Surface Plasmon Resonance-Based Gold-Coated Hollow-Core Negative Curvature Optical Fiber Sensor

Abstract

:1. Introduction

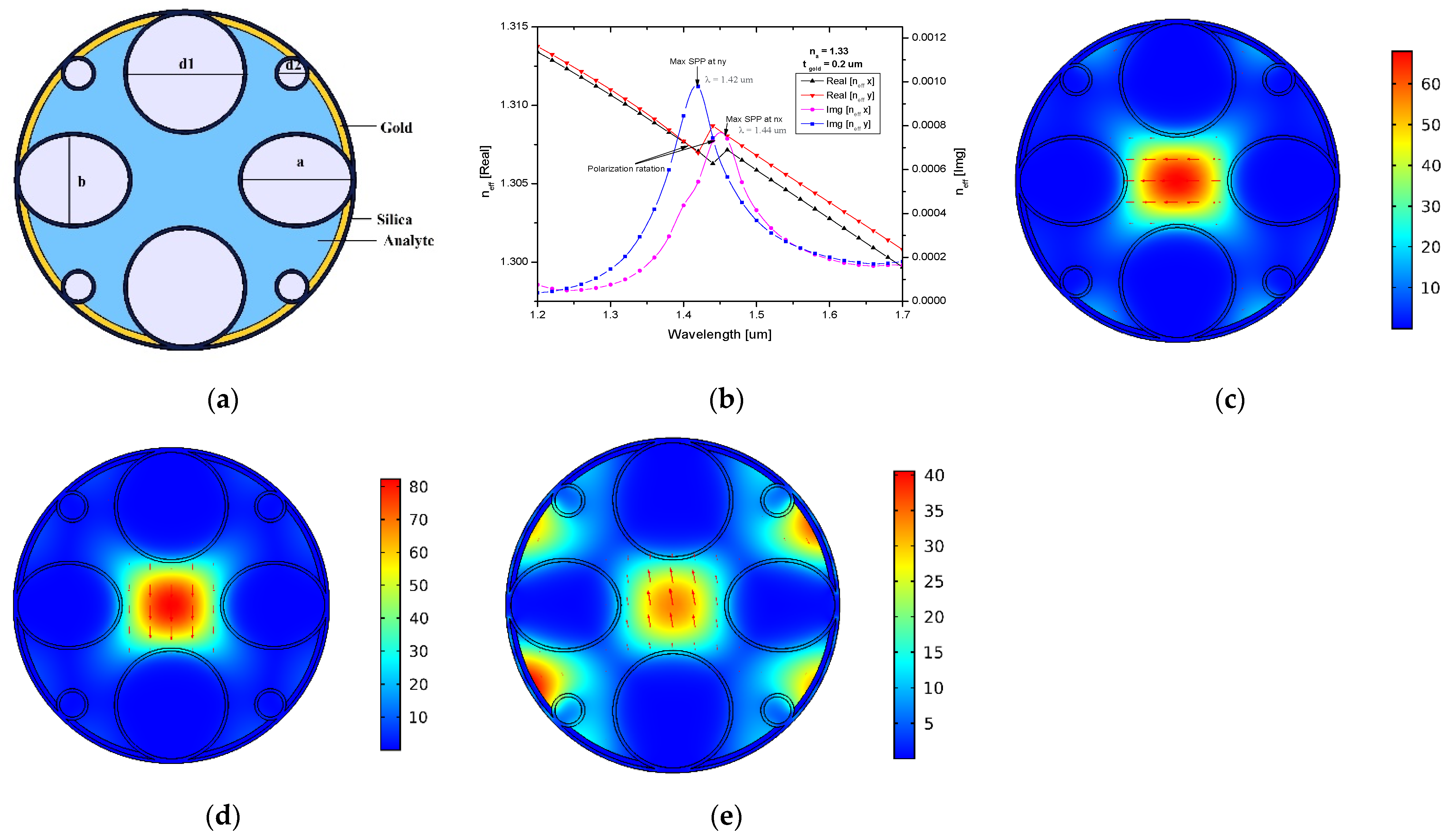

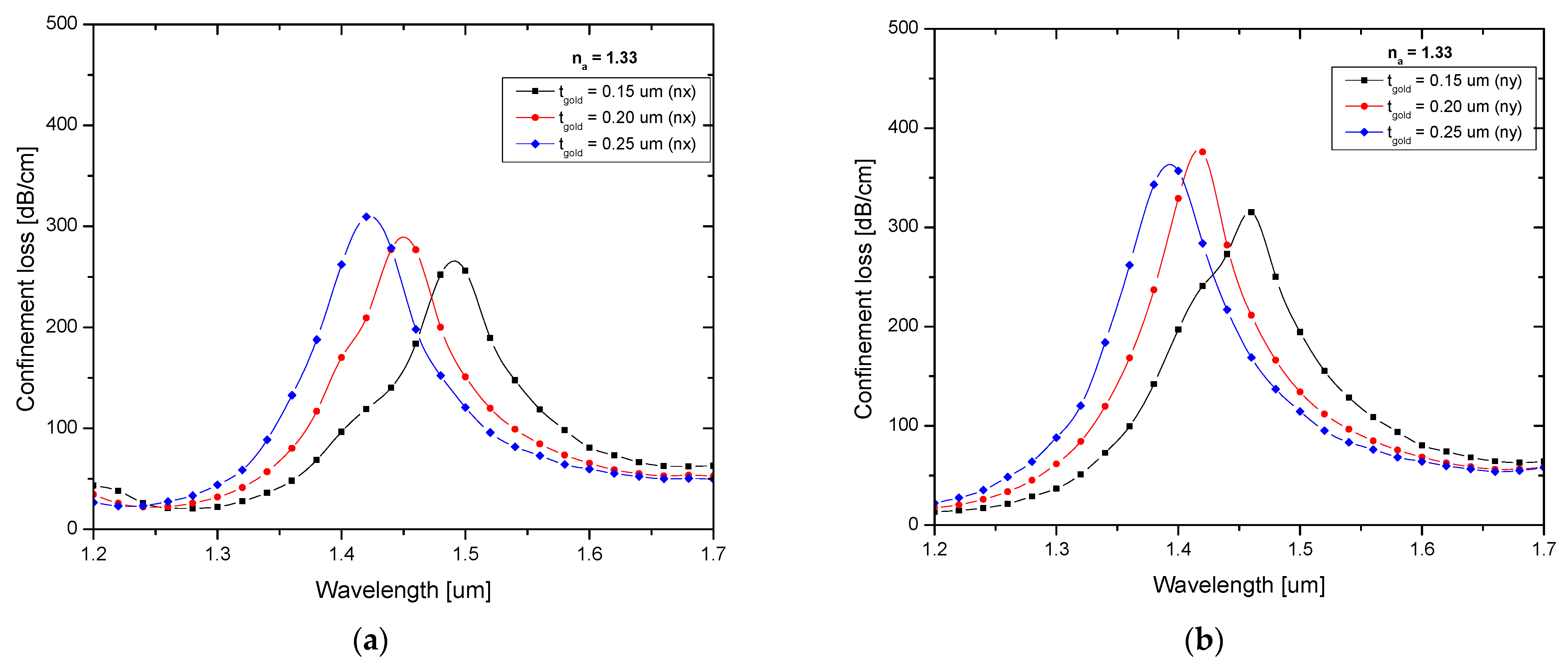

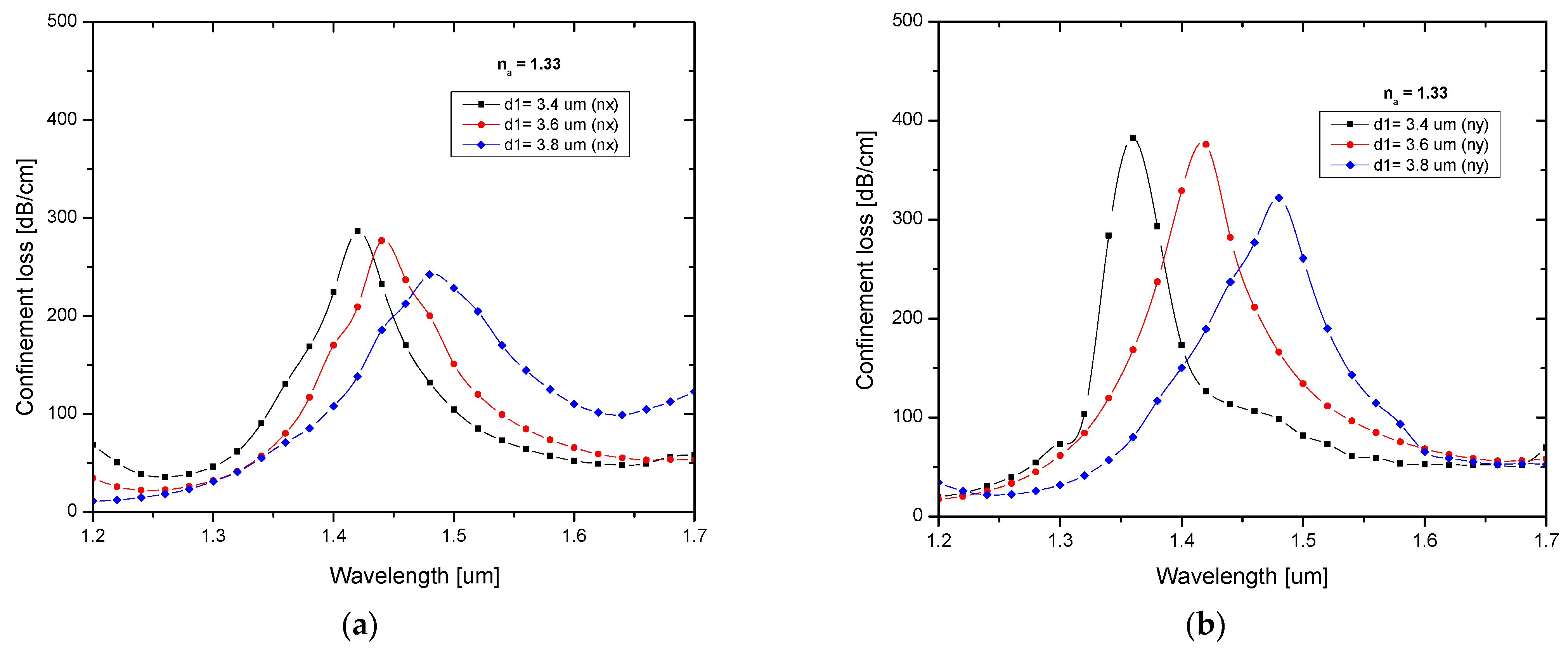

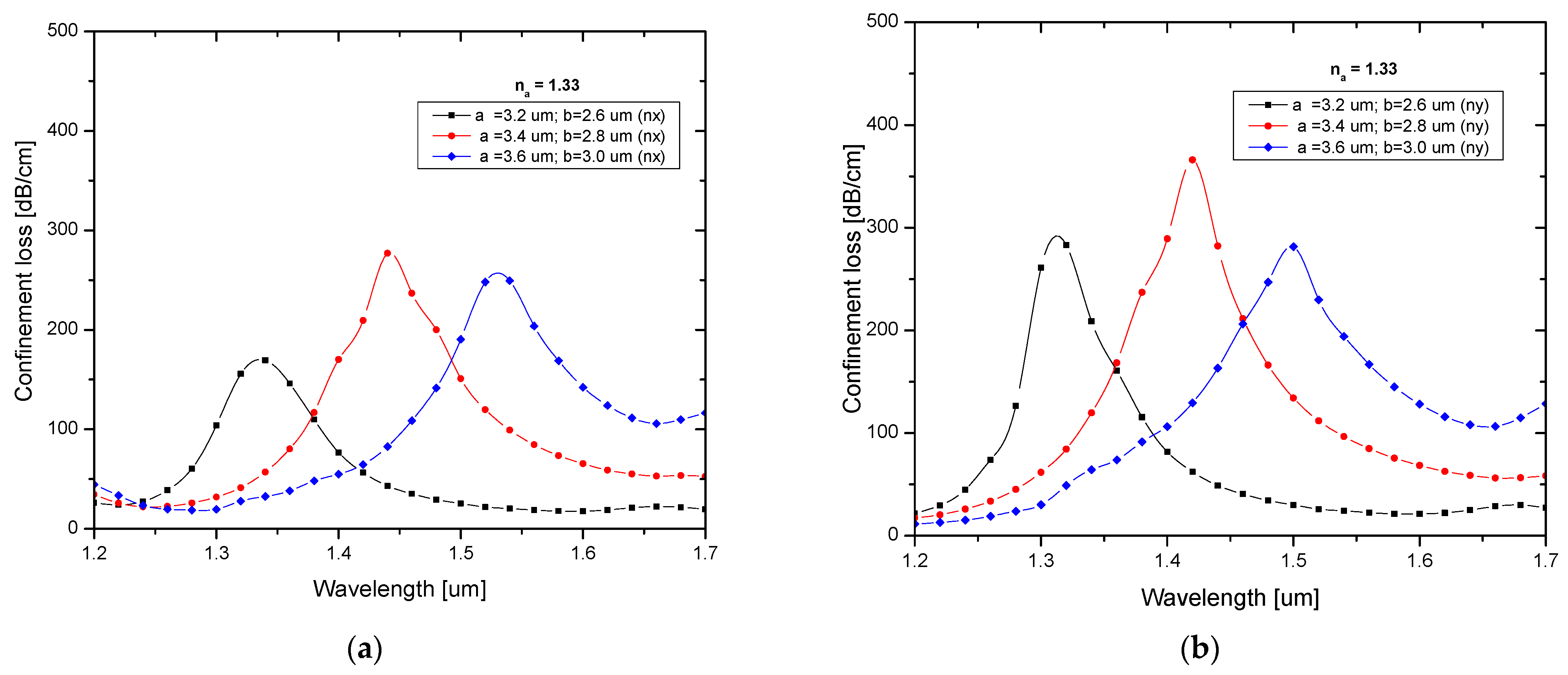

2. Materials and Methods

3. Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Luo, W.; Liu, B.; Liu, J.; Wu, T.; Liu, Q.; Wang, M.Y.; Wu, Q. Tapered side-polished micro fibre sensor for high sensitivity hCG detection. IEEE Sens. J. 2022, 22, 7727–7733. [Google Scholar] [CrossRef]

- Mohammed, H.A.; Rashid, S.A.; Abu Bakar, M.H.; Ahmad Anas, S.B.; Mahdi, M.A.; Yaacob, M.H. Fabrication and characterizations of a novel etched-tapered single mode optical fiber ammonia sensors integrating PANI/GNF nanocomposite. Sens. Actuators B Chem. 2019, 287, 71–77. [Google Scholar] [CrossRef]

- Huong, V.T.; Phuong, N.T.T.; Tai, N.T.; An, N.T.; Lam, V.D.; Manh, D.H.; Tran, N.H.T. Gold nanoparticles modified a multimode clad-free fiber for ultrasensitive detection of bovine serum albumin. J. Nanomater. 2021, 2021, 5530709. [Google Scholar] [CrossRef]

- Kim, D.M.; Park, J.S.; Jung, S.W.; Yeom, J.; Yoo, S.M. Biosensing applications using nanostructure-based localized surface plasmon resonance sensors. Sensors 2021, 21, 3191. [Google Scholar] [CrossRef] [PubMed]

- Elsherif, M.; Salih, A.E.; Muñoz, M.G.; Alam, F.; AlQattan, B.; Antonysamy, D.S.; Butt, H. Optical fiber sensors: Working principle, applications, and limitations. Adv. Photonics Res. 2022, 3, 2100371. [Google Scholar] [CrossRef]

- Yang, F.; Chang, T.L.; Liu, T.; Wu, D.; Du, H.; Liang, J.; Tian, F. Label-free detection of Staphylococcus aureus bacteria using long-period fiber gratings with functional polyelectrolyte coatings. Biosens. Bioelectron. 2019, 133, 147–153. [Google Scholar] [CrossRef]

- Ivanov, O.V.; Yang, F.; Tian, F.; Du, H. Thin-core fiber structures with overlays for sensing applications. Opt. Express 2017, 25, 31197. [Google Scholar] [CrossRef]

- Islam, M.R.; Iftekher, A.N.M.; Hasan, K.R.; Nayen, M.J.; Islam, S.B. Dual-polarized highly sensitive surface-plasmon-resonance-based chemical and biomolecular sensor. Appl. Opt. 2020, 59, 3296–3305. [Google Scholar] [CrossRef]

- Islam, M.R.; Khan, M.M.I.; Al Rafid, R.; Mehjabin, F.; Rashid, M.S.; Chowdhury, J.A.; Islam, M. Trigonal cluster-based ultra-sensitive surface plasmon resonance sensor for multipurpose sensing. Sens. Bio-Sens. Res. 2022, 35, 100477. [Google Scholar] [CrossRef]

- Ayyanar, N.; Sreekanth, K.V.; Raja, G.T.; Rajan, M.S.M. Photonic crystal fiber-based reconfigurable biosensor using phase change material. IEEE Trans. Nanobiosci. 2021, 20, 338–344. [Google Scholar] [CrossRef]

- Zhao, Y.; Tong, R.J.; Xia, F.; Peng, Y. Current status of optical fiber biosensor based on surface plasmon resonance. Biosens. Bioelectron. 2019, 142, 111505. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q.; Wang, L. Lab-on-fiber: Plasmonic nano-arrays for sensing. Nanoscale 2020, 12, 7485–7499. [Google Scholar] [CrossRef] [PubMed]

- Islam, M.R.; Iftekher, A.N.M.; Hasan, K.R.; Nayen, M.; Islam, S.B.; Hossain, A.; Tahsin, T. Design and numerical analysis of a gold-coated photonic crystal fiber based refractive index sensor. Opt. Quantum Electron. 2021, 53, 1–18. [Google Scholar] [CrossRef]

- Kumar, D.; Sharma, M.; Singh, V. Surface plasmon resonance implemented silver thin film PCF sensor with multiple–hole microstructure for wide ranged refractive index detection. Mater. Today: Proc. 2022, 62, 6590–6595. [Google Scholar] [CrossRef]

- Yang, T.; Zhang, L.; Shi, Y.; Liu, S.; Dong, Y. A highly birefringent photonic crystal fiber for terahertz spectroscopic chemical sensing. Sensors 2021, 21, 1799. [Google Scholar] [CrossRef] [PubMed]

- Sharma, A.K.; Pandey, A.K.; Kaur, B. A Review of advancements (2007–2017) in plasmonics-based optical fiber sensors. Opt. Fiber Technol. 2018, 43, 20–34. [Google Scholar] [CrossRef]

- Yu, R.; Chen, Y.; Shui, L.; Xiao, L. Hollow-core photonic crystal fiber gas sensing. Sensors 2020, 20, 2996. [Google Scholar] [CrossRef]

- Liu, C.; Fu, H.; Lv, Y.; Yi, Z.; Lin, J.; Lv, J.; Chu, P.K. HE1,1 mode-excited surface plasmon resonance for refractive index sensing by photonic crystal fibers with high sensitivity and long detection distance. Optik 2022, 265, 169471. [Google Scholar] [CrossRef]

- Momota, M.R.; Hasan, M.R. Hollow-core silver coated photonic crystal fiber plasmonic sensor. Opt. Mater. 2018, 76, 287–294. [Google Scholar] [CrossRef]

- Nazeri, K.; Ahmed, F.; Ahsani, V.; Joe, H.-E.; Bradley, C.; Toyserkani, E.; Jun, M.B.G. Hollow-Core Photonic Crystal Fiber Mach–Zehnder Interferometer for Gas Sensing. Sensors 2020, 20, 2807. [Google Scholar] [CrossRef]

- Kolyadin, A.N.; Alagashev, G.K.; Pryamikov, A.D.; Mouradian, L.; Zeytunyan, A.; Toneyan, H.; Bufetov, I.A. Negative curvature hollow-core fibers: Dispersion properties and femtosecond pulse delivery. Phys. Procedia 2015, 73, 59–66. [Google Scholar] [CrossRef] [Green Version]

- Debord, B.; Alharbi, M.; Bradley, T.; Fourcade-Dutin, C.; Wang, Y.Y.; Vincetti, L.; Benabid, F. Hypocycloid-shaped hollow-core photonic crystal fiber part I: Arc curvature effect on confinement loss. Opt. Express 2013, 21, 28597. [Google Scholar] [CrossRef] [PubMed]

- Hossain, S.; Mollah, A.; Hosain, K.; Ankan, I.M. THz spectroscopic sensing of liquid chemicals using hollow-core anti-resonant fiber. OSA Contin. 2021, 4, 621. [Google Scholar] [CrossRef]

- Khozeymeh, F.; Melli, F.; Capodaglio, S.; Corradini, R.; Benabid, F.; Vincetti, L.; Cucinotta, A. Hollow-core fiber-based biosensor: A platform for lab-in-fiber optical biosensors for DNA detection. Sensors 2022, 22, 5144. [Google Scholar] [CrossRef]

- Qiu, S.; Yuan, J.; Zhou, X.; Li, F.; Wang, Q.; Qu, Y.; Yan, B.; Wu, Q.; Wang, K.; Sang, X.; et al. Hollow-core negative curvature fiber with high birefringence for low refractive index sensing based on surface plasmon resonance effect. Sensors 2020, 20, 6539. [Google Scholar] [CrossRef] [PubMed]

- Chao, C.-T.C.; Kooh, M.R.R.; Chau, Y.-F.C.; Thotagamuge, R. Susceptible plasmonic photonic crystal fiber sensor with elliptical air holes and external-flat gold-coated surface. Photonics 2022, 9, 916. [Google Scholar] [CrossRef]

- Liu, Q.; Li, S.; Chen, H. Two kinds of polarization filter based on photonic crystal fiber with nanoscale gold film. IEEE Photonics J. 2015, 7, 1–11. [Google Scholar] [CrossRef]

- Selvendran, S.; Raja, A.S.; Yogalakshmi, S. A highly sensitive surface plasmon resonance biosensor using photonic crystal fiber filled with gold nanowire encircled by silicon lining. Optik 2018, 156, 112–120. [Google Scholar] [CrossRef]

- Jasion, G.T.; Hayes, J.R.; Wheeler, N.V.; Chen, Y.; Bradley, T.D.; Richardson, D.J.; Poletti, F. Fabrication of tubular anti-resonant hollow core fibers: Modelling, draw dynamics and process optimization. Opt. Express 2019, 27, 20567. [Google Scholar] [CrossRef] [PubMed]

- Takeyasu, N.; Tanaka, T.; Kawata, S. Metal deposition deep into microstructure by electroless plating. Jpn. J. Appl. Phys. 2005, 44, 1134–1137. [Google Scholar] [CrossRef]

- Akowuah, K.; Gorman, T.; Ademgil, H.; Haxha, S.; Robinson, G.K.; Oliver, J.V. Numerical analysis of a photonic crystal fiber for biosensing applications. IEEE J. Quantum Electron. 2012, 48, 1403–1410. [Google Scholar] [CrossRef]

- Maji, P.S.; Roy Chaudhuri, P. A New design for all-normal near zero dispersion photonic crystal fiber with selective liquid infiltration for broadband supercontinuum generation at 1.55 μm. J. Photonics 2014, 2014, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Islam, M.R.; Jamil, M.A.; Ahsan, S.A.H.; Khan, M.M.I.; Mehjabin, F.; Chowdhury, J.A.; Islam, M. Highly birefringent gold-coated SPR sensor with extremely enhanced amplitude and wavelength sensitivity. Eur. Phys. J. Plus 2021, 136, 238. [Google Scholar] [CrossRef]

- Habib, M.S.; Bang, O.; Bache, M. Low-loss single-mode hollow-core fiber with anisotropic anti-resonant elements. Opt. Express 2016, 24, 8429. [Google Scholar] [CrossRef] [Green Version]

- Nasirifar, R.; Danaie, M.; Dideban, A. Hollow-core graded index optical fiber refractive index sensor based on surface plasmon resonance. Opt. Quantum Electron. 2020, 52, 1–23. [Google Scholar] [CrossRef]

- Ermatov, T.; Noskov, R.E.; Machnev, A.A.; Gnusov, I.; Atkin, V.; Lazareva, E.N.; Gorin, D.A. Multispectral sensing of biological liquids with hollow-core microstructured optical fibres. Light Sci. Appl. 2020, 9, 173. [Google Scholar] [CrossRef] [PubMed]

- Stawska, H.I.; Popenda, M.A. Refractive index sensors based on long-period grating in a negative curvature hollow-core fiber. Sensors 2021, 21, 1803. [Google Scholar] [CrossRef] [PubMed]

- Sultana, J.; Islam, M.S.; Cordeiro, C.M.; Habib, M.S.; Dinovitser, A.; Kaushik, M.; Abbott, D. Hollow core inhibited coupled antiresonant terahertz fiber: A numerical and experimental study. IEEE Trans. Terahertz Sci. Technol. 2021, 11, 245–260. [Google Scholar] [CrossRef]

- Habib, M.; Anower, M.; AlGhamdi, A.; Faragallah, O.S.; Eid, M.; Rashed, A.N.Z. Efficient way for detection of alcohols using hollow core photonic crystal fiber sensor. Opt. Rev. 2021, 28, 383–392. [Google Scholar] [CrossRef]

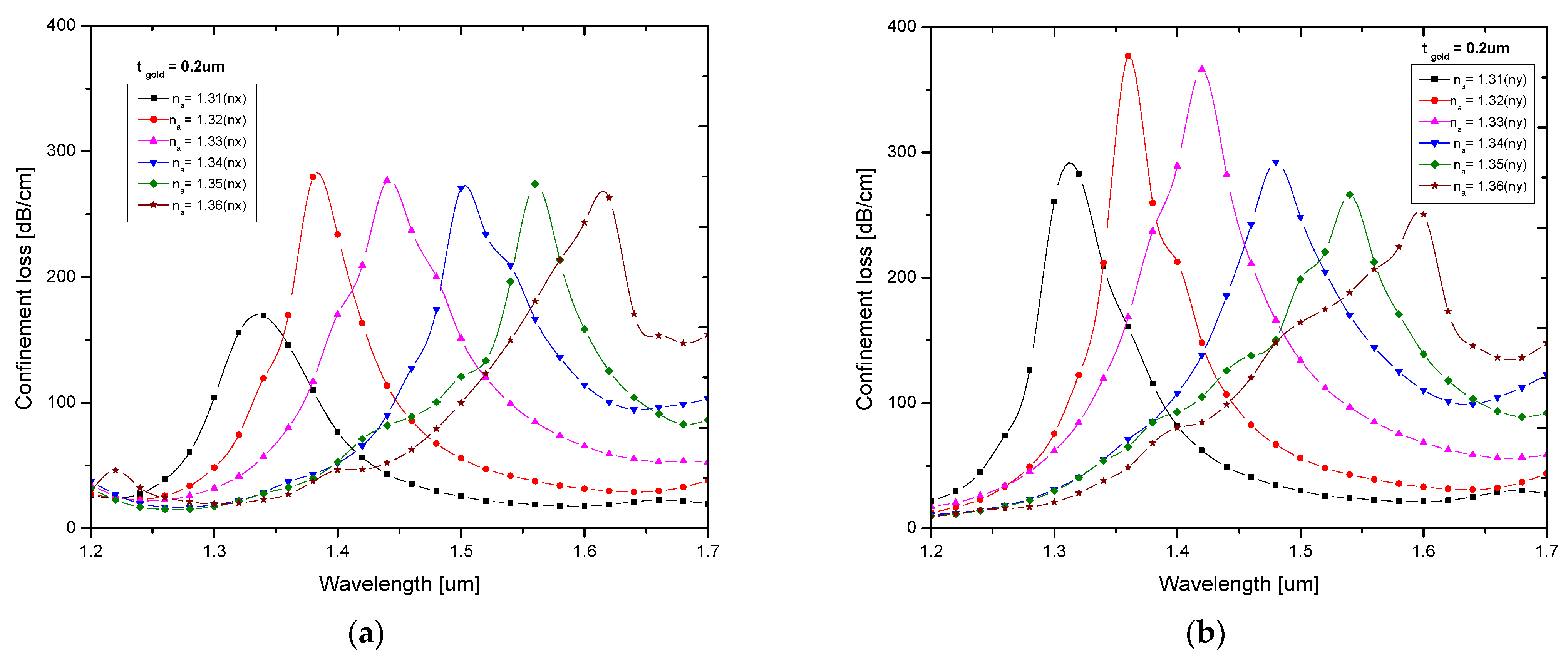

| Refractive Index | X-Polarization | Y-Polarization | Refractive Index Resolution (RIU) | Sensitivity (nm/RIU) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Resonance Wavelength (µm) | Confinement Loss (dB/cm) | FWHM (nm) | FOM (RIU−1) | Resonance Wavelength (µm) | Confinement Loss (dB/cm) | FWHM (nm) | FOM (RIU−1) | |||

| 1.31 | 1.34 | 169.34 | 12 | - | 1.32 | 283.07 | 04 | - | 2.5 × 10−5 | - |

| 1.32 | 1.38 | 279.69 | 05 | 800 | 1.36 | 376.83 | 02 | 2000 | 1.67 × 10−5 | 4000 |

| 1.33 | 1.44 | 276.90 | 09 | 666.7 | 1.42 | 366.07 | 03 | 2000 | 1.67 × 10−5 | 6000 |

| 1.34 | 1.5 | 270.94 | 08 | 750 | 1.48 | 292.27 | 05 | 1200 | 1.67 × 10−5 | 6000 |

| 1.35 | 1.56 | 274.13 | 07 | 857 | 1.54 | 266.36 | 05 | 1200 | 1.67 × 10−5 | 6000 |

| 1.36 | 1.62 | 262.97 | 09 | 666.7 | 1.6 | 250.58 | 07 | 857.1 | - | 6000 |

| Ref. | Structures | Material Used | Sensitivity (nm/RIU) | RI Range |

|---|---|---|---|---|

| [19] | Hollow-core PCF | Silver | 4200 | 1.33–1.37 |

| [20] | Hollow-core PCF | - | 4629 | 1.000034–1.000449 |

| [25] | Hollow-core NCF | Gold | 5700 | 1.2–1.34 |

| [35] | Hollow-core graded-index fiber | Silver | 4350 | 1.38–1.49 |

| [36] | Hollow-core micro-structured fiber | - | 3000 | 1.325–1.36 |

| [37] | Negative-curvature HC fiber | - | 4411 | 1.33–1.39 |

| Proposed work | Hollow-core NCF | Gold | 6000 | 1.31–1.36 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Divya, J.; Selvendran, S. Surface Plasmon Resonance-Based Gold-Coated Hollow-Core Negative Curvature Optical Fiber Sensor. Biosensors 2023, 13, 148. https://doi.org/10.3390/bios13020148

Divya J, Selvendran S. Surface Plasmon Resonance-Based Gold-Coated Hollow-Core Negative Curvature Optical Fiber Sensor. Biosensors. 2023; 13(2):148. https://doi.org/10.3390/bios13020148

Chicago/Turabian StyleDivya, J., and S. Selvendran. 2023. "Surface Plasmon Resonance-Based Gold-Coated Hollow-Core Negative Curvature Optical Fiber Sensor" Biosensors 13, no. 2: 148. https://doi.org/10.3390/bios13020148

APA StyleDivya, J., & Selvendran, S. (2023). Surface Plasmon Resonance-Based Gold-Coated Hollow-Core Negative Curvature Optical Fiber Sensor. Biosensors, 13(2), 148. https://doi.org/10.3390/bios13020148