Effect of WC Grain Size and Abrasive Type on the Wear Performance of HVOF-Sprayed WC-20Cr3C2-7Ni Coatings

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Coating Preparation

2.3. Characterization

2.4. Abrasion Wear Tests

2.4.1. Two-body Abrasion Wear Test

2.4.2. Three-body Abrasion Wear Test

3. Experimental Results

3.1. The Phase Composition of the Three WC-20Cr3C2-7Ni Coatings

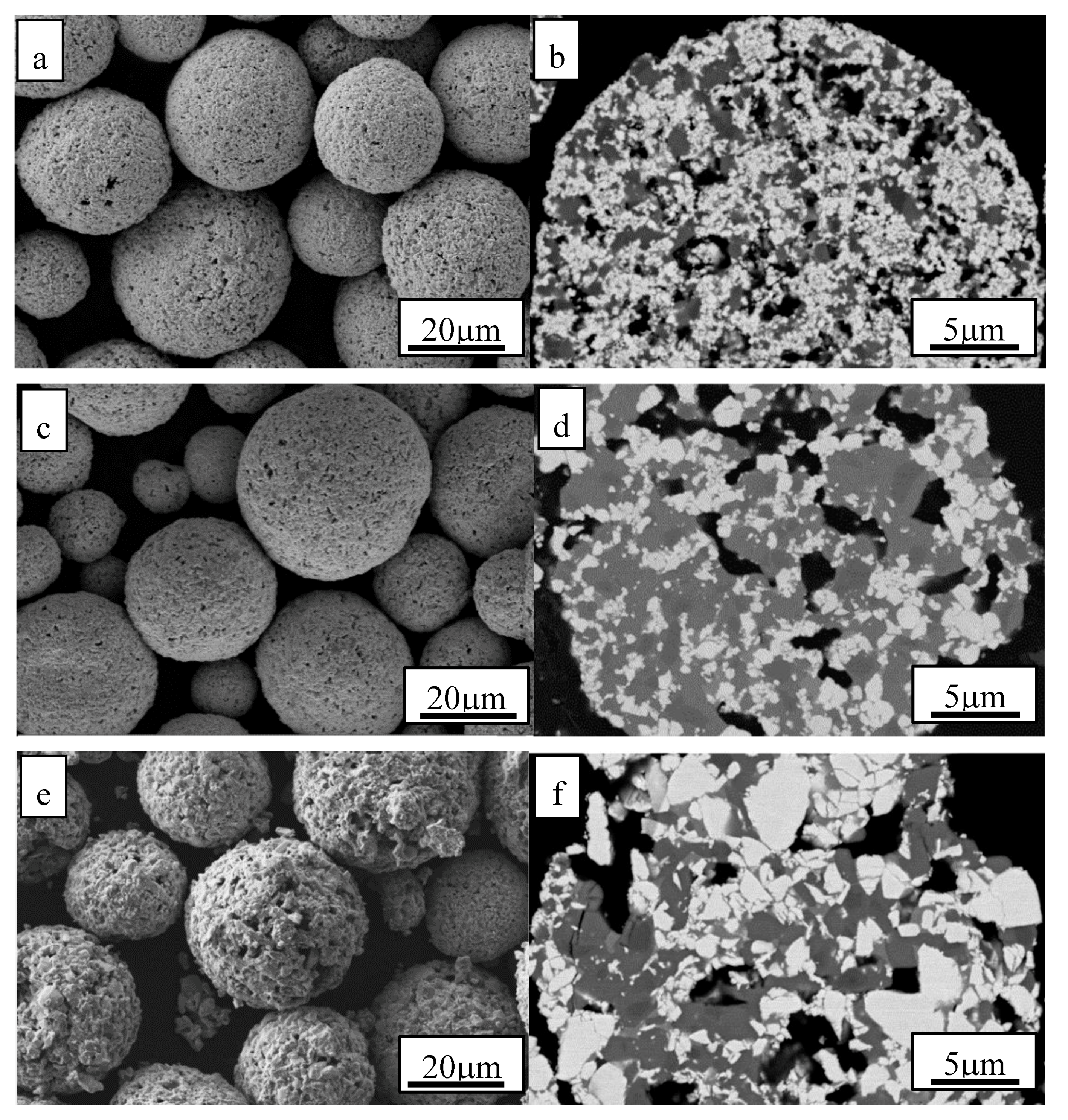

3.2. The Cross-Sectional Surface of the Three WC-20Cr3C2-7Ni Coatings

3.3. The Properties of the WC-20Cr3C2-7Ni Coatings

3.4. Abrasive Wear Results

4. Discussions

- The hardness of the abrasive is lower than that of the hard phase of the composite.The soft binder phase of the composite is preferentially removed, and then the protrusion of the hard phase will be gradually pulled off from the composite without enough support and fixation offered by the binder at a relatively low speed (Figure 9a). At the same instance, a small amount of hard phase and a large area of matrix will be damaged under the repeated reciprocal impact of abrasive particles during the three-body abrasive wear test;

- The hardness of the abrasive particle is similar to that of the hard phase of the composite.The matrix of the composites is preferentially cut, and the hard phases are broken and removed from the binder phase by the repeated impact of the abrasives at a relatively medium speed (Figure 9b);

- The hardness of abrasive particles is higher than that of the hard phase of the composite.

5. Conclusions

- The decarburization of WC in the HVOF-sprayed WC-20Cr3C2-7Ni coating increased with the decrease in WC grain size, even though the decarburization level of all three WC-20Cr3C2-7Ni coatings was not serious;

- The coating hardness increased, but the fracture toughness and porosity decreased with the decrease in WC grain size;

- The three-body-specific wear rates of the WC-20Cr3C2-7Ni coatings increased with the size of the WC grains when the lower hardness SiO2 abrasive was used, but an opposite wear rate trend was observed when the high-hardness SiC was used in both the two- and the three-body abrasive wear test. In addition, the coatings’ three-body-specific wear rates caused by the SiO2 abrasive were less than those caused by the SiC abrasive with a similar size and slurry concentration;

- The specific wear rates of the WC-20Cr3C2-7Ni coatings in the three-body abrasive wear test were less than those in the two-body abrasive wear test when a similar size of the SiC abrasive was used.

Author Contributions

Funding

Conflicts of Interest

References

- Vashishtha, N.; Khatirkar, R.K.; Sapate, S.G. Tribological behaviour of HVOF sprayed WC-12Co, WC-10Co-4Cr and Cr3C2-25NiCr coatings. Tribol. Int. 2017, 105, 55–68. [Google Scholar] [CrossRef]

- Santacruz, G.; Takimi, A.S.; De Camargo, F.V.; Bergmann, C.P.; Fragassa, C. Comparative study of jet slurry erosion of martensitic stainless steel with tungsten carbide HVOF coating. Metals 2019, 9, 600. [Google Scholar] [CrossRef] [Green Version]

- Liu, J.; Bai, X.; Chen, T.; Yuan, C. Effects of cobalt content on the microstructure, mechanical properties and cavitation erosion resistance of HVOF sprayed coatings. Coatings 2019, 9, 534. [Google Scholar] [CrossRef] [Green Version]

- Chen, Y.; Wu, Y.; Hong, S.; Long, W.; Ji, X. The effect of impingement angle on erosion wear characteristics of HVOF sprayed WC-Ni and WC-Cr3C2-Ni cermet composite coatings. Mater. Res. Express 2020, 7, 026503. [Google Scholar]

- Cho, J.; Hwang, S.; Kim, K. Corrosion behavior of thermal sprayed WC cermet coatings having various metallic binders in strong acidic environment. Surf. Coat. Technol. 2006, 200, 2653–2662. [Google Scholar] [CrossRef]

- Xu, L.; Song, J.; Zhang, X.; Deng, C.; Liu, M.; Zhou, K. Microstructure and corrosion resistance of WC-Based cermet/Fe-based amorphous alloy composite coatings. Coatings 2018, 8, 393. [Google Scholar] [CrossRef] [Green Version]

- Jonda, E.; Latka, L.; Pakiela, W. Microstructure and selected properties of Cr3C2-NiCr coatings obtained by HVOF on magnesium alloy substrates. Materials 2020, 13, 2775. [Google Scholar] [CrossRef] [PubMed]

- Hou, G.L.; An, Y.L.; Zhao, X.Q.; Chen, J.; Chen, J.M.; Zhou, H.D.; Liu, G. Effect of heat treatment on wear behaviour of WC-(W,Cr)2C-Ni coating. Surf. Eng. 2012, 28, 786–790. [Google Scholar] [CrossRef]

- Janka, L.; Berger, L.-M.; Norpoth, J.; Trache, R.; Thiele, S.; Tomastik, C.; Matikainen, V.; Vuoristo, P. Improving the high temperature abrasion resistance of thermally sprayed Cr3C2-NiCr coatings by WC addition. Surf. Coat. Technol. 2018, 337, 296–305. [Google Scholar] [CrossRef]

- Mayrhofer, E.; Janka, L.; Mayr, W.P.; Norpoth, J.; Ripoll, M.R.; Groeschl, M. Cracking resistance of Cr3C2-NiCr and WC-Cr3C2-Ni thermally sprayed coatings under tensile bending stress. Surf. Coat. Technol. 2015, 281, 169–175. [Google Scholar] [CrossRef]

- Bolelli, G.; Berger, L.-M.; Bonetti, L.M.; Lusvarghi, L. Comparative study of the dry sliding wear behaviour of HVOF-sprayed WC-(W,Cr)2C-Ni and WC-CoCr hardmetal coatings. Wear 2014, 309, 96–111. [Google Scholar] [CrossRef]

- Ishikawa, Y.; Kuroda, S.; Kawakita, J.; Sakamoto, Y.; Takaya, M. Sliding wear properties of HVOF sprayed WC-20%Cr3C2-7%Ni cermet coatings. Surf. Coat. Technol. 2007, 201, 4718–4727. [Google Scholar] [CrossRef]

- Sidhu, V.P.S.; Goyal, K.; Goyal, R. Hot corrosion behaviour of HVOF-sprayed 93(WC-Cr3C2)-7Ni and 83WC-17Co coatings on boiler tube steel in coal fired boiler. Aust. J. Mech. Eng. 2019, 17, 127–132. [Google Scholar] [CrossRef]

- Zimmermann, S.; Keller, H.; Schwier, G. New carbide based materials for HVOF spraying. Therm. Spray 2003: Adv. Sci. Appl. Technol. 2003, 1, 5–8. [Google Scholar]

- Berget, J.; Rogne, T.; Bardal, E. Erosion-corrosion properties of different WC-Co-Cr coatings deposited by the HVOF process—Influence of metallic matrix composition and spray powder size distribution. Surf. Coat. Technol. 2007, 201, 7619–7625. [Google Scholar] [CrossRef]

- Lee, C.W.; Han, J.H.; Yoon, J.; Shin, M.C.; Kwun, S.I. A study on powder mixing for high fracture toughness and wear resistance of WC-Co-Cr coatings sprayed by HVOF. Surf. Coat. Technol. 2010, 204, 2223–2229. [Google Scholar] [CrossRef]

- Wang, H.; Song, X.; Liu, X.; Wei, C.; Gao, Y.; Fu, J. Effect of heat-treatment of spray-dried powder on properties of ultrafine-structured WC-Co coating. Surf. Coat. Technol. 2012, 207, 117–122. [Google Scholar] [CrossRef]

- Qiao, Y.F.; Fischer, T.E.; Dent, A. The effects of fuel chemistry and feedstock powder structure on the mechanical and tribological properties of HVOF thermal-sprayed WC-Co coatings with very fine structures. Surf. Coat. Technol. 2003, 172, 24–41. [Google Scholar] [CrossRef]

- Ding, X.; Ke, D.; Yuan, C.; Ding, Z.; Cheng, X. Microstructure and cavitation erosion resistance of HVOF deposited WC-Co coatings with different sized WC. Coatings 2018, 8, 307. [Google Scholar] [CrossRef] [Green Version]

- Al-Mutairi, S.; Hashmi, M.; Yilbas, B.; Stokes, J. Microstructural characterization of HVOF/plasma thermal spray of micro/nano WC–12%Co powders. Surf. Coat. Technol. 2015, 264, 175–186. [Google Scholar] [CrossRef]

- Ghabchi, A.; Varis, T.; Turunen, E.; Suhonen, T.; Liu, X.; Hannula, S.P. Behavior of HVOF WC-10Co4Cr coatings with different carbide size in fine and coarse particle abrasion. J. Therm. Spray Technol. 2010, 19, 368–377. [Google Scholar] [CrossRef]

- Usmani, S.; Sampath, S.; Houck, D.L.; Lee, D. Effect of carbide grain size on the sliding and abrasive wear behavior of thermally sprayed WC-Co coatings. Tribol. Trans. 1997, 40, 470–478. [Google Scholar] [CrossRef]

- Kumari, K.; Anand, K.; Bellacci, M.; Giannozzi, M. Effect of microstructure on abrasive wear behavior of thermally sprayed WC-10Co-4Cr coatings. Wear 2010, 268, 1309–1319. [Google Scholar] [CrossRef]

- Wang, Q.; Xiang, J.; Chen, G.; Cheng, Y.; Zhao, X.; Zhang, S. Propylene flow, microstructure and performance of WC-12Co coatings using a gas-fuel HVOF spray process. J. Mater. Process. Technol. 2013, 213, 1653–1660. [Google Scholar] [CrossRef]

- Wang, Q.; Chen, Z.; Li, L.; Yang, G. The parameters optimization and abrasion wear mechanism of liquid fuel HVOF sprayed bimodal WC-12Co coating. Surf. Coat. Technol. 2012, 206, 2233–2241. [Google Scholar] [CrossRef]

- Wang, Q.; Zhang, S.; Cheng, Y.; Xiang, J.; Zhao, X.; Yang, G. Wear and corrosion performance of WC-10Co4Cr coatings deposited by different HVOF and HVAF spraying processes. Surf. Coat. Technol. 2013, 218, 127–136. [Google Scholar] [CrossRef]

- Evans, A.; Wilshaw, T.R. Quasi-static solid particle damage in brittle solids—I. Observations analysis and implications. Acta Metall. 1976, 24, 939–956. [Google Scholar] [CrossRef]

- Guilemany, J.; De Paco, J.; Miguel, J.; Nutting, J. Characterization of the W2C phase formed during the high velocity oxygen fuel spraying of a WC+ 12 pct Co powder. Metall. Mater. Trans. A 1999, 30, 1913–1921. [Google Scholar] [CrossRef]

- Berger, L.-M.; Saaro, S.T.; Kasparova, M.; Zahalka, F. Microstructure and properties of HVOF-sprayed WC-(W,Cr)2C-Ni coatings. J. Therm. Spray Technol. 2008, 17, 395–403. [Google Scholar] [CrossRef]

- Totten, G.E. Friction, lubrication, and wear technology. In ASM Handbook; Batchelor, A.W., Liang, H., et al., Eds.; ASM International: Materials Park, OH, USA, 2017; Volume 18, pp. 223–224. [Google Scholar]

- Asl, M.S.; Kakroudi, M.G.; Noori, S. Hardness and toughness of hot pressed ZrB2-SiC composites consolidated under relatively low pressure. J. Alloy. Compd. 2015, 619, 481–487. [Google Scholar] [CrossRef]

- Kenneth, C.L.; Oyelayo, O.A. Friction, Wear, Lubrication: A Textbook in Tribology, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2018. [Google Scholar]

- Houdkova, S.; Zahalka, F.; Kasparova, M.; Berger, L.M. Comparative study of thermally sprayed coatings under different types of wear conditions for hard chromium replacement. Tribol. Lett. 2011, 43, 139–154. [Google Scholar] [CrossRef]

| Designation Code | WC Size (μm) | Cr3C2 Size(μm) | Ni Size (μm) | Size Distribution (μm) | Apparent Density (g/cm3) |

|---|---|---|---|---|---|

| FP | 0.8 | 5 | 9 | 15–45 | 4.41 |

| MP | 2.5 | 5 | 9 | 15–45 | 4.42 |

| CP | 8 | 5 | 9 | 15–45 | 4.24 |

| Kerosene (L/h) | Oxygen (m3/h) | Carrier Gas (m3/h) | Step (mm) | Velocity (mm/s) | Spraying Distance (mm) | Feed Rate (g/min) |

|---|---|---|---|---|---|---|

| 24.6 | 56.6 | 0.65 | 5 | 500 | 380 | 70 |

| Coating | Hardness (HV0.3) | Porosity (%) | Fracture Toughness (MPam1/2) |

|---|---|---|---|

| FC | 1167.9 ± 78.4 | 0.63 ± 0.08 | 2.19 ± 0.59 |

| MC | 1093.4 ± 46.5 | 1.01 ± 0.37 | 2.41 ± 0.51 |

| CC | 1045.8 ± 123.1 | 1.35 ± 0.19 | 4.11 ± 0.66 |

| Coating No. | λ1 (SiO2) | λ2 (SiC) |

|---|---|---|

| FC | 0.73-0.94 | 2.40 |

| MC | 0.82-1.01 | 2.56 |

| CC | 0.81-1.05 | 2.68 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Q.; Zhang, Y.; Ding, X.; Wang, S.; Ramachandran, C.S. Effect of WC Grain Size and Abrasive Type on the Wear Performance of HVOF-Sprayed WC-20Cr3C2-7Ni Coatings. Coatings 2020, 10, 660. https://doi.org/10.3390/coatings10070660

Wang Q, Zhang Y, Ding X, Wang S, Ramachandran CS. Effect of WC Grain Size and Abrasive Type on the Wear Performance of HVOF-Sprayed WC-20Cr3C2-7Ni Coatings. Coatings. 2020; 10(7):660. https://doi.org/10.3390/coatings10070660

Chicago/Turabian StyleWang, Qun, Yingpeng Zhang, Xiang Ding, Shaoyi Wang, and Chidambaram Seshadri Ramachandran. 2020. "Effect of WC Grain Size and Abrasive Type on the Wear Performance of HVOF-Sprayed WC-20Cr3C2-7Ni Coatings" Coatings 10, no. 7: 660. https://doi.org/10.3390/coatings10070660

APA StyleWang, Q., Zhang, Y., Ding, X., Wang, S., & Ramachandran, C. S. (2020). Effect of WC Grain Size and Abrasive Type on the Wear Performance of HVOF-Sprayed WC-20Cr3C2-7Ni Coatings. Coatings, 10(7), 660. https://doi.org/10.3390/coatings10070660