Plasmonic Colour Printing by Light Trapping in Two-Metal Nanostructures

Abstract

:1. Introduction

2. Materials and Methods

2.1. Simulations

2.2. Experimental

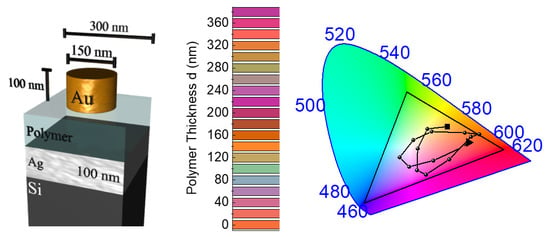

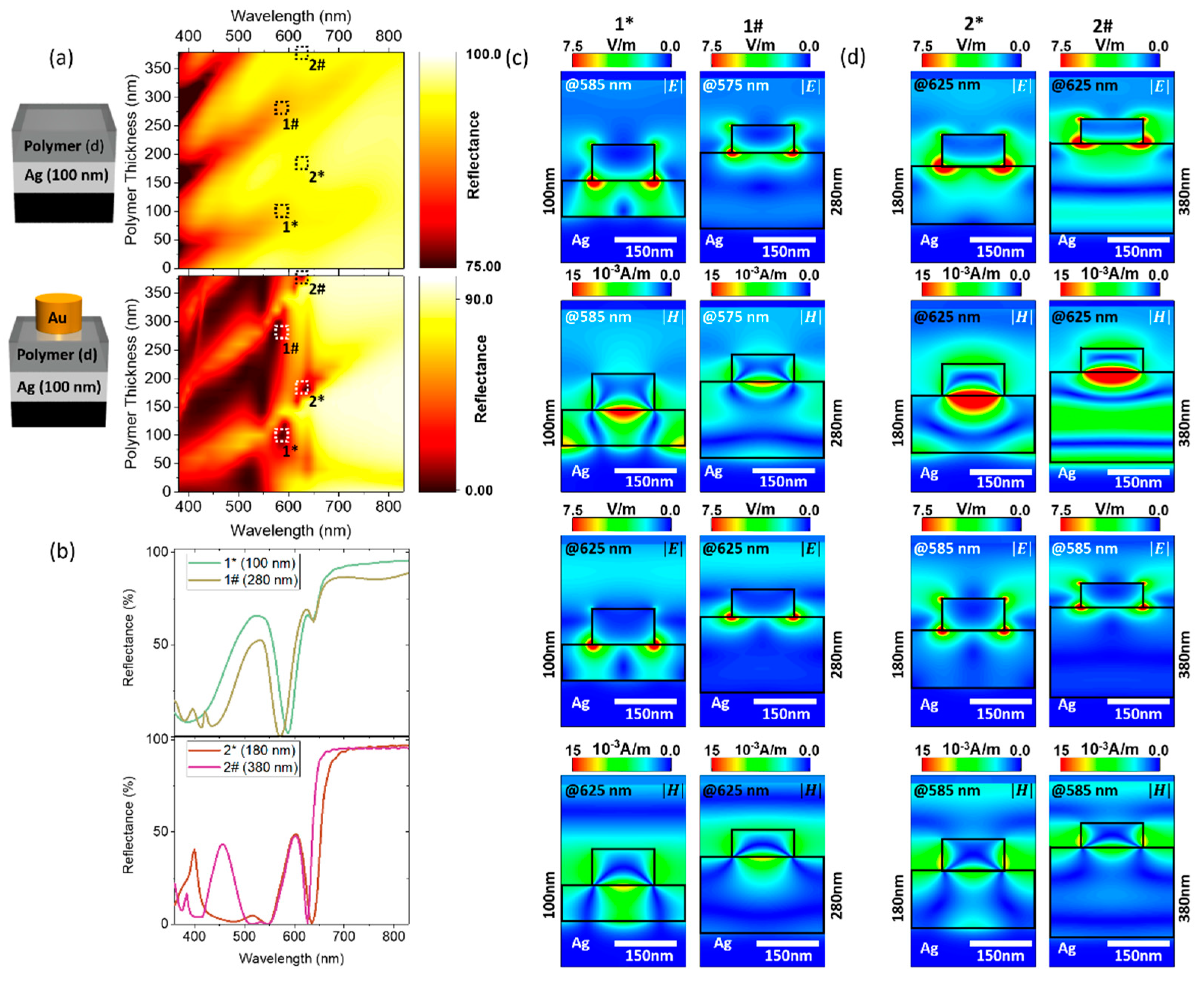

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kumar, K.; Duan, H.; Hegde, R.S.; Koh, S.C.W.; Wei, J.N.; Yang, J.K.W. Printing colour at the optical diffraction limit. Nat. Nanotechnol. 2012, 7, 557–561. [Google Scholar] [CrossRef] [PubMed]

- Gu, Y.; Zhang, L.; Yang, J.K.W.; Yeo, S.P.; Qiu, C.W. Color generation via subwavelength plasmonic nanostructures. Nanoscale 2015, 7, 6409–6419. [Google Scholar] [CrossRef] [PubMed]

- Kristensen, A.; Yang, J.K.W.; Bozhevolnyi, S.I.; Link, S.; Nordlander, P.; Halas, N.J.; Mortensen, N.A. Plasmonic colour generation. Nat. Rev. Mater. 2016, 2, 16088. [Google Scholar] [CrossRef] [Green Version]

- Lee, S.Y.; Forestiere, C.; Pasquale, A.J.; Trevino, J.; Walsh, G.; Galli, P.; Romagnoli, M.; Negro, L.D. Plasmon-enhanced structural coloration of metal films with isotropic Pinwheel nanoparticle arrays. Opt. Express 2011, 19, 23818–23830. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lee, T.; Jang, J.; Jeong, H.; Rho, J. Plasmonic- and dielectric-based structural coloring: From fundamentals to practical applications. Nano Converg. 2018, 5, 1. [Google Scholar] [CrossRef] [PubMed]

- Lee, H.-S.; Yoon, Y.-T.; Lee, S.-S.; Kim, S.-H.; Lee, K.-D. Color filter based on a subwavelength patterned metal grating. Opt. Express 2007, 15, 15457–15463. [Google Scholar] [CrossRef]

- Diest, K.; Dionne, J.A.; Spain, M. Tunable color filters based on metal–insulator–metal resonators. Nano Lett. 2009, 9, 2579–2583. [Google Scholar] [CrossRef]

- Yoon, Y.-T.; Lee, S.-S. Transmission type color filter incorporating a silver film based etalon. Opt. Express 2010, 18, 5344–5349. [Google Scholar] [CrossRef]

- Si, G.; Zhao, Y.; Lv, J.; Lu, M.; Wang, F.; Liu, H.; Xiang, N.; Huang, J.; Danner, A.; Teng, J.; et al. Reflective plasmonic color filters based on lithographically patterned silver nanorod arrays. Nanoscale 2013, 5, 6243–6248. [Google Scholar] [CrossRef] [Green Version]

- Smith, A.F.; Skrabalak, S.E. Metal nanomaterials for optical anti-counterfeit labels. J. Mater. Chem. C 2017, 5, 3207–3215. [Google Scholar] [CrossRef]

- Fan, J.R.; Wu, W.G. Metal-dielectric-metal plasmonic nanohelms as broad-color-gamut tunable pixels for vivid display. In Proceedings of the 29th International Conference on Micro Electro Mechanical Systems (MEMS), Shanghai, China, 24–28 January 2016. [Google Scholar]

- Yokogawa, S.; Burgos, S.P.; Atwater, H.A. Plasmonic Color Filters for CMOS Image Sensor Applications. Nano Lett. 2012, 12, 4349–4354. [Google Scholar] [CrossRef] [PubMed]

- Chen, Q.; Chitnis, D.; Walls, K.; Drysdale, T.D.; Collins, S.; Cumming, D.R.S. CMOS Photodetectors Integrated with Plasmonic Color Filters. IEEE Photonics Technol. Lett. 2012, 24, 197–199. [Google Scholar] [CrossRef]

- Kats, M.A.; Blanchard, R.; Genevet, P.; Capasso, F. Nanometre optical coatings based on strong interference effects in highly absorbing media. Nat. Mater. 2012, 12, 20–24. [Google Scholar] [CrossRef] [PubMed]

- Kreibig, U.; Vollmer, M. Optical Properties of Metal Clusters; Springer: Berlin, German, 1995; ISBN 978-3-64-2081-910. [Google Scholar]

- Maier, S.A. Plasmonics: Fundamentals and Applications; Springer: Berlin, Germany, 2007; ISBN 978-0-38-7378-251. [Google Scholar]

- Maniyara, R.A.; Rodrigo, D.; Yu, R.; Canet-Ferrer, J.; Ghosh, D.S.; Yongsunthon, R.; Baker, D.E.; Rezikyan, A.; García de Abajo, F.J.; Pruneri, V. Tunable plasmons in ultrathin metal films. Nat. Photonics 2019, 13, 328–333. [Google Scholar] [CrossRef] [Green Version]

- Yu, R.; Mazumder, P.; Borrelli, N.F.; Carrilero, A.; Ghosh, D.S.; Maniyara, R.A.; Baker, D.; García de Abajo, F.J.; Pruneri, V. Structural Coloring of Glass Using Dewetted Nanoparticles and Ultrathin Films of Metals. ACS Photonics 2016, 3, 1194–1201. [Google Scholar] [CrossRef]

- Kelly, K.L.; Coronado, E.; Zhao, L.L.; Schatz, G.C. The optical properties of metal nanoparticles: The influence of size, shape, and dielectric environment. J. Phys. Chem. B 2003, 107, 668–677. [Google Scholar] [CrossRef]

- Jain, P.K.; Lee, K.S.; El-Sayed, I.H.; El-Sayed, M.A. Calculated absorption and scattering properties of gold nanoparticles of different size, shape, and composition: Applications in biological imaging and biomedicine. J. Phys. Chem. B 2006, 110, 7238–7248. [Google Scholar] [CrossRef] [PubMed]

- Khlebtsov, B.N.; Khlebtsov, N.G. Multipole plasmons in metal nanorods: Scaling properties and dependence on particle size, shape, orientation, and dielectric environment. J. Phys. Chem. C 2007, 111, 11516–11527. [Google Scholar] [CrossRef]

- Zeng, B.; Gao, Y.; Bartoli, F.J. Ultrathin Nanostructured Metals for Highly Transmissive Plasmonic Subtractive Color Filters. Sci. Rep. 2013, 3, 2840. [Google Scholar] [CrossRef] [Green Version]

- Franklin, D.; Chen, Y.; Vazquez-Guardado, A.; Modak, S.; Boroumand, J.; Xu, D.; Wu, S.-T.; Chanda, D. Polarization-independent actively tunable colour generation on imprinted plasmonic surfaces. Nat. Commun. 2015, 6, 7337. [Google Scholar] [CrossRef] [Green Version]

- Ng, R.J.H.; Goh, X.M.; Yang, J.K.W. All-metal nanostructured substrates as subtractive color reflectors with near-perfect absorptance. Opt. Express 2015, 23, 32597–32605. [Google Scholar] [CrossRef] [PubMed]

- Goh, X.M.; Ng, R.J.H.; Wang, S.; Tan, S.J.; Yang, J.K.W. Comparative Study of Plasmonic Colors from All-Metal Structures of Posts and Pits. ACS Photonics 2016, 3, 1000–1009. [Google Scholar] [CrossRef]

- Cheng, F.; Gao, J.; Luk, T.S.; Yang, X. Structural color printing based on plasmonic metasurfaces of perfect light absorption. Sci. Rep. 2015, 5, 11045. [Google Scholar] [CrossRef] [PubMed]

- Miyata, M.; Hatada, H.; Takahara, J. Full-color subwavelength printing with gap-plasmonic optical antennas. Nano Lett. 2016, 16, 3166–3172. [Google Scholar] [CrossRef] [PubMed]

- Tan, S.J.; Zhang, L.; Zhu, D.; Goh, X.M.; Wang, Y.M.; Kumar, K.; Qiu, C.-W.; Yang, J.K.W. Plasmonic Color Palettes for Photorealistic Printing with Aluminum Nanostructures. Nano Lett. 2014, 14, 4023–4029. [Google Scholar] [CrossRef] [PubMed]

- Roberts, A.S.; Pors, A.; Albrektsen, O.; Bozhevolnyi, S.I. Subwavelength Plasmonic Color Printing Protected for Ambient Use. Nano Lett. 2014, 14, 783–787. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Wang, X.; Yan, C.; Zhao, H.; Zhang, J.; Santschi, C.; Martin, O.J.F. Full Color Generation Using Silver Tandem Nanodisks. ACS Nano 2017, 11, 4419–4427. [Google Scholar] [CrossRef] [PubMed]

- Ye, M.; Sun, L.; Hu, X.; Shi, B.; Zeng, B.; Wang, L.; Zhao, J.; Yang, S.; Tai, R.; Fecht, H.-J.; et al. Angle-insensitive plasmonic color filters with randomly distributed silver nanodisks. Opt. Lett. 2015, 40, 4979–4982. [Google Scholar] [CrossRef] [PubMed]

- Stewart, J.W.; Akselrod, G.M.; Smith, D.R.; Mikkelsen, M.H. Toward Multispectral Imaging with Colloidal Metasurface Pixels. Adv. Mater. 2018, 29, 1602971. [Google Scholar] [CrossRef]

- Ellenbogen, T.; Seo, K.; Crozier, K.B. Chromatic Plasmonic Polarizers for Active Visible Color Filtering and Polarimetry. Nano Lett. 2012, 12, 1026–1031. [Google Scholar] [CrossRef]

- Fang, B.; Yang, C.; Shen, W.; Zhang, X.; Zhang, Y.; Liu, X. Highly efficient omnidirectional structural color tuning method based on dielectric–metal–dielectric structure. Appl. Opt. 2017, 56, C175–C180. [Google Scholar] [CrossRef] [PubMed]

- Goh, X.M.; Zheng, Y.; Tan, S.J.; Zhang, L.; Kumar, K.; Qiu, C.-W.; Yang, J.K.W. Three-dimensional plasmonic stereoscopic prints in full colour. Nat. Commun. 2014, 5, 5361. [Google Scholar] [CrossRef] [PubMed]

- Olson, J.; Manjavacas, A.; Liu, L.; Chang, W.-S.; Foerster, B.; King, N.S.; Knight, M.W.; Nordlander, P.; Halas, N.J.; Link, S. Vivid, full-color aluminum plasmonic pixels. Proc. Natl. Acad. Sci. USA 2014, 111, 14348–14353. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wu, Y.-K.R.; Hollowell, A.E.; Zhang, C.; Guo, L.J. Angle-Insensitive Structural Colours based on Metallic Nanocavities and Coloured Pixels beyond the Diffraction Limit. Sci. Rep. 2013, 3, 1194. [Google Scholar] [CrossRef] [PubMed]

- Gwyn, C.W.; Stulen, R.; Sweeney, D.; Attwood, D. Extreme ultraviolet lithography. J. Vac. Sci. Technol. B Microelectron. Nanom. Struct. 1998, 16, 3142–3149. [Google Scholar] [CrossRef]

- Xia, D.; Ku, Z.; Lee, S.C.; Brueck, S.R.J. Nanostructures and Functional Materials Fabricated by Interferometric Lithography. Adv. Mater. 2011, 23, 147–179. [Google Scholar] [CrossRef]

- Zhang, J.; Ou, J.-Y.; Papasimakis, N.; Chen, Y.; MacDonald, K.F.; Zheludev, N.I. Continuous metal plasmonic frequency selective surfaces. Opt. Express 2011, 19, 23279–23285. [Google Scholar] [CrossRef]

- Ebbesen, T.W.; Lezec, H.J.; Ghaemi, H.F.; Thio, T.; Wolff, P.A. Extraordinary optical transmission through sub-wavelength hole arrays. Nature 1998, 391, 667–669. [Google Scholar] [CrossRef]

- Chen, Q.; Cumming, D.R.S. High transmission and low color cross-talk plasmonic color filters using triangular-lattice hole arrays in aluminum films. Opt. Express 2010, 18, 14056–14062. [Google Scholar] [CrossRef]

- Miroshnichenko, A.E.; Flach, S.; Kivshar, Y.S. Fano resonances in nanoscale structures. Rev. Mod. Phys. 2010, 82, 2257–2298. [Google Scholar] [CrossRef] [Green Version]

- Shen, Y.; Rinnerbauer, V.; Wang, I.; Stelmakh, V.; Joannopoulos, J.D.; Soljačić, M. Structural Colors from Fano Resonances. ACS Photonics 2015, 2, 27–32. [Google Scholar] [CrossRef]

- Chu, Y.; Crozier, K.B. Experimental study of the interaction between localized and propagating surface plasmons. Opt. Lett. 2009, 34, 244–246. [Google Scholar] [CrossRef] [PubMed]

- Liu, N.; Mesch, M.; Weiss, T.; Hentschel, M.; Giessen, H. Infrared perfect absorber and its application as plasmonic sensor. Nano Lett. 2010, 10, 2342–2348. [Google Scholar] [CrossRef] [PubMed]

- Zhou, F.; Liu, Y.; Cai, W. Huge local electric field enhancement in hybrid plasmonic arrays. Opt. Lett. 2014, 39, 1302–1305. [Google Scholar] [CrossRef] [PubMed]

- Lin, L.; Zheng, Y. Optimizing plasmonic nanoantennas via coordinated multiple coupling. Sci. Rep. 2015, 5, 14788. [Google Scholar] [CrossRef] [PubMed]

- Nicolas, R.; Lévêque, G.; Marae-Djouda, J.; Montay, G.; Madi, Y.; Plain, J.; Herro, Z.; Kazan, M.; Adam, P.-M.; Maurer, T. Plasmonic mode interferences and Fano resonances in metal-insulator-metal nanostructured interface. Sci. Rep. 2015, 5, 14419. [Google Scholar] [CrossRef]

- Xiong, K.; Tordera, D.; Emilsson, G.; Olsson, O.; Linderhed, U.; Jonsson, M.P.; Dahlin, A.B. Switchable Plasmonic Metasurfaces with High Chromaticity Containing Only Abundant Metals. Nano Lett. 2017, 17, 7033–7039. [Google Scholar] [CrossRef] [Green Version]

- Choi, D.; Shin, C.K.; Yoon, D.; Chung, D.S.; Jin, Y.W.; Lee, L.P. Plasmonic Optical Interference. Nano Lett. 2014, 14, 3374–3381. [Google Scholar] [CrossRef]

- Chen, Y.; Duan, X.; Matuschek, M.; Zhou, Y.; Neubrech, F.; Duan, H.; Liu, N. Dynamic Color Displays Using Stepwise Cavity Resonators. Nano Lett. 2017, 17, 5555–5560. [Google Scholar] [CrossRef] [Green Version]

- Xiong, K.; Emilsson, G.; Maziz, A.; Yang, X.; Shao, L.; Jager, E.W.H.H.; Dahlin, A.B. Plasmonic Metasurfaces with Conjugated Polymers for Flexible Electronic Paper in Color. Adv. Mater. 2016, 28, 9956–9960. [Google Scholar] [CrossRef]

- Cai, W.; Chettiar, U.K.; Yuan, H.-K.; de Silva, V.C.; Kildishev, A.V.; Drachev, V.P.; Shalaev, V.M. Metamagnetics with rainbow colors. Opt. Express 2007, 15, 3333–3341. [Google Scholar] [CrossRef] [PubMed]

- Fang, Z.; Zhen, Y.-R.; Fan, L.; Zhu, X.; Nordlander, P. Tunable wide-angle plasmonic perfect absorber at visible frequencies. Phys. Rev. B 2012, 85, 245401. [Google Scholar] [CrossRef]

- Kim, W.; Simpkins, B.S.; Long, J.P.; Zhang, B.; Hendrickson, J.; Guo, J. Localized and nonlocalized plasmon resonance enhanced light absorption in metal-insulator-metal nanostructures. JOSA B 2015, 32, 1686–1692. [Google Scholar] [CrossRef]

- Pinton, N.; Grant, J.; Collins, S.; Cumming, D.R.S. Exploitation of Magnetic Dipole Resonances in Metal-Insulator-Metal Plasmonic Nanostructures to Selectively Filter Visible Light. ACS Photonics 2018, 5, 1250–1261. [Google Scholar] [CrossRef]

- Zhang, B.; Zhao, Y.; Hao, Q.; Kiraly, B.; Khoo, I.-C.; Chen, S.; Huang, T.J. Polarization-independent dual-band infrared perfect absorber based on a metal-dielectric-metal elliptical nanodisk array. Opt. Express 2011, 19, 15221–15228. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, B.; Hendrickson, J.; Guo, J. Multispectral near-perfect metamaterial absorbers using spatially multiplexed plasmon resonance metal square structures. J. Opt. Soc. Am. B 2013, 30, 656–662. [Google Scholar] [CrossRef] [Green Version]

- Liu, B.; Tang, C.; Chen, J.; Yan, Z.; Zhu, M.; Sui, Y.; Tang, H. The coupling effects of surface plasmon polaritons and magnetic dipole resonances in metamaterials. Nanoscale Res. Lett. 2017, 12, 586. [Google Scholar] [CrossRef] [PubMed]

- Palik, E.D. Handbook of Optical Constants of Solids; Academic Press: New York, NY, USA, 2012. [Google Scholar]

- Babar, S.; Weaver, J.H. Optical constants of Cu, Ag, and Au revisited. Appl. Opt. 2015, 54, 477–481. [Google Scholar] [CrossRef]

- Zhou, W.; Suh, J.Y.; Hua, Y.; Odom, T.W. Hybridization of Localized and Guided Modes in 2D Metal–Insulator–Metal Nanocavity Arrays. J. Phys. Chem. C 2013, 117, 2541–2546. [Google Scholar] [CrossRef]

- International Commission on Illumination. Colorimetry: Understanding the CIE System; Schanda, J., Ed.; International Commission on Illumination: Vienna, Austria, 2007; ISBN 978-0-47-0175-620. [Google Scholar]

- Choudhury, R.; Kumar, A. Principles of Colour and Appearance Measurements; Woodhead Publishing: Cambridge, UK, 2014. [Google Scholar]

- Reinhard, E.; Khan, E.; Akyüz, A.; Johnson, G. Color Imaging: Fundamentals and Applications; Peters, A.K., Ed.; CRC PRESS: Boca Raton, FL, USA, 2008; ISBN 978-1-56-8813-448. [Google Scholar]

- Oleari, C. (Ed.) Standard Colorimetry; John Wiley & Sons, Ltd.: Chichester, UK, 2015; ISBN 978-1-11-8894-477. [Google Scholar]

- Kaplan, A.F.; Xu, T.; Jay Guo, L. High efficiency resonance-based spectrum filters with tunable transmission bandwidth fabricated using nanoimprint lithography. Appl. Phys. Lett. 2011, 99, 143111. [Google Scholar] [CrossRef] [Green Version]

- Fleischman, D.; Sweatlock, L.A.; Murakami, H.; Atwater, H. Hyper-selective plasmonic color filters. Opt. Express 2017, 25, 27386–27395. [Google Scholar] [CrossRef] [PubMed]

- Langhammer, C.; Schwind, M.; Kasemo, B.; Zorić, I. Localized surface plasmon resonances in aluminum nanodisks. Nano Lett. 2008, 8, 1461–1471. [Google Scholar] [CrossRef] [PubMed]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wilson, K.; Marocico, C.A.; Pedrueza-Villalmanzo, E.; Smith, C.; Hrelescu, C.; Bradley, A.L. Plasmonic Colour Printing by Light Trapping in Two-Metal Nanostructures. Nanomaterials 2019, 9, 963. https://doi.org/10.3390/nano9070963

Wilson K, Marocico CA, Pedrueza-Villalmanzo E, Smith C, Hrelescu C, Bradley AL. Plasmonic Colour Printing by Light Trapping in Two-Metal Nanostructures. Nanomaterials. 2019; 9(7):963. https://doi.org/10.3390/nano9070963

Chicago/Turabian StyleWilson, Keith, Cristian A. Marocico, Esteban Pedrueza-Villalmanzo, Christopher Smith, Calin Hrelescu, and A. Louise Bradley. 2019. "Plasmonic Colour Printing by Light Trapping in Two-Metal Nanostructures" Nanomaterials 9, no. 7: 963. https://doi.org/10.3390/nano9070963