Transparent Conductive p-Type Cuprous Oxide Films in Vis-NIR Region Prepared by Ion-Beam Assisted DC Reactive Sputtering

Abstract

1. Introduction

2. Materials and Methods

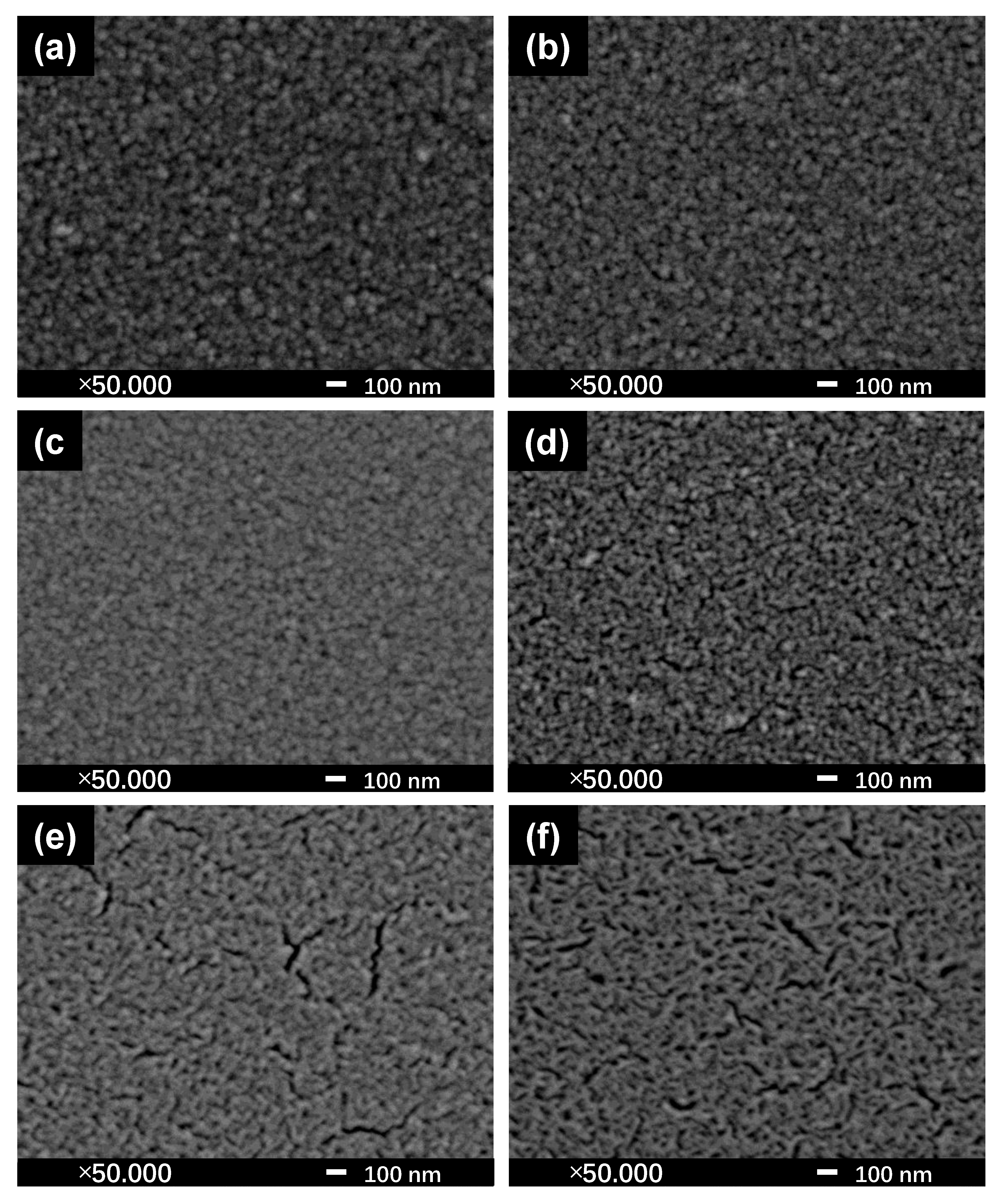

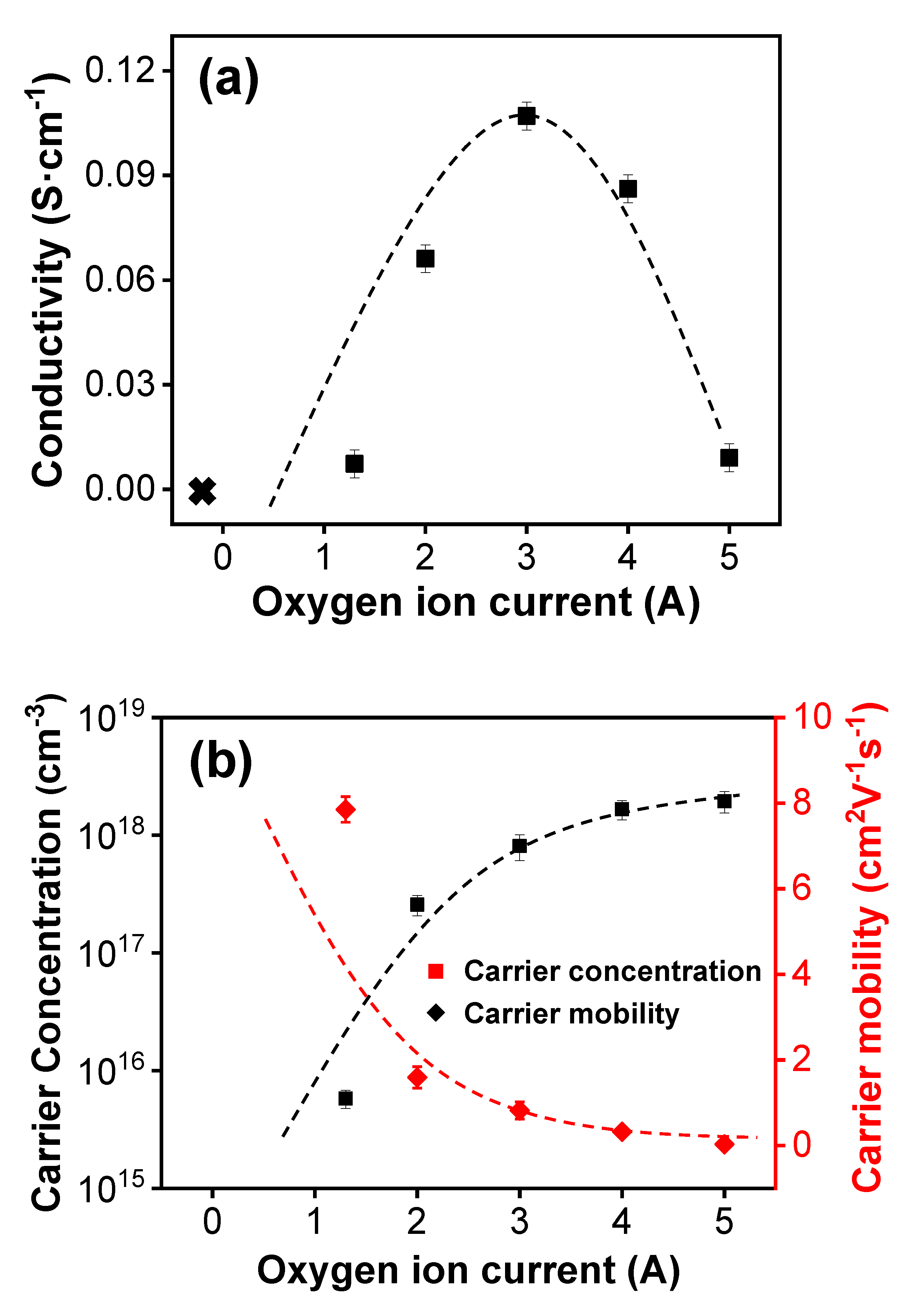

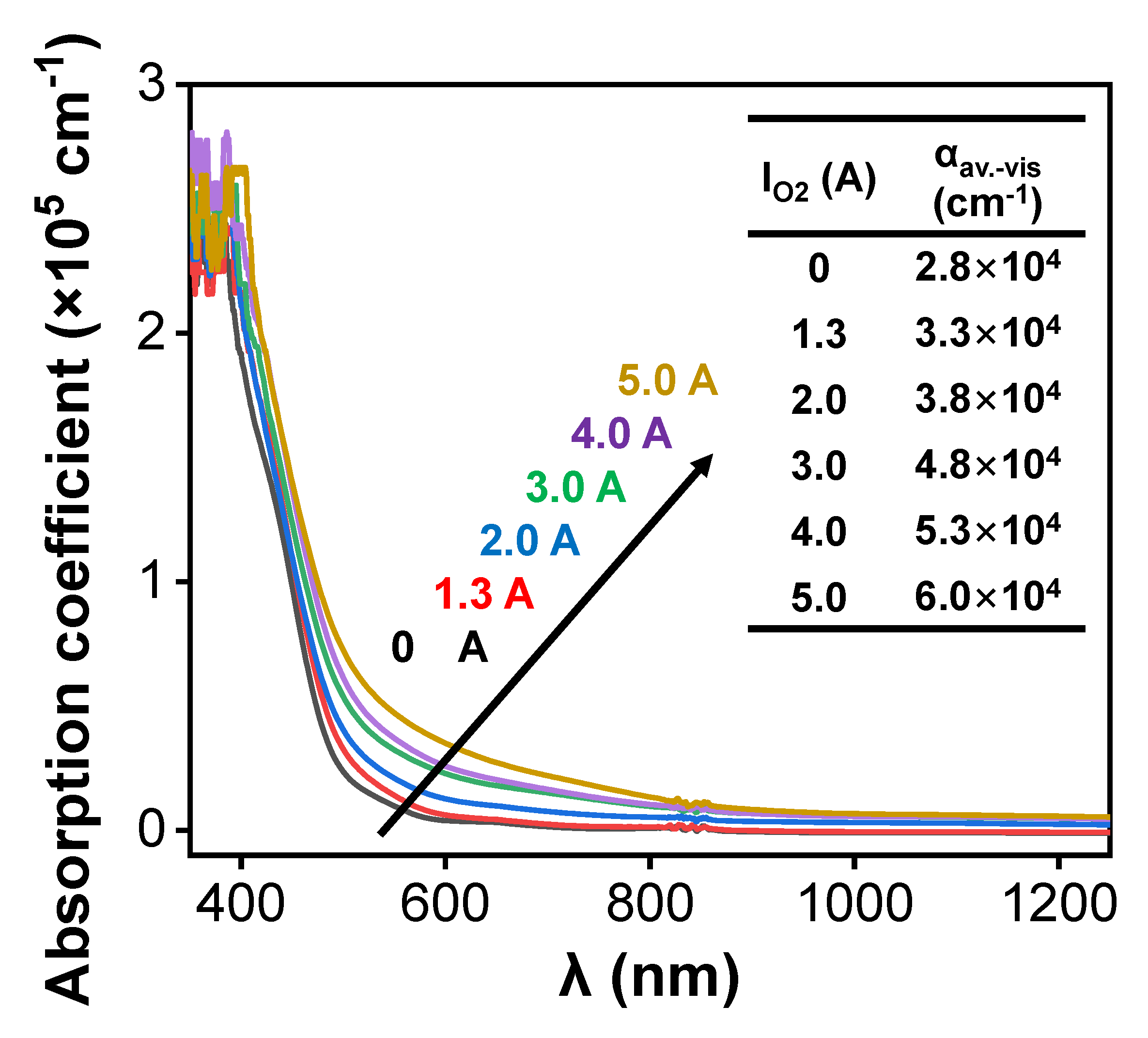

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Wen, L.; Sahu, B.B.; Kim, H.R.; Han, J.G. Study on the electrical, optical, structural, and morphological properties of highly transparent and conductive AZO thin films prepared near room temperature. Appl. Surf. Sci. 2019, 473, 649–656. [Google Scholar] [CrossRef]

- Jen, S.U.; Sun, H.; Chiang, H.P.; Chen, S.C.; Chen, J.Y.; Wang, X. Optoelectronic properties and the electrical stability of Ga-doped ZnO thin films prepared via radio frequency sputtering. Materials 2016, 9, 987. [Google Scholar] [CrossRef]

- Sun, H.; Jen, S.U.; Chen, S.C.; Ye, S.S.; Wang, X. The electrical stability of In-doped ZnO thin films deposited by RF sputtering. J. Phys. D 2017, 50, 045102. [Google Scholar] [CrossRef]

- Jeong, W.L.; Min, J.H.; Kwak, H.M.; Jeon, Y.J.; Lee, H.J.; Kim, K.P.; Lee, J.S.; Kang, S.J.; Kim, D.Y.; Lee, D.S. A highly conductive and flexible metal mesh/ultrathin ITO hybrid transparent electrode fabricated using low-temperature crystallization. J. Alloys Compd. 2019, 794, 114–119. [Google Scholar] [CrossRef]

- Zhu, B.L.; Liu, F.; Li, K.; Lv, K.; Wu, J.; Gan, Z.H.; Liu, J.; Zeng, D.W.; Xie, C.S. Sputtering deposition of transparent conductive F-doped SnO2 (FTO) thin films in hydrogen-containing atmosphere. Ceram. Int. 2017, 43, 10288–10298. [Google Scholar] [CrossRef]

- Sun, H.; Jen, S.U.; Chiang, H.P.; Chen, S.C.; Lin, M.H.; Chen, J.Y.; Wang, X. Investigation of optoelectronic performance in In, Ga co-doped ZnO thin films with various In and Ga levels. Thin Solid Films 2017, 641, 12–18. [Google Scholar] [CrossRef]

- Alonso-Alvarez, D.; Llin, L.F.; Mellor, A.; Paul, D.J.; Ekins-Daukes, N.J. ITO and AZO films for low emissivity coatings in hybrid photovoltaic-thermal applications. Sol. Energy 2017, 155, 82–92. [Google Scholar] [CrossRef]

- Koseoglu, H.; Turkoglu, F.; Kurt, M.; Yaman, M.D.; Akca, F.G.; Aygun, G.; Ozyuzer, L. Improvement of optical and electrical properties of ITO thin films by electro-annealing. Vacuum 2015, 120, 8–13. [Google Scholar] [CrossRef]

- Wang, K.L.; Xin, Y.Q.; Zhao, J.F.; Song, S.M.; Chen, S.C.; Lv, Y.B.; Sun, H. High transmittance in IR region of conductive ITO/AZO multilayers deposited by RF magnetron sputtering. Ceram. Int. 2018, 44, 6769–6774. [Google Scholar] [CrossRef]

- Coutts, T.J.; Young, D.L.; Li, X. Characterization of transparent conducting oxides. MRS Bull. 2000, 25, 58–65. [Google Scholar] [CrossRef]

- Solieman, A.; Aegerter, M.A. Modeling of optical and electrical properties of In2O3:Sn coatings made by various techniques. Thin Sol. Films 2006, 502, 205. [Google Scholar] [CrossRef]

- Ederth, J.; Heszler, P.; Hultaker, A.; Niklasson, G.A.; Granqvist, C.G. Indium tin oxide films made from nanoparticles: Models for the optical and electrical properties. Thin Sol. Films 2003, 445, 199. [Google Scholar] [CrossRef]

- Hamberg, I.; Granqvist, C.G. Evaporated Sn-doped In2O3 films: Basic optical properties and applications to energy-efficient windows. J. Appl. Phys. 1986, 60, R123. [Google Scholar] [CrossRef]

- Sun, H.; Arab Pour Yazdi, M.; Chen, S.C.; Wen, C.K.; Sanchette, F.; Billard, A. Ag composition gradient CuCr0.93Mg0.07O2/Ag/CuCr0.93Mg0.07O2 coatings with improved p-type optoelectronic performances. J. Mater. Sci. 2017, 52, 11537–11546. [Google Scholar] [CrossRef]

- Sun, H.; Arab Pour Yazdi, M.; Briois, P.; Pierson, J.F.; Sanchette, F.; Billard, A. Towards delafossite structure of Cu-Cr-O thin films deposited by reactive magnetron sputtering: Influence of substrate temperature on optoelectronics properties. Vacuum 2015, 114, 101–107. [Google Scholar] [CrossRef]

- Sun, H.; Arab Pour Yazdi, M.; Sanchette, F.; Billard, A. Optoelectronic properties of delafossite structure CuCr0.93Mg0.07O2 sputter deposited coatings. J. Phys. D 2016, 49, 185105. [Google Scholar] [CrossRef]

- Sun, H.; Chen, S.C.; Wen, C.K.; Chuang, T.H.; Arab Pour Yazdi, M.; Sanchette, F.; Billard, A. p-type cuprous oxide thin films with high conductivity deposited by high power impulse magnetron sputtering. Ceram. Int. 2017, 43, 6214–6220. [Google Scholar] [CrossRef]

- Huang, Q.; Li, J.; Bi, X.F. The improvement of hole transport property and optical band gap for amorphous Cu2O films. J. Alloys Compd. 2015, 647, 585–589. [Google Scholar] [CrossRef]

- Kavoulakis, G.M.; Chang, Y.C.; Baym, G. Fine structure of excitons in Cu2O. Phys. Rev. B 1997, 55, 7593–7599. [Google Scholar] [CrossRef]

- Sun, S.D. Recent advances in hybrid Cu2O-based heterogeneous nanostructures. Nanoscale 2015, 7, 10850–10882. [Google Scholar] [CrossRef]

- Sun, H.; Wen, C.K.; Chen, S.C.; Chuang, T.H.; Arab Pour Yazdi, M.; Sanchette, F.; Billard, A. Microstructures and optoelectronic properties of CuxO films deposited by high-power impulse magnetron sputtering. J. Alloys Compd. 2016, 688, 672–678. [Google Scholar] [CrossRef]

- Brandt, I.S.; Tumelero, M.A.; Lima, E., Jr.; Silva, D.L.D.; Zysler, R.D.; Faccio, R.; Pasa, A.A. Enhanced defect-mediated ferromagnetism in Cu2O by Co doping. J. Magn. Magn. Mater. 2017, 441, 374–386. [Google Scholar] [CrossRef]

- Nolan, M.; Elliott, S.D. The p-type conduction mechanism in Cu2O: A first principles study. Phys. Chem. Chem. Phys. 2006, 8, 5350–5358. [Google Scholar] [CrossRef] [PubMed]

- Sun, H.; Arab Pour Yazdi, M.; Ducros, C.; Chen, S.C.; Aubry, E.; Wen, C.K.; Hsieh, J.H.; Sanchette, F.; Billard, A. Thickness-dependence optoelectronic properties of CuCr0.93Mg0.07O2 thin films deposited by reactive magnetron sputtering. Mater. Sci. Semicond. Process. 2017, 63, 295. [Google Scholar] [CrossRef]

- Badillo-Avila, M.A.; Castanedo-Perez, R.; Marquez-Marin, J.; Guzman-Caballero, D.E.; Torroes-Delgado, G. Fast rate oxidation to Cu2O, at room temperature, of metallic copper films produced by the argon-plasma bombardment of CuO films. Mater. Chem. Phys. 2019, 236, 121759. [Google Scholar] [CrossRef]

- Badillo-Avila, M.A.; Castanedo-Perez, R.; Villarreal-Andrade, M.A.; Torres-Delgado, G. Cu2O thin films obtained at low temperature by mono-ethanolamine decomposition in open atmosphere. Mater. Sci. Semicond. Process. 2018, 85, 168–176. [Google Scholar] [CrossRef]

- Demichelis, F.; Kaniadakis, G.; Tagliaferro, A.; Tresso, E. New approach to optical analysis of absorbing thin solid films. Appl. Opt. 1987, 26, 1737–1740. [Google Scholar]

- Tauc, J. Amorphous and Liquid Semiconductors; Plenum Publishing Company: London, UK, 1974. [Google Scholar]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dai, M.-J.; Lin, S.-S.; Shi, Q.; Liu, F.; Wang, W.-X.; Chen, S.-C.; Kuo, T.-Y.; Sun, H. Transparent Conductive p-Type Cuprous Oxide Films in Vis-NIR Region Prepared by Ion-Beam Assisted DC Reactive Sputtering. Coatings 2020, 10, 473. https://doi.org/10.3390/coatings10050473

Dai M-J, Lin S-S, Shi Q, Liu F, Wang W-X, Chen S-C, Kuo T-Y, Sun H. Transparent Conductive p-Type Cuprous Oxide Films in Vis-NIR Region Prepared by Ion-Beam Assisted DC Reactive Sputtering. Coatings. 2020; 10(5):473. https://doi.org/10.3390/coatings10050473

Chicago/Turabian StyleDai, Ming-Jiang, Song-Sheng Lin, Qian Shi, Fen Liu, Wan-Xia Wang, Sheng-Chi Chen, Tsung-Yen Kuo, and Hui Sun. 2020. "Transparent Conductive p-Type Cuprous Oxide Films in Vis-NIR Region Prepared by Ion-Beam Assisted DC Reactive Sputtering" Coatings 10, no. 5: 473. https://doi.org/10.3390/coatings10050473

APA StyleDai, M.-J., Lin, S.-S., Shi, Q., Liu, F., Wang, W.-X., Chen, S.-C., Kuo, T.-Y., & Sun, H. (2020). Transparent Conductive p-Type Cuprous Oxide Films in Vis-NIR Region Prepared by Ion-Beam Assisted DC Reactive Sputtering. Coatings, 10(5), 473. https://doi.org/10.3390/coatings10050473