Development of Single-Walled Carbon Nanotube-Based Electrodes with Enhanced Dispersion and Electrochemical Properties for Blood Glucose Monitoring

Abstract

1. Introduction

2. Materials and Methods

2.1. Chemicals

2.2. Solvent Suspension and Dispersion of CNTs

2.3. Biosensor Development with SWCNTs

2.4. Detection of Glucose by the Fabricated Biosensor

3. Results

3.1. Dispersion Characteristics of CNTs in Various Solvents

3.2. Dispersion Analysis of CNTs in Various Solvents

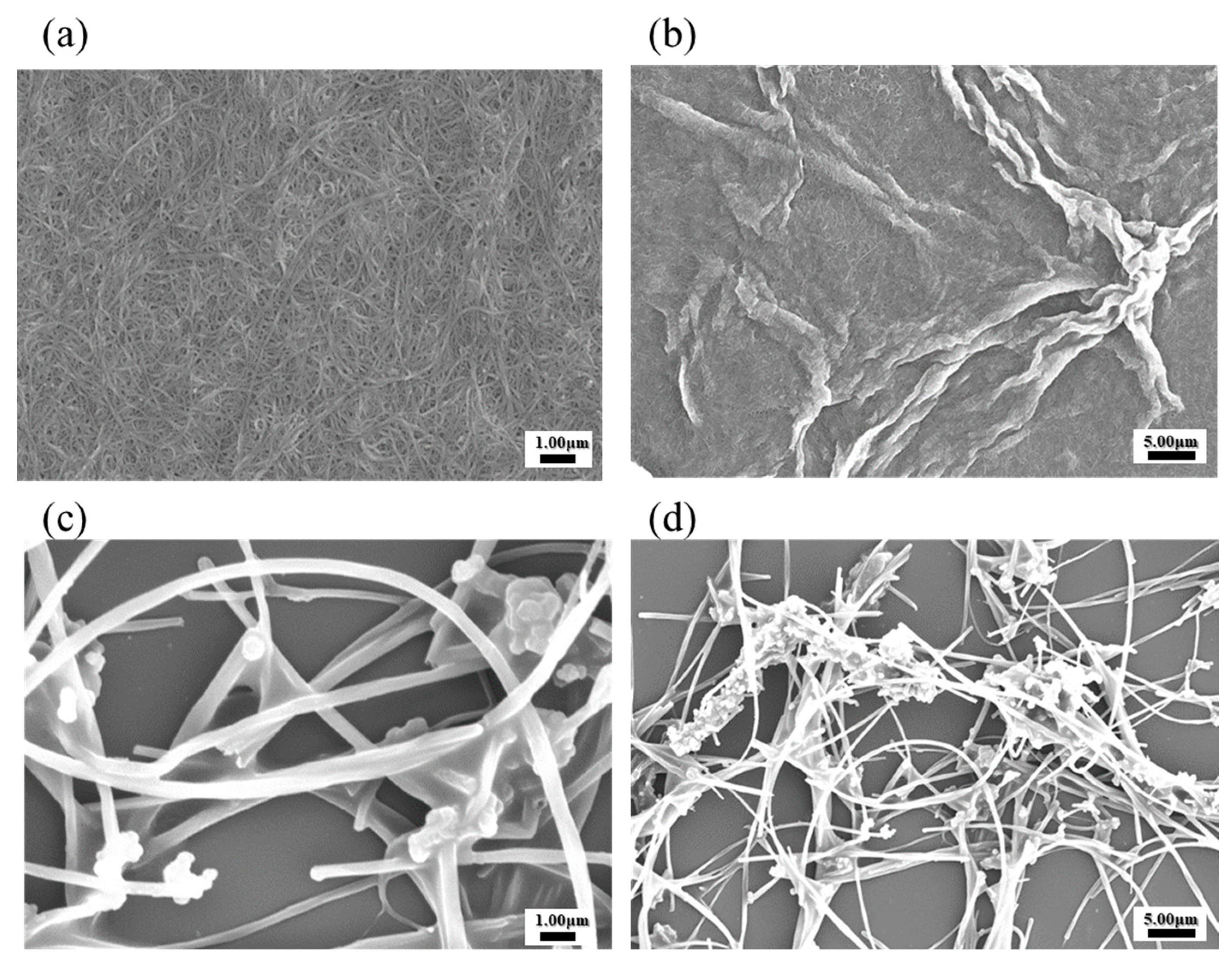

3.3. Morphological Analysis of SWCNTs and MWCNTs via SEM

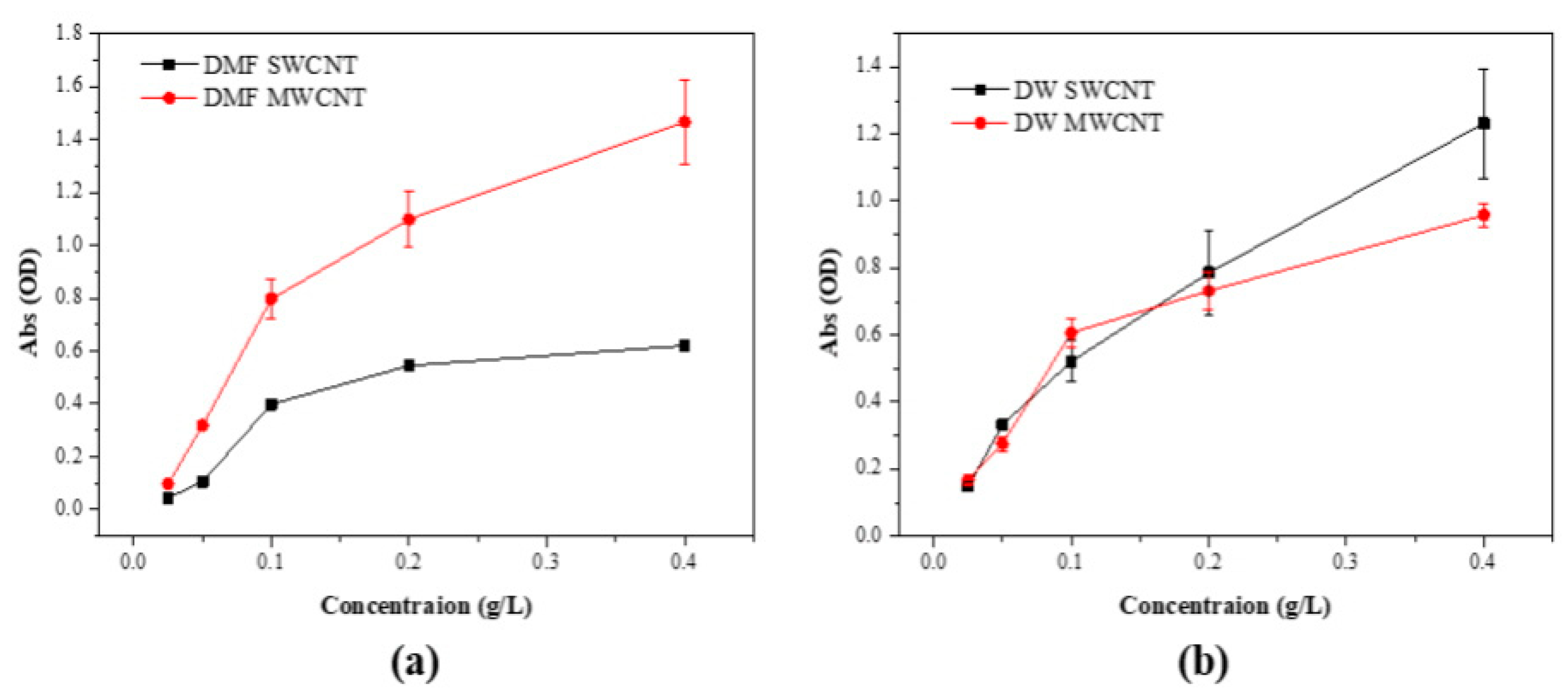

3.4. UV–Visible Spectral Analysis of CNT Dispersions

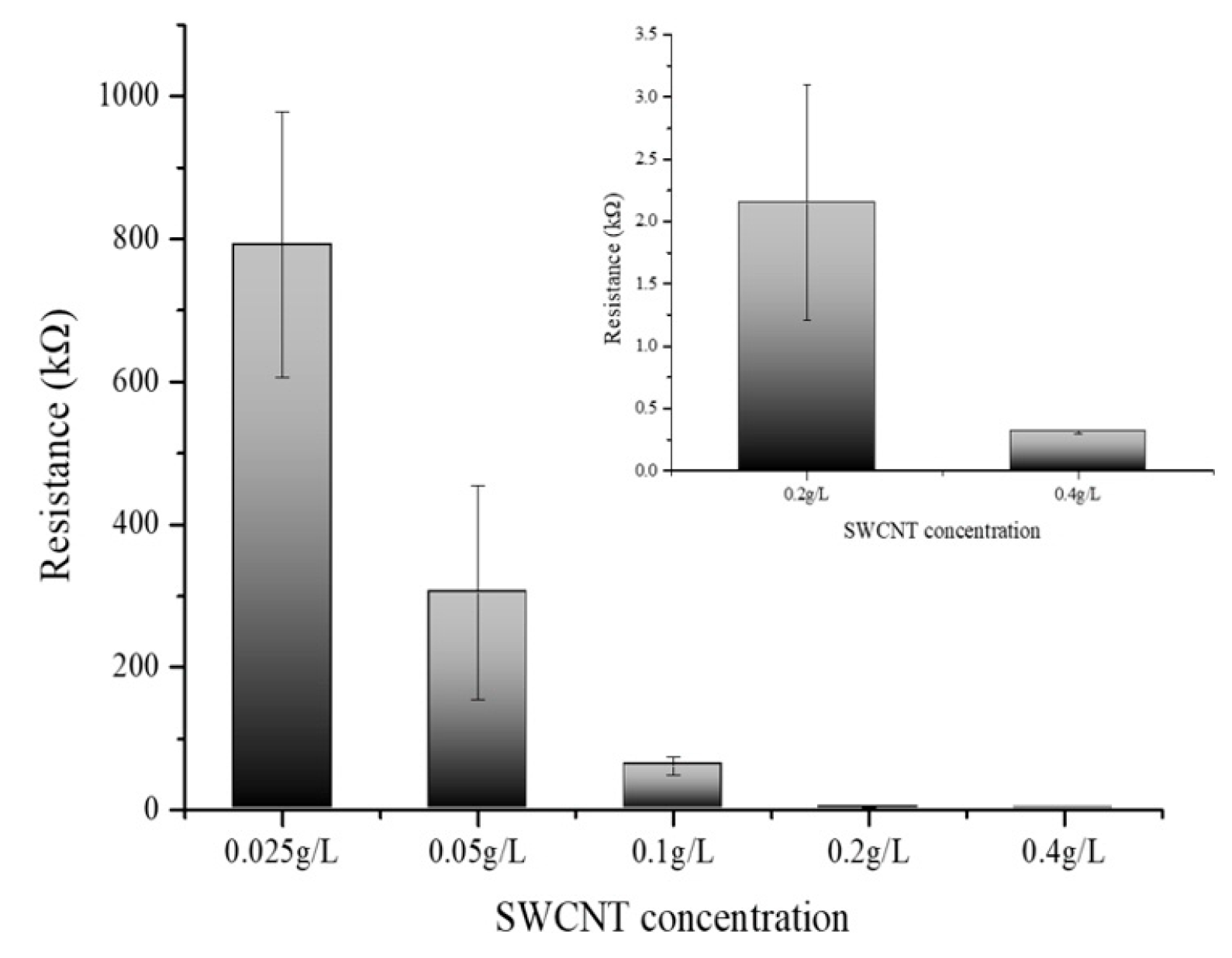

3.5. Quantitative Analysis of Electrical Resistance in CNT Dispersions

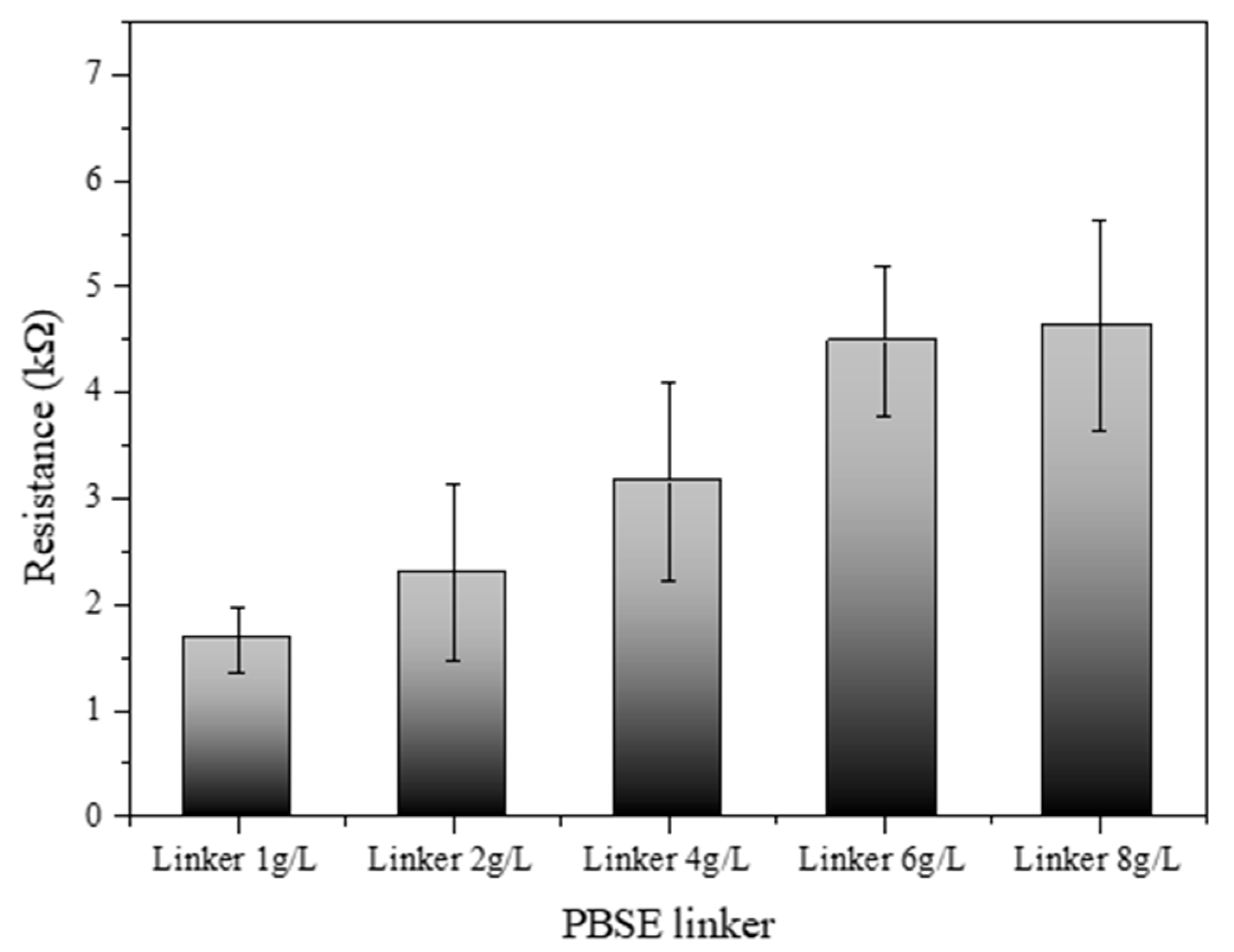

3.6. Electrical Resistance Variation with Developed Biosensors with PBSE Concentrations

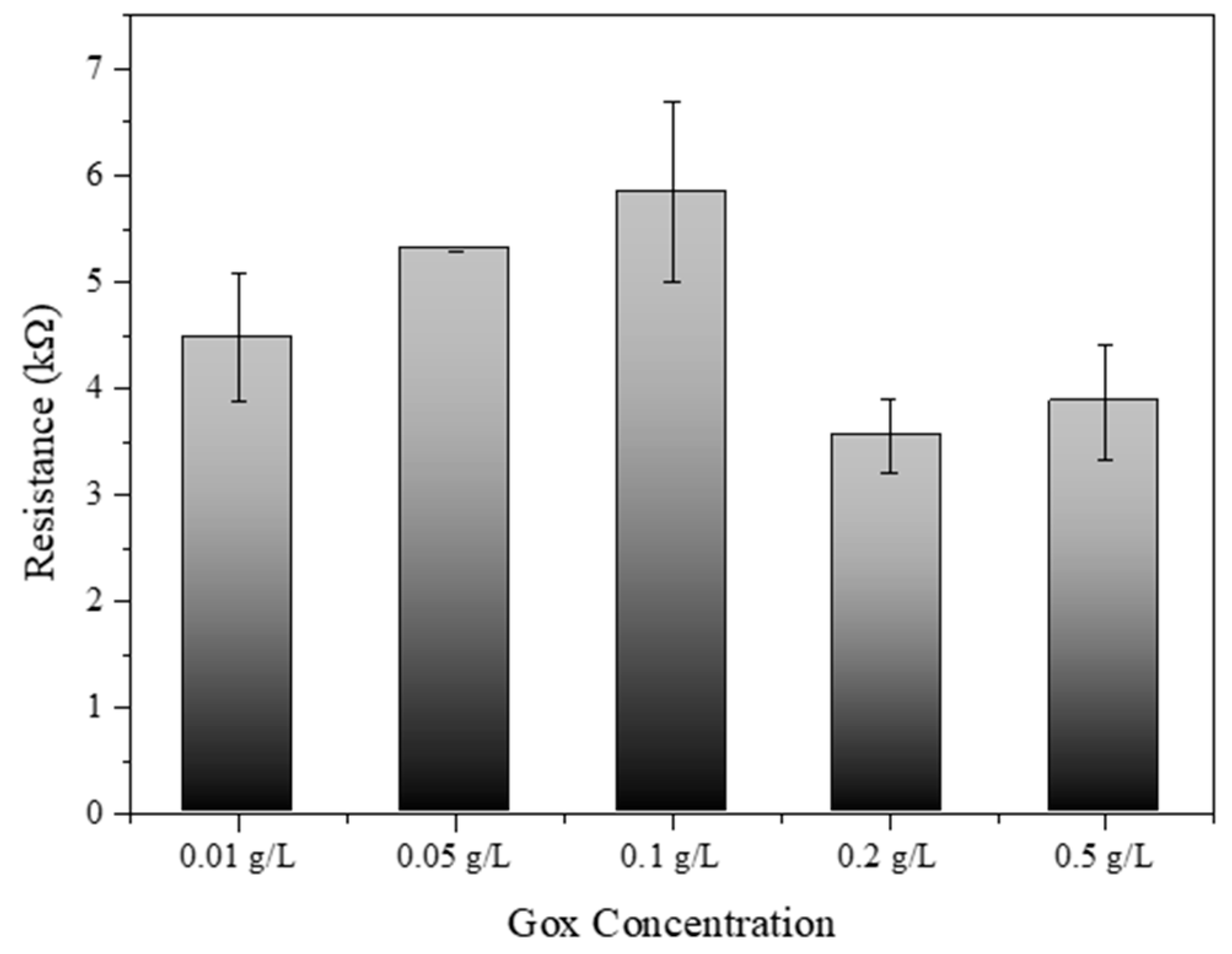

3.7. Optimization of Gox Concentration with Developed Biosensors

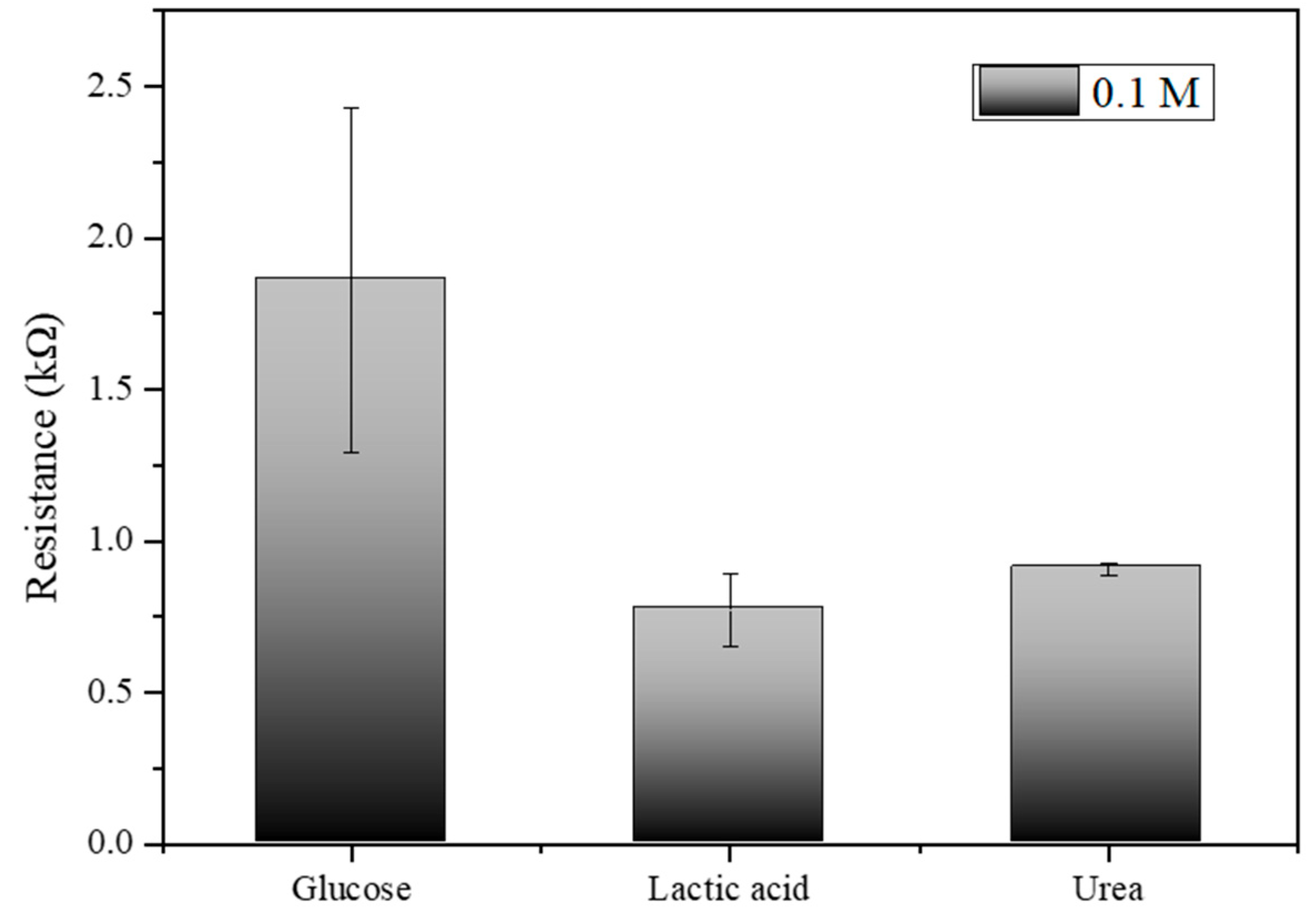

3.8. Glucose Concentration Impact on Electrical Resistance in the Developed Biosensors

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lotfy, M.; Adeghate, J.; Kalasz, H.; Singh, J.; Adeghate, E. Chronic Complications of Diabetes Mellitus: A Mini Review. Curr. Diabetes Rev. 2017, 13, 3–10. [Google Scholar] [CrossRef]

- Diabetes Care in the Hospital: Standards of Medical Care in Diabetes. Diabetes Care 2020, 44 (Suppl. 1), S211–S220. [CrossRef]

- Erbach, M.; Freckmann, G.; Hinzmann, R.; Kulzer, B.; Ziegler, R.; Heinemann, L.; Schnell, O. Interferences and Limitations in Blood Glucose Self-Testing. J. Diabetes Sci. Technol. 2016, 10, 1161–1168. [Google Scholar] [CrossRef] [PubMed]

- Gao, F.; Liu, C.; Zhang, L.; Liu, T.; Wang, Z.; Song, Z.; Cai, H.; Fang, Z.; Chen, J.; Wang, J.; et al. Wearable and flexible electrochemical sensors for sweat analysis: A review. Microsyst. Nanoeng. 2023, 9, 1. [Google Scholar] [CrossRef]

- Wani, M.Y.; Ganie, N.A.; Dar, K.A.; Dar, S.Q.; Khan, A.H.; Khan, N.A.; Zahmatkesh, S.; Manzar, M.S.; Banerjee, R. Nanotechnology future in food using carbohydrate macromolecules: A state-of-the-art review. Int. J. Biol. Macromol. 2023, 239, 124350. [Google Scholar] [CrossRef] [PubMed]

- Sobhan, A.; Oh, J.H.; Park, M.K.; Lee, J. Reusability of a single-walled carbon nanotube-based biosensor for detecting peanut allergens and Y. enterocolitica. Microelectron. Eng. 2020, 225, 111281. [Google Scholar] [CrossRef]

- Hina, A.; Saadeh, W. Noninvasive Blood Glucose Monitoring Systems Using Near-Infrared Technology—A Review. Sensors 2022, 22, 485. [Google Scholar] [CrossRef] [PubMed]

- Psoma, S.D.; Kanthou, C. Wearable Insulin Biosensors for Diabetes Management: Advances and Challenges. Biosensors 2023, 13, 719. [Google Scholar] [CrossRef]

- Sobhan, A.; Lee, J.; Pakr, M.K.; Oh, J.H. Rapid detection of Yersinia enterocolitica using a single–walled carbon nanotube-based biosensor for Kimchi product. LWT 2019, 108, 48–54. [Google Scholar] [CrossRef]

- Joseph, W. Carbon-Nanotube Based Electrochemical Biosensors: A Review. Electroanalysis 2005, 17, 7–14. [Google Scholar] [CrossRef]

- Sireesha, M.; Babu, V.J.; Kiran, A.S.K.; Ramakrishna, S. A review on carbon nanotubes in biosensor devices and their applications in medicine. Nanocomposites 2018, 4, 2. [Google Scholar] [CrossRef]

- Janssen, J.; Lambeta, M.; White, P.; Byagowi, A. Carbon Nanotube-Based Electrochemical Biosensor for Label-Free Protein Detection. Biosensors 2019, 9, 144. [Google Scholar] [CrossRef] [PubMed]

- Liu, P.; Jiao, Y.; Chai, X.; Ma, Y.; Liu, S.; Fang, X.; Fan, F.; Xue, L.; Han, J.; Liu, Q. High-performance electric and optical biosensors based on single-walled carbon nanotubes. J. Lumin. 2022, 250, 119084. [Google Scholar] [CrossRef]

- Nißler, R.; Ackermann, J.; Ma, C.; Kruss, S. Prospects of fluorescent single-chirality carbon nanotube-based biosensors. Anal. Chem. 2022, 94, 9941–9951. [Google Scholar] [CrossRef] [PubMed]

- Alatzoglou, C.; Tzianni, E.I.; Patila, M.; Trachioti, M.G.; Prodromidis, M.I.; Stamatis, H. Structure-Function Studies of Glucose Oxidase in the Presence of Carbon Nanotubes and Bio-Graphene for the Development of Electrochemical Glucose Biosensors. Nanomaterials 2024, 14, 85. [Google Scholar] [CrossRef] [PubMed]

- Yoon, H.; Russ, T.; Hwang, B. Dispersibility study of carbon nanotubes using multiple light scattering: A mini-review. Colloid Interface Sci. Commun. 2023, 52, 100686. [Google Scholar] [CrossRef]

- Lee, J. Carbon Nanotube-Based Biosensors Using Fusion Technologies with Biologicals & Chemicals for Food Assessment. Biosensors 2023, 13, 183. [Google Scholar] [CrossRef] [PubMed]

- Gao, Y.; Luo, J.; Li, Z.; Teng, F.; Zhang, J.; Gao, S.; Ma, M.; Zhou, X.; Tao, X. Dispersion of carbon nanotubes in aqueous cementitious materials: A review. Nanotechnol. Rev. 2023, 12, 20220560. [Google Scholar] [CrossRef]

- Sobhan, A.; Oh, J.H.; Park, M.K.; Kim, S.W.; Park, C.; Lee, J. Single walled carbon nanotube-based biosensor for detection of peanut allergy-inducing protein ara h1. Korean J. Chem. Eng. 2018, 35, 172–178. [Google Scholar] [CrossRef]

- Oishi, Y.; Ogi, H.; Hagiwara, S.; Otani, M.; Kusakabe, K. Theoretical Analysis on the Stability of 1-Pyrenebutanoic Acid Succinimidyl Ester Adsorbed on Graphene. ACS Omega 2022, 7, 31120–31125. [Google Scholar] [CrossRef]

- Rostami, A.; Abdelrasoul, A.; Shokri, Z.; Shirvandi, Z. Applications and mechanisms of free and immobilized laccase in detoxification of phenolic compounds. Korean J. Chem. Eng. 2022, 39, 821–832. [Google Scholar] [CrossRef]

- Kim, D.S.; Yang, X.; Lee, J.H.; Yoo, H.Y.; Park, C.; Kim, S.W.; Lee, J. Development of GO/Co/Chitosan-Based Nano-Biosensor for Real-Time Detection of D-Glucose. Biosensors 2022, 12, 464. [Google Scholar] [CrossRef]

- Rizvi, M.; Gerengi, H.; Gupta, P. Functionalization of Nanomaterials: Synthesis and Characterization. In Functionalized Nanomaterials for Corrosion Mitigation: Synthesis, Characterization, and Applications; American Chemical Society: Washington, DC, USA, 2022; Volume 1, pp. 1–26. [Google Scholar] [CrossRef]

- Kumar, N.; Sinha Ray, S. Synthesis and Functionalization of Nanomaterials, Processing of Polymer-based Nanocomposites. Polym.-Based Nanocomposites 2018, 277, 15–55. [Google Scholar] [CrossRef]

- Yang, X.; Chen, Y.; Zhang, C.; Duan, G.; Jiang, S. Electrospun carbon nanofibers and their reinforced composites: Preparation, modification, applications, and perspectives. Compos. Part. B Eng. 2022, 249, 110386. [Google Scholar] [CrossRef]

- Thongam, D.D.H. Chaturvedi, Functionalization of Pristine, Metallic, and Semiconducting-SWCNTs by ZnO for Efficient Charge Carrier ransfer: Analysis through Critical Coagulation Concentration. ACS Omega 2022, 13, 14784–14796. [Google Scholar] [CrossRef]

- Podkolodnaya, Y.A.; Kokorina, A.A.; Ponomaryova, T.S.; Goryacheva, O.A.; Drozd, D.D.; Khitrov, M.S.; Huang, L.; Yu, Z.; Tang, D.; Goryacheva, Y.I. Luminescent Composite Carbon/SiO2 Structures: Synthesis and Applications. Biosensors 2022, 12, 392. [Google Scholar] [CrossRef] [PubMed]

- Chamorro, R.; de Juan-Fernández, L.; Nieto-Ortega, B.; Mayoral, M.J.; Casado, S.; Ruiz-González, L.; Pérez, E.M.; González-Rodríguez, D. Reversible dispersion and release of carbon nanotubes via cooperative clamping interactions with hydrogen-bonded nanorings. Chem. Sci. 2018, 17, 4176–4184. [Google Scholar] [CrossRef] [PubMed]

- Daneshvar, F.; Chen, H.; Noh, K.; Sue, H.J. Critical challenges and advances in the carbon nanotube–metal interface for next-generation electronics. Nanoscale Adv. 2021, 3, 942–962. [Google Scholar] [CrossRef]

- Stando, G.; Han, S.; Kumanek, B.; Łukowiec, D.; Janas, D. Tuning wettability and electrical conductivity of single-walled carbon nanotubes by the modified Hummers method. Sci. Rep. 2022, 12, 4358. [Google Scholar] [CrossRef]

- Krasulina, A.; Myasnikova, Y.; Saik, V.; Predtechensky, M.; Smirnov, S.N. Improved Characterization of Aqueous Single-Walled Carbon Nanotube Dispersions Using Dynamic Light Scattering and Analytical Centrifuge Methods. ACS Omega 2023, 8, 39233–39241. [Google Scholar] [CrossRef]

- Metze, F.K.; Sant, S.; Meng, Z.; Klok, H.A.; Kaur, K. Swelling-Activated, Soft Mechanochemistry in Polymer Materials. Langmuir 2023, 39, 3546–3557. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, H.H.; Lee, S.H.; Lee, U.J.; Fermin, D.C.; Kim, M. Immobilized Enzymes in Biosensor Applications. Materials 2019, 12, 121. [Google Scholar] [CrossRef] [PubMed]

- Manish, D.K.; Andleeb, Z.; Mohd, A.; Mukesh, M.; Laxmi, A.; Siddhartha, S.; Shruti, S.; Ram, U.S.; Ruben, M.B.; Vivek, B.K. Improvement Strategies, Cost Effective Production, and Potential Applications of Fungal Glucose Oxidase (GOD): Current Updates. Front. Microbiol. 2017, 8, 1032. [Google Scholar] [CrossRef]

- Kim, D.S.; Yang, X.; Sobhan, A.; Park, C.; Kim, S.; Lee, J. Development of a glucose enzyme fuel cell based on thin film electrode using biocatalysts. Biotechnol. Bioprocess Eng. 2024, 29, 529–542. [Google Scholar] [CrossRef]

- Hsu, C.W.; Wang, G.J. Highly sensitive glucose biosensor based on Au–Ni coaxial nanorod array having high aspect ratio. Biosens. Bioelectron. 2014, 56, 204–209. [Google Scholar] [CrossRef]

- Palsaniya, S.; Nemade, H.B.; Dasmahapatra, A.K. Mixed Surfactant-Mediated Synthesis of Hierarchical PANI Nanorods for an Enzymatic Glucose Biosensor. ACS Appl. Polym. Mater. 2019, 1, 647–656. [Google Scholar] [CrossRef]

- Sanaeifar, N.; Rabiee, M.; Abdolrahim, M.; Tahriri, M.; Vashaee, D.; Tayebi, L. A novel electrochemical biosensor based on Fe3O4 nanoparticles-polyvinyl alcohol composite for sensitive detection of glucose. Anal. Biochem. 2017, 519, 19–26. [Google Scholar] [CrossRef] [PubMed]

- Zhai, D.; Liu, B.; Shi, Y.; Pan, L.; Wang, Y.; Li, W.; Zhang, R.; Yu, G. Highly Sensitive Glucose Sensor Based on Pt Nanoparticle/Polyaniline Hydrogel Heterostructures. ACS Nano 2013, 7, 3540–3546. [Google Scholar] [CrossRef]

| Electrode | Substrate | Linear Range (mM) | Detection Limit (uM) | Ref |

|---|---|---|---|---|

| SWCNT-Gox | Glucose | 1.0–100 | 10.0 | This study |

| Au–Nicoaxialnanorad array/GOx | Glucose | 0.0275–27.75 | 5.5 | [36] |

| PANI-SDS-F127 (1:1)/GOx | Glucose | 5.0–50 | 3.2 | [37] |

| GOx/PVA-Fe3O4/Sn | Glucose | 0.005–30 | 8.0 | [38] |

| GOx/PtNP/PANI/PtE | Glucose | 0.01–8.0 | 0.7 | [39] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, D.-S.; Sobhan, A.; Oh, J.-H.; Lee, J.; Park, C.; Lee, J. Development of Single-Walled Carbon Nanotube-Based Electrodes with Enhanced Dispersion and Electrochemical Properties for Blood Glucose Monitoring. Biosensors 2024, 14, 630. https://doi.org/10.3390/bios14120630

Kim D-S, Sobhan A, Oh J-H, Lee J, Park C, Lee J. Development of Single-Walled Carbon Nanotube-Based Electrodes with Enhanced Dispersion and Electrochemical Properties for Blood Glucose Monitoring. Biosensors. 2024; 14(12):630. https://doi.org/10.3390/bios14120630

Chicago/Turabian StyleKim, Dong-Sup, Abdus Sobhan, Jun-Hyun Oh, Jahyun Lee, Chulhwan Park, and Jinyoung Lee. 2024. "Development of Single-Walled Carbon Nanotube-Based Electrodes with Enhanced Dispersion and Electrochemical Properties for Blood Glucose Monitoring" Biosensors 14, no. 12: 630. https://doi.org/10.3390/bios14120630

APA StyleKim, D.-S., Sobhan, A., Oh, J.-H., Lee, J., Park, C., & Lee, J. (2024). Development of Single-Walled Carbon Nanotube-Based Electrodes with Enhanced Dispersion and Electrochemical Properties for Blood Glucose Monitoring. Biosensors, 14(12), 630. https://doi.org/10.3390/bios14120630