Effect of Annealing on the Structural, Magnetic, Surface Energy and Optical Properties of Co32Fe30W38 Films Deposited by Direct-Current Magnetron Sputtering

Abstract

:1. Introduction

2. Materials and Methods

3. Results

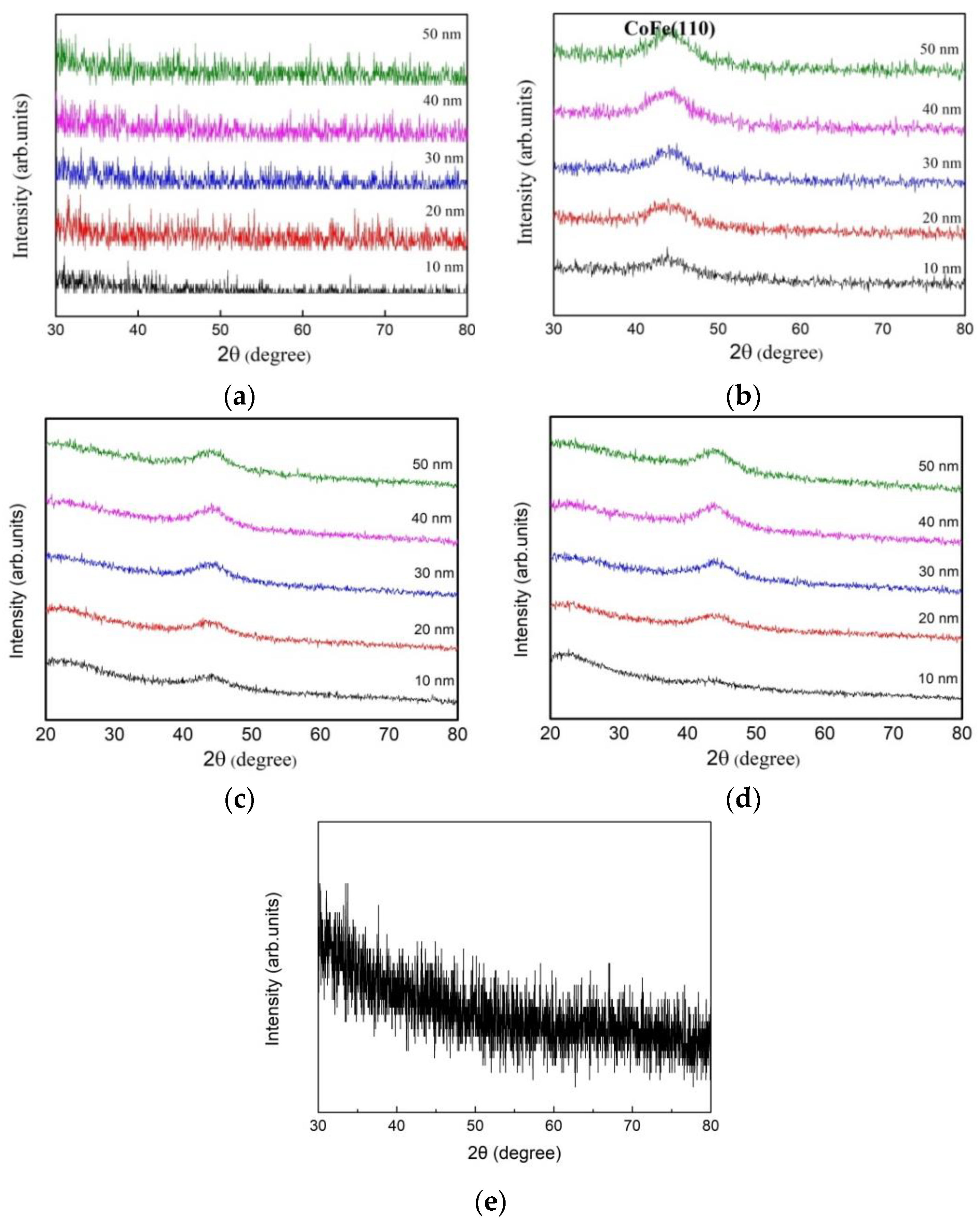

3.1. Structure Property and Composition Analysis

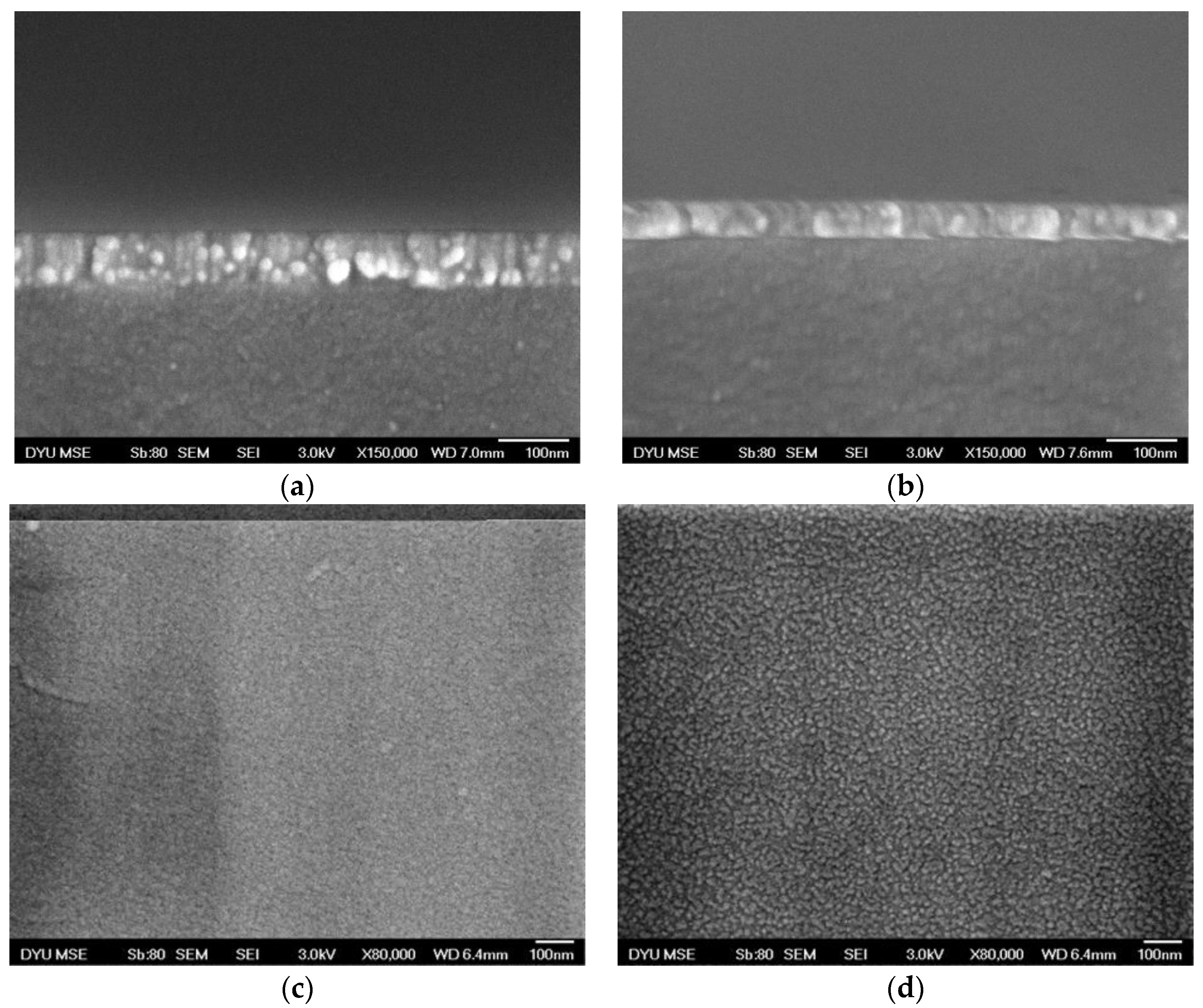

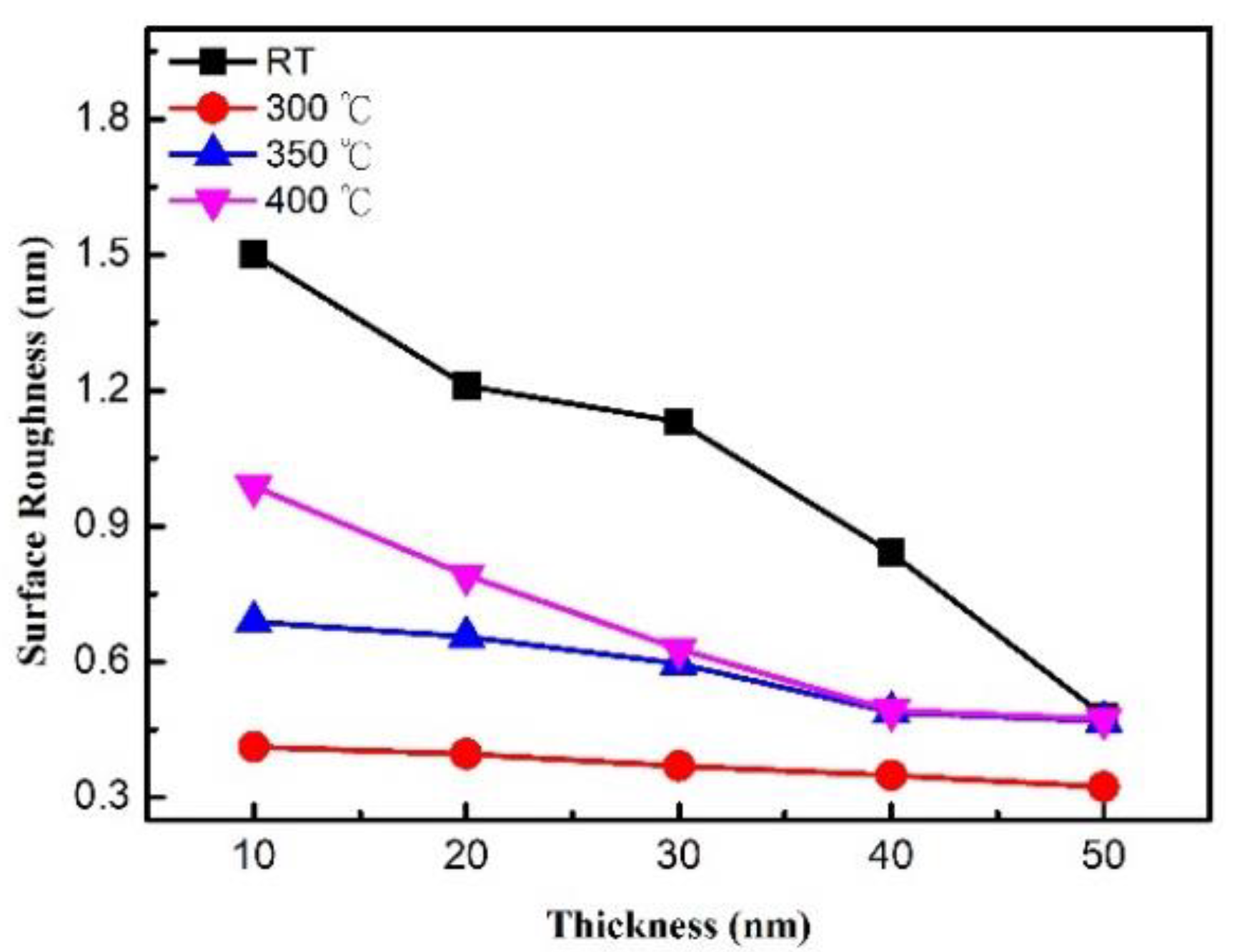

3.2. Surface Roughness

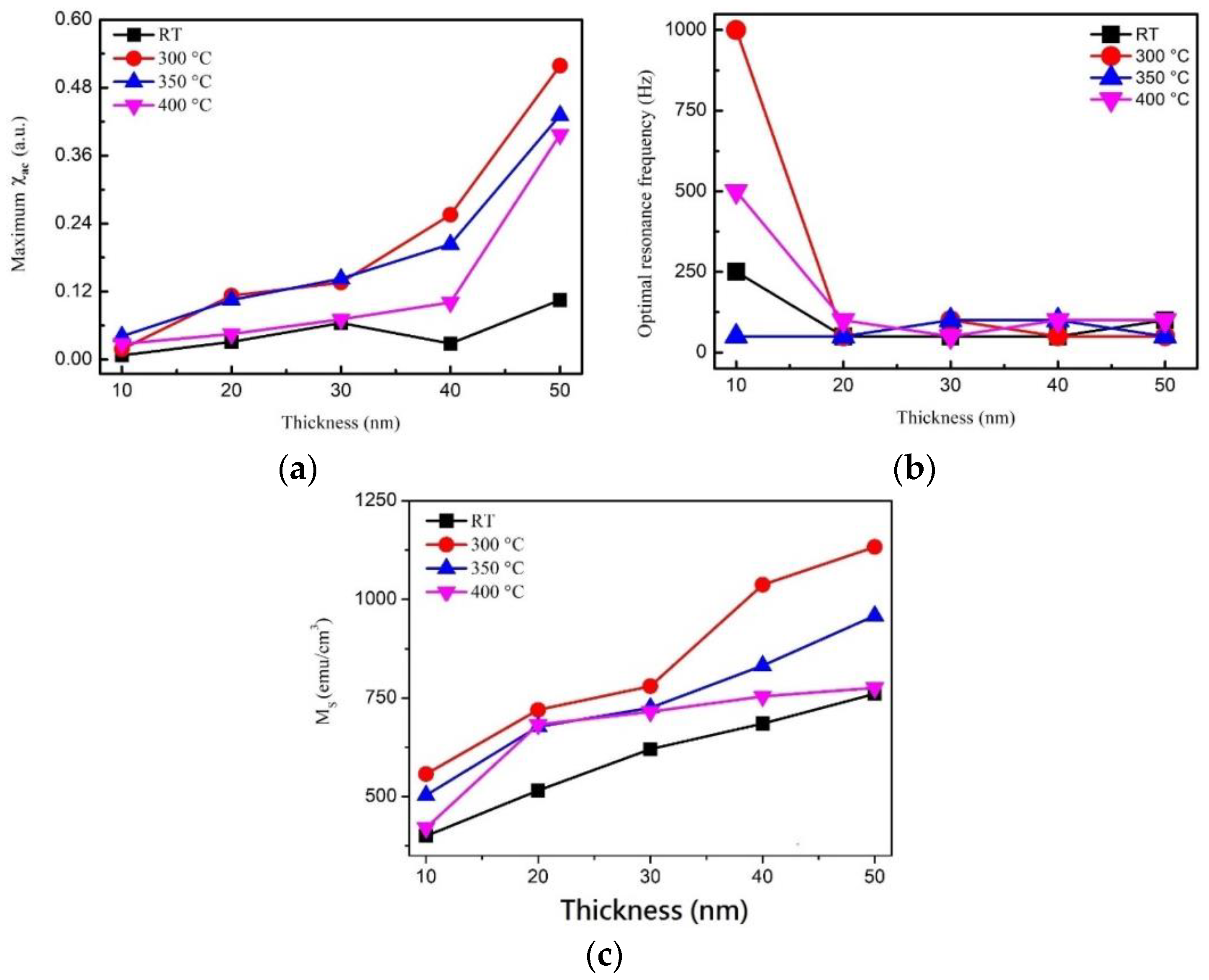

3.3. Magnetic Properties

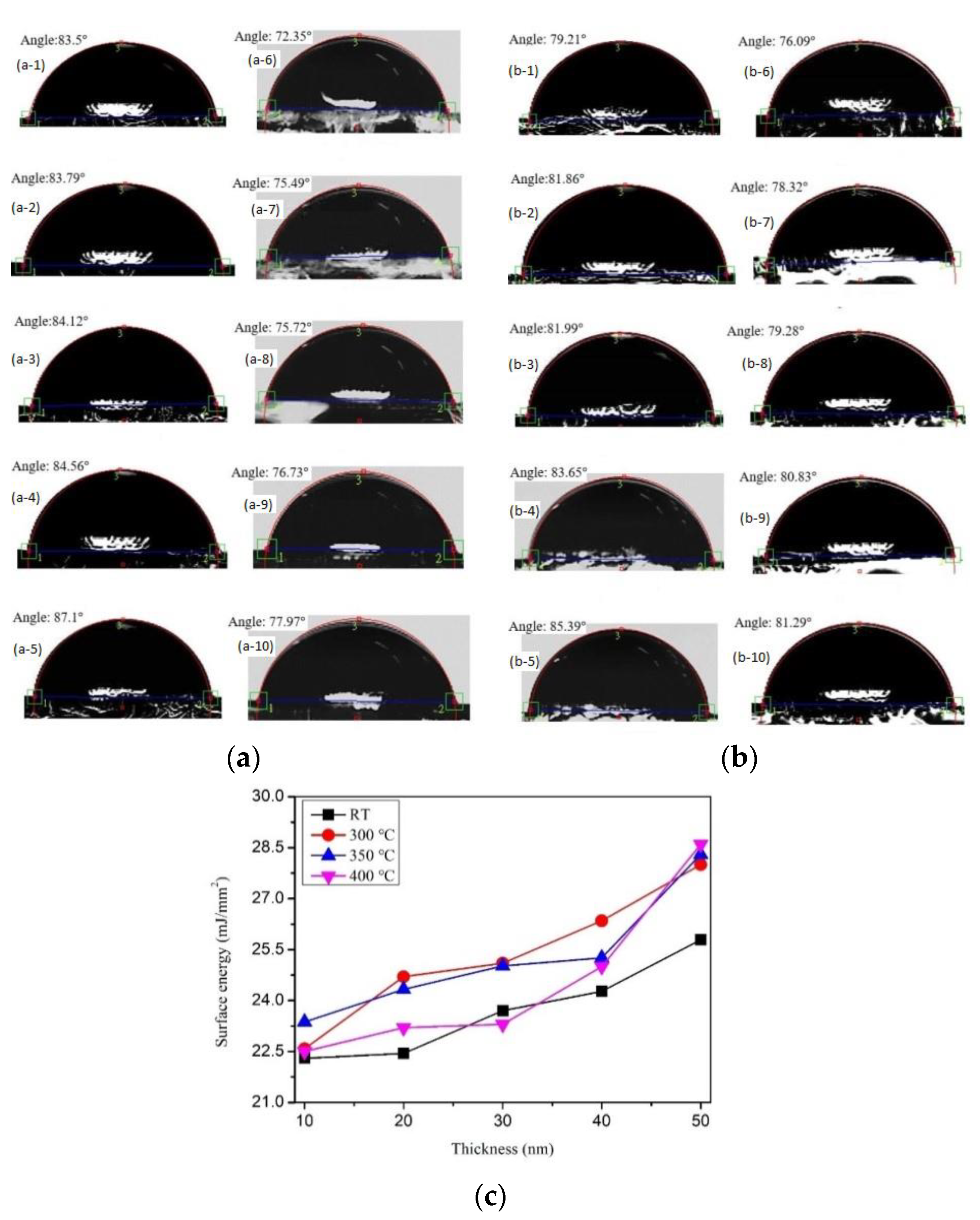

3.4. Analysis of Surface Energy

3.5. Analysis of Optical Properties

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Mehrizi, S.; Sohi, M.H.; Ebrahimi, S.S.A. Study of microstructure and magnetic properties of electrodeposited nanocrystalline CoFeNiCu thin films. Surf. Coat. Technol. 2011, 205, 4757–4763. [Google Scholar] [CrossRef]

- Ricq, L.; Lallemand, F.; Gigandet, M.P.; Pagetti, J. Influence of sodium saccharin on the electrodeposition and characterization of CoFe magnetic film. Surf. Coat. Technol. 2001, 138, 278–283. [Google Scholar] [CrossRef]

- Kalu, E.E.; Bell, R.; Dupree, M. Improvement of the corrosion behavior of electrodeposited CoFeCu thin films. Mater. Chem. Phys. 2010, 124, 689–693. [Google Scholar] [CrossRef]

- Kumari, T.P.; Raja, M.M.; Kumar, A.; Srinath, S.; Kamat, S.V. Effect of thickness on structure, microstructure, residual stress and soft magnetic properties of DC sputtered Fe65Co35 soft magnetic thin films. J. Magn. Magn. Mater. 2014, 365, 93–99. [Google Scholar] [CrossRef]

- Kim, S.N.; Chung, K.H.; Choi, J.W.; Lim, S.H. Manipulation of free-layer bias field in giant-magnetoresistance spin valve by controlling pinned-layer thickness. J. Alloy. Compd. 2020, 823, 153727. [Google Scholar] [CrossRef]

- Zeng, M.; Chen, B.J.; Lim, S.T. Interfacial electric field and spin-orbitronic properties of heavy-metal/CoFe bilayers. Appl. Phys. Lett. 2019, 114, 012401. [Google Scholar] [CrossRef]

- Naumova, L.I.; Milyaev, M.A.; Zavornitsyn, R.S.; Krinitsina, T.P.; Proglyado, V.V.; Ustinov, V.V. Spin valve with a composite dysprosium-based pinned layer as a tool for determining Dy nanolayer helimagnetism. Curr. Appl. Phys. 2019, 19, 1252–1258. [Google Scholar] [CrossRef]

- Noh, S.; Kang, D.H.; Shin, M. Simulation of strain-assisted switching in synthetic antiferromagnetic free layer-based magnetic tunnel junction. IEEE Trans. Magn. 2019, 55, 3400705. [Google Scholar] [CrossRef]

- Kim, S.N.; Choi, J.W.; Lim, S.H. Tailoring of magnetic properties of giant magnetoresistance spin valves via insertion of ultrathin non-magnetic spacers between pinned and pinning layers. Sci. Rep. 2019, 9, 1617. [Google Scholar] [CrossRef]

- Swindells, C.; Hindmarch, A.T.; Gallant, A.J.; Atkinson, D. Spin current propagation through ultra-thin insulating layers in multilayered ferromagnetic systems. Appl. Phys. Lett. 2020, 116, 042403. [Google Scholar] [CrossRef] [Green Version]

- Ogasawara, T.; Oogane, M.; Mahdawi, M.A.; Tsunoda, M.; Ando, Y. Effect of second-order magnetic anisotropy on nonlinearity of conductance in CoFeB/MgO/CoFeB magnetic tunnel junction for magnetic sensor devices. Sci. Rep. 2019, 9, 17018. [Google Scholar] [CrossRef] [PubMed]

- Devolder, T.; Couet, S.; Swerts, J.; Mertens, S.; Rao, S.; Kar, G.S. Effect of tantalum spacer thickness and deposition conditions on the properties of MgO/CoFeB/Ta/CoFeB/MgO free layers. IEEE Magn. Lett. 2019, 10, 5505804. [Google Scholar] [CrossRef] [Green Version]

- Honjo, H.; Ikeda, S.; Sato, H.; Nishioka, K.; Watanabe, T.; Miura, S.; Nasuno, T.; Noguchi, Y.; Yasuhira, M.; Tanigawa, T.; et al. Impact of tungsten sputtering condition on magnetic and transport properties of double-MgO magnetic tunneling junction with CoFeB/W/CoFeB free layer. IEEE Trans. Magn. 2017, 53, 2501604. [Google Scholar] [CrossRef]

- Manos, O.; Bougiatioti, P.; Dyck, D.; Huebner, T.; Rott, K.; Schmalhorst, J.M.; Reiss, G. Correlation of tunnel magnetoresistance with the magnetic properties in perpendicular CoFeB-based junctions with exchange bias. J. Appl. Phys. 2019, 125, 023905. [Google Scholar] [CrossRef] [Green Version]

- Lv, H.; Fidalgo, J.; Silva, A.V.; Leitao, D.C.; Kampfe, T.; Riedel, S.; Langer, J.; Wrona, J.; Ocker, B.; Freitas, P.P.; et al. Assessment of conduction mechanisms through MgO ultrathin barriers in CoFeB/MgO/CoFeB perpendicular magnetic tunnel junctions. Appl. Phys. Lett. 2019, 114, 102402. [Google Scholar] [CrossRef]

- Pai, C.F.; Liu, L.; Li, Y.; Tseng, H.W.; Ralph, D.C.; Buhrman, R.A. Spin transfer torque devices utilizing the giant spin Hall effect of tungsten. Appl. Phys. Lett. 2012, 101, 122404. [Google Scholar] [CrossRef]

- Ghaferi, Z.; Sharafi, S.; Bahrololoomb, M.E. The role of electrolyte pH on phase evolution and magnetic properties of CoFeW codeposited films. Appl. Surf. Sci. 2016, 375, 35–41. [Google Scholar] [CrossRef]

- Almasi, H.; Sun, C.L.; Li, X.; Newhouse-Illige, T.; Bi, C.; Price, K.C.; Nahar, S.; Grezes, C.; Hu, Q.; Amiri, P.K.; et al. Perpendicular magnetic tunnel junction with W seed and capping layers. J. Appl. Phys. 2017, 121, 153902. [Google Scholar] [CrossRef] [Green Version]

- Kim, J.H.; Lee, J.B.; An, G.G.; Yang, S.M.; Chung, W.S.; Park, H.S.; Hong, J.P. Ultrathin W space layer-enabled thermal stability enhancement in a perpendicular MgO/CoFeB/W/CoFeB/MgO recording frame. Sci. Rep. 2015, 5, 16903. [Google Scholar] [CrossRef] [Green Version]

- An, G.G.; Lee, J.B.; Yang, S.M.; Kim, J.H.; Chung, W.S.; Hong, J.P. Highly stable perpendicular magnetic anisotropies of CoFeB/MgO frames employing W buffer and capping layers. Acta Mater. 2015, 87, 259–265. [Google Scholar] [CrossRef]

- Kockar, H.; Ozergin, E.; Karaagac, O.; Alper, M. Characterisations of CoFeCu films: Influence of Fe concentration. J. Alloy. Compd. 2014, 586, 326–330. [Google Scholar] [CrossRef]

- Liu, W.J.; Chen, Y.T.; Chan, W.H.; Fu, S.H.; Li, W.H.; Wu, T.H. Structure and in-plane magnetic properties, and surface energy of Co60Fe60V20 thin films. J. Nanosci. Nanotechnol. 2018, 18, 5119–5123. [Google Scholar] [CrossRef]

- Liu, W.J.; Ou, S.L.; Chang, Y.H.; Chen, Y.T.; Chiang, M.R.; Hsu, S.C.; Chu, C.L. Adhesive characteristic, surface morphology, and optical properties of Co40Fe40V20 films. Optik Int. J. Light Electron Opt. 2020, 216, 164587. [Google Scholar] [CrossRef]

- Liu, W.J.; Chen, Y.T.; Chang, Y.H.; Chiang, M.R.; Li, W.H.; Tseng, J.Y.; Chi, P.W.; Wu, T.H. Structure and magnetic properties of Co40Fe40V20 thin films. J. Nanosci. Nanotechnol. 2019, 19, 5974–5978. [Google Scholar] [CrossRef] [PubMed]

- Liu, W.J.; Ou, S.L.; Chang, Y.H.; Chen, Y.T.; Wang, Y.T.; Liang, Y.C.; Tseng, J.Y.; Chi, P.W. Magnetic susceptibility, optical, and adhesive properties of Co40Fe40V10B10 films. Surf. Eng. 2020, 36, 405–410. [Google Scholar] [CrossRef]

- Ou, S.L.; Liu, W.J.; Chang, Y.H.; Chen, Y.T.; Wang, Y.T.; Li, W.H.; Tseng, J.Y.; Wu, T.H.; Chi, P.W.; Chu, C.L. Structure, magnetic property, surface morphology, and surface energy of Co40Fe40V10B10 films on Si(100) substrate. Appl. Sci. 2020, 10, 449. [Google Scholar] [CrossRef] [Green Version]

- Ma, K.; Chung, T.S.; Good, R.J. Surface energy of thermotropic liquid crystalline polyesters and polyesteramide. J. Polym. Sci. 1998, 36, 2327–2337. [Google Scholar] [CrossRef]

- Owens, D.K.; Wendt, R.C. Estimation of the surface free energy of polymers. J. Appl. Polym. Sci. 1969, 13, 1741–1747. [Google Scholar] [CrossRef]

- Kaelble, D.H.; Uy, K.C. A Reinterpretation of organic liquid-polytetrafluoroethylene surface interactions. J. Adhes. 1970, 2, 50–60. [Google Scholar] [CrossRef]

- Ikeda, H.; Iwai, M.; Nakajima, D.; Kikuchi, T.; Natsui, S.; Sakaguchi, N.; Suzuki, R.O. Nanostructural characterization of ordered gold particle arrays fabricated via aluminum anodizing, sputter coating, and dewetting. Appl. Surf. Sci. 2019, 465, 747–753. [Google Scholar] [CrossRef]

- Yamazaki, T.; Ikeda, N.; Tawara, H.; Sato, M. Investigation of composition uniformity of MoSix sputtering films based on measurement of angular distribution of sputtered atoms. Thin Solid Films 1993, 235, 71–75. [Google Scholar] [CrossRef] [Green Version]

- Choe, G.; Steinback, M. Surface roughness effects on magnetoresistive and magnetic properties of NiFe thin films. J. Appl. Phys. 1999, 85, 5777–5779. [Google Scholar] [CrossRef]

- Budde, T.; Gatzen, H.H. Magnetic properties of an SmCo/NiFe system for magnetic microactuators. J. Magn. Magn. Mater. 2004, 272–276, 2027–2028. [Google Scholar] [CrossRef]

- Wen, D.; Li, J.; Gan, G.; Yang, Y.; Zhang, H.; Liu, Y. Double peaks of the permeability spectra of obliquely sputtered CoFeB amorphous films. Mater. Res. Bull. 2019, 110, 107–111. [Google Scholar] [CrossRef]

- Yang, S.Y.; Chien, J.J.; Wang, W.C.; Yu, C.Y.; Hing, N.S.; Hong, H.E.; Hong, C.Y.; Yang, H.C.; Chang, C.F.; Lin, H.Y. Magnetic nanoparticles for high-sensitivity detection on nucleicacids via superconducting quantum-interference-device-based immunomagnetic reduction assay. J. Magn. Magn. Mater. 2011, 323, 681–685. [Google Scholar] [CrossRef]

- Chen, Y.T.; Xie, S.M.; Jheng, H.Y. The low-frequency alternative-current magnetic susceptibility and electrical properties of Si(100)/Fe40Pd40B20(X Å)/ZnO(500 Å) and Si(100)/ZnO(500 Å)/Fe40Pd40B20(Y Å) systems. J. Appl. Phys. 2013, 113, 17B303. [Google Scholar] [CrossRef]

- Liu, Y.; Yu, T.; Zhu, Z.; Zhong, H.; Khamis, K.M.; Zhu, K. High thermal stability in W/MgO/CoFeB/W/CoFeB/W stacks via ultrathin W insertion with perpendicular magnetic anisotropy. J. Magn. Magn. Mater. 2016, 410, 123–127. [Google Scholar] [CrossRef]

- Miyakawa, N.; Worledge, D.C.; Kita, K. Impact of Ta diffusion on the perpendicular magnetic anisotropy of Ta/CoFeB/MgO. IEEE Magn. Lett. 2013, 4, 100104. [Google Scholar] [CrossRef]

- Romero, R.; Martin, F.; Barrado, J.R.R.; Leinen, D. Synthesis and characterization of nanostructured nickel oxide thin films prepared with chemical spray pyrolysis. Thin Solid Films 2010, 518, 4499–4502. [Google Scholar] [CrossRef]

| Material | Thickness (nm) | Maximum χac (a.u.) | Optimal Resonance Frequency, fres (Hz) | Surface Energy (mJ/mm2) |

|---|---|---|---|---|

| Glass/Co60Fe20V20 [22] | 3–13 at RT | – | – | 22.3–33.3 |

| Glass/Co40Fe40V20 [23,24] | 10–100 at RT | 0.021–0.046 | 50–1000 | 27.8–45.4 |

| Glass/Co40Fe40V10B10 [25] | 10–40 at RT | 0.068–0.098 | 50–1000 | 65.5–38 |

| Si(100)/Co40Fe40V10B10 [26] | 10–40 at RT | 0.013–0.019 | 50–200 | 34.2–51.5 |

| Glass/Co32Fe30W38 (*) | 10–50 at RT and annealed conditions | 0.02–0.52 | 50–1000 | 22.3–28.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, W.-J.; Chang, Y.-H.; Ou, S.-L.; Chen, Y.-T.; Li, W.-H.; Jhou, T.-Y.; Chu, C.-L.; Wu, T.-H.; Tseng, S.-W. Effect of Annealing on the Structural, Magnetic, Surface Energy and Optical Properties of Co32Fe30W38 Films Deposited by Direct-Current Magnetron Sputtering. Coatings 2020, 10, 1028. https://doi.org/10.3390/coatings10111028

Liu W-J, Chang Y-H, Ou S-L, Chen Y-T, Li W-H, Jhou T-Y, Chu C-L, Wu T-H, Tseng S-W. Effect of Annealing on the Structural, Magnetic, Surface Energy and Optical Properties of Co32Fe30W38 Films Deposited by Direct-Current Magnetron Sputtering. Coatings. 2020; 10(11):1028. https://doi.org/10.3390/coatings10111028

Chicago/Turabian StyleLiu, Wen-Jen, Yung-Huang Chang, Sin-Liang Ou, Yuan-Tsung Chen, Wei-Hsuan Li, Tian-Yi Jhou, Chun-Lin Chu, Te-Ho Wu, and Shih-Wen Tseng. 2020. "Effect of Annealing on the Structural, Magnetic, Surface Energy and Optical Properties of Co32Fe30W38 Films Deposited by Direct-Current Magnetron Sputtering" Coatings 10, no. 11: 1028. https://doi.org/10.3390/coatings10111028