma, J.F.; Li, W.X. The Pulmonary Toxicity of Multi-Wall Carbon Nanotubes in Mice 30 and 60 Days After Inhalation Exposure. J. Nanosci. Nanotechnol. 2009, 9, 1384–1387. [Google Scholar] [CrossRef]

- Scoville, C.; Cole, R.; Hogg, J.; Farooque, O.; Russel, A. Carbon Nanotubes. Available online: https://docslib.org/doc/13279829/carbon-nanotubes-by-chris-scoville-robin-cole-jason-hogg-omar-farooque-and-archie-russell (accessed on 18 March 2025).

- Li, Y.; Wang, S.; Lv, Z.; Wang, Z.; Zhao, Y.; Xie, Y.; Xu, Y.; Qian, L.; Yang, Y.; Zhao, Z.; et al. Transforming the Synthesis of Carbon Nanotubes with Machine Learning Models and Automation. Matter 2025, 8, 101913. [Google Scholar] [CrossRef]

- Simon-Deckers, A.; Gouget, B.; Mayne-L’Hermite, M.; Herlin-Boime, N.; Reynaud, C.; Carrière, M. In Vitro Investigation of Oxide Nanoparticle and Carbon Nanotube Toxicity and Intracellular Accumulation in A549 Human Pneumocytes. Toxicology 2008, 253, 137–146. [Google Scholar] [CrossRef]

- Pulskamp, K.; Diabate, S.; Krug, H. Carbon Nanotubes Show No Sign of Acute Toxicity but Induce Intracellular Reactive Oxygen Species in Dependence on Contaminants. Toxicol. Lett. 2007, 168, 58–74. [Google Scholar] [CrossRef]

- Wick, P.; Manser, P.; Limbach, L.; Dettlaffweglikowska, U.; Krumeich, F.; Roth, S.; Stark, W.; Bruinink, A. The Degree and Kind of Agglomeration Affect Carbon Nanotube Cytotoxicity. Toxicol. Lett. 2007, 168, 121–131. [Google Scholar] [CrossRef]

- Monteiro-Riviere, N.A.; Inman, A.O.; Wang, Y.Y.; Nemanich, R.J. Surfactant Effects on Carbon Nanotube Interactions with Human Keratinocytes. Nanomedicine 2005, 1, 293–299. [Google Scholar] [CrossRef]

- Pantarotto, D.; Briand, J.-P.; Prato, M.; Bianco, A. Translocation of Bioactive Peptides across Cell Membranes by Carbon Nanotubes. Chem. Commun. 2004, 1, 16–17. [Google Scholar] [CrossRef]

- Manna, S.K.; Sarkar, S.; Barr, J.; Wise, K.; Barrera, E.V.; Jejelowo, O.; Rice-Ficht, A.C.; Ramesh, G.T. Single-Walled Carbon Nanotube Induces Oxidative Stress and Activates Nuclear Transcription Factor-ΚB in Human Keratinocytes. Nano Lett. 2005, 5, 1676–1684. [Google Scholar] [CrossRef]

- Shvedova, A.; Castranova, V.; Kisin, E.; Schwegler-Berry, D.; Murray, A.; Gandelsman, V.; Maynard, A.; Baron, P. Exposure to Carbon Nanotube Material: Assessment of Nanotube Cytotoxicity Using Human Keratinocyte Cells. J. Toxicol. Environ. Health A 2003, 66, 1909–1926. [Google Scholar] [CrossRef] [PubMed]

- Shvedova, A.A.; Kisin, E.R.; Mercer, R.; Murray, A.R.; Johnson, V.J.; Potapovich, A.I.; Tyurina, Y.Y.; Gorelik, O.; Arepalli, S.; Schwegler-Berry, D.; et al. Unusual Inflammatory and Fibrogenic Pulmonary Responses to Single-Walled Carbon Nanotubes in Mice. Am. J. Physiol.-Lung Cell. Mol. Physiol. 2005, 289, L698–L708. [Google Scholar] [CrossRef] [PubMed]

- Dumortier, H.; Lacotte, S.; Pastorin, G.; Marega, R.; Wu, W.; Bonifazi, D.; Briand, J.-P.; Prato, M.; Muller, S.; Bianco, A. Functionalized Carbon Nanotubes Are Non-Cytotoxic and Preserve the Functionality of Primary Immune Cells. Nano Lett. 2006, 6, 1522–1528. [Google Scholar] [CrossRef] [PubMed]

- Sayes, C.M.; Liang, F.; Hudson, J.L.; Mendez, J.; Guo, W.; Beach, J.M.; Moore, V.C.; Doyle, C.D.; West, J.L.; Billups, W.E.; et al. Functionalization Density Dependence of Single-Walled Carbon Nanotubes Cytotoxicity in Vitro. Toxicol. Lett. 2006, 161, 135–142. [Google Scholar] [CrossRef]

- Shi Kam, N.W.; Jessop, T.C.; Wender, P.A.; Dai, H. Nanotube Molecular Transporters: Internalization of Carbon Nanotube−Protein Conjugates into Mammalian Cells. J. Am. Chem. Soc. 2004, 126, 6850–6851. [Google Scholar] [CrossRef]

- Fenoglio, I.; Tomatis, M.; Lison, D.; Muller, J.; Fonseca, A.; Nagy, J.B.; Fubini, B. Reactivity of Carbon Nanotubes: Free Radical Generation or Scavenging Activity? Free Radic. Biol. Med. 2006, 40, 1227–1233. [Google Scholar] [CrossRef]

- Sun, Z.; Liu, Z.; Meng, J.; Meng, J.; Duan, J.; Xie, S.; Lu, X.; Zhu, Z.; Wang, C.; Chen, S.; et al. Carbon Nanotubes Enhance Cytotoxicity Mediated by Human Lymphocytes In Vitro. PLoS ONE 2011, 6, e21073. [Google Scholar] [CrossRef]

- Cui, D.; Tian, F.; Ozkan, C.S.; Wang, M.; Gao, H. Effect of Single Wall Carbon Nanotubes on Human HEK293 Cells. Toxicol. Lett. 2005, 155, 73–85. [Google Scholar] [CrossRef]

- Jia, G.; Wang, H.; Yan, L.; Wang, X.; Pei, R.; Yan, T.; Zhao, Y.; Guo, X. Cytotoxicity of Carbon Nanomaterials: Single-Wall Nanotube, Multi-Wall Nanotube, and Fullerene. Environ. Sci. Technol. 2005, 39, 1378–1383. [Google Scholar] [CrossRef]

- Pacurari, M.; Yin, X.J.; Zhao, J.; Ding, M.; Leonard, S.S.; Schwegler-Berry, D.; Ducatman, B.S.; Sbarra, D.; Hoover, M.D.; Castranova, V.; et al. Raw Single-Wall Carbon Nanotubes Induce Oxidative Stress and Activate MAPKs, AP-1, NF-ΚB, and Akt in Normal and Malignant Human Mesothelial Cells. Environ. Health Perspect. 2008, 116, 1211–1217. [Google Scholar] [CrossRef]

- Kisin, E.R.; Murray, A.R.; Keane, M.J.; Shi, X.-C.; Schwegler-Berry, D.; Gorelik, O.; Arepalli, S.; Castranova, V.; Wallace, W.E.; Kagan, V.E.; et al. Single-Walled Carbon Nanotubes: Geno- and Cytotoxic Effects in Lung Fibroblast V79 Cells. J. Toxicol. Environ. Health A 2007, 70, 2071–2079. [Google Scholar] [CrossRef] [PubMed]

- Francis, A.P.; Devasena, T. Toxicity of Carbon Nanotubes: A Review. Toxicol. Ind. Health 2018, 34, 200–210. [Google Scholar] [CrossRef] [PubMed]

- Muller, J.; Huaux, F.; Moreau, N.; Misson, P.; Heilier, J.-F.; Delos, M.; Arras, M.; Fonseca, A.; Nagy, J.B.; Lison, D. Respiratory Toxicity of Multi-Wall Carbon Nanotubes. Toxicol. Appl. Pharmacol. 2005, 207, 221–231. [Google Scholar] [CrossRef] [PubMed]

- Hirano, S.; Kanno, S.; Furuyama, A. Multi-Walled Carbon Nanotubes Injure the Plasma Membrane of Macrophages. Toxicol. Appl. Pharmacol. 2008, 232, 244–251. [Google Scholar] [CrossRef]

- Monteiro-Riviere, N.A.; Nemanich, R.J.; Inman, A.O.; Wang, Y.Y.; Riviere, J.E. Multi-Walled Carbon Nanotube Interactions with Human Epidermal Keratinocytes. Toxicol. Lett. 2005, 155, 377–384. [Google Scholar] [CrossRef]

- Monteiro-Riviere, N.A.; Inman, A.O. Challenges for Assessing Carbon Nanomaterial Toxicity to the Skin. Carbon 2006, 44, 1070–1078. [Google Scholar] [CrossRef]

- Yang, H.; Liu, C.; Yang, D.; Zhang, H.; Xi, Z. Comparative Study of Cytotoxicity, Oxidative Stress and Genotoxicity Induced by Four Typical Nanomaterials: The Role of Particle Size, Shape and Composition. J. Appl. Toxicol. 2009, 29, 69–78. [Google Scholar] [CrossRef]

- Ding, L.; Stilwell, J.; Zhang, T.; Elboudwarej, O.; Jiang, H.; Selegue, J.P.; Cooke, P.A.; Gray, J.W.; Chen, F.F. Molecular Characterization of the Cytotoxic Mechanism of Multiwall Carbon Nanotubes and Nano-Onions on Human Skin Fibroblast. Nano Lett. 2005, 5, 2448–2464. [Google Scholar] [CrossRef]

- Soto, K.F.; Carrasco, A.; Powell, T.G.; Garza, K.M.; Murr, L.E. Comparative in Vitro Cytotoxicity Assessment of Some Manufacturednanoparticulate Materials Characterized by Transmissionelectron Microscopy. J. Nanopart. Res. 2005, 7, 145–169. [Google Scholar] [CrossRef]

- Murr, L.E.; Garza, K.M.; Soto, K.F.; Carrasco, A.; Powell, T.G.; Ramirez, D.A.; Guerrero, P.A.; Lopez, D.A.; Venzor, J. Cytotoxicity Assessment of Some Carbon Nanotubes and Related Carbon Nanoparticle Aggregates and the Implications for Anthropogenic Carbon Nanotube Aggregates in the Environment. Int. J. Environ. Res. Public. Health 2005, 2, 31–42. [Google Scholar] [CrossRef]

- Bottini, M.; Bruckner, S.; Nika, K.; Bottini, N.; Bellucci, S.; Magrini, A.; Bergamaschi, A.; Mustelin, T. Multi-Walled Carbon Nanotubes Induce T Lymphocyte Apoptosis. Toxicol. Lett. 2006, 160, 121–126. [Google Scholar] [CrossRef] [PubMed]

- Lam, C.-W. Pulmonary Toxicity of Single-Wall Carbon Nanotubes in Mice 7 and 90 Days After Intratracheal Instillation. Toxicol. Sci. 2003, 77, 126–134. [Google Scholar] [CrossRef] [PubMed]

- Warheit, D.B. Comparative Pulmonary Toxicity Assessment of Single-Wall Carbon Nanotubes in Rats. Toxicol. Sci. 2003, 77, 117–125. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Hulderman, T.; Salmen, R.; Chapman, R.; Leonard, S.S.; Young, S.-H.; Shvedova, A.; Luster, M.I.; Simeonova, P.P. Cardiovascular Effects of Pulmonary Exposure to Single-Wall Carbon Nanotubes. Environ. Health Perspect. 2007, 115, 377–382. [Google Scholar] [CrossRef]

- Mutlu, G.M.; Budinger, G.R.S.; Green, A.A.; Urich, D.; Soberanes, S.; Chiarella, S.E.; Alheid, G.F.; McCrimmon, D.R.; Szleifer, I.; Hersam, M.C. Biocompatible Nanoscale Dispersion of Single-Walled Carbon Nanotubes Minimizes in Vivo Pulmonary Toxicity. Nano Lett. 2010, 10, 1664–1670. [Google Scholar] [CrossRef]

- Mitchell, L.A.; Lauer, F.T.; Burchiel, S.W.; McDonald, J.D. Mechanisms for How Inhaled Multiwalled Carbon Nanotubes Suppress Systemic Immune Function in Mice. Nat. Nanotechnol. 2009, 4, 451–456. [Google Scholar] [CrossRef]

- Muller, J.; Huaux, F.; Fonseca, A.; Nagy, J.B.; Moreau, N.; Delos, M.; Raymundo-Piñero, E.; Béguin, F.; Kirsch-Volders, M.; Fenoglio, I.; et al. Structural Defects Play a Major Role in the Acute Lung Toxicity of Multiwall Carbon Nanotubes: Toxicological Aspects. Chem. Res. Toxicol. 2008, 21, 1698–1705. [Google Scholar] [CrossRef]

- Donaldson, K.; Aitken, R.; Tran, L.; Stone, V.; Duffin, R.; Forrest, G.; Alexander, A. Carbon Nanotubes: A Review of Their Properties in Relation to Pulmonary Toxicology and Workplace Safety. Toxicol. Sci. 2006, 92, 5–22. [Google Scholar] [CrossRef]

- Inoue, K.; Yanagisawa, R.; Koike, E.; Nishikawa, M.; Takano, H. Repeated Pulmonary Exposure to Single-Walled Carbon Nanotubes Exacerbates Allergic Inflammation of the Airway: Possible Role of Oxidative Stress. Free Radic. Biol. Med. 2010, 48, 924–934. [Google Scholar] [CrossRef]

- Kobayashi, N.; Naya, M.; Ema, M.; Endoh, S.; Maru, J.; Mizuno, K.; Nakanishi, J. Biological Response and Morphological Assessment of Individually Dispersed Multi-Wall Carbon Nanotubes in the Lung after Intratracheal Instillation in Rats. Toxicology 2010, 276, 143–153. [Google Scholar] [CrossRef]

- Morimoto, Y.; Hirohashi, M.; Ogami, A.; Oyabu, T.; Myojo, T.; Todoroki, M.; Yamamoto, M.; Hashiba, M.; Mizuguchi, Y.; Lee, B.W.; et al. Pulmonary Toxicity of Well-Dispersed Multi-Wall Carbon Nanotubes Following Inhalation and Intratracheal Instillation. Nanotoxicology 2012, 6, 587–599. [Google Scholar] [CrossRef] [PubMed]

- Grubek-Jaworska, H.; Nejman, P.; Czumińska, K.; Przybyłowski, T.; Huczko, A.; Lange, H.; Bystrzejewski, M.; Baranowski, P.; Chazan, R. Preliminary Results on the Pathogenic Effects of Intratracheal Exposure to One-Dimensional Nanocarbons. Carbon 2006, 44, 1057–1063. [Google Scholar] [CrossRef]

- Francis, A.P.; Ganapathy, S.; Palla, V.R.; Murthy, P.B.; Ramaprabhu, S.; Devasena, T. One Time Nose-Only Inhalation of MWCNTs: Exploring the Mechanism of Toxicity by Intermittent Sacrifice in Wistar Rats. Toxicol. Rep. 2015, 2, 111–120. [Google Scholar] [CrossRef] [PubMed]

- Simeonova, P.P.; Erdely, A. Engineered Nanoparticle Respiratory Exposure and Potential Risks for Cardiovascular Toxicity: Predictive Tests and Biomarkers. Inhal. Toxicol. 2009, 21, 68–73. [Google Scholar] [CrossRef]

- Pietroiusti, A.; Massimiani, M.; Fenoglio, I.; Colonna, M.; Valentini, F.; Palleschi, G.; Camaioni, A.; Magrini, A.; Siracusa, G.; Bergamaschi, A.; et al. Low Doses of Pristine and Oxidized Single-Wall Carbon Nanotubes Affect Mammalian Embryonic Development. ACS Nano 2011, 5, 4624–4633. [Google Scholar] [CrossRef]

- Bai, Y.; Zhang, Y.; Zhang, J.; Mu, Q.; Zhang, W.; Butch, E.R.; Snyder, S.E.; Yan, B. Repeated Administrations of Carbon Nanotubes in Male Mice Cause Reversible Testis Damage without Affecting Fertility. Nat. Nanotechnol. 2010, 5, 683–689. [Google Scholar] [CrossRef]

- Philbrook, N.A.; Walker, V.K.; Afrooz, A.R.M.N.; Saleh, N.B.; Winn, L.M. Investigating the Effects of Functionalized Carbon Nanotubes on Reproduction and Development in Drosophila Melanogaster and CD-1 Mice. Reprod. Toxicol. 2011, 32, 442–448. [Google Scholar] [CrossRef]

- Møller, P.; Wils, R.S.; Di Ianni, E.; Gutierrez, C.A.T.; Roursgaard, M.; Jacobsen, N.R. Genotoxicity of Multi-Walled Carbon Nanotube Reference Materials in Mammalian Cells and Animals. Mutat. Res./Rev. Mutat. Res. 2021, 788, 108393. [Google Scholar] [CrossRef]

- Sargent, L.M.; Hubbs, A.F.; Young, S.-H.; Kashon, M.L.; Dinu, C.Z.; Salisbury, J.L.; Benkovic, S.A.; Lowry, D.T.; Murray, A.R.; Kisin, E.R.; et al. Single-Walled Carbon Nanotube-Induced Mitotic Disruption. Mutat. Res./Genet. Toxicol. Environ. Mutagen. 2012, 745, 28–37. [Google Scholar] [CrossRef]

- Lash, L.H. Special Issue: Membrane Transporters in Toxicology. Toxicol. Appl. Pharmacol. 2005, 204, 197. [Google Scholar] [CrossRef]

- Murray, A.R.; Kisin, E.; Leonard, S.S.; Young, S.H.; Kommineni, C.; Kagan, V.E.; Castranova, V.; Shvedova, A.A. Oxidative Stress and Inflammatory Response in Dermal Toxicity of Single-Walled Carbon Nanotubes. Toxicology 2009, 257, 161–171. [Google Scholar] [CrossRef] [PubMed]

- Orecchioni, M.; Bedognetti, D.; Sgarrella, F.; Marincola, F.M.; Bianco, A.; Delogu, L.G. Impact of Carbon Nanotubes and Graphene on Immune Cells. J. Transl. Med. 2014, 12, 138. [Google Scholar] [CrossRef]

- Svadlakova, T.; Holmannova, D.; Kolackova, M.; Malkova, A.; Krejsek, J.; Fiala, Z. Immunotoxicity of Carbon-Based Nanomaterials, Starring Phagocytes. Int. J. Mol. Sci. 2022, 23, 8889. [Google Scholar] [CrossRef] [PubMed]

- Kan, H.; Pan, D.; Castranova, V. Engineered Nanoparticle Exposure and Cardiovascular Effects: The Role of a Neuronal-Regulated Pathway. Inhal. Toxicol. 2018, 30, 335–342. [Google Scholar] [CrossRef]

- Alidori, S.; Bowman, R.L.; Yarilin, D.; Romin, Y.; Barlas, A.; Mulvey, J.J.; Fujisawa, S.; Xu, K.; Ruggiero, A.; Riabov, V.; et al. Deconvoluting Hepatic Processing of Carbon Nanotubes. Nat. Commun. 2016, 7, 12343. [Google Scholar] [CrossRef]

- Reddy, A.R.N.; Reddy, Y.N.; Krishna, D.R.; Himabindu, V. Multi Wall Carbon Nanotubes Induce Oxidative Stress and Cytotoxicity in Human Embryonic Kidney (HEK293) Cells. Toxicology 2010, 272, 11–16. [Google Scholar] [CrossRef]

- Facciolà, A.; Visalli, G.; La Maestra, S.; Ceccarelli, M.; D’Aleo, F.; Nunnari, G.; Pellicanò, G.F.; Di Pietro, A. Carbon Nanotubes and Central Nervous System: Environmental Risks, Toxicological Aspects and Future Perspectives. Environ. Toxicol. Pharmacol. 2019, 65, 23–30. [Google Scholar] [CrossRef]

- Zheng, W.; McKinney, W.; Kashon, M.; Salmen, R.; Castranova, V.; Kan, H. The Influence of Inhaled Multi-Walled Carbon Nanotubes on the Autonomic Nervous System. Part. Fibre Toxicol. 2015, 13, 8. [Google Scholar] [CrossRef]

- Aragon, M.J.; Topper, L.; Tyler, C.R.; Sanchez, B.; Zychowski, K.; Young, T.; Herbert, G.; Hall, P.; Erdely, A.; Eye, T.; et al. Serum-Borne Bioactivity Caused by Pulmonary Multiwalled Carbon Nanotubes Induces Neuroinflammation via Blood–Brain Barrier Impairment. Proc. Natl. Acad. Sci. USA 2017, 114, E1968–E1976. [Google Scholar] [CrossRef]

- Gholamine, B.; Karimi, I.; Salimi, A.; Mazdarani, P.; Becker, L.A. Neurobehavioral Toxicity of Carbon Nanotubes in Mice. Toxicol. Ind. Health 2017, 33, 340–350. [Google Scholar] [CrossRef]

- Larner, S.F.; Wang, J.; Goodman, J.; O’Donoghue Altman, M.B.; Xin, M.; Wang, K.K.W. In Vitro Neurotoxicity Resulting from Exposure of Cultured Neural Cells to Several Types of Nanoparticles. J. Cell Death 2017, 10, 117967071769452. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.; Zheng, X.; Nicholas, J.; Humes, S.T.; Loeb, J.C.; Robinson, S.E.; Bisesi, J.H.; Das, D.; Saleh, N.B.; Castleman, W.L.; et al. Single-Walled Carbon Nanotubes Modulate Pulmonary Immune Responses and Increase Pandemic Influenza a Virus Titers in Mice. Virol. J. 2017, 14, 242. [Google Scholar] [CrossRef] [PubMed]

- Park, E.-J.; Choi, J.; Kim, J.-H.; Lee, B.-S.; Yoon, C.; Jeong, U.; Kim, Y. Subchronic Immunotoxicity and Screening of Reproductive Toxicity and Developmental Immunotoxicity Following Single Instillation of HIPCO-Single-Walled Carbon Nanotubes: Purity-Based Comparison. Nanotoxicology 2016, 10, 1188–1202. [Google Scholar] [CrossRef] [PubMed]

- Khang, D.; Lee, S.; Kim, S.-H. High Dispersity of Carbon Nanotubes Diminishes Immunotoxicity in Spleen. Int. J. Nanomed. 2015, 10, 2697–2710. [Google Scholar] [CrossRef]

- Qi, W.; Bi, J.; Zhang, X.; Wang, J.; Wang, J.; Liu, P.; Li, Z.; Wu, W. Damaging Effects of Multi-Walled Carbon Nanotubes on Pregnant Mice with Different Pregnancy Times. Sci. Rep. 2014, 4, 4352. [Google Scholar] [CrossRef]

- Cheng, J.; Cheng, S.H. Influence of Carbon Nanotube Length on Toxicity to Zebrafish Embryos. Int. J. Nanomed. 2012, 7, 3731–3739. [Google Scholar] [CrossRef]

- Huang, X.; Zhang, F.; Sun, X.; Choi, K.-Y.; Niu, G.; Zhang, G.; Guo, J.; Lee, S.; Chen, X. The Genotype-Dependent Influence of Functionalized Multiwalled Carbon Nanotubes on Fetal Development. Biomaterials 2014, 35, 856–865. [Google Scholar] [CrossRef]

- Zhu, B.; Zhu, S.; Li, J.; Hui, X.; Wang, G.-X. The Developmental Toxicity, Bioaccumulation and Distribution of Oxidized Single Walled Carbon Nanotubes in Artemia salina. Toxicol. Res. 2018, 7, 897–906. [Google Scholar] [CrossRef]

- Lindberg, H.K.; Falck, G.C.-M.; Singh, R.; Suhonen, S.; Järventaus, H.; Vanhala, E.; Catalán, J.; Farmer, P.B.; Savolainen, K.M.; Norppa, H. Genotoxicity of Short Single-Wall and Multi-Wall Carbon Nanotubes in Human Bronchial Epithelial and Mesothelial Cells in Vitro. Toxicology 2013, 313, 24–37. [Google Scholar] [CrossRef]

- Lettiero, B.; Andersen, A.J.; Hunter, A.C.; Moghimi, S.M. Complement System and the Brain: Selected Pathologies and Avenues toward Engineering of Neurological Nanomedicines. J. Control. Release 2012, 161, 283–289. [Google Scholar] [CrossRef]

- Moghimi, S.M.; Peer, D.; Langer, R. Reshaping the Future of Nanopharmaceuticals: Ad iudicium. ACS Nano 2011, 5, 8454–8458. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Davis, C.; Cai, W.; He, L.; Chen, X.; Dai, H. Circulation and Long-Term Fate of Functionalized, Biocompatible Single-Walled Carbon Nanotubes in Mice Probed by Raman Spectroscopy. Proc. Natl. Acad. Sci. USA 2008, 105, 1410–1415. [Google Scholar] [CrossRef] [PubMed]

- Yang, S.; Fernando, K.A.S.; Liu, J.; Wang, J.; Sun, H.; Liu, Y.; Chen, M.; Huang, Y.; Wang, X.; Wang, H.; et al. Covalently PEGylated Carbon Nanotubes with Stealth Character In Vivo. Small 2008, 4, 940–944. [Google Scholar] [CrossRef] [PubMed]

- Pondman, K.M.; Pednekar, L.; Paudyal, B.; Tsolaki, A.G.; Kouser, L.; Khan, H.A.; Shamji, M.H.; ten Haken, B.; Stenbeck, G.; Sim, R.B.; et al. Innate Immune Humoral Factors, C1q and Factor H, with Differential Pattern Recognition Properties, Alter Macrophage Response to Carbon Nanotubes. Nanomedicine 2015, 11, 2109–2118. [Google Scholar] [CrossRef]

- Silva, R.M.; Doudrick, K.; Franzi, L.M.; TeeSy, C.; Anderson, D.S.; Wu, Z.; Mitra, S.; Vu, V.; Dutrow, G.; Evans, J.E.; et al. Instillation versus Inhalation of Multiwalled Carbon Nanotubes: Exposure-Related Health Effects, Clearance, and the Role of Particle Characteristics. ACS Nano 2014, 8, 8911–8931. [Google Scholar] [CrossRef]

- Liu, Y.; Zhao, Y.; Sun, B.; Chen, C. Understanding the Toxicity of Carbon Nanotubes. Acc. Chem. Res. 2013, 46, 702–713. [Google Scholar] [CrossRef]

- Zhu, Y.; Li, W.; Li, Q.; Li, Y.; Li, Y.; Zhang, X.; Huang, Q. Effects of Serum Proteins on Intracellular Uptake and Cytotoxicity of Carbon Nanoparticles. Carbon 2009, 47, 1351–1358. [Google Scholar] [CrossRef]

- Dong, X.; Sun, Z.; Wang, X.; Leng, X. An Innovative MWCNTs/DOX/TC Nanosystem for Chemo-Photothermal Combination Therapy of Cancer. Nanomedicine 2017, 13, 2271–2280. [Google Scholar] [CrossRef]

- Yan, Y.; Wang, R.; Hu, Y.; Sun, R.; Song, T.; Shi, X.; Yin, S. Stacking of Doxorubicin on Folic Acid-Targeted Multiwalled Carbon Nanotubes for in Vivo Chemotherapy of Tumors. Drug Deliv. 2018, 25, 1607–1616. [Google Scholar] [CrossRef]

- Awasthi, S.; De, S.; Pandey, S.K. Surface Grafting of Carbon Nanostructures. In Handbook of Functionalized Carbon Nanostructures; Springer International Publishing: Cham, Switzerland, 2024; pp. 1–45. [Google Scholar]

- Rele, S.; Thakur, C.K.; Khan, F.; Baral, B.; Saini, V.; Karthikeyan, C.; Moorthy, N.S.H.N.; Jha, H.C. Curcumin Coating: A Novel Solution to Mitigate Inherent Carbon Nanotube Toxicity. J. Mater. Sci. Mater. Med. 2024, 35, 24. [Google Scholar] [CrossRef]

- Wu, L.; Man, C.; Wang, H.; Lu, X.; Ma, Q.; Cai, Y.; Ma, W. PEGylated Multi-Walled Carbon Nanotubes for Encapsulation and Sustained Release of Oxaliplatin. Pharm. Res. 2013, 30, 412–423. [Google Scholar] [CrossRef] [PubMed]

- Costa, P.M.; Bourgognon, M.; Wang, J.T.-W.; Al-Jamal, K.T. Functionalised Carbon Nanotubes: From Intracellular Uptake and Cell-Related Toxicity to Systemic Brain Delivery. J. Control. Release 2016, 241, 200–219. [Google Scholar] [CrossRef] [PubMed]

- Sohaebuddin, S.K.; Thevenot, P.T.; Baker, D.; Eaton, J.W.; Tang, L. Nanomaterial Cytotoxicity Is Composition, Size, and Cell Type Dependent. Part. Fibre Toxicol. 2010, 7, 22. [Google Scholar] [CrossRef] [PubMed]

- Heras, A.; Colina, A.; López-Palacios, J.; Ayala, P.; Sainio, J.; Ruiz, V.; Kauppinen, E.I. Electrochemical Purification of Carbon Nanotube Electrodes. Electrochem. Commun. 2009, 11, 1535–1538. [Google Scholar] [CrossRef]

- Mercier, G.; Hérold, C.; Marêché, J.-F.; Cahen, S.; Gleize, J.; Ghanbaja, J.; Lamura, G.; Bellouard, C.; Vigolo, B. Selective Removal of Metal Impurities from Single Walled Carbon Nanotube Samples. New J. Chem. 2013, 37, 790. [Google Scholar] [CrossRef]

- Pełech, I.; Narkiewicz, U.; Kaczmarek, A.; Jędrzejewska, A.; Pełech, R. Removal of Metal Particles from Carbon Nanotubes Using Conventional and Microwave Methods. Sep. Purif. Technol. 2014, 136, 105–110. [Google Scholar] [CrossRef]

- Madani, S.Y.; Mandel, A.; Seifalian, A.M. A Concise Review of Carbon Nanotube’s Toxicology. Nano Rev. 2013, 4, 21521. [Google Scholar] [CrossRef]

- Sallam, A.A.; Ahmed, M.M.; El-Magd, M.A.; Magdy, A.; Ghamry, H.I.; Alshahrani, M.Y.; Abou El-Fotoh, M.F. Quercetin-Ameliorated, Multi-Walled Carbon Nanotubes-Induced Immunotoxic, Inflammatory, and Oxidative Effects in Mice. Molecules 2022, 27, 2117. [Google Scholar] [CrossRef]

- Zhang, D.; Deng, X.; Ji, Z.; Shen, X.; Dong, L.; Wu, M.; Gu, T.; Liu, Y. Long-Term Hepatotoxicity of Polyethylene-Glycol Functionalized Multi-Walled Carbon Nanotubes in Mice. Nanotechnology 2010, 21, 175101. [Google Scholar] [CrossRef]

- Pérez-Luna, V.; Moreno-Aguilar, C.; Arauz-Lara, J.L.; Aranda-Espinoza, S.; Quintana, M. Interactions of Functionalized Multi-Wall Carbon Nanotubes with Giant Phospholipid Vesicles as Model Cellular Membrane System. Sci. Rep. 2018, 8, 17998. [Google Scholar] [CrossRef]

- Adenuga, A.A.; Truong, L.; Tanguay, R.L.; Remcho, V.T. Preparation of Water Soluble Carbon Nanotubes and Assessment of Their Biological Activity in Embryonic Zebrafish. Int. J. Biomed. Nanosci. Nanotechnol. 2013, 3, 38. [Google Scholar] [CrossRef] [PubMed]

- Lay, C.L.; Liu, H.Q.; Tan, H.R.; Liu, Y. Delivery of Paclitaxel by Physically Loading onto Poly(Ethylene Glycol) (PEG)-Graftcarbon Nanotubes for Potent Cancer Therapeutics. Nanotechnology 2010, 21, 065101. [Google Scholar] [CrossRef] [PubMed]

- Naqvi, S.T.R.; Rasheed, T.; Hussain, D.; Najam ul Haq, M.; Majeed, S.; Shafi, S.; Ahmed, N.; Nawaz, R. Modification Strategies for Improving the Solubility/Dispersion of Carbon Nanotubes. J. Mol. Liq. 2020, 297, 111919. [Google Scholar] [CrossRef]

- Saleemi, M.A.; Hosseini Fouladi, M.; Yong, P.V.C.; Chinna, K.; Palanisamy, N.K.; Wong, E.H. Toxicity of Carbon Nanotubes: Molecular Mechanisms, Signaling Cascades, and Remedies in Biomedical Applications. Chem. Res. Toxicol. 2021, 34, 24–46. [Google Scholar] [CrossRef]

- Barosova, H.; Karakocak, B.B.; Septiadi, D.; Petri-Fink, A.; Stone, V.; Rothen-Rutishauser, B. An In Vitro Lung System to Assess the Proinflammatory Hazard of Carbon Nanotube Aerosols. Int. J. Mol. Sci. 2020, 21, 5335. [Google Scholar] [CrossRef]

- Hou, P.-X.; Liu, C.; Cheng, H.-M. Purification of Carbon Nanotubes. Carbon 2008, 46, 2003–2025. [Google Scholar] [CrossRef]

- Yang, M.; Zhang, M. Biodegradation of Carbon Nanotubes by Macrophages. Front. Mater. 2019, 6, 225. [Google Scholar] [CrossRef]

- Yang, H.; Yang, T.; Heng, C.; Zhou, Y.; Jiang, Z.; Qian, X.; Du, L.; Mao, S.; Yin, X.; Lu, Q. Quercetin Improves Nonalcoholic Fatty Liver by Ameliorating Inflammation, Oxidative Stress, and Lipid Metabolism in Db/Db Mice. Phytother. Res. 2019, 33, 3140–3152. [Google Scholar] [CrossRef]

- Di Petrillo, A.; Orrù, G.; Fais, A.; Fantini, M.C. Quercetin and Its Derivates as Antiviral Potentials: A Comprehensive Review. Phytother. Res. 2022, 36, 266–278. [Google Scholar] [CrossRef]

- Nakanishi, J.; Morimoto, Y.; Ogura, I.; Kobayashi, N.; Naya, M.; Ema, M.; Endoh, S.; Shimada, M.; Ogami, A.; Myojyo, T.; et al. Risk Assessment of the Carbon Nanotube Group. Risk Anal. 2015, 35, 1940–1956. [Google Scholar] [CrossRef]

- Kumar Babele, P.; Kumar Verma, M.; Kant Bhatia, R. Carbon Nanotubes: A Review on Risks Assessment, Mechanism of Toxicity and Future Directives to Prevent Health Implication. BIOCELL 2021, 45, 267–279. [Google Scholar] [CrossRef]

- Duraia, E.M.; Opoku, M.; Beall, G.W. Efficient Eco-Friendly Synthesis of Carbon Nanotubes over Graphite Nanosheets from Yellow Corn: A One-Step Green Approach. Sci. Rep. 2024, 14, 16405. [Google Scholar] [CrossRef] [PubMed]

- Fisher, C.; Rider, A.E.; Jun Han, Z.; Kumar, S.; Levchenko, I.; Ostrikov, K. Applications and Nanotoxicity of Carbon Nanotubes and Graphene in Biomedicine. J. Nanomater. 2012, 2012, 315185. [Google Scholar] [CrossRef]

- Gendron, D.; Bubak, G. Carbon Nanotubes and Graphene Materials as Xenobiotics in Living Systems: Is There a Consensus on Their Safety? J. Xenobiot. 2023, 13, 740–760. [Google Scholar] [CrossRef]

- Zumwalde, R.D. Current Intelligence Bulletin 65: Occupational Exposure to Carbon Nanotubes and Nanofibers; The National Institute for Occupational Safety and Health (NIOSH): Atlanta, GA, USA, 2013. [Google Scholar]

- European Union Eur-Lex. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=OJ:JOC_2022_229_R_0001 (accessed on 13 March 2025).

- EU-OSHA—The Swedish Work Environment Authority. Carbon Nanotubes—Exposure, Toxicology and Protective Measures in the Work Environment; EU-OSHA—The Swedish Work Environment Authority: Solna, Sweden, 2011. [Google Scholar]

- Schulte, P.A.; Murashov, V.; Zumwalde, R.; Kuempel, E.D.; Geraci, C.L. Occupational Exposure Limits for Nanomaterials: State of the Art. J. Nanopart. Res. 2010, 12, 1971–1987. [Google Scholar] [CrossRef]

- Kerr, R.; McHugh, M.; McCrory, M. HSE Management Standards and Stress-Related Work Outcomes. Occup. Med. 2009, 59, 574–579. [Google Scholar] [CrossRef]

| Types of CNTs | Synthesis Method | Concentration | Species | Main Findings | Ref. |

|---|---|---|---|---|---|

| SWCNTs | CO disproportionation | 5 µg/mL | E. coli | Releasing intracellular content due to irrecoverable outer membrane damage | [26] |

| SWCNTs | CO disproportionation | 5 µg/mL | E. coli | Microbial cells lost their cellular integrity | [27] |

| MWCNTs | CVD method | 5 µg/mL | E. coli | Many of the bacterial cells remain intact and preserve their outer membrane | [20] |

| SWCNTs/MWCNTs | CVD method | 20, 50, 100 µg/mL | L. acidophilus, E. coli B. adolescentis, E. faecalis S. aureus | Antimicrobial mechanism associated with length-dependent wrapping and diameter-dependent piercing upon microbial cell membrane damage and the release of intracellular contents | [28] |

| MWCNTs | Nanocycle productions | 1.5–100 mg/L | E. coli | Low microbial toxicity | [103] |

| MWCNTs | - | - | E. coli, B. subtilis P. aeruginosa | 2-log cell density reduction in viability of pathogens | [104] |

| DWCNTs/MWCNTs | NE scientific productions | 20/100 µg/mL | S. aureus, P. aeruginosa K. pneumoniae, C. albicans | MWNTs’ antimicrobial activity is higher than DWNTs | [97] |