Edible Films of Whey and Cassava Starch: Physical, Thermal, and Microstructural Characterization

Abstract

:1. Introduction

2. Materials and Methods

2.1. Film Production

2.2. Film Characterization

2.3. Statistical Analysis

3. Results and Discussion

3.1. Physical and Optical Properties

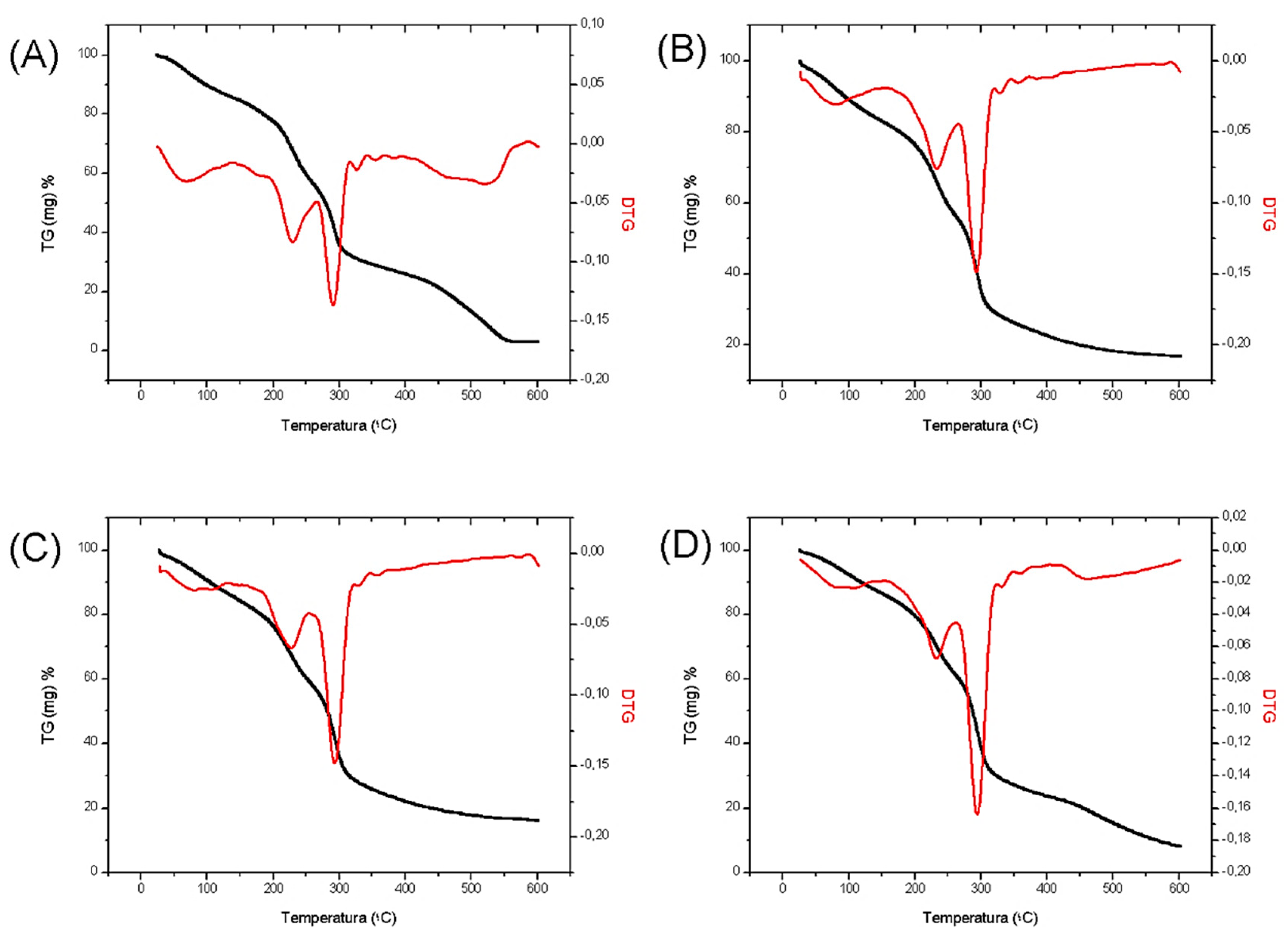

3.2. Thermal Analysis

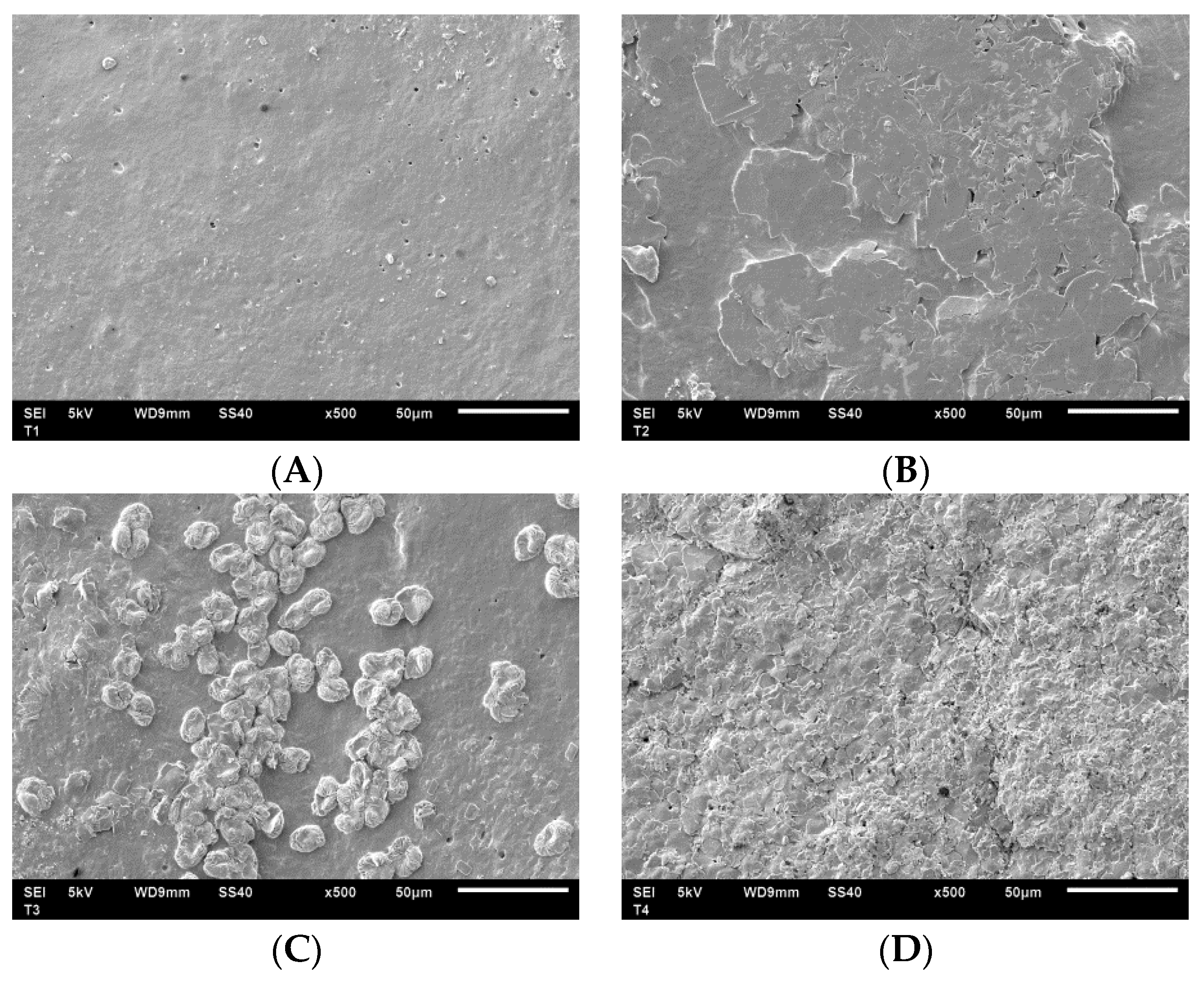

3.3. Scanning Electron Microscopy (SEM)

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Filho, J.G.D.O.; De Deus, I.P.B.; Valadares, A.C.F.; Fernandes, C.C.; Estevam, E.B.B.; Egea, M.B. Chitosan Film with Citrus limonia Essential Oil: Physical and Morphological Properties and Antibacterial Activity. Colloids Interfaces 2020, 4, 18. [Google Scholar] [CrossRef]

- Mahcene, Z.; Khelil, A.; Hasni, S.; Akman, P.K.; Bozkurt, F.; Birech, K.; Goudjil, M.B.; Tornuk, F. Development and characterization of sodium alginate based active edible films incorporated with essential oils of some medicinal plants. Int. J. Biol. Macromol. 2020, 145, 124–132. [Google Scholar] [CrossRef]

- Dai, L.; Zhang, J.; Cheng, F. Cross-linked starch-based edible coating reinforced by starch nanocrystals and its preservation effect on graded Huangguan pears. Food Chem. 2020, 311, 125891. [Google Scholar] [CrossRef]

- De Oliveira-Filho, J.G.; Lemes, A.C.; Braga, A.R.C.; Egea, M.B. Biodegradable Eco-Friendly Packaging and Coatings Incorporated of Natural Active Compounds. In Food Packaging: Advanced Materials, Technologies, and Innovations; Siengchin, S., Ed.; CRC Press: Boca Raton, FL, USA, 2020; pp. 171–206. [Google Scholar]

- Jeevahan, J.J.; Chandrasekaran, M.; Venkatesan, S.; Sriram, V.; Joseph, G.B.; Mageshwaran, G.; Durairaj, R.; Jeevahan, J.; Britto, J.G. Scaling up difficulties and commercial aspects of edible films for food packaging: A review. Trends Food Sci. Technol. 2020, 100, 210–222. [Google Scholar] [CrossRef]

- Ramos, Ó.L.; Reinas, I.; Silva, S.I.; Fernandes, J.C.; Cerqueira, M.A.; Pereira, R.N.; Vicente, A.A.; Poças, M.F.; Pintado, M.E.; Malcata, F.X. Effect of whey protein purity and glycerol content upon physical properties of edible films manufactured therefrom. Food Hydrocoll. 2013, 30, 110–122. [Google Scholar] [CrossRef]

- Agudelo-Cuartas, C.; Granda-Restrepo, D.; Sobral, P.J.; Hernandez, H.; Castro, W. Characterization of whey protein-based films incorporated with natamycin and nanoemulsion of α-tocopherol. Heliyon 2020, 6, e03809. [Google Scholar] [CrossRef]

- Schmid, M.; Merzbacher, S.; Müller, K. Time-dependent crosslinking of whey protein based films during storage. Mater. Lett. 2018, 215, 8–10. [Google Scholar] [CrossRef]

- Thakur, R.; Pristijono, P.; Scarlett, C.J.; Bowyer, M.; Singh, S.; Vuong, Q.V. Starch-based films: Major factors affecting their properties. Int. J. Biol. Macromol. 2019, 132, 1079–1089. [Google Scholar] [CrossRef]

- Kim, S.R.B.; Choi, Y.-G.; Kim, J.-Y.; Lim, S.-T. Improvement of water solubility and humidity stability of tapioca starch film by incorporating various gums. LWT 2015, 64, 475–482. [Google Scholar] [CrossRef]

- Chiumarelli, M.; Hubinger, M.D. Evaluation of edible films and coatings formulated with cassava starch, glycerol, carnauba wax and stearic acid. Food Hydrocoll. 2014, 38, 20–27. [Google Scholar] [CrossRef]

- Aisyah, Y.; Irwanda, L.P.; Haryani, S.; Safriani, N. Characterization of corn starch-based edible film incorporated with nutmeg oil nanoemulsion; IOP Conference Series: Materials Science and Engineering; IOP Publishing: Banda Aceh, Indonesia, 2018; p. 012050. [Google Scholar]

- Chollakup, R.; Pongburoos, S.; Boonsong, W.; Khanoonkon, N.; Kongsin, K.; Sothornvit, R.; Sukyai, P.; Sukatta, U.; Harnkarnsujarit, N. Antioxidant and antibacterial activities of cassava starch and whey protein blend films containing rambutan peel extract and cinnamon oil for active packaging. LWT 2020, 130. [Google Scholar] [CrossRef]

- Yousuf, B.; Qadri, O.S.; Srivastava, A.K. Recent developments in shelf-life extension of fresh-cut fruits and vegetables by application of different edible coatings: A review. LWT 2018, 89, 198–209. [Google Scholar] [CrossRef]

- Sukhija, S.; Singh, S.; Riar, C.S. Analyzing the effect of whey protein concentrate and psyllium husk on various characteristics of biodegradable film from lotus (Nelumbo nucifera) rhizome starch. Food Hydrocoll. 2016, 60, 128–137. [Google Scholar] [CrossRef]

- Azevedo, V.M.; Borges, S.V.; Marconcini, J.M.; Yoshida, M.I.; Neto, A.R.S.; Pereira, T.C.; Pereira, C.F.G. Effect of replacement of corn starch by whey protein isolate in biodegradable film blends obtained by extrusion. Carbohydr. Polym. 2017, 157, 971–980. [Google Scholar] [CrossRef] [Green Version]

- Kavoosi, G.; Rahmatollahi, A.; Dadfar, S.M.M.; Purfard, A.M. Effects of essential oil on the water binding capacity, physico-mechanical properties, antioxidant and antibacterial activity of gelatin films. LWT 2014, 57, 556–561. [Google Scholar] [CrossRef]

- Oliveira Filho, J.G.D.; Rodrigues, J.M.; Valadares, A.C.F.; De Almeida, A.B.; De Lima, T.M.; Takeuchi, K.P.; Alves, C.C.F.; Sousa, H.A.D.F.; Da Silva, E.R.; Dyszy, F.H.; et al. Active food packaging: Alginate films with cottonseed protein hydrolysates. Food Hydrocoll. 2019, 92, 267–275. [Google Scholar] [CrossRef]

- Wang, N.; Zhang, X.; Han, N.; Bai, S. Effect of citric acid and processing on the performance of thermoplastic starch/montmorillonite nanocomposites. Carbohydr. Polym. 2009, 76, 68–73. [Google Scholar] [CrossRef]

- Muñoz, L.; Aguilera, J.; Rodriguez-Turienzo, L.; Cobos, A.; Diaz, O. Characterization and microstructure of films made from mucilage of Salvia hispanica and whey protein concentrate. J. Food Eng. 2012, 111, 511–518. [Google Scholar] [CrossRef]

- McHugh, T.H.; Aujard, J.-F.; Krochta, J.M. Plasticized Whey Protein Edible Films: Water Vapor Permeability Properties. J. Food Sci. 1994, 59, 416–419. [Google Scholar] [CrossRef]

- Sharma, K.; Kumar, V.; Kaur, J.; Tanwar, B.; Goyal, A.; Sharma, R.; Gat, Y.; Kumar, A. Health effects, sources, utilization and safety of tannins: A critical review. Toxin Rev. 2019, 2019, 1–13. [Google Scholar] [CrossRef]

- Azevedo, V.M.; Dias, M.V.; Borges, S.V.; Costa, A.L.R.; Silva, E.K.; Medeiros, É.A.A.; Soares, N.D.F.F. Development of whey protein isolate bio-nanocomposites: Effect of montmorillonite and citric acid on structural, thermal, morphological and mechanical properties. Food Hydrocoll. 2015, 48, 179–188. [Google Scholar] [CrossRef]

- Mendes, J.; Norcino, L.; Martins, H.; Manrich, A.; Otoni, C.; Carvalho, E.; Piccoli, R.; Oliveira, J.; Pinheiro, A.; Mattoso, L. Correlating emulsion characteristics with the properties of active starch films loaded with lemongrass essential oil. Food Hydrocoll. 2020, 100, 105428. [Google Scholar] [CrossRef]

- Nogueira, G.F.; Fakhouri, F.M.; De Oliveira, R.A. Extraction and characterization of arrowroot (Maranta arundinaceae L.) starch and its application in edible films. Carbohydr. Polym. 2018, 186, 64–72. [Google Scholar] [CrossRef]

- Zhu, P.; Wang, M.; Du, X.; Chen, Z.; Liu, C.; Zhao, H. Morphological and physicochemical properties of rice starch dry heated with whey protein isolate. Food Hydrocoll. 2020, 109, 106091. [Google Scholar] [CrossRef]

- Harper, B.; Barbut, S.; Lim, L.-T.; Marcone, M. Characterization of ‘wet’ alginate and composite films containing gelatin, whey or soy protein. Food Res. Int. 2013, 52, 452–459. [Google Scholar] [CrossRef]

- Huntrakul, K.; Yoksan, R.; Sane, A.; Harnkarnsujarit, N. Effects of pea protein on properties of cassava starch edible films produced by blown-film extrusion for oil packaging. Food Packag. Shelf Life 2020, 24, 100480. [Google Scholar] [CrossRef]

- Sun, Q.; Sun, C.; Xiong, L. Mechanical, barrier and morphological properties of pea starch and peanut protein isolate blend films. Carbohydr. Polym. 2013, 98, 630–637. [Google Scholar] [CrossRef] [PubMed]

| Ingredients (%) | Formulations | |||

|---|---|---|---|---|

| F1 | F2 | F3 | F4 | |

| Liquid whey | 67.50 | 66.25 | 65.00 | 63.75 |

| Cassava starch | 7.50 | 8.75 | 10.00 | 11.25 |

| Glycerol | 5.00 | 5.00 | 5.00 | 5.00 |

| Acetic acid | 20.00 | 20.00 | 20.00 | 20.00 |

| Parameters | Formulations | |||

|---|---|---|---|---|

| F1 | F2 | F3 | F4 | |

| Solubility (%) | 53.63 ± 4.64ab | 57.06 ± 6.04a | 42.95 ± 9.84c | 46.43 ± 6.92bc |

| Thickness (mm) | 0.70 ± 0.10a | 0.79 ± 0.22a | 0.71 ± 0.07a | 0.68 ± 0.11a |

| hº | 1.07 ± 0.48a | 1.12 ± 0.43a | 0.40 ± 0.66a | 0.89 ± 0.53a |

| Chroma | 1.86 ± 0.69a | 1.98 ± 0.62a | 0.98 ± 0.34b | 1.16 ± 0.36b |

| ΔE* | 58.38 ± 3.27b | 62.32 ± 2.35a | 56.20 ± 1.77c | 59.02 ± 1.32b |

| Films | First Stage | Second Stage | Third Stage | |||

|---|---|---|---|---|---|---|

| Temperature (°C) | Weight Loss (%) | Temperature (°C) | Weight Loss (%) | Temperature (°C) | Weight Loss (%) | |

| F1 | 32 | 99.5 − 90.2 = 9.3 | 201 | 74.5 − 54.5 = 20 | 267 | 55 − 37 = 18 |

| F2 | 31 | 99 − 90 = 9 | 193 | 79.2 − 58 = 21.2 | 264 | 56 − 32 = 24 |

| F3 | 31 | 99 − 89 = 9 | 183 | 80 − 69 = 11 | 263 | 57.2 − 31 = 26.2 |

| F4 | 30.5 | 99.3 − 91.2 = 8.1 | 160 | 85.4 − 70.5 = 14.9 | 260 | 62 − 32 = 30 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Andrade Martins, Y.A.; Ferreira, S.V.; Silva, N.M.; Sandre, M.F.B.; Filho, J.G.O.; Leão, P.V.T.; Leão, K.M.; Nicolau, E.S.; Plácido, G.R.; Egea, M.B.; et al. Edible Films of Whey and Cassava Starch: Physical, Thermal, and Microstructural Characterization. Coatings 2020, 10, 1059. https://doi.org/10.3390/coatings10111059

Andrade Martins YA, Ferreira SV, Silva NM, Sandre MFB, Filho JGO, Leão PVT, Leão KM, Nicolau ES, Plácido GR, Egea MB, et al. Edible Films of Whey and Cassava Starch: Physical, Thermal, and Microstructural Characterization. Coatings. 2020; 10(11):1059. https://doi.org/10.3390/coatings10111059

Chicago/Turabian StyleAndrade Martins, Yasmine Ariadne, Samuel Viana Ferreira, Nayane Matias Silva, Marcella Fernandes Borges Sandre, Josemar Gonçalves Oliveira Filho, Paulo Victor Toledo Leão, Karen Martins Leão, Edmar Soares Nicolau, Geovana Rocha Plácido, Mariana Buranelo Egea, and et al. 2020. "Edible Films of Whey and Cassava Starch: Physical, Thermal, and Microstructural Characterization" Coatings 10, no. 11: 1059. https://doi.org/10.3390/coatings10111059