Surface Morphological Features of Molybdenum Irradiated by a Single Laser Pulse

Abstract

1. Introduction

2. Material and Experimental Section

2.1. Sample Characteristics

2.2. Laser Source

3. Results and Discussion

4. Conclusions

- the crater is larger and shallower in the case of Mo;

- the volume of Mo ablated from the surface by a single laser pulse is about ten times that of W owing to the remarkably higher latent heat of fusion and latent heat of vaporization of W;

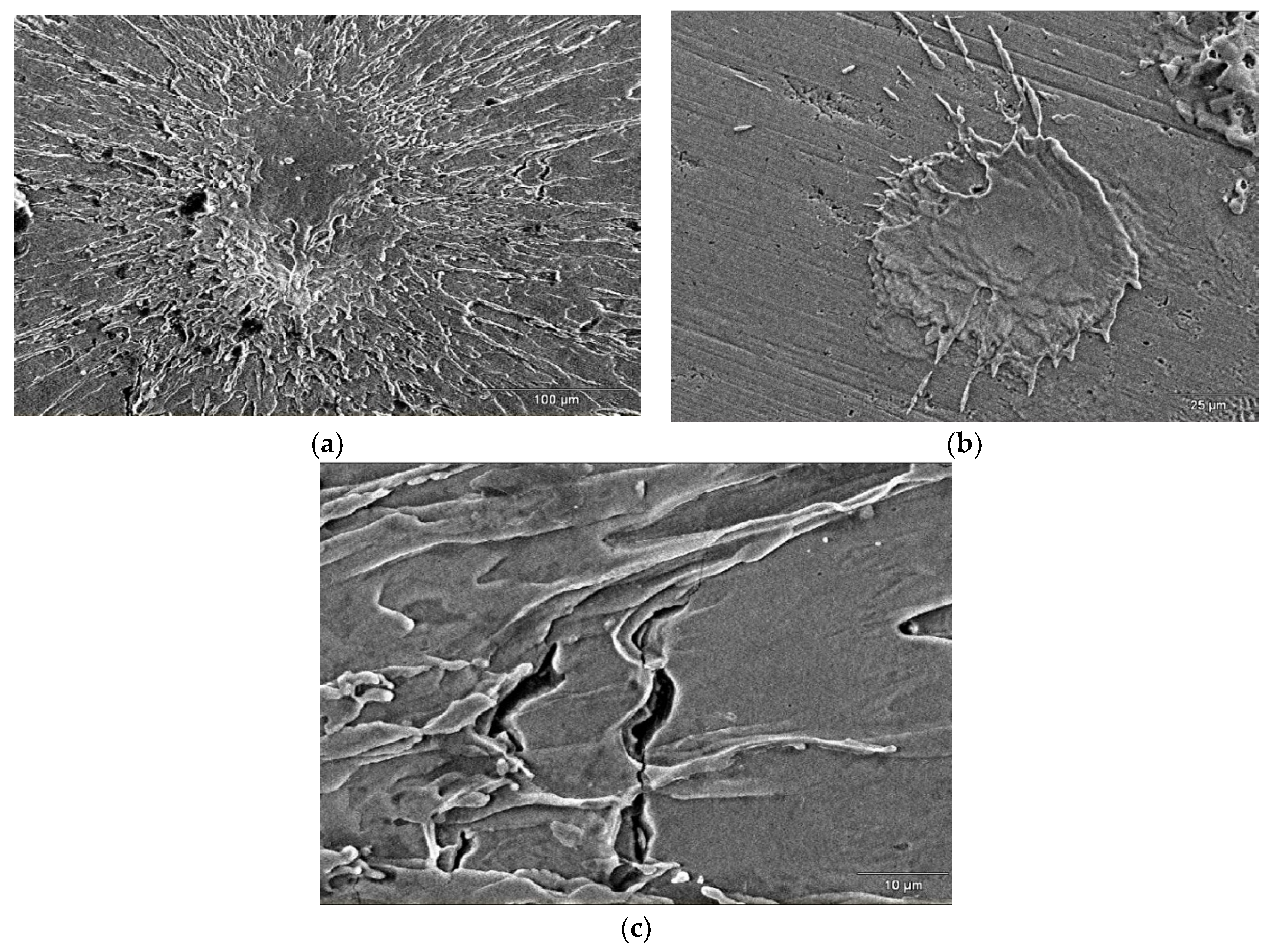

- the morphological features of the Mo crater walls are characterized by long filaments, not observed in the case of W, because the lower viscosity and surface tension of Mo allow an easier flow of the liquid metal;

- grain growth has been observed in a material layer of about 1 mm under the crater, with the effects decreasing as the distance from the surface increases.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Riccardi, B.; Pizzuto, A.; Orsini, A.; Libera, S.; Visca, E.; Bertamini, L.; Casadei, F.; Severini, E.; Montanari, R.; Vesprini, R.; et al. Tungsten thick coatings for plasma facing components. Fusion Technol. 1998, 31, 223–226. [Google Scholar]

- Roedig, M.; Kuehnlein, W.; Linke, J.; Merola, M.; Rigal, E.; Schedler, B.; Visca, E. Investigation of tungsten alloys as plasma facing materials for the ITER divertor. Fusion Eng. Des. 2002, 61, 135–140. [Google Scholar] [CrossRef]

- Bolt, H.; Barabash, V.; Krauss, W.; Linke, J.; Neu, R.; Suzuki, S.; Nyoshida, N. Materials for the plasma facing components of fusion reactors. J. Nucl. Mater. 2004, 329, 66–73. [Google Scholar] [CrossRef]

- Uytdenhouwen, I.; Decreton, M.; Hirai, T.; Linke, J.; Pintsuk, G.; Van Oost, G. Influence of recrystallization on thermal shock resistance of various tungsten grades. J. Nucl. Mater. 2007, 363, 1099–1103. [Google Scholar] [CrossRef]

- Maier, H.; Hirai, T.; Rubel, M.; Neu, R.; Mertens, P.; Greuner, H.; Hopf, C.; Matthews, G.F.; Neubauer, O.; Piazza, G.; et al. Tungsten and beryllium armour development for the JET ITER-like wall project. Nucl. Fusion 2007, 47, 222. [Google Scholar] [CrossRef]

- Herrmann, A.; Greuner, H.; Fuchs, J.C.; de Marné, P.; Neu, R.; ASDEX Upgrade Team. Experiences with tungsten coatings in high heat flux tests and under plasma load in ASDEX Upgrade. Phys. Scr. 2009, T138, 014059. [Google Scholar] [CrossRef]

- Cui, S.; Simmonds, M.; Qin, W.; Ren, F.; Tynan, G.R.; Doerner, R.P.; Chen, R. Thermal conductivity reduction of tungsten plasma facing material due to helium plasma irradiation in PISCES using the improved 3-omega method. J. Nucl. Mater. 2017, 486, 267–273. [Google Scholar] [CrossRef]

- Kajita, S.; De Temmerman, G.; Morgan, T.; Van Eden, S.; de Kruif, T.; Ohno, N. Thermal response of nanostructured tungsten. Nucl. Fusion 2014, 54, 033005. [Google Scholar] [CrossRef]

- Uytdenhouwen, I.; Massaut, V.; Linke, J.; Van Oost, G. Plasma wall interaction phenomena on tungsten armour materials for fusion applications. In Proceedings of the International Youth Nuclear Congress 2008, Interlaken, Switzerland, 20–26 September 2008. [Google Scholar]

- Lemahieu, N.; Linke, J.; Pintsuk, G.; Van Oost, G.; Wirtz, M.; Zhou, Z. Performance of yttrium doped tungsten under “edge localized mode”-like loading conditions. Phys. Scr. 2014, T159, 014035. [Google Scholar] [CrossRef]

- Shirokova, V.; Laas, T.; Ainsaar, A.; Priimets, J.; Ugaste, U.; Väli, B.; Gribkov, V.A.; Maslyaev, S.A.; Demina, E.V.; Dubrovsky, A.D.; et al. Armor materials’ behavior under repetitive dense plasma shots. Phys. Scr. 2014, T161, 014045. [Google Scholar] [CrossRef]

- De Temmerman, G.C.; Bystrov, K.E.; Zielinski, J.J.; Balden, M.; Matern, G.; Arnas, C.; Marot, L. Nanostructuring of molybdenum and tungsten surfaces by low-energy helium ions. J. Vac. Sci. Technol. A Vac. Surf. Film. 2012, 30, 41306. [Google Scholar] [CrossRef]

- Tripathi, J.K.; Novakowski, T.J.; Hassanein, A. Tailoring molybdenum nanostructure evolution by low energy He+ ion irradiation. Appl. Surf. Sci. 2015, 353, 1070–1081. [Google Scholar] [CrossRef]

- Sinclair, G.; Tripathi, J.K.; Diwakar, P.K.; Hassanein, A. Structural response of transient heat loading on molybdenum surface exposed to low-energy helium ion irradiation. Nucl. Fusion 2016, 56, 36005. [Google Scholar] [CrossRef]

- Brooks, J.N.; El-Guebaly, L.; Hassanein, A.; Sizyuk, T. Plasma-facing material alternatives to tungsten. Nucl. Fusion 2015, 55, 43002. [Google Scholar] [CrossRef]

- Sinclair, G.; Tripathi, J.K.; Diwakar, P.K.; Hassanein, A. Melt layer erosion during ELM-like heat loading on molybdenum as an alternative plasma-facing material. Sci. Rep. 2017, 7, 12273. [Google Scholar] [CrossRef]

- Rieth, M.; Dudarev, S.L.; De Vicente, S.M.G.; Aktaa, J.; Ahlgren, T.; Antusch, S.; Armstrong, D.E.J.; Balden, M.; Baluc, N.; Barthe, M.-F.; et al. Recent progress in research on tungsten materials for nuclear fusion applications in Europe. J. Nucl. Mater. 2013, 432, 482–500. [Google Scholar] [CrossRef]

- Cottrell, G.A. Sigma phase formation in irradiated tungsten, tantalum and molybdenum in a fusion power plant. J. Nucl. Mater. 2004, 334, 166–168. [Google Scholar] [CrossRef]

- Sizyuk, T.; Hassanein, A. Dynamic analysis and evolution of mixed materials bombarded with multiple ions beams. J. Nucl. Mater. 2010, 404, 60. [Google Scholar] [CrossRef]

- Sharpe, J.P.; Kolasinski, R.D.; Shimada, M.; Calderoni, P.; Causey, R.A. Retention behavior in tungsten and molybdenum exposed to high fluences of deuterium ions in TPE. J. Nucl. Mater. 2009, 390, 709–712. [Google Scholar] [CrossRef]

- Richetta, M.; Gaudio, P.; Montanari, R.; Pakhomova, E.; Antonelli, L. Laser pulse simulation of high energy transient thermal loads on bulk and plasma sprayed W for NFR. Mater. Sci. Forum 2017, 879, 1576–1581. [Google Scholar] [CrossRef]

- Montanari, R.; Pakhomova, E.; Pizzoferrato, R.; Richetta, M.; Varone, A. Laser pulse effects on plasma sprayed and bulk tungsten. Metals 2017, 7, 454. [Google Scholar] [CrossRef]

- Gaudio, P.; Montanari, R.; Pakhomova, E.; Richetta, M.; Varone, A. W-1%La2O3 submitted to a single laser pulse: Effect of particles on heat transfer and surface morphology. Metals 2018, 8, 389. [Google Scholar] [CrossRef]

- Rubel, M.; Brezinsek, S.; Coenen, J.W.; Huber, A.; Kirschner, A.; Kreter, A.; Petersson, P.; Philipps, V.; Pospieszczyk, A.; Schweer, B.; et al. Overview of wall probes for erosion and deposition studies in the TEXTOR tokamak. Matter Radiat. Extrem. 2017, 2, 87–104. [Google Scholar] [CrossRef]

- International Centre for Diffraction Data; JCPDS: Newtown Square, PA, USA, 1907.

- Williamson, G.K.; Smallman, R.A. Dislocation densities in some annealed and cold-worked metals from measurements on the X-ray Debye-Scherrer spectrum. Philos. Mag. 1956, 1, 34–45. [Google Scholar] [CrossRef]

- Gondi, P.; Donato, A.; Montanari, R.; Sili, A. Miniaturized test method for the mechanical characterization of structural materials for fusion reactors. J. Nucl. Mater. 1996, 233, 1557–1560. [Google Scholar] [CrossRef]

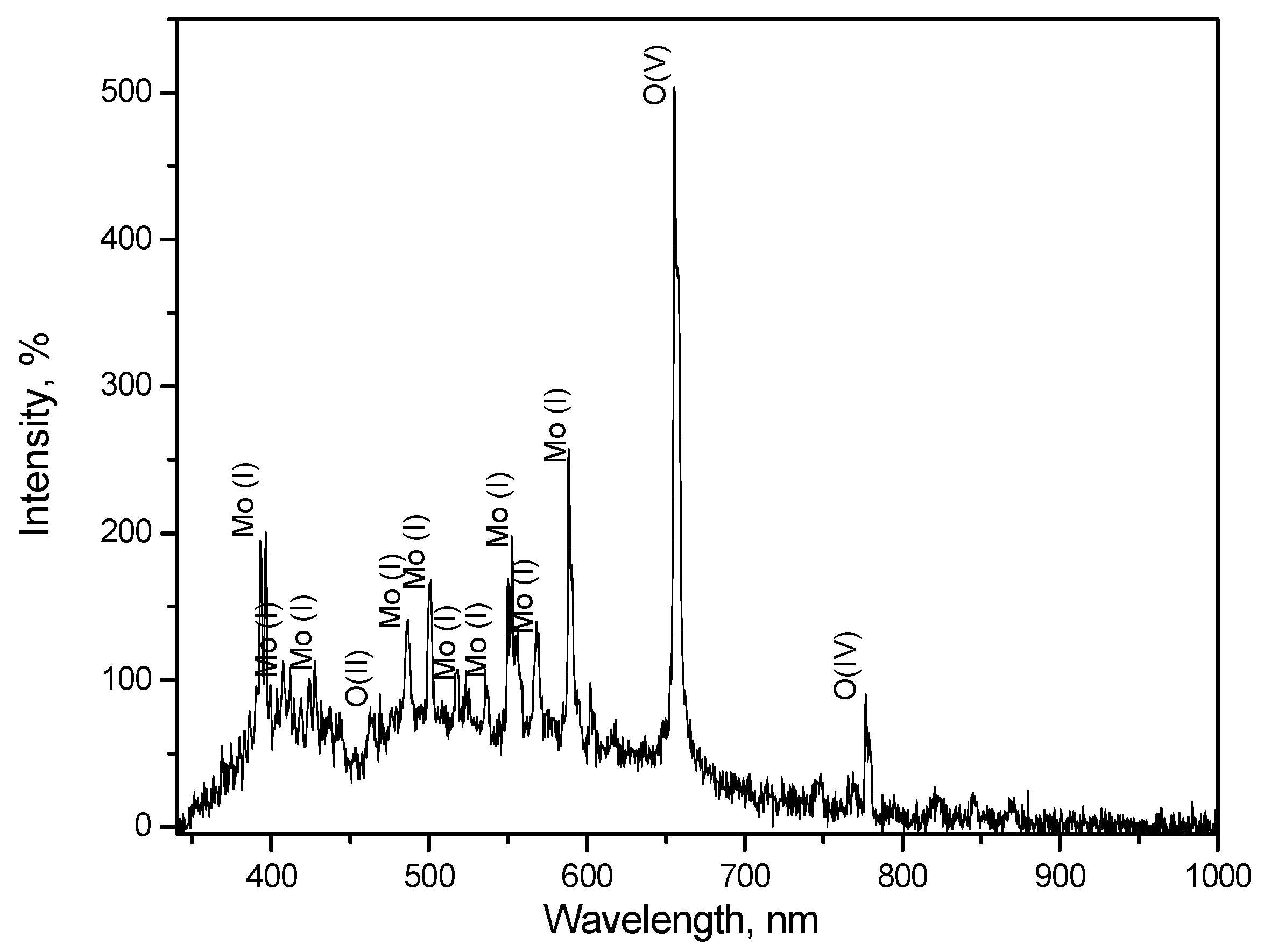

- Francucci, M.; Gaudio, P.; Martellucci, S.; Richetta, M. Spectroscopy methods and applications of the Tor Vergata laser-plasma facility driven by GW-level laser system. Int. J. Spectrosc. 2011, 2011. [Google Scholar] [CrossRef]

- Dong, H.; Wen, B.; Melnik, R. Relative importance of grain boundaries and size effects in thermal conductivity of nanocrystalline materials. Nat. Sci. Rep. 2014, 4, 7037. [Google Scholar] [CrossRef]

- Swartz, E.T.; Pohl, R.O. Thermal boundary resistance. Rev. Mod. Phys. 1989, 61, 605. [Google Scholar] [CrossRef]

- Nan, C.-W.; Birringer, R.; Clarke, D.R.; Gleiter, H. Effective thermal conductivity of particulate composites with interfacial thermal resistance. J. Appl. Phys. 1997, 81, 6692–6699. [Google Scholar] [CrossRef]

- Yang, H.-S.; Bai, G.-R.; Thompson, L.; Eastman, J. Interfacial thermal resistance in nanocrystalline yttria-stabilized zirconia. Acta Mater. 2002, 50, 2309–2317. [Google Scholar] [CrossRef]

- Paradis, P.F.; Ishikawa, T.; Koike, N. Non-contact measurements of the surface tension and viscosity of molybdenum using an electrostatic levitation furnace. Int. J. Refract. Met. Hard Mater. 2007, 25, 95–100. [Google Scholar] [CrossRef]

- Paradis, P.F.; Ishikawa, T.; Fujii, R.; Yoda, S. Physical properties of liquid and undercooled tungsten by levitation techniques. Appl. Phys. Lett. 2005, 86, 041901. [Google Scholar] [CrossRef]

- Cagran, C.; Wilthan, B.; Pottlacher, G. Normal spectral emissivity at a wavelength of 684.5 nm and thermophysical properties of solid and liquid molybdenum. In Proceedings of the 5th Symposium on Thermophysical Properties, Boulder, CO, USA, 23–28 June 2003. [Google Scholar]

- Ishikawa, T.; Paradis, P.-F.; Okada, J.T.; Kumar, M.V.; Watanabe, Y. Viscosity of molten Mo, Ta, Os, Re, and W measured by electrostatic levitation. J. Chem. Thermodyn. 2013, 65, 1–6. [Google Scholar] [CrossRef]

- Straus, J.; Kolacek, K.; Schmidt, J.; Frolov, O.; Vilemova, M.; Matejicek, J.; Jager, A.; Juha, L.; Toufarova, M.; Choukourov, A.; et al. Response of fusion plasma-facing materials to nanosecond pulses of extreme ultraviolet radiation. Laser Part. Beam 2018, 36, 293–307. [Google Scholar] [CrossRef]

- Eksaeva, A.; Borodin, D.; Romazanov, J.; Kirschner, A.; Kreter, A.; Eichler, M.; Rasinski, M.; Pospieszczyk, A.; Unterberg, B.; Brezinsek, S.; et al. Surface roughness effect on Mo physical sputtering and re-deposition in the linear plasma device PSI-2 predicted by ERO2.0. Nucl. Mater. Energy 2019, 19, 13–18. [Google Scholar] [CrossRef]

- Wurster, S.; Baluc, N.; Battabyal, M.; Crosby, T.; Du, J.; Garca-Rosales, C.; Hasegawa, A.; Hoffmann, A.; Kimura, A.; Kurishita, H.; et al. Recent progress in R&D on tungsten alloys for divertor structural and plasma facing materials. J. Nucl. Mater. 2013, 442, S181–S189. [Google Scholar]

- Linsmeier, C.; Rieth, M.; Aktaa, J.; Chikada, T.; Hoffmann, A.; Hoffmann, J.; Houben, A.; Kurishita, H.; Jin, X.; Li, M.; et al. Development of advanced high heat flux and plasma-facing materials. Nucl. Fusion 2017, 57, 092007. [Google Scholar] [CrossRef]

| Metal | Z | ρA at 20 °C [g·cm−3] | TM [°C] | TB [°C] | ξ [W·m−1·K−1] | DBTT [°C] | EM [kJ·mole−1] | EV [kJ·mole−1] |

|---|---|---|---|---|---|---|---|---|

| W | 74 | 19.25 | 3422 | 5555 | 110 | +400 | 35.4 | 824 |

| Mo | 42 | 10.22 | 2623 | 4639 | 142 | −20 | 32 | 598 |

| Miller Index {hkl} | 110 | 200 | 211 | 220 | 310 |

|---|---|---|---|---|---|

| JCPDS-ICDD | 100 | 16 | 31 | 9 | 14 |

| Sample | 100 | 8 | 9 | 6 | 4 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Montanari, R.; Pakhomova, E.; Rossi, R.; Richetta, M.; Varone, A. Surface Morphological Features of Molybdenum Irradiated by a Single Laser Pulse. Coatings 2020, 10, 67. https://doi.org/10.3390/coatings10010067

Montanari R, Pakhomova E, Rossi R, Richetta M, Varone A. Surface Morphological Features of Molybdenum Irradiated by a Single Laser Pulse. Coatings. 2020; 10(1):67. https://doi.org/10.3390/coatings10010067

Chicago/Turabian StyleMontanari, Roberto, Ekaterina Pakhomova, Riccardo Rossi, Maria Richetta, and Alessandra Varone. 2020. "Surface Morphological Features of Molybdenum Irradiated by a Single Laser Pulse" Coatings 10, no. 1: 67. https://doi.org/10.3390/coatings10010067

APA StyleMontanari, R., Pakhomova, E., Rossi, R., Richetta, M., & Varone, A. (2020). Surface Morphological Features of Molybdenum Irradiated by a Single Laser Pulse. Coatings, 10(1), 67. https://doi.org/10.3390/coatings10010067