Antibacterial Efficiency of Stainless-Steel Grids Coated with Cu-Ag by Thermionic Vacuum Arc Method

Abstract

:1. Introduction

2. Materials and Methods

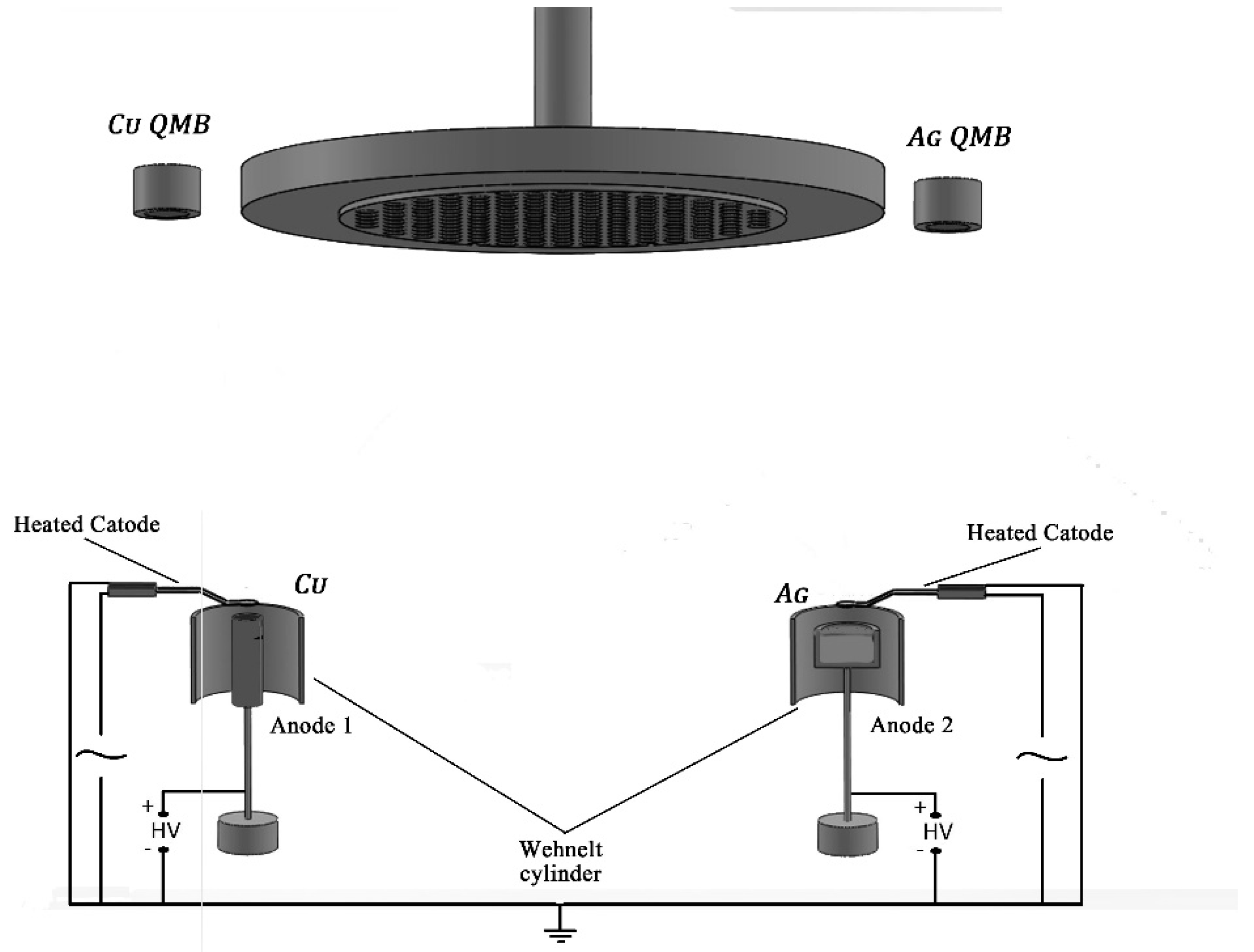

2.1. Thin films Coating Method

2.2. Morphological, Structural, and Compositional Analysis of Cu-Ag Thin Layers

2.3. Antibacterial Properties Evaluation

3. Results and Discussion

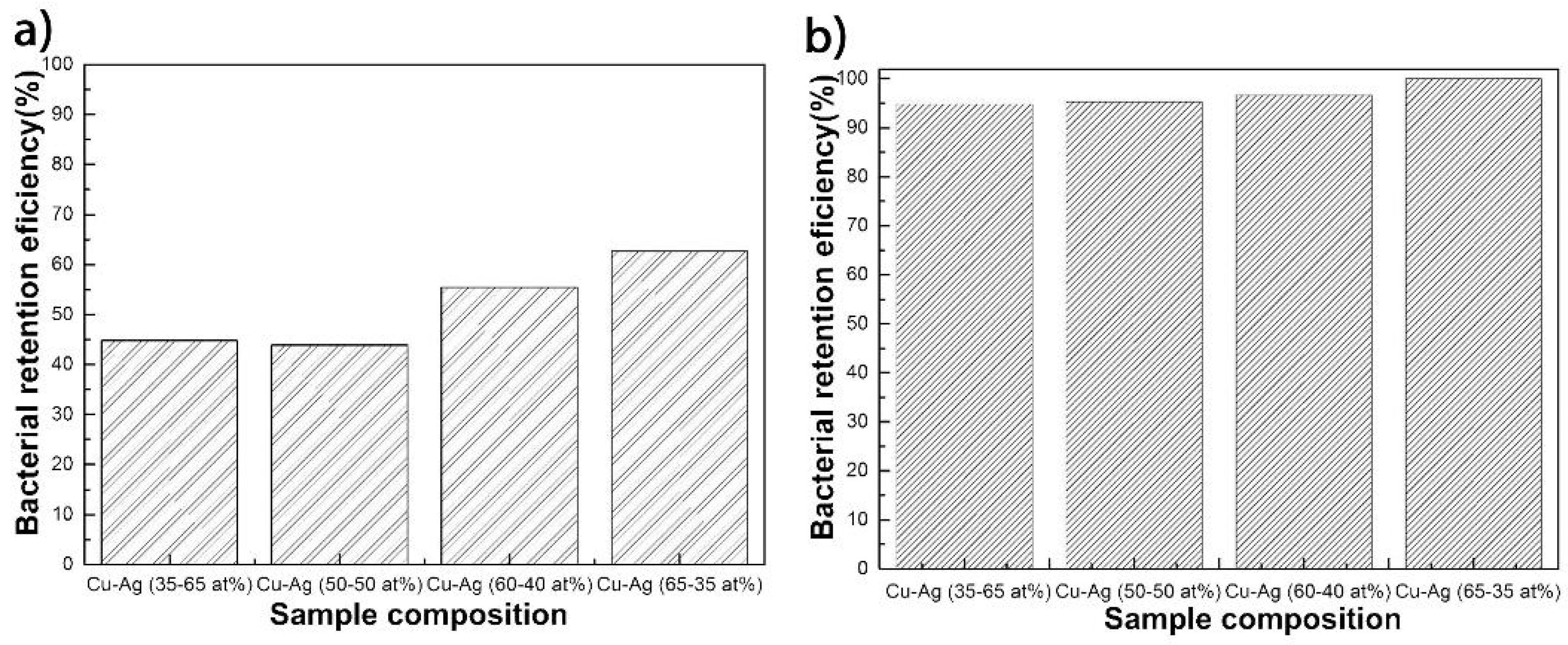

3.1. Bactericidal Efficiency and Air Quality Improvement

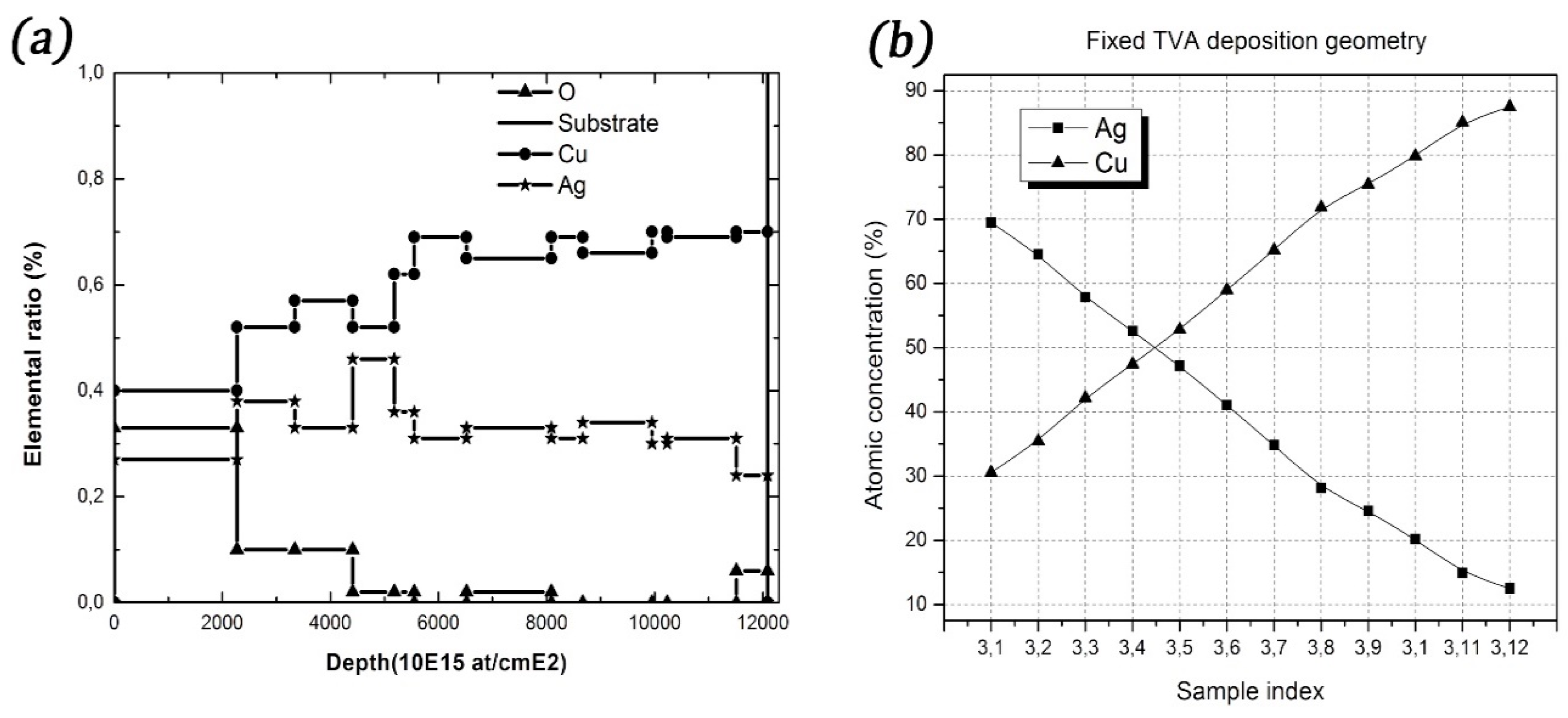

3.2. Atomic Composition and Depth Profile

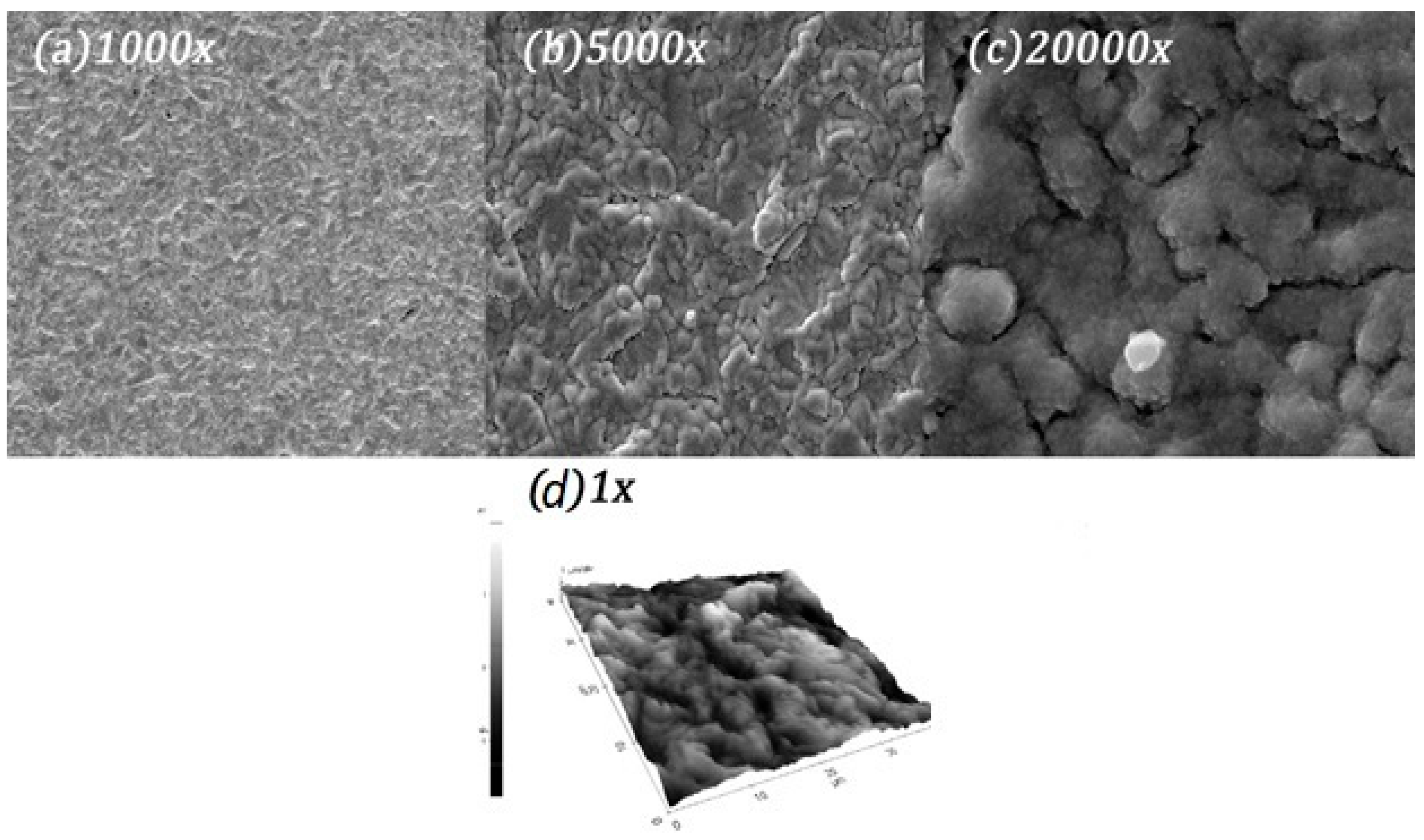

3.3. Surface Morphology

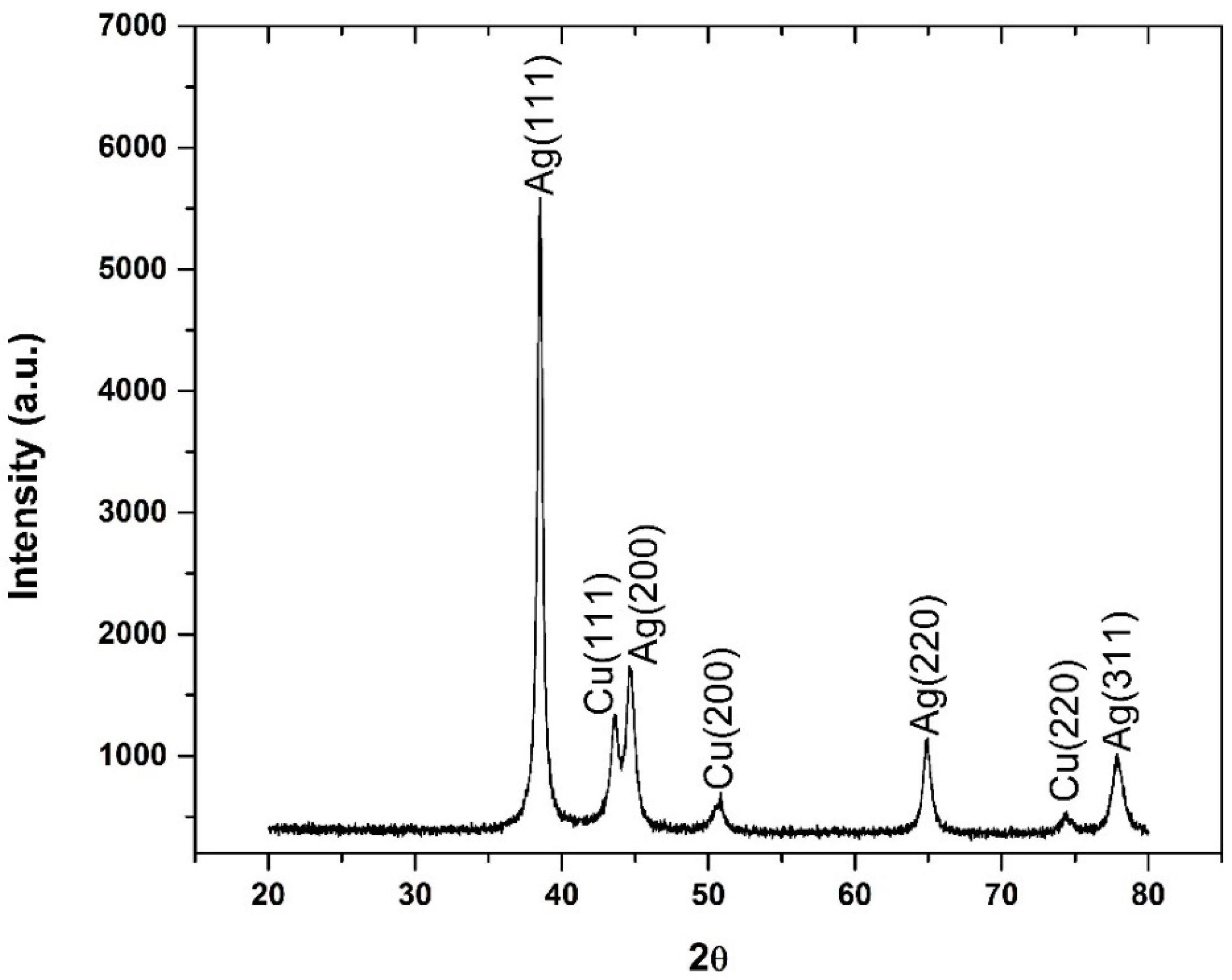

3.4. Structural Characterization

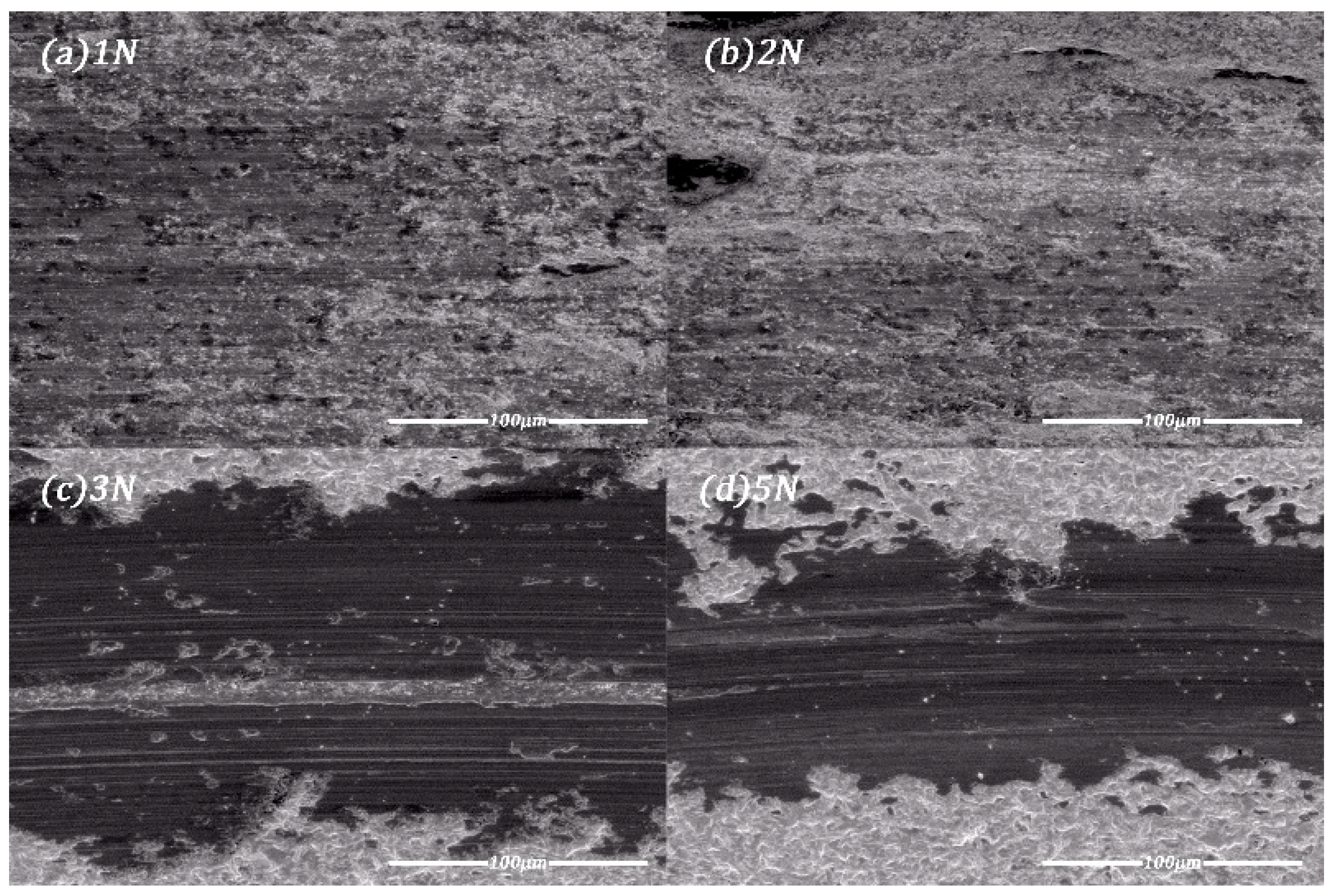

3.5. Sliding Wear Behavior of Cu-Ag Thin Films

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Miaśkiewicz-Peska, E.; Łebkowska, M. Effect of antimicrobial air filter treatment on bacterial survival. Fibres. Text. East. Eur. 2011, 19, 73–77. [Google Scholar]

- Payne, S.C.; Benninger, M.S. Benninger, Staphylococcus aureus is a Major Pathogen in Acute Bacterial Rhinosinusitis: A Meta-Analysis. Clin. Infect. Dis. 2007, 45, 121–127. [Google Scholar] [CrossRef]

- Durupt, F.; Mayor, L.; Bes, M.; Reverdy, M.E.; Vandenesch, F.; Thomas, L. JEtienne Prevalence of Staphylococcus aureus toxins and nasal carriage in furuncles and impetigo. Br. J. Dermatol. 2007, 157, 1161–1167. [Google Scholar] [CrossRef] [PubMed]

- Gorwitz, R.J. A Review of Community-Associated Methicillin-Resistant Staphylococcus aureus Skin and Soft Tissue Infections. Pediatr. Infect. Dis. 2008, 27, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Liu, G.Y. Molecular Pathogenesis of Staphylococcus aureus. Infect. Pediatr. Res. 2009, 65, 71–77. [Google Scholar] [CrossRef] [PubMed]

- Wertheim, H.F.; Melles, D.C.; Vos, M.C.; van Leeuwen, W.; van Belkum, A.; Verbrugh, H.A.; Nouwen, J.L. The role of nasal carriage in Staphylococcus aureus infections. Lancet Infect. Dis. 2005, 5, 751–762. [Google Scholar] [CrossRef]

- Lowy, F.D. Staphylococcus aureus infections. N. Engl. J. Med. 1998, 339, 520–532. [Google Scholar] [CrossRef]

- Gordon, R.J.; Lowy, F.D. Pathogenesis of methicillin-resistant Staphylococcus aureus infection. Clin. Infect. Dis. 2008, 46, S350–S359. [Google Scholar] [CrossRef] [Green Version]

- van Belkum, A.; Emonts, M.; Wertheim, H.; de Jongh, C.; Nouwen, J.; Bartels, H.; Cole, A.; Hermans, P.; Boelens, H.; Toom, N.L.; et al. The role of human innate immune factors in nasal colonization by Staphylococcus aureus. Microbes. Infect. 2007, 9, 1471–1477. [Google Scholar] [CrossRef]

- Kawada-Matsuo, M.; Komatsuzawa, H. Factors affecting susceptibility of Staphylococcus aureus to antibacterial agents. J. Oral Biosci. 2012, 54, 86–91. [Google Scholar] [CrossRef] [Green Version]

- Wertheim, H.F.; Vos, M.C.; Ott, A.; van Belkum, A.; Voss, A.; Kluytmans, J.A.; van Keulen, P.H.; Vandenbroucke-Grauls, C.M.; Meester, M.H.; Verbrugh, H.A. Risk and outcome of nosocomial Staphylococcus aureus bacteraemia in nasal carriers versus non-carriers. Lancet 2004, 364, 703–705. [Google Scholar] [CrossRef]

- Rooijakkers, S.H.; van Kessel, K.P.; van Strijp, J.A. Staphylococcal innate immune evasion. Trends Microbiol. 2005, 13, 596–601. [Google Scholar] [CrossRef] [PubMed]

- McLean, R.J.; Hussain, A.A.; Sayer, M.; Vincent, P.J.; Hughes, D.J.; Smith, T.J. Antibacterial activity of multilayer silver–copper surface films on catheter material. Can. J. Microbiol. 1993, 39, 895–899. [Google Scholar] [CrossRef] [PubMed]

- Ren, G.; Hu, D.; Cheng, E.W.; Vargas-Reus, M.A.; Reip, P.; Allaker, R.P. Characterisation of copper oxide nanoparticles for antimicrobial applications. Int. J. Antimicrob. Agents 2009, 33, 587–590. [Google Scholar] [CrossRef] [PubMed]

- Santo, C.E.; Morais, P.V.; Grass, G. Isolation and characterization of bacteria resistant to metalic Copper surfaces. Appl. Environ. Microbiol. 2010, 76, 1341–1348. [Google Scholar] [CrossRef] [Green Version]

- Jung, J.; Hwang, G.; Lee, J.; Bae, G. Preparation of airborne Ag/CNT hybrid nanoparticles using an aerosol process and their application to antimicrobial air filtration. Langmuir 2011, 27, 10256–10264. [Google Scholar] [CrossRef]

- Brobbey, K.; Haapanen, J.; Gunell, M.; Mäkelä, J.; Eerola, E.; Toivakka, M.; Saarinen, J. One-step flame synthesis of silver nanoparticles for roll-to-roll production of antibacterial paper. Appl. Surf. Sci. 2017, 420, 558–565. [Google Scholar] [CrossRef]

- Hassan, I.; Parkin, I.; Nair, S.; Carmalt, C. 2014 Antimicrobial activity if copper and copperI oxide thin films deposited via aerosol-assisted CVD. J. Mater. Chem. B 2014, 2, 2855. [Google Scholar] [CrossRef]

- Lungu, C.P.; Mustata, I.; Musa, G.; Lungu, A.M.; Zaroschi, V.; Iwasaki, K.; Tanaka, R.; Matsumura, Y.; Iwanaga, I.; Tanaka, H.; et al. Formation of nanostructured Re-Cr-Ni diffusion barrier coatings on Nb superalloys by TVA method. Fujita Surf. Coat. Technol. 2005, 200, 399. [Google Scholar] [CrossRef]

- Lungu, C.P.; Mustata, I.; Zaroschi, V.; Lungu, A.M.; Anghel, A.; Chiru, P.; Rubel, M.; Coad, P.; Matthews, G.F. JET-EFDA contributors. Beryllium Coatings on Metals: Development of Process and Characterizations of Layers. Phys. Scr. T 2007, 128, 157. [Google Scholar] [CrossRef]

- Surdu-Bob, C.; Mustata, I.; Iacob, C. General characteristics of the Thermoionic Vacuum Arc plasma. J. Optoelectron. Adv. Mater. 2007, 9, 2932–2934. [Google Scholar]

- Lungu, C.P.; Mustata, I.; Musa, G.; Lungu, A.M.; Brinza, O.; Moldovan, C.; Rotaru, C.; Iosub, R.; Sava, F.; Popescu, M.; et al. Unstressed carbon-metal films deposited by thermionic vacuum arc method. J. Optoelectron. Adv. Mater. 2006, 8, 74–77. [Google Scholar]

- Santo, C.E.; Lam, E.W.; Elowsky, C.G.; Quaranta, D.; Domaille, D.W.; Chang, C.J.; Grass, G. Antimicrobial metallic copper surfaces kill Staphylococcus haemolyticus via membrane damage. Appl. Environ. Microbiol. 2011, 77, 794–802. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Molteni, C.; Abicht, H.K.; Solioz, M. Killing of bacteria by copper surfaces involves dissolved copper. Appl. Environ. Microbiol. 2010, 76, 4099–4101. [Google Scholar] [CrossRef] [Green Version]

- Ibrahim, M.; Wang, F.; Lou, M.M.; Xie, G.L.; Li, B.; Bo, Z.; Zhang, G.Q.; Liu, H.; Wareth, A. Copper as an antibacterial agent for human pathogenic multidrug resistant Burkholderia cepacia complex bacteria. J. Biosci. Bioeng. 2011, 112, 570–576. [Google Scholar] [CrossRef]

- Balagna, C.; Perero, S.; Bosco, F.; Mollea, C.; Irfan, M.; Ferraris, M. Antipathogen nanostructured coating for air filters. Appl. Surf. Sci. 2020, 508, 145283. [Google Scholar] [CrossRef]

- Fletcher, M. Bacterial Adhesion: Molecular and Ecological Diversity; Wiley–Liss: New York, NY, USA, 1996; pp. 1–24. [Google Scholar]

- Razatos, A.; Ong, Y.; Sharma, M.M.; Georgious, G. Molecular determinants of bacterial adhesion monitored by atomic force microscopy. Proc. Natl. Acad. Sci. USA 1998, 95, 11059–11064. [Google Scholar] [CrossRef] [Green Version]

- Nan, L.; Liu, Y.; Lu, M.; Yang, K. Study on antibacterial mechanism of copper-bearing austenitic antibacterial stainless steel by atomic force microscopy. J. Mater. Sci. Mater. Med. 2008, 19, 3057–3062. [Google Scholar] [CrossRef]

- Dou, X.; Zhang, D.; Feng, C.; Jiang, L. Bioinspired Hierarchical Surface Structures with Tunable Wettability for Regulating Bacteria Adhesion. ACS Nano 2015, 9, 10664–10672. [Google Scholar] [CrossRef]

- Panagopoulos, C.N.; Georgarakis, K.G.; Petroutzakou, S. Sliding wear behaviour of zinc–cobalt alloy electrodeposits. J. Mater. Process. Technol. 2005, 160, 234–244. [Google Scholar] [CrossRef]

| Sample Type | Measurements |

|---|---|

| Cu-Ag layers deposited on air filtration coarse and fine mesh grids |

|

| Cu-Ag layers deposited on silicon substrates |

|

| Cu-Ag layers deposited on stainless steel disks |

|

| Nr. | Experimental Setup | Exposure Time (h) | Microbiological Markers (CFUa) | |||

|---|---|---|---|---|---|---|

| Microbiota | E. coli | P. aeruginosa | S. aureus | |||

| 1 | Background measurement | 1 | 20 | 1 | 2 | 1 |

| 3 | Microfungi | 4 | 0 | 0 | ||

| 2 | Uncoated grid 1 × 1 mm2 | 1 | 13 | 4 | 0 | 0 |

| 3 | 19 | 3 | 0 | 0 | ||

| 3 | Uncoated grid 0.5 × 0.5 mm2 | 1 | 6 | 1 | 0 | 0 |

| 3 | 5 | 1 | 0 | 0 | ||

| 4 | Cu-Ag (65–35 at.%) coatedgrid 1 × 1 mm2 | 1 | 1 | 0 | 0 | 0 |

| 3 | 1 | 0 | 0 | 0 | ||

| 5 | Cu-Ag (65–35 at.%) coated grid 0.5 × 0.5 mm2 | 1 | 0 | 0 | 0 | 0 |

| 3 | 1 | 0 | 0 | 0 | ||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dinca, P.; Butoi, B.; Lungu, M.; Porosnicu, C.; Jepu, I.; Staicu, C.; Lungu, C.P.; Niculescu, A.; Burducea, I.; Trusca, O.; et al. Antibacterial Efficiency of Stainless-Steel Grids Coated with Cu-Ag by Thermionic Vacuum Arc Method. Coatings 2020, 10, 322. https://doi.org/10.3390/coatings10040322

Dinca P, Butoi B, Lungu M, Porosnicu C, Jepu I, Staicu C, Lungu CP, Niculescu A, Burducea I, Trusca O, et al. Antibacterial Efficiency of Stainless-Steel Grids Coated with Cu-Ag by Thermionic Vacuum Arc Method. Coatings. 2020; 10(4):322. https://doi.org/10.3390/coatings10040322

Chicago/Turabian StyleDinca, P., B. Butoi, M. Lungu, C. Porosnicu, I. Jepu, C. Staicu, C.P. Lungu, A. Niculescu, I. Burducea, O. Trusca, and et al. 2020. "Antibacterial Efficiency of Stainless-Steel Grids Coated with Cu-Ag by Thermionic Vacuum Arc Method" Coatings 10, no. 4: 322. https://doi.org/10.3390/coatings10040322

APA StyleDinca, P., Butoi, B., Lungu, M., Porosnicu, C., Jepu, I., Staicu, C., Lungu, C. P., Niculescu, A., Burducea, I., Trusca, O., Diaconu, M., Cretescu, I., & Soreanu, G. (2020). Antibacterial Efficiency of Stainless-Steel Grids Coated with Cu-Ag by Thermionic Vacuum Arc Method. Coatings, 10(4), 322. https://doi.org/10.3390/coatings10040322