Toughening Mechanism of Mullite Matrix Composites: A Review

Abstract

:1. Introduction

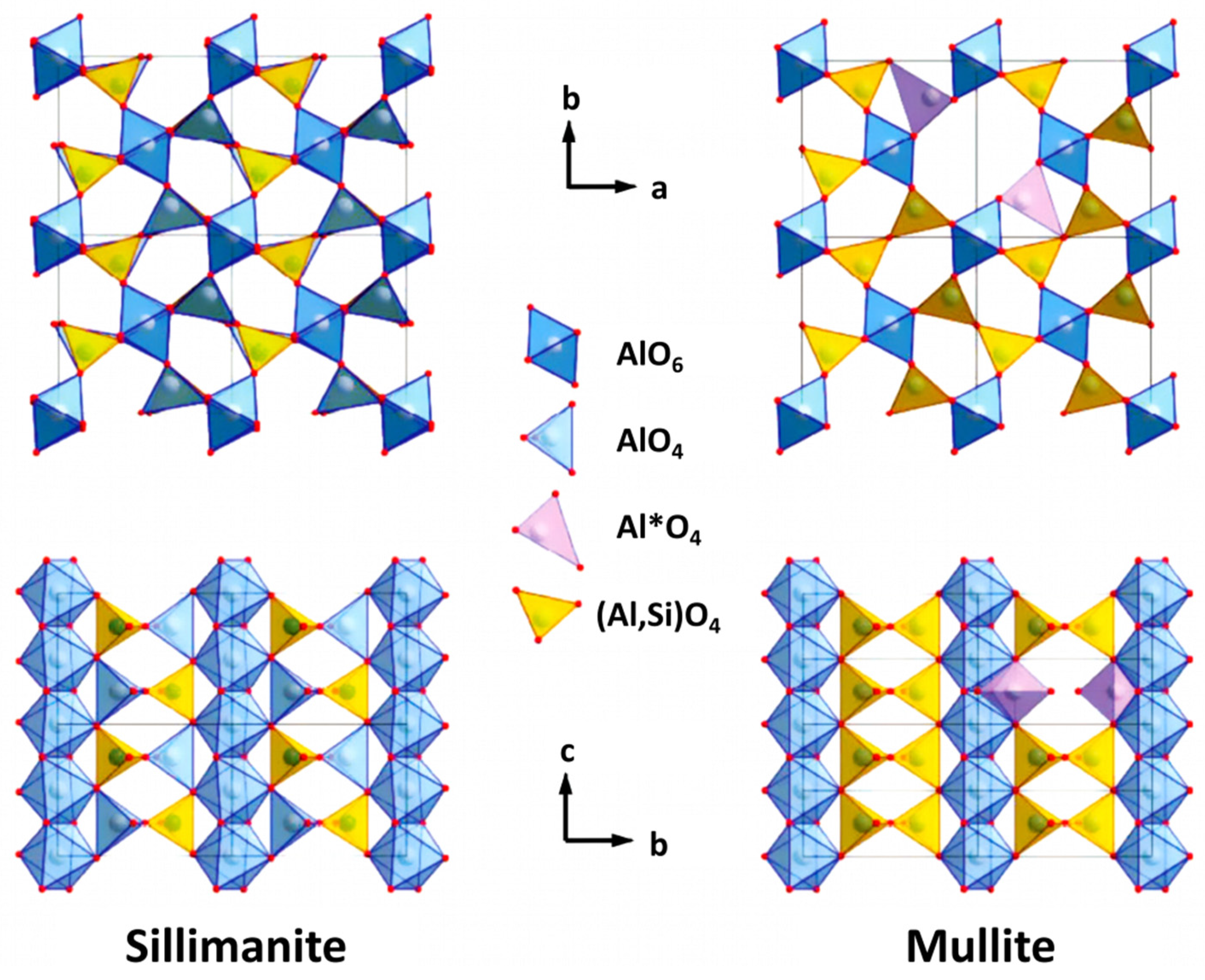

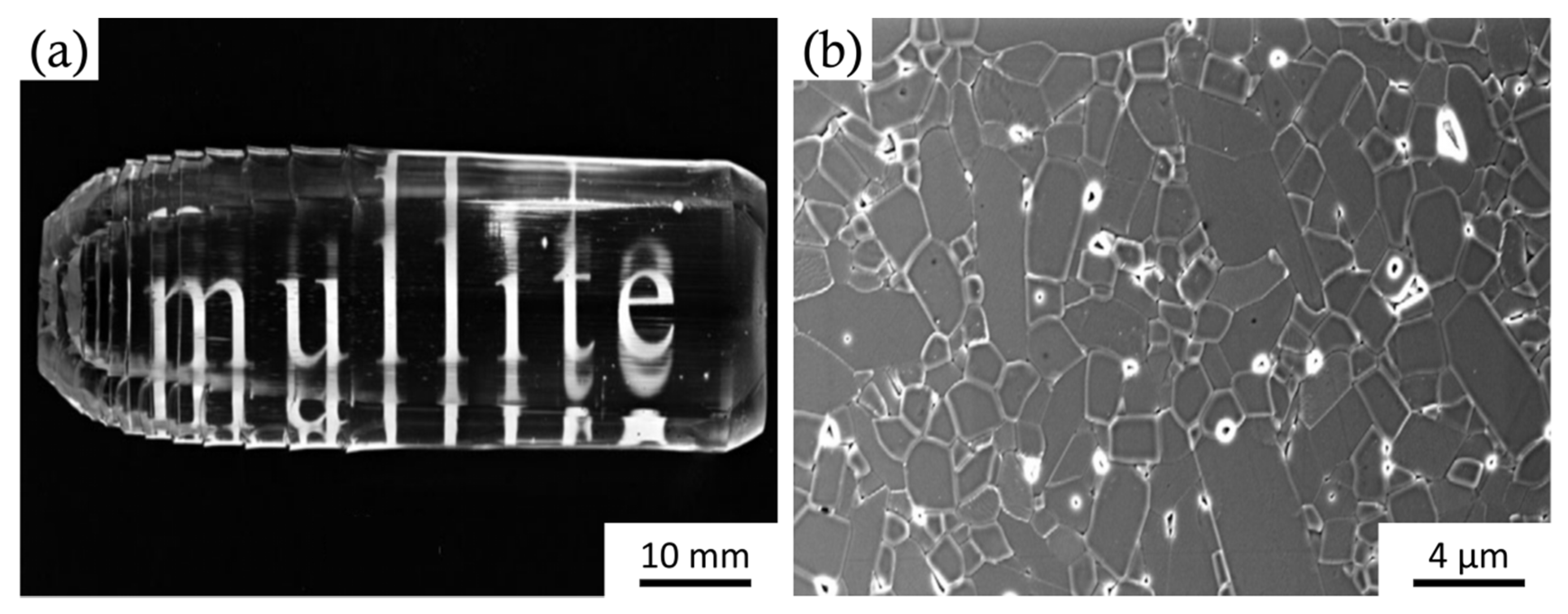

2. Physical and Chemical Properties of Mullite

- Sinter-mullites depend mainly on the solid reaction between the raw materials at 1600–1700 °C, and the enhancement in sintering is imputed to a liquid phase formation. These mullites tend to be “stoichiometric”, i.e., 3/2-composition (3Al2O3·2SiO2, i.e., ≈72 wt.% Al2O3, x = 0.25).

- Fused-mullites are formed by crystallizing aluminum silicate melt. These mullites tend to be rich in Al2O3, and their composition is close to 2/1 (2Al2O3·SiO2, i.e., ≈78 wt.% Al2O3, x = 0.40).

- Chemical-mullites are produced by heat treatment of organic or inorganic precursors. The composition is strongly dependent on raw materials and treatment temperature. Al2O3-rich compounds have been identified at synthesis temperatures below 1000 °C (>90 wt.% Al2O3, x > 0.80).

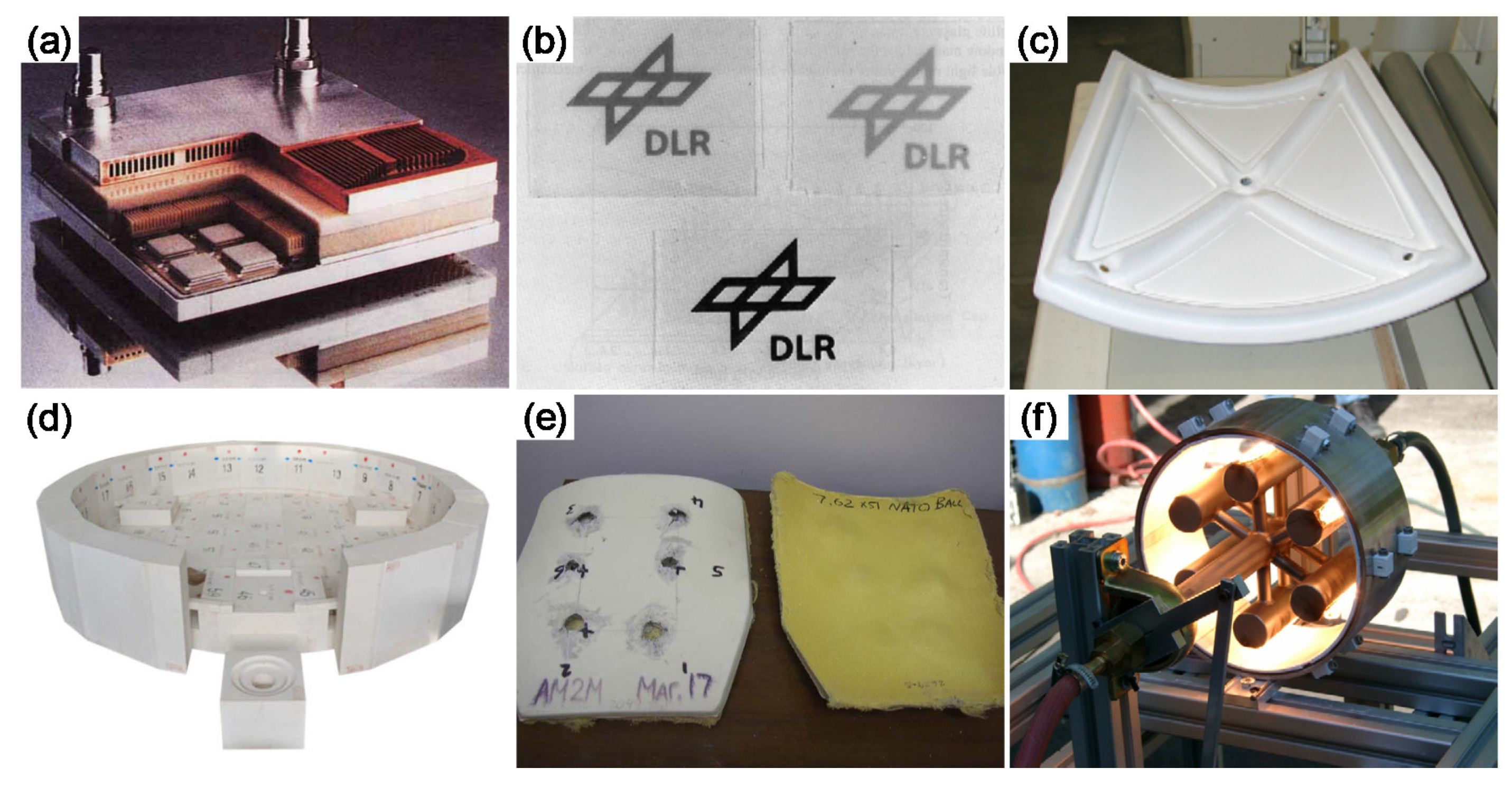

3. Application of Mullite and Mullite Matrixcomposites

4. Modification and Reinforcement Methods of Mullite Ceramics

4.1. Preparation Method of Discontinuous Phase Reinforced Mullite

4.2. Preparation Method of Continuous Fiber Reinforce Mullite

- Slurry Impregnation Process

- Sol-Gel Process

- Precursor Infiltration and Pyrolysis (PIP) Process

- Chemical Vapor Infiltration (Cvi) Process

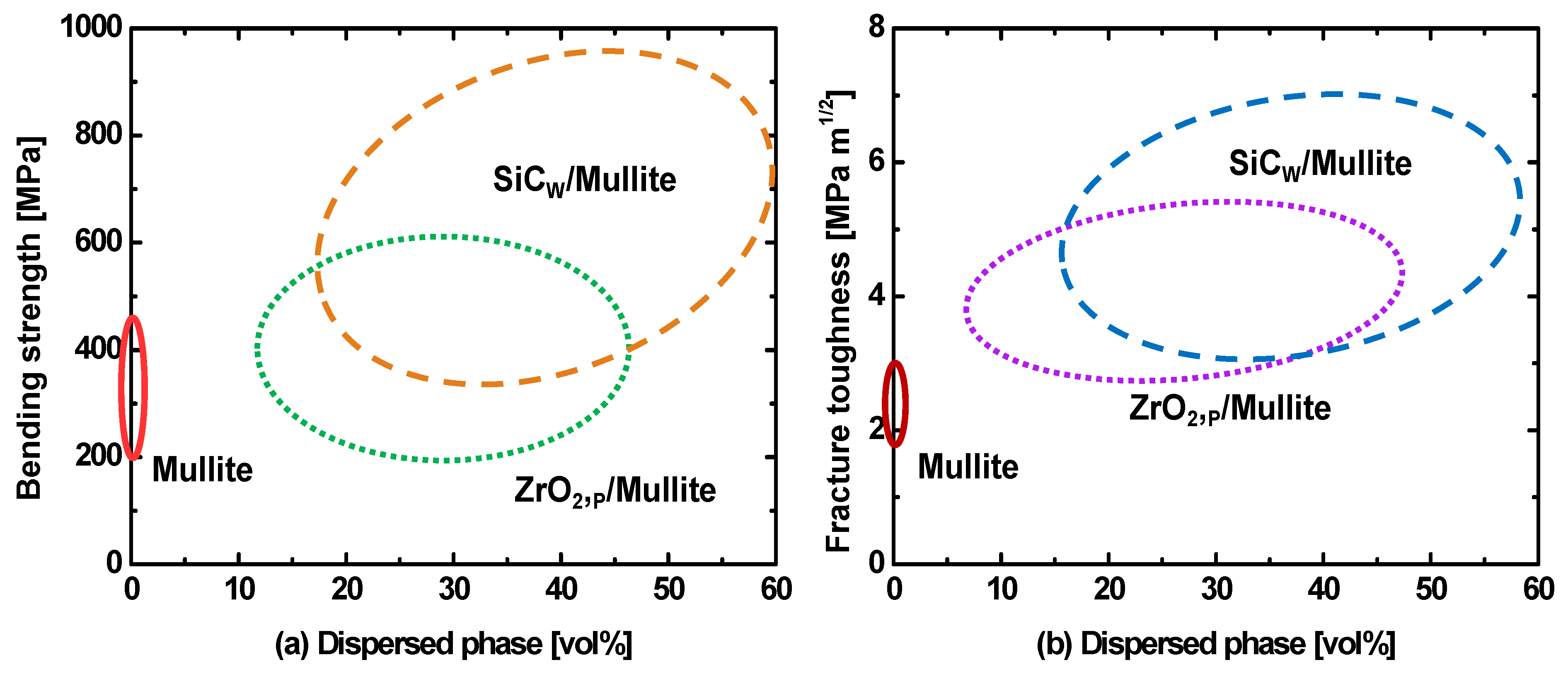

5. Toughening Mechanism of Mullite by Discontinuous Phase

5.1. Toughening Mechanism of Second Phase Particles

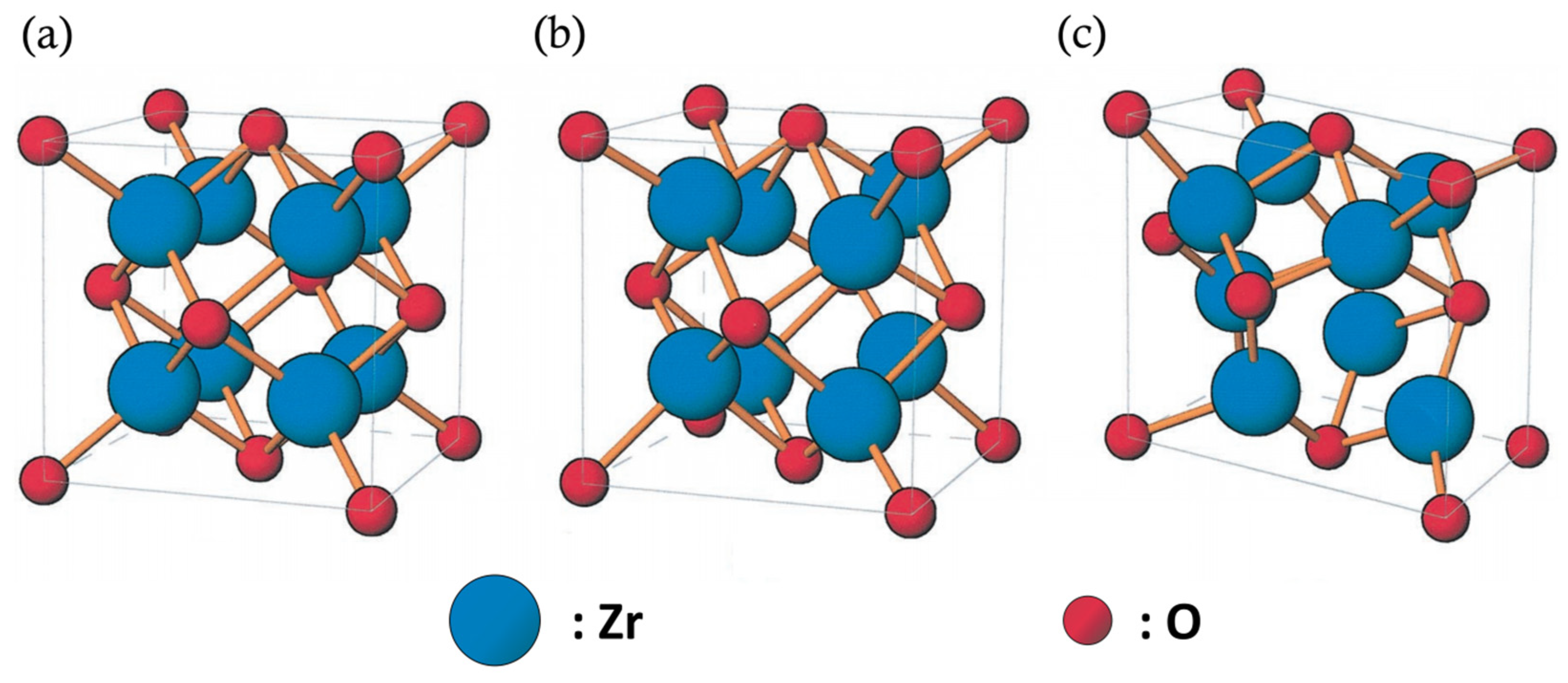

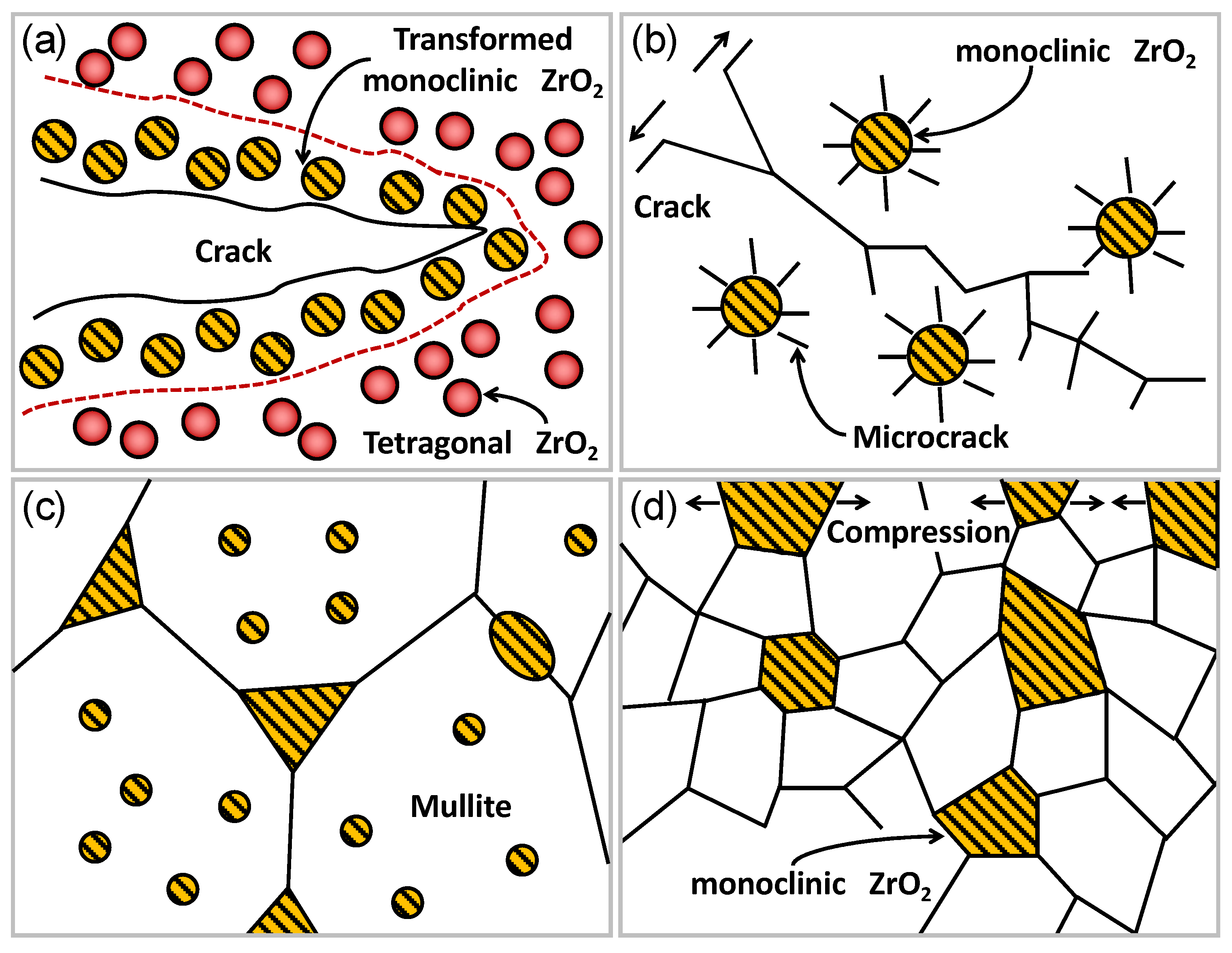

5.1.1. Phase Transformation Toughening Mechanism of ZrO2 Particles

5.1.2. Non-phase Transformation Toughening Mechanism of ZrO2 Particles

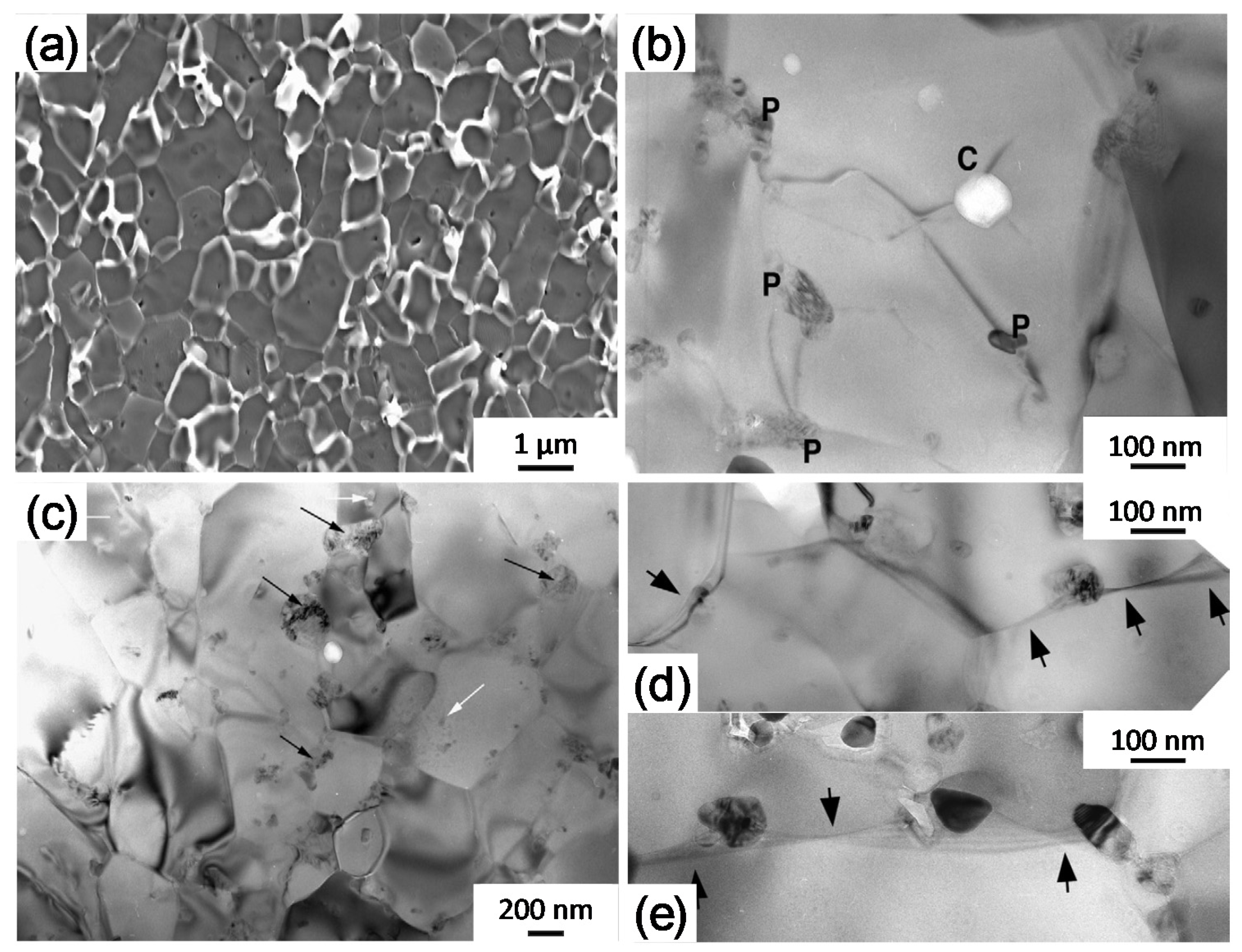

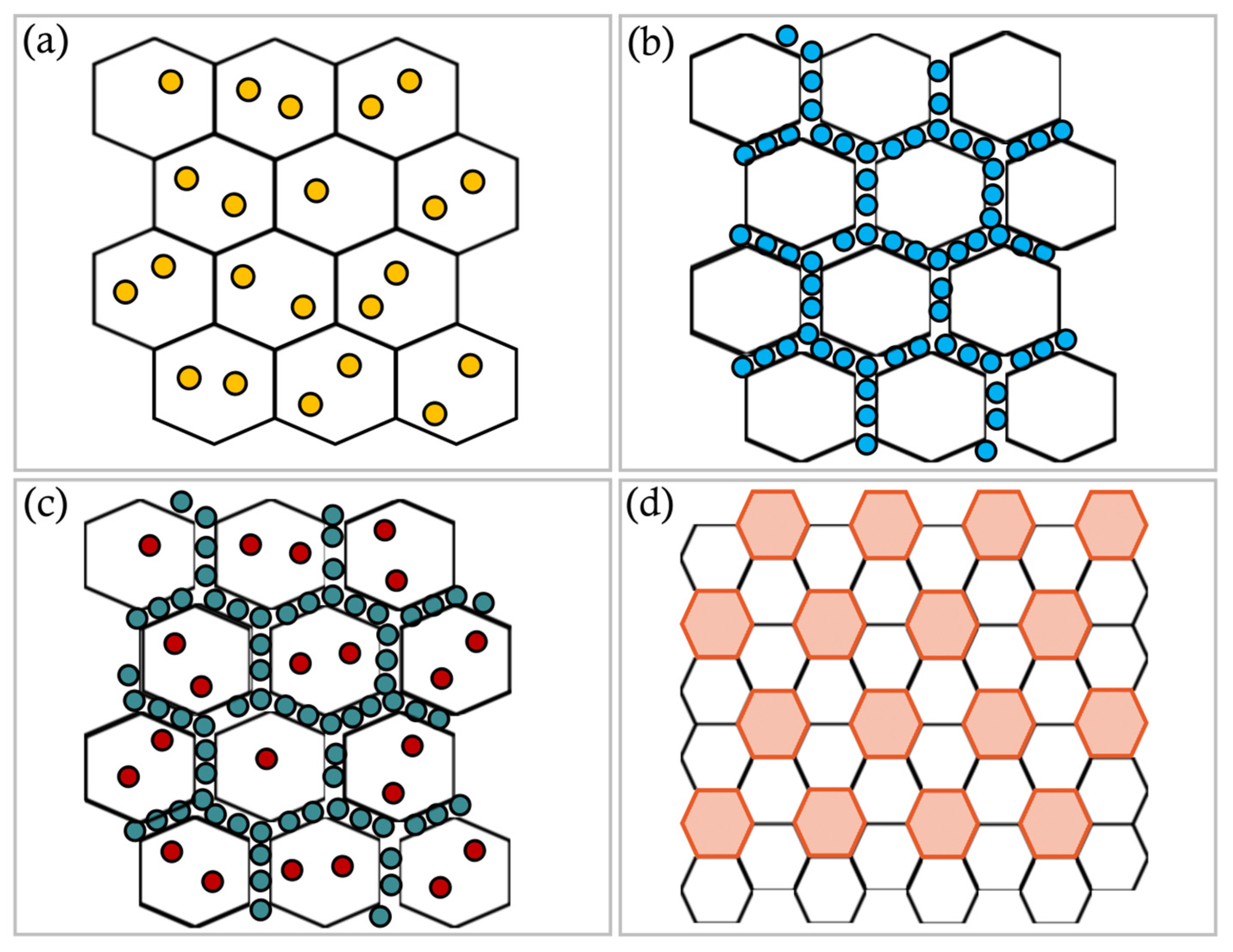

5.1.3. Toughening Mechanism of Nanoparticles

- Fine Grain Strengthening Theory

- Transgranular Theory

- Pinning Theory

5.2. Toughening Mechanism of Whisker

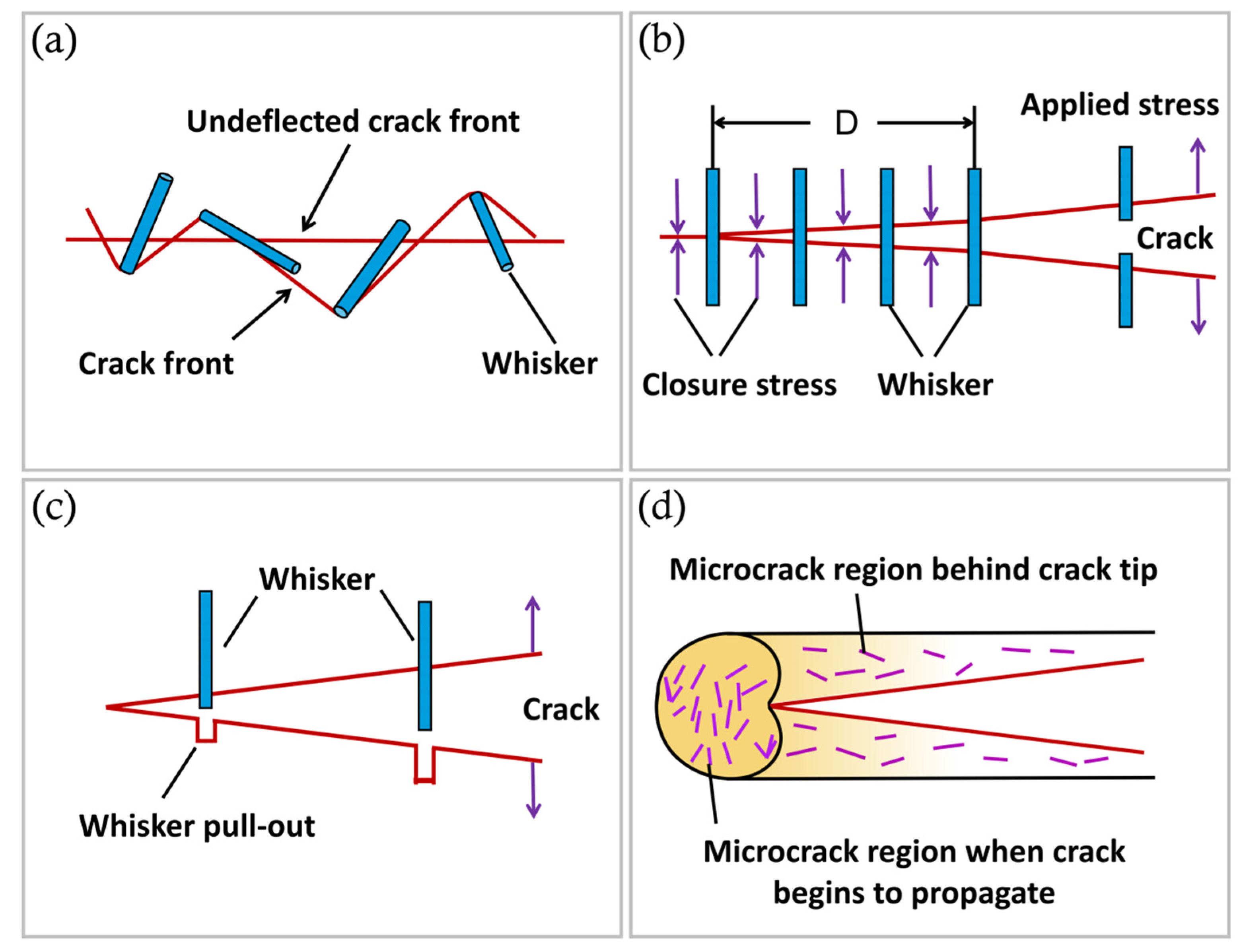

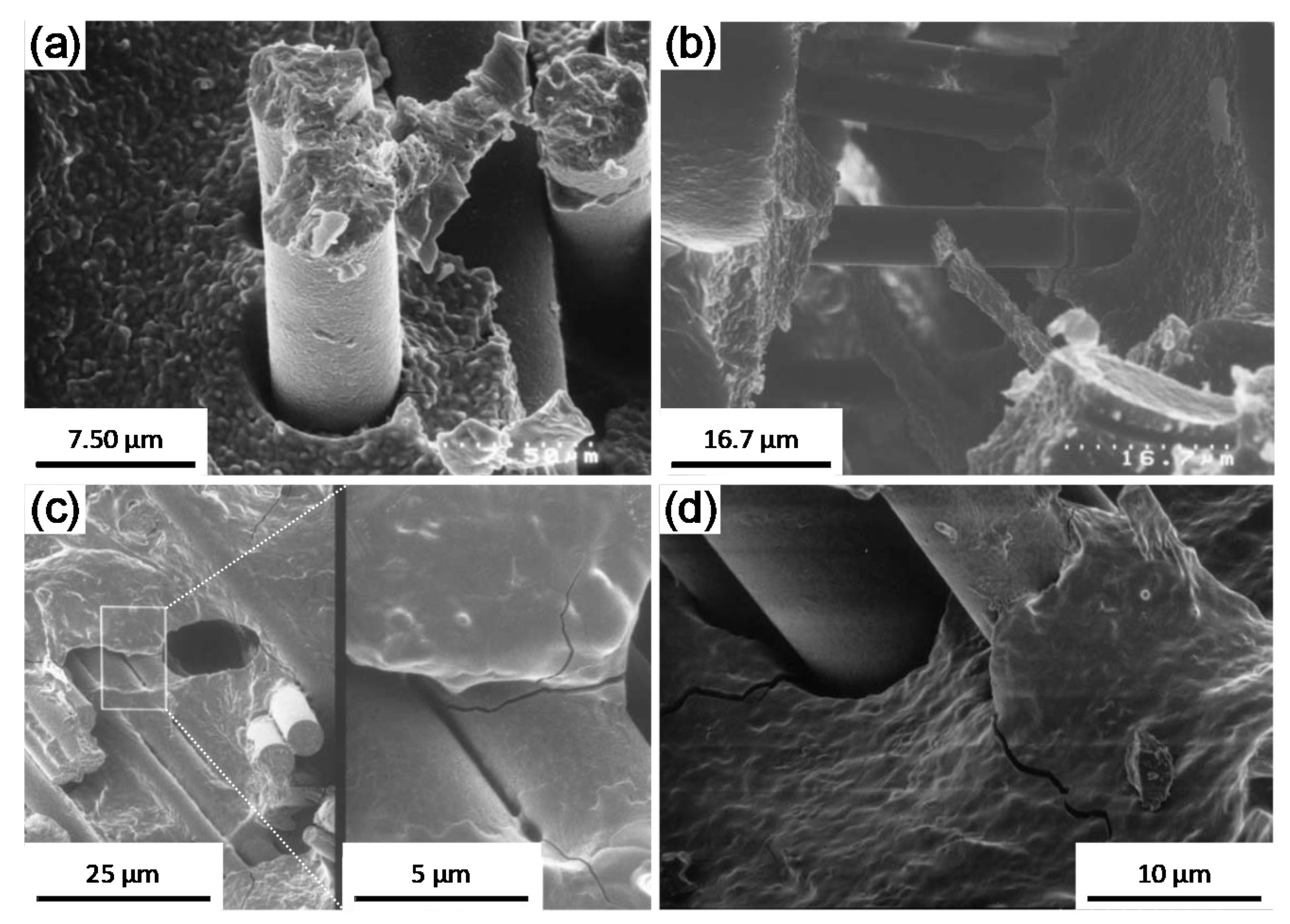

- Crack deflection: When the crack extends to the whisker, the crack in the substrate is generally difficult to pass through the whisker, and will generally expand by bypassing the whisker, that is the crack deflects. This is mainly due to the high whisker modulus, the existence of the stress field around the whisker. Therefore, more energy needs to be consumed in the process of crack propagation, which makes it difficult for the crack to continue to propagate [114]. As shown in Figure 10a.

- Crack bridging: When the whiskers in the matrix are distributed in a specific direction, the cracks in the matrix are difficult to deflect and can only continue to propagate according to the original propagation direction. At this time, the whisker close to the crack tip is not broken, which will generate a compressive stress on the crack surface and resist the further propagation of the crack. In other words, whiskers set up small bridges on both sides of the crack to connect the two sides, as shown in Figure 10b.

- A whisker pull-out region is also present behind that interfacial crack region [115], as shown in Figure 10c, whisker pullout will relax the stress at the crack tip to slow down the crack propagation. The research and analysis show that whisker pullout is often accompanied by crack bridging. When the crack size is small, whisker bridging plays a major role, while with the increase of crack displacement, whiskers at the crack tip are further destroyed, and whisker pullout plays a major toughening mechanism [116].

6. Toughening Mechanism of Continuous Fibers

6.1. Oxide Fibers

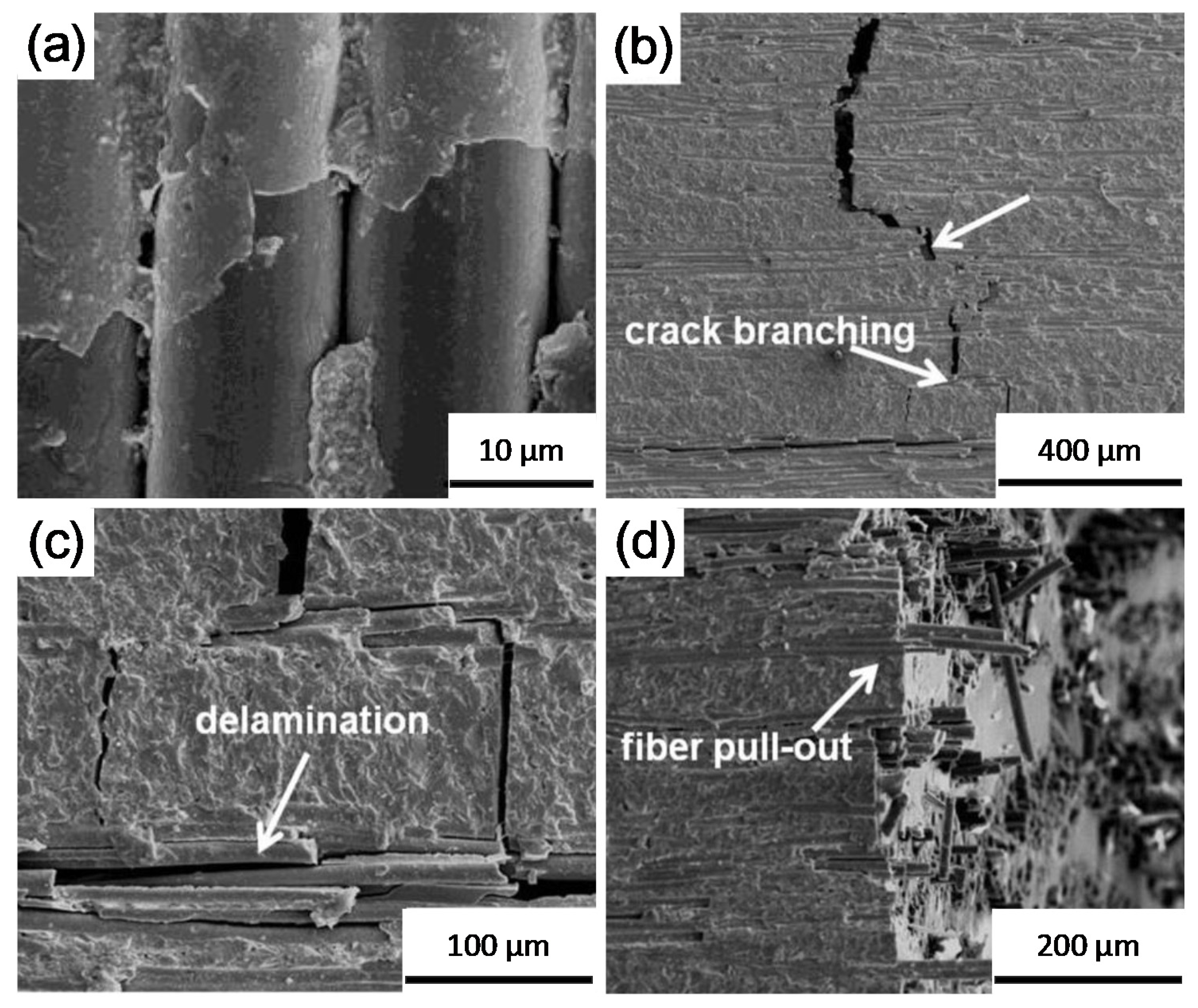

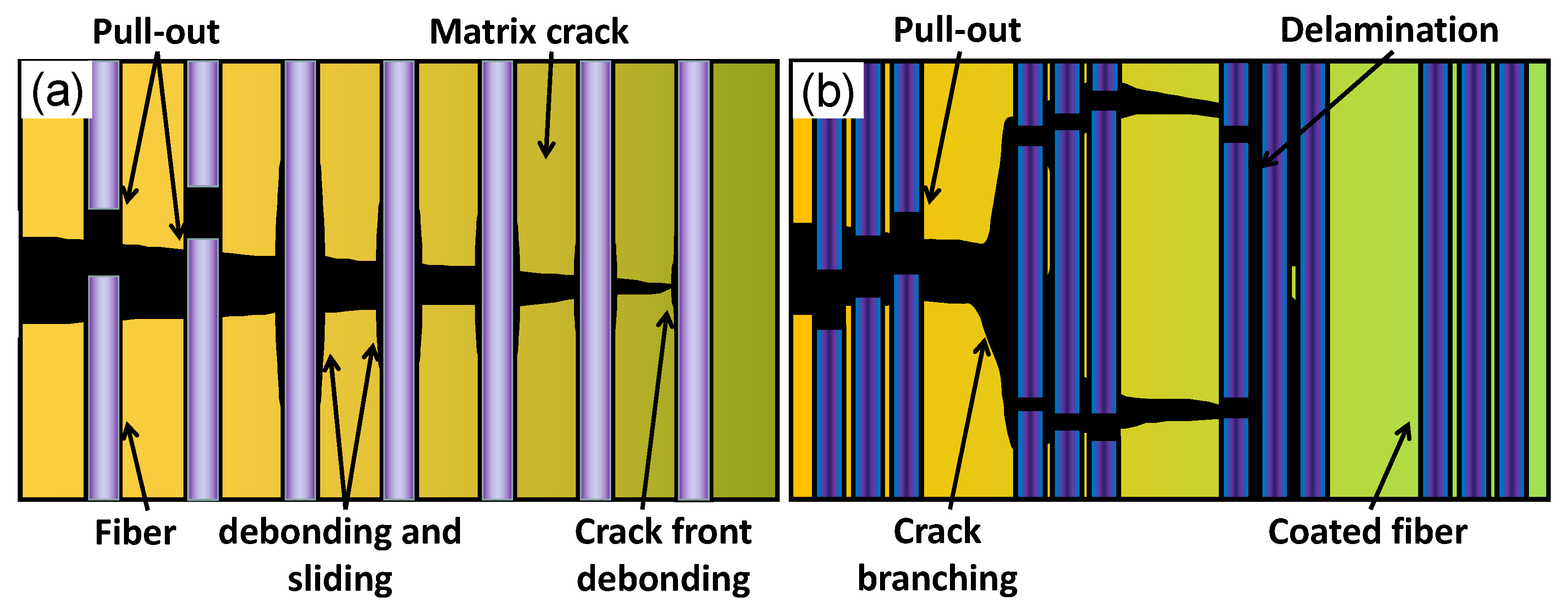

- The toughening mechanism of fiber reinforced mullite matrix composite includes crack deflection and crack branching, which will release the regionally stress at the tip of crack.

- The introduction of an interface between the fiber and the matrix can significantly improve the performance of the composite material, weak interface adhesion between the fiber and matrix or fibers resulted in delamination along the smooth interface.

- Fiber pullout will effectively consume energy and thus play a role in toughening mullite.

6.2. Non-Oxide Fibers

7. Conclusions and Prospects

- The strength of mullite composites reinforced by discontinuous ZrO2 or SiC particles or whiskers has been significantly improved, but the toughness has not been significantly improved. Therefore, the preparation processes of various reinforcement methods need to be studied and improved, such as improving the dispersibility of reinforcements and their bonding ability with matrix, controlling the coarsening of nano-phases, etc. In addition, the forming of complex components, the efficiency and cost of discontinuous enhancement will play an increasingly important role in future research. The theoretical research on the fiber/matrix interface behavior, fiber failure process, and toughened mechanism of continuous fibers under service conditions should be strengthened. And the preparation technology of the materials also should be improved, so as to reduce the damage of fibers in the composites and increase the density of the composites.

- The main representative of phase transformation toughening is ZrO2. The toughening mechanisms of ZrO2 generally include stress-induced phase transformation toughening, microcrack toughening, zirconia doping toughening, and compression surface toughening. The mechanism of phase transformation toughening has strong temperature sensitivity, so the toughening effect at high temperature is greatly limited, especially the stress-induced phase transformation toughening almost completely fails at high temperature. Therefore, how to expand the effective temperature range of the existing mechanism and seek a new phase change toughening mechanism will be the key to solve the problem of high temperature toughening.

- The mechanism of toughening mullite with non-phase change second phase particles is mainly the mismatch of the elastic modulus and thermal expansion coefficient between the matrix and particles. The strengthening and toughening mechanism of nano-composite ceramics can be basically summarized as refinement, transgranulation and pinning theories, but a systematic and complete concept has not yet been formed. It is still necessary to conduct in-depth research on the bonding state and stress state of the interface by using fracture mechanics, fracture morphology, numerical analysis, and other methods. The toughening behavior of whisker toughened mullite is affected by many factors, and the main mechanisms include crack bridging, crack deflection, pullout effect, etc. According to the actual conditions, the specific mechanism can be selected, and new composites can be developed by using the excellent properties of whiskers.

- Continuous fiber reinforced mullite is the main research direction in the near future. The main mechanisms of continuous fiber toughening mullite include fiber bridging, crack deflection, fiber fracture, pullout, etc. The toughening mechanism of coated fiber reinforced mullite composites includes crack deflection, crack branching, fiber delamination and fiber pullout. Improving the service performance of fibers in harsh environment and developing oxide fibers with better heat resistance are the directions of continuous efforts. The performance of the existing system can be effectively improved through interface material selection and design. On this basis, the interface layer connection can be completed through designing an effective and reasonable technological process to realize the expected material function.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Anggono, J. Mullite Ceramics: Its properties, structure, and synthesis. Jurnal Teknik Mesin 2005, 7, 1–10. [Google Scholar] [CrossRef]

- Zhang, G.M.; Wang, Y.C.; Fu, Z.Y.; Wang, H.; Wang, W.M.; Zhang, J.Y.; Lee, S.W.; Niihara, K. Transparent mullite ceramic from single-phase gel by spark plasma sintering. J. Eur. Ceram. Soc. 2009, 29, 2705–2711. [Google Scholar] [CrossRef]

- Vargas, F.; Restrepo, E.; Rodríguez, J.E.; Vargas, F.; Arbeláez, L.; Caballero, P.; Arias, J.; López, E.; Latorre, G.; Duarte, G. Solid-state synthesis of mullite from spent catalysts for manufacturing refractory brick coatings. Ceram. Int. 2017, 44, 3556–3562. [Google Scholar] [CrossRef]

- Aksay, I.A.; Dabbs, D.M.; Sarikaya, M. Mullite for structural, electronic, and optical applications. J. Am. Ceram. Soc. 1991, 74, 2343–2358. [Google Scholar] [CrossRef]

- Tummala, R.R. Ceramic and glass-ceramic packaging in the 1990s. J. Am. Ceram. Soc. 1991, 74, 895–908. [Google Scholar] [CrossRef]

- Sprague, J.L. Multilayer ceramic packaging alternatives. IEEE Trans. Compon. Hybrids Manuf. Technol. 1990, 13, 390–396. [Google Scholar] [CrossRef]

- Ribero, D.; Restrepo, R.; Paucar, C.; García, C. Highly refractory mullite obtained through the route of hydroxyhydrogels. J Mater Process Technol. 2009, 209, 986–990. [Google Scholar] [CrossRef]

- Schneider, H.; Schmücker, M.; Ikeda, K.; Kaysser, W.A. Optically translucent mullite ceramics. J. Am. Ceram. Soc. 1993, 76, 2912–2914. [Google Scholar] [CrossRef]

- Sarkar, P.; Datta, S.; Nicholson, P.S. A functionally graded ceramic/ceramic and metal/ceramic composites by electrophoretic deposition. Compos. Part B-Eng. 2003, 28, 49–56. [Google Scholar] [CrossRef]

- Takada, H.; Nakahira, A.; Ueda, S.; Niihara, K.; Ohnishi, H. Improvement of mechanical properties of natural mullite/SiC nano-composites. J. Jpn. Soc. 1991, 38, 348–351. [Google Scholar] [CrossRef]

- Huang, Z.R. Studyonthe SPS densification of SiC whisker reinforced mullite composites. J. Ceram. 2001, 33, 115–120. (In Chinese) [Google Scholar]

- Iwata, M.O.; Shima, K.; Isoda, T. Weak interface dominated high temperature fracture strength of carbon fiber reinforced mullitematrix composites. J. Eur. Ceram. Soc. 2017, 37, 2991–2996. [Google Scholar] [CrossRef]

- Schneider, H.; Fischer, R.X.; Schreuer, J. Mullite: Crystal structure and related properties. J. Am. Ceram. Soc. 2015, 98, 2948–2967. [Google Scholar] [CrossRef]

- Aryal, S.; Rulis, P.; Ching, W.Y. Mechanical properties and electronic structure of mullite phases using first-principles modeling. J. Am. Ceram. Soc. 2012, 95, 2075–2088. [Google Scholar] [CrossRef]

- Schneider, H.; Schreuer, J.; Hildmann, B. Structure and properties of mullite—A review. J. Eur. Ceram. Soc. 2008, 28, 329–344. [Google Scholar] [CrossRef]

- Fischer, R.X.; Andrea, G.K.; Birkenstock, J.; Schneider, H. Mullite and mullite-type crystal structures. Int. J. Mater. Res. 2012, 103, 402–407. [Google Scholar] [CrossRef]

- Schneider, H.; Fischer, R.X.; Gesing, T.M.; Schreuer, J.; Mühlberg, M. Crystal chemistry and properties of mullite-type Bi2M4O9: An overview. Int. J. Mater. Res. 2012, 103, 422–429. [Google Scholar] [CrossRef]

- Fischer, R.X.; Schneider, H.; Voll, D. Formation of aluminum rich 9:1 mullite and its transformation to low alumina mullite upon heating. J. Eur. Ceram. Soc. 1996, 16, 109–113. [Google Scholar] [CrossRef]

- Bowen, N.L.; Greig, J.W. The system: Al2O3·SiO2. J. Am. Ceram. Soc. 1924, 7, 238–254. [Google Scholar] [CrossRef]

- Johnson, B.R.; Kriven, W.M.; Schneider, J. Crystal structure development during devitrification of quenched mullite. J. Eur. Ceram. Soc. 2001, 21, 2541–2562. [Google Scholar] [CrossRef]

- Koyama, T.; Hayashi, S.; Yasumori, A.; Okada, K.; Schmucker, M.; Schneider, H. Microstructure and mechanical properties of mullite/zirconia composites prepared from alumina and zircon under various firing conditions. J. Eur. Ceram. Soc. 1996, 16, 231–237. [Google Scholar] [CrossRef]

- Qi, M.Y.; Jia, Q.T.; Zheng, G.J. Preparation and properties of zirconia-toughened mullite ceramics. J. Am. Ceram. Soc. 1986, 69, 265–267. [Google Scholar] [CrossRef]

- Zhou, M.; Ferreira, J.; Fonseca, A.T.; Baptista, J.L. In Situ formed alpha-alumina platelets in a mullite-alumina composite. J. Eur. Ceram. Soc. 1998, 18, 495–500. [Google Scholar] [CrossRef]

- Schneider, H.; Okada, K. Mullite matrix composites. In Mullite; Schneider, H., Komarneni, S., Eds.; Wiley Online Library: Hoboken, NJ, USA, 2005. [Google Scholar] [CrossRef]

- Gustafsson, S.; Falk, L.K.L.; Pitchford, J.E.; Clegg, W.J.; Lidén, E.; Carlstr, M.E. Development of microstructure during creep of polycrystalline mullite and a nanocomposite mullite/5vol.%SiC. J. Eur. Ceram. Soc. 2009, 29, 539–550. [Google Scholar] [CrossRef]

- Scribante, A.; Vallittu, P.K.; Özcan, M. Fiber-reinforced composites for dental applications. Biomed Res. Int. 2018, 4, 1–2. [Google Scholar] [CrossRef] [PubMed]

- Yao, S.; Zhou, H.; Wu, S.; Kou, M.; Song, B.; Xu, R.; He, R. Microstructure and physical properties of a mullite brick in blast furnace hearth: Influence of temperature. Ironmak. Steelmak. 2020, 3, 1–7. [Google Scholar] [CrossRef]

- Chan, C.F.; Ko, Y.C. Effect of Cr2O3 on slag resistance of Al2O3-SiO2 refractories. J. Am. Ceram. Soc. 1992, 75, 2857–2861. [Google Scholar] [CrossRef]

- Liu, M.Z.; Zhu, Z.W.; Zhang, Z.; Chu, Y.C.; Yuan, B.; Wei, Z.L. Development of highly porous mullite whisker ceramic membranes for oil-in-water separation and resource utilization of coal gangue. Sep. Purif. Technol. 2020, 237, 1–10. [Google Scholar] [CrossRef]

- Zhang, Y.Y.; Li, Y.G.; Bai, C.G. Microstructure and oxidation behavior of Si-MoSi2 functionally graded coating on Mo substrate. Ceram. Int. 2017, 43, 6250–6256. [Google Scholar] [CrossRef]

- Zhang, Y.Y.; Qie, J.M.; Cui, K.K.; Fu, T.; Fan, X.L.; Wang, J.; Zhang, X. Effect of hot dip silicon-plating temperature on microstructure characteristics of silicide coating on tungsten substrate. Ceram. Int. 2020, 46, 5223–5228. [Google Scholar] [CrossRef]

- Zhang, Y.Y.; Ni, W.J.; Li, Y.G. Effect of siliconizing temperature on microstructure and phase constitution of Mo–MoSi2 functionally graded materials. Ceram. Int. 2018, 44, 11166–11171. [Google Scholar] [CrossRef]

- Zhang, Y.Y.; Cui, K.K.; Fu, T.; Wang, J.; Qie, J.M.; Zhang, X. Synthesis WSi2 coating on W substrate by HDS method with various deposition times. Appl. Surf. Sci. 2020, 511, 145551. [Google Scholar] [CrossRef]

- Zhang, Y.Y.; Zhao, J.; Li, J.H.; Lei, J.; Cheng, X.K. Effect of hot-dip siliconizing time on phase composition and microstructure of Mo-MoSi2 high temperature structural materials. Ceram. Int. 2019, 45, 5588–5593. [Google Scholar] [CrossRef]

- Zhang, Y.Y.; Cui, K.K.; Gao, Q.J.; Hussain, S.; Lv, Y. Investigation of morphology and texture properties of WSi2 coatings on W substrate based on contact-mode AFM and EBSD. Surf. Coat. Technol. 2020, 396, 125966. [Google Scholar] [CrossRef]

- Botero, C.A.; Jimenez, E.P.; Martín, R.; Kulkarni, T.; Sarin, V.K.; Llanes, L. Influence of temperature and hot corrosion on the micro–nanomechanical behavior of protective mullite EBCs. Int. J. Refract. Hard. Met. 2015, 49, 383–391. [Google Scholar] [CrossRef]

- Lee, K.N.; Fox, D.S.; Eldridge, J.I.; Zhu, D.; Robinson, R.C.; Bansal, N.P. Upper temperature limit of environmental barrier coatings based on mullite and BSAS. J. Am. Ceram. Soc. 2003, 86, 1299–1306. [Google Scholar] [CrossRef] [Green Version]

- Aydin, H.; Tokatas, G. Characterization and production of slip casts mullite-zirconia composites. SN Appl. Sci. 2019, 1. [Google Scholar] [CrossRef] [Green Version]

- Medvedovski, E. Alumina-mullite ceramics for structural applications. Ceram. Int. 2006, 32, 369–375. [Google Scholar] [CrossRef]

- Long, L.; Xiao, P.; Luo, H.; Zhou, W.; Li, Y. Enhanced electromagnetic shielding property of cf/mullite composites fabricated by spark plasma sintering. Ceram. Int. 2019, 45, 18988–18993. [Google Scholar] [CrossRef]

- Boccaccini, A.R.; Atiq, S.; Boccaccini, D.N.; Dlouhy, I.; Kaya, C. Fracture behaviour of mullite fibre reinforced-mullite matrix composites under quasi-static and ballistic impact loading. Compos. Sci. Technol. 2005, 65, 325–333. [Google Scholar] [CrossRef]

- Kanka, B.; Schneider, H. Aluminosilicate fiber/mullite matrix composites with favorable high-temperature properties. J. Eur. Ceram. Soc. 2000, 20, 619–623. [Google Scholar] [CrossRef]

- Zhang, W.; Ma, Q.S.; Dai, K.W.; Mao, W.G. Preparation of three-dimensional braided carbon fiber reinforced mullite composites from a sol with high solid content. Trans. Nonferrous Met. Soc. China 2018, 28, 2248–2254. [Google Scholar] [CrossRef]

- Zhang, J.; Wu, H.; Zhang, S.; Yu, J.; Hou, S. Preparation of mullite whiskers and their enhancement effect on ceramic matrix composites. J. WuHan Univ. Technol. 2013, 3, 69–73. [Google Scholar] [CrossRef]

- Rangel, E.R.; Sebastián, D.T.; Umemoto, M.; Miyamoto, H.; Heberto, B.R. Zirconia-mullite composites consolidated by spark plasma reaction sintering from zircon and alumina. J. Am. Ceram. Soc. 2005, 88, 1150–1157. [Google Scholar] [CrossRef]

- Haldar, M.K. Effect of magnesia additions on the properties of zirconia-mullite composites derived from sillimanite beach sand. Ceram. Int. 2003, 29, 573–581. [Google Scholar] [CrossRef]

- Lin, C.C.; Zangvil, A.; Ruh, R. Phase Evolution in silicon carbide-whisker-reinforced mullite/zirconia composite during long-term oxidation at 1000 °C to 1350 °C. J. Am. Ceram. Soc. 2004, 83, 1797–1803. [Google Scholar] [CrossRef] [Green Version]

- Gerhardt, R.A.; Ruh, R. Volume fraction and whisker orientation dependence of the electrical properties of SiC-whisker-reinforced mullite composites. J. Am. Ceram. Soc. 2001, 84, 2328–2334. [Google Scholar] [CrossRef]

- Zhang, F.C.; Luo, H.H.; Wang, T.S.; Zhang, M.; Sun, Y.N. Stress state and fracture behavior of alumina-mullite intragranular particulate composites. Compos. Sci. Technol. 2008, 68, 3245–3250. [Google Scholar] [CrossRef]

- Bodhak, S.; Bose, S.; Bandyopadhyay, A. Densification study and mechanical properties of microwave-sintered mullite and mullite-zirconia composites. J. Am. Ceram. Soc. 2011, 94, 32–41. [Google Scholar] [CrossRef]

- Gao, L.; Jin, X.H.; Kawaoka, H.; Sekino, T.; Niihara, K. Microstructure and mechanical properties of SiC-mullite nanocomposite prepared by spark plasma sintering. Mater. Sci. Eng. A 2002, 334, 262–266. [Google Scholar] [CrossRef]

- Ghahremani, D.; Ebadzadeh, T.; Maghsodipour, A. Densification, microstructure and mechanical properties of mullite-TiC composites prepared by spark plasma sintering. Ceram. Int. 2015, 41, 1957–1962. [Google Scholar] [CrossRef]

- Esharghawi, A.; Penot, C.; Nardou, F. Elaboration of porous mullite-based materials via SHS reaction. Ceram. Int. 2010, 36, 231–239. [Google Scholar] [CrossRef]

- Ganesh, I.; Ferreira, J.M.F. Influence of raw material type and of the overall chemical composition on phase formation and sintered microstructure of mullite aggregates. Ceram. Int. 2009, 35, 2007–2015. [Google Scholar] [CrossRef]

- Cividanes, L.S.; Campos, T.M.B.; Rodrigues, L.A.; Brunelli, D.D.; Thim, G.P. Review of mullite synthesis routes by sol-gel method. J. Sol-Gel Sci. Technol. 2010, 55, 111–125. [Google Scholar] [CrossRef]

- Wang, S.; Shen, X.Q.; Yao, H.C.; Li, Z.J. Synthesis and sintering of pre-mullite powders obtained via carbonate precipitation. Ceram. Int. 2010, 36, 761–766. [Google Scholar] [CrossRef]

- Park, H.C.; Yoon, H.C.; Stevens, R. Preparation of zirconia-mullite composites by an infiltration route. Mater. Sci. Eng. A 2005, 405, 233–238. [Google Scholar] [CrossRef]

- Roy, J.; Bandyopadhyay, N.; Das, S.; Maitra, S. Role of V2O5 on the formation of chemical mullite from aluminosilicate precursor. Ceram. Int. 2010, 36, 1603–1608. [Google Scholar] [CrossRef]

- Mechnich, P.; Schneider, H. Reaction bonding of mullite (RBM) in presence of scandia Sc2O3. J. Eur. Ceram. Soc. 2008, 28, 473–478. [Google Scholar] [CrossRef]

- Sacks, M.D.; Bozkurt, N.; Scheiffele, G.W. Fabrication of mullite and mullite-matrix composites by transient viscous sintering of composite powders. J. Am. Ceram. Soc. 1991, 74, 2428–2437. [Google Scholar] [CrossRef]

- Chen, Z.; Zhang, L.; Cheng, L.; Xiao, P.; Duo, G.B. Novel method of adding seeds for preparation of mullite. J. Mater. Process. Technol. 2005, 166, 183–187. [Google Scholar] [CrossRef]

- Griggio, F.; Bernardo, E. Kinetic studies of mullite synthesis from alumina nanoparticles and a preceramic polymer. J. Am. Ceram. Soc. 2008, 91, 2529–2533. [Google Scholar] [CrossRef]

- Huang, Z.; Shen, Z.; Lin, L.; Nygren, M.; Jiang, D. Spark-plasma-sintering consolidation of sic-whisker-reinforced mullite composites. J. Am. Ceram. Soc. 2004, 81, 42–46. [Google Scholar] [CrossRef]

- Bin, M.; Hui, P.J. Optimization on influencing factors of fracture toughness of corundum-mullite toughened by in situ synthesized mullite whiskers by response surface methodology. Adv. Mat. Res. 2012, 581, 819–822. [Google Scholar] [CrossRef]

- Yi, P.; Zhao, P.D.; Zhang, D.Q.; Zhang, H.; Zhao, H.Z. Preparation and characterization of mullite microspheres based porous ceramics with enhancement of in-situ mullite whiskers. Ceram. Int. 2019, 45, 14517–14523. [Google Scholar] [CrossRef]

- Dey, A.; Chatterjeeet, M.L.; Naskar, M.; Basu, K. Near-net-shape fibre-reinforced ceramic matrix composites by the sol infiltration technique. Mater. Lett. 2003, 57, 2919–2926. [Google Scholar] [CrossRef]

- Boccaccini, A.R.; Kaya, C. Use of electrophoretic deposition in the processing of fibre reinforced ceramic and glass matrix composites: A review. Compos. Part. A-Appl. Sci. Manuf. 2001, 32, 997–1006. [Google Scholar] [CrossRef]

- Garshin, A.P.; Kulik, V.I.; Matveev, S.A.; Nilov, A.S. Contemporary technology for preparing fiber-reinforced composite materials with a ceramic refractory matrix (review). Refract. Ind. Ceram. 2017, 58, 148–161. [Google Scholar] [CrossRef]

- Yang, J.Y.; Weaver, J.H.; Zok, F.W.; Mack, J.J. Processing of oxide composites with three-dimensional fiber architectures. J. Am. Ceram. Soc. 2009, 92, 1087–1092. [Google Scholar] [CrossRef]

- Holmquist, M.G.; Radsick, T.C.; Sudre, O.H.; Lange, F.F. Fabrication and testing of all-oxide CFCC tubes. Compos. Part. A-Appl. Sci. Manuf. 2003, 34, 163–170. [Google Scholar] [CrossRef]

- Holmquist, M.G.; Lange, F.F. Processing and properties of a porous oxide matrix composite reinforced with continuous oxide fibers. J. Am. Ceram. Soc. 2003, 86, 1733–1740. [Google Scholar] [CrossRef]

- Gerardin, C.; Sundaresan, S.; Benziger, J.; Navrotsky, A. Structural investigation and energetics of mullite formation from sol-gel precursors. Chem. Mater. 1994, 6, 160–170. [Google Scholar] [CrossRef]

- Zeng, K.H.; Li, Z.Q.; Liang, S.L.; Lv, X.; Ma, Q.S. Thermal properties of carbon fiber reinforced mullite composites derived from sol-gel. Key Eng. Mater. 2017, 727, 461–465. [Google Scholar] [CrossRef]

- Wu, J.; Jones, F.; James, P. Continuous fibre reinforced mullite matrix composites by sol-gel processing: Part I Fabrication and microstructures. J. Mater. Sci. 1997, 32, 3361–3368. [Google Scholar] [CrossRef]

- Wu, J.; Jones, F.; James, P. Continuous fibre reinforced mullite matrix composites by sol-gel processing: Part II properties and fracture behaviour. J. Mater. Sci. 1997, 32, 3629–3635. [Google Scholar] [CrossRef]

- Dong, R.; Hirata, Y.; Sueyoshi, H.; Higo, M.; Uemura, Y. Polymer impregnation and pyrolysis (PIP) method for the preparation of laminated woven fabric/mullite matrix composites with pseudoductility. J. Eur. Ceram. Soc. 2004, 24, 53–64. [Google Scholar] [CrossRef]

- Chen, Z.F.; Tao, J.; Liu, Z.L.; Pan, L.; Dai, Y. Mullite ceramic composites fabricated by chemical vapor infiltration. J. Nanjing Univ. Aeronaut. Astronaut. 2005, 37, 562–566. [Google Scholar] [CrossRef]

- Leuchs, M. Matrix composites: CVI (chemical vapor infiltration). In Wiley Encyclopedia of Composites; Nicolais, L., Ed.; Wiley Online Library: Hoboken, NJ, USA, 2011. [Google Scholar] [CrossRef]

- Ashizuka, M.; Honda, T.; Kubota, Y. Creep in mullite ceramics containing zirconia. J. Ceram. Soc. Jpn. 1991, 99, 357–360. [Google Scholar] [CrossRef] [Green Version]

- Lin, C.C.; Zangvil, A.; Ruh, R. Modes of oxidation in SiC-reinforced mullite/ZrO2 composites: Oxidation vs. depth behavior. Acta Mater. 1999, 47, 1977–1986. [Google Scholar] [CrossRef]

- Rendtorff, N.; Garrido, L.; Aglietti, E. Mullite-zirconia-zircon composites: Properties and thermal shock resistance. Ceram. Int. 2009, 35, 779–786. [Google Scholar] [CrossRef]

- Ruh, R.; Mazdiyasni, K.S.; Mendiratta, M.G. Mechanical and microstructural characterization of mullite and mullite-SiC-whisker and ZrO2-toughened-mullite-SiC-whisker composites. J. Am. Ceram. Soc. 1988, 71, 503–512. [Google Scholar] [CrossRef]

- Nakonieczny, D.S.; Antonowicz, M.; Paszenda, Z.K.; Radko, T.; Drewniak, S.; Bogacz, W.; Krawczyk, C. Experimental investigation of particle size distribution and morphology of alumina-yttria-ceria-zirconia powders obtained via sol-gel route. Biocybern. Biomed. Eng. 2018, 38, 535–543. [Google Scholar] [CrossRef]

- Nakonieczny, D.S.; Ziębowicz, A.; Paszenda, Z.K.; Krawczyk, C. Trends and perspectives in modification of zirconium oxide for a dental prosthetic applications—A review. Biocybern. Biomed. Eng. 2017, 37, 229–245. [Google Scholar] [CrossRef]

- Claussen, N.; Jahn, J. Mechanical properties of sintered, in situ-reacted mullite-zirconia composites. J. Am. Ceram. Soc. 1980, 64, 228–229. [Google Scholar] [CrossRef]

- Chu, M.C.; Sato, S.; Kobayashi, Y.; Ando, K. Strengthening of mullite by dispersion of carbide ceramics particles. JSME Int. J. 1996, 39, 259–265. [Google Scholar] [CrossRef]

- Zhong, H.L.; Yong, Z.; Schmauder, S. Transformation, microcrack, and thermal residual stress as interactive processes in ZrO2-Toughened Al2O3, Simulated by the finite element method. Metall. Mater. Trans. A 1994, 25, 1725–1731. [Google Scholar] [CrossRef]

- Hannink, R. Transformation toughening in zirconia-containing ceramics. J. Am. Ceram. Soc. 2000, 83, 461–487. [Google Scholar] [CrossRef]

- Shin, Y.S.; Rhee, Y.W.; Kang, S.L. Experimental evaluation of toughening mechanisms in alumina-zirconia composites. J. Am. Ceram. Soc. 1999, 82, 1229–1232. [Google Scholar] [CrossRef]

- Guan, S.H.; Zhang, X.J.; Liu, Z.P. Energy landscape of zirconia phase transitions. J. Am. Ceram. Soc. 2015, 137, 8010–8013. [Google Scholar] [CrossRef]

- Rühle, M.; Claussen, N.; Heuer, A.H. Transformation and microcrack toughening as complementary processes in ZrO2-toughened Al2O3. J. Am. Ceram. Soc. 1986, 69, 195–197. [Google Scholar] [CrossRef]

- Rühle, M. Microcrack and transformation toughening of zirconia-containing alumina. Mater. Sci. Eng. A 105- 1988, 106, 77–82. [Google Scholar] [CrossRef]

- Chu, M.C.; Sato, S.; Kobayashi, Y.; Ando, K. Damage healing and strengthening behaviour in intellignt mullite/SiC ceramicsFatigue. Fract. Eng. Mater. Struct. 1995, 18, 1019–1029. [Google Scholar] [CrossRef]

- Akpinar, S.; Kusoglu, I.M.; Ertugrul, O.; Onel, K. Silicon carbide particle reinforced mullite composite foams. Ceram. Int. 2012, 38, 6163–6169. [Google Scholar] [CrossRef]

- Aramide, F.O. Effects of silicon carbide on the phase developments in mullite-carbon ceramic composite. Leonardo J. Pract. Technol. 2017, 31, 45–58. [Google Scholar] [CrossRef]

- Ding, S.Q.; Zhu, S.M.; Zeng, Y.P.; Jiang, D.L. Fabrication of mullite-bonded porous silicon carbide ceramics by in situ reaction bonding. J. Eur. Ceram. Soc. 2007, 27, 2095–2102. [Google Scholar] [CrossRef]

- Taya, M.; Hayashi, S.; Kobayashi, A.; Yoon, H.S. Toughening of a particulate-reinforced ceramic-matrix composite by thermal residual stress. J. Am. Ceram. Soc. 1990, 73, 1382–1391. [Google Scholar] [CrossRef]

- Koichi, N. New design concept of structural ceramics. J. Ceram. Soc. Japan 1991, 99, 974–982. [Google Scholar] [CrossRef] [Green Version]

- Tjong, S.C. Novel nanoparticle-reinforced metal matrix composites with enhanced mechanical properties. Adv. Eng. Mater. 2007, 9, 639–652. [Google Scholar] [CrossRef]

- Yoshimura, M.; Tatsuki, O.; Mutsuo, S.; Choa, Y.H.; Sekino, T.; Niihara, K. Oxidation-induced strengthening and toughening behavior in micro- and nano-composites of Y2O3/SiC system. Mater. Lett. 1998, 35, 139–143. [Google Scholar] [CrossRef]

- Elyas, H.; Kim, T.W.; Jang, B.K.; Lee, K.S. Damage and wear resistance of Al2O3-SiC microcomposites with hard and elastic properties. J. Ceram. Soc. Japan 2018, 126, 21–26. [Google Scholar] [CrossRef] [Green Version]

- Gao, L.; Wang, H.Z.; Hong, J.S.; Miyamoto, H.; Miyamoto, K.; Nishikawa, Y.; Díaz, S. Mechanical properties and microstructure of nano-SiC-Al2O3 composites densified by spark plasma sintering. J. Eur. Ceram. Soc. 1999, 19, 609–613. [Google Scholar] [CrossRef]

- Deng, Z.Y.; Shi, J.L.; Zhang, Y.F.; Jiang, D.Y.; Guo, J.K. Pinning effect of SiC particles on mechanical properties of Al2O3-SiC ceramic matrix composites. J. Eur. Ceram. Soc. 1998, 18, 501–508. [Google Scholar] [CrossRef]

- Li, S.; Zhang, Y.M.; Han, J.C.; Zhou, Y.F. Fabrication and characterization of SiC whisker reinforced reaction bonded SiC composite. Ceram. Int. 2013, 39, 449–455. [Google Scholar] [CrossRef]

- Luo, Y.; Zheng, S.L. Mullite-bonded SiC-whisker-reinforced SiC matrix composites: Preparation, characterization, and toughening mechanisms. J. Eur. Ceram. Soc. 2018, 38, 5282–5293. [Google Scholar] [CrossRef]

- Zou, L.H.; Huang, Y.; Park, D.S.; Cho, B.U.; Kim, H.; Hahn, B.D. R-curve behavior of Si3N4 whisker-reinforced Si3N4 matrix composites. Ceram. Int. 2005, 31, 197–204. [Google Scholar] [CrossRef]

- Zhang, C.; Zeng, Y.P.; Yao, D.; Yin, J.; Zuo, K.; Xia, Y. The improved mechanical properties of Al matrix composites reinforced with oriented β-Si3N4 whisker. J. Mater. Sci. Technol. 2019, 35, 1345–1353. [Google Scholar] [CrossRef]

- Wang, M.C.; Liu, J.C.; Du, H.Y.; Guo, A.; Tao, X.; Dong, X.; Geng, H. A SiC whisker reinforced high-temperature resistant phosphate adhesive for bonding carbon/carbon composites. J. Alloy. Compd. 2015, 633, 145–152. [Google Scholar] [CrossRef]

- Zhou, L.; Fu, Q.G.; Huo, C.X.; Tong, M.D.; Liu, X.S.; Hu, D. Mullite whisker-mullite/yttrium aluminosilicate oxidation protective coatings for SiC coated C/C composites. Ceram. Int. 2019, 45, 24022–24030. [Google Scholar] [CrossRef]

- Lv, X.Y.; Ye, F.; Cheng, L.F.; Fan, S.W.; Liu, Y.S. Fabrication of SiC whisker-reinforced SiC ceramic matrix composites based on 3D printing and chemical vapor infiltration technology. J. Eur. Ceram. Soc. 2019, 39, 3380–3386. [Google Scholar] [CrossRef]

- Wang, Q.B.; Guo, M.Y. Synthesis of SiC whisker and its application in composite materials. Int. J. Coal Sci. Technol. 1997, 3, 49–53. [Google Scholar] [CrossRef]

- Tamari, N.; Kondok, I.; Tanaka, T. Mechanical properties of alumina whisker/mullite composite ceramics. J. Ceram. Soc. Japan 1995, 103, 199–201. [Google Scholar] [CrossRef] [Green Version]

- Hirata, Y.; Matsushita, S.C.; Ishihara, Y.; Katsuki, H. Colloidal processing and mechanical properties of whisker-reinforced mullite matrix composites. J. Am. Ceram. Soc. 1991, 74, 2438–2442. [Google Scholar] [CrossRef]

- Rödel, J. Interaction between crack deflection and crack bridging. J. Eur. Ceram. Soc. 1992, 10, 143–150. [Google Scholar] [CrossRef]

- Fan, B.; Zhu, S.G.; Ding, H.; Bai, Y.F.; Luo, Y.L.; Di, P. Influence of MgO whisker addition on microstructures and mechanical properties of WC-MgO composite. Mater. Chem. Phys. 2019, 238, 11–17. [Google Scholar] [CrossRef]

- Lairdii, G.; Kennedy, T.C. Crack wake toughening mechanisms in a whisker-reinforced ceramic. Finite Elem. Anal. Des. 1991, 9, 113–124. [Google Scholar] [CrossRef]

- Paul, F.B.; Hsueh, C.H.; Angelini, P.; Tiegs, T.N. Toughening behavior in whisker-reinforced ceramic matrix composites. J. Am. Ceram. Soc. 1988, 71, 1050–1061. [Google Scholar] [CrossRef]

- Dolgopolsky, A.; Karbhari, V.; Kwak, S.S. Microcrack induced toughening-an interaction model. Acta Metall. 1989, 37, 1349–1354. [Google Scholar] [CrossRef]

- Radsick, T.; Saruhan, B.; Schneider, H. Damage tolerant oxide/oxide fiber laminate composites. J. Eur. Ceram. Soc. 2000, 20, 545–550. [Google Scholar] [CrossRef]

- Kriven, W.M.; Palko, J.W.; Sinogeikin, S.V.; Bass, J.; Sayir, A.; Brunauer, G.; Boysen, H.; Frey, F.; Schneider, J. High Temperature single crystal properties of mullite. J. Eur. Ceram. Soc. 1999, 19, 2529–2541. [Google Scholar] [CrossRef]

- Chawla, K.K.; Coffin, C.; Xu, Z.R. Interface engineering in oxide fibre/oxide matrix composites. Int. Mater. Rev. 2000, 45, 165–189. [Google Scholar] [CrossRef]

- Kaufmann, H.; Mortensen, A. Wetting of SAFFIL alumina fiber preforms by aluminum at 973 K. Metall. Mater. Trans. A 1992, 23, 2071–2073. [Google Scholar] [CrossRef]

- Hay, R.S.; Fair, G.E.; Tidball, T. Fiber strength after grain growth in nextel 610 alumina fiber. J. Am. Ceram. Soc. 2015, 98, 1907–1914. [Google Scholar] [CrossRef]

- Schawaller, D.; Clau, B.; Buchmeiser, M.R. Ceramic filament fibers—A review. Macromol. Mater. Eng. 2012, 297, 502–522. [Google Scholar] [CrossRef]

- Volkmann, E.; Evangelista, L.L.; Tushtev, K.; Koch, D.; Wilhelmi, C.; Rezwan, K. Oxidation-induced microstructural changes of a polymer-derived nextelâ, ¢ 610 ceramic composite and impact on the mechanical performance. J. Mater. Sci. 2014, 49, 710–719. [Google Scholar] [CrossRef]

- Pearce, D.H.; Rusch, J.J.; Boccaccini, A.R.; Ponton, C.B.; Rohr, L. Characterisation of a pressureless sintered sapphire fibre reinforced mullite matrix composite. Mater. Sci. Eng. A 1996, 214, 170–173. [Google Scholar] [CrossRef]

- Kaya, C.; Kaya, F.; Mori, H. Damage assessment of alumina fibre-reinforced mullite ceramic matrix composites subjected to cyclic fatigue at ambient and elevated temperatures. J. Eur. Ceram. Soc. 2002, 22, 447–452. [Google Scholar] [CrossRef]

- Hinoki, T.; Yang, W.; Nozawa, T.; Shibayama, T.; Katoh, Y.; Kohyama, A. Improvement of mechanical properties of sic/sic composites by various surface treatments of fibers. J. Nucl. Mater. 2001, 289, 23–29. [Google Scholar] [CrossRef]

- Chawla, K.K.; Xu, Z.R.; Ha, J.S. Processing, structure, and properties of mullite fiber/mullite matrix composites. J. Eur. Ceram. Soc. 1996, 16, 293–299. [Google Scholar] [CrossRef]

- Liu, D.Z.; Hu, P.; Fang, C.; Han, W.B. Fabrication of unidirectional continuous fiber-reinforced mullite matrix composite with excellent mechanical property. Ceram. Int. 2018, 44, 13487–13494. [Google Scholar] [CrossRef]

- Wang, P.R.; Liu, F.Q.; Wang, H.; Li, H.; Guo, Y.Z. A review of third generation SiC fibers and SiCf/SiC composites. J. Mater. Sci. Technol. 2019, 35, 2743–2750. [Google Scholar] [CrossRef]

- Ishikawa, T. Recent developments of the SiC fiber nicalon and its composites, including properties of the SiC fiber Hi-Nicalon for ultra-high temperature. Compos. Sci. Technol. 1994, 51, 135–144. [Google Scholar] [CrossRef]

- Ma, Q.S.; Chen, Z.H.; Zheng, W.W.; Hu, H.F. Fabrication and mechanical properties of three-dimensional carbon fibre reinforced mullite composites via sol-gel. RMMAE 2004, 33, 111–114. (In Chinese) [Google Scholar]

| Compound | Tieillite | Cordierite | Spinel | α-Alumina | Zirconia | Mullite |

|---|---|---|---|---|---|---|

| Composition | Al2O3·TiO2 | 2MgO·2Al2O3·5SiO2 | MgO· Al2O3 | Al2O3 | ZrO2 | 3Al2O3· 2SiO2 |

| Melting Point (℃) | 1860 | 1465 | 2135 | 2050 | 2600 | ≈1830 |

| Density (g cm–3) | 3.68 | 2.2 | 3.65 | 3.96 | 5.60 | ≈3.2 |

| Linear Thermal Expansion (× 10–6·°C–1) 20–1400 ℃ | ≈1 | ≈0 | 9 | 8 | 10 | ≈4.5 |

| Thermal Conductivity (kcal·m−1·h–1·°C–1) 20–1400 °C | 1.5–22.5 | ≈10–5 | 134 | 264 | 1.52 | 63 |

| Strength (MPa) | 30 | 120 | 180 | 500 | 200 | ≈200 |

| Fracture Toughness KIC (MPa·m1/2) | – | ≈1.5 | – | ≈4.5 | ≈2.4 | ≈2 |

| Producer Fiber | Composition (wt.%) | Diameter (μm) | Density (g·cm–3) | Tensile Strength /Modulus (GPa/GPa) | Structure |

|---|---|---|---|---|---|

| Dupont FP | Al2O3:100 | 20 | 3.9 | >1.40/380–400 | α-Al2O3 |

| Saphikon Sapphire | Al2O3:100 | 75–225 | 4.0 | 2.10–3.40/414 | α-Al2O3 |

| 3M Nextel 610 | Al2O3:100 Fe2O3:0.7 SiO2:0.3 | 10–12 | 3.9 | 3.10/380 | α-Al2O3 |

| 3M Nextel 720 | Al2O3:85 SiO2:15 | 10–12 | 3.4 | 2.10/260 | Mullite+α-Al2O3 |

| 3M Nextel 550 | Al2O3:73 SiO2:27 | 10–12 | 3.03 | 2.0/193 | γ-Al2O3+α-SiO2 |

| 3M Nextel 440 | Al2O3:70 SiO2:28 B2O3:2 | 10–12 | 3.05 | 2.0/190 | Mullite+γ-Al2O3+ α-SiO2 |

| Dupont PRD-166 | Al2O3:80 ZrO2:20 | 19 | 4.2 | 2.07/380 | α-Al2O3+ w/o zirconia |

| Nitivy Nitivy ALF | Al2O3:70 SiO2:28 B2O3:2 | 10 | 3.0 | 1.75/190 | γ-Al2O3+α-SiO2 |

| Brand | C | SiC | ||||

|---|---|---|---|---|---|---|

| T300 | T800 | T1000 | Nicalon 202 | Hi-Nicalon | Hi-NicalonType-S | |

| Density (g·cm−3) | 1.77 | 1.81 | 1.82 | 2.55 | 2.74 | 3.05 |

| Fiber diameter (μm) | 7.0 | 5.2 | 5.3 | 14 | 12 | 12 |

| Tensile strength (GPa) | 3.53 | 5.59 | 7.06 | 3 | 2.8 | 2.5 |

| Tensile modulus (GPa) | 230 | 294 | 294 | 185 | 400 | 400 |

| Fracture strain (%) | 1.5 | 1.9 | 2.4 | 1 | 0.6 | 0.6 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cui, K.; Zhang, Y.; Fu, T.; Wang, J.; Zhang, X. Toughening Mechanism of Mullite Matrix Composites: A Review. Coatings 2020, 10, 672. https://doi.org/10.3390/coatings10070672

Cui K, Zhang Y, Fu T, Wang J, Zhang X. Toughening Mechanism of Mullite Matrix Composites: A Review. Coatings. 2020; 10(7):672. https://doi.org/10.3390/coatings10070672

Chicago/Turabian StyleCui, Kunkun, Yingyi Zhang, Tao Fu, Jie Wang, and Xu Zhang. 2020. "Toughening Mechanism of Mullite Matrix Composites: A Review" Coatings 10, no. 7: 672. https://doi.org/10.3390/coatings10070672

APA StyleCui, K., Zhang, Y., Fu, T., Wang, J., & Zhang, X. (2020). Toughening Mechanism of Mullite Matrix Composites: A Review. Coatings, 10(7), 672. https://doi.org/10.3390/coatings10070672