Wood Surface Modification—Classic and Modern Approaches in Wood Chemical Treatment by Esterification Reactions

Abstract

:1. Introduction

- Chemical methods: pre-treatment of wood fibers surface, grafting, use of coupling agents and functionalized polyolefin-coupling agents [42].

2. Wood Surface Modification by Esterification Reactions Using Anhydrides

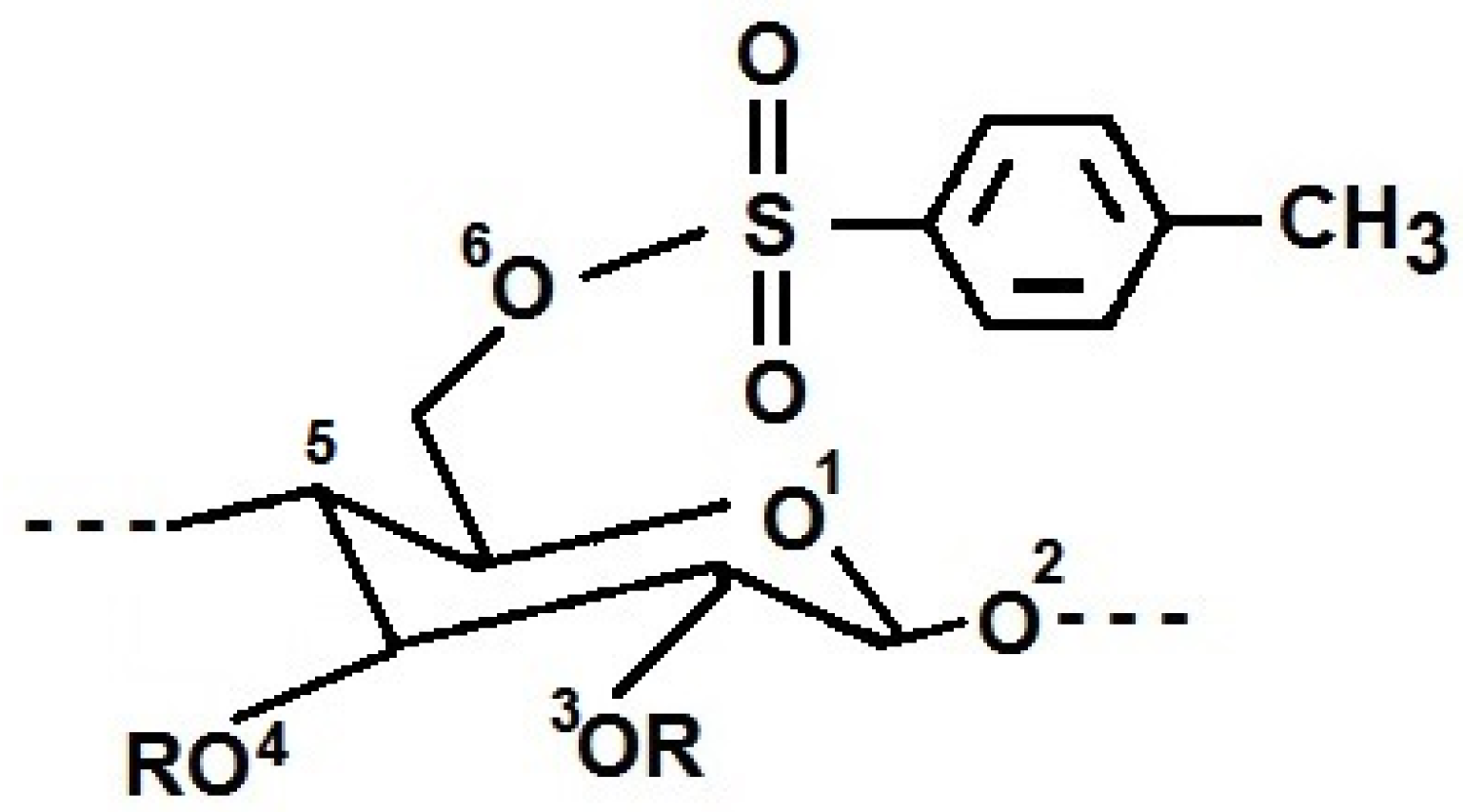

3. Wood Surface Modification by Tosylation Reaction

4. Wood Surface Modification by Esterification Reactions Using Carboxylic Acids

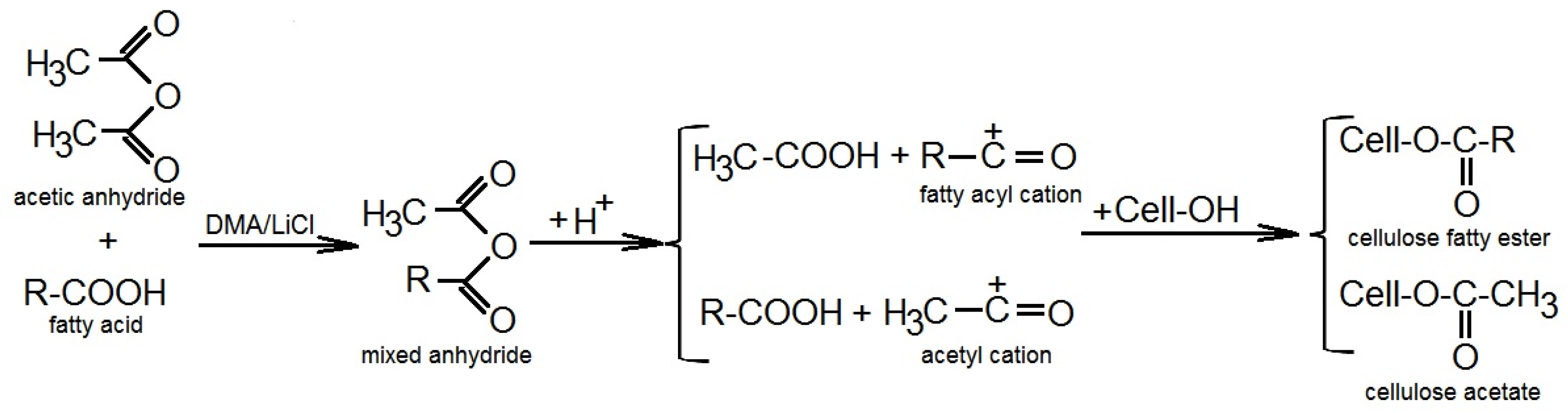

4.1. Wood Surface Modification by Esterification Reactions Using Fatty Acids

4.2. Wood Surface Modification by Esterification Reactions Using Unsaturated Carboxylic Acids

4.3. Wood Surface Modification by Esterification Reactions Using Polycarboxylic Acids

- the small size of wood particles created a significantly increased active surface for functionalization;

- the high amount of CA (20 wt.%) provided a larger number of carboxylic groups;

- the temperature regime favored the reaction rate and degree of substitution;

- the pressure applied during processing enhanced the penetration of CA molecules to reaction sites not easily accessible;

- the short heating time prevented further degradative thermo-chemical processes.

- the amount of nanoclay (2%) and its total exfoliation claimed by authors, and supported with XRD and TEM data, and the nanoclay structural features;

- HCl favored the multiple esterification, unlike Cloisite 30B, proved by thermal data;

- for samples prepared with nanoclay, density was not significantly improved compared to HCl samples, and the water vapor sorption was poor (this is an indication of the increased tortuosity of the material, which entailed slow transfer of water vapors in and out of the material), although dimensional stability and hardness increased;

- knowing the reinforcing effect of nanoclays in different types of composite materials, then it is possible to conclude that nanoparticulate clay may have been acting more as a reinforcing agent than a catalyst, even in low amounts. Further studies with nanoclay in various ratios are, though, necessary to elucidate the role of this component and its mechanism of action.

4.4. Wood Surface Modification by Esterification Reactions Using Other Acids

4.5. Wood Surface Modification by Miscellaneous Procedures

4.5.1. Wood Esterification with Ketene

4.5.2. Direct Esterification of Wood with ε-Caprolactone

4.5.3. Transesterification Reactions for Wood Modification

5. Conclusions

Funding

Acknowledgments

Conflicts of Interest

References

- Gérardin, P. New alternatives for wood preservation based on thermal and chemical modification of wood—A review. Ann. For. Sci. 2016, 73, 559–570. [Google Scholar] [CrossRef] [Green Version]

- Rowell, R.M. Chemical modification of wood. In Handbook of Wood Chemistry and Wood Composites, 2nd ed.; Rowell, R.M., Ed.; Chapter 15; CRC Press: Boca Raton, FL, USA, 2012; pp. 537–598. [Google Scholar]

- Rowell, R.M. Chemical modification of wood: A short review. Wood Mat. Sci. Eng. 2006, 1, 29–33. [Google Scholar] [CrossRef]

- Hill, C.A.S. Wood Modification: Chemical, Thermal and Other Processes; John Wiley & Sons Ltd.: Chichester, UK, 2006. [Google Scholar]

- Norimoto, M. Chemical modification of wood. In Wood and Cellulose Chemistry, 2nd ed.; Hon, D.N.S., Shiraishi, N., Eds.; Marcel Dekker: New York, NY, USA, 2001; pp. 573–598. [Google Scholar]

- Kudanga, T.; Prasetyo, E.N.; Sipila, J.; Guebitz, G.M.; Nyanhongo, G.S. Reactivity of long chain alkylamines to lignin moieties: Implications on hydrophobicity of lignocellulose materials. J. Biotechnol. 2010, 149, 81–87. [Google Scholar] [CrossRef] [PubMed]

- Suurnakki, A.; Buchert, J.; Gronqvist, S.; Mikkonen, H.; Peltonen, S.; Viikari, L. Bringing new properties to lignin rich fiber materials. VTT Symposium 2006, 244, 61–70. [Google Scholar]

- Yamaguchi, H.; Maeda, Y.; Sakata, I. Bonding among woody fibers by use of enzymatic phenol dehydrogenative polymerization. Mokuzai Gakkaishi 1994, 40, 185–190. [Google Scholar]

- Teacă, C.-A.; Roşu, D.; Mustată, F.; Rusu, T.; Roşu, L.; Roşca, I.; Varganici, C.-D. Natural bio-based products for wood coating and protection against degradation: A review. BioResources 2019, 4, 4873–4901. [Google Scholar]

- Bodîrlău, R.; Spiridon, I.; Teacă, C.-A. Chemical investigation of wood tree species in a temperate forest, east-northern Romania. BioResources 2007, 2, 41–57. [Google Scholar]

- Bodîrlău, R.; Teacă, C.-A.; Spiridon, I. Chemical modification of beech wood: Effect on thermal stability. BioResources 2008, 3, 789–800. [Google Scholar]

- Zelinka, S.L.; Ringman, R.; Pilgård, A.; Thybring, E.E.; Jakes, J.E.; Richter, K. The role of chemical transport in the brown-rot decay resistance of modified wood. Int. Wood Prod. J. 2016, 7, 66–70. [Google Scholar] [CrossRef]

- Nagarajappa, G.B.; Pandey, K.K. UV resistance and dimensional stability of wood modified with isopropenyl acetate. J. Photochem. Photobiol. B Biol 2016, 155, 20–27. [Google Scholar] [CrossRef]

- Ringman, R.; Pilgard, A.; Brischke, C.; Richter, K. Mode of action of brow rot decay resistance in modified wood: A review. Holzforschung 2014, 68, 239–246. [Google Scholar] [CrossRef]

- Thybring, E.E. The decay resistance of modified wood influenced by moisture exclusion and swelling reduction. Int. Biodeter. Biodegrad. 2013, 82, 87–95. [Google Scholar] [CrossRef]

- Baur, S.I.; Easteal, A.J. Improved photoprotection of wood by chemical modification with silanes: NMR and ESR studies. Polym. Adv. Technol. 2013, 24, 97–103. [Google Scholar] [CrossRef]

- Xiao, Z.F.; Xie, Y.J.; Mai, C. The fungal resistance of wood modified with glutaraldehyde. Holzforschung 2012, 66, 237–243. [Google Scholar] [CrossRef]

- Papadopoulos, A.N. Chemical modification of pine wood with propionic anhydride: Effect on decay resistance and sorption of water vapour. Bioresources 2006, 1, 67–74. [Google Scholar]

- Papadopoulos, A.N.; Hill, C.A.S. The biological effectiveness of wood modified with linear chain carboxylic acid anhydrides against Coniophoraputeana. HolzRohWerkst 2002, 60, 329–332. [Google Scholar]

- Xiao, Z.; Xie, Y.; Adamopoulos, S.; Mai, C. Effects of chemical modification with glutaraldehyde on the weathering performance of Scots pine sapwood. Wood Sci. Technol. 2012, 46, 749–767. [Google Scholar] [CrossRef] [Green Version]

- Roşu, D.; Teacă, C.-A.; Bodîrlău, R.; Roşu, L. FTIR and color change of the modified wood as a result of artificial light irradiation. J. Photochem. Photobiol. B Biol. 2010, 99, 144–149. [Google Scholar] [CrossRef]

- Jebrane, M.; Sèbe, G.; Cullis, I.; Evans, P.D. Photostabilization of wood using aromatic vinyl esters. Polym. Degrad. Stab. 2009, 94, 151–157. [Google Scholar] [CrossRef]

- Evans, P.D.; Owen, N.L.; Schmid, S.; Webster, R.D. Weathering and photostability of benzoylated wood. Polym. Degrad. Stab. 2002, 76, 291–303. [Google Scholar] [CrossRef]

- Chang, S.T.; Chang, H.-T. Comparisons of the photostability of esterified wood. Polym. Degrad. Stab. 2001, 71, 261–266. [Google Scholar] [CrossRef]

- Roşu, D.; Bodîrlău, R.; Teacă, C.-A.; Roşu, L.; Varganici, C.-D. Epoxy and succinic anhydride functionalized soybean oil for wood protection against UV light action. J. Clean. Prod. 2016, 112, 1175–1183. [Google Scholar] [CrossRef]

- Roşu, L.; Varganici, C.D.; Mustață, F.; Rusu, T.; Roşu, D.; Roşca, I.; Tudorachi, N.; Teacă, C.-A. Enhancing the thermal and fungal resistance of wood treated with natural and synthetic derived epoxy resins. ACS Sustain. Chem. Eng. 2018, 6, 5470–5478. [Google Scholar] [CrossRef]

- Bodîrlău, R.; Teacă, C.-A.; Spiridon, I. Preparation and characterization of composites comprising modified hardwood and wood polymers/poly(vinyl chloride). BioResources 2009, 4, 1285–1304. [Google Scholar]

- Zhang, Y.; Xue, Y.; Toghiani, H.; Zhang, J.; Pittman, C.U. Modification of wood flour surfaces by esterification with acid chlorides: Use in HDPE/wood flour composites. Compos. Interfaces 2009, 16, 671–686. [Google Scholar] [CrossRef]

- Ou, R.; Wang, Q.; Wolcott, M.P.; Sui, S.; Xie, Y. Rheological behavior and mechanical properties of wood flour/high density polyethylene blends: Effects of esterification of wood with citric acid. Polym. Compos. 2014, 37, 553–560. [Google Scholar] [CrossRef]

- Adekunle, K.F. Surface treatments of natural fibres—A review: Part 1. Open J. Polym. Chem. 2015, 5, 41–46. [Google Scholar] [CrossRef] [Green Version]

- Kalia, S.; Kaith, B.S.; Kaur, I. Pretreatments of natural fibers and their application as reinforcing material in polymer composites—A review. Polym. Eng. Sci. 2009, 49, 1253–1272. [Google Scholar] [CrossRef]

- Vick, C.B.; Rowell, R.M. Adhesive bonding of acetylated wood. Int. J. Adhesion Adhesives 1990, 10, 263–272. [Google Scholar] [CrossRef]

- Frihart, C.R.; Brandon, R.; Beecher, J.F.; Ibach, R.E. Adhesives for achieving durable bonds with acetylated wood. Polymers 2017, 9, 731. [Google Scholar] [CrossRef] [Green Version]

- Teacă, C.-A.; Tanasă, F.; Zănoagă, M. Multi-component polymer systems comprising wood as bio-based component and thermoplastic polymer matrices—An overview. BioResources 2018, 13, 4728–4769. [Google Scholar] [CrossRef] [Green Version]

- Riedl, B.; Angel, C.; Prégent, J.; Blanchet, P.; Stafford, L. Effect of wood surface modification by atmospheric-pressure plasma on waterborne coating adhesion. BioResources 2014, 9, 4908–4923. [Google Scholar] [CrossRef] [Green Version]

- Wang, H.Y.; Du, G.B.; Li, Q.; Xu, R.Y.; Yuan, S.F. Bonding performance of wood treatment by oxygen and nitrogen cold plasma. Appl. Mechanics Mater. 2014, 633–634, 583–588. [Google Scholar] [CrossRef]

- Acda, M.N.; Devera, E.E.; Cabangon, R.J.; Ramos, H.J. Effects of plasma modification on adhesion properties of wood. Int. J. Adhesion Adhesives 2012, 32, 70–75. [Google Scholar] [CrossRef]

- Kim, B.-S.; Chun, B.-H.; Woo, I.L.; Hwang, B.-S. Effect of plasma treatment on the wood flour for wood flour/PP composites. J. Thermoplast. Compos. Mater. 2009, 22, 21–28. [Google Scholar] [CrossRef]

- Podgorski, L.; Chevet, B.; Onic, L.; Merlin, A. Modification of wood wettability by plasma and corona treatments. Int. J. Adhesion Adhesives 2000, 20, 103–111. [Google Scholar] [CrossRef]

- Pelaez-Samaniego, M.R.; Yadama, V.; Lowell, E.; Espinoza-Herrera, R. A review of wood thermal pretreatments to improve wood composite properties. Wood Sci. Technol. 2013, 47, 1285–1319. [Google Scholar] [CrossRef]

- Borysiak, S. Influence of wood mercerization on the crystallization of polypropylene in wood/PP composites. J. Therm. Anal. Calorim. 2012, 109, 595–603. [Google Scholar] [CrossRef]

- Lu, J.Z.; Wu, Q.; McNabb, H.S., Jr. Chemical coupling in wood fiber and polymer composites: A review of coupling agents and treatments. Wood Fiber Sci. 2000, 32, 88–104. [Google Scholar]

- Bodîrlău, R.; Teacă, C.-A.; Resmeriţă, A.-M.; Spiridon, I. Investigation of structural and thermal properties of different wood species treated with toluene-2,4-diisocyanate. Cell. Chem. Technol. 2012, 46, 381–387. [Google Scholar]

- Maldas, D.; Kokta, B.V. Surface modification of wood fibers using maleic anhydride and isocyanate as coating components and their performance in polystyrene composites. J. Adhes. Sci. Technol. 1991, 5, 727–740. [Google Scholar] [CrossRef]

- Li, Q.; Matuana, L.M. Surface of cellulosic materials modified with functionalized polyethylene coupling agents. J. Appl. Polym. Sci. 2003, 88, 278–286. [Google Scholar] [CrossRef]

- Farsi, M. Wood–plastic composites: Influence of wood flour chemical modification on the mechanical performance. J. Reinf. Plast. Compos. 2010, 29, 3587–3592. [Google Scholar] [CrossRef]

- Xie, H.; Jarvi, P.; Karesoja, M.; King, A.; Kilpelainen, I.; Argyropoulos, D.S. Highly compatible wood thermoplastic composites from lignocellulosic material modified in ionic liquids: Preparation and thermal properties. J. Appl. Polym. Sci. 2009, 111, 2468–2476. [Google Scholar] [CrossRef]

- Teacă, C.-A.; Bodîrlău, R.; Spiridon, I. Maleic anhydride treatment of softwood—effect on wood structure and properties. Cell. Chem. Technol. 2014, 48, 863–868. [Google Scholar]

- Bodîrlău, R.; Teacă, C.-A. Fourier transform infrared spectroscopy and thermal analysis of lignocellulose fillers treated with organic anhydrides. Rom. J. Phys. 2009, 54, 93–104. [Google Scholar]

- Bodîrlău, R.; Teacă, C.-A. Softwood chemical modification by reaction with organic anhydrides. Rev. Roum. Chim. 2008, 53, 1059–1064. [Google Scholar]

- Bodîrlău, R.; Teacă, C.-A.; Roşu, D.; Roşu, L.; Varganici, C.-D.; Coroabă, A. Physico-chemical properties investigation of softwood surface after treatment with organic anhydride. Cent. Eur. J. Chem. 2013, 11, 2098–2106. [Google Scholar]

- Doczekalska, B.; Bartkowiak, M.; Zakrzewski, R. Modification of sawdust from pine and beech wood with the succinic anhydride. HolzRohWerkst 2007, 65, 187–191. [Google Scholar] [CrossRef]

- Ichazo, M.N.; Albano, C.; Gonzalez, J.; Perera, R.; Candal, M.V. Polypropylene/wood flour composites: Treatments and properties. Compos. Struct. 2001, 54, 207–214. [Google Scholar] [CrossRef]

- Yang, T.; Cao, J.; Ma, E. How does delignification influence the furfurylation of wood? Ind. Crops Prod. 2019, 135, 91–98. [Google Scholar] [CrossRef]

- Sejati, P.S.; Imbert, A.; Gérardin-Charbonnier, C.; Dumarçay, S.; Fredon, E.; Masson, E.; Nandika, D.; Priadi, T.; Gérardin, P. Tartaric acid catalyzed furfurylation of beech wood. Wood Sci. Technol. 2017, 51, 379–394. [Google Scholar] [CrossRef] [Green Version]

- Li, W.; Ren, D.; Zhang, X.; Wang, H.; Yu, Y. The furfurylation of wood: A nanomechanical study of modified wood cells. BioResources 2016, 11, 3614–3625. [Google Scholar] [CrossRef]

- Li, W.; Wang, H.; Ren, D.; Yu, Y.S.; Yu, Y. Wood modification with furfuryl alcohol catalysed by a new composite acidic catalyst. Wood Sci. Technol. 2015, 49, 845–856. [Google Scholar] [CrossRef]

- Pfriem, A.; Dietrich, T.; Buchelt, B. Furfuryl alcohol impregnation for improved plasticization and fixation during the densification of wood. Holzforschung 2012, 66, 215–218. [Google Scholar] [CrossRef]

- Esteves, B.; Nunes, L.; Pereira, H. Properties of furfurylated wood (Pinus pinaster). Eur. J. Wood Prod. 2011, 69, 521–525. [Google Scholar] [CrossRef]

- Gaye KöseDemirel, G.; Güdül, H.; Temiz, A.; Kuştaş, S.; Aydin, İ. Effect of alkyl ketene dimer on the physical, mechanical, and biological durability of plywood. BioResources 2017, 13, 147–156. [Google Scholar]

- Zhang, H. Effect of a novel coupling agent, alkyl ketene dimer, on the mechanical properties of wood-plastic composites. Mater. Design 2014, 59, 130–134. [Google Scholar] [CrossRef]

- Hundhausen, U.; Militz, H.; Mai, C. Use of alkyl ketene dimer (AKD) for surface modification of particleboard chips. Eur. J. Wood Prod. 2009, 67, 37–45. [Google Scholar] [CrossRef] [Green Version]

- Rowell, R.M.; Wang, R.H.S.; Hyatt, J.A. Flakeboards made from aspen and southern pine wood flakes reacted with gaseous ketene. J. Wood Chem. Technol. 1986, 6, 449–471. [Google Scholar] [CrossRef]

- Çetin, N.S.; Ozmen, N. Dimensional changes in Corsican and Scots pine sapwood due to reaction with crotonic anhydride. Wood Sci. Technol. 2001, 35, 257–267. [Google Scholar] [CrossRef]

- Hill, C.A.S.; Cetin, N.S. Surface activation of wood for graft polymerization. Int. J. Adhesion Adhesives 2000, 20, 71–76. [Google Scholar] [CrossRef]

- Del Menezzi, C.; Amirou, S.; Pizzi, A.; Xi, X.; Delmotte, L. Reactions with wood carbohydrates and lignin of citric acid as a bond promoter ofwood veneer panels. Polymers 2018, 10, 833. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Amirou, S.; Pizzi, A.; Delmotte, L. Citric acid as waterproofing additive in butt joints linear wood welding. Eur. J. Wood Prod. 2017, 75, 651–654. [Google Scholar] [CrossRef]

- Essoua Essoua, G.G.; Blanchet, P.; Landry, V.; Beauregard, R. Pine wood treated with a citric acid and glycerol mixture: Biomaterial performance improved by a bio-byproduct. BioResources 2016, 11, 3049–3072. [Google Scholar] [CrossRef] [Green Version]

- Umemura, K.; Ueda, T.; Kawai, S. Characterization of wood-based molding bonded with citric acid. J. Wood Sci. 2012, 58, 38–45. [Google Scholar] [CrossRef] [Green Version]

- Umemura, K.; Kawai, S. Development of wood-based materials bonded with citric acid. For. Prod. J. 2015, 65, 38–42. [Google Scholar] [CrossRef]

- Feng, X.; Xiao, Z.; Sui, S.; Wang, Q.; Xie, Y. Esterification of wood with citric acid: The catalytic effects of sodium hypophosphite (SHP). Holzforschung 2014, 68, 427–433. [Google Scholar] [CrossRef]

- Umemura, K.; Ueda, T.; Munawar, S.S.; Kawai, S. Application of citric acid as natural adhesive for wood. J. Appl. Polym. Sci. 2012, 123, 1991–1996. [Google Scholar] [CrossRef]

- Bischof Vukusic, S.; Katovic, D.; Schramm, C.; Trajkovic, J.; Sefc, B. Polycarboxylic acids as non-formaldehyde anti-swelling agents for wood. Holzforschung 2006, 60, 439–444. [Google Scholar] [CrossRef]

- Hauptmann, M.; Gindl-Altmutter, W.; Hansmann, C.; Bacher, M.; Rosenau, T.; Liebner, F.; D’Amico, S.; Schwanninger, M. Wood modification with tricine. Holzforschung 2015, 69, 985–991. [Google Scholar] [CrossRef]

- Hauptmann, M.; Rosenau, T.; Gindl-Altmutter, W.; Hansmann, C. Effects of UV-irradiation on tricine impregnated wood. Eur. J. Wood Prod. 2014, 72, 617–622. [Google Scholar] [CrossRef]

- Larsson-Brelid, P. Benchmarking and State of-the-Art Report for Modified Wood; SP Report no. 54; SP Technical Research Institute of Sweden: Stockholm, Sweden, 2013; pp. 1–31. [Google Scholar]

- Militz, H. Treatment of timber with water soluble dimethylol resins to improve their dimensional stability and durability. Wood Sci. Technol. 1993, 27, 347–355. [Google Scholar] [CrossRef]

- Xie, Y.; Krause, A.; Mai, C.; Militz, H.; Richter, K.; Urban, K.; Evans, P.D. Weathering of wood modifiedwith the N-methylol compound 1, 3-dimethylol-4, 5-dihydroxyethyleneurea. Polym. Degrad. Stabil. 2005, 89, 189–199. [Google Scholar] [CrossRef]

- Xie, Y.; Krause, A.; Militz, H.; Turkulin, H.; Richter, K.; Mai, C. Effect of treatments with 1,3-dimethylol-4, 5-dihydroxyethyleneurea (DMDHEU) on the tensile properties of wood. Holzforschung 2007, 61, 43–50. [Google Scholar] [CrossRef] [Green Version]

- Xie, Y.; Krause, A.; Militz, H.; Mai, C. Weathering of uncoated and coated wood treated withmethylated 1, 3-dimethylol-4, 5-dihydroxyethyleneurea (mDMDHEU). Holz Roh Werkst. 2008, 66, 455–464. [Google Scholar] [CrossRef]

- Shin, Y.; Winder, E.M.; Han, K.S.; Lee, H.; Bonheyo, G.T. Enhanced capacities of mixed fatty acid-modified sawdust aggregators for remediation of crude oil spill. ACS Omega 2019, 4, 412–420. [Google Scholar] [CrossRef]

- Salla, J.; Pandey, K.K.; Prakash, G.K.; Mahadevan, K.M. Photobleaching and dimensional stability of rubberwood esterified by fatty acid chlorides. J. Wood. Chem. Technol. 2012, 32, 121–136. [Google Scholar] [CrossRef]

- Prakash, G.K.; Mahadevan, K.M. Enhancing the properties of wood through chemical modification with palmitoyl chloride. Appl. Surf. Sci. 2008, 254, 1751–1756. [Google Scholar] [CrossRef]

- Wang, X.J.; Zhang, M.H.; Wang, X.M. Properties of esterificated wood with oxalic acid and cetyl alcohol. Adv. Mater. Res. 2010, 123–125, 1187–1190. [Google Scholar] [CrossRef]

- Matsuda, H. Chemical modification of solid wood. In Chemical Modification of Lignocellulosic Materials; Hon, D.N.S., Ed.; Marcel Dekker: New York, NY, USA, 1996; pp. 159–183. [Google Scholar]

- Nunez, A.J.; Kenny, J.M.; Reboredo, M.M.; Aranguren, M.I.; Marcovich, N.E. Thermal and dynamic mechanical characterization of polypropylene-wood flour composites. Polym. Eng. Sci. 2002, 42, 733–742. [Google Scholar] [CrossRef]

- Cofta, G.; Borysiak, S.; Doczekalska, B.; Garbarczyk, J. Resistance of polypropylene-wood composites to fungi. Polimery 2006, 51, 276–279. [Google Scholar] [CrossRef]

- Chang, H.-T.; Chang, S.-T. Modification of wood with isopropyl glycidyl ether and its effects on decay resistance and light stability. Bioresour. Technol. 2006, 97, 1265–1271. [Google Scholar] [CrossRef] [PubMed]

- Hill, C.A.S.; Cetin, N.S.; Ozmen, Z. Potential catalysts for the acetylation of wood. Holzforschung 2000, 54, 269–272. [Google Scholar] [CrossRef]

- Evans, P.D.; Wallis, A.F.A.; Owen, N.L. Weathering of chemically modified wood surfaces—Natural weathering of Scots pine acetylated to different weight gains. Wood Sci. Technol. 2000, 34, 151–165. [Google Scholar] [CrossRef]

- Clemons, C.; Young, R.A.; Rowell, R.M. Moisture sorption properties of composite boards from esterified aspen fiber. Wood Fiber Sci. 1992, 24, 353–363. [Google Scholar]

- Mishra, S.; Naik, J.B. Absorption of water at ambient temperature and steam in wood–polymer composites prepared from agro-waste and polystyrene. J. Appl. Polym. Sci. 1998, 68, 681–686. [Google Scholar] [CrossRef]

- Iwamoto, Y.; Itoh, T. Vapor phase reaction of wood with maleic anhydride (I): Dimensional stability and durability of treated wood. J. Wood Sci. 2005, 51, 595–600. [Google Scholar] [CrossRef]

- Nenkova, S.; Dobrilova, T.Z.V.; Natov, M.; Vasilieva, S.; Velev, P. Modification of wood flour with maleic anhydride for manufacture of wood-polymer composites. Polym. Polym. Compos. 2006, 14, 185–194. [Google Scholar] [CrossRef]

- Tanasa, F. Hi-tech polymers by direct polycondensation reactions. In Functional Polymeric Materials Designed for Hi-Tech Applications; Nechifor, M., Ed.; Transworld Research Network: Kerala, India, 2010; pp. 155–175. [Google Scholar]

- Sealey, J.; Samaranayake, G.; Todd, J.; Glasser, W.G. Novel cellulose derivatives. IV. Preparation and thermal analysis of waxy ester of cellulose. J. Polym. Sci. 1996, 34, 1613–1620. [Google Scholar] [CrossRef]

- Narayan, R.; Biermann, C.J.; Hunt, M.O.; Horn, D.P. Cellulose graft copolymers for potential adhesive applications. In Bonding of Plastics to Wood, volume 385, Adhesives from Renewable Resources; ACS Symposium Series; Hemingway, R.W., Conner, A.H., Branham, S.J., Eds.; Chapter 24; ACS: Washington, DC, USA, 1989; pp. 337–354. [Google Scholar]

- Rowell, R.M. Distribution of reacted chemicals in southern pine modified with acetic anhydride. Wood Sci. 1982, 15, 172–182. [Google Scholar]

- Rowell, R.M. Chemical Modification of Wood: A Review; Commonwealth Forestry Bureau: Oxford, UK, 1983; Volume 6, pp. 363–382. [Google Scholar]

- Mantanis, G.I. Chemical modification of wood by acetylation or furfurylation: A review of the present scaled-up technologies. BioResources 2017, 12, 4478–4489. [Google Scholar] [CrossRef] [Green Version]

- Tarkow, H. Decay Resistance of Acetylated Balsa; USDA Forest Service, Forest Prod. Lab.: Madison, WI, USA, 1945; p. 4. [Google Scholar]

- Rowell, R.M. Acetylation of wood—A review. Int. J. Lignocellulosic Products 2014, 1, 1–27. [Google Scholar]

- Rowell, R. Acetylation of wood—Journey from analytical technique to commercial reality. Forest Prod. J. 2006, 56, 4–12. [Google Scholar]

- Tarkow, H.; Stamm, A.J.; Erickson, E. Acetylated Wood; Report no. 1593; USDA Forest Service, Forest Products Laboratory: Madison, WI, USA, 1946; p. 29. [Google Scholar]

- Rowell, R.M. The chemistry of solid wood. In Advances in Chemistry Series; No. 207; American Chemical Society: Washington, DC, USA, 1984; p. 540. [Google Scholar] [CrossRef]

- Jones, D.; Sandberg, D.; Goli, G.; Todaro, L. Wood Modification in Europe: A State-of-the Art about Processes, Products and Applications; Firenze University Press: Firenze, Italy, 2019; p. 123. [Google Scholar]

- Hill, C.A.S. Wood modification: An update. BioResources 2011, 6, 918–919. [Google Scholar]

- Rahn, K.; Diamantoglou, M.; Klemm, D.; Berghmans, H.; Heinze, T. Homogeneous synthesis of cellulose p-toluenesulfonates in N,N-dimethylacetamide/LiCl solvent system. Angew. Makromol. Chem. Appl. Macromol. Chem. Phys. 1996, 238, 143–163. [Google Scholar] [CrossRef]

- Ermeydan, M.A.; Cabane, E.; Gierlinger, N.; Koetz, J.; Burgert, I. Improvement of wood material properties via in situ polymerization of styrene into tosylated cell walls. RSC Adv. 2014, 4, 12981–12988. [Google Scholar] [CrossRef] [Green Version]

- Ermeydan, M.A.; Cabane, E.; Masic, A.; Koetz, J.; Burgert, I. Flavonoid insertion into cell walls improves wood properties. ACS Appl. Mater. Interfaces 2012, 4, 5782–5789. [Google Scholar] [CrossRef]

- Heinze, T.; Liebert, T. Unconventional methods in cellulose functionalization. Prog. Polym. Sci. 2001, 26, 1689–1762. [Google Scholar] [CrossRef]

- Ma, P.; Gao, Y.; Zhai, H. Fractionated wheat straw lignin and its application as antioxidant. BioResources 2013, 8, 5581–5595. [Google Scholar] [CrossRef] [Green Version]

- Ujihara, M.; Nakatsubo, F.; Katahira, R. A novel selective cleavage method for β-O-4 substructure in lignins named TIZ method. I. Degradation of guaiacyl and syringyl models. J. Wood Chem. Technol. 2003, 23, 71–87. [Google Scholar] [CrossRef]

- Diop, A.; Awada, H.; Zerrouki, R.; Daneault, C.; Montplaisir, D. Tosylation and characterization of lignin in water. Ind. Eng. Chem. Res. 2014, 53, 16771–16776. [Google Scholar] [CrossRef]

- Panovic, I.; Montgomery, J.R.; Lancefield, C.S.; Puri, D.; Lebl, T.; Westwood, N.J. Grafting of technical lignins through regioselective triazole formation on β-O-4 linkages. ACS Sustain. Chem. Eng. 2017, 5, 10640–10648. [Google Scholar] [CrossRef] [Green Version]

- Heinze, T.; Liebert, T.F.; Pfeiffer, K.S.; Hussain, M.A. Unconventional cellulose esters: Synthesis, characterization and structure–property relations. Cellulose 2003, 10, 283–296. [Google Scholar] [CrossRef]

- Ziemann, E. Surface modification of cellulose membranes. In Reviews in Global Water Cycle; OSF Preprints: Leeuwarden, The Netherlands, 2017. [Google Scholar] [CrossRef]

- Kishida, A.; Mishima, K.; Corretge, E.; Konishi, H.; Ikada, Y. Interactions of poly(ethyleneglycol)-grafted cellulose membranes with proteins and platelets. Biomaterials 1992, 13, 113–118. [Google Scholar] [CrossRef]

- Gardner, D.J.; Schulz, T.P.; McGinnis, G.D. The pyrolytic behavior of selected lignin preparations. J. Wood Chem. Technol. 1985, 5, 85–110. [Google Scholar] [CrossRef]

- Gericke, M.; Fardim, P.; Heinze, T. Ionic liquids—Promising but challenging solvents for homogeneous derivatization of cellulose. Molecules 2012, 17, 7458–7502. [Google Scholar] [CrossRef] [Green Version]

- Liebert, T.; Heinze, T. Interaction of ionic liquids with polysaccharides. 5. Solvents and reaction media for the modification of cellulose. BioResources 2008, 3, 576–601. [Google Scholar]

- Heinze, T.; Gericke, M. Ionic liquids as solvents for homogeneous derivatization of cellulose: Challenges and opportunities. In Production of Biofuels and Chemicals with Ionic Liquids; Fang, Z., Smith, R.L., Jr., Qi, X., Eds.; Springer: Dordrecht, The Netherlands, 2014; pp. 107–144. [Google Scholar]

- Vitz, J.; Erdmenger, T.; Haensch, C.; Schubert, U.S. Extended dissolution studies of cellulose in imidazolium based ionic liquids. Green Chem. 2009, 11, 417–424. [Google Scholar] [CrossRef]

- Trivedi, P.; Fardim, P. Recent advances in cellulose chemistry and potential applications. In Production of Materials from Sustainable Biomass Resources; Fang, Z., Smith, R.L., Jr., Tian, X., Eds.; Springer: Singapore, 2019; pp. 99–115. [Google Scholar]

- Granström, M.; Kavakka, J.; King, A.; Majoinen, J.; Mäkelä, V.; Helaja, J.; Hietala, S.; Virtanen, T.; Maunu, S.L.; Argyropoulos, D.S.; et al. Tosylation and acylation of cellulose in 1-allyl-3-methylimidazolium chloride. Cellulose 2008, 15, 481–488. [Google Scholar] [CrossRef] [Green Version]

- Gericke, M.; Schaller, J.; Liebert, T.; Fardim, P.; Meister, F.; Heinze, T. Studies on the tosylation of cellulose in mixtures of ionic liquids and a co-solvent. Carbohydr. Polym. 2012, 89, 526–536. [Google Scholar] [CrossRef] [PubMed]

- Möllmann, E.; Heinze, T.; Liebert, T.; Köhler, S. Homogeneous Synthesis of Cellulose Ethers in Ionic Liquids. U.S. Patent Application 20090221813 A1, 3 September 2009. [Google Scholar]

- Vitz, J.; Yevlampieva, N.P.; Rjumtsev, E.; Schubert, U.S. Cellulose molecular properties in 1-alkyl-3- methylimidazolium-based ionic liquid mixtures with pyridine. Carbohydr. Polym. 2010, 82, 1046–1053. [Google Scholar] [CrossRef]

- Kohler, S.; Heinze, T. Efficient synthesis of cellulose furoates in 1-N-butyl-3-methylimidazolium chloride. Cellulose 2007, 14, 489–495. [Google Scholar] [CrossRef]

- Buchanan, C.M.; Buchanan, N.L.; Guzman-Morales, E. Cellulose solutions comprising tetraalkylammoniumalkyl phosphate and products produced therefrom. U.S. Patent Application WO/2010/120269, US2009/004626, 21 October 2010. [Google Scholar]

- Jessop, P.G. Searching for green solvents. Green Chem. 2011, 13, 1391–1398. [Google Scholar] [CrossRef]

- Deetlefs, M.; Seddon, K.R. Assessing the greenness of some typical laboratory ionic liquid preparations. Green Chem. 2010, 12, 17–30. [Google Scholar] [CrossRef]

- Shimizu, Y.; Hayashi, J. Acylation of cellulose with carboxylic acids. Cell. Chem. Technol. 1989, 23, 661–670. [Google Scholar]

- Shimizu, Y.; Hayashi, J. A new method for cellulose acetylation with acetic acid. Sen’IGakkaishi 1988, 44, 451–456. [Google Scholar] [CrossRef] [Green Version]

- Heinze, T.; Schaller, J. New water soluble cellulose ester synthesized by an effective acylation procedure. Macromol. Chem. Phys. 2000, 201, 1214–1218. [Google Scholar] [CrossRef]

- Orzeszko, A.; Gralewska, R.; Starosciak, B.J.; Kazimierczuk, Z. Synthesis and antimicrobial activity of new adamantane derivatives. Acta Biochim. Pol. 2000, 47, 87–94. [Google Scholar] [CrossRef] [Green Version]

- Samaranayake, G.; Glasser, W.G. Cellulose derivatives with low DS. 1. A novel acylation system. Carbohydr. Polym. 1993, 22, 1–7. [Google Scholar] [CrossRef]

- Samaranayake, G.; Glasser, W.G. Cellulose derivatives with low DS. 2. Analysis of alkanoates. Carbohydr. Polym. 1993, 22, 79–86. [Google Scholar] [CrossRef]

- Gräbner, D.; Liebert, T.; Heinze, T. Synthesis of novel adamantoyl cellulose using differently activated carboxylic acid derivatives. Cellulose 2002, 9, 193–201. [Google Scholar] [CrossRef]

- Vaca-Garcia, C.; Thiebaud, S.; Borredon, M.E.; Gozzelino, G. Cellulose esterification with fatty acids and acetic anhydride in lithium chloride/N, N-dimethylacetamide medium. J. Am. Oil Chem. Soc. 1998, 75, 315–319. [Google Scholar] [CrossRef] [Green Version]

- Thiebaud, S.; Borredon, M.E. Solvent-free wood esterification with fatty acid chlorides. Bioresour. Technol. 1995, 52, 169–173. [Google Scholar] [CrossRef]

- Nakagami, T.; Amimoto, H.; Yokota, T. Esterification of wood with unsaturated carboxylic acids. I.: Preparation of several wood-esters by the TFAA method. Bull. Kyoto Univ. For. 1974, 46, 217–224. [Google Scholar]

- Nakagami, T.; Yokota, T. Esterification of wood with unsaturated carboxylic acids. II: Reaction conditions of esterification and properties of the prepared esters of wood. Bull. Kyoto Univ. For. 1975, 47, 178–183. [Google Scholar]

- Arni, P.C.; Gray, J.D.; Scougall, R.K. Chemical modification of wood. I Use of trifluoroacetic anhydride in the esterification of wood by carboxylic acids. J. Appl. Chem. 1961, 11, 157–163. [Google Scholar] [CrossRef]

- Despot, R.; Hasan, M.; Jug, M.; Šefc, B. Biological durability of wood modified by citric acid. Drv. Ind. 2008, 59, 55–59. [Google Scholar]

- Mubarok, M.; Militz, H.; Dumarçay, S.; Gérardin, P. Beech wood modification based on in situ esterification with sorbitol and citric acid. Wood Sci. Technol. 2020, 54, 1–24. [Google Scholar] [CrossRef] [Green Version]

- L’Hostis, C.; Thévenon, M.F.; Fredon, E.; Gérardin, P. Improvement of beech wood properties by in situ formation of polyesters of citric and tartaric acid in combination with glycerol. Holzforschung 2018, 72, 291–299. [Google Scholar] [CrossRef]

- Essoua Essoua, G.G. Développement d’une Stratégie de Modification du bois afin de Limiter les Variations Dimensionnelles du Produit Lambris dans un Contexte Éco-Responsible. Available online: https://corpus.ulaval.ca/jspui/handle/20.500.11794/27111 (accessed on 10 June 2020).

- Zoldners, J.; Kiseleva, T. Modification of hemicelluloses with polycarboxylic acids. Holzforschung 2013, 67, 567–571. [Google Scholar] [CrossRef]

- Guo, W.; Xiao, Z.; Wentzel, M.; Emmerich, L.; Xie, Y.; Militz, H. Modification of Scots pine with activated glucose and citric acid: Physical and mechanical properties. BioResources 2019, 14, 3445–3458. [Google Scholar]

- BischofVukusic, S.; Katovic, D.; Grgac, S.F.; Trajkovic, J.; Sefc, B.; Voncina, B. Study of the wood modification process with polycarboxylic acids and microwave treatment. Wood Res.-Slovakia 2010, 55, 121–130. [Google Scholar]

- Miklečić, J.; Jirouš-Rajković, V. Accelerated weathering of coated and uncoated beech wood modified with citric acid. Wood Ind./Drv. 2011, 62, 277–282. [Google Scholar] [CrossRef]

- Šefc, B.; Trajković, J.; Sinković, T.; Hasan, M.; Ištok, I. Compression strength of fir and beech wood modified by citric acid. Wood Ind./Drv. 2012, 63, 45–50. [Google Scholar] [CrossRef] [Green Version]

- Berube, M.A.; Schorr, D.; Ball, R.J.; Landry, V.; Blanchet, P. Determination of in situ esterification parameters of citric acid-glycerol based polymers for wood impregnation. J. Polym. Environ. 2018, 26, 970–979. [Google Scholar] [CrossRef]

- Hasan, M.; Despot, R.; Trajkovic, J.; Šefc, B. Role of modification processes at increasing biological durability of wood. In Proceedings of the International Conference European Union–Challenges and Perspectives for the Wood-Processing Industry, Zagreb, Croatia, 13 October 2006; pp. 153–158. [Google Scholar]

- Teacă, C.A.; Bodîrlău, R. Photochemical behavior of wood-based materials. In Photochemical Behavior of Multicomponent Polymeric-Based Materials; Rosu, D., Visakh, P.M., Eds.; Springer International Publishing: Cham, Switzerland, 2016; pp. 91–107. [Google Scholar] [CrossRef]

- Kranitz, K.; Sonderegger, W.; Bues, C.T.; Niemz, P. Effects of aging on wood: A literature review. Wood Sci. Technol. 2016, 50, 7–22. [Google Scholar] [CrossRef]

- Low, K.S.; Lee, C.K.; Mak, S.M. Sorption of copper and lead by citric acid modified wood. Wood Sci. Technol. 2004, 38, 629–640. [Google Scholar] [CrossRef]

- McSweeny, J.D.; Rowell, R.M.; Min, S.H. Effect of citric acid modification of aspen wood on sorption of copper ion. J. Nat. Fibers 2006, 3, 43–58. [Google Scholar] [CrossRef]

- Yang, J.S.; Park, Y.T.; Baek, K.; Choi, J. Removal of metal ions from aqueous solutions using sawdust modified with citric acid or tartaric acid. Sep. Sci. Technol. 2010, 45, 1963–1974. [Google Scholar] [CrossRef]

- Zhou, Y.; Gu, X.; Zhang, R.; Lu, J. Removal of aniline from aqueous solution using pine sawdust modified with citric acid and β-cyclodextrin. Ind. Eng. Chem. Res. 2014, 53, 887–894. [Google Scholar] [CrossRef]

- Liu, M.; Zhao, Z.; Yu, W. Citric acid modified wood membranes for efficient adsorption of tetracycline: Effect of alkali pretreatment concentration and adsorption mechanism. Chem. Eng. J. 2020, 393, 124748. [Google Scholar] [CrossRef]

- Widyorini, R.; Yudha, A.P.; Adifandi, Y.; Umemura, K.; Kawai, S. Characteristic of bamboo particleboard bonded with citric acid. Wood Res. J. 2013, 4, 31–35. [Google Scholar]

- Kusumah, S.S.; Umemura, K.; Guswenrivo, I.; Yoshimura, T.; Kanajama, K. Utilization of sweet sorghum bagasse and citric acid for manufacturing of particleboard II: Influences of pressing temperature and time on particleboard properties. J. Wood Sci. 2017, 63, 161–172. [Google Scholar] [CrossRef] [Green Version]

- Kusumah, S.S.; Umemura, K.; Oshioka, K.Y.; Miyafuji, H.; Kanajama, K. Utilisation of sweet sorghum bagasseand citric acid for manufacturing particleboard I: Effects of pre-drying treatment and citric acid content onthe board properties. Ind. Crops Prod. 2016, 84, 34–42. [Google Scholar] [CrossRef] [Green Version]

- Liao, R.; Xu, J.; Umemura, K. Low density sugarcane bagasse particleboard bonded with citric acid and sucrose: Effect of board density and additive content. BioResources 2016, 11, 2174–2185. [Google Scholar] [CrossRef]

- Widyorini, R.; Nugraha, P.; Rahman, M.; Prayitno, T. Bonding ability of a new adhesive composed of citric acid-sucrose for particleboard. BioResources 2016, 11, 4526–4535. [Google Scholar] [CrossRef]

- Umemura, K.; Ueda, T.; Kawai, S. Effects of moulding temperature on the physical properties of wood-based moulding bonded with citric acid. Forest Prod. J. 2012, 62, 63–68. [Google Scholar] [CrossRef]

- Young, N.W.G.; O’Sullivan, G.R. The influence of ingredients on product stability and shelf life. In Food and Beverage Stability and Shelf Life; Woodhead Publishing Series in Food Science, Technology and Nutrition; Woodhead Publishing: Cambridge, UK, 2011; pp. 132–183. [Google Scholar]

- Romero, A.; Esther, E.; Sastre, Á.; Nieto-Márquez, A. Conversion of biomass into sorbitol: Cellulose hydrolysis on MCM-48 and d-Glucose hydrogenation on Ru/MCM-48. Micropor. Mesopor. Mater. 2016, 224, 1–8. [Google Scholar] [CrossRef]

- Okoye, P.U.; Hameed, B.H. Review on recent progressin catalytic carboxylation and acetylation of glycerol as abyproduct of biodiesel production. Renew. Sustain. Energy Rev. 2016, 53, 558–574. [Google Scholar] [CrossRef]

- Essoua Essoua, G.G.; Beauregard, R.; Amor, B.; Blanchet, P.; Landry, V. Evaluation of environmental impacts of citric acid and glycerol outdoor softwood treatment: Case-study. J. Clean. Prod. 2017, 164, 1507–1518. [Google Scholar] [CrossRef]

- L’Hostis, C.; Fredon, E.; Thévenon, M.-F.; Santiago-Medina, F.-J.; Gérardin, P. Beech wood treated with polyglycerol succinate: A new effective method for its protection and stabilization. Holzforschung 2020, 74, 351–361. [Google Scholar] [CrossRef] [Green Version]

- Larnøy, E.; Karaca, A.; Gobakken, L.R.; Hill, C.A.S. Polyesterification of wood using sorbitol and citric acid under aqueous conditions. Int. Wood Prod. J. 2018, 9, 66–73. [Google Scholar] [CrossRef] [Green Version]

- Schorr, D.; Blanchet, P.; Essoua Essoua, G.G. Glycerol and citric acid treatment of lodgepole pine. J. Wood Chem. Technol. 2018, 38, 123–136. [Google Scholar] [CrossRef]

- El-Sheikh, A.H.; Fasfous, I.I.; Al-Salamin, R.M.; Newman, A.P. Immobilization of citric acid and magnetite on sawdust for competitive adsorption and extraction of metal ions from environmental waters. J. Environ. Chem. Eng. 2018, 6, 5186–5195. [Google Scholar] [CrossRef]

- Shah, J.; Jan, M.; Khan, M.; Amir, S. Removal and recovery of cadmium from aqueous solutions using magnetic nanoparticle-modified sawdust: Kinetics and adsorption isotherm studies. Desalin. Water Treat. 2015, 57, 9736–9744. [Google Scholar] [CrossRef]

- Kuo, C.; Wu, C.; Chen, M. Adsorption of lead ions from aqueous solutions by citric acid-modified celluloses. Desalin. Water Treat. 2015, 55, 1–7. [Google Scholar] [CrossRef]

- Sun, R.; Fanga, J.M.; Tomkinson, J.; Hill, C.A.S. Esterification of hemicelluloses from poplar chips in homogenous solution of N,N-dimethylformamide/lithium chloride. J. Wood Chem. Technol. 1999, 19, 287–306. [Google Scholar] [CrossRef]

- Sun, R.C.; Sun, X.F.; Wang, S.Q.; Zhu, W.; Wang, X.Y. Ester and ether linkages between hydroxycinnamic acids and lignins from wheat, rice, rye, and barley straws, maize stems, and fast-growing poplar wood. Ind. Crops Prod. 2002, 15, 179–188. [Google Scholar] [CrossRef]

- Talaba, P.; Srokova, I.; Hodul, P.; Ebringerova, A. New procedure for the preparation of cellulose esters with aromatic carboxylic acids. Chem. Papers 1996, 50, 365–368. [Google Scholar]

- Hon, D.N.-S.; Ou, N.-H. Thermoplasticization of wood. I. Benzylation of wood. J. Polym. Sci. Part A Polym. Chem. 1989, 27, 2457–2482. [Google Scholar] [CrossRef]

- Teacă, C.-A.; Roşu, D.; Bodîrlău, R.; Roşu, L. Structural changes in wood under artificial UV light irradiation determined by FTIR spectroscopy and color measurements—A brief review. BioResources 2013, 8, 1478–1507. [Google Scholar] [CrossRef]

- Zanoaga, M.; Tanasa, F. Photochemical behavior of synthetic polymeric multicomponent materials composites and nanocomposites. In Photochemical Behavior of Multicomponent Polymeric-Based Materials; Rosu, D., Visakh, P.M., Eds.; Advanced Structured Materials, Springer: Cham, Switzerland, 2016; Volume 26, pp. 109–164. [Google Scholar]

- Kevrešan, S.; Kovačević, B.; Ćirin-Novta, V.; Kuhajda, K.; Kandrač, J.; Pavlović, K.; Grbović, L. Biochemical changes in cuttings of Robiniapseudoacacia after treatment with naphthenate. J. Serb. Chem. Soc. 2007, 72, 953–959. [Google Scholar] [CrossRef]

- Muhammed, S.; Musgrave, O.C.; Petty, J.A. Impregnation of rubberwood and other Malaysian timbers with copper naphthenate and trimethyl borate. J. Trop. For. Sci. 2009, 21, 345–352. [Google Scholar]

- Dawson, B.S.W.; Kroese, H.W.; Hong, S.O.; Lane, G.T. Resin bleed after painting from radiata pine boards treated with tributyltin naphthenate (light organic solvent preservative) or copper, chromium and arsenic compounds (water-borne preservative). HolzRohWerkstg 2002, 60, 8–24. [Google Scholar] [CrossRef]

- Brient, J.A.; Wessner, P.J.; Doyle, M.N. Naphthenic acids. In Kirk-OthmerEncyclopaedia of Chemical Technology, 4th ed.; Kroschwitz, J.I., Ed.; John Wiley and Sons: New York, NY, USA, 1995; pp. 1017–1029. [Google Scholar]

- Schnabelrauch, M.; Vogt, S.; Klemm, D.; Nehls, I.; Philipp, B. Readily hydrolyzable cellulose esters as intermediates for the regioselective derivatization of cellulose, 1. Synthesis and characterization of soluble, low-substituted cellulose formates. Angew. Makromol. Chem. Appl. Macromol. Chem. Phys. 1992, 198, 155–164. [Google Scholar] [CrossRef]

- Liebert, T.; Klemm, D.; Heinze, T. Synthesis and carboxymethylation of organo-soluble trifluoroacetates and formates of cellulose. J. Macromol. Sci. Part A Pure Appl. Chem. 1996, 33, 613–626. [Google Scholar] [CrossRef]

- Li, D.; Henschen, J.; Ek, M. Esterification and hydrolysis of cellulose using oxalic acid dihydrate in a solvent-free reaction suitable for preparation of surface-functionalised cellulose nanocrystals with high yield. Green Chem. 2017, 19, 5564–5567. [Google Scholar] [CrossRef] [Green Version]

- Jia, C.; Chen, L.; Shao, Z.; Agarwal, U.P.; Hu, L.; Zhu, J.Y. Using a fully recyclable dicarboxylic acid for producing dispersible and thermally stable cellulose nanomaterials from different cellulosic sources. Cellulose 2017, 24, 2483–2498. [Google Scholar] [CrossRef]

- Akhtar, M.; Kenealy, W.; Horn, E.; Swaney, R.; Winandy, J. Medium-Density Fiberboard (MDF) with Improved Water Resistance. U.S. Patent No. 8,123,904 B2, 28 February 2012. [Google Scholar]

- Gardea-Hernández, G.; Ibarra-Gómez, R.; Flores-Gallardo, S.G.; Hernández-Escobar, C.A.; Pérez-Romo, P.; Zaragoza-Contreras, E.A. Fast wood fiber esterification. I. Reaction with oxalic acid and cetyl alcohol. Carbohydr. Polym. 2008, 71, 1–8. [Google Scholar] [CrossRef]

- Abdel-Raouf, M.E.S.; Abdul-Raheim, A.R.M. Rosin: Chemistry, Derivatives, and Applications: A Review. Available online: https://bioaccent.org/chemistry/chemistry39.php (accessed on 10 June 2020).

- Dong, Y.; Yan, Y.; Wang, K.; Li, J.; Zhang, S.; Xia, C.; Shi, S.Q.; Cai, L. Improvement of water resistance, dimensional stability, and mechanical properties of poplar wood by rosin impregnation. Eur. J. Wood Wood Prod. 2016, 74, 177–184. [Google Scholar] [CrossRef]

- Dong, Y.; Zhang, W.; Hughes, M.; Wu, M.; Zhang, S.; Li, J. Various polymeric monomers derived from renewable rosin for the modification of fast-growing poplar wood. Compos. Part. B Eng. 2019, 174, 106902. [Google Scholar] [CrossRef]

- Wang, F.; Tanaka, H. Aminated poly-N-vinylformamide as a modern retention aid of alkaline paper sizing with acid rosin sizes. J. Appl. Polym. Sci. 2000, 78, 1805–1810. [Google Scholar] [CrossRef]

- Matsushita, Y.; Iwatsuki, A.; Yasuda, S. Application of cationic polymer prepared from sulfuric acid lignin as a retention aid for usual rosin sizes to neutral papermaking. J. Wood Sci. 2004, 50, 540–544. [Google Scholar] [CrossRef] [Green Version]

- Miller, R.; Abaecherli, C.; Said, A.; Jackson, B. Ketenes. In Ullmann’s Encyclopedia of Industrial Chemistry, 6th ed.; Wiley-VCH: Weinheim, Germany, 2003; Volume 18, pp. 717–732. [Google Scholar]

- Rowell, R.M. Chemical modification of wood. In Handbook of Engineering Biopolymers, Homopolymers, Blends, and Composites; Hanser Gardner Publications: Cincinnati, OH, USA, 2007; pp. 673–691. [Google Scholar]

- Nilsson, T.; Rowell, R.M.; Simonson, R.; Tillman, A.-M. Fungal resistance of pine particle boards made from various types of acetylated chips. Holzforschung 1988, 42, 123–126. [Google Scholar] [CrossRef]

- Azeh, Y.; Olatunji, G.A.; Mamza, P.A. Scanning electron microscopy and kinetic studies of ketene-acetylated wood/cellulose high-density polyethylene blends. Int. J. Carbohydr. Chem. 2012, 7. [Google Scholar] [CrossRef]

- Azeh, Y.; Olatunji, G.A.; Oladoye, S.; Atolani, O. Ketene acetylated wood cellulose for industrial applications in wood-base and polymer industry. J. Environ. Sci. Technol. 2012, 5, 168–176. [Google Scholar] [CrossRef]

- Yan, Y.; Amer, H.; Rosenau, T.; Zollfrank, C.; Dörrstein, J.; Jobst, C.; Zimmermann, T.; Keckes, J.; Veigel, S.; Gindl-Altmutter, W.; et al. Dry, hydrophobic microfibrillated cellulose powder obtained in a simple procedure using alkyl ketene dimer. Cellulose 2016, 23, 1189–1197. [Google Scholar] [CrossRef] [Green Version]

- Mini-Encyclopedia of Papermaking Wet-End Chemistry. Available online: https://projects.ncsu.edu/project/hubbepaperchem/AKD.html (accessed on 10 June 2020).

- Lindström, T.; Larsson, P.T. Alkyl ketene dimer (AKD) sizing—A review. Nordic Pulp Paper Res. J. 2008, 23, 202–209. [Google Scholar] [CrossRef]

- Ermeydan, M.A.; Cabane, E.; Hass, P.; Koetz, J.; Burgert, I. Fully biodegradable modification of wood for improvement of dimensional stability and water absorption properties by poly (ε-caprolactone) grafting into the cell walls. Green Chem. 2014, 16, 3313–3321. [Google Scholar] [CrossRef] [Green Version]

- Ermeydan, M.A.; Tomak, E.D.; Kartal, Z.N. Wood property improvement of siberian pine by combination of boric acid impregnation and in-situ polymerization of ε-caprolactone. PoliteknikDergisi 2019, 22, 157–161. [Google Scholar]

- Ermeydan, M.A.; Gonultas, O.; Candan, Z. Chemical modification of paulownia, poplar, and eucalyptus wood by ε-caprolactone grafting inside cell walls to improve wood properties. İleriTeknolojiBilimleriDergisi 2017, 6, 323–330. [Google Scholar]

- Jebrane, M.; Heinmaa, I. Covalent fixation of boron in wood through transesterification with vinyl ester of carboxyphenylboronic acid. Holzforschung 2016, 70, 577–583. [Google Scholar] [CrossRef]

- Jebrane, M.; Sèbe, G. A new process for the esterification of wood by reaction with vinyl esters. Carbohydr. Polym. 2008, 72, 657–663. [Google Scholar] [CrossRef]

- Wei, L.; McDonald, A.G.; Freitag, C.; Morrell, J.J. Effects of wood fiber esterification on properties, weatherability and biodurability of wood plastic composites. Polymer Degrad. Stabil. 2013, 98, 1348–1361. [Google Scholar] [CrossRef]

- Özmen, N.; Çetin, N.S.; Tingaut, P.; Sèbe, G. A new route for the functionalisation of wood through transesterification reactions. Eur. Polym. J. 2006, 42, 1617–1624. [Google Scholar] [CrossRef]

- Pandey, K.K.; Chandrashekar, N. Photostability of wood surfaces esterified by benzoyl chloride. J. Appl. Polym. Sci. 2005, 99, 2367–2374. [Google Scholar] [CrossRef]

- Çetin, N.S.; Özmen, N.; Tingaut, P.; Sèbe, G. New transesterification reaction between acetylated wood and tetramethoxysilane: A feasibility study. Eur. Polym. J. 2005, 41, 2704–2710. [Google Scholar] [CrossRef]

- Özmen, N.; Çetin, N.S.; Tingaut, P.; Sèbe, G. Transesterification reaction between acetylated wood and trialkoxysilane coupling agents. J. Appl. Polym. Sci. 2007, 105, 570–575. [Google Scholar] [CrossRef]

- Pries, M. Treatment of Solid Wood with Silanes, Polydimethylsiloxanes and Silica Sols. Available online: https://d-nb.info/106277065X/34 (accessed on 12 June 2020).

- Donath, S.; Militz, H.; Mai, C. Wood modification with alkoxysilanes. Wood Sci. Technol. 2004, 38, 555–566. [Google Scholar] [CrossRef]

- Saha, P.; Manna, S.; Sen, R.; Roy, D.; Adhikari, B. Durability of lignocellulosic fibers treated with vegetable oil–phenolic resin. Carbohydr. Polym. 2012, 87, 1628–1636. [Google Scholar] [CrossRef]

| Type of Treatment | Reference |

|---|---|

| Isocyanate treatment (ease reaction in the presence of pyridine or acidic catalysts) | [43,44] |

| Acrylation | [45] |

| Benzoylation | [23,46,47] |

| Acid chlorides treatment (ex. octanoyl chloride and palmitoyl chloride) | [28] |

| Acid anhydride treatment: -acetic anhydride -maleic anhydride -succinic anhydride | [2,4] [48,49] [21,25,50,51,52] |

| Silane treatment | [16,53] |

| Furfurylation treatment | [54,55,56,57,58,59] |

| Ketene treatment (usually applied for wood acetylation in order to avoid formation of acetic acid as by-product) | [60,61,62,63] |

| Other anhydrides: ex. crotonic, propionic or methacrylic anhydride | [64,65] |

| Polycarboxylic acids treatment:1,2,3,4-butanetetracarboxylic acid, citric acid (through impregnation) | [29,66,67,68,69,70,71,72,73] |

| Tricine treatment (tricine is a zwitterionic aminoacid) | [74,75] |

| 1,3-Dimethylol-4,5-dihydroxyethyleneurea (DMDHEU) treatment | [76,77,78,79,80] |

| Fatty acids treatment | [81] |

| Fatty acid chlorides treatment (induce thermo-plasticity into wood) | [82,83] |

| Oxalic acid and cetyl alcohol treatment | [84] |

| Isopropenyl acetate (in the presence of anhydrous aluminum chloride as a catalyst) | [13] |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Teacă, C.-A.; Tanasă, F. Wood Surface Modification—Classic and Modern Approaches in Wood Chemical Treatment by Esterification Reactions. Coatings 2020, 10, 629. https://doi.org/10.3390/coatings10070629

Teacă C-A, Tanasă F. Wood Surface Modification—Classic and Modern Approaches in Wood Chemical Treatment by Esterification Reactions. Coatings. 2020; 10(7):629. https://doi.org/10.3390/coatings10070629

Chicago/Turabian StyleTeacă, Carmen-Alice, and Fulga Tanasă. 2020. "Wood Surface Modification—Classic and Modern Approaches in Wood Chemical Treatment by Esterification Reactions" Coatings 10, no. 7: 629. https://doi.org/10.3390/coatings10070629

APA StyleTeacă, C.-A., & Tanasă, F. (2020). Wood Surface Modification—Classic and Modern Approaches in Wood Chemical Treatment by Esterification Reactions. Coatings, 10(7), 629. https://doi.org/10.3390/coatings10070629