Powder Properties and Processing Conditions Affecting Cold Spray Deposition

Abstract

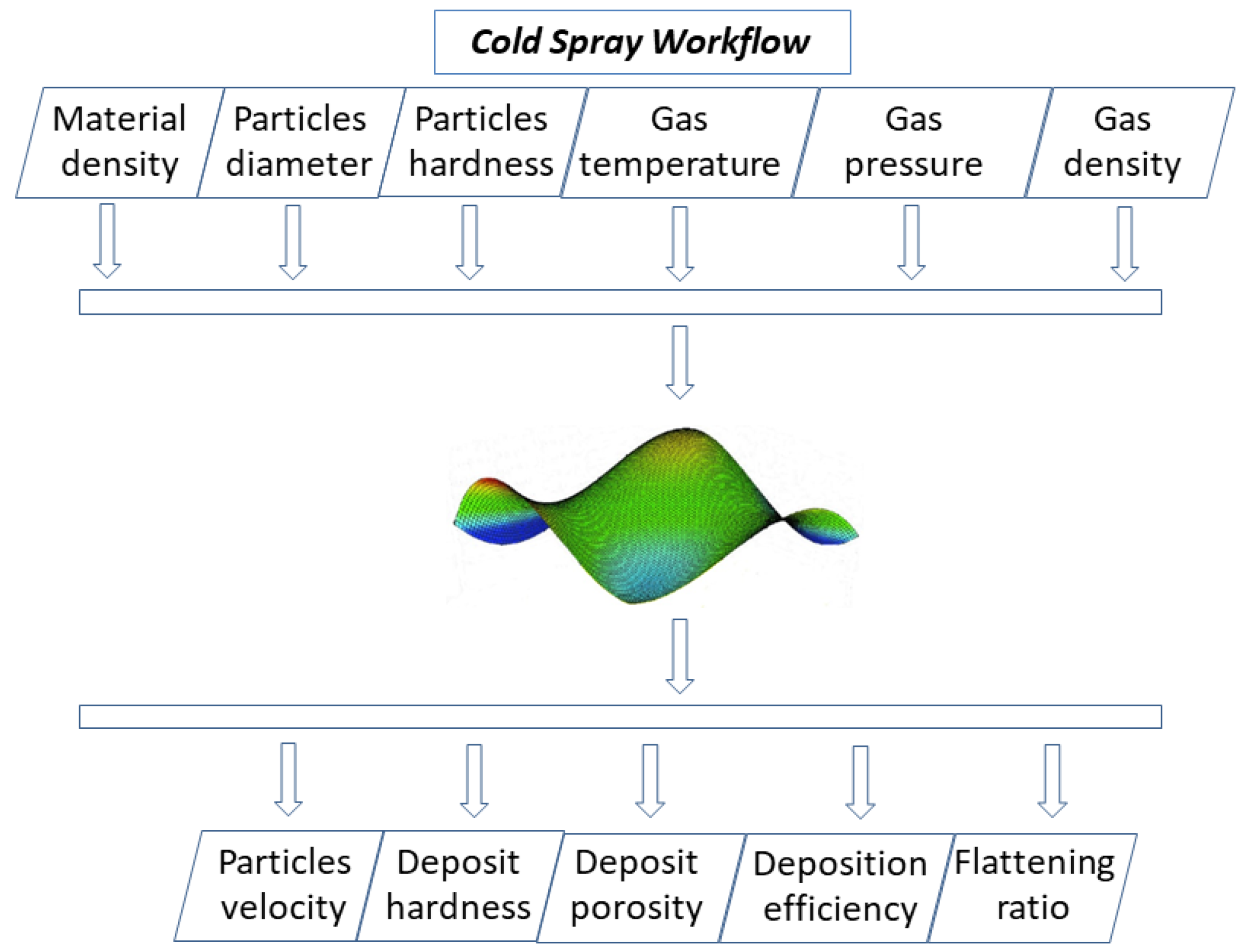

:1. Introduction

2. Materials and Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Raoelison, R.N.; Xie, Y.; Sapanathan, T.; Planche, M.P.; Kromer, R.; Costil, S.; Langlade, C. Cold gas dynamic spray technology: A comprehensive review of processing conditions for various technological developments till to date. Addit. Manuf. 2018, 19, 134–159. [Google Scholar] [CrossRef]

- Yin, S.; Cavaliere, P.; Aldwell, B.; Jenkins, R.; Liao, H.; Lid, W.; Lupoi, R. Cold spray additive manufacturing and repair: Fundamentals and applications. Addit. Manuf. 2018, 21, 628–650. [Google Scholar] [CrossRef]

- Ichikawa, Y.; Tokoro, R.; Tanno, M.; Ogawa, K. Elucidation of cold-spray deposition mechanism by auger electron spectroscopic evaluation of bonding interface oxide film. Acta Mater. 2019, 164, 39–49. [Google Scholar] [CrossRef]

- Hassani-Gangaraj, M.; Veysset, D.; Champagne, V.K.; Nelson, K.A.; Schuh, C.A. Adiabatic shear instability is not necessary for adhesion in cold spray. Acta Mater. 2018, 158, 430–439. [Google Scholar] [CrossRef]

- Grujicic, M.; Saylor, J.R.; Beasley, D.E.; De Rosset, W.S.; Helfritch, D. Computational analysis of the interfacial bonding between feed-powder particles and the substrate in the cold-gas dynamic-spray process. Appl. Surf. Sci. 2003, 219, 211–227. [Google Scholar] [CrossRef]

- Cavaliere, P.; Perrone, A.; Silvello, A. Crystallization evolution of cold-sprayed pure Ni coatings. J. Therm. Spray Technol. 2016, 25, 1158–1167. [Google Scholar] [CrossRef]

- Rafaja, D.; Schucknecht, T.; Klemm, V.; Paul, A.; Berek, H. Microstructural characterisation of titanium coatings deposited using cold gas spraying on Al2O3 substrates. Surf. Coat. Technol. 2009, 203, 3206–3213. [Google Scholar] [CrossRef]

- Theimer, S.; Graunitz, M.; Schulze, M.; Gaertner, F.; Klassen, T. Optimization adhesion in cold spraying onto hard substrates: A case study for brass coatings. J. Therm. Spray Technol. 2019, 28, 124–134. [Google Scholar] [CrossRef]

- Cavaliere, P.; Silvello, A. Fatigue behavior of cold sprayed metals and alloys: A critical review. Surf. Eng. 2016, 32, 631–640. [Google Scholar] [CrossRef]

- Yin, S.; Meyer, M.; Li, W.; Liao, H.; Lupoi, R. Gas flow, particle acceleration, and heat transfer in cold spray: A review. J. Therm. Spray Technol. 2016, 25, 874–896. [Google Scholar] [CrossRef]

- Prisco, U. Size-dependent distributions of particle velocity and temperature at impact in the cold-gas dynamic-spray process. J. Mater. Proc. Technol. 2015, 216, 302–314. [Google Scholar] [CrossRef]

- Ozdemir, O.C.; Widener, C.A. Influence of powder injection parameters in high-pressure cold spray. J. Therm. Spray Technol. 2017, 26, 1411–1422. [Google Scholar] [CrossRef]

- Krull, F.; Hesse, R.; Breuninger, P.; Antonyuk, S. Impact behaviour of microparticles with microstructured surfaces: Experimental study and DEM simulation. Chem. Eng. Res. Des. 2018, 175–184. [Google Scholar] [CrossRef]

- Leitz, K.H.; O’Sullivan, M.; Plankensteiner, A.; Lichtenegger, T.; Pirker, S.; Kestler, H.; Sigl, L.S. CFDEM modelling of particle heating and acceleration in cold spraying. Int. J. Refr. Met. Hard Mat. 2018, 73, 192–198. [Google Scholar] [CrossRef]

- Assadi, H.; Kreye, H.; Gartner, F.; Klassen, T. Cold spraying—A materials perspective. Acta Mater. 2016, 116, 382–407. [Google Scholar] [CrossRef] [Green Version]

- Champagne, V.K.; Helfritch, D.J.; Trexler, M.D.; Gabriel, B.M. The effect of cold spray impact velocity on deposit hardness. Modell. Simul. Mater. Sci. Eng. 2010, 18, 065011. [Google Scholar] [CrossRef]

- Assadi, H.; Schmidt, T.; Richter, H.; Kliemann, J.-O.; Binder, K.; Gärtner, F.; Klassen, T.; Kreye, H. On parameter selection in cold spraying. J. Therm. Spray Technol. 2010, 20, 1161–1176. [Google Scholar] [CrossRef]

- Katanoda, H.; Fukuhara, M.; Iino, N. Numerical study of combination parameters for particle impact velocity and temperature in cold spray. J. Therm. Spray Technol. 2007, 16, 627–633. [Google Scholar] [CrossRef] [Green Version]

- Lee, C.; Kim, J. Microstructure of kinetic spray coatings: A review. J. Therm. Spray Technol. 2015, 24, 592–610. [Google Scholar] [CrossRef]

- Rokni, M.R.; Nutt, S.R.; Widener, C.A.; Champagne, V.K.; Hrabe, R.H. Review of relationship between particle deformation, coating microstructure, and properties in high-pressure cold spray. J. Therm. Spray Technol. 2017, 26, 1308–1355. [Google Scholar] [CrossRef]

- Maestracci, R.; Sova, A.; Jeandin, M.; Malhaire, J.-M.; Movchan, I.; Bertrand, P.H.; Smurov, I. Deposition of composite coatings by cold spray using stainless steel 316L, copper and tribaloy T-700 powder mixtures. Surf. Coat. Technol. 2016, 287, 1–8. [Google Scholar] [CrossRef]

- Huang, J.; Ma, W.; Xie, Y.; Fukanum, H.; Zhang, K.; Wang, G.; Huang, R. Influence of cold gas spray processing conditions on the properties of 316L stainless steel coatings. Surf. Eng. 2019, 1–8. [Google Scholar] [CrossRef]

- Coddet, P.; Verdy, C.; Coddet, C.; Debray, F.; Lecouturier, F. Mechanical properties of thick 304L stainless steel deposits processed by He cold spray. Surf. Coat. Technol. 2015, 277, 74–80. [Google Scholar] [CrossRef]

- Concustell, A.; Henao, J.; Dosta, S.; Cinca, N.; Cano, I.G.; Guilemany, J.M. On the formation of metallic glass coatings by means of cold gas spray technology. J. Alloys Compd. 2015, 651, 764–772. [Google Scholar] [CrossRef]

- Luzin, V.; Spencer, K.; Zhang, M.-X. Residual stress and thermo-mechanical properties of cold spray metal coatings. Act. Mater. 2011, 59, 1259–1270. [Google Scholar] [CrossRef]

- Cavaliere, P. Cold-Spray Coatings: Recent Trends and Future Perspectives; Springer: New York, NY, USA, 2018. [Google Scholar] [CrossRef]

- Gilmore, D.L.; Dykhuizen, R.C.; Neiser, R.A.; Roemer, T.J.; Smith, M.F. Particle velocity and deposition efficiency in the cold spray process. J. Therm. Spray Technol. 1999, 8, 576–582. [Google Scholar] [CrossRef]

- McCune, R.C.; Donlon, W.T.; Popoola, O.O.; Cartwright, E.L. Characterization of copper layers produced by cold gas-dynamic spraying. J. Therm. Spray Technol. 2000, 5, 73–82. [Google Scholar] [CrossRef]

- Chavan, N.M.; Kumar, M.V.; Phani, S.P.; Pant, P.; Sundararajan, G. Influence of nozzle throat dimension on microstructure and properties of cold sprayed coatings. J. Therm. Spray Technol. 2019, 28, 1718–1729. [Google Scholar] [CrossRef]

- Huang, R.; Fukanuma, H. Study of the influence of particle velocity on adhesive strength of cold spray deposits. J. Therm. Spray Technol. 2012, 21, 541–549. [Google Scholar] [CrossRef]

- Huang, R.; Ma, W.; Fukanuma, H. Development of ultra-strong adhesive strength coatings using cold spray. Surf. Coat. Technol. 2014, 258, 832–841. [Google Scholar] [CrossRef]

- Zahiri, S.H.; Fraser, D.; Gulizia, S.; Jahedi, M. Effect of processing conditions on porosity formation in cold gas dynamic spraying of copper. J. Therm. Spray Technol. 2006, 15, 422–430. [Google Scholar] [CrossRef]

- Yin, S.; Liu, Q.; Liao, H.; Wang, X. Effect of injection pressure on particle acceleration, dispersion and deposition in cold spray. Comput. Mater. Sci. 2014, 90, 7–15. [Google Scholar] [CrossRef]

- Taylor, K.; Jodoin, B.; Karov, J. Particle loading effect in cold spray. J. Therm. Spray Technol. 2006, 15, 273–279. [Google Scholar] [CrossRef]

- Goupil, G.; Jucken, S.; Poirier, D.; Legoux, J.G.; Irissou, E.; Davis, B.; Guay, D.; Roué, L. Cold sprayed Cu–Ni–Fe anode for Al production. Corrosion Sci. 2015, 90, 259–265. [Google Scholar] [CrossRef]

- Li, W.-Y.; Li, C.-J.; Wang, H.-T.; Li, C.-X.; Bang, H.-S. Measurement and numerical simulation of particle velocity in cold spraying. J. Therm. Spray Technol. 2006, 15, 559–562. [Google Scholar] [CrossRef]

- Spencer, K.; Luzin, V.; Matthews, N.; Zhang, M.-X. Residual stresses in cold spray Al coatings: The effect of alloying and of process parameters. Surf. Coat. Technol. 2012, 206, 4249–4255. [Google Scholar] [CrossRef]

- Choi, W.B.; Li, L.; Luzin, V.; Neiser, R.; Gnäupel-Herold, T.; Prask, H.J.; Sampath, S.; Gouldstone, A. Integrated characterization of cold sprayed aluminum coatings. Acta Mater. 2007, 55, 857–866. [Google Scholar] [CrossRef]

- Van Steenkiste, T.H.; Smith, J.R.; Teets, R.E. Aluminum coatings via kinetic spray with relatively large powder particles. Surf. Coat. Technol. 2002, 154, 237–252. [Google Scholar] [CrossRef]

- De Force, B.S.; Eden, T.J.; Potter, J.K. Cold spray Al-5% mg coatings for the corrosion protection of magnesium alloys. J. Therm. Spray Technol. 2011, 20, 1352–1358. [Google Scholar] [CrossRef]

- Sova, A.; Doubenskaia, M.; Grigoriev, S.; Okunkova, A.; Smurov, I. Parameters of the gas-powder supersonic jet in cold spraying using a mask. J. Therm. Spray Technol. 2013, 22, 551–556. [Google Scholar] [CrossRef]

- Ozdemir, O.C.; Widener, C.A.; Helfritch, D.; Delfanian, F. Estimating the effect of helium and nitrogen mixing on deposition efficiency in cold spray. J. Therm. Spray Technol. 2016, 25, 660–671. [Google Scholar] [CrossRef]

- Ning, X.-J.; Jang, J.-H.; Kim, H.-J.; Li, C.-J.; Lee, C. Cold spraying of Al–Sn binary alloy: Coating characteristics and particle bonding features. Surf. Coat. Technol. 2008, 202, 1681–1687. [Google Scholar] [CrossRef]

- Li, W.-Y.; Zhang, C.; Guo, X.P.; Zhang, G.; Liao, H.L.; Coddet, C. Deposition characteristics of Al–12Si alloy coating fabricated by cold spraying with relatively large powder particles. Appl. Surf. Sci. 2007, 253, 7124–7130. [Google Scholar] [CrossRef]

- Zahiri, S.H.; Antonio, C.I.; Jahedi, M. Elimination of porosity in directly fabricated titanium via cold gas dynamic spraying. J. Mater. Proc. Technol. 2009, 209, 922–929. [Google Scholar] [CrossRef]

- Goldbaum, D.; Shockley, J.M.; Chromik, R.R.; Rezaeian, A.; Yue, S.; Legoux, J.-G.; Irissou, E. The effect of deposition conditions on adhesion strength of Ti and Ti6Al4V cold spray splats. J. Therm. Spray Technol. 2011, 21, 288–303. [Google Scholar] [CrossRef]

- Wong, W.; Irissou, E.; Ryabinin, A.N.; Legoux, J.-G.; Yue, S. Influence of helium and nitrogen gases on the properties of cold gas dynamic sprayed pure titanium coatings. J. Therm. Spray Technol. 2010, 20, 213–226. [Google Scholar] [CrossRef] [Green Version]

- Li, C.-J.; Li, W.-Y. Deposition characteristics of titanium coating in cold spraying. Surf. Coat. Technol. 2003, 167, 278–283. [Google Scholar] [CrossRef]

- Marrocco, T.; McCartney, D.G.; Shipway, P.H.; Sturgeon, A.J. Production of titanium deposits by cold-gas dynamic spray: Numerical modeling and experimental characterization. J. Therm. Spray Technol. 2006, 15, 263–272. [Google Scholar] [CrossRef]

- Goldbaum, D.; Chromik, R.R.; Yue, S.; Irissou, E.; Legoux, J.-G. Mechanical property mapping of cold sprayed Ti splats and coatings. J. Therm. Spray Technol. 2010, 20, 486–496. [Google Scholar] [CrossRef] [Green Version]

- Kim, K.H.; Kuroda, S.; Watanabe, M.; Huang, R.Z.; Fukanuma, H.; Katanoda, H. Comparison of oxidation and microstructure of warm-sprayed and cold-sprayed titanium coatings. J. Therm. Spray Technol. 2011, 21, 550–560. [Google Scholar] [CrossRef]

- Vo, P.; Irissou, E.; Legoux, J.-G.; Yue, S. Mechanical and microstructural characterization of cold-sprayed Ti–6Al–4V after heat treatment. J. Therm. Spray Technol. 2013, 22, 954–964. [Google Scholar] [CrossRef]

- Khun, N.W.; Tan, A.W.Y.; Bi, K.J.W.; Liu, E. Effects of working gas on wear and corrosion resistances of cold sprayed Ti–6Al–4V coatings. Surf. Coat. Technol. 2016, 302, 1–12. [Google Scholar] [CrossRef]

- Bhattiprolu, V.S.; Johnson, K.W.; Ozdemir, O.C.; Crawford, G.A. Influence of feedstock powder and cold spray processing parameters on microstructure and mechanical properties of Ti–6Al–4V cold spray depositions. Surf. Coat. Technol. 2018, 335, 1–12. [Google Scholar] [CrossRef]

- Ajdelsztajn, L.; Jodoin, B.; Schoenung, J.M. Synthesis and mechanical properties of nanocrystalline Ni coatings produced by cold gas dynamic spraying. Surf. Coat. Technol. 2006, 201, 1166–1172. [Google Scholar] [CrossRef]

- Richer, P.; Zúñiga, A.; Yandouzi, M.; Jodoin, B. CoNiCrAlY microstructural changes induced during cold gas dynamic spraying. Surf. Coat. Technol. 2008, 203, 364–371. [Google Scholar] [CrossRef]

- Cavaliere, P.; Perrone, A.; Silvello, A. Cold-sprayed nanostructured pure cobalt coatings. J. Therm. Spray Technol. 2016, 25, 1168–1176. [Google Scholar] [CrossRef]

- Seraj, R.A.; Abdollah-zadeha, A.; Dosta, S.; Canales, H.; Assadi, H.; Cano, I.G. The effect of traverse speed on deposition efficiency of cold sprayed stellite 21. Surf. Coat. Technol. 2019, 366, 24–34. [Google Scholar] [CrossRef]

- Wong, W.; Irissou, E.; Vo, P.; Sone, M.; Bernier, F.; Legoux, J.-G.; Fukanuma, H.; Yue, S. Cold spray forming of inconel 718. J. Therm. Spray Technol. 2012, 22, 413–421. [Google Scholar] [CrossRef]

- Ma, W.; Xie, Y.; Chen, C.; Fukanuma, H.; Wang, J.; Ren, Z.; Huang, R. Microstructural and mechanical properties of high-performance Inconel 718 alloy by cold spraying. J. Alloys Compd. 2019, 792, 456–467. [Google Scholar] [CrossRef]

- Cavaliere, P.; Silvello, A.; Cinca, N.; Canales, H.; Dosta, S.; Cano, I.G.; Guilemany, J.M. Microstructural and fatigue behavior of cold sprayed Ni-based superalloys coatings. Surf. Coat. Technol. 2017, 324, 390–402. [Google Scholar] [CrossRef]

- Chaudhuri, A.; Raghupathy, Y.; Srinivasan, D.; Suwas, S.; Srivastava, C. Microstructural evolution of cold-sprayed Inconel 625 superalloy coatings on low alloy steel substrate. Acta Mater. 2017, 129, 11–25. [Google Scholar] [CrossRef]

- Luo, X.-T.; Li, Y.-J.; Li, C.-X.; Yang, G.-J.; Li, C.-J. Effect of spray conditions on deposition behavior and microstructure of cold sprayed Ni coatings sprayed with a porous electrolytic Ni powder. Surf. Coat. Technol. 2016, 289, 85–93. [Google Scholar] [CrossRef]

- Xie, Y.; Planche, M.-P.; Raoelison, R.; Hervé, P.; Suo, X.; He, P.; Liao, H. Investigation on the influence of particle preheating temperature on bonding of cold-sprayed nickel coatings. Surf. Coat. Technol. 2017, 318, 99–105. [Google Scholar] [CrossRef]

- Van Steenkiste, T.; Gorkiewicz, D.W. Analysis of tantalum coatings produced by the kinetic spray process. J. Therm. Spray Technol. 2003, 13, 265–273. [Google Scholar] [CrossRef]

- Suo, X.; Yin, S.; Planche, M.-P.; Liu, T.; Liao, H. Strong effect of carrier gas species on particle velocity during cold spray processes. Surf. Coat. Technol. 2015, 268, 90–93. [Google Scholar] [CrossRef]

- Wong, W.; Rezaeian, A.; Irissou, E.; Legoux, J.G.; Yue, S. Cold spray characteristics of commercially pure Ti and Ti–6Al–4V. Adv. Mater. Res. 2010, 89, 639–644. [Google Scholar] [CrossRef]

- Cavaliere, P.; Perrone, A.; Silvello, A. Multi-objective optimization of steel nitriding. Eng. Sci. Technol. 2016, 19, 292–312. [Google Scholar] [CrossRef] [Green Version]

- Cavaliere, P.; Perrone, A.; Silvello, A. Steel nitriding optimization through multi-objective and FEM analysis. J. Comput. Des. Eng. 2016, 3, 71–90. [Google Scholar] [CrossRef] [Green Version]

- Karimi, M.; Rankin, G.W.; Fartaj, A. Parametric study of exhaust pattern in cold spray using CFD and particle-wall impact analysis. J. Appl. Fluid Mech. 2014, 7, 75–87. [Google Scholar]

- Stoltenhoff, T.; Kreye, H.; Richter, H.J. An analysis of the cold spray process and its coatings. J. Therm. Spray Technol. 2002, 11, 542–550. [Google Scholar] [CrossRef]

- Kosarev, V.F.; Klinkov, S.V.; Alkimov, A.P.; Papyrin, A.N. On Some aspects of gas dynamics of the cold spray process. J. Therm. Spray Technol. 2003, 12, 265–281. [Google Scholar] [CrossRef]

- Grujicic, M.; Zhao, C.L.; Tong, C.; DeRosset, W.S.; Helfritch, D. Analysis of the impact velocity of powder particles in the cold-gas dynamic-spray process. Mater. Sci. Eng. 2004, 368, 222–230. [Google Scholar] [CrossRef]

- Koivuluoto, H.; Matikainen, V.; Larjo, J.; Vuoristo, P. Novel online diagnostic analysis for in-flight particle properties in cold spraying. J. Therm. Spray Technol. 2018, 27, 423–432. [Google Scholar] [CrossRef]

- Borchers, C.; Schmidt, T.; Gärtner, F.; Kreye, H. High strain rate deformation microstructures of stainless steel 316L by cold spraying and explosive powder compaction. Appl. Phys. 2008, 90, 517–526. [Google Scholar] [CrossRef] [Green Version]

- Bae, G.; Kang, K.; Na, H.; Kim, J.-J.; Lee, C.H. Effect of particle size on the microstructure and properties of kinetic sprayed nickel coatings. Surf. Coat. Technol. 2010, 204, 3326–3335. [Google Scholar] [CrossRef]

- Lange, F.F. Powder processing science and technology for increased reliability. J. Am. Ceram. Soc. 1989, 72, 3–15. [Google Scholar] [CrossRef]

- Champagne, V.; Helfritch, D. The unique abilities of cold spray deposition. Int. Mater. Rev. 2016, 61, 437–455. [Google Scholar] [CrossRef]

- Klinkov, S.V.; Kosarev, V.F. Measurements of cold spray deposition efficiency. J. Therm. Spray Technol. 2006, 15, 364–371. [Google Scholar] [CrossRef]

- Mauer, G.; Singh, R.; Rauwald, K.-H.; Schrüfer, S.; Wilson, S.; Vaßen, R. Diagnostics of cold-sprayed particle velocities approaching critical deposition conditions. J. Therm. Spray Technol. 2017, 26, 1423–1433. [Google Scholar] [CrossRef]

- Luo, X.-T.; Yao, M.-L.; Ma, N.; Takahashi, M.; Li, C.-J. Deposition behavior, microstructure and mechanical properties of an in-situ micro-forging assisted cold spray enabled additively manufactured Inconel 718 alloy. Mater. Des. 2018, 155, 384–395. [Google Scholar] [CrossRef]

- Fukanuma, H.; Ohno, N.; Sun, B.; Huang, R. In-flight particle velocity measurements with DPV-2000 in cold spray. Surf. Coat. Technol. 2006, 201, 1935–1941. [Google Scholar] [CrossRef]

- Wu, J.; Fang, H.; Yoon, S.; Kim, H.J.; Lee, C. Measurement of particle velocity and characterization of deposition in aluminum alloy kinetic spraying process. Appl. Surf. Sci. 2005, 252, 1368–1377. [Google Scholar] [CrossRef]

- Li, Y.-J.; Luo, X.-T.; Li, C.-J. Dependency of deposition behavior, microstructure and properties of cold sprayed Cu on morphology and porosity of the powder. Surf. Coat. Technol. 2017, 328, 304–312. [Google Scholar] [CrossRef]

- Chu, X.; Che, H.; Vo, P.; Chakrabarty, R.; Sun, B.; Song, J.; Yue, S. Understanding the cold spray deposition efficiencies of 316L/Fe mixed powders by performing splat tests onto as-polished coatings. Surf. Coat. Technol. 2017, 304, 353–360. [Google Scholar] [CrossRef]

- Jodoin, B.; Raletzb, T.F.; Vardelle, M. Cold spray modeling and validation using an optical diagnostic method. Surf. Coat. Technol. 2006, 200, 4424–4432. [Google Scholar] [CrossRef]

- Luo, X.-T.; Wei, Y.-K.; Wang, Y.; Li, C.-J. Microstructure and mechanical property of Ti and Ti6Al4V prepared by an in-situ shot peening assisted cold spraying. Mater. Des. 2015, 85, 527–533. [Google Scholar] [CrossRef]

- Wong, W.; Vo, P.; Irissou, E.; Ryabinin, A.N.; Legoux, J.-G.; Yue, S. Effect of particle morphology and size distribution on cold-sprayed pure titanium coatings. J. Therm. Spray Technol. 2013, 22, 1140–1153. [Google Scholar] [CrossRef]

- Dykhuizen, R.C.; Smith, M.F.; Neiser, R.A.; Gilmore, D.L.; Jiang, X.; Sampath, S. Impact of high velocity cold spray particles. J. Therm. Spray Technol. 1998, 8, 559–564. [Google Scholar] [CrossRef]

- Hall, A.; Brewer, L.; Roemer, T. Preparation of aluminum coatings containing homogenous nanocrystalline microstructures using the cold spray process. J. Therm. Spray Technol. 2008, 17, 352–359. [Google Scholar] [CrossRef]

- Assadi, H.; Gärtner, F.; Stoltenhoff, T.; Kreye, H. Bonding mechanism in cold gas spraying. Acta Mater. 2003, 51, 4379–4394. [Google Scholar] [CrossRef]

| Material | Density (g/cm3) | Particle Diameter (μm) | Particle Hardness (GPa) | Spray Temperature (°C) | Spray Pressure (MPa) | Gas Density (g/cm3) | References |

|---|---|---|---|---|---|---|---|

| Fe and Fe Alloys | 7.9–8 | 5–35 | 1.5–2.5 | 200–1000 | 1.5–5 | 0.1–1.75 | [21,22,23,24] |

| Cu and Cu Alloys | 8.3–8.96 | 5–60 | 1.5–2.25 | 25–1000 | 0.6–5 | 0.1–2.85 | [25,26,27,28,29,30,31,32,33,34,35,36] |

| Al and Al Alloys | 2.35–3.6 | 6.7–150 | 0.37–1.1 | 20–560 | 0.6–3.4 | 0.06–2 | [37,38,39,40,41,42,43,44] |

| Ti and Ti Alloys | 3.95–4.5 | 15–60 | 1.4–4.3 | 50–950 | 0.5–5 | 0.065–2.35 | [45,46,47,48,49,50,51,52,53,54] |

| Co and Co Alloys | 7.95–8.86 | 24–40 | 1.04–4.5 | 550–800 | 1–4 | 0.09–1.16 | [55,56,57,58] |

| Ni and Ni Alloys | 8.22–8.9 | 12–50 | 4–6.3 | 5–1000 | 1–7 | 0.096–2.7 | [59,60,61,62,63,64] |

| Ta | 16.7 | 75 | 1.52 | 230–430 | 1–2.5 | 0.068–1.67 | [65] |

| Mg and Mg Alloys | 1.74–1.83 | 58–60 | 0.3–0.55 | 350–630 | 2.5–3 | 0.16–1.92 | [66] |

| Material | Density (g/cm3) | Particle Diameter (μm) | Distribution Area | Spray Temperature (°C) | Spray Pressure (MPa) | Particle Velocity (m/s) | References |

|---|---|---|---|---|---|---|---|

| Ni and Ni Alloys | 7.9–8 | 13.5–148.5 | 225–1100 | 400–1000 | 2–5 | 230–860 | [59,60,61,80,81] |

| Fe and Fe Alloys | 7.9–8 | 5–45 | 223–533 | 200–1000 | 1.5–5 | 460–990 | [22,23,82,85] |

| Correlation Coefficients | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Input/Output | Material Density | Particle Diameter | Particle Hardness | Gas Pressure | Gas Temperature | Gas Density | Particle Velocity | Deposit Hardness | Porosity | Deposition Efficiency | Flattening Ratio |

| Material density | 1 | 0 | 0.745 | 0 | 0 | 0 | −0.316 | 0.578 | −0.056 | 0.579 | −0.249 |

| Particle diameter | 0 | 1 | 0 | 0 | 0 | 0 | −0.431 | −0.187 | −0.213 | 0.104 | 0.097 |

| Particle hardness | 0.745 | 0 | 1 | 0 | 0 | 0 | 0 | 0.935 | 0.109 | 0 | −0.324 |

| Gas pressure | 0 | 0 | 0 | 1 | 0 | 0.893 | 0.594 | 0.417 | −0.682 | 0.768 | 0.804 |

| Gas temperature | 0 | 0 | 0 | 0 | 1 | −0.702 | 0.498 | 0.297 | −0.471 | 0.592 | 0.897 |

| Gas density | 0 | 0 | 0 | 0.893 | −0.702 | 1 | −0.341 | −0.458 | −0.395 | −0.738 | −0.582 |

| Particle velocity | −0.316 | −0.431 | 0 | 0.594 | 0.498 | −0.341 | 1 | 0.682 | −0.734 | 0.803 | 0.817 |

| Deposit hardness | 0.578 | −0.187 | 0.935 | 0.417 | 0.297 | −0.458 | 0.682 | 1 | 0 | 0 | −0.352 |

| Porosity | −0.056 | −0.213 | 0.109 | −0.682 | −0.471 | −0.395 | −0.734 | 0 | 1 | 0 | −0.819 |

| Deposition efficiency | 0.579 | 0.104 | 0 | 0.768 | 0.592 | −0.738 | 0.803 | 0 | 0 | 1 | 0 |

| Flattening ratio | −0.249 | 0.097 | −0.324 | 0.804 | 0.897 | −0.582 | 0.817 | −0.352 | −0.819 | 0 | 1 |

| Correlation Coefficients | ||||||||

|---|---|---|---|---|---|---|---|---|

| Input/Output | Process Parameter | Process Parameter/Material Density | Particle Velocity | Deposit Hardness | Porosity | Deposition Efficiency | Flattening Ratio | Hardness to Porosity |

| Process parameter | 1 | 1 | 0.785 | 0.607 | −0.439 | 0.871 | 0.893 | 0.674 |

| Process parameter/material density | 1 | 1 | 0.894 | 0.573 | −0.493 | 0.747 | 0.894 | 0.784 |

| Particle velocity | 0.785 | 0.894 | 1 | 0.682 | −0.734 | 0.803 | 0.817 | 0.832 |

| Deposit hardness | 0.607 | 0.573 | 0.682 | 1 | 0 | 0 | −0.352 | 0.988 |

| Porosity | −0.439 | −0.493 | −0.734 | 0 | 1 | 0 | −0.819 | −0.964 |

| Deposition efficiency | 0.871 | 0.747 | 0.803 | 0 | 0 | 1 | 0 | 0 |

| Flattening ratio | 0.893 | 0.894 | 0.817 | −0.352 | −0.819 | 0 | 1 | 0 |

| Hardness to porosity | 0.674 | 0.784 | 0.832 | 0.988 | −0.964 | 0 | 0 | 1 |

| Correlation Coefficients | ||||||

|---|---|---|---|---|---|---|

| Output | Particles Velocity | Deposit Hardness | Porosity | Deposition Efficiency | Flattering Ratio | |

| Input | ||||||

| Material density | −0.316 | 0.578 | −0.056 | 0.579 | −0.249 | |

| Particle diameter | −0.431 | -0.187 | −0.213 | 0.104 | 0.097 | |

| Particle hardness | 0 | 0.935 | 0.109 | 0 | −0.324 | |

| Gas pressure | 0.594 | 0.417 | −0.682 | 0.768 | 0.804 | |

| Gas temperature | 0.498 | 0.297 | −0.471 | 0.592 | 0.897 | |

| Gas density | −0.341 | −0.458 | −0.395 | −0.738 | −0.582 | |

| Correlation Coefficients | |||||||

|---|---|---|---|---|---|---|---|

| Output | Particles Velocity | Deposit Hardness | Porosity | Deposition Efficiency | Flattering Ratio | Hardness to Porosity | |

| Input | |||||||

| Process parameter | 0.785 | 0.607 | −0.439 | 0.871 | 0.893 | 0.674 | |

| Process parameter/material density | 0.894 | 0.573 | −0.493 | 0.747 | 0.894 | 0.784 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Silvello, A.; Cavaliere, P.D.; Albaladejo, V.; Martos, A.; Dosta, S.; Cano, I.G. Powder Properties and Processing Conditions Affecting Cold Spray Deposition. Coatings 2020, 10, 91. https://doi.org/10.3390/coatings10020091

Silvello A, Cavaliere PD, Albaladejo V, Martos A, Dosta S, Cano IG. Powder Properties and Processing Conditions Affecting Cold Spray Deposition. Coatings. 2020; 10(2):91. https://doi.org/10.3390/coatings10020091

Chicago/Turabian StyleSilvello, Alessio, Pasquale Daniele Cavaliere, Vicente Albaladejo, Ana Martos, Sergi Dosta, and Irene G. Cano. 2020. "Powder Properties and Processing Conditions Affecting Cold Spray Deposition" Coatings 10, no. 2: 91. https://doi.org/10.3390/coatings10020091

APA StyleSilvello, A., Cavaliere, P. D., Albaladejo, V., Martos, A., Dosta, S., & Cano, I. G. (2020). Powder Properties and Processing Conditions Affecting Cold Spray Deposition. Coatings, 10(2), 91. https://doi.org/10.3390/coatings10020091