Preparation of WC Reinforced Co-Based Alloy Gradient Coatings on a H13 Mold Steel Substrate by Laser Cladding

Abstract

:1. Introduction

2. Experimental Materials and Methods

2.1. Material and Sample Preparation

2.2. Analysis Methods

3. Results and Discussion

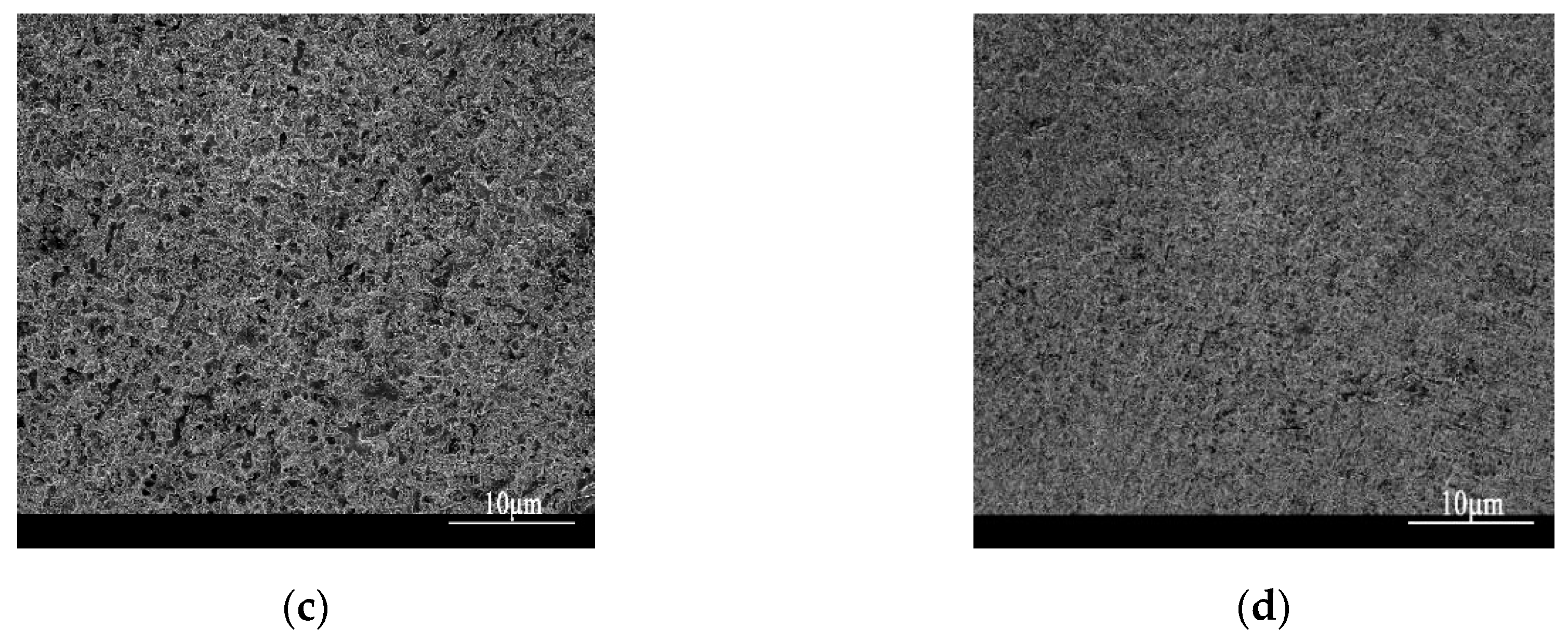

3.1. Morphology and Microstructure

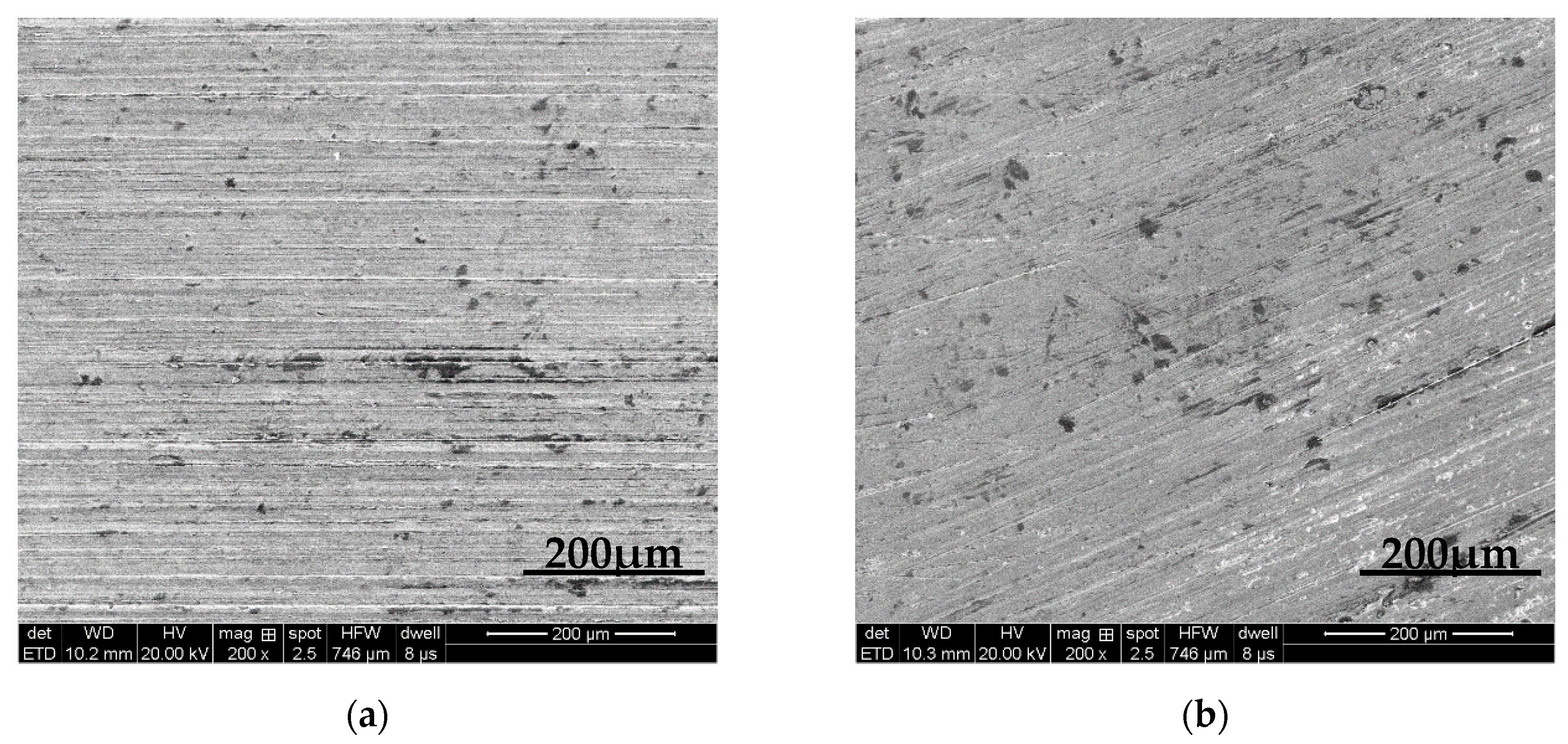

3.2. Hardness and Tribological Measurements

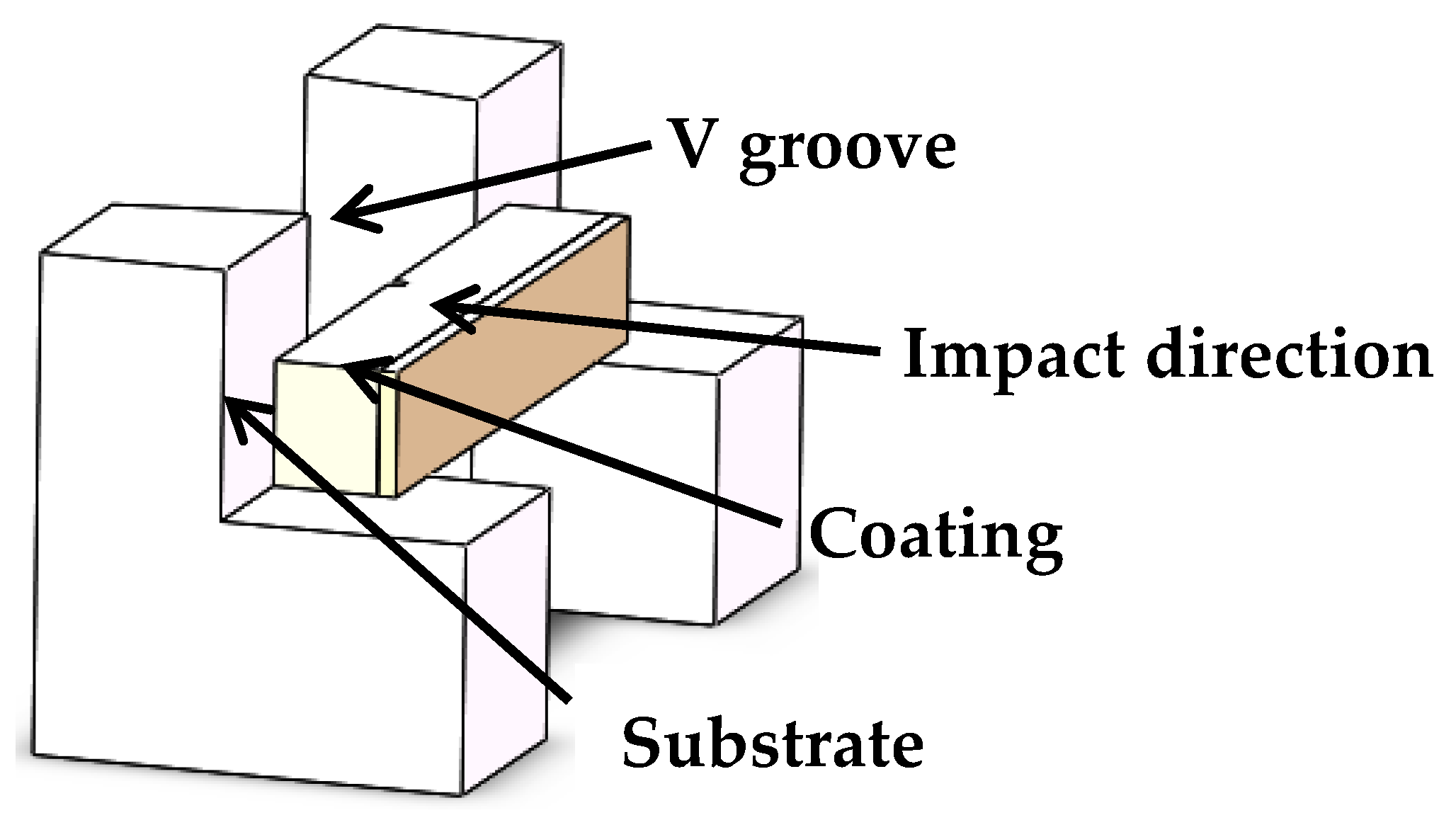

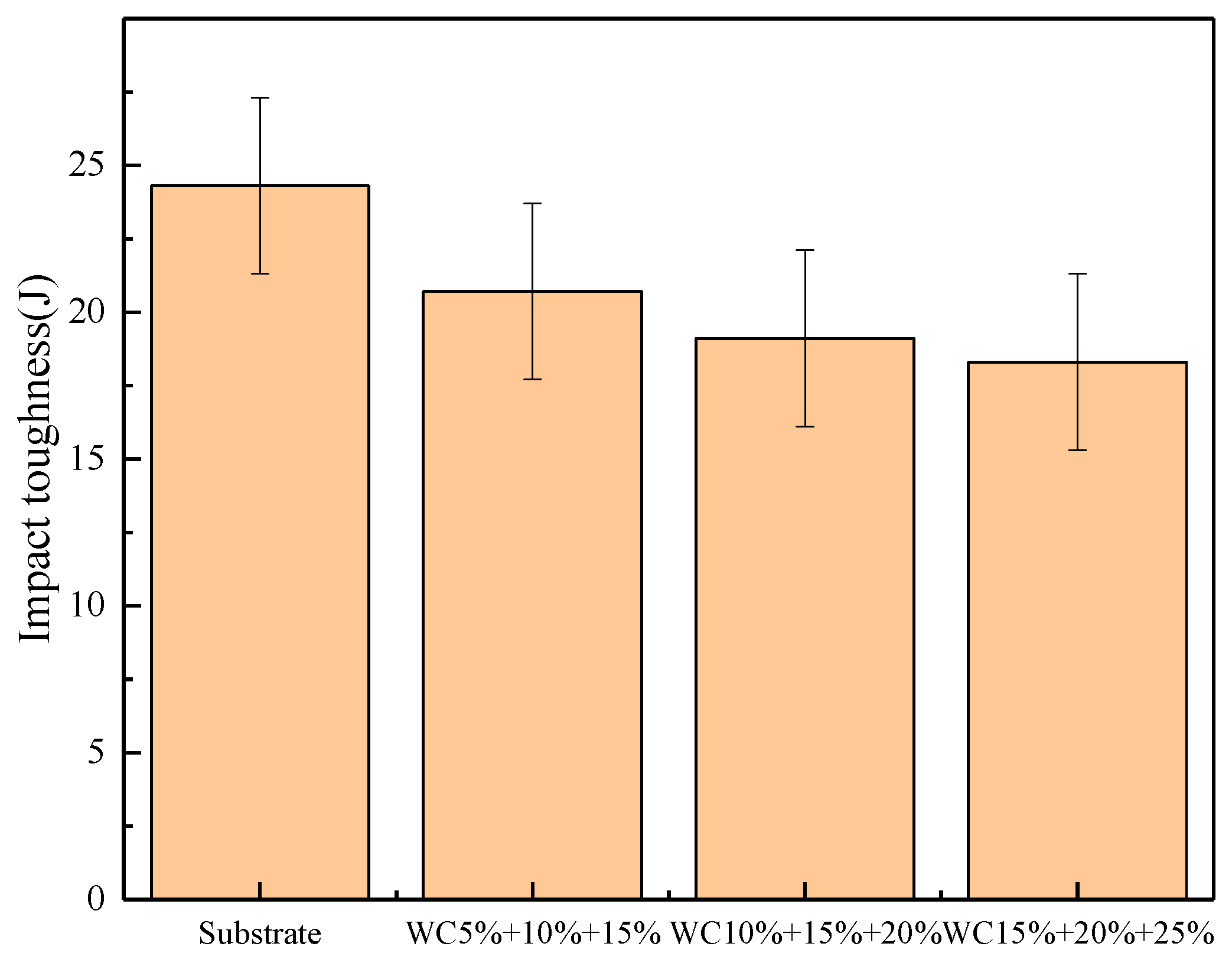

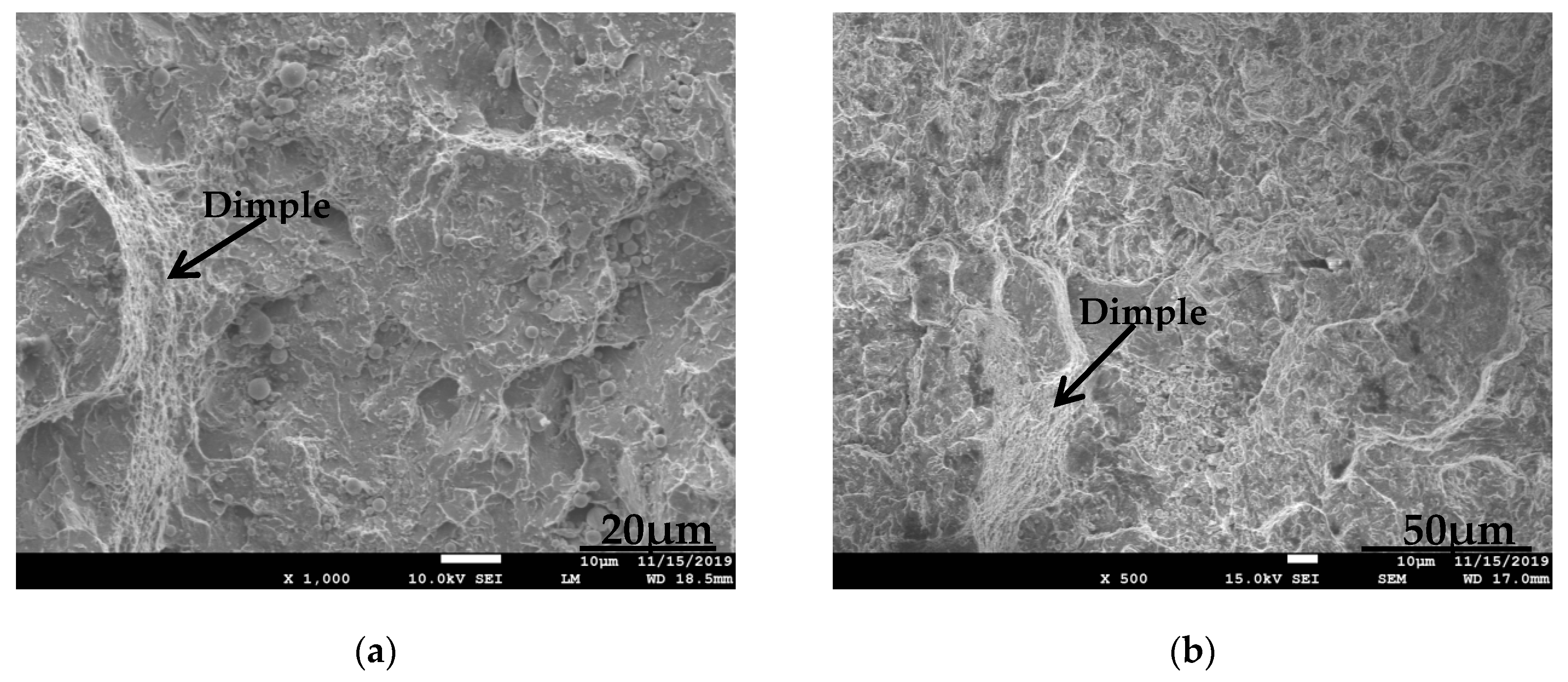

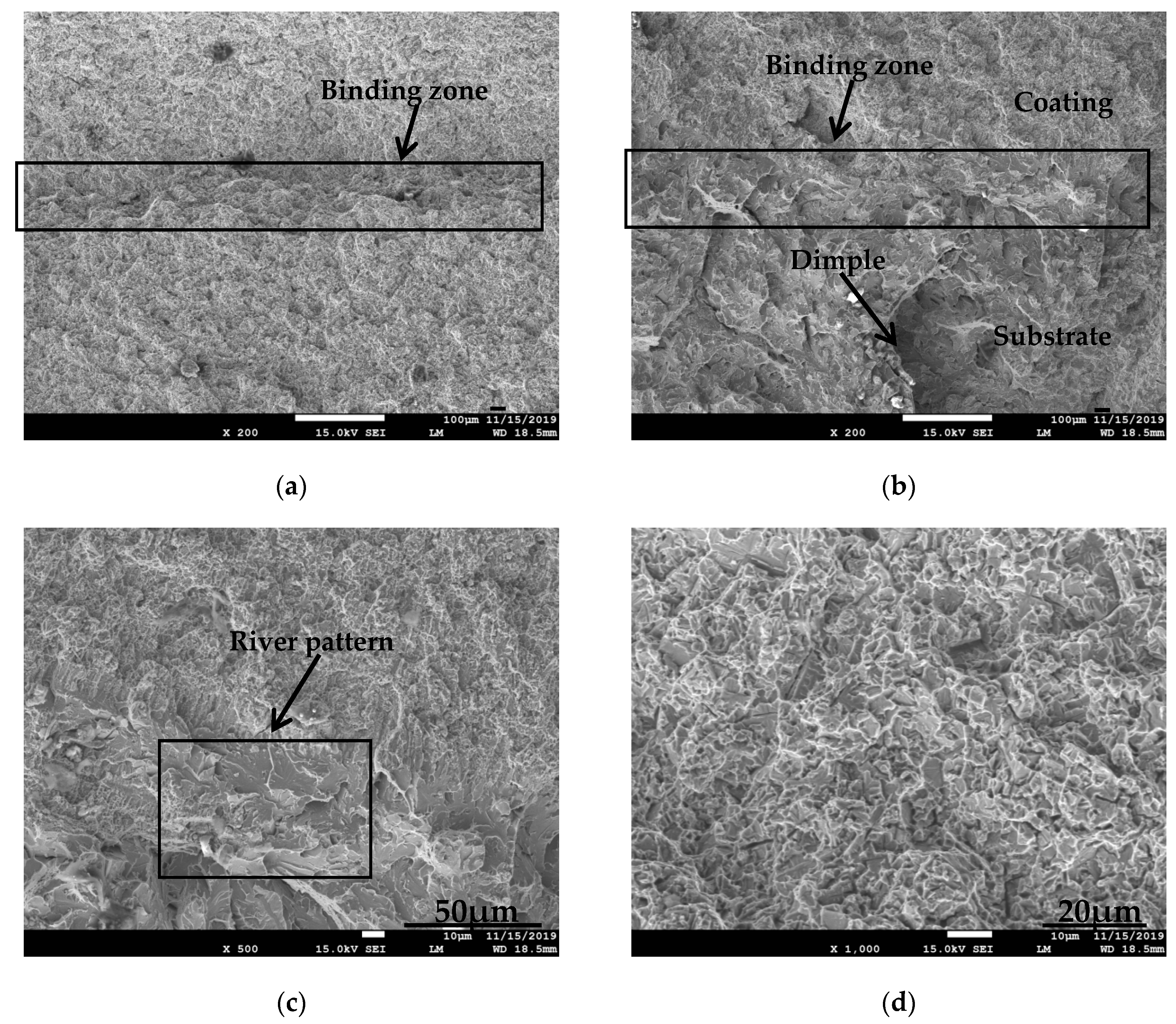

3.3. Impact Toughness Measurements

3.4. Corrosion Resistance Measurements

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Wang, X.Y.; Wang, J.H.; Gao, Z.M.; Xia, D.H.; Hu, W.B. Tempering effects on the microstructure and properties of submerged arc surfacing layers of H13 steel. J. Mater. Process. Technol. 2019, 269, 26–34. [Google Scholar] [CrossRef]

- Li, X.; Yan, X.; Zhang, Z. Springback Prediction of a Hot Stamping Component Based on the Area Fractions of Phases. Metals 2019, 9, 694. [Google Scholar] [CrossRef] [Green Version]

- Praveen, A.S.; Arjunan, A. Effect of nano-Al2O3 addition on the microstructure and erosion wear of HVOF sprayed NiCrSiB coatings. Mater. Res. Express 2019, 7, 015006. [Google Scholar] [CrossRef] [Green Version]

- Praveen, A.S.; Arjunan, A. Parametric optimisation of high-velocity oxy-fuel nickel-chromium-silicon-boron and aluminium-oxide coating to improve erosion wear resistance. Mater. Res. Express 2019, 6, 096560. [Google Scholar] [CrossRef]

- Zhu, J.; Zhang, Z.H.; Xie, J.X. Improving strength and ductility of H13 die steel by pre-tempering treatment and its mechanism. Mater. Sci. Eng. A 2019, 752, 101–114. [Google Scholar] [CrossRef]

- Zang, C.L.; Zhou, T.; Zhou, H.; Yuan, Y.H.; Zhang, P.; Meng, C.; Zhang, Z.H. Effects of substrate microstructure on biomimetic unit properties and wear resistance of H13 steel processed by laser remelting. Opt. Laser Technol. 2018, 106, 299–310. [Google Scholar] [CrossRef]

- Nusrat, T.; Roger, C.; Sumsun, N. Progress in numerical simulation of the laser cladding process. Opt. Lasers Eng. 2019, 122, 151–163. [Google Scholar] [CrossRef]

- Rodríguez-Barrero, S.; Fernández-Larrinoa, J.; Azkona, I.; López de Lacalle, L.N.; Polvorosa, R. Enhanced Performance of Nanostructured Coatings for Drilling by Droplet Elimination. Mater. Manuf. Process. 2014, 31, 593–602. [Google Scholar] [CrossRef]

- Mohammad, E.; Reza, S.R.; Hassan, A.P.; Hamidreza, M.S. Influence of using electroless Ni-P coated WC-Co powder on laser cladding of stainless steel. Surf. Coat. Technol. 2018, 348, 41–54. [Google Scholar] [CrossRef]

- Gao, W.Y.; Chang, C.; Li, G.; Xue, Y.F.; Wang, J.L.; Zhang, Z.Y.; Lin, X.C. Study on the laser cladding of FeCrNi coating. Optik 2019, 178, 950–957. [Google Scholar] [CrossRef]

- Alexandru, P.; Julia, M.R.; Elena, M.S. Laser cladding: From experimental research to industrial applications. Mater. Today Proc. 2019, 19, 1059–1065. [Google Scholar] [CrossRef]

- Muro, M.; Artola, G.; Leunda, J.; Soriano, C.; Angulo, C. Compositional Modification of Tool Steel to Improve Its Wear Resistance. Metall. Mater. Trans. A 2019, 50, 3912–3921. [Google Scholar] [CrossRef]

- Muro, M.; Leunda, J.; Artola, G.; Soriano, C. Microstructural Tuning of a Laser-Cladding Layer by Means of a Mix of Commercial Inconel 625 and AISI H13 Powders. Materials 2019, 12, 544. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Balokhonov, R.R.; Romanova, V.A.; Schmauder, S.; Emelianova, E.S. A numerical study of plastic strain localization and fracture across multiple spatial scales in materials with metal-matrix composite coatings. Theor. Appl. Fract. Mech. 2019, 101, 342–355. [Google Scholar] [CrossRef]

- He, X.; Yuan, X.H.; Xu, H.; Song, P.; Yu, X.; Li, C.; Huang, T.H.; Li, Q.L.; Lü, K.Y.; Feng, J.; et al. Analysis of structure and microhardness of Al2O3-40 wt.% TiO2/NiCoCrAl gradient coating with in-situ needle-like phase reinforcement after high-temperature treatment. Ceram. Int. 2019, 45, 14546–14554. [Google Scholar] [CrossRef]

- Bai, H.Q.; Zhong, L.S.; Shang, Z.; Xu, Y.H.; Wu, H.; Bai, J.M.; Ding, Y.C. Microstructure and mechanical properties of TiC-Fe surface gradient coating on a pure titanium substrate prepared in situ. J. Alloys Compd. 2019, 771, 406–417. [Google Scholar] [CrossRef]

- Zhang, M.Y.; Li, M.; Chi, J.; Wang, S.F.; Yang, S.; Yang, J.; Wei, Y.J. Effect of Ti on microstructure characteristics, carbide precipitation mechanism and tribological behavior of different WC types reinforced Ni-based gradient coating. Surf. Coat. Technol. 2019, 374, 645–655. [Google Scholar] [CrossRef]

- Elmkhah, H.; Mahboubi, F.; Abdollah-zadeh, A.; Sabour Rouhaghdam, A.R. A new approach to improve the surface properties of H13 steel for metal forming applications by applying the TiAlN multi-layer coating. J. Manuf. Process. 2018, 32, 873–877. [Google Scholar] [CrossRef]

| Element | C | Si | Mn | Cr | Mo | V | P | S | Fe |

|---|---|---|---|---|---|---|---|---|---|

| Content (wt.%) | 0.32~0.45 | 0.80~1.20 | 0.20~0.50 | 4.75~5.50 | 1.10~1.75 | 0.80~1.20 | ≤0.03 | ≤0.03 | Bal. |

| Element | C | Si | Mn | Cr | Mo | Fe | Ni | W | Co |

|---|---|---|---|---|---|---|---|---|---|

| Content (wt.%) | 1.15 | 1.10 | 0.50 | 29.00 | 1.00 | 3.00 | 3.00 | 4.00 | Bal. |

| First Layer | Second Layer | Third Layer | |

|---|---|---|---|

| First sample | 95% Co + 5% WC | 90% Co + 10% WC | 85% Co + 15% WC |

| Second sample | 90% Co + 10% WC | 85% Co + 15% WC | 80% Co + 20% WC |

| Third sample | 85% Co + 15% WC | 80% Co + 20% WC | 75% Co + 25% WC |

| Parameter | Defocusing Amount (mm) | Frequency (Hz) | Scanning Speed (mm/min) | Pulse Width (ms) | Single Pulse Energy (J) |

|---|---|---|---|---|---|

| Value | 20 | 30 | 100 | 2.0 | 6.5 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, C.; Yang, X.; Wang, S.; Wang, Y.; Cao, J. Preparation of WC Reinforced Co-Based Alloy Gradient Coatings on a H13 Mold Steel Substrate by Laser Cladding. Coatings 2020, 10, 176. https://doi.org/10.3390/coatings10020176

Li C, Yang X, Wang S, Wang Y, Cao J. Preparation of WC Reinforced Co-Based Alloy Gradient Coatings on a H13 Mold Steel Substrate by Laser Cladding. Coatings. 2020; 10(2):176. https://doi.org/10.3390/coatings10020176

Chicago/Turabian StyleLi, Chenchen, Xuefeng Yang, Shouren Wang, Yanjun Wang, and Jinlong Cao. 2020. "Preparation of WC Reinforced Co-Based Alloy Gradient Coatings on a H13 Mold Steel Substrate by Laser Cladding" Coatings 10, no. 2: 176. https://doi.org/10.3390/coatings10020176

APA StyleLi, C., Yang, X., Wang, S., Wang, Y., & Cao, J. (2020). Preparation of WC Reinforced Co-Based Alloy Gradient Coatings on a H13 Mold Steel Substrate by Laser Cladding. Coatings, 10(2), 176. https://doi.org/10.3390/coatings10020176