Wafer-Scale LSPR Substrate: Oblique Deposition of Gold on a Patterned Sapphire Substrate

Abstract

:1. Introduction

2. Materials and Methods

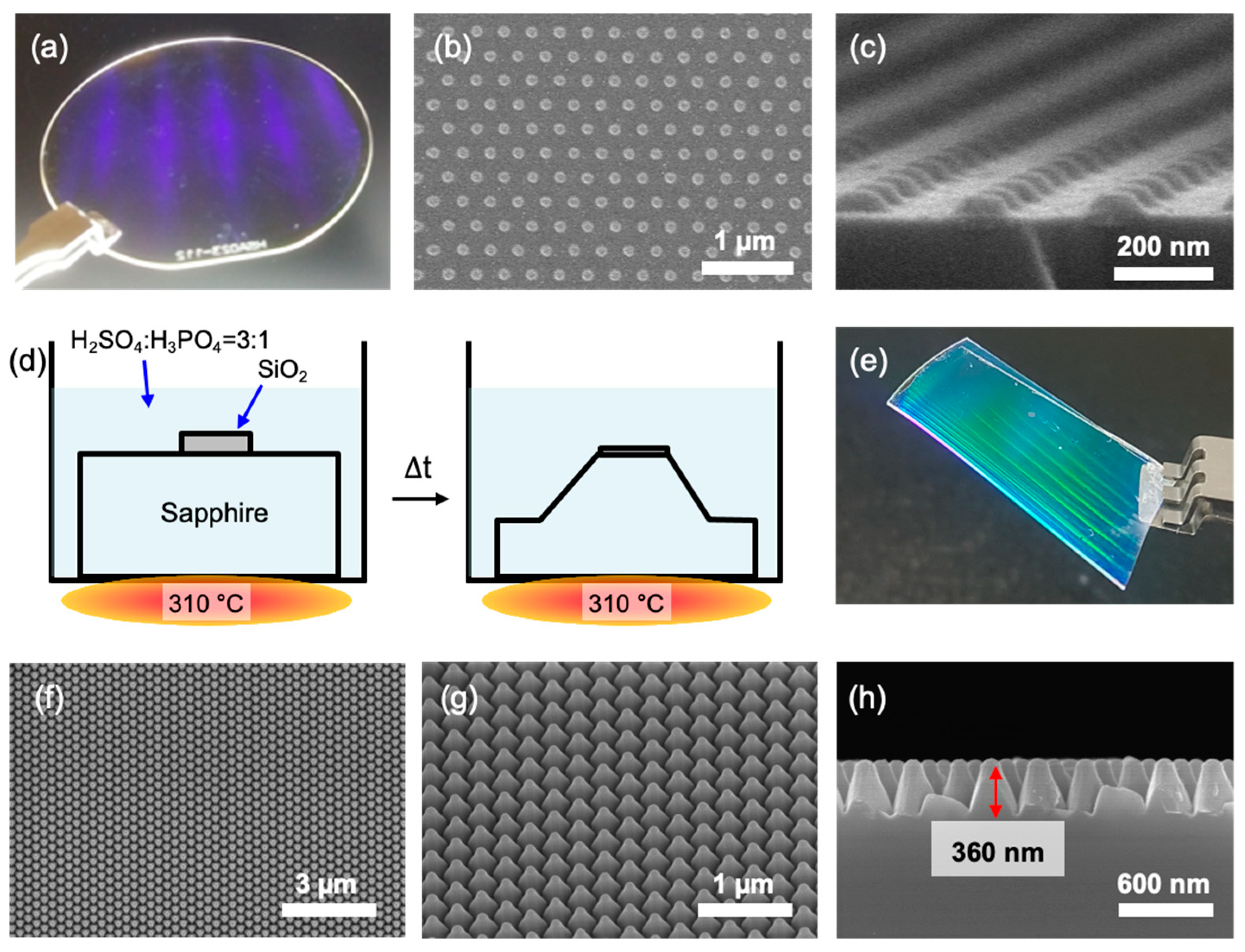

2.1. Formation of a SiO2-Nanodot on the Sapphire Wafer

2.2. Fabrication of PSS via Wet-Etch

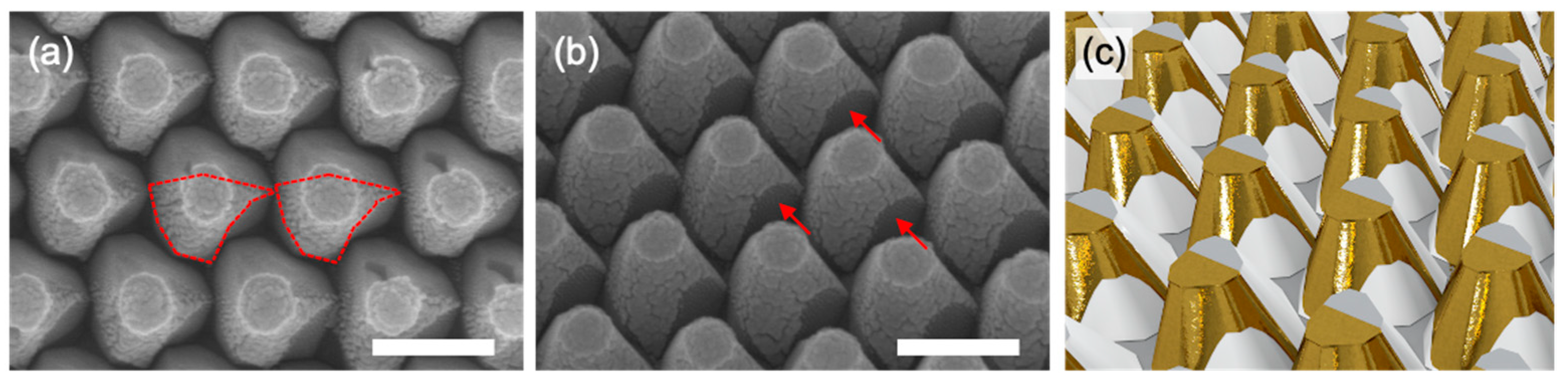

2.3. Formation of Metal Nanostructures on the PSS

2.4. LSPR Shift of the Au Nanostructure-Formed PSS Due to Biomolecule Attachment

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kaur, B.; Kumar, S.; Kaushik, B.K. Recent Advancements in Optical Biosensors for Cancer Detection. Biosens. Bioelectron. 2022, 197, 113805. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Dai, C.; Yao, X.; Qiao, T.; Chen, M.; Li, S.; Shi, Z.; Wang, M.; Huang, Z.; Hu, X.; et al. Asymmetric Angular Dependence for Multicolor Display Based on Plasmonic Inclined-Nanopillar Array. Nanoscale 2021, 13, 7273–7278. [Google Scholar] [CrossRef] [PubMed]

- Jaculbia, R.B.; Imada, H.; Miwa, K.; Iwasa, T.; Takenaka, M.; Yang, B.; Kazuma, E.; Hayazawa, N.; Taketsugu, T.; Kim, Y. Single-Molecule Resonance Raman Effect in a Plasmonic Nanocavity. Nat. Nanotechnol. 2020, 15, 105–110. [Google Scholar] [CrossRef] [PubMed]

- Bai, J.; Yao, Y. Highly Efficient Anisotropic Chiral Plasmonic Metamaterials for Polarization Conversion and Detection. ACS Nano 2021, 15, 14263–14274. [Google Scholar] [CrossRef] [PubMed]

- Rissi, N.C.; Comparetti, E.J.; Estevão, B.M.; Mastelaro, V.R.; Zucolotto, V. Doped Plasmonic Zinc Oxide Nanoparticles with Near-Infrared Absorption for Antitumor Activity. ACS Appl. Nano Mater. 2021, 4, 9779–9789. [Google Scholar] [CrossRef]

- Fruncillo, S.; Su, X.; Liu, H.; Wong, L.S. Lithographic Processes for the Scalable Fabrication of Micro-and Nanostructures for Biochips and Biosensors. ACS Sens. 2021, 6, 2002–2024. [Google Scholar] [CrossRef]

- Lu, X.; Yao, C.; Sun, L.; Li, Z. Plasmon-Enhanced Biosensors for MicroRNA Analysis and Cancer Diagnosis. Biosens. Bioelectron. 2022, 203, 114041. [Google Scholar] [CrossRef]

- Chang, Y.-L.; Lai, I.-C.; Lu, L.-C.; Chang, S.-W.; Sun, A.Y.; Wan, D.; Chen, H.-L. Wafer-Scale Nanocracks Enable Single-Molecule Detection and on-Site Analysis. Biosens. Bioelectron. 2022, 200, 113920. [Google Scholar] [CrossRef]

- Chi, J.; Xia, C.; Guo, Z.; Huang, G.; Lin, X. Gold Nanoparticle-Decorated Porous Silica for Surface-Enhanced Raman Scattering-Based Detection of Trace Molecules in Liquid Phase. ACS Appl. Nano Mater. 2022, 5, 527–536. [Google Scholar] [CrossRef]

- Wang, Z.; Chen, J.; Khan, S.A.; Li, F.; Shen, J.; Duan, Q.; Liu, X.; Zhu, J. Plasmonic Metasurfaces for Medical Diagnosis Applications: A Review. Sensors 2021, 22, 133. [Google Scholar] [CrossRef]

- Lee, S.-W.; Lee, K.-S.; Ahn, J.; Lee, J.-J.; Kim, M.-G.; Shin, Y.-B. Highly Sensitive Biosensing Using Arrays of Plasmonic Au Nanodisks Realized by Nanoimprint Lithography. ACS Nano 2011, 5, 897–904. [Google Scholar] [CrossRef]

- Aćimović, S.S.; Šípová, H.; Emilsson, G.; Dahlin, A.B.; Antosiewicz, T.J.; Käll, M. Superior LSPR Substrates Based on Electromagnetic Decoupling for On-a-Chip High-Throughput Label-Free Biosensing. Light Sci. Appl. 2017, 6, e17042. [Google Scholar] [CrossRef] [PubMed]

- Grzelczak, M.; Pérez-Juste, J.; Mulvaney, P.; Liz-Marzán, L.M. Shape Control in Gold Nanoparticle Synthesis. Chem. Soc. Rev. 2008, 37, 1783. [Google Scholar] [CrossRef] [PubMed]

- Personick, M.L.; Mirkin, C.A. Making Sense of the Mayhem behind Shape Control in the Synthesis of Gold Nanoparticles. J. Am. Chem. Soc. 2013, 135, 18238–18247. [Google Scholar] [CrossRef] [PubMed]

- Zhu, M.; Lerum, M.Z.; Chen, W. How to Prepare Reproducible, Homogeneous, and Hydrolytically Stable Aminosilane-Derived Layers on Silica. Langmuir 2012, 28, 416–423. [Google Scholar] [CrossRef] [Green Version]

- Jones, J.A.; Qin, L.A.; Meyerson, H.; Kwon, I.K.; Matsuda, T.; Anderson, J.M. Instability of Self-Assembled Monolayers as a Model Material System for Macrophage/FBGC Cellular Behavior. J. Biomed. Mater. Res. 2008, 86A, 261–268. [Google Scholar] [CrossRef] [Green Version]

- Pujari, S.P.; Scheres, L.; Marcelis, A.T.M.; Zuilhof, H. Covalent Surface Modification of Oxide Surfaces. Angew. Chem. Int. Ed. 2014, 53, 6322–6356. [Google Scholar] [CrossRef]

- Karakouz, T.; Maoz, B.M.; Lando, G.; Vaskevich, A.; Rubinstein, I. Stabilization of Gold Nanoparticle Films on Glass by Thermal Embedding. ACS Appl. Mater. Interfaces 2011, 3, 978–987. [Google Scholar] [CrossRef]

- Kyaw, H.H.; Al-Harthi, S.H.; Sellai, A.; Dutta, J. Self-Organization of Gold Nanoparticles on Silanated Surfaces. Beilstein J. Nanotechnol. 2015, 6, 2345–2353. [Google Scholar] [CrossRef]

- Jensen, T.R.; Malinsky, M.D.; Haynes, C.L.; Van Duyne, R.P. Nanosphere Lithography: Tunable Localized Surface Plasmon Resonance Spectra of Silver Nanoparticles. J. Phys. Chem. B 2000, 104, 10549–10556. [Google Scholar] [CrossRef]

- Near, R.; Tabor, C.; Duan, J.; Pachter, R.; El-Sayed, M. Pronounced Effects of Anisotropy on Plasmonic Properties of Nanorings Fabricated by Electron Beam Lithography. Nano Lett. 2012, 12, 2158–2164. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, X.; Ye, S.; Zhang, J.; Wang, T.; Fang, L.; Zhang, J.; Yang, B. The Fabrication of Long-Range Ordered Nanocrescent Structures Based on Colloidal Lithography and Parallel Imprinting. Nanotechnology 2013, 24, 105307. [Google Scholar] [CrossRef] [PubMed]

- Jo, N.R.; Shin, Y.-B. Enhancing Biosensing Sensitivity of Metal Nanostructures through Site-Selective Binding. Sci. Rep. 2020, 10, 1024. [Google Scholar] [CrossRef] [PubMed]

- Kwon, B.; Kim, J.H. Importance of Molds for Nanoimprint Lithography: Hard, Soft, and Hybrid Molds. J. Nanosci. 2016, 2016, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Aota, N.; Aida, H.; Kimura, Y.; Kawamata, Y.; Uneda, M. Fabrication Mechanism for Patterned Sapphire Substrates by Wet Etching. ECS J. Solid State Sci. Technol. 2014, 3, N69–N74. [Google Scholar] [CrossRef]

- Shen, J.; Zhang, D.; Wang, Y.; Gan, Y. AFM and SEM Study on Crystallographic and Topographical Evolutions of Wet-Etched Patterned Sapphire Substrate (PSS): Part II. Cone-Shaped PSS Etched in H2SO4 and H3PO4 Mixture with Varying Volume Ratio at 230 °C. ECS J. Solid State Sci. Technol. 2017, 6, R122–R130. [Google Scholar] [CrossRef] [Green Version]

- Xu, T.; Geng, Z. Strategies to Improve Performances of LSPR Biosensing: Structure, Materials, and Interface Modification. Biosens. Bioelectron. 2021, 174, 112850. [Google Scholar] [CrossRef]

- Pellas, V.; Hu, D.; Mazouzi, Y.; Mimoun, Y.; Blanchard, J.; Guibert, C.; Salmain, M.; Boujday, S. Gold Nanorods for LSPR Biosensing: Synthesis, Coating by Silica, and Bioanalytical Applications. Biosensors 2020, 10, 146. [Google Scholar] [CrossRef]

- Xue, Y.; Li, X.; Li, H.; Zhang, W. Quantifying Thiol–Gold Interactions towards the Efficient Strength Control. Nat. Commun. 2014, 5, 4348. [Google Scholar] [CrossRef] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, K.; Lee, K.J.; Jo, N.R.; Jo, E.-J.; Shin, Y.-B.; Kim, M.-G. Wafer-Scale LSPR Substrate: Oblique Deposition of Gold on a Patterned Sapphire Substrate. Biosensors 2022, 12, 158. https://doi.org/10.3390/bios12030158

Kim K, Lee KJ, Jo NR, Jo E-J, Shin Y-B, Kim M-G. Wafer-Scale LSPR Substrate: Oblique Deposition of Gold on a Patterned Sapphire Substrate. Biosensors. 2022; 12(3):158. https://doi.org/10.3390/bios12030158

Chicago/Turabian StyleKim, Kihyeun, Ki Joong Lee, Na Rae Jo, Eun-Jung Jo, Yong-Beom Shin, and Min-Gon Kim. 2022. "Wafer-Scale LSPR Substrate: Oblique Deposition of Gold on a Patterned Sapphire Substrate" Biosensors 12, no. 3: 158. https://doi.org/10.3390/bios12030158