A Highly Efficient Visible Absorber Coating on a Curved Substrate

Abstract

:1. Introduction

2. Materials and Methods

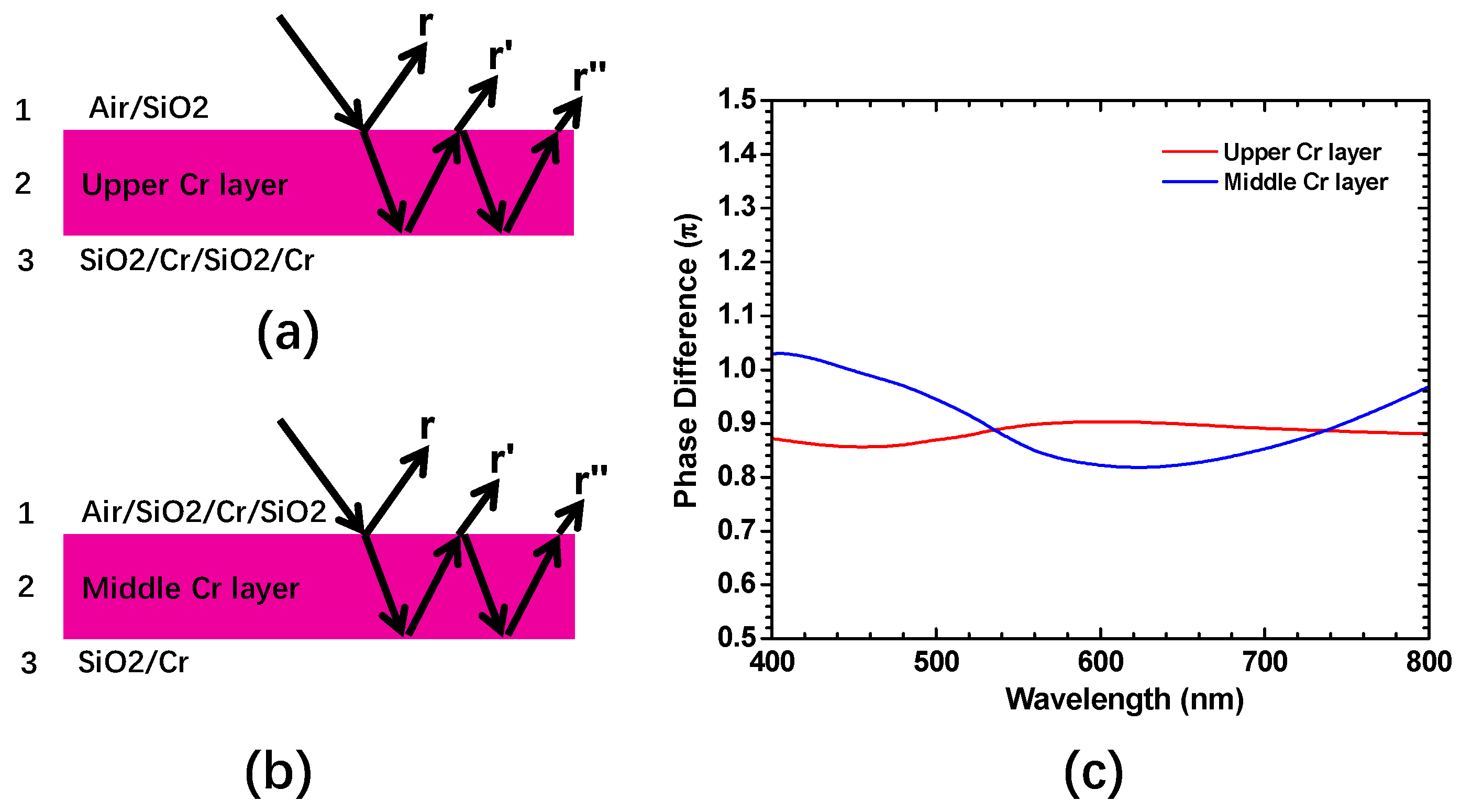

3. Results and Discussions

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Theocharous, E.; Chunnilall, C.J.; Mole, R.; Gibbs, D.; Fox, N.; Shang, N.; Howlett, G.; Jensen, B.; Taylor, R.; Reveles, R.J.; et al. The partial space qualification of a vertically aligned carbon nanotube coating on aluminium substrates for EO applications. Opt. Express 2014, 22, 7290–7307. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.; Luo, F.; Kao, T.S.; Li, X.; Ho, W.G.; Teng, J.; Luo, X.; Hong, M. Design and fabrication of broadband ultralow reflectivity black Si surfaces by laser micro/nanoprocessing. Light Sci. Appl. 2014, 3, e185. [Google Scholar] [CrossRef]

- Liu, X.; Gao, J.; Yang, L.; Wang, X.; Wang, T.; Shen, Z.; Liu, Z.; Liu, H.; Zhang, J.; Li, Z.; et al. Microcavity electrodynamics of hybrid surface plasmon polariton modes in highquality multilayer trench gratings. Light Sci. Appl. 2018, 3, 14. [Google Scholar]

- Liu, Y.; Hong, M. Ultralow broadband optical reflection of silicon nanostructured surfaces coupled with antireflection coating. J. Mater. Sci. 2012, 47, 1594–1597. [Google Scholar] [CrossRef]

- Hagopian, J.G.; Getty, S.A.; Quijada, M.; Tveekrem, J.; Shiri, R.; Roman, P.; Butler, J.; Georgiev, G.; Livas, J.; Hunt, C.; et al. Multiwalled carbon nanotubes for stray light suppression in space flight instruments. In Proceedings of the International Society for Optics and Photonics, San Diego, CA, USA, 1–5 August 2010; Volume 7761, p. 77610F. [Google Scholar]

- Chunnilall, C.J.; Lehman, J.H.; Theocharous, E.; Sanders, A. Infrared hemispherical reflectance of carbon nanotube mats and arrays in the 5–50 um wavelength region. Carbon 2012, 50, 5348–5350. [Google Scholar] [CrossRef]

- Ji, D.; Song, H.; Zeng, X.; Hu, H.; Liu, K.; Zhang, N.; Gan, Q. Broadband absorption engineering of hyperbolic metafilm patterns. Sci. Rep. 2014, 4, 4498. [Google Scholar] [CrossRef] [Green Version]

- Hedayati, M.K.; Javaherirahim, M.; Mozooni, B.; Abdekaziz, R.; Tavassolizadeh, A.; Chakravadhanula, K.S.V.; Zaporojtchenko, V.; Strunkus, T.; Faupel, F.; Elbahri, M. Design of a perfect black absorber at visible frequencies using plasmonic metamaterials. Adv. Mater. 2011, 23, 5410–5414. [Google Scholar] [CrossRef] [Green Version]

- Bora, M.; Behymer, E.M.; Dehlinger, D.A.; Britten, A.J.; Larson, C.C.; Chang, A.S.P.; Munechika, K.; Nguyen, T.H.; Bond, C.T. Plasmonic black metals in resonant nanocavities. Appl. Phys. Lett. 2013, 102, 251105. [Google Scholar] [CrossRef]

- Steglich, M.; Lehr, D.; Ratzsch, S.; Kasebier, K.; Schrempel, F.; Kley, E.; Tunnermann, A. An ultra-black silicon absorber. Laser Photonics Rev. 2014, 8, L13–L17. [Google Scholar] [CrossRef]

- Ding, F.; Mo, L.; Zhu, J.; He, S. Lithography-free, broadband, omnidirectional, and polarization-insensitive thin optical absorber. Appl. Phys. Lett. 2015, 106, 061108. [Google Scholar] [CrossRef]

- Kats, M.A.; Blanchard, R.; Genevet, P.; Capasso, F. Nanometre optical coatings based on strong interference effects in highly absorbing media. Nat. Mater. 2013, 12, 20. [Google Scholar] [CrossRef] [PubMed]

- Lee, K.T.; Ji, C.; Guo, L.J. Wide-angle, polarization-independent ultrathin broadband visible absorbers. Appl. Phys. Lett. 2016, 108, 031107. [Google Scholar] [CrossRef]

- Liu, N.; Mesch, M.; Weiss, T.; Hentschel, M.; Giessen, H. Infrared perfect absorber and its application as plasmonic sensor. Nano Lett. 2010, 10, 2342–2348. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Starr, T.; Starr, A.F.; Padilla, W.J. Infrared spatial and frequency selective metamaterial with near-unity absorbance. Phys. Rev. Lett. 2010, 104, 207403. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, Q.; Gao, J.; Yang, H.; Liu, H. A super meta-cone absorber for near-infrared wavelengths. Plasmonics 2016, 11, 1067–1072. [Google Scholar] [CrossRef]

- Cui, Y.; Xu, J.; Hung, F.K.; Jin, Y.; Kumar, A.; He, S.; Fang, N.X. A thin film broadband absorber based on multi-sized nanoantennas. Appl. Phys. Lett. 2011, 99, 253101. [Google Scholar] [CrossRef]

- Liu, Z.; Liu, H.; Wang, X.; Yang, H.; Gao, J. Large area and broadband ultra-black absorber using microstructured aluminum doped silicon films. Sci. Rep. 2017, 7, 42750. [Google Scholar] [CrossRef] [Green Version]

- Song, H.; Guo, L.; Liu, Z.; Liu, K.; Zeng, X.; Ji, D.; Zhang, N.; Hu, H.; Jiang, S.; Gan, Q. Nanocavity enhancement for ultra-thin film optical absorber. Adv. Mater. 2014, 26, 2737–2743. [Google Scholar] [CrossRef]

- Macleod, H.A. Thin-Film Optical Filters, 4th ed.; CRC Press: Boca Raton, FL, USA; Taylor & Francis Group: London, UK; New York, NY, USA, 2010. [Google Scholar]

- Smith, S.D. Design of multilayer filters by considering two effective interfaces. J. Opt. Soc. Am. A 1958, 48, 43–50. [Google Scholar] [CrossRef]

- Liu, D.; Yu, H.; Yang, Z.; Duan, Y. Ultrathin planar broadband absorber through effective medium design. Nano Res. 2016, 9, 2354–2363. [Google Scholar] [CrossRef]

- Gires, F.; Tournois, P. Interferometre utilisable pour la compression d’impulsions lumineuses modulees en frequence. Comptes Rendus de l’Académie des Sciences Série I. Mathématique 1964, 258, 6112–6615. [Google Scholar]

- Born, M.; Wolf, E. Principles of Optics, 6th ed.; Pergamon Press Ltd.: London, UK, 1980. [Google Scholar]

- Karabacak, T. Thin-film growth dynamics with shadowing and re-emission effects. J. Nanophotonics 2011, 5, 052501. [Google Scholar] [CrossRef] [Green Version]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, R.; Bayan, H.; Yang, F.; Wang, Y.; Liu, Z.; Liu, H.; Shen, Z.; Li, Q.; Li, Z.; Wang, X.; et al. A Highly Efficient Visible Absorber Coating on a Curved Substrate. Coatings 2020, 10, 71. https://doi.org/10.3390/coatings10010071

Gao R, Bayan H, Yang F, Wang Y, Liu Z, Liu H, Shen Z, Li Q, Li Z, Wang X, et al. A Highly Efficient Visible Absorber Coating on a Curved Substrate. Coatings. 2020; 10(1):71. https://doi.org/10.3390/coatings10010071

Chicago/Turabian StyleGao, Ruoqian, Heshig Bayan, Fei Yang, Yanchao Wang, Zhen Liu, Hai Liu, Zhenfeng Shen, Qiang Li, Zizheng Li, Xiaoyi Wang, and et al. 2020. "A Highly Efficient Visible Absorber Coating on a Curved Substrate" Coatings 10, no. 1: 71. https://doi.org/10.3390/coatings10010071