Study of the Durability and Aesthetical Properties of Powder Coatings Admixed with Pearlescent Pigments

Abstract

1. Introduction

2. Materials and Methods

3. Results

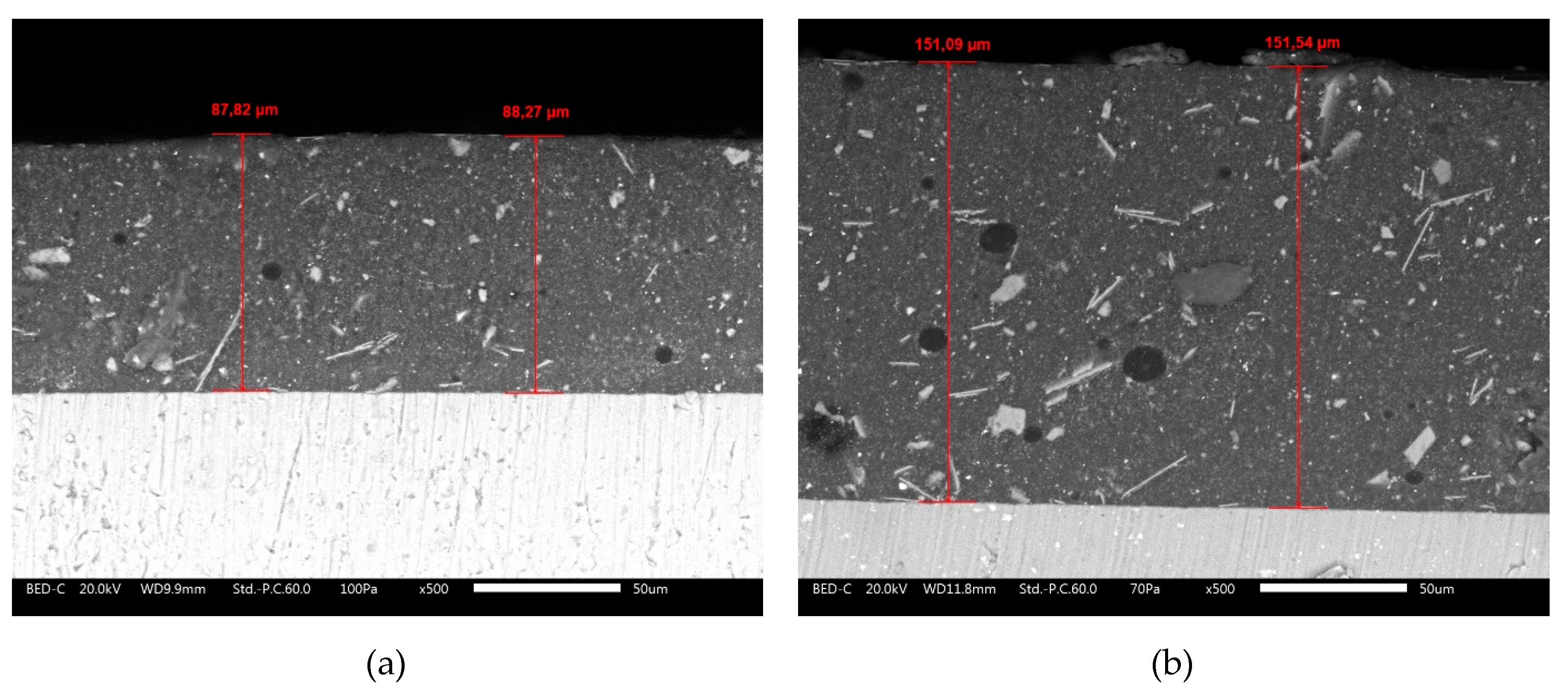

3.1. Morphology and Chemical Characterization

3.2. Gloss and Roughness Evaluation after UV Exposure

3.3. Color Evaluation after UV Exposure

3.4. FT-IR Analysis after UVA and UVB Exposures

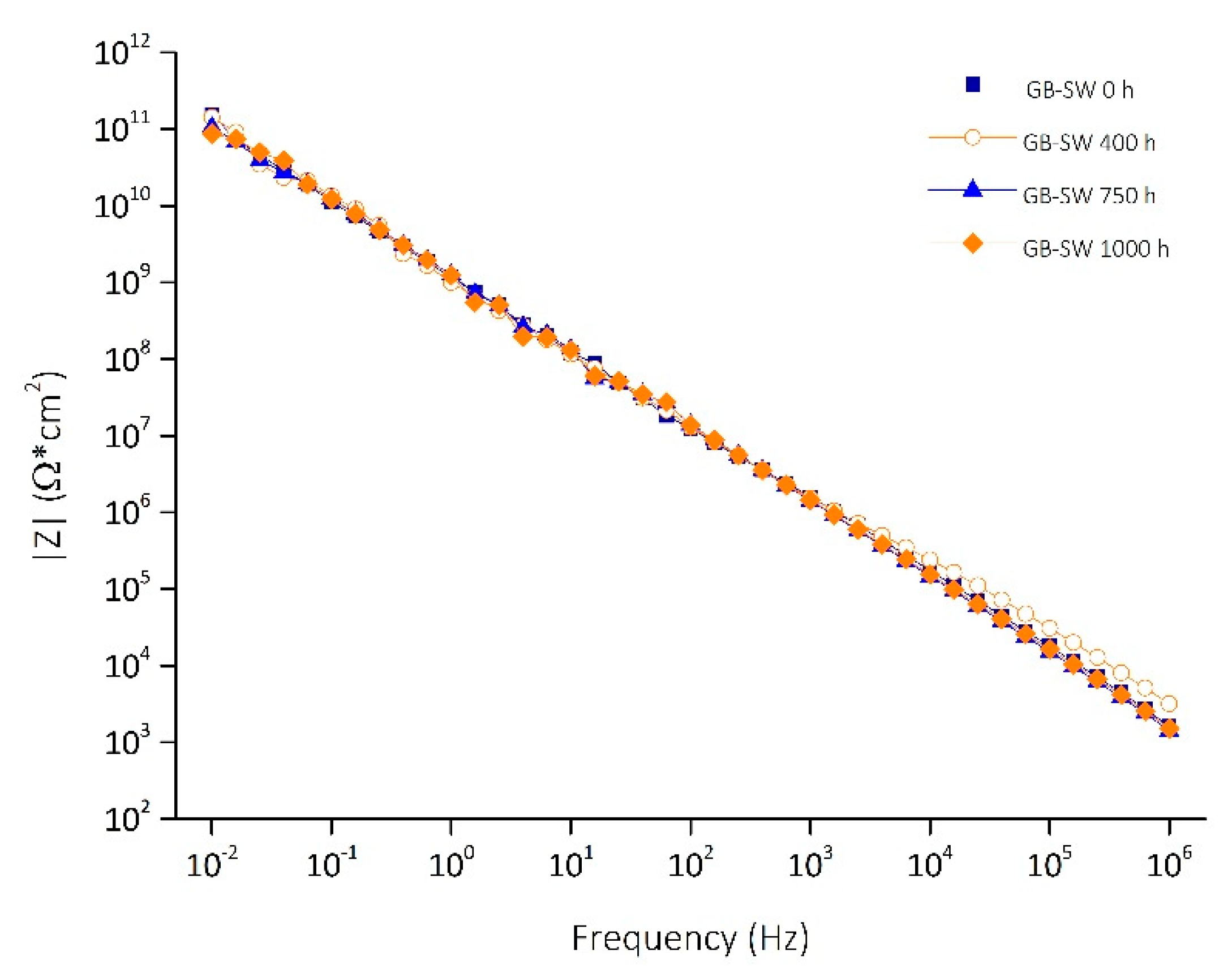

3.5. Exposure to an Aggressive Environment: Acetic Salt Spray Exposure

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ashby, M.F.; Johnson, K. Materials and Design: The Art and Science of Material Selection in Product Design, 2nd ed.; Butterworth-Heinemann: Oxford, UK, 2009. [Google Scholar]

- Rossi, S.; Deflorian, F.; Scrinzi, E. Reduction of aesthetical properties of organic coatings caused by mechanical damage. Mater. Des. 2009, 30, 1511–1517. [Google Scholar] [CrossRef]

- Perera, D.Y. Effect of pigmentation on organic coating characteristics. Prog. Org. Coat. 2004, 50, 247–262. [Google Scholar] [CrossRef]

- Pfaff, G.; Franz, K.; Emmert, K.; Nitta, R. Pigments, Inorganic. In Ullmann’s Encyclopedia of Industrial Chemistry, 6th ed.; Wiley-VCH: Weinheim, Germany, 1998. [Google Scholar]

- Bauxbaum, G.; Pfaff, G. Industrial Inorganic Pigments, 3rd ed.; Wiley-VCH: Weinheim, Germany, 2005. [Google Scholar] [CrossRef]

- Jansen, M.; Letschert, H.P. Inorganic yellow-red pigments without toxic metals. Nature 2000, 404, 980–982. [Google Scholar] [CrossRef] [PubMed]

- Wendusu, T.; Masui, T.; Imanaka, N. Novel environmental-friendly inorganic red pigments based on (Bi, Er, Y, Fe)2O3 solid solutions. J. Asian Ceram. Soc. 2014, 2, 195–198. [Google Scholar] [CrossRef]

- Faulkner, E.B.; Schwartz, R.J. High Performance Pigments, 2nd ed.; Wiley-VCH: Weinheim, Germany, 2009. [Google Scholar] [CrossRef]

- Maisch, R.; Weigand, M. Pearl Luster Pigments, Physical Principles, Properties, Applications; Verlag Moderne Industrie: Landsberg, Germany, 1992. [Google Scholar]

- Pfaff, G. Special Effect Pigments: Technical Basics and Applications; Vincentz Network GmbH & Co KG: Hannover, Germany, 2008. [Google Scholar]

- Maile, F.J.; Pfaff, G.; Reynders, P. Effect pigments – past, present and future. Prog. Org. Coat. 2005, 54, 150–163. [Google Scholar] [CrossRef]

- Maisch, R.; Stahlecker, O.; Kieser, M. Mica pigments in solvent free coatings systems. Prog. Org. Coat. 1996, 27, 145–152. [Google Scholar] [CrossRef]

- Pfaff, G.; Becker, M. Special effect pigments in cosmetic applications. Househ. Pers. Care Today 2012, 1, 12–15. [Google Scholar]

- Pfaff, G. Special effect pigments based on silica flakes. Inorg. Mater. 2003, 39, 123–126. [Google Scholar] [CrossRef]

- ASTM G154-16 Standard Standard Practice for Operating Fluorescent Ultraviolet (UV) Lamp Apparatus for Exposure Non-Metallic Materials; ASTM International: West Conshohocken, PA, USA, 2016.

- ASTM D523-14(2018) Standard Standard Test Method for Specular Gloss; ASTM International: West Conshohocken, PA, USA, 2018.

- ISO 4288:1996 Standard Geometrical Product Specification (GPS)—Surface Texture: Profile Method—Rules and Procedures for the Assessment of Surface Texture; International Organization for Standardization: Geneva, Switzerland, 2018.

- ASTM B117-19 Standard Standard Practice for Operating Salt Spray (Fog) Apparatus; ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM G85-19 Standard Standard Practice for Modified Salt Spray (Fog) Testing; ASTM International: West Conshohocken, PA, USA, 2019.

- UNI EN ISO 4628-8(2013) Standard Evaluation of Degradation of Coatings—Designation of Quantity and Size of Defects, and Intensity of Uniform Changes in Appearance—Part 8; UNI Ente Nazionale Italiano di Unificazione: Milano, Italy, 2013.

- Topuz, B.B.; Gündüz, G.; Mavis, B.; Çolak, Ü. The effect of tin dioxide (SnO2) on the anatase-rutile phase transformation of titania (TiO2) in mica-titania pigments and their use in paint. Dye. Pigm. 2011, 90, 123–128. [Google Scholar] [CrossRef]

- Gao, Q.; Wu, X.; Fan, Y. The effect of iron ions on the anatase-rutile phase transformation of titania (TiO2) in mica and titania pigments. Dye. Pigm. 2012, 95, 96–101. [Google Scholar] [CrossRef]

- Hosseini Zori, M. Particle size and kind of mica in synthesis of nontoxic bronze and gold pearlescent pigments based on nanoencapsulated hematite. J. Ultrafine Grained Nanostruct. 2015, 48, 101–112. [Google Scholar] [CrossRef]

- GSB AL 631 Standard, “International Quality Regulations for the Coating of Building Components—Aluminium”; GSB International e.V.: Düsseldorf, Germany, 2017.

- Hunter, R.S.; Harold, R.W. The Measurement of Appearance, 2nd ed.; John Wiley & Sons: Hoboken, NJ, USA, 1987. [Google Scholar]

- ASTM E308-18 Standard, “Standard Practice for Computing the Colors of Objectives by Using the CIE System”; ASTM International: West Conshohocken, PA, USA, 2018.

- Zhang, Q.; Shen, J.; Wang, J.; Wu, G.; Chen, L. Sol-gel derived ZrO2–SiO2 highly reflective coatings. Int. J. Inorg. Mater. 2000, 2, 319–323. [Google Scholar] [CrossRef]

- Wei, B.-X.; Zhao, L.; Wang, T.-J.; Gao, H.; Wu, H.-X.; Jin, Y. Photo-stability of TiO2 particles coated with several transition metal oxides and its measurements by rhodamine-B degradation. Adv. Powder Technol. 2013, 24, 708–713. [Google Scholar] [CrossRef]

- Mathivanan, L.; Arof, A.K. The effect of zirconium oxide and quartz pigments on the heat and corrosion resistance properties of the silicone based coatings. Pigm. Resin Technol. 2000, 29, 10–15. [Google Scholar] [CrossRef]

- Rossi, S.; Fedel, M.; Petrolli, S.; Deflorian, F. Behaviour of different removers on permanent anti-graffiti organic coatings. J. Build. Eng. 2016, 5, 104–113. [Google Scholar] [CrossRef]

- Gheno, G.; Ganzerla, R.; Bortoluzzi, M.; Paganica, R. Accelerated weathering degradation behaviour of polyester thermosetting powder coatings. Prog. Org. Coat. 2016, 101, 90–99. [Google Scholar] [CrossRef]

- Maetens, D. Weathering degradation mechanism in polyester powder coatings. Prog. Org. Coat. 2007, 58, 172–179. [Google Scholar] [CrossRef]

- UNI EN ISO 4628-2(2016) Standard, “Evaluation of Degradation of Coatings—Designation of Quantity and Size of Defects, and Intensity of Uniform Changes in Appearance—Part 2”; UNI Ente Nazionale Italiano di Unificazione: Milano, Italy, 2016.

- Mirabedini, S.; Scantlebury, J.D.; Thompson, G.E.; Moradian, S. Adhesive strength of powder coated aluminium substrates. Int. J. Adhes. Adhes. 2005, 25, 484–494. [Google Scholar] [CrossRef]

- Fedrizzi, L.; Stenico, M.; Deflorian, F.; Maschio, S.; Bonora, P.L. Effect of powder painting procedures on the filiform corrosion of aluminium profiles. Prog. Org. Coat. 2007, 59, 230–238. [Google Scholar] [CrossRef]

| Coating Name | Pigment Type | Pigment wt.% | Powder Coating wt.% |

|---|---|---|---|

| GB-SW | Xirallic T60-23 SW Galaxy Blue | 4.00 | 96.00 |

| GB-WNT | Xirallic T60-23 WNT Galaxy Blue | 4.00 | 96.00 |

| LG | Xirallic NXT M260-30 SW Leonis Gold | 4.00 | 96.00 |

| PS | Xirallic NXT M60-69 WNT Panthera Silver | 4.00 | 96.00 |

| TB | Xirallic NXT M260-23 Tigris Blue | 4.00 | 96.00 |

| Pigment | O % | Si % | Al % | Ti % | Sn % | Zr % | Fe% | Cu % |

|---|---|---|---|---|---|---|---|---|

| Xirallic T60-23 SW Galaxy Blue | 51.0 | 1.4 | 28.1 | 18.1 | 1.4 | – | – | – |

| Xirallic T60-23 WNT Galaxy Blue | 48.4 | 1.3 | 31.4 | 18.1 | 0.3 | 0.3 | 0.1 | 0.1 |

| Xirallic NXT M260-30 SW Leonis Gold | 40.6 | 0.8 | 29.1 | 10.7 | 1.0 | – | 17.8 | – |

| Xirallic NXT M60-69 WNT Phantera Silver | 49.2 | 0.5 | 41.5 | 5.9 | 0.2 | 0.6 | 2.1 | – |

| Xirallic NXT M260-23 Tigris Blue | 52.1 | 1.4 | 28.4 | 17.8 | 0.3 | – | – | – |

| Coating Name | Ra As-Made (μm) | Ra 1000 h UVA (μm) | Ra 1000 h UVB (μm) |

|---|---|---|---|

| GB-SW | 0.66 ± 0.08 | 0.65 ± 0.05 | 0.77 ± 0.33 |

| GB-WNT | 0.86 ± 0.24 | 0.79 ± 0.12 | 0.97 ± 0.10 |

| LG | 0.65 ± 0.04 | 0.69 ± 0.08 | 0.87 ± 0.08 |

| PS | 0.74 ± 0.14 | 0.69 ± 0.08 | 0.82 ± 0.12 |

| TB | 0.66 ± 0.11 | 0.59 ± 0.08 | 0.75 ± 0.11 |

| Coating Name | 0 h | 400 h | 750 h | 1000 h |

|---|---|---|---|---|

| GB-SW | 1.56 × 1011 | 1.43 × 1011 | 1.06 × 1011 | 8.66 × 1010 |

| GB-WNT | 1.57 × 1011 | 1.06 × 1011 | 8.66 × 1010 | 8.40 × 1010 |

| LG | 1.66 × 1011 | 1.38 × 1011 | 9.25 × 1010 | 8.67 × 1010 |

| PS | 1.23 × 1011 | 8.67 × 1010 | 6.70 × 1010 | 6.23 × 1010 |

| TB | 1.59 × 1011 | 1.38 × 1011 | 9.58 × 1010 | 8.69 × 1010 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rossi, S.; Russo, F.; Bouchakour Rahmani, L. Study of the Durability and Aesthetical Properties of Powder Coatings Admixed with Pearlescent Pigments. Coatings 2020, 10, 229. https://doi.org/10.3390/coatings10030229

Rossi S, Russo F, Bouchakour Rahmani L. Study of the Durability and Aesthetical Properties of Powder Coatings Admixed with Pearlescent Pigments. Coatings. 2020; 10(3):229. https://doi.org/10.3390/coatings10030229

Chicago/Turabian StyleRossi, Stefano, Francesca Russo, and Lotfi Bouchakour Rahmani. 2020. "Study of the Durability and Aesthetical Properties of Powder Coatings Admixed with Pearlescent Pigments" Coatings 10, no. 3: 229. https://doi.org/10.3390/coatings10030229

APA StyleRossi, S., Russo, F., & Bouchakour Rahmani, L. (2020). Study of the Durability and Aesthetical Properties of Powder Coatings Admixed with Pearlescent Pigments. Coatings, 10(3), 229. https://doi.org/10.3390/coatings10030229