Research on a Magnetic Separation-Based Rapid Nucleic Acid Extraction System and Its Detection Applications

Abstract

:1. Introduction

2. Materials and Methods

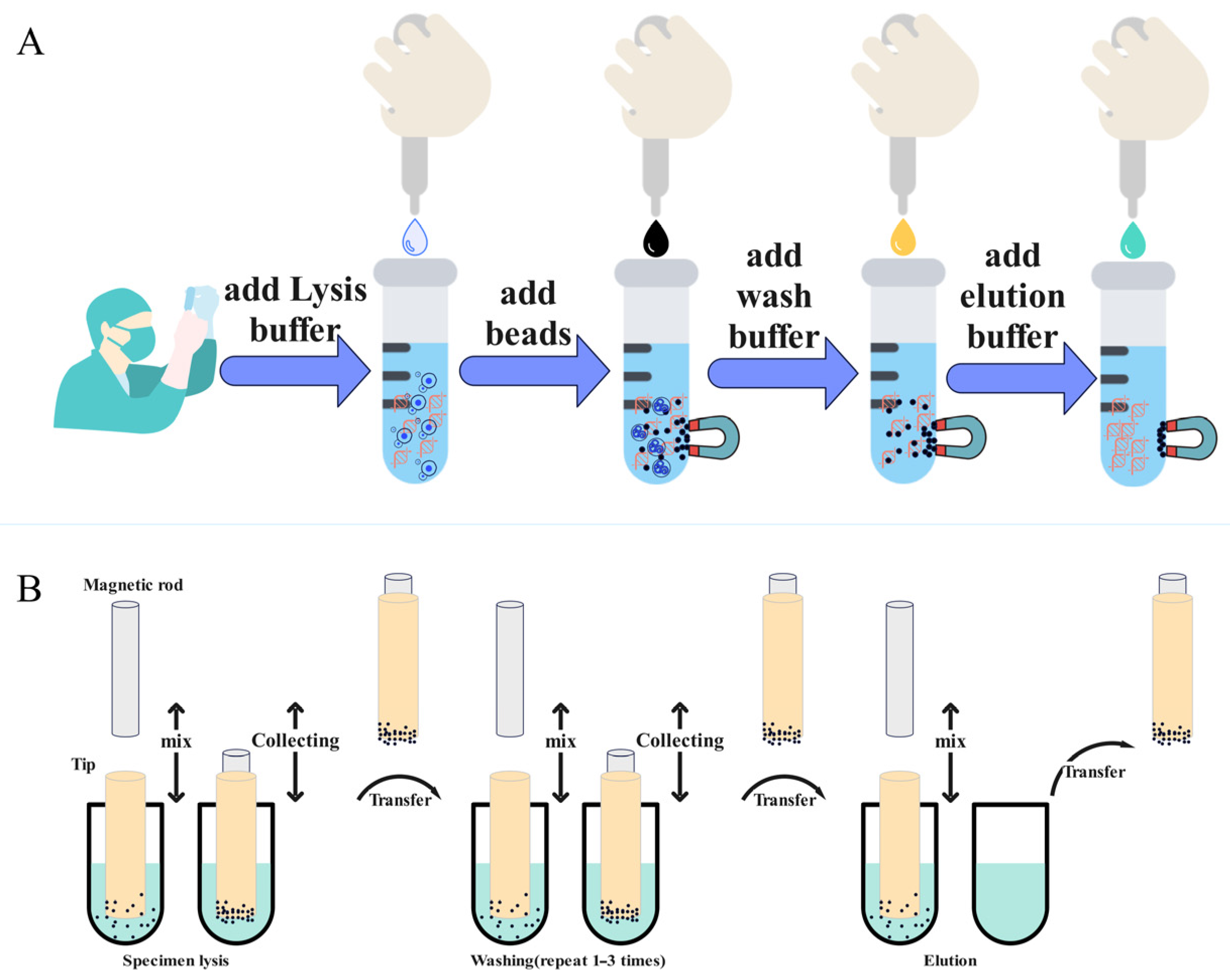

2.1. Structural Design

2.2. Hardware Design

2.3. Software Design

2.4. DNA Extraction and RT-PCR Detection

3. Results and Discussions

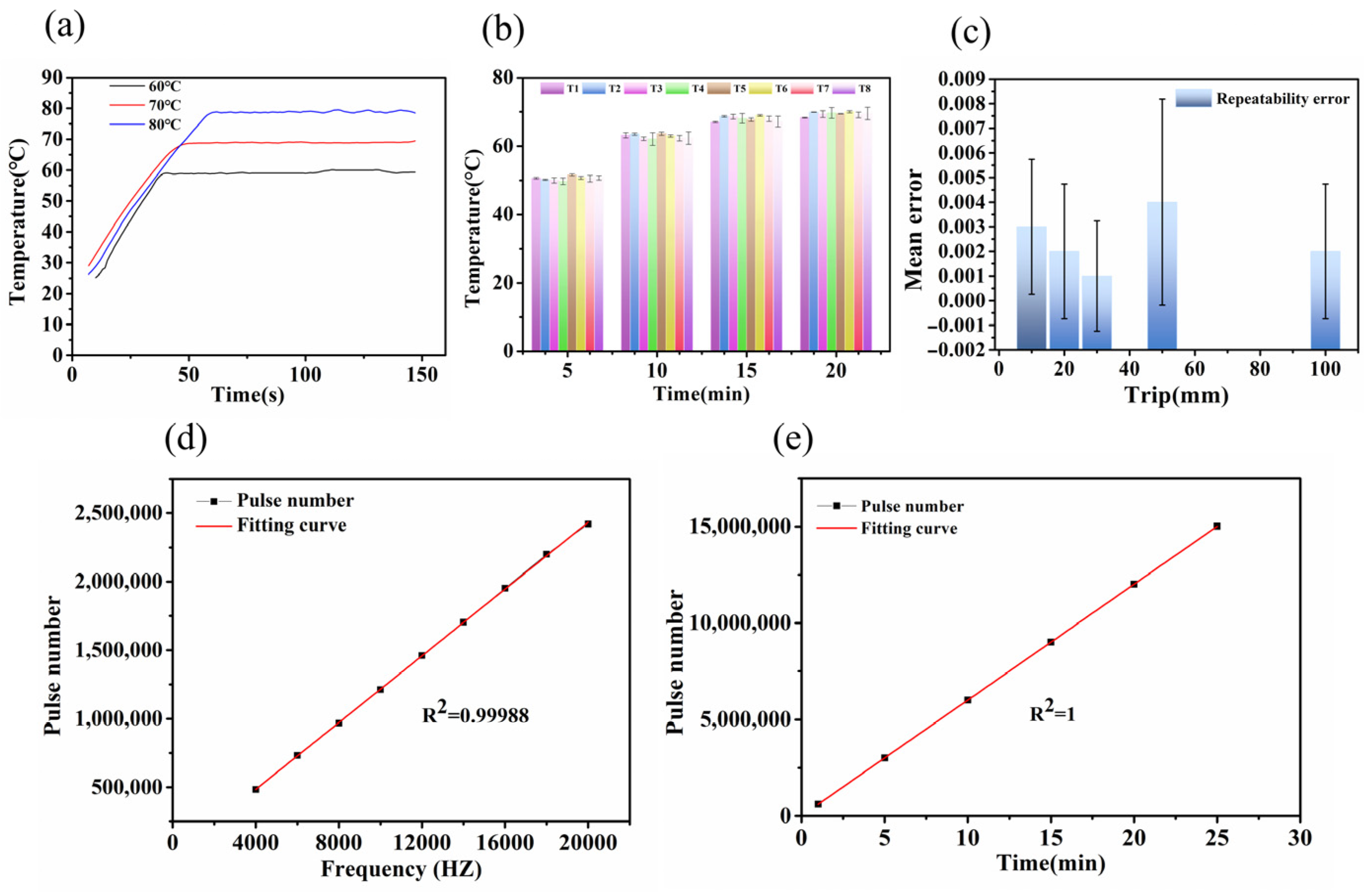

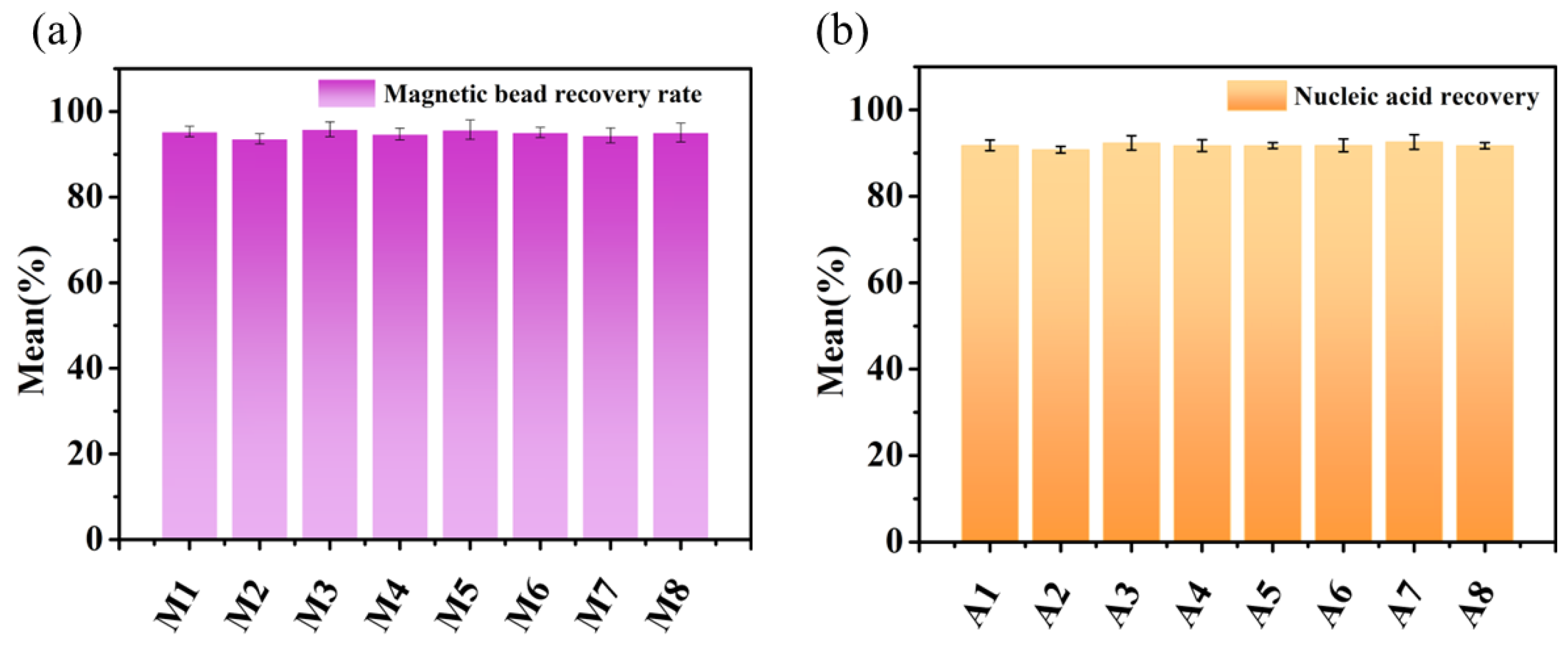

3.1. Performance Index Evaluation of Automatic Extractor

3.2. Comparisons in Different Samples

3.3. Sensitivity Evaluation and Optimization

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Xu, X.; Shang, Y.; Liu, F.; Jiang, Q.; Ding, B. Logic devices based on nucleic acid self-assembly. InfoMat 2021, 3, 1070–1082. [Google Scholar] [CrossRef]

- Zhang, Y.Y.; Guillon, F.X.; Griveau, S.; Bedioui, F.; Lazerges, M.; Slim, C. Evolution of nucleic acids biosensors detection limit III. Anal. Bioanal. Chem. 2022, 414, 943–968. [Google Scholar] [CrossRef]

- Cao, X.; Chen, C.; Zhu, Q. Biosensors based on functional nucleic acids and isothermal amplification techniques. Talanta 2023, 253, 123977. [Google Scholar] [CrossRef] [PubMed]

- Patel, P.G.; Selvarajah, S.; Guérard, K.P.; Bartlett, J.M.S.; Lapointe, J.; Berman, D.M.; Okello, J.B.A.; Park, P.C. Reliability and performance of commercial RNA and DNA extraction kits for FFPE tissue cores. PLoS ONE 2017, 12, e0179732. [Google Scholar] [CrossRef] [PubMed]

- Knapp, J.; Lallemand, S.; Monnien, F.; Felix, S.; Valmary-Degano, S.; Courquet, S.; Demonmerot, F.; Heyd, B.; Turco, C.; Doussot, A.; et al. Molecular diagnosis of alveolar echinococcosis in patients based on frozen and formalin-fixed paraffin-embedded tissue samples. Parasite 2022, 29, 4. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.; Zhao, K.; He, Z.; Luo, X.; Qin, Z.; Tan, Y.; Zheng, X.; Wu, Z.; Deng, Y.; Chen, H.; et al. Development and evaluation of a thermostatic nucleic acid testing device based on magnesium pyrophosphate precipitation for detecting Enterocytozoon hepatopenaei. Chin. Chem. Lett. 2022, 33, 4053–4056. [Google Scholar] [CrossRef]

- Hou, L.; Wei, Y.; Lin, Y.; Wang, X.; Lai, Y.; Yin, M.; Chen, Y.; Guo, X.; Wu, S.; Zhu, Y.; et al. Concurrent binding to DNA and RNA facilitates the pluripotency reprogramming activity of Sox2. Nucleic Acids Res. 2020, 48, 3869–3887. [Google Scholar] [CrossRef]

- Liu, S.; He, X.; Zhang, T.; Zhao, K.; Xiao, C.; Tong, Z.; Jin, L.; He, N.; Deng, Y.; Li, S.; et al. Highly sensitive smartphone-based detection of Listeria monocytogenes using SYTO9. Chin. Chem. Lett. 2022, 33, 1933–1935. [Google Scholar] [CrossRef]

- Zuo, T.; Liu, Q.; Zhang, F.; Yeoh, Y.K.; Wan, Y.; Zhan, H.; Lui, G.C.Y.; Chen, Z.; Li, A.Y.L.; Cheung, C.P.; et al. Temporal landscape of human gut RNA and DNA virome in SARS-CoV-2 infection and severity. Microbiome 2021, 9, 91. [Google Scholar] [CrossRef]

- Nguyen, H.Q.; Bui, H.K.; Phan, V.M.; Seo, T.S. An internet of things-based point-of-care device for direct reverse-transcription-loop mediated isothermal amplification to identify SARS-CoV-2. Biosens. Bioelectron. 2022, 195, 113655. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, L.; Zeng, W.; Zhang, L.; He, N.; Lu, Z. High-throughput quantitative detection of triple-negative breast cancer-associated expressed miRNAs by rolling circle amplification on fluorescence-encoded microspheres. Chin. Chem. Lett. 2023, 34, 108141. [Google Scholar] [CrossRef]

- Zhang, R.; Zhang, X.; Tang, Y.; Mao, J. Composition, isolation, purification and biological activities of Sargassum fusiforme polysaccharides: A review. Carbohydr. Polym. 2020, 228, 115381. [Google Scholar] [CrossRef]

- Manzoor, M.F.; Ahmad, N.; Ahmed, Z.; Siddique, R.; Zeng, X.A.; Rahaman, A.; Muhammad Aadil, R.; Wahab, A. Novel extraction techniques and pharmaceutical activities of luteolin and its derivatives. J. Food Biochem. 2019, 43, e12974. [Google Scholar] [CrossRef]

- Athira, K.K.; Gardas, R.L. Insights into the partitioning of DNA in aqueous biphasic system containing ammonium-based ionic liquid and phosphate buffer. Fluid Phase Equilibria 2022, 558, 113463. [Google Scholar] [CrossRef]

- Chen, Y.; Liu, Y.; Shi, Y.; Ping, J.; Wu, J.; Chen, H. Magnetic particles for integrated nucleic acid purification, amplification and detection without pipetting. Trends Anal. Chem. 2020, 127, 115912. [Google Scholar] [CrossRef]

- Dawson, P.; Buyukyavuz, A.; Ionita, C.; Northcutt, J. Effects of DNA extraction methods on the real time PCR quantification of Campylobacter jejuni, Campylobacter coli, and Campylobacter lari in chicken feces and ceca contents. Poult. Sci. 2023, 102, 102369. [Google Scholar] [CrossRef]

- Hong, J.; Liu, X.; Yang, X.; Wang, Y.; Zhao, L. Ionic liquid-based dispersive liquid-liquid microextraction followed by magnetic solid-phase extraction for determination of quinolones. Mikrochim. Acta 2021, 189, 8. [Google Scholar] [CrossRef] [PubMed]

- Arabi, M.; Ostovan, A.; Bagheri, A.R.; Guo, X.; Wang, L.; Li, J.; Wang, X.; Li, B.; Chen, L. Strategies of molecular imprinting-based solid-phase extraction prior to chromatographic analysis. TrAC-Trends Anal. Chem. 2020, 128, 115923. [Google Scholar] [CrossRef]

- Perez-Toralla, K.; Pereiro, I.; Garrigou, S.; Federico, F.D.; Proudhon, C.; Bidard, F.-C.; Viovy, J.-L.; Taly, V.; Descroix, S. Microfluidic extraction and digital quantification of circulating cell-free DNA from serum. Sens. Actuators B-Chem. 2019, 286, 533–539. [Google Scholar] [CrossRef]

- Fan, Y.; Dai, R.; Guan, X.; Lu, S.; Yang, C.; Lv, X.; Li, X. Rapid automatic nucleic acid purification system based on gas-liquid immiscible phase. J. Sep. Sci. 2023, 46, e2200801. [Google Scholar] [CrossRef] [PubMed]

- Liu, S.; Li, Z.; Yu, B.; Wang, S.; Shen, Y.; Cong, H. Recent advances on protein separation and purification methods. Adv. Colloid Interface Sci. 2020, 284, 102254. [Google Scholar] [CrossRef] [PubMed]

- Ayoib, A.; Hashim, U.; Gopinath, S.C.B.; Md Arshad, M.K. DNA extraction on bio-chip: History and preeminence over conventional and solid-phase extraction methods. Appl. Microbiol. Biotechnol. 2017, 101, 8077–8088. [Google Scholar] [CrossRef]

- Dundas, N.; Leos, N.K.; Mitui, M.; Revell, P.; Rogers, B.B. Comparison of automated nucleic acid extraction methods with manual extraction. J. Mol. Diagn. JMD 2008, 10, 311–316. [Google Scholar] [CrossRef]

- Chen, S.Y.; Chou, Y.C.; Huang, J.W.; Er, T.K. Comparison of Manual and Automated Nucleic Acid Extraction Methods in Virus Transport Medium. Clin. Lab. 2021, 67, 107754. [Google Scholar] [CrossRef] [PubMed]

- Frickmann, H.; Hinz, R.; Hagen, R.M. Comparison of an automated nucleic acid extraction system with the column-based procedure. Eur. J. Microbiol. Immunol. 2015, 5, 94–102. [Google Scholar] [CrossRef]

- Dhibika, M.; Madhusudhan, N.S.; Malini, A.; Natarajan, M. Comparison of Manual and Automated Nucleic Acid (RNA) Extraction Methods for the Detection of SARS-CoV-2 by qRT-PCR. Cureus 2023, 15, e36773. [Google Scholar] [CrossRef] [PubMed]

- Emaus, M.N.; Varona, M.; Eitzmann, D.R.; Hsieh, S.; Zeger, V.R.; Anderson, J.L. Nucleic acid extraction: Fundamentals of sample preparation methodologies, current advancements, and future endeavors. TrAC Trends Anal. Chem. 2020, 130, 115985. [Google Scholar] [CrossRef]

- Clark, D.J.; Moore, C.M.; Flanagan, M.; Bocxlaer, K.V.; Piperaki, E.T.; Yardley, V.; Croft, S.L.; Tyson, J.; Whitehouse, S.P.; O’Halloran, J.; et al. An efficient and novel technology for the extraction of parasite genomic DNA from whole blood or culture. Biotechniques 2020, 68, 79–84. [Google Scholar] [CrossRef]

- Yu, C.Y.; Chan, K.G.; Yean, C.Y.; Ang, G.Y. Nucleic Acid-Based Diagnostic Tests for the Detection SARS-CoV-2: An Update. Diagnostics 2021, 11, 53. [Google Scholar] [CrossRef]

- Obino, D.; Vassalli, M.; Franceschi, A.; Alessandrini, A.; Facci, P.; Viti, F. An Overview on Microfluidic Systems for Nucleic Acids Extraction from Human Raw Samples. Sensors 2021, 21, 3058. [Google Scholar] [CrossRef]

- Zhao, X.; Huang, Y.; Li, X.; Yang, W.; Lv, Y.; Sun, W.; Huang, J.; Mi, S. Full integration of nucleic acid extraction and detection into a centrifugal microfluidic chip employing chitosan-modified microspheres. Talanta 2022, 250, 123711. [Google Scholar] [CrossRef]

- Sullivan, B.P.; Bender, A.T.; Ngyuen, D.N.; Zhang, J.Y.; Posner, J.D. Nucleic acid sample preparation from whole blood in a paper microfluidic device using isotachophoresis. J. Chromatogr. B Anal. Technol. Biomed. Life Sci. 2021, 1163, 122494. [Google Scholar] [CrossRef] [PubMed]

- Hussain, M.; Zou, J.; Liu, X.; Chen, R.; Tang, S.; Huang, Z.; Zhuang, J.; Zhang, L.; Tang, Y. Pseudomonas aeruginosa detection based on droplets incubation using an integrated microfluidic chip, laser spectroscopy, and machine learning. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2023, 288, 122206. [Google Scholar] [CrossRef]

- Byrne, R.L.; Cocker, D.; Alyayyoussi, G.; Mphasa, M.; Charles, M.; Mandula, T.; Williams, C.T.; Rigby, J.; Hearn, J.; Feasey, N.; et al. A novel, magnetic bead-based extraction method for the isolation of antimicrobial resistance genes with a case study in river water in Malawi. J. Appl. Microbiol. 2022, 133, 3191–3200. [Google Scholar] [CrossRef]

- Haile, S.; Nikiforuk, A.M.; Pandoh, P.K.; Twa, D.D.W.; Smailus, D.E.; Nguyen, J.; Pleasance, S.; Wong, A.; Zhao, Y.; Eisler, D.; et al. Optimization of magnetic bead-based nucleic acid extraction for SARS-CoV-2 testing using readily available reagents. J. Virol. Methods 2022, 299, 114339. [Google Scholar] [CrossRef]

- Pearlman, S.I.; Leelawong, M.; Richardson, K.A.; Adams, N.M.; Russ, P.K.; Pask, M.E.; Wolfe, A.E.; Wessely, C.; Haselton, F.R. Low-Resource Nucleic Acid Extraction Method Enabled by High-Gradient Magnetic Separation. ACS Appl. Mater. Interfaces 2020, 12, 12457–12467. [Google Scholar] [CrossRef] [PubMed]

- Bulgakova, A.; Chubarov, A.; Dmitrienko, E. Magnetic nylon 6 nanocomposites for the microextraction of nucleic acids from biological samples. Magnetochemistry 2022, 8, 85. [Google Scholar] [CrossRef]

- Yu, L.; Adamson, P.; Lay Yap, P.; Tung, T.; Makar, S.; Turra, M.; Higgins, G.; Losic, D. From Biowaste to Lab-Bench: Low-Cost Magnetic Iron Oxide Nanoparticles for RNA Extraction and SARS-CoV-2 Diagnostics. Biosensors 2023, 13, 196. [Google Scholar] [CrossRef]

- Ecke, A.; Westphalen, T.; Hornung, J.; Voetz, M.; Schneider, R.J. A rapid magnetic bead-based immunoassay for sensitive determination of diclofenac. Anal. Bioanal. Chem. 2022, 414, 1563–1573. [Google Scholar] [CrossRef]

- Fang, Y.; Wang, Y.; Zhu, L.; Liu, H.; Su, X.; Liu, Y.; Chen, Z.; Chen, H.; He, N. A novel cartridge for nucleic acid extraction, amplification and detection of infectious disease pathogens with the help of magnetic nanoparticles. Chin. Chem. Lett. 2023, 34, 108092. [Google Scholar] [CrossRef]

- Wei, S.; Dou, Y.; Yu, Y.; Yang, J.; Yu, F.; Sha, W.; Li, T. A novel biosensor based on a bio-barcode for the detection of Mycobacterium tuberculosis. Anal. Methods 2023, 15, 3683–3691. [Google Scholar] [CrossRef] [PubMed]

- Ali, Z.; Wang, J.; Mou, X.; Tang, Y.; Li, T.; Liang, W.; Shah, M.A.A.; Ahmad, R.; Li, Z.; He, N. Integration of Nucleic Acid Extraction Protocol with Automated Extractor for Multiplex Viral Detection. J. Nanosci. Nanotechnol. 2017, 17, 862–870. [Google Scholar] [CrossRef] [PubMed]

- Yamaguchi, A.; Matsuda, K.; Uehara, M.; Honda, T.; Saito, Y. A novel automated device for rapid nucleic acid extraction utilizing a zigzag motion of magnetic silica beads. Anal. Chim. Acta 2016, 906, 1–6. [Google Scholar] [CrossRef] [PubMed]

- Ota, H.; Lim, T.K.; Tanaka, T.; Yoshino, T.; Harada, M.; Matsunaga, T. Automated DNA extraction from genetically modified maize using aminosilane-modified bacterial magnetic particles. J. Biotechnol. 2006, 125, 361–368. [Google Scholar] [CrossRef]

- He, L.; Huang, R.; Xiao, P.; Liu, Y.; Jin, L.; Liu, H.; Li, S.; Deng, Y.; Chen, Z.; Li, Z.; et al. Current signal amplification strategies in aptamer-based electrochemical biosensor: A review. Chin. Chem. Lett. 2021, 32, 1593–1602. [Google Scholar] [CrossRef]

- Xing, G.; Zhang, W.; Li, N.; Pu, Q.; Lin, J. Recent progress on microfluidic biosensors for rapid detection of pathogenic bacteria. Chin. Chem. Lett. 2022, 33, 1743–1751. [Google Scholar] [CrossRef]

- Liu, Y.; Jiang, D.; Wang, S.; Cai, G.; Xue, L.; Li, Y.; Liao, M.; Lin, J. A microfluidic biosensor for rapid detection of Salmonella typhimurium based on magnetic separation, enzymatic catalysis and electrochemical impedance analysis. Chin. Chem. Lett. 2022, 33, 3156–3160. [Google Scholar] [CrossRef]

- Guo, Y.; He, Z.Y.; Chen, Z.; Chen, F.L.; Wang, C.M.; Zhou, W.L.; Liu, J.; Liu, H.; Shi, R.Z. Inhibition of Th17 cells by donepezil ameliorates experimental lung fibrosis and pulmonary hypertension. Theranostics 2023, 13, 1826–1842. [Google Scholar] [CrossRef]

| Method | Purity | Stability | Skills Requirement | Hazardous Reagents | Time | Multi-Step Centrifugation | Automation |

|---|---|---|---|---|---|---|---|

| Phenol chlorine method | High | Low | High | Need | Longer | Need | No |

| High salt precipitation method | Low | Low | High | Unnecessary | Long | Need | No |

| silica-based column method | High | High | Low | Unnecessary | Short | Need | Yes |

| Ion exchange method | Higher | High | High | Unnecessary | Longer | Unnecessary | Yes |

| Magnetic separation method | Higher | High | Low | Unnecessary | Short | Unnecessary | Yes |

| Sample | Time (min) | OD260/OD280 | OD260/OD230 | C, ng/μL |

|---|---|---|---|---|

| Pseudomonas aeruginosa | 5 | 1.94 | 1.85 | 148.7 |

| 10 | 1.95 | 1.99 | 152.4 | |

| 15 | 1.88 | 2.01 | 155.8 | |

| Mouse liver tissue | 5 | 2.01 | 2.03 | 974.1 |

| 10 | 2.04 | 2.13 | 1004.6 | |

| 15 | 2.03 | 2.02 | 988.9 | |

| Blood | 5 | 1.91 | 1.92 | 16.3 |

| 10 | 1.94 | 2.00 | 12.5 | |

| 15 | 1.94 | 1.98 | 13.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Liu, S.; Wang, Y.; Wang, Y.; Li, S.; He, N.; Deng, Y.; Chen, Z. Research on a Magnetic Separation-Based Rapid Nucleic Acid Extraction System and Its Detection Applications. Biosensors 2023, 13, 903. https://doi.org/10.3390/bios13100903

Li Y, Liu S, Wang Y, Wang Y, Li S, He N, Deng Y, Chen Z. Research on a Magnetic Separation-Based Rapid Nucleic Acid Extraction System and Its Detection Applications. Biosensors. 2023; 13(10):903. https://doi.org/10.3390/bios13100903

Chicago/Turabian StyleLi, Yao, Sha Liu, Yuanyuan Wang, Yue Wang, Song Li, Nongyue He, Yan Deng, and Zhu Chen. 2023. "Research on a Magnetic Separation-Based Rapid Nucleic Acid Extraction System and Its Detection Applications" Biosensors 13, no. 10: 903. https://doi.org/10.3390/bios13100903

APA StyleLi, Y., Liu, S., Wang, Y., Wang, Y., Li, S., He, N., Deng, Y., & Chen, Z. (2023). Research on a Magnetic Separation-Based Rapid Nucleic Acid Extraction System and Its Detection Applications. Biosensors, 13(10), 903. https://doi.org/10.3390/bios13100903