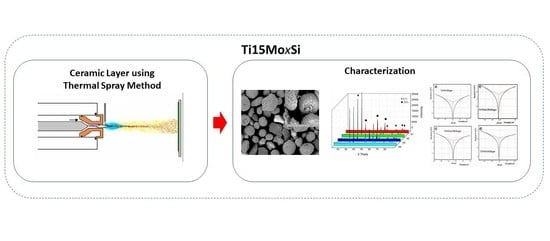

Microstructural Analysis and Tribological Behavior of Ti-Based Alloys with a Ceramic Layer Using the Thermal Spray Method

Abstract

:1. Introduction

2. Materials and Methods

2.1. Ti-Mo-Si Substrate Alloys

2.2. Atmospheric Plasma Jet Deposition

2.3. Morphological and Structural Analysis

2.4. Micro-Indentation Test

2.5. Electrochemical Analysis

3. Results and Discussion

3.1. Microstructural Analysis

3.2. Micro-Indentation Analysis

3.3. Electrochemical Analysis

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Niinomi, M. Titanium Alloys. In Encyclopedia of Biomedical Engineering; Elsevier: Amsterdam, The Netherlands, 2019; pp. 213–224. [Google Scholar]

- Chen, Q.; Thouas, G.A. Metallic implant biomaterials. Mater. Sci. Eng. R 2015, 87, 1–57. [Google Scholar] [CrossRef]

- Bombac, D.M.; Brojan, M.; Fajfar, P.; Kosel, F.; Turk, R. Review of materials in medical applications. RMZ Mater. Geoenviron. 2007, 54, 471–499. [Google Scholar]

- Antoniac, I. (Ed.) Handbook of Bioceramics and Biocomposites; Springer: Berlin/Heidelberg, Germany, 2016; Available online: https://www.springer.com/gp/book/9783319124599 (accessed on 15 September 2020).

- Song, Y.; Xu, D.S.; Yang, R.; Li, D.; Wu, W.T.; Guo, Z.X. Theoretical study of the effects of alloying elements on the strength and modulus of β-type bio-titanium alloys. Mater. Sci. Eng. A 1999, 260, 269–274. [Google Scholar] [CrossRef]

- Bermúdez, M.-D.; Carrión, F.J.; Martínez-Nicolás, G.; López, R. Erosion–corrosion of stainless steels, titanium, tantalum and zirconium. Wear 2005, 258, 693–700. [Google Scholar] [CrossRef]

- Sandu, A.V.; Baltatu, M.S.; Nabialek, M.; Savin, A.; Vizureanu, P. Characterization and mechanical proprieties of new TiMo alloys used for medical applications. Materials 2019, 12, 2973. [Google Scholar] [CrossRef] [Green Version]

- Geetha, M.; Singh, A.K.; Asokamani, R.; Gogia, A.K. Ti based biomaterials, the ultimate choice for orthopaedic implants—A review. Mater. Sci. 2009, 54, 397–425. [Google Scholar] [CrossRef]

- Niinomi, M. Mechanical properties of biomedical titanium alloys. Mater. Sci. Eng. A 1998, 243, 231–236. [Google Scholar] [CrossRef]

- Elias, C.N.; Lima, J.H.C.; Valiev, R.; Meyers, M.A. Biomedical applications of titanium and its alloys (Review). Biol. Mater. Sci. 2008, 60, 46–49. [Google Scholar] [CrossRef]

- Baltatu, M.S.; Tugui, C.A.; Perju, M.C.; Benchea, M.; Spataru, M.C.; Sandu, A.V.; Vizureanu, P. Biocompatible titanium alloys used in medical applications. Rev. Chim. 2019, 70, 1302–1306. [Google Scholar] [CrossRef]

- Minciuna, M.G.; Vizureanu, P.; Geanta, V.; Voiculescu, I.; Sandu, A.V.; Achitei, D.C.; Vitalariu, A.M. Effect of Si on the mechanical properties of biomedical CoCrMo alloys. Rev. Chim. 2015, 66, 891–894. [Google Scholar]

- Baltatu, M.S.; Vizureanu, P.; Balan, T.; Lohan, M.; Tugui, C.A. Preliminary tests for Ti-Mo-Zr-Ta alloys as potential biomaterials. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Iasi, Romania, 17–18 May 2018; p. 12023. [Google Scholar] [CrossRef]

- Baltatu, M.S.; Vizureanu, P.; Geanta, V.; Nejneru, C.; Tugui, C.A.; Focsaneanu, S.C. Obtaining and Mechanical Properties of Ti-Mo-Zr-Ta Alloys. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Iasi, Romania, 25–26 May 2017; p. 12019. [Google Scholar] [CrossRef] [Green Version]

- Kirmanidou, Y.; Sidira, M.; Drosou, M.E.; Bennani, V.; Bakopoulou, A.; Tsouknidas, A.; Michailidis, N.; Michalakis, K. New Ti-Alloys and Surface Modifications to Improve the Mechanical Properties and the Biological Response to Orthopedic and Dental Implants: A Review. BioMed Res. Int. 2016, 2016, 2908570. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Simoes, S. Recent Progress in the Joining of Titanium Alloys to Ceramics. Metals 2018, 8, 876. [Google Scholar] [CrossRef] [Green Version]

- Feng, J.; Dai, X.; Wang, D.; Li, R.; Cao, J. Microstructure evolution and mechanical properties of ZrO2/TiAl joints vacuum brazed by Ag-Cu filler metal. Mater. Sci. Eng. A 2015, 639, 739–746. [Google Scholar] [CrossRef]

- Baltatu, M.S.; Vizureanu, P.; Goanţă, V.; Tugui, C.A.; Voiculescu, I. Mechanical tests for Ti-based alloys as new medical materials. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Iasi, Romania, 16–17 May 2019; p. 012029. [Google Scholar]

- Gautam, C.; Joyner, J.; Gautam, A.; Rao, J.; Vajtai, R. Zirconia based dental ceramics: Structure, mechanical properties, biocompatibility and applications. Dalton Trans. 2016, 45, 19194–19215. [Google Scholar] [CrossRef]

- Alghazzawi, T.F.; Janowski, G.M. Effect of liner and porcelain application on zirconia surface structure and composition. Int. J. Oral Sci. 2016, 8, 164–171. [Google Scholar] [CrossRef] [Green Version]

- Baloyi, N.M.; Popoola, A.P.I.; Pityana, S.L. Laser coating of Zirconium and ZrO2 composites on Ti6Al4V for biomedical applications. S. Afr. J. Ind. Eng. 2014, 25, 62–70. [Google Scholar] [CrossRef] [Green Version]

- Li, J.N.; Chen, C.Z. Effect of ZrO2 (YPSZ) on microstructure characteristic and wear resistance of the Ti3Al/TiC laser-cladded ceramic layer on titanium alloy. Int. J. Appl. Ceram. Technol. 2012, 9, 947–952. [Google Scholar] [CrossRef]

- Wang, Y.; Li, C.; Jiang, F.; Zhang, J.; An, X. Microstructure and mechanical properties of ultrasonic assisted laser cladding Al2O3–ZrO2 ceramic coating. Mater. Res. Express 2019, 6, 106563. [Google Scholar] [CrossRef]

- Vilardell, A.M.; Cinca, N.; Garcia-Giralt, N.; Dosta, S.; Cano, I.G.; Nogues, X.; Guilemany, J.M. In-vitro comparison of hydroxyapatite coatings obtained by cold spray and conventional thermal spray technologies. Mater. Sci. Eng. C 2020, 107, 110306. [Google Scholar] [CrossRef]

- Marquer, M.; Phiippon, S.; Faure, L.; Chassaing, G.; Tardelli, J.; Demmou, K. Influence of two APS coatings on the high-speed tribological behavior of a contact between titanium alloys. Tribol. Int. 2019, 136, 13–22. [Google Scholar] [CrossRef]

- Stern, K.H. Metallurgical and Ceramic Protective Coatings; Springer: Dordrecht, The Netherlands, 1996. [Google Scholar]

- Chevalier, J.; Gremillard, L.; Deville, S. Low-temperature degradation of zirconia and implications for biomedical implants. Ann. Rev. Mater. Res. 2007, 37, 1–32. [Google Scholar] [CrossRef] [Green Version]

- Stescu, C.; Chicet, D.L.; Munteanu, C.M.; Istrate, B.; Benchea, M.; Basescu, G.N. Aspects regarding the influence of the processing regime on the surface quality of thermal sprayed coatings. In IOP Conference Series: Materials Science and Engineering; IOP Publishing Ltd.: Bristol, UK, 2018; Volume 444, p. 032012. [Google Scholar] [CrossRef]

- Zheng, K.; Li, L.; Dong, Y.; Gao, J.; Hei, H.; Ma, Y.; Zhou, B.; He, Z.; Wang, Y.; Yu, S.; et al. Preparation, microstructure, mechanical properties and biocompatibility of Ta-coated 3Y-TZP ceramic deposited by a plasma surface alloying technique. Materials 2020, 13, 1265. [Google Scholar] [CrossRef] [Green Version]

- Lupescu, S.; Munteanu, C.; Istrate, B.; Earar, K. The influence of zr on microstructure, mechanical properties and corrosion resistance in Mg-Y-Zr biodegradable alloys. Rev. Chim. 2018, 69, 3382–3385. [Google Scholar] [CrossRef]

- Hannink, R.H.; Kelly, P.M.; Muddle, B.C. Transformation toughening in zirconia—containing ceramics. J. Am. Ceram. Soc. 2010, 83, 461–487. [Google Scholar] [CrossRef]

| Sample | Ti (wt.%) | Mo (wt.%) | Si (wt.%) | |

|---|---|---|---|---|

| S1 | Average | 84.5 | 15.5 | - |

| Stdev | ±0.2 | ±0.2 | - | |

| S2 | Average | 84.7 | 15.0 | 0.3 |

| Stdev | ±0.2 | ±0.3 | ±0.1 | |

| S3 | Average | 83.8 | 15.3 | 0.9 |

| Stdev | ±0.9 | ±0.2 | ±0.1 | |

| S4 | Average | 83.9 | 15.1 | 1.0 |

| Stdev | ±0.6 | ±0.5 | ±0.1 | |

| Powder | Gun Type | Ar | H2 | Electric | Powder Feeder 9 MP | Spraying Distance [mm] | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Pressure [MPa] | Gas Flow [NLPM] | Pressure [MPa] | Gas Flow [NLPM] | DC [A] | DC [V] | Carrier Gas Flow [NLPM] | Air Pressure [MPa] | Quantity [g/min] | |||

| ZrO2 | 9 MB | 350 | 40 | 350 | 6.7 | 400 | 70–80 | 5.1 | 150 | 126 | 105 |

| Sample * | S1 | S2 | S3 | S4 | |

|---|---|---|---|---|---|

| Average chemical composition | Zr (wt.%) | 78.3 ± 0.3 | 74.3± 0.1 | 77.7 ± 0.1 | 70.8 ± 0.2 |

| O (wt.%) | 21.7 ± 0.1 | 25.7 ± 0.2 | 22.3 ± 0.3 | 29.2 ± 0.2 | |

| Sample | Layer Thickness (µm) |

|---|---|

| S1-ZrO2 | 83.30 ± 3.3 |

| S2-ZrO2 | 82.56 ± 4.4 |

| S3-ZrO2 | 85.77 ± 4.1 |

| S4-ZrO2 | 84.30 ± 3.0 |

| Sample | Loading Deformation [N] | Release Deformation [μm] | Young’s Modulus [GPa] | Stiffness [N/μm] | Specimen Poisson Ration |

|---|---|---|---|---|---|

| S1-ZrO2 | 13.5 ± 0.5 | 12.2 ± 0.5 | 48.3 ± 0.5 | 6.2 ± 0.5 | 0.23 |

| S2-ZrO2 | 13.5 ± 0.5 | 9.7 ± 0.5 | 51.7 ± 0.5 | 5.8 ± 0.5 | 0.23 |

| S3-ZrO2 | 13.5 ± 0.5 | 12.1 ± 0.5 | 49.1 ± 0.5 | 6.3 ± 0.5 | 0.23 |

| S4-ZrO2 | 13.5 ± 0.5 | 11.4 ± 0.5 | 50.7 ± 0.5 | 6.2 ± 0.5 | 0.23 |

| Sample | Ecor, [mV] | Rp, [kohm.cm2] | Icor, [A/cm2] | Vcor, [m/year] | ba, [mV/dec.] | bc, [mV/dec.] |

|---|---|---|---|---|---|---|

| S1-ZrO2 | −303 | 11.18 | 3.033 | 29.30 | 194 | −180 |

| S2-ZrO2 | −266 | 14.91 | 2.131 | 20.59 | 200 | −192 |

| S3-ZrO2 | −223 | 7.49 | 4.458 | 43.09 | 222 | −166 |

| S4-ZrO2 | −309 | 8.99 | 3.963 | 38.30 | 278 | −152 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Baltatu, M.S.; Vizureanu, P.; Sandu, A.V.; Munteanu, C.; Istrate, B. Microstructural Analysis and Tribological Behavior of Ti-Based Alloys with a Ceramic Layer Using the Thermal Spray Method. Coatings 2020, 10, 1216. https://doi.org/10.3390/coatings10121216

Baltatu MS, Vizureanu P, Sandu AV, Munteanu C, Istrate B. Microstructural Analysis and Tribological Behavior of Ti-Based Alloys with a Ceramic Layer Using the Thermal Spray Method. Coatings. 2020; 10(12):1216. https://doi.org/10.3390/coatings10121216

Chicago/Turabian StyleBaltatu, Madalina Simona, Petrica Vizureanu, Andrei Victor Sandu, Corneliu Munteanu, and Bogdan Istrate. 2020. "Microstructural Analysis and Tribological Behavior of Ti-Based Alloys with a Ceramic Layer Using the Thermal Spray Method" Coatings 10, no. 12: 1216. https://doi.org/10.3390/coatings10121216

APA StyleBaltatu, M. S., Vizureanu, P., Sandu, A. V., Munteanu, C., & Istrate, B. (2020). Microstructural Analysis and Tribological Behavior of Ti-Based Alloys with a Ceramic Layer Using the Thermal Spray Method. Coatings, 10(12), 1216. https://doi.org/10.3390/coatings10121216