Piezoelectric Hybrid Heterostructures PVDF/(Ba,Ca)(Zr,Ti)O3 Obtained by Laser Techniques

Abstract

:1. Introduction

2. Materials and Methods

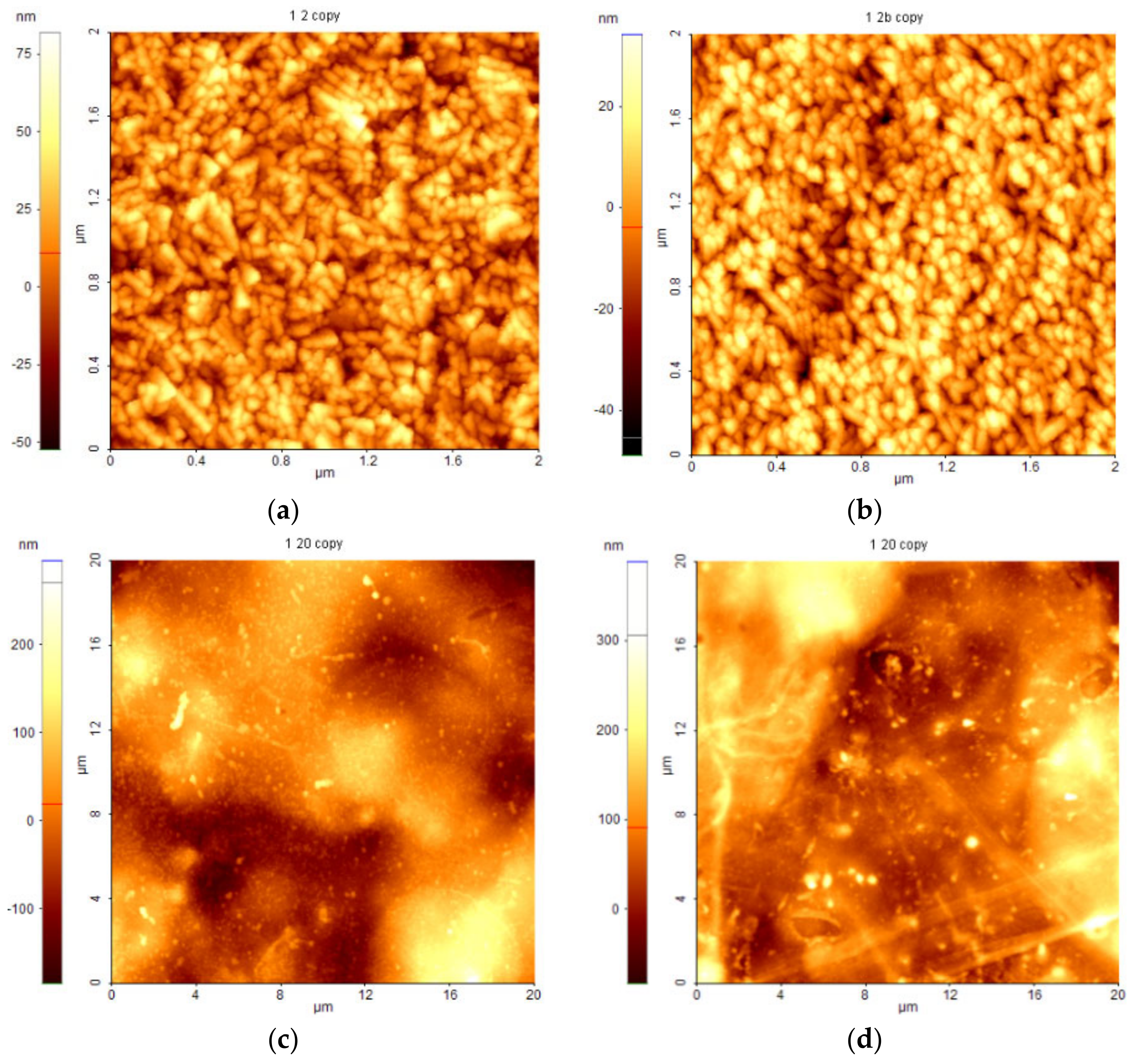

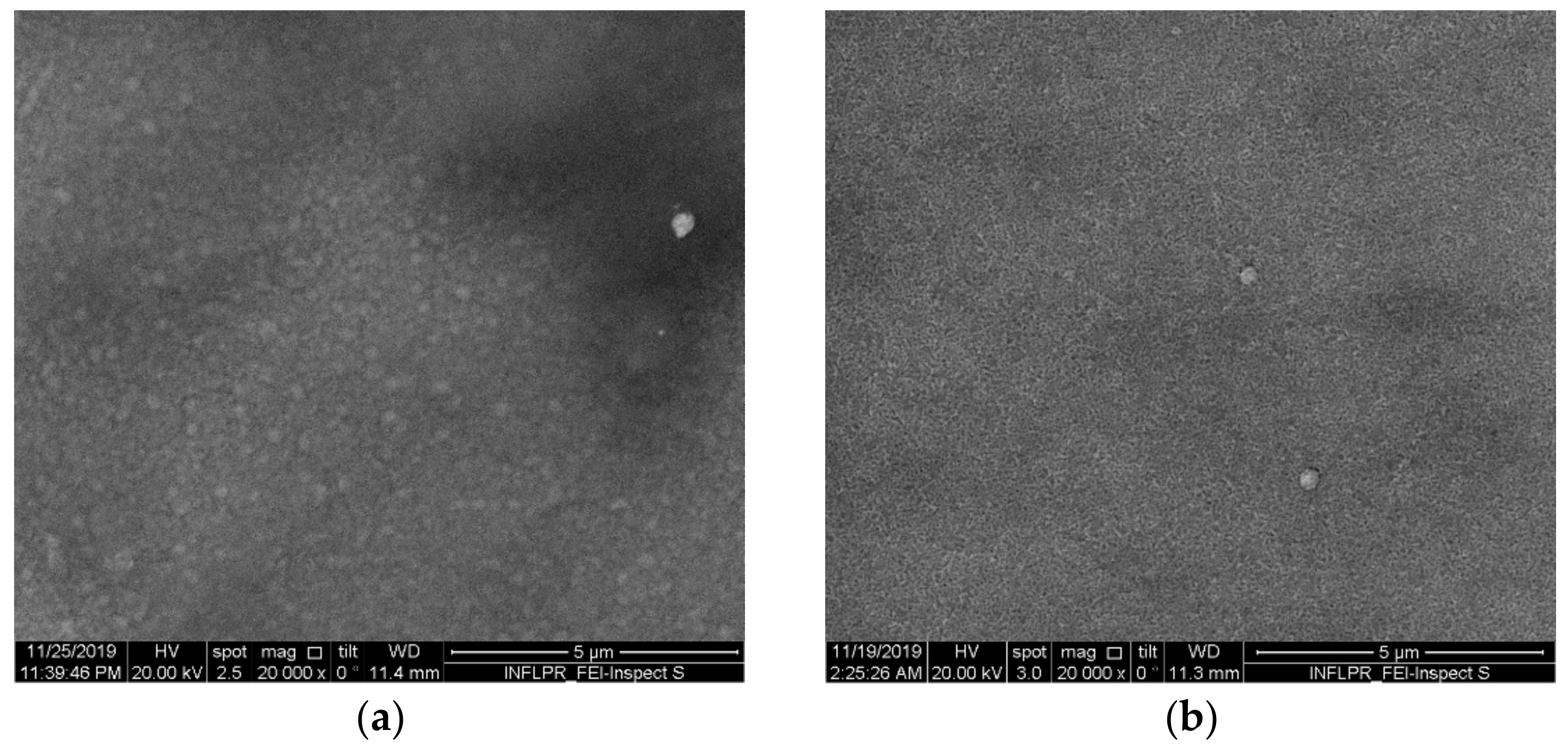

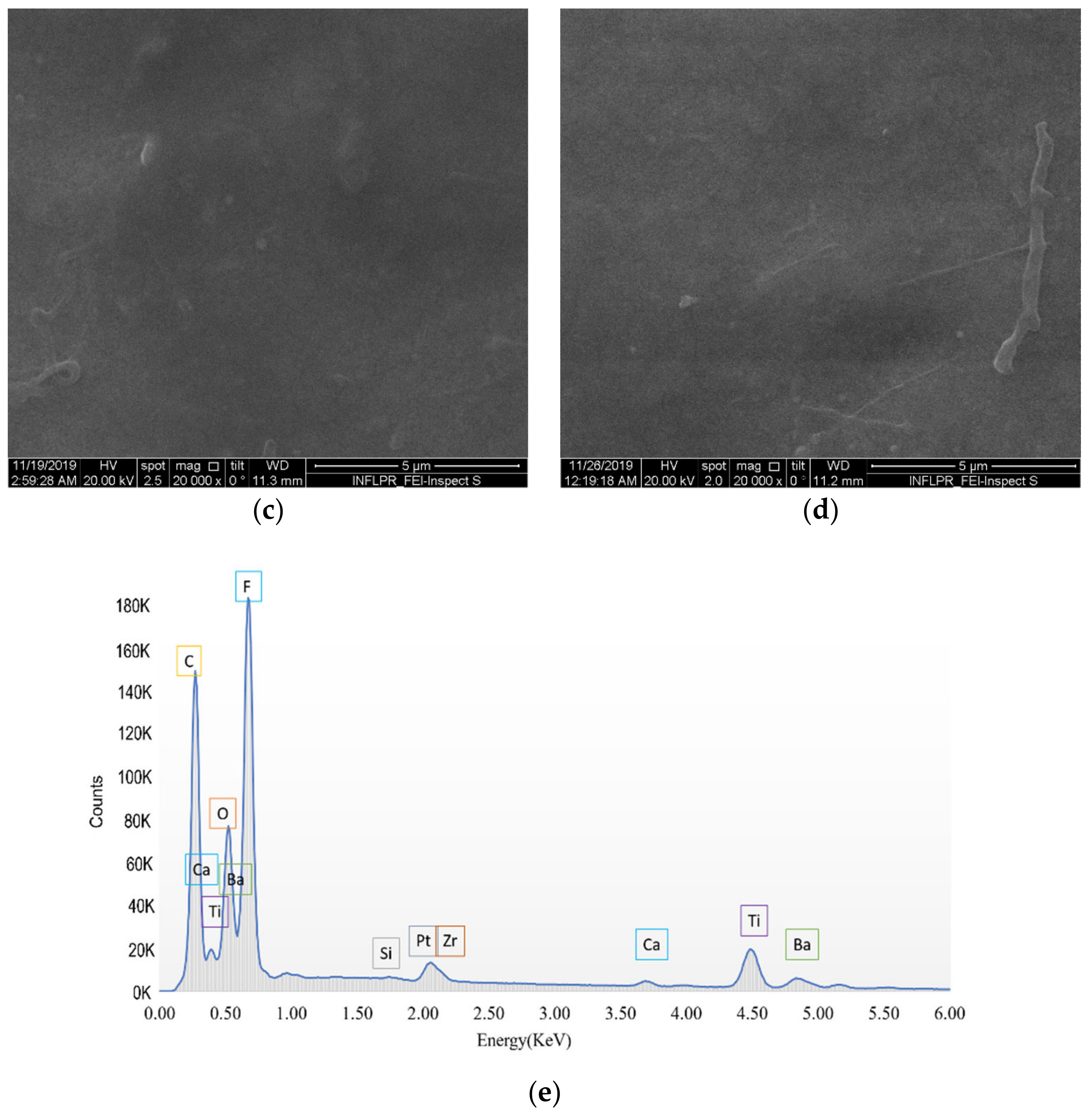

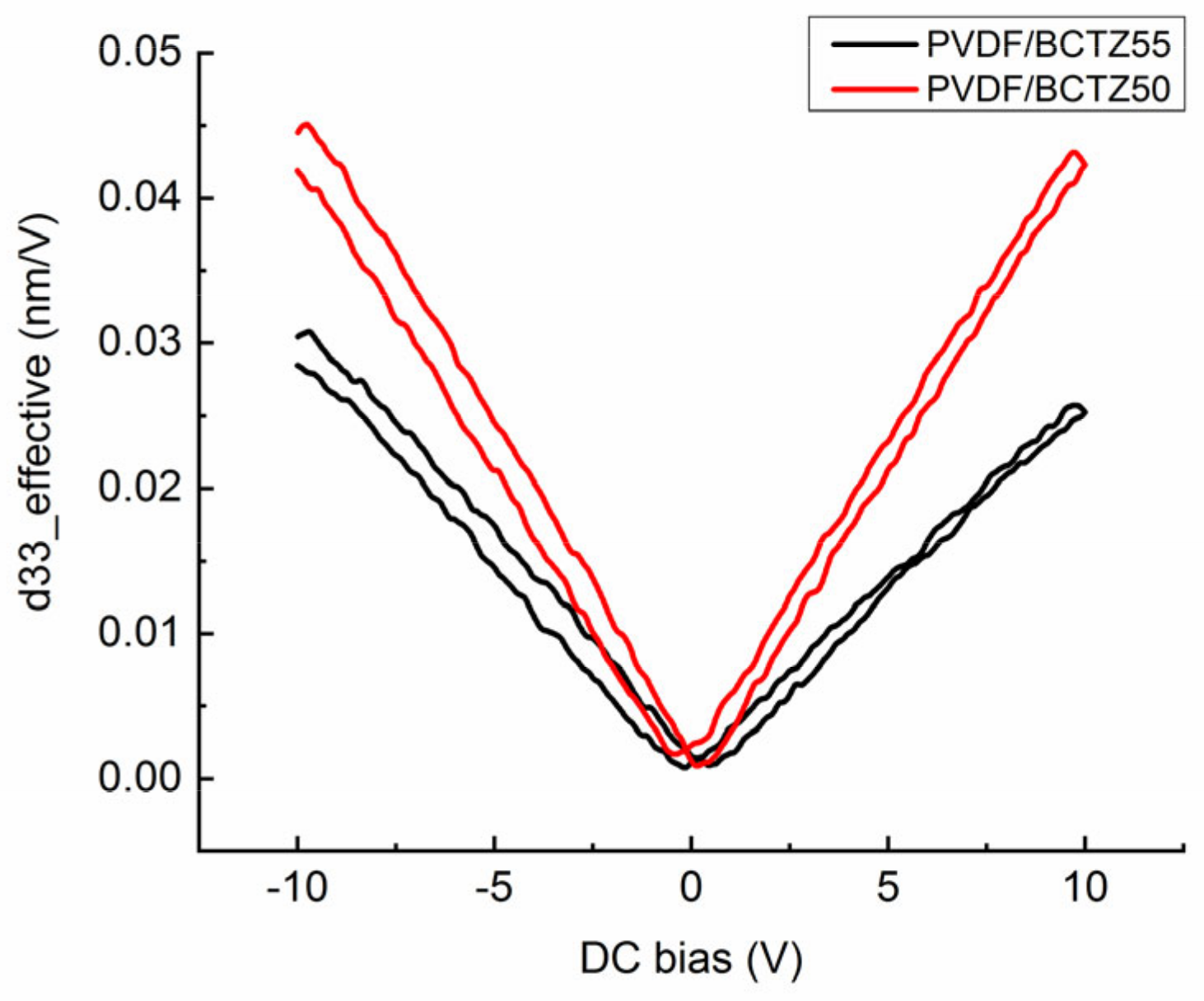

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Jaffe, B.; Roth, R.S.; Marzullo, S. Piezoelectric properties of lead zirconate-lead titanate solid-solution ceramics. J. Appl. Phys. 1954, 25, 809–810. [Google Scholar] [CrossRef]

- Yamamoto, T. Ferroelectric properties of the PbZrO3–PbTiO3 system. Jpn. J. Appl. Phys. 1996, 35, 5104–5108. [Google Scholar] [CrossRef]

- Georges, R. Characterization of PLZT ceramics for optical sensor and actuator devices. In Ceramic Materials—Progress in Modern Ceramics; IntechOpen: London, UK, 2012. [Google Scholar]

- Muralt, P. PZT thin films for microsensors and actuators: Where do we stand? IEEE Trans. Ultrason. Ferroelectr. Freq. Control. 2000, 47, 903–915. [Google Scholar] [CrossRef]

- Kim, H.; In, C.; Yoon, G.; Kim, J. Design and fabrication of a micro PZT cantilever array actuator for applications in fluidic systems. J. Mech. Sci. Technol. 2005, 19, 1544–1553. [Google Scholar] [CrossRef]

- Kueppers, H.; Hoffmann, M.; Leuerer, T.; Schneller, T.; Boettger, U.; Waser, R.; Mokwa, W.; Schnakenberg, U. Basic investigations on a piezoelectric bending actuator for micro-electro-mechanical applications. Integr. Ferroelectr. 2001, 35, 269–281. [Google Scholar] [CrossRef]

- Sreenivas, K.; Sayer, M. Characterization of Pb(Zr,Ti)O3 thin films deposited from multielement metal targets. J. Appl. Phys. 1988, 64, 1484–1493. [Google Scholar] [CrossRef]

- Krupanidhi, S.B.; Maffei, N.; Sayer, M.; El-Assal, K. rf planar magnetron sputtering and characterization of ferroelectric Pb(Zr,Ti)O3 films. J. Appl. Phys. 1983, 54, 6601. [Google Scholar] [CrossRef]

- Spierings, G.A.C.M.; Ulenaers, M.J.E.; Kampschöer, G.L.M.; Van Hal, H.A.M.; Larsen, P.K. Preparation and ferroelectric properties of PbZr0.53Ti0.47O3 thin films by spin coating and metalorganic decomposition. J. Appl. Phys. 1991, 70, 2290–2298. [Google Scholar] [CrossRef]

- Verardi, P.; Dinescu, M.; Craciun, F. Pulsed laser deposition and characterization of PZT thin films. Appl. Surf. Sci. 2000, 154, 514–518. [Google Scholar] [CrossRef]

- Roy, D.; Krupanidhi, S.B.; Dougherty, J.P. Excimer laser ablated lead zirconate titanate thin films. J. Appl. Phys. 1991, 69, 7930–7932. [Google Scholar] [CrossRef]

- Qin, Y.; Wang, X.; Wang, Z.L. Erratum: Microfibre–nanowire hybrid structure for energy scavenging. Nat. Cell Biol. 2009, 457, 340. [Google Scholar] [CrossRef] [Green Version]

- Shenck, N.S.; Paradiso, J.A. Energy scavenging with shoe-mounted piezoelectrics. IEEE Micro 2001, 21, 30–42. [Google Scholar] [CrossRef]

- Xue, D.; Zhou, Y.; Bao, H.; Zhou, C.; Gao, J.; Ren, X. Elastic, piezoelectric, and dielectric properties of Ba(Zr0.2Ti0.8)O3-50(Ba0.7Ca0.3)TiO3 Pb-free ceramic at the morphotropic phase boundary. J. Appl. Phys. 2011, 109, 054110. [Google Scholar] [CrossRef] [Green Version]

- Dezhen, X.; Yumei, Z.; Huixin, B.; Jinghui, G.; Chao, Z.; Xiaobing, R. Large piezoelectric effect in Pb-free Ba(Ti,Sn)O3−x(Ba,Ca)TiO3 ceramics. Appl. Phys. Lett. 2011, 99, 122901. [Google Scholar] [CrossRef]

- Scarisoreanu, N.D.; Craciun, F.; Ion, V.; Birjega, R.; Bercea, A.; Dinca, V.; Dinescu, M.; Sima, L.E.; Icriverzi, M.; Roseanu, A.; et al. Lead-free piezoelectric (Ba,Ca)(Zr,Ti)O3 thin films for biocompatible and flexible devices. ACS Appl. Mater. Interfaces 2016, 9, 266–278. [Google Scholar] [CrossRef]

- Scarisoreanu, N.D.; Craciun, F.; Moldovan, A.; Ion, V.; Birjega, R.; Ghica, C.; Negrea, R.F.; Dinescu, M. High permittivity (1−x)Ba(Zr0.2Ti0.8)O3−x(Ba0.7Ca0.3)TiO3 (x = 0.45) epitaxial thin films with nanoscale phase fluctuations. ACS Appl. Mater. Interfaces 2015, 7, 23984–23992. [Google Scholar] [CrossRef] [Green Version]

- Ion, V.; Craciun, F.; Scarisoreanu, N.D.; Moldovan, A.; Andrei, A.; Birjega, R.; Ghica, C.; Di Pietrantonio, F.; Cannata, D.; Benetti, M.; et al. Impact of thickness variation on structural, dielectric and piezoelectric properties of (Ba,Ca)(Ti,Zr)O3 epitaxial thin films. Sci. Rep. 2018, 8, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Li, S.; Lin, M.M.; Toprak, M.S.; Kim, D.K.; Muhammed, M. Nanocomposites of polymer and inorganic nanoparticles for optical and magnetic applications. Nano Rev. 2010, 1. [Google Scholar] [CrossRef] [PubMed]

- Baumgärtel, K.H.; Zöllner, D.; Krieger, K.-L. Classification and Simulation Method for Piezoelectric PVDF Sensors. Proc. Technol. 2016, 26, 491–498. [Google Scholar] [CrossRef] [Green Version]

- Kim, H.; Fernando, T.; Li, M.; Lin, Y.; Tseng, T.-L.B. Fabrication and characterization of 3D printed BaTiO3/PVDF nanocomposites. J. Compos. Mater. 2018, 52, 197–206. [Google Scholar] [CrossRef] [Green Version]

- Sadhu, S.P.P.; Siddabattuni, S.; Varma, K.B.R. Enhanced dielectric properties and energy storage density of surface engineered BCZT/PVDF-HFP nanodielectrics. J. Mater. Sci. Mater. Electron. 2018, 29, 6174–6182. [Google Scholar] [CrossRef]

- Luo, B.; Wang, X.; Wang, Y.; Li, L. Fabrication, characterization, properties and theoretical analysis of ceramic/PVDF composite flexible films with high dielectric constant and low dielectric loss. J. Mater. Chem. A 2014, 2, 510–519. [Google Scholar] [CrossRef]

- Itina, T. Laser Ablation—From Fundamentals to Applications; Croatia InTech: Rijeka, Croatia, 2017; ISBN 978-953-51-3700-9. [Google Scholar]

- Caricato, A.P.; Luches, A. Applications of the matrix-assisted pulsed laser evaporation method for the deposition of organic, biological and nanoparticle thin films: A review. Appl. Phys. A 2011, 105, 565–582. [Google Scholar] [CrossRef]

- Piqué, A.; Wu, P.; Ringeisen, B.R.; Bubb, D.; Melinger, J.S.; McGill, R.; Chrisey, D. Processing of functional polymers and organic thin films by the matrix-assisted pulsed laser evaporation (MAPLE) technique. Appl. Surf. Sci. 2002, 186, 408–415. [Google Scholar] [CrossRef]

- Leonard, C.; Halary, J.L.; Monnerie, L. Crystallization of poly(vinylidene fluoride)-poly(methyl methacrylate) blends: Analysis of the molecular parameters controlling the nature of poly(vinylidene fluoride) crystalline phase. Macromolecules 1988, 21, 2988–2994. [Google Scholar] [CrossRef]

- Li, M.; Stingelin, N.; Michels, J.J.; Spijkman, M.-J.; Asadi, K.; Feldman, K.; Blom, P.W.M.; De Leeuw, D.M. Ferroelectric phase diagram of PVDF:PMMA. Macromolecules 2012, 45, 7477–7485. [Google Scholar] [CrossRef] [Green Version]

- Palik, E. Handbook of Optical Constants of Solids; Elsevier BV: Amsterdam, The Netherlands, 1985; Volume 1. [Google Scholar]

- Fujiwara, H. Spectroscopic Ellipsometry Principles and Applications; John Wiley & Sons Ltd.: Hoboken, NJ, USA, 2007; ISBN 978-0-470-01608-4. [Google Scholar]

- Harland, G.; Hilfiker, J.N. Spectroscopic Ellipsometry- Practical Application to Thin Film Characterization; Momentum Press Enginneering: New York, NJ, USA, 2016. [Google Scholar]

- Lin, Y.; Wu, G.; Qin, N.; Bao, D. Structure, dielectric, ferroelectric, and optical properties of (1−x)Ba(Zr0.2Ti0.8)O3−x(Ba0.7Ca0.3)TiO3 thin films prepared by sol–gel method. Thin Solid Films 2012, 520, 2800–2804. [Google Scholar] [CrossRef]

- Wang, H.; Xu, J.; Zhao, P.; Ma, C.; Wang, L.; Bian, L.; Chang, A. Optical character of barium titanate based thin films around the phase transition. Ferroelectrics 2016, 491, 8–14. [Google Scholar] [CrossRef]

- Duan, C.-G.; Mei, W.N.; Yin, W.G.; Liu, J.; Hardy, J.R.; Bai, M.; Ducharme, S. Theoretical study on the optical properties of polyvinylidene fluoride crystal. J. Phys. Condens. Matter 2003, 15, 3805–3811. [Google Scholar] [CrossRef] [Green Version]

- Ismail, A.; Mohammed, M.; Fouad, S. Optical and structural properties of polyvinylidene fluoride (PVDF)/reduced graphene oxide (RGO) nanocomposites. J. Mol. Struct. 2018, 1170, 51–59. [Google Scholar] [CrossRef]

- The Vacuum Deposition of Gold. Available online: https://link.springer.com/journal/13404/volumes-and-issues/4-2 (accessed on 10 October 2020).

- Southin, J.E.A.; Wilson, S.A.; Schmitt, D.; Whatmore, R.W. e31,f determination for PZT films using a conventional ‘d33′ meter. J. Phys. D Appl. Phys. 2001, 34, 1456–1460. [Google Scholar] [CrossRef]

- Gao, J.; Xue, D.; Wang, Y.; Wang, D.; Zhang, L.; Wu, H.; Guo, S.; Bao, H.; Zhou, C.; Liu, W.; et al. Microstructure basis for strong piezoelectricity in Pb-free Ba(Zr0.2Ti0.8)O3-(Ba0.7Ca0.3)TiO3 ceramics. Appl. Phys. Lett. 2011, 99, 092901. [Google Scholar] [CrossRef]

- Cordero, F.; Craciun, F.; Dinescu, M.; Scarisoreanu, N.D.; Galassi, C.; Schranz, W.; Soprunyuk, V.P. Elastic response of (1–x)Ba(Ti0.8Zr0.2)O3−x(Ba0.7Ca0.3)TiO3 (x = 0.45–0.55) and the role of the intermediate orthorhombic phase in enhancing the piezoelectric coupling. Appl. Phys. Lett. 2014, 105, 232904. [Google Scholar] [CrossRef]

- Kalkur, T.S.; Yi, W.-C.; Philofsky, E.; Kammerdiner, L.; Rywak, T. Electrical characteristics of high dielectric constant BCTZ thin films. Integr. Ferroelectr. 2001, 38, 289–295. [Google Scholar] [CrossRef]

- Bao, H.; Zhou, C.; Xue, D.; Gao, J.; Ren, X. A modified lead-free piezoelectric BZT–xBCT system with higher TC. J. Phys. D Appl. Phys. 2010, 43, 465401. [Google Scholar] [CrossRef]

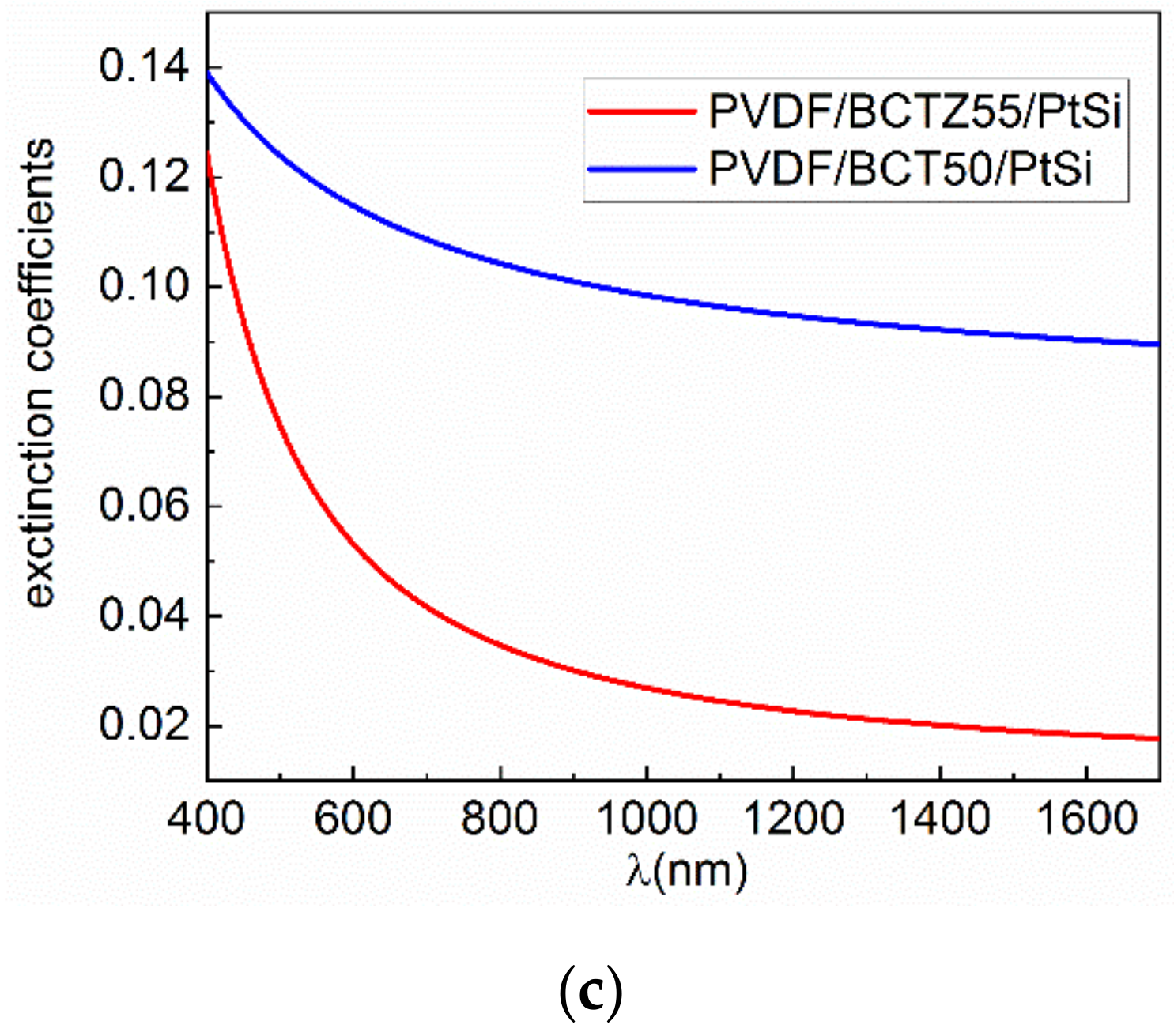

| Probe | Thickness (nm) | Roughness (nm) |

|---|---|---|

| PVDF/BCTZ55/PtSi | 467.53 ± 0.0625 | 25.287 ± 0.0462 |

| PVDF/BCTZ50/PtSi | 470.12 ± 0.0901 | 33.797 ± 0.0661 |

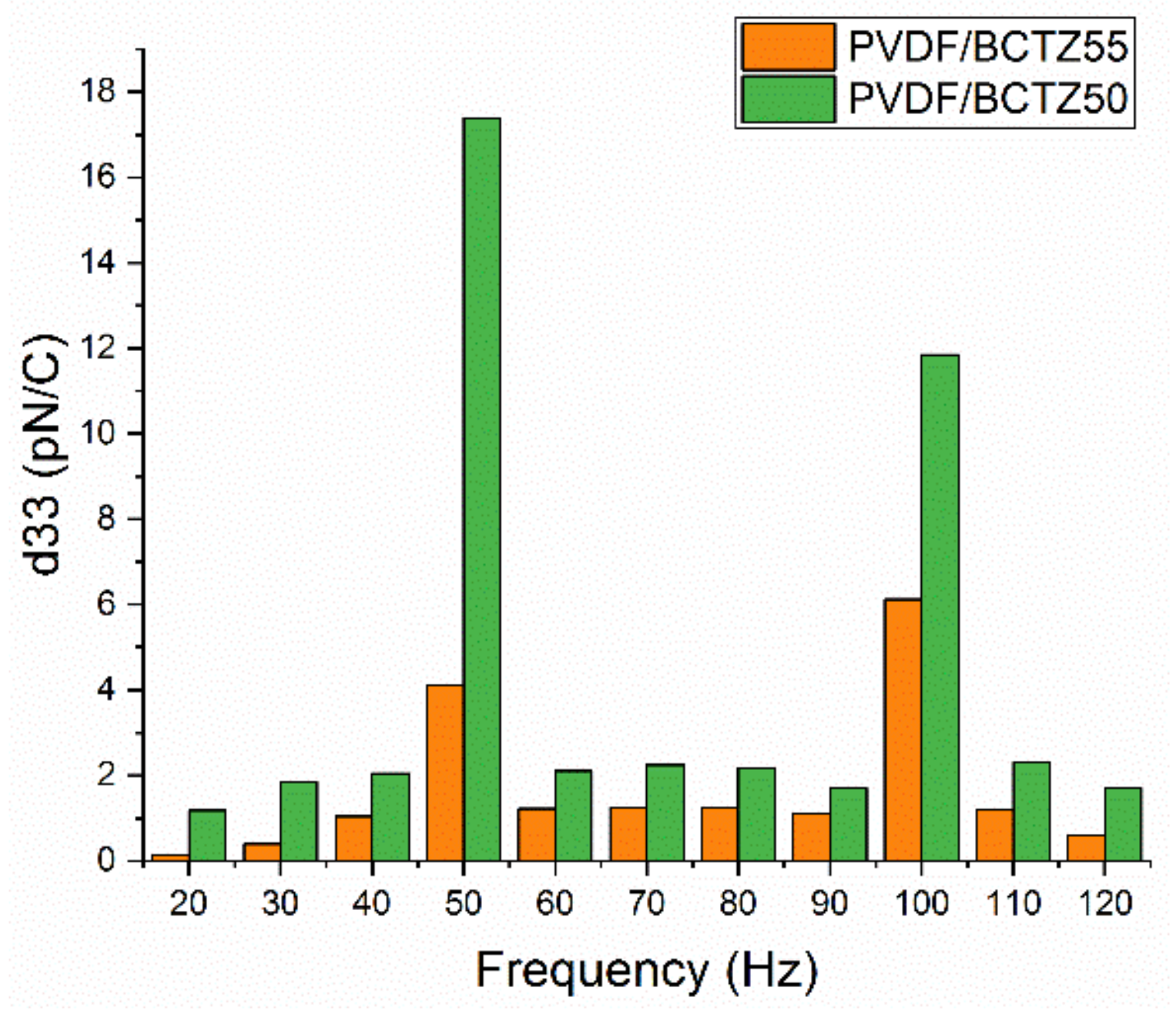

| Probe | Capacitance (pF) | Dielectric Loss (Tan δ) |

|---|---|---|

| PVDF/BCTZ55 | 147 | 0.0006 |

| PVDF/BCTZ50 | 5970 | 0.036 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Enea, N.; Ion, V.; Moldovan, A.; Bonciu, A.; Scarisoreanu, N.D. Piezoelectric Hybrid Heterostructures PVDF/(Ba,Ca)(Zr,Ti)O3 Obtained by Laser Techniques. Coatings 2020, 10, 1155. https://doi.org/10.3390/coatings10121155

Enea N, Ion V, Moldovan A, Bonciu A, Scarisoreanu ND. Piezoelectric Hybrid Heterostructures PVDF/(Ba,Ca)(Zr,Ti)O3 Obtained by Laser Techniques. Coatings. 2020; 10(12):1155. https://doi.org/10.3390/coatings10121155

Chicago/Turabian StyleEnea, Nicoleta, Valentin Ion, Antoniu Moldovan, Anca Bonciu, and Nicu Doinel Scarisoreanu. 2020. "Piezoelectric Hybrid Heterostructures PVDF/(Ba,Ca)(Zr,Ti)O3 Obtained by Laser Techniques" Coatings 10, no. 12: 1155. https://doi.org/10.3390/coatings10121155