Highly Specific Peptide-Mediated Cuvette-Form Localized Surface Plasmon Resonance (LSPR)-Based Fipronil Detection in Egg

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Screening of Fipronil-Binding Peptide through Phage Display Technique

2.3. Fabrication of LSPR Sensor Chip

2.4. Performance of LSPR Sensor Chips on Standard Fipronil Solutions

2.5. Performance of LSPR Sensor Chips on Spiked Egg Samples

3. Results and Discussion

3.1. Screening of Fipronil-Specific Binding Peptide through Phage Display Technique

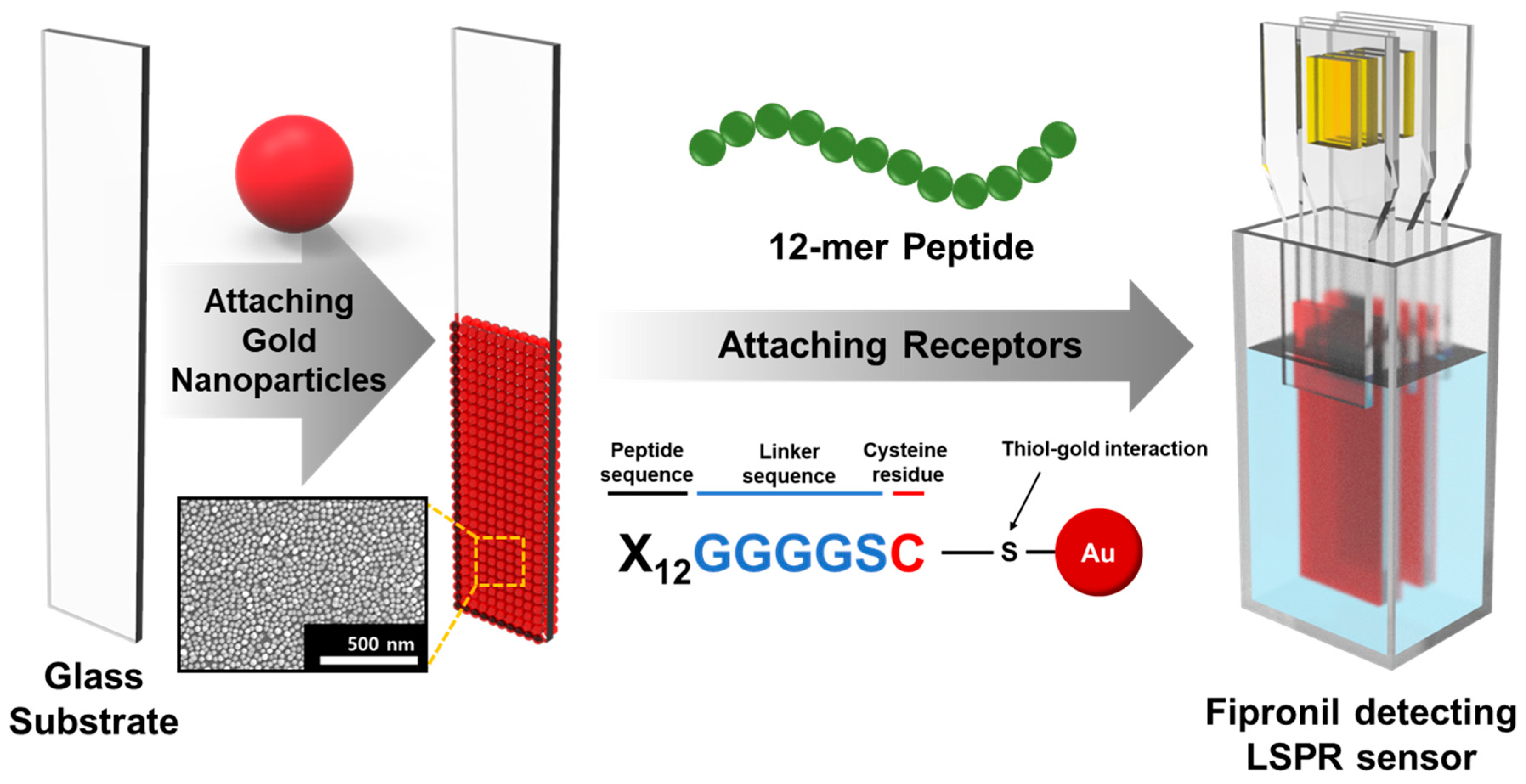

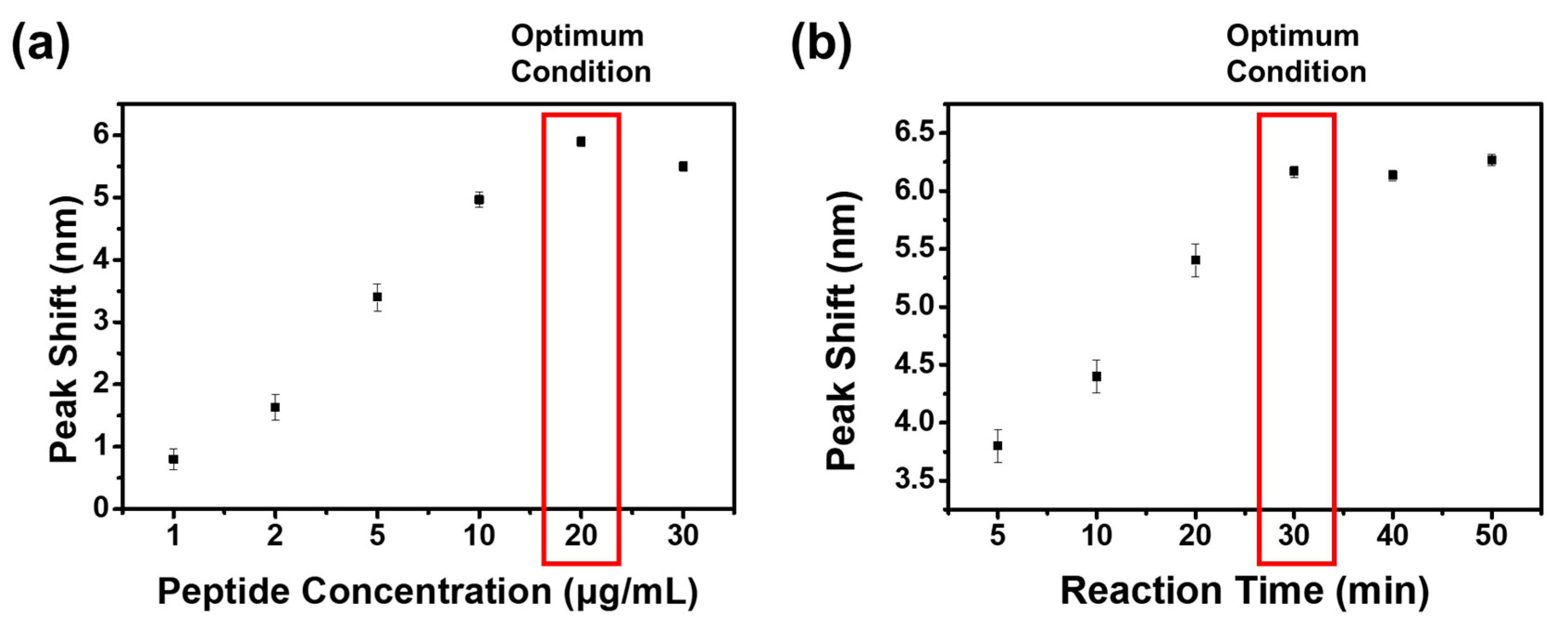

3.2. Fabrication of Fipronil-Specific Localized Surface Plasmon Resonance Sensor

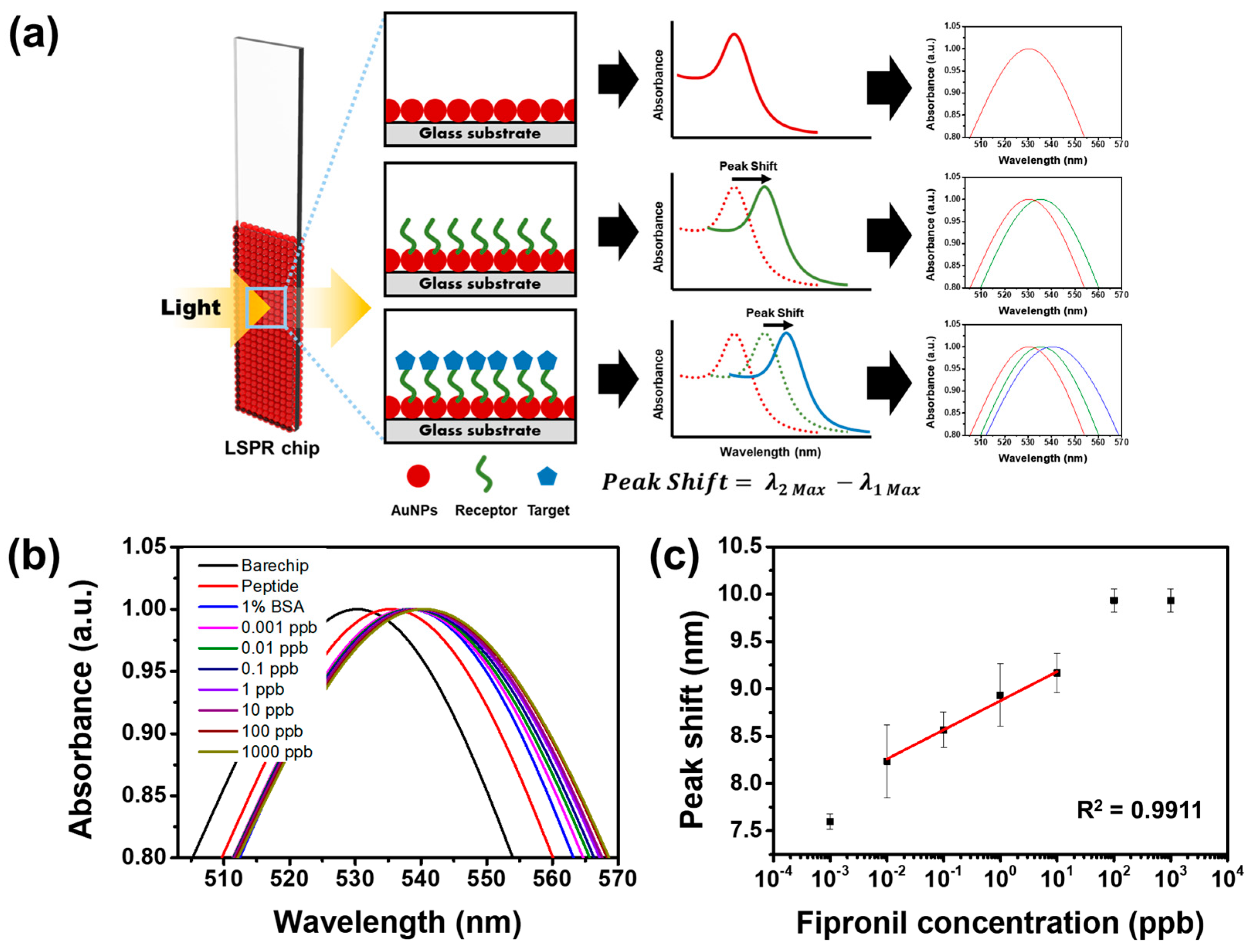

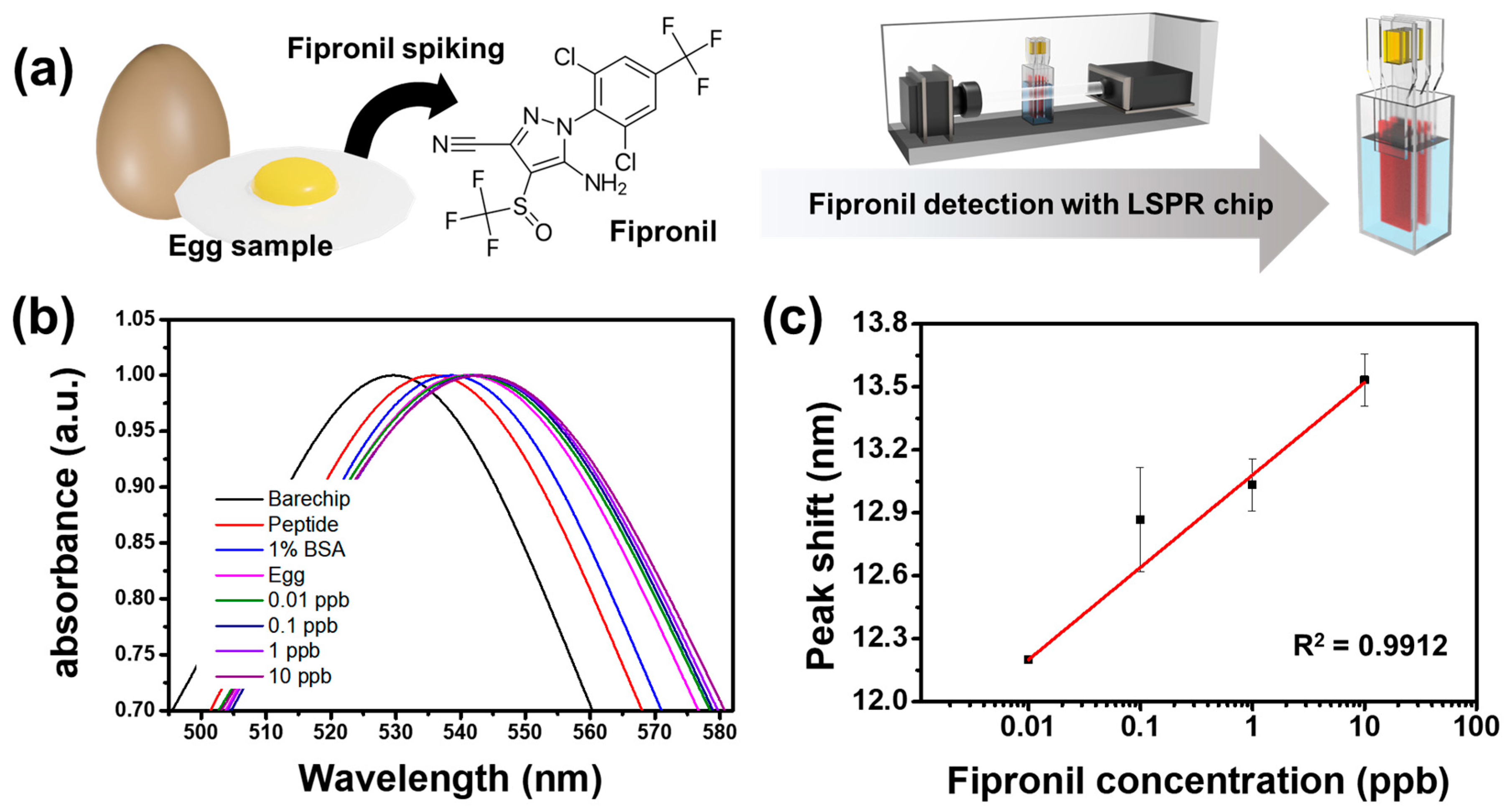

3.3. Detection of Fipronil Based on Standard Solutions and Spike Samples

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Simon-Delso, N.; Amaral-Rogers, V.; Belzunces, L.P.; Bonmatin, J.M.; Chagnon, M.; Downs, C.; Furlan, L.; Gibbons, D.W.; Giorio, C.; Girolami, V.; et al. Systemic insecticides (neonicotinoids and fipronil): Trends, uses, mode of action and metabolites. Environ. Sci. Pollut. Res. Int. 2015, 22, 5–34. [Google Scholar] [CrossRef] [PubMed]

- Fung, H.T.; Chan, K.K.; Ching, W.M.; Kam, C.W. A Case of Accidental Ingestion of Ant Bait Containing Fipronil. J. Toxicol. Clin. Toxicol. 2003, 41, 245–248. [Google Scholar] [CrossRef]

- Lee, S.-J.; Mulay, P.; Diebolt-Brown, B.; Lackovic, M.J.; Mehler, L.N.; Beckman, J.; Waltz, J.; Prado, J.B.; Mitchell, Y.A.; Higgins, S.A.; et al. Acute illnesses associated with exposure to fipronil—Surveillance data from 11 states in the United States, 2001–2007. Clin. Toxicol. 2010, 48, 737–744. [Google Scholar] [CrossRef] [PubMed]

- Ghaffar, A.; Hussain, R.; Abbas, G.; Khan, R.; Akram, K.; Latif, H.; Ali, S.; Baig, S.; Du, X.; Khan, A. Assessment of genotoxic and pathologic potentials of fipronil insecticide in Labeo rohita (Hamilton, 1822). Toxin Rev. 2021, 40, 1289–1300. [Google Scholar] [CrossRef]

- European Food Safety Authority. Open call for new scientific information as regards the risk to bees from the uses of the active substance fipronil in the EU. EFSA Support. Publ. 2016, 13, 1012E. [Google Scholar]

- Cochran, R.C.; Yu, L.; Krieger, R.I.; Ross, J.H. Postapplication Fipronil Exposure Following Use on Pets. J. Toxicol. Environ. Health Part A 2015, 78, 1217–1226. [Google Scholar] [CrossRef]

- EPA, US. Fipronil: Third Reevaluation—Report of the Hazard Identification Assessment Review Committee; HED Doc. No. 014400; U.S. Environmental Protection Agency, Health Effects Division, U.S. Government Printing Office: Washington, DC, USA, 2000; pp. 1–24.

- Kim, Y.A.; Yoon, Y.S.; Kim, H.S.; Jeon, S.J.; Cole, E.; Lee, J.; Kho, Y.; Cho, Y.H. Distribution of fipronil in humans, and adverse health outcomes of in utero fipronil sulfone exposure in newborns. Int. J. Hyg. Environ. Health 2019, 222, 524–532. [Google Scholar] [CrossRef]

- Wang, K.; Vasylieva, N.; Wan, D.; Eads, D.A.; Yang, J.; Tretten, T.; Barnych, B.; Li, J.; Li, Q.X.; Gee, S.J.; et al. Quantitative Detection of Fipronil and Fipronil-Sulfone in Sera of Black-Tailed Prairie Dogs and Rats after Oral Exposure to Fipronil by Camel Single-Domain Antibody-Based Immunoassays. Anal. Chem. 2019, 91, 1532–1540. [Google Scholar] [CrossRef] [PubMed]

- Biswas, S.; Mondal, R.; Mukherjee, A.; Sarkar, M.; Kole, R.K. Simultaneous determination and risk assessment of fipronil and its metabolites in sugarcane, using GC-ECD and confirmation by GC-MS/MS. Food Chem. 2019, 272, 559–567. [Google Scholar] [CrossRef] [PubMed]

- Zhang, M.; Bian, K.; Zhou, T.; Song, X.; Liu, Q.; Meng, C.; He, L. Determination of residual fipronil in chicken egg and muscle by LC–MS/MS. J. Chromatogr. B 2016, 1014, 31–36. [Google Scholar] [CrossRef]

- Hutter, E.; Fendler, J.H. Exploitation of Localized Surface Plasmon Resonance. Adv. Mater. 2004, 16, 1685–1706. [Google Scholar] [CrossRef]

- Mayer, K.M.; Hafner, J.H. Localized Surface Plasmon Resonance Sensors. Chem. Rev. 2011, 111, 3828–3857. [Google Scholar] [CrossRef] [PubMed]

- Barbir, R.; Pem, B.; Kalčec, N.; Kastner, S.; Podlesnaia, K.; Csáki, A.; Fritzsche, W.; Vinković Vrček, I. Application of Localized Surface Plasmon Resonance Spectroscopy to Investigate a Nano–Bio Interface. Langmuir 2021, 37, 1991–2000. [Google Scholar] [CrossRef]

- Murray, W.A.; Auguié, B.; Barnes, W.L. Sensitivity of Localized Surface Plasmon Resonances to Bulk and Local Changes in the Optical Environment. J. Phys. Chem. C 2009, 113, 5120–5125. [Google Scholar] [CrossRef] [Green Version]

- Zhou, J.; Qi, Q.; Wang, C.; Qian, Y.; Liu, G.; Wang, Y.; Fu, L. Surface plasmon resonance (SPR) biosensors for food allergen detection in food matrices. Biosens. Bioelectron. 2019, 142, 111449. [Google Scholar] [CrossRef] [PubMed]

- Masson, J.-F. Surface Plasmon Resonance Clinical Biosensors for Medical Diagnostics. ACS Sens. 2017, 2, 16–30. [Google Scholar] [CrossRef] [PubMed]

- Haes, A.J.; Van Duyne, R.P. A Nanoscale Optical Biosensor: Sensitivity and Selectivity of an Approach Based on the Localized Surface Plasmon Resonance Spectroscopy of Triangular Silver Nanoparticles. J. Am. Chem. Soc. 2002, 124, 10596–10604. [Google Scholar] [CrossRef]

- Smith, G.P.; Petrenko, V.A. Phage Display. Chem. Rev. 1997, 97, 391–410. [Google Scholar] [CrossRef] [PubMed]

- Winter, G.; Griffiths, A.D.; Hawkins, R.E.; Hoogenboom, H.R. Making Antibodies by Phage Display Technology. Annu. Rev. Immunol. 1994, 12, 433–455. [Google Scholar] [CrossRef] [PubMed]

- Bang, H.B.; Choi, I.H.; Jang, J.H.; Jeong, K.J. Engineering of Escherichia coli for the Economic Production L-phenylalanine in Large-scale Bioreactor. Biotechnol. Bioprocess Eng. 2021, 26, 468–475. [Google Scholar] [CrossRef]

- Kuk, M.U.; Lee, Y.H.; Kim, J.W.; Hwang, S.Y.; Park, J.Y.; Song, E.S.; Kwon, H.W.; Oh, S.; Park, J.T. Rapid and Efficient BAC Recombineering: Gain & Loss Screening System. Biotechnol. Bioprocess Eng. 2021, 26, 1023–1033. [Google Scholar]

- Pande, J.; Szewczyk, M.M.; Grover, A.K. Phage display: Concept, innovations, applications and future. Biotechnol. Adv. 2010, 28, 849–858. [Google Scholar] [CrossRef] [PubMed]

- Arap, W.; Kolonin, M.G.; Trepel, M.; Lahdenranta, J.; Cardó-Vila, M.; Giordano, R.J.; Mintz, P.J.; Ardelt, P.U.; Yao, V.J.; Vidal, C.I.; et al. Steps toward mapping the human vasculature by phage display. Nat. Med. 2002, 8, 121–127. [Google Scholar] [CrossRef] [PubMed]

- Cho, C.H.; Son, S.-Y.; Bang, J.K.; Jeon, Y.H.; Park, J.P. Biophysical and electrochemical approaches for studying molecular recognition of IL-33 binding peptides identified via phage display. Anal. Chim. Acta 2022, 1197, 339522. [Google Scholar] [CrossRef]

- Rader, C.; Cheresh, D.A.; Barbas, C.F. A phage display approach for rapid antibody humanization: Designed combinatorial V gene libraries. Proc. Natl. Acad. Sci. USA 1998, 95, 8910–8915. [Google Scholar] [CrossRef] [Green Version]

- Xu, T.; Geng, Z. Strategies to improve performances of LSPR biosensing: Structure, materials, and interface modification. Biosens. Bioelectron. 2021, 174, 112850. [Google Scholar] [CrossRef]

- Wang, Y.; Zhou, J.; Li, J. Construction of Plasmonic Nano-Biosensor-Based Devices for Point-of-Care Testing. Small Methods 2017, 1, 1700197. [Google Scholar] [CrossRef]

- Willets, K.A.; Van Duyne, R.P. Localized surface plasmon resonance spectroscopy and sensing. Annu. Rev. Phys. Chem. 2007, 58, 267–297. [Google Scholar] [CrossRef] [Green Version]

- Dong, J.; Carpinone, P.L.; Pyrgiotakis, G.; Demokritou, P.; Moudgil, B.M. Synthesis of precision gold nanoparticles using Turkevich method. KONA Powder Part. J. 2020, 37, 224–232. [Google Scholar] [CrossRef] [Green Version]

- Kim, R.; Nam, Y. Fabrication of a Nanoplasmonic Chip to Enhance Neuron Membrane Potential Imaging by Metal-Enhanced Fluorescence Effect. Biochip J. 2021, 15, 171–178. [Google Scholar] [CrossRef]

- Chen, J.-S.; Chen, P.-F.; Lin, H.T.-H.; Huang, N.-T. A Localized surface plasmon resonance (LSPR) sensor integrated automated microfluidic system for multiplex inflammatory biomarker detection. Analyst 2020, 145, 7654–7661. [Google Scholar] [CrossRef] [PubMed]

- Borse, S.D.; Joshi, S.S. Optical and structural properties of PVA capped gold nanoparticles and their antibacterial efficacy. Adv. Chem. Lett. 2013, 1, 15–23. [Google Scholar] [CrossRef]

- Haiss, W.; Thanh, N.T.; Aveyard, J.; Fernig, D.G. Determination of size and concentration of gold nanoparticles from UV−Vis spectra. Anal. Chem. 2007, 79, 4215–4221. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yoo, J.; Han, S.; Park, B.; Sonwal, S.; Alhammadi, M.; Kim, E.; Aliya, S.; Lee, E.-S.; Jeon, T.-J.; Oh, M.-H.; et al. Highly Specific Peptide-Mediated Cuvette-Form Localized Surface Plasmon Resonance (LSPR)-Based Fipronil Detection in Egg. Biosensors 2022, 12, 914. https://doi.org/10.3390/bios12110914

Yoo J, Han S, Park B, Sonwal S, Alhammadi M, Kim E, Aliya S, Lee E-S, Jeon T-J, Oh M-H, et al. Highly Specific Peptide-Mediated Cuvette-Form Localized Surface Plasmon Resonance (LSPR)-Based Fipronil Detection in Egg. Biosensors. 2022; 12(11):914. https://doi.org/10.3390/bios12110914

Chicago/Turabian StyleYoo, Jingon, Soobin Han, Bumjun Park, Sonam Sonwal, Munirah Alhammadi, Eunsu Kim, Sheik Aliya, Eun-Seon Lee, Tae-Joon Jeon, Mi-Hwa Oh, and et al. 2022. "Highly Specific Peptide-Mediated Cuvette-Form Localized Surface Plasmon Resonance (LSPR)-Based Fipronil Detection in Egg" Biosensors 12, no. 11: 914. https://doi.org/10.3390/bios12110914

APA StyleYoo, J., Han, S., Park, B., Sonwal, S., Alhammadi, M., Kim, E., Aliya, S., Lee, E. -S., Jeon, T. -J., Oh, M. -H., & Huh, Y. S. (2022). Highly Specific Peptide-Mediated Cuvette-Form Localized Surface Plasmon Resonance (LSPR)-Based Fipronil Detection in Egg. Biosensors, 12(11), 914. https://doi.org/10.3390/bios12110914