Micropillar Compression Study on the Deformation Behavior of Electrodeposited Ni–Mo Films

Abstract

1. Introduction

2. Materials and Methods

2.1. Film-Processing by Electrodeposition

2.2. Microstructure Characterization of the As-Grown Film by Transmission Electron Microscopy

2.3. Characterization of the Crystallographic Texture of the Ni–Mo Films

2.4. Micropillar Compression Test

2.5. Characterization of the Microstructure of the Micropillars before and after Compression

3. Results

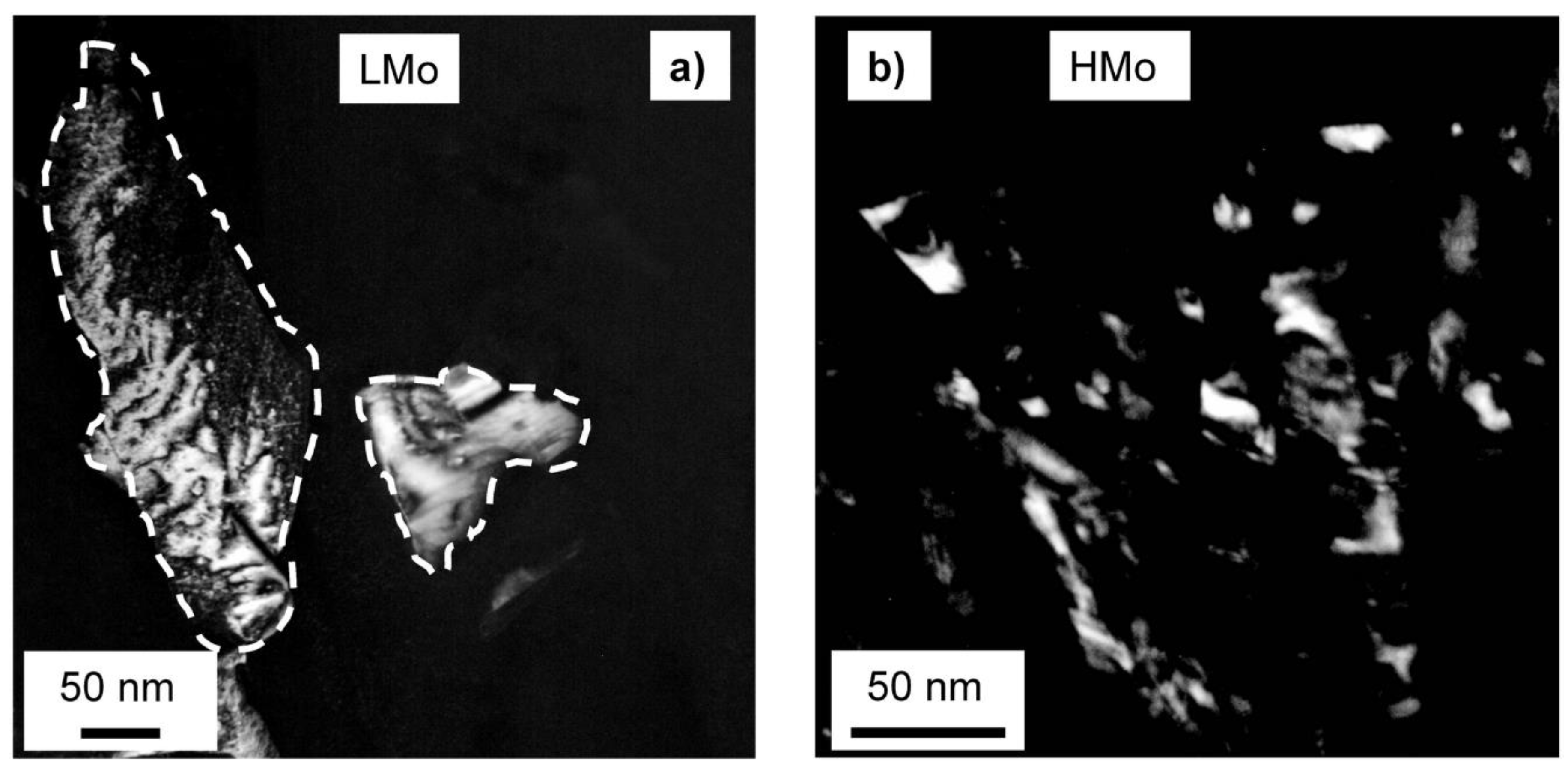

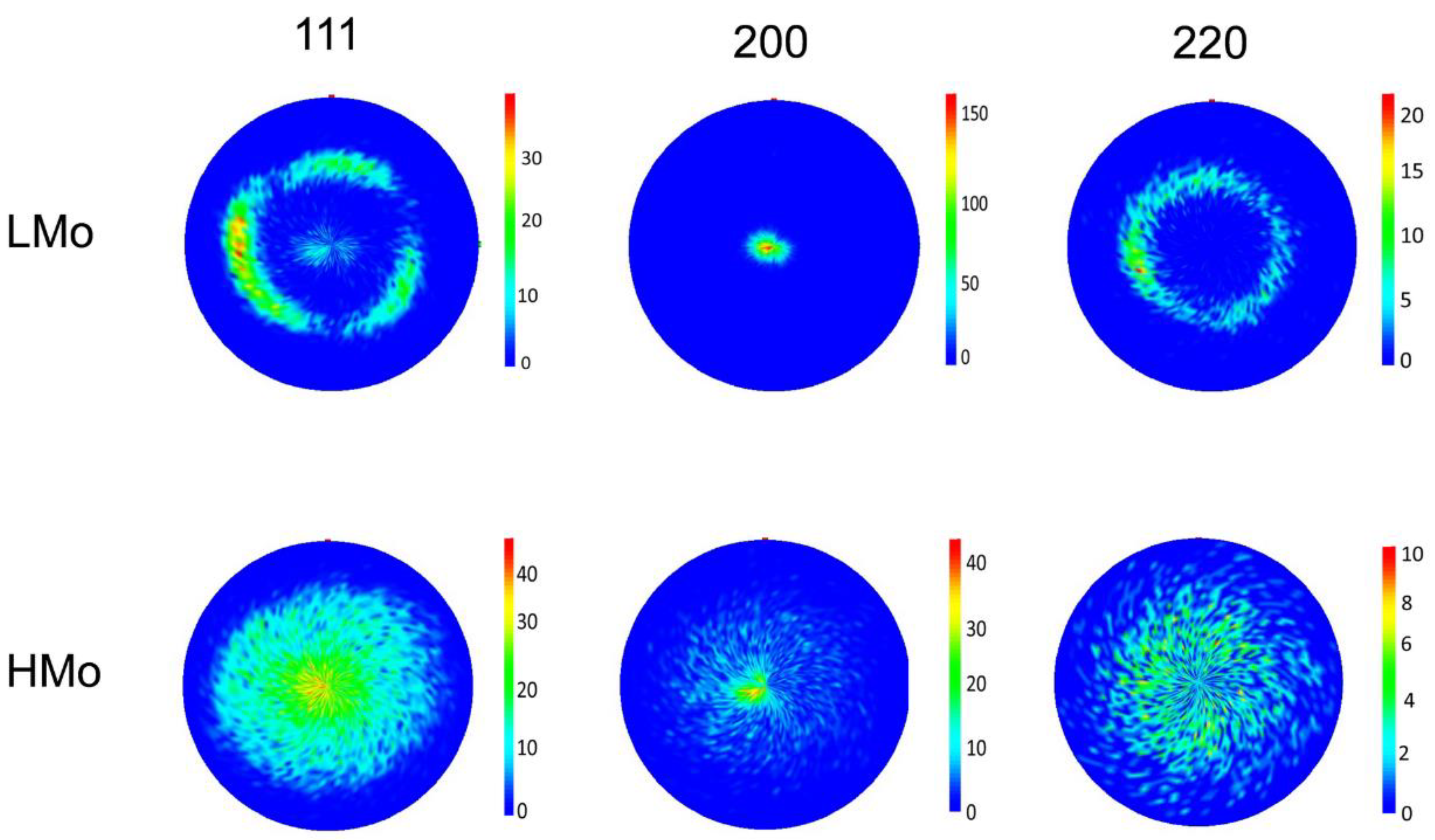

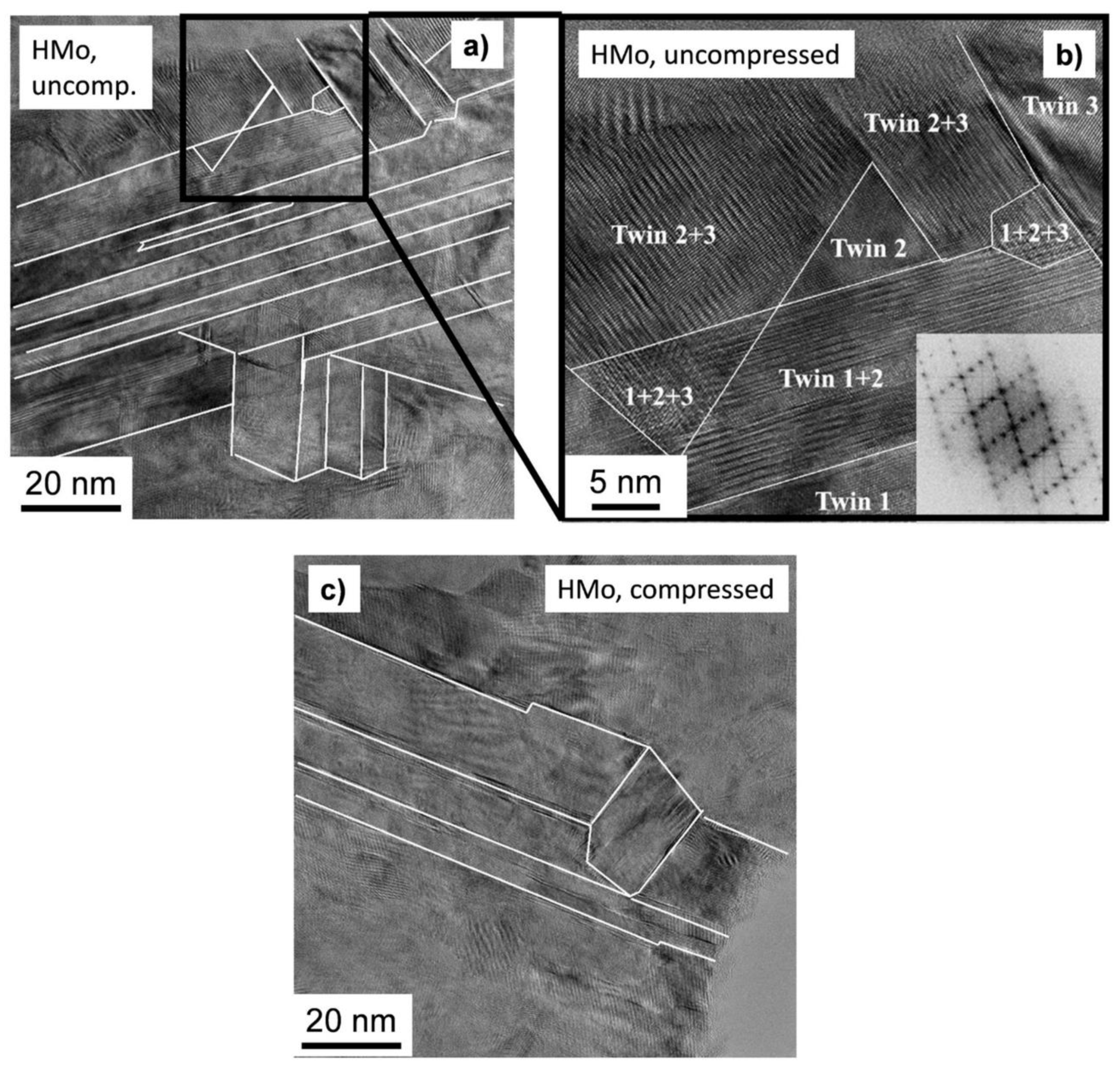

3.1. Microstructure of the As-Deposited Ni Films with Low and High Mo Contents

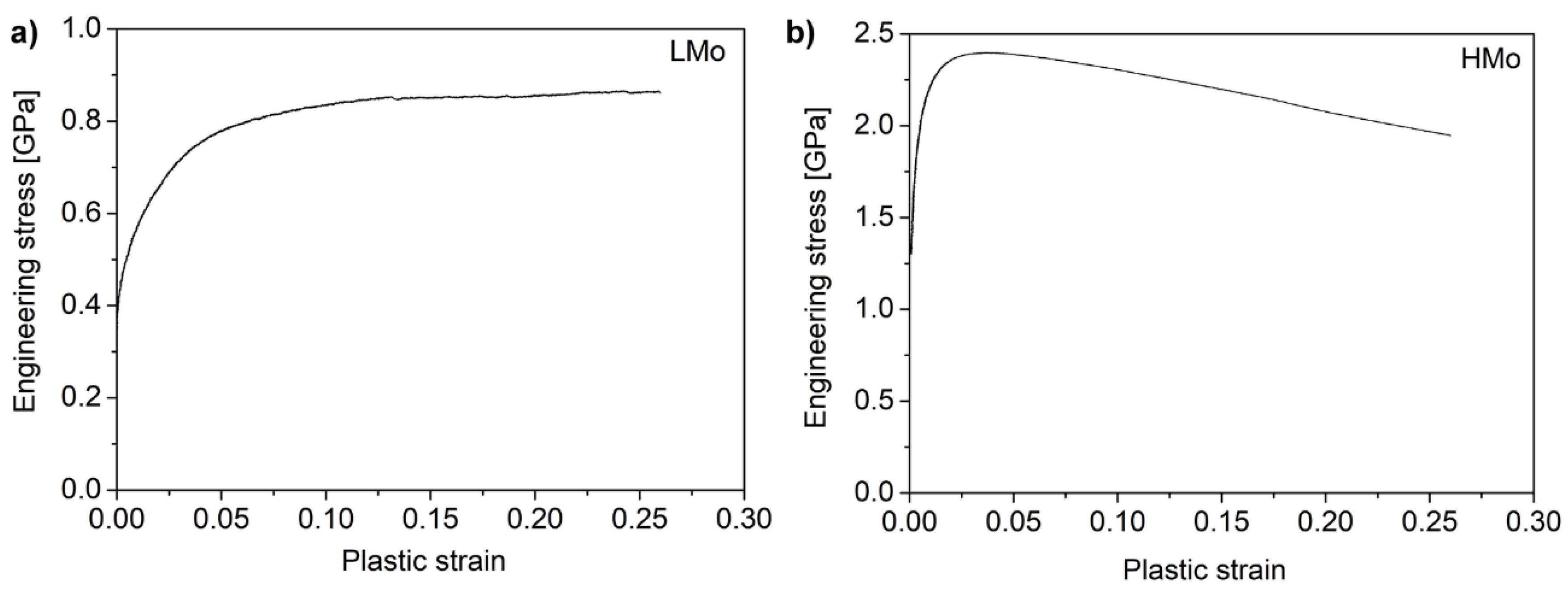

3.2. Compression Behavior of the Micropillars Fabricated from the Ni–Mo Films

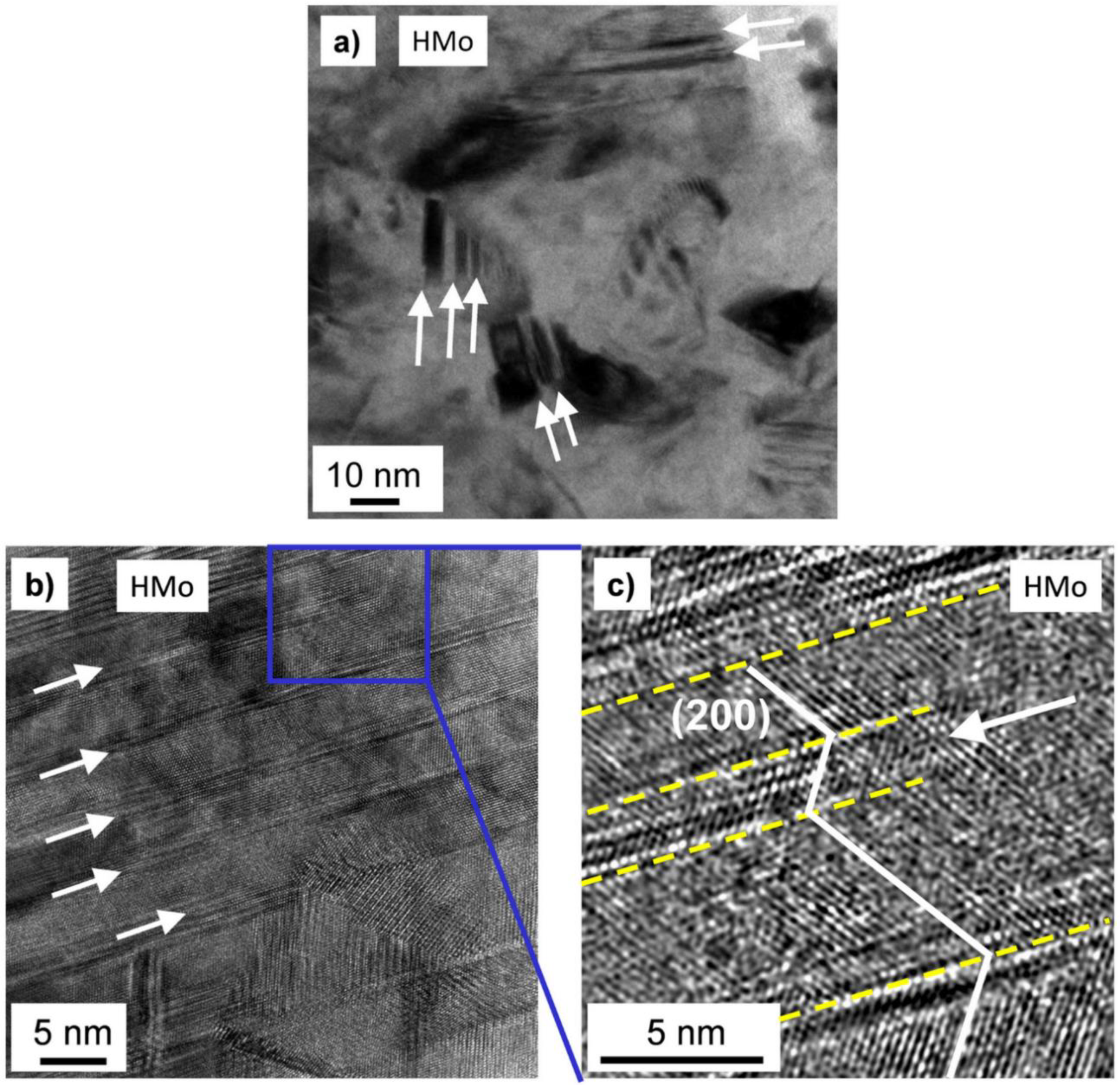

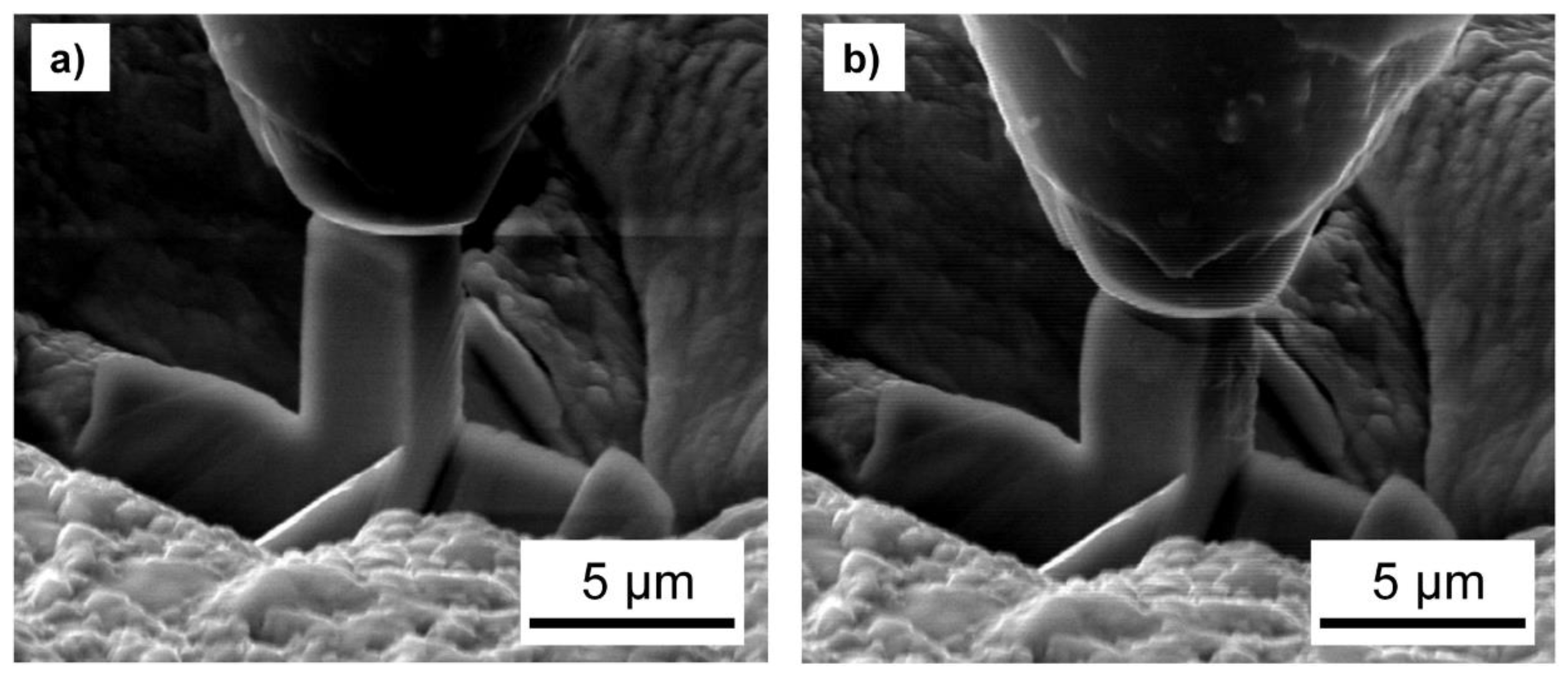

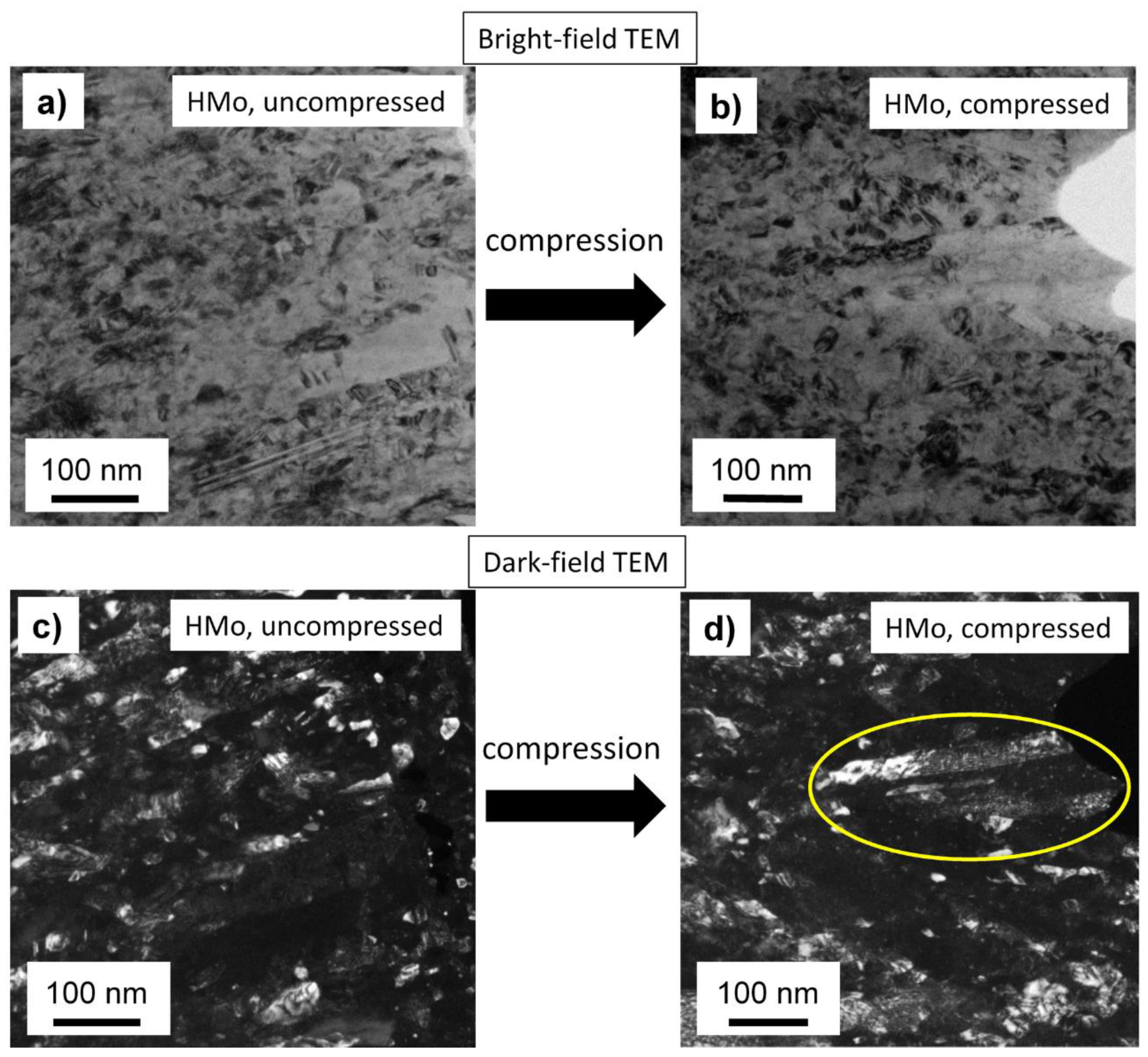

3.3. Changes of the Microstructure in the Ni Film with High Mo Content during Micropillar Compression

4. Discussion

5. Conclusions

- The film with high (5.3 at.%) Mo concentration had a much larger yield strength (1.3 GPa) than the value obtained for low (0.4 at.%) Mo content (0.35 GPa). This difference can be attributed to the higher solute hardening, the much smaller grain size and the higher defect density in the former sample. In film HMo, nanotwins with an average spacing of ~5 nm were formed while considerable twinning was not observed in specimen LMo. In addition, a strong 200 texture was observed for film LMo while no considerable texture was detected in sample HMo, and this change also contributed to the higher yield strength of the latter specimen.

- The Ni film with low Mo concentration exhibited strain-hardening in the studied strain range, yielding a maximum compressive stress of 0.86 GPa. At the same time, layer HMo showed a fast hardening to the stress of 2.4 GPa which was followed by a continous softening between the strains of 0.04 and 0.26.

- The strain-softening for film HMo cannot be explained by grain coarsening since the average grain size remained about 26 nm during compression. On the other hand, a decrease of the twin density during compression was observed by comparing the TEM images taken on the pillars before and after deformation. This detwinning process caused the observed softening.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Karolus, M.; Lagiewka, E. The Structural Studies on nanocrystalline Ni-Mo alloys after annealing. In Proceedings of the XIX Conference of Applied Crystallography, Kraków, Poland, 1–4 September 2003; Morawiec, H., Stróz, D., Eds.; World Scientific: Singapore, 2004; pp. 337–341. [Google Scholar] [CrossRef]

- Lehman, E.B.; Bigos, A.; Indyka, P.; Kot, M. Electrodeposition and Characterisation of Nanocrystalline Ni–Mo Coatings. Surf. Coat. Technol. 2011, 211, 67–71. [Google Scholar] [CrossRef]

- Lekka, M. Electrochemical Deposition of Composite Coatings. In Encyclopedia of Interfacial Chemistry; Wandelt, K., Ed.; Elsevier: Amsterdam, The Netherlands, 2018; pp. 54–67. ISBN 9780128098943. [Google Scholar] [CrossRef]

- Kapoor, G.; Péter, L.; Fekete, É.; Lábár, J.; Gubicza, J. The Influence of Mo Addition on the Microstructure and its Thermal Stability for Electrodeposited Ni Films. Mater. Charact. 2018, 145, 563–572. [Google Scholar] [CrossRef]

- Kolonits, T.; Czigány, Z.; Péter, L.; Bakonyi, I.; Gubicza, J. Influence of Bath Additives on the Thermal Stability of the Nanostructure and Hardness of Ni Films Processed by Electrodeposition. Coatings 2019, 9, 644. [Google Scholar] [CrossRef]

- Rupert, T.J.; Trelewicz, J.R.; Schuh, C.A. Grain boundary relaxation strengthening of nanocrystalline Ni-W alloys. J. Mater. Res. 2012, 27, 1285–1294. [Google Scholar] [CrossRef]

- Brown, D.; Mahmood, M.; Man, M.; Turner, A. Preparation and Characterization of Low Overvoltage Transition Metal Alloy Electrocatalysts for Hydrogen Evolution in Alkaline Solutions. Electrochim. Acta 1984, 29, 1551–1556. [Google Scholar] [CrossRef]

- Schulz, R.; Huot, J.Y.; Trudeau, M.L.; Bailey, L.D.; Yan, Z.H.; Jin, S.; Lamarre, A.; Ghali, E.; Neste, A.V. Nanocrystalline Ni-Mo alloys and their Application in Electrocatalysis. J. Mater. Res. 1994, 9, 2998–3008. [Google Scholar] [CrossRef]

- McKone, J.; Sadtler, B.R.; Werlang, C.A.; Lewis, N.S.; Gray, H.B. Ni–Mo Nanopowders for Efficient Electrochemical Hydrogen Evolution. ACS Catal. 2013, 3, 166–169. [Google Scholar] [CrossRef]

- Eickemeyer, J.; Selbmann, D.; Opitz, R.; Boer, B.; Holzapfel, B.; Schultz, L.; Miller, U. Nickel-Refractory Metal Substrate Tapes with High Cube Texture Stability. Supercond. Sci. Technol. 2001, 14, 152–159. [Google Scholar] [CrossRef]

- Podlaha, E.; Landolt, D. An Experimental Investigation of Ni-Mo alloys. J. Electrochem. Soc. 1996, 143, 885–892. [Google Scholar] [CrossRef]

- Podlaha, E.J.; Landolt, D. A Mathematical Model Describing the Electrodeposition of Ni-Mo Alloys. J. Electrochem. Soc. 1996, 143, 893–899. [Google Scholar] [CrossRef]

- Chassaing, E.; Portail, N.; Levy, A.F.; Wang, G. Characterisation of Electrodeposited Nanocrystalline Ni-Mo Alloys. J. Appl. Electrochem. 2004, 34, 1085–1091. [Google Scholar] [CrossRef]

- Bigos, A.; Beltowska-Lehman, E.; Kot, M. Studies on electrochemical deposition and physicochemical properties of nanocrystalline Ni-Mo alloys. Surf. Coat. Technol. 2017, 317, 103–109. [Google Scholar] [CrossRef]

- Podlaha, E. Electrodeposition of High Mo Content Ni-Mo Alloys under Forced Convection. J. Electrochem. Soc. 1993, 140, L149–L151. [Google Scholar] [CrossRef]

- Sun, S.; Podlaha, E. Electrodeposition of Mo-Rich, MoNi Alloys from an Aqueous Electrolyte. J. Electrochem. Soc. 2011, 159, D97–D102. [Google Scholar] [CrossRef]

- Allahyarzadeh, M.H.; Roozbehani, B.; Ashrafi, A.; Shadizadeh, S.R.; Kheradmand, E. Electrodeposition of High Mo Content Amorphous/Nanocrystalline Ni-Mo Using Ionic Liquids as Additive. ECS Trans. 2012, 41, 11–28. [Google Scholar] [CrossRef]

- Huang, P.C.; Hou, K.H.; Wang, G.L.; Chen, M.L.; Wang, J.R. Corrosion Resistance of the Ni-Mo Alloy Coatings Related to Coating’s Electroplating Parameters. Int. J. Electrochem. Sci. 2015, 10, 4972–4984. [Google Scholar]

- Wasekar, N.; Verulkar, S.; Vamsi, M.; Sundararajan, G. Influence of Molybdenum on the Mechanical Properties, Electrochemical Corrosion and Wear Behavior of Electrodeposited Ni-Mo alloy. Surf. Coat. Technol. 2019, 370, 298–310. [Google Scholar] [CrossRef]

- Hu, J.; Shi, Y.; Sauvage, X.; Sha, G.; Lu, K. Grain Boundary Stability Governs Hardening and Softening in Extremely Fine Nanograined Metals. Science 2017, 355, 1292–1296. [Google Scholar] [CrossRef]

- Zheng, X.; Hu, J.; Li, J.; Shi, Y. Achieving Ultrahigh Hardness in Electrodeposited Nanograined Ni-Based Binary Alloys. Nanomaterials 2019, 9, 546. [Google Scholar] [CrossRef]

- Khalajhedayati, A.; Rupert, T.J. Emergence of localized plasticity and failure through shear banding during microcompression of a nanocrystalline alloy. Acta Mater. 2014, 65, 326–337. [Google Scholar] [CrossRef]

- Mohanty, G.; Wheeler, J.M.; Raghavan, R.; Wehrs, J.; Hasegawa, M.; Mischler, S.; Philippe, L.; Michler, J. Elevated temperature, strain rate jump microcompression of nanocrystalline nickel. Philos. Mag. 2015, 95, 1878–1895. [Google Scholar] [CrossRef]

- Mohanty, G.; Wehrs, J.; Boyce, B.L.; Taylor, A.; Hasegawa, M.; Philippe, L.; Michler, J. Room temperature stress relaxation in nanocrystalline Ni measured by micropillar compression and miniature tension. J. Mater. Res. 2016, 31, 1085–1095. [Google Scholar] [CrossRef]

- Jarząbek, D.M.; Dziekoński, C.; Dera, W.; Chrzanowska, J.; Wojciechowski, T. Influence of Cu coating of SiC particles on mechanical properties of Ni/SiC co-electrodeposited composites. Ceram. Int. 2018, 44, 21750–21758. [Google Scholar] [CrossRef]

- Mech, K.; Zabinski, P.; Mucha, M.; Kowalik, R. Electrodeposition of Catalytically Active Ni-Mo Alloys. Arch. Metall. Mater. 2013, 58, 227–229. [Google Scholar] [CrossRef]

- Hegyi, Á.; Ispánovity, P.; Knapek, M.; Tüzes, D.; Máthis, K.; Chmelík, F.; Dankházi, Z.; Varga, G.; Groma, I. Micron-Scale Deformation: A Coupled in Situ Study of Strain Bursts and Acoustic Emission. Microsc. Microanal. 2017, 23, 1076–1081. [Google Scholar] [CrossRef]

- Wang, J.; Li, N.; Anderoglu, O.; Zhang, X.; Misra, A.; Huang, J.; Hirth, J. Detwinning Mechanisms For Growth Twins In Face-Centered Cubic Metals. Acta Mater. 2010, 58, 2262–2270. [Google Scholar] [CrossRef]

- Pashley, D.; Stowell, M. Electron Microscopy and Diffraction OF Twinned Structures in Evaporated Films of Gold. Philos. Mag. 1963, 8, 1605–1632. [Google Scholar] [CrossRef]

- Lu, K.; Lu, L.; Suresh, S. Strengthening Materials by Engineering Coherent Internal Boundaries at the Nanoscale. Science 2009, 324, 349–352. [Google Scholar] [CrossRef]

- Rath, B.B.; Imam, M.A.; Pande, M.A. Nucleation and Growth of Twin Interfaces in Fcc Metals and Alloys. Mater. Phys. Mech. 2000, 1, 61–66. [Google Scholar]

- Clausen, B.; Lorentzen, T.; Leffers, T. Self-Consistent Modelling of the Plastic Deformation of F.C.C. Polycrystals and Its Implications for Diffraction Measurements of Internal Stresses. Acta Mater. 1998, 46, 3087–3098. [Google Scholar] [CrossRef]

- Ni, S.; Wang, Y.B.; Liao, X.Z.; Alhajeri, S.N.; Li, H.Q.; Zhao, Y.H.; Lavernia, E.J.; Ringer, S.P.; Langdon, T.G.; Zhu, Y.T. Strain Hardening and Softening in a Nanocrystalline Ni–Fe Alloy Induced by Severe Plastic Deformation. Mater. Sci. Eng. A 2011, 528, 3398–3403. [Google Scholar] [CrossRef]

- Ni, S.; Wang, Y.B.; Liao, X.Z.; Li, H.Q.; Figueiredo, R.B.; Ringer, S.P.; Langdon, T.G.; Zhu, Y.T. Effect of Grain Size on the Competition Between Twinning and Detwinning in Nanocrystalline Metals. Phys. Rev. B 2011, 84, 235401. [Google Scholar] [CrossRef]

- An, X.; Ni, S.; Song, M.; Liao, X. Deformation Twinning and Detwinning in Face-Centered Cubic Metallic Materials. Adv. Eng. Mater. 2019, 22, 1900479. [Google Scholar] [CrossRef]

- Mullner, P.; Solenthaler, C. On the Effect of Deformation Twinning on Defect Densities. Mater. Sci. Eng. A 1997, 230, 107–115. [Google Scholar] [CrossRef]

- Jin, Z.H.; Gumbsch, P.; Albe, K.; Ma, E.; Lu, K.; Gleiter, H.; Hahn, H. Interactions between Non-Screw Lattice Dislocations and Coherent Twin Boundaries in Face-Centered Cubic Metals. Acta Mater. 2008, 56, 1126–1135. [Google Scholar] [CrossRef]

- Ni, S.; Wang, Y.B.; Liao, X.; Figueiredo, R.B.; Li, H.Q.; Ringer, S.P.; Langdon, T.G.; Zhu, Y.T. The Effect of Dislocation Density on the Interactions between Dislocations and Twin Boundaries in Nanocrystalline Materials. Acta Mater. 2012, 60, 3181–3189. [Google Scholar] [CrossRef]

- Kapoor, G.; Huang, Y.; Sarma, V.; Langdon, T.; Gubicza, J. Effect of Mo Addition on the Microstructure and Hardness of Ultrafine-Grained Ni Alloys Processed by a Combination of Cryorolling and High-Pressure Torsion. Mater. Sci. Eng. A 2017, 688, 92–100. [Google Scholar] [CrossRef]

- Li, L.; Ungar, T.; Wang, Y.D.; Fan, G.J.; Yang, Y.L.; Jia, N.; Ren, Y.; Tichy, G.; Lendvai, J.; Choo, H.; et al. Simultaneous Reductions of Dislocation and Twin Densities with Grain Growth During Cold Rolling in a Nanocrystalline Ni–Fe alloy. Scr. Mater. 2009, 60, 317–320. [Google Scholar] [CrossRef]

- Li, L.; Ungár, T.; Wang, Y.D.; Morris, J.R.; Tichy, G.; Lendvai, J.; Yang, Y.L.; Ren, Y.; Choo, H.; Liaw, P.K. Microstructure Evolution During Cold Rolling in a Nanocrystalline Ni–Fe Alloy Determined by Synchrotron X-Ray Diffraction. Acta Mater. 2009, 57, 4988–5000. [Google Scholar] [CrossRef]

- Han, J.; Sun, J.; Han, Y.; Zhu, H.; Fang, L. Strengthening versus Softening of Nanotwinned Copper Depending on Prestress and Twin Spacing. Metals 2018, 8, 344. [Google Scholar] [CrossRef]

- Lu, L.; Chen, X.; Huang, X.; Lu, K. Revealing the Maximum Strength in Nanotwinned Copper. Science 2009, 323, 607–610. [Google Scholar] [CrossRef] [PubMed]

- Wen, H.; Zhao, Y.; Li, Y.; Ertorer, O.; Nesterov, K.M.; Islamgaliev, R.K.; Valiev, R.Z.; Lavernia, E.J. High-Pressure Torsion-Induced Grain Growth and Detwinning in cryomilled Cu powders. Philos. Mag. 2010, 90, 4541–4550. [Google Scholar] [CrossRef]

- Gubicza, J. Defect Structure and Properties of Nanomaterials, 2nd ed.; Woodhead Publishing: Duxford, UK, 2017; ISBN 9780081019184. [Google Scholar]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gubicza, J.; Kapoor, G.; Ugi, D.; Péter, L.; Lábár, J.L.; Radnóczi, G. Micropillar Compression Study on the Deformation Behavior of Electrodeposited Ni–Mo Films. Coatings 2020, 10, 205. https://doi.org/10.3390/coatings10030205

Gubicza J, Kapoor G, Ugi D, Péter L, Lábár JL, Radnóczi G. Micropillar Compression Study on the Deformation Behavior of Electrodeposited Ni–Mo Films. Coatings. 2020; 10(3):205. https://doi.org/10.3390/coatings10030205

Chicago/Turabian StyleGubicza, Jenő, Garima Kapoor, Dávid Ugi, László Péter, János L. Lábár, and György Radnóczi. 2020. "Micropillar Compression Study on the Deformation Behavior of Electrodeposited Ni–Mo Films" Coatings 10, no. 3: 205. https://doi.org/10.3390/coatings10030205

APA StyleGubicza, J., Kapoor, G., Ugi, D., Péter, L., Lábár, J. L., & Radnóczi, G. (2020). Micropillar Compression Study on the Deformation Behavior of Electrodeposited Ni–Mo Films. Coatings, 10(3), 205. https://doi.org/10.3390/coatings10030205