In Vitro Corrosion of Titanium Nitride and Oxynitride-Based Biocompatible Coatings Deposited on Stainless Steel

Abstract

:1. Introduction

2. Materials and Methods

2.1. Coating and Specimens

2.2. Characterization of Coatings

3. Results and Discussions

3.1. Elemental Composition

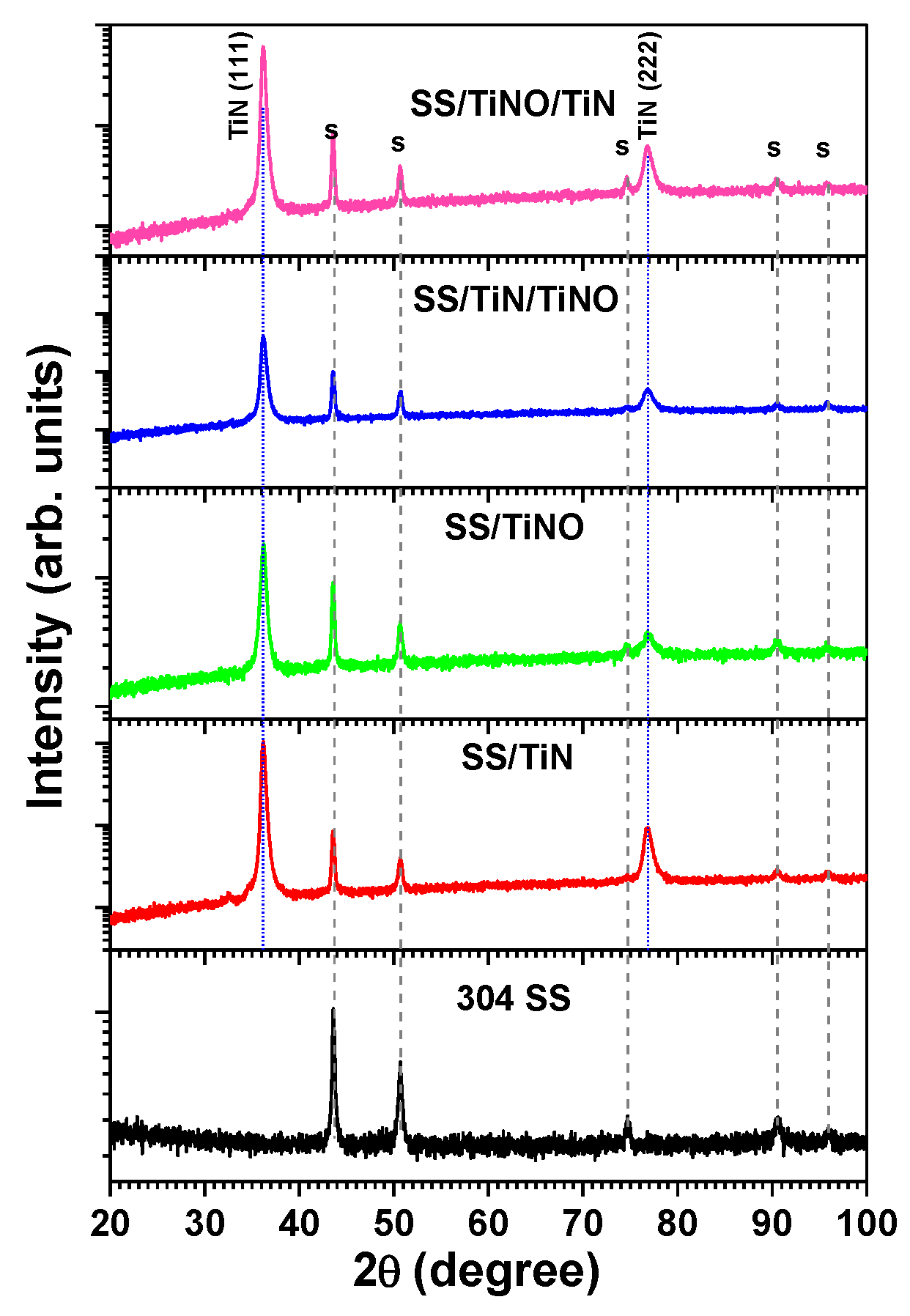

3.2. Phase Composition and Grain Size

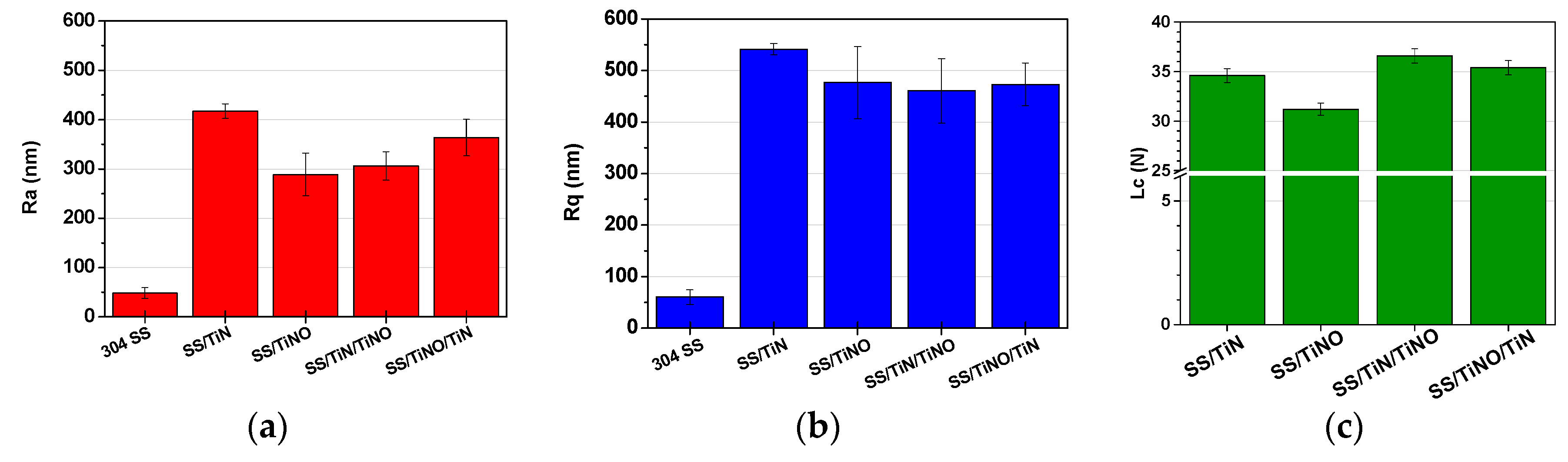

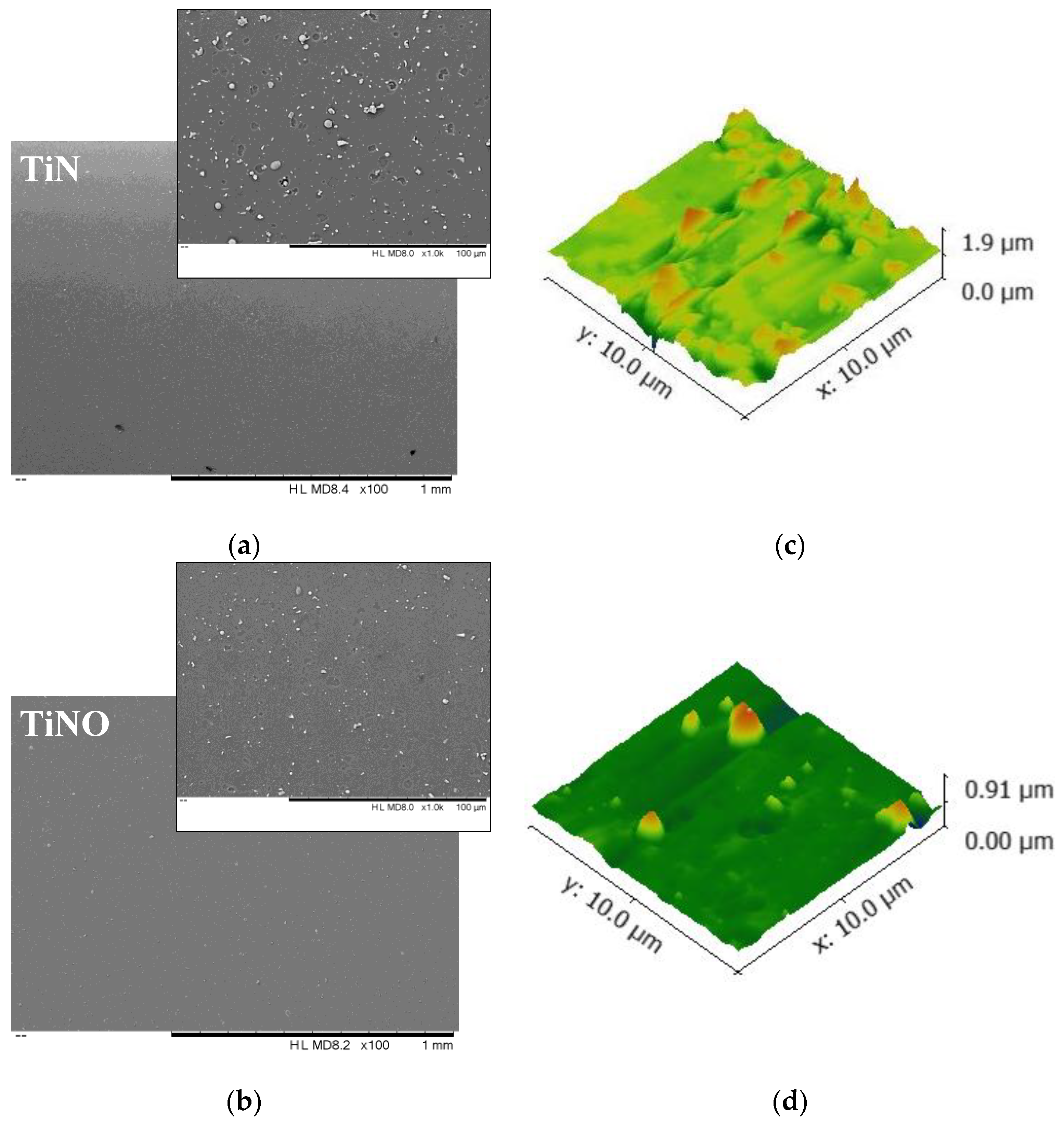

3.3. Coating Roughness and Adhesion to the Substrate

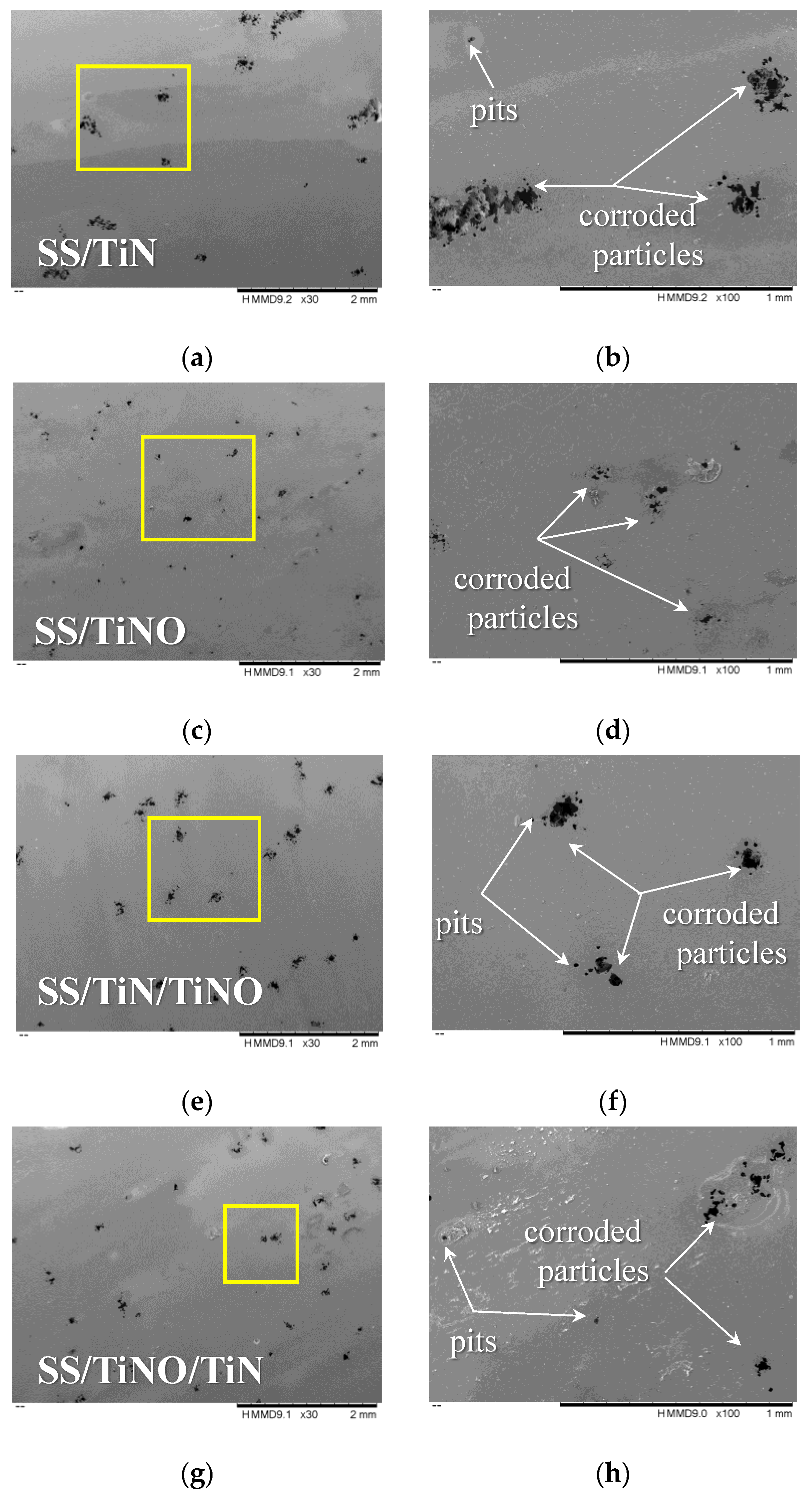

3.4. In Vitro Corrosion Tests

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Sippel, T.; He, X.; Ahn, T. Corrosion of Borated Stainless Steel in Water and Humid Air; USA Nuclear Regulatory Commission: Washington, DC, USA, 2011. [Google Scholar]

- Burkert, A.; Müller, T.; Lehmann, J.; Mietz, J. Long-term corrosion behaviour of stainless steels in marine atmosphere. Mater. Corros. 2018, 69, 20–28. [Google Scholar] [CrossRef]

- Liu, W.; Lu, S.L.; Zhang, Y.; Fang, Z.C.; Wang, X.M.; Lu, M.X. Corrosion performance of 3% Cr steel in CO2-H2S environment compared with carbon steel. Mater. Corros. 2015, 66, 1232–1244. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, J. Effect of dissolved oxygen content on stress corrosion cracking of a cold worked 316L stainless steel in simulated pressurized water reactor primary water environment. J. Nucl. Mater. 2014, 446, 15–26. [Google Scholar] [CrossRef]

- Abbasi Aghuy, A.; Zakeri, M.; Moayed, M.H.; Mazinani, M. Effect of grain size on pitting corrosion of 304L austenitic stainless steel. Corros. Sci. 2015, 94, 368–376. [Google Scholar] [CrossRef]

- Mackey, E.D.; Seacord, T.F. Guidelines for using stainless steel in the water and desalination industries. J. Am. Water Works Assoc. 2017, 109, 158–169. [Google Scholar] [CrossRef]

- Manivasagam, G.; Dhinasekaran, D.; Rajamanickam, A. Biomedical implants: corrosion and its prevention—A review. Recent Pat. Corros. Sci. 2010, 2, 40–54. [Google Scholar] [CrossRef] [Green Version]

- Blackwood, D.J.; Pereira, B.P. No corrosion of 304 stainless steel implant after 40 years of service. J. Mater. Sci. Mater. Med. 2004, 15, 755–758. [Google Scholar] [CrossRef]

- Liang, W. Surface modification of AISI 304 austenitic stainless steel by plasma nitriding. Appl. Surf. Sci. 2003, 211, 308–314. [Google Scholar] [CrossRef]

- Wang, J.; Shi, H. The study of surface modification 304 stainless steel in simulated PEMFC environments. Adv. Mater. Res. 2013, 608–609, 865–869. [Google Scholar] [CrossRef]

- Wang, G.Q.; Lei, M.K.; Guo, D.M. Interactions between Surface Integrity Parameters on AISI 304 Austenitic Stainless Steel Components by Ultrasonic Impact Treatment. Procedia CIRP 2016, 45, 323–326. [Google Scholar] [CrossRef] [Green Version]

- Bao, Z.; Wang, C.; Zhang, Y.; Zhao, Q.-Z. Modification of wettability of stainless steel by picosecond laser surface microstructuring. Photonics Res. 2015, 3, 180. [Google Scholar] [CrossRef]

- Beaumier, E.P.; Pearce, A.J.; See, X.Y.; Tonks, I.A. Modern applications of low-valent early transition metals in synthesis and catalysis. Nat. Rev. Chem. 2019, 3, 15–34. [Google Scholar] [CrossRef] [PubMed]

- Hafeez, N.; Liu, J.; Wang, L.; Wei, D.; Tang, Y.; Lu, W.; Zhang, L.C. Superelastic response of low-modulus porous beta-type Ti-35Nb-2Ta-3Zr alloy fabricated by laser powder bed fusion. Addit. Manuf. 2020, 34, 101264. [Google Scholar] [CrossRef]

- Liu, S.; Liu, J.; Wang, L.; Ma, R.L.W.; Zhong, Y.; Lu, W.; Zhang, L.C. Superelastic behavior of in-situ eutectic-reaction manufactured high strength 3D porous NiTi-Nb scaffold. Scr. Mater. 2020, 181, 121–126. [Google Scholar] [CrossRef]

- Wang, L.; Xie, L.; Zhang, L.C.; Chen, L.; Ding, Z.; Lv, Y.; Zhang, W.; Lu, W.; Zhang, D. Microstructure evolution and superelasticity of layer-like NiTiNb porous metal prepared by eutectic reaction. Acta Mater. 2018, 143, 214–226. [Google Scholar] [CrossRef]

- Zhang, L.C.; Chen, L.Y.; Wang, L. Surface Modification of Titanium and Titanium Alloys: Technologies, Developments, and Future Interests. Adv. Eng. Mater. 2020, 22. [Google Scholar] [CrossRef]

- Licausi, M.P.; Igual Muñoz, A.; Amigó Borrás, V. Influence of the fabrication process and fluoride content on the tribocorrosion behaviour of Ti6Al4V biomedical alloy in artificial saliva. J. Mech. Behav. Biomed. Mater. 2013, 20, 137–148. [Google Scholar] [CrossRef]

- Fadlallah, S.A.; El-Bagoury, N.; Gad El-Rab, S.M.F.; Ahmed, R.A.; El-Ousamii, G. An overview of NiTi shape memory alloy: Corrosion resistance and antibacterial inhibition for dental application. J. Alloy. Compd. 2014, 583, 455–464. [Google Scholar] [CrossRef]

- Lazar, A.-M.; Yespica, W.P.; Marcelin, S.; Pébère, N.; Samélor, D.; Tendero, C.; Vahlas, C. Corrosion protection of 304L stainless steel by chemical vapor deposited alumina coatings. Corros. Sci. 2014, 81, 125–131. [Google Scholar] [CrossRef] [Green Version]

- Volovitch, P.; Vu, T.N.; Allély, C.; Abdel Aal, A.; Ogle, K. Understanding corrosion via corrosion product characterization: II. Role of alloying elements in improving the corrosion resistance of Zn-Al-Mg coatings on steel. Corros. Sci. 2011, 53, 2437–2445. [Google Scholar] [CrossRef]

- Krishna, N.G.; Thinaharan, C.; George, R.P.; Parvathavarthini, N.; Kamachi Mudali, U. Surface modification of type 304 stainless steel with duplex coatings for corrosion resistance in sea water environments. Surf. Eng. 2015, 31, 39–47. [Google Scholar] [CrossRef]

- Jiao, Z.; Peterkin, S.; Felix, L.; Liang, R.; Oliveira, J.P.; Schell, N.; Scotchmer, N.; Toyserkani, E.; Zhou, Y. Surface Modification of 304 Stainless Steel by Electro-Spark Deposition. J. Mater. Eng. Perform. 2018, 27, 4799–4809. [Google Scholar] [CrossRef] [Green Version]

- Modiri, F.; Savaloni, H. A study of the corrosion of stainless steel 304L coated with a 190 nm-thick manganese layer and annealed with nitrogen flux in a 0.4-mole solution of H2SO4 at different temperatures. J. Theor. Appl. Phys. 2020, 14, 21–35. [Google Scholar] [CrossRef] [Green Version]

- Zhang, S.; Zhu, W. TiN coating of tool steels: A review. J. Mater. Process. Tech. 1993, 39, 165–177. [Google Scholar] [CrossRef]

- Jindal, P.C.; Santhanam, A.T.; Schleinkofer, U.; Shuster, A.F. Performance of PVD TiN, TiCN, and TiAlN coated cemented carbide tools in turning. Int. J. Refract. Met. Hard Mater. 1999, 17, 163–170. [Google Scholar] [CrossRef]

- Deng, J.; Liu, J.; Ding, Z.; Niu, M. Unlubricated friction and wear behaviors of ZrN coatings against hardened steel. Mater. Des. 2008, 29, 1828–1834. [Google Scholar] [CrossRef]

- Atar, E.; Alpaslan, Ö.; Çelik, Ö.; Çimenoĝlu, H. Tribological properties of CrN coated H13 grade tool steel. J. Iron Steel Res. Int. 2014, 21, 240–245. [Google Scholar] [CrossRef]

- Birol, Y. Sliding wear of CrN, AlCrN and AlTiN coated AISI H13 hot work tool steels in aluminium extrusion. Tribol. Int. 2013, 57, 101–106. [Google Scholar] [CrossRef]

- Sresomroeng, B.; Premanond, V.; Kaewtatip, P.; Khantachawana, A.; Kurosawa, A.; Koga, N. Performance of CrN radical nitrided tools on deep drawing of advanced high strength steel. Surf. Coat. Technol. 2011, 205, 4198–4204. [Google Scholar] [CrossRef]

- Li, K.-H.; Alfaraj, N.; Kang, C.H.; Braic, L.; Zoita, N.C.; Kiss, A.E.; Ng, T.K.; Ooi, B. Deep-ultraviolet beta-Ga2O3 photodetectors grown on MgO substrates with a TiN template. In Proceedings of the 2019 IEEE Photonics Conference (IPC), San Antonio, TX, USA, 29 September–3 October 2019; IEEE: Piscataway, NJ, USA, 2019. [Google Scholar]

- Balaceanu, M.; Braic, V.; Braic, M.; Kiss, A.; Zoita, C.N.; Vladescu, A.; Drob, P.; Vasilescu, C.; Dudu, D.; Muresanu, O. Structural, mechanical and corrosion properties of TiOxNy/ZrOxNy multilayer coatings. Surf. Coat. Technol. 2008, 202. [Google Scholar] [CrossRef]

- Braic, M.; Balaceanu, M.; Vladescu, A.; Kiss, A.; Braic, V.; Epurescu, G.; Dinescu, G.; Moldovan, A.; Birjega, R.; Dinescu, M. Preparation and characterization of titanium oxy-nitride thin films. Appl. Surf. Sci. 2007, 253, 8210–8214. [Google Scholar] [CrossRef]

- Subramanian, B.; Muraleedharan, C.V.; Ananthakumar, R.; Jayachandran, M. A comparative study of titanium nitride (TiN), titanium oxy nitride (TiON) and titanium aluminum nitride (TiAlN), as surface coatings for bio implants. Surf. Coat. Technol. 2011, 205, 5014–5020. [Google Scholar] [CrossRef]

- Cubillos, G.I.; Bethencourt, M.; Olaya, J.J.; Alfonso, J.E.; Marco, J.F. The influence of deposition temperature on microstructure and corrosion resistance of ZrOxNy/ZrO2 coatings deposited using RF sputtering. Appl. Surf. Sci. 2014, 309, 181–187. [Google Scholar] [CrossRef] [Green Version]

- Alves, E.; Ramos, A.R.; Barradas, N.P.; Vaz, F.; Cerqueira, P.; Rebouta, L.; Kreissig, U. Ion beam studies of TiNxOy thin films deposited by reactive magnetron sputtering. Surf. Coat. Technol. 2004, 180–181, 372–376. [Google Scholar] [CrossRef]

- Jung, M.J.; Nam, K.H.; Chung, Y.M.; Boo, J.H.; Han, J.G. The physiochemical properties of TiOxNyfilms with controlled oxygen partial pressure. Surf. Coat. Technol. 2003, 171, 71–74. [Google Scholar] [CrossRef]

- Vaz, F.; Cerqueira, P.; Rebouta, L.; Nascimento, S.M.C.; Alves, E.; Goudeau, P.; Rivière, J.P. Preparation of magnetron sputtered TiNxOy thin films. Surf. Coat. Technol. 2003, 174–175, 197–203. [Google Scholar] [CrossRef]

- Cotrut, C.M.; Braic, L.; Vranceanu, D.M.; Kiss, A.; Dinu, M.; Balaceanu, M.; Braic, V.; Vladescu, A. Influence of the annealing treatment on the structure, morphology, and corrosion resistance of sputtered Zr-Ti-Si-O coatings used for biomedical applications. Mater. Corros. 2017, 68, 552–559. [Google Scholar] [CrossRef]

- Sollazzo, V.; Pezzetti, F.; Scarano, A.; Piattelli, A.; Bignozzi, C.A.; Massari, L.; Brunelli, G.; Carinci, F. Zirconium oxide coating improves implant osseointegration in vivo. Dent. Mater. 2008, 24, 357–361. [Google Scholar] [CrossRef]

- Giavaresi, G.; Giardino, R.; Ambrosio, L.; Battiston, G.; Gerbasi, R.; Fini, M.; Rimondini, L.; Torricelli, P. In vitro biocompatibility of titanium oxide for prosthetic devices nanostructured by low pressure metal-organic chemical vapor deposition. Int. J. Artif. Organs 2003, 26, 774–780. [Google Scholar] [CrossRef]

- Dinu, M.; Braic, L.; Padmanabhan, S.C.; Morris, M.A.; Titorencu, I.; Pruna, V.; Parau, A.; Romanchikova, N.; Petrik, L.F.; Vladescu, A. Characterization of electron beam deposited Nb2O5 coatings for biomedical applications. J. Mech. Behav. Biomed. Mater. 2020, 103, 103582. [Google Scholar] [CrossRef]

- Scopel, W.L.; Fantini, M.C.A.; Alayo, M.I.; Pereyra, I. Local structure and bonds of amorphous silicon oxynitride thin films. Thin Solid Film. 2002, 413, 59–64. [Google Scholar] [CrossRef]

- Kazemeini, M.H.; Berezin, A.A.; Fukuhara, N. Formation of thin TiN x O y films by using a hollow cathode reactive DC sputtering system. Thin Solid Film. 2000, 372, 70–77. [Google Scholar] [CrossRef]

- Nasir, M.E.; Peruch, S.; Vasilantonakis, N.; Wardley, W.P.; Dickson, W.; Wurtz, G.A.; Zayats, A.V. Tuning the effective plasma frequency of nanorod metamaterials from visible to telecom wavelengths. Appl. Phys. Lett. 2015, 107. [Google Scholar] [CrossRef]

- Rtimi, S.; Baghriche, O.; Sanjines, R.; Pulgarin, C.; Bensimon, M.; Kiwi, J. TiON and TiON-Ag sputtered surfaces leading to bacterial inactivation under indoor actinic light. J. Photochem. Photobiol. A Chem. 2013, 256, 52–63. [Google Scholar] [CrossRef] [Green Version]

- Braic, L.; Vasilantonakis, N.; Mihai, A.; Garcia, I.J.V.; Fearn, S.; Zou, B.; Alford, N.M.; Doiron, B.; Oulton, R.F.; Maier, S.A.; et al. Titanium Oxynitride Thin Films with Tunable Double Epsilon-Near-Zero Behavior for Nanophotonic Applications. ACS Appl. Mater. Interfaces 2017, 9, 29857–29862. [Google Scholar] [CrossRef]

- Duta, O.C.; Ficai, D.; Ficai, A.; Andronescu, E.; Beshchasna, N.; Saqib, M.; Opitz, J.; Kraśkiewicz, H.; Wasyluk, Ł.; Kuzmin, O.; et al. Titanium oxynitride coatings deposited by magnetron sputtering for improvement of cardiovascular stent design. In Proceedings of the World Congress on New Technologies, Madrid, Spain, 19–21 August 2018; pp. 18–20. [Google Scholar]

- Braic, M.; Braic, V.; Balaceanu, M.; Kiss, A.; Cotrut, C.; Drobe, P.; Vladescu, A.; Vasilescu, C. On some characteristics of Ti oxynitrides obtained by pulsed magnetron sputtering. Plasma Process. Polym. 2007, 4. [Google Scholar] [CrossRef]

- Ahmed, M.; Xinxin, G. A review of metal oxynitrides for photocatalysis. Inorg. Chem. Front. 2016, 3, 578–590. [Google Scholar] [CrossRef]

- Asahi, R.; Morikawa, T.; Ohwaki, T.; Aoki, K.; Taga, Y. Visible-light photocatalysis in nitrogen-doped titanium oxides. Science 2001, 293, 269–271. [Google Scholar] [CrossRef]

- El-Fattah, H.A.A.; El-Mahallawi, I.S.; Shazly, M.H.; Khalifa, W.A. Optical properties and microstructure of TiNxOy and TiN thin films before and after annealing at different conditions. Coatings 2019, 9, 22. [Google Scholar] [CrossRef] [Green Version]

- Dunn, D.S. An electrochemical approach to predicting longterm localized corrosion of corrosion-resistant high-level waste container materials. Corrosion 2000, 56, 90–104. [Google Scholar] [CrossRef]

- Tsyganov, I.A.; Maitz, M.F.; Richter, E.; Reuther, H.; Mashina, A.I.; Rustichelli, F. Hemocompatibility of titanium-based coatings prepared by metal plasma immersion ion implantation and deposition. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2007, 257, 122–127. [Google Scholar] [CrossRef]

- Venkataraj, S.; Severin, D.; Mohamed, S.H.; Ngaruiya, J.; Kappertz, O.; Wuttig, M. Towards understanding the superior properties of transition metal oxynitrides prepared by reactive DC magnetron sputtering. Thin Solid Film. 2006, 502, 228–234. [Google Scholar] [CrossRef]

- Colović, B.; Kisić, D.; Jokanović, B.; Rakočević, Z.; Nasov, I.; Petkoska, A.T.; Jokanović, V. Wetting properties of titanium oxides, oxynitrides and nitrides obtained by DC and pulsed magnetron sputtering and cathodic arc evaporation. Mater. Sci. Pol. 2019, 37, 173–181. [Google Scholar] [CrossRef] [Green Version]

- Braic, V.; Zoita, C.N.N.; Balaceanu, M.; Kiss, A.; Vladescu, A.; Popescu, A.; Braic, M. TiAlN/TiAlZrN multilayered hard coatings for enhanced performance of HSS drilling tools. Surf. Coat. Technol. 2010, 204, 1925–1928. [Google Scholar] [CrossRef]

- Sadeghimeresht, E. Electrochemical Behavior of Bilayer Thermal-Spray Coatings in Low-Temperature Corrosion Protection. Coatings 2017, 7, 162. [Google Scholar] [CrossRef] [Green Version]

- Dinu, M.; Mouele, E.S.M.; Parau, A.C.; Vladescu, A.; Petrik, L.F.; Braic, M. Enhancement of the corrosion resistance of 304 stainless steel by Cr-N and Cr(N,O) coatings. Coatings 2018, 8, 132. [Google Scholar] [CrossRef] [Green Version]

- Alegría-Ortega, J.; Ocampo-Carmona, L.M.; Rodríguez, F.; Forlerer, E. Cr/CrN bilayer coating behavior under erosion-corrosion degradation by jet impingement testing Comportamiento de un recubrimiento bicapa de Cr/CrN bajo degradación por erosión-corrosión por ensayo de impacto con chorro. Dyna 2016, 83, 146–153. [Google Scholar] [CrossRef]

- Braic, M.; Balaceanu, M.; Vladescu, A.; Kiss, A.; Braic, V.; Purice, A.; Dinescu, G.; Scarisoreanu, N.; Stokker-Cheregi, F.; Moldovan, A.; et al. TiN/ZrN heterostructures deposition and characterisation. Surf. Coat. Technol. 2006, 200. [Google Scholar] [CrossRef]

- Boveris, A.; Oshino, N.; Chance, B. The cellular production of hydrogen peroxide. Biochem. J. 1972, 128, 617–630. [Google Scholar] [CrossRef]

- Halliwell, B.; Clement, M.V.; Long, L.H. Hydrogen peroxide in the human body. FEBS Lett. 2000, 486, 10–13. [Google Scholar] [CrossRef] [Green Version]

- Satoh, T.; Uchida, S.; Sugama, J.I.; Yamashiro, N.; Hirose, T.; Morishima, Y.; Satoh, Y.; Iinuma, K. Effects of hydrogen peroxide on corrosion of stainless steel, (I) improved control of hydrogen peroxide remaining in a high temperature high pressure hydrogen peroxide loop. J. Nucl. Sci. Technol. 2004, 41, 610–618. [Google Scholar] [CrossRef]

- Al Kharafi, F.M.; Ghayad, I.M.; Abdullah, R.M. Effect of hydrogen peroxide on the dezincification of brass in acidified sodium sulfate solution under free corrosion conditions. J. Mater. Environ. Sci. 2010, 1, 58–69. [Google Scholar]

- Zhang, Y.; Addison, O.; Yu, F.; Troconis, B.C.R.; Scully, J.R.; Davenport, A.J. Time-dependent enhanced corrosion of Ti6Al4V in the presence of H2O2and albumin. Sci. Rep. 2018, 8, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Dinu, M.; Hauffman, T.; Cordioli, C.; Vladescu, A.; Braic, M.; Hubin, A.; Cotrut, C.M.C.M. Protective performance of Zr and Cr based silico-oxynitrides used for dental applications by means of potentiodynamic polarization and odd random phase multisine electrochemical impedance spectroscopy. Corros. Sci. 2017, 115, 118–128. [Google Scholar] [CrossRef]

- Braic, L.; Zoita, N.C. Influence of the deposition time and temperature on the texture of InN thin films grown by RF-magnetron sputtering. Optoelectron. Adv. Mater. Rapid Commun. 2010, 4, 2013–2017. [Google Scholar]

- Deutsches Institut fur Normung E.V. Norm Advanced Technical Ceramics—Methods of Test for Ceramic Coatings—Part 3: Determination of Adhesion and Other Mechanical Failure Modes by a Scratch Test; DIN: Berlin, Germany, 2003. [Google Scholar]

- Pace, M.T.; Thomson, R.C.; Wells, J.; Peterson, W.; Gould, J.E.; Barnes, D.J.; American Society for Testing and Materials; Paul, S. ASTM C1624-05: Standard Test Method for Adhesion Strength and Mechanical Failure Modes of Ceramic by Quantitative Single Point Scratch Testing. Coatings 2015. [Google Scholar] [CrossRef]

- Stern, M.; Geary, L. Electrochemical polarization I. A theoritical analysis of the shape of polarization curves. J. Electrochem. Soc. 1957, 104, 56–63. [Google Scholar] [CrossRef]

- Pruncu, C.I.C.I.; Braic, M.; Dearn, K.D.K.D.; Farcau, C.; Watson, R.; Constantin, L.R.L.R.; Balaceanu, M.; Braic, V.; Vladescu, A. Corrosion and tribological performance of quasi-stoichiometric titanium containing carbo-nitride coatings. Arab. J. Chem. 2017, 10, 1015–1028. [Google Scholar] [CrossRef]

- Vladescu, A.; Vranceanu, D.M.D.M.; Kulesza, S.; Ivanov, A.N.A.N.; Bramowicz, M.; Fedonnikov, A.S.A.S.; Braic, M.; Norkin, I.A.I.A.; Koptyug, A.; Kurtukova, M.O.M.O.; et al. Influence of the electrolyte’s pH on the properties of electrochemically deposited hydroxyapatite coating on additively manufactured Ti64 alloy. Sci. Rep. 2017, 7, 1–20. [Google Scholar] [CrossRef]

- Dudin, S.; Cotrut, C.M.; Dinu, M.; Zykova, A.; Parau, A.C.; Yakovin, S.; Vladescu, A. Comparative study of the hydroxyapatite coatings prepared with/without substrate bias. Ceram. Int. 2017, 43, 14968–14975. [Google Scholar] [CrossRef]

- International Centre for Diffraction Data. Powder Diffraction File: 04-017-6803, JCPDS; ICCD: Delaware County, PA, USA, 2010. [Google Scholar]

- Scherrer, P. Bestimmung der Grosse und der Inneren Struktur von Kolloidteilchen Mittels Rontgenstrahlen. Nachrichten von der Gesellschaft der Wissenschaften, Gottingen, Mathematisch-Physikalische Klasse 1918, 1918, 98–100. [Google Scholar]

- Huang, C.N.; Bow, J.S.; Zheng, Y.; Chen, S.Y.; Ho, N.J.; Shen, P. Nonstoichiometric titanium oxides via pulsed laser ablation in water. Nanoscale Res. Lett. 2010, 5, 972–985. [Google Scholar] [CrossRef] [Green Version]

- Jokanović, V.; Čolović, B.; Bundaleski, N.; Jokanović, M.; Petkoska, A.T.; Ferrara, M.; Nasov, I.; Rakočević, Z. TixOy thin films with extremely low extinction coefficients obtained by pulsed magnetron sputtering. J. Optoelectron. Adv. Mater. 2018, 20, 169–174. [Google Scholar]

- Wennerberg, A.; Albrektsson, T. Suggested guidelines for the topographic evaluation of implant surfaces. Int. J. Oral. Maxillofac. Implant. 2000, 15, 331–344. [Google Scholar]

- Mendonça, G.; Mendonça, D.B.S.; Aragão, F.J.L.; Cooper, L.F. Advancing dental implant surface technology—From micron- to nanotopography. Biomaterials 2008, 29, 3822–3835. [Google Scholar] [CrossRef] [PubMed]

- Webster, T.J.; Ejiofor, J.U. Increased osteoblast adhesion on nanophase metals: Ti, Ti6Al4V, and CoCrMo. Biomaterials 2004, 25, 4731–4739. [Google Scholar] [CrossRef]

- Hao, L.; Lawrence, J.; Phua, Y.F.; Chian, K.S.; Lim, G.C.; Zheng, H.Y. Enhanced human osteoblast cell adhesion and proliferation on 316 LS stainless steel by means of CO2 laser surface treatment. J. Biomed. Mater. Res. Part B Appl. Biomater. 2005, 73, 148–156. [Google Scholar] [CrossRef]

- Abadias, G.; Michel, A.; Tromas, C.; Jaouen, C.; Dub, S.N. Stress, interfacial effects and mechanical properties of nanoscale multilayered coatings. Surf. Coat. Technol. 2007, 202, 844–853. [Google Scholar] [CrossRef]

- Samal, S.; Tyc, O.; Heller, L.; Šittner, P.; Malik, M.; Poddar, P.; Catauro, M.; Blanco, I. Study of interfacial adhesion between nickel-titanium shape memory alloy and a polymer matrix by laser surface pattern. Appl. Sci. 2020, 10, 2172. [Google Scholar] [CrossRef] [Green Version]

- Helmersson, U.; Todorova, S.; Barnett, S.A.; Sundgren, J.E.; Markert, L.C.; Greene, J.E. Growth of single-crystal TiN/VN strained-layer superlattices with extremely high mechanical hardness. J. Appl. Phys. 1987, 62, 481–484. [Google Scholar] [CrossRef]

- Mirkarimi, P.B.; Hultman, L.; Barnett, S.A. Enhanced hardness in lattice-matched single-crystal TiN/V 0.6Nb0.4N superlattices. Appl. Phys. Lett. 1990, 57, 2654–2656. [Google Scholar] [CrossRef]

- Wiberg, N.; Holleman, A.F.; Wiberg, E. Inorganic Chemistry; Wiberg, N., Ed.; Academic Press: San Diego, CA, USA; New York, NY, USA; De Gruyter: Berlin, Germany; San Diego, CA, USA; New York, NY, USA, 2001. [Google Scholar]

- Velasco, L.; Olaya, J.J.; Rodil, S.E. Effect of Si addition on the structure and corrosion behavior of NbN thin films deposited by unbalanced magnetron sputtering. Appl. Phys. A Mater. Sci. Process. 2016, 122, 1–10. [Google Scholar] [CrossRef]

- Zhang, X.G. Corrosion potential and corrosion current. In Corrosion and Electrochemistry of Zinc; Zhang, X.G., Ed.; Springer: Boston, MA, USA, 1996; pp. 125–156. ISBN 978-1-4757-9877-7. [Google Scholar]

- Ding, J.C.; Wang, Q.M.; Liu, Z.R.; Jeong, S.; Zhang, T.F.; Kim, K.H. Influence of bias voltage on the microstructure, mechanical and corrosion properties of AlSiN films deposited by HiPIMS technique. J. Alloy. Compd. 2019, 772, 112–121. [Google Scholar] [CrossRef]

- Kertzman, Z.; Marchal, J.; Suarez, M.; Staia, M.H.; Filip, P.; Kohli, P.; Aouadi, S.M. Mechanical, tribological, and biocompatibility properties of ZrN-Ag nanocomposite films. J. Biomed. Mater. Res. Part A 2008, 84, 1061–1067. [Google Scholar] [CrossRef]

- Pressouyre, G.M.; Bernstein, I.M. An example of the effect of hydrogen trapping on hydrogen embrittlement. Metall. Trans. A 1981, 12, 835–844. [Google Scholar] [CrossRef]

- Darken, L.S.; Smith, R.P. Behaviour of hydrogen in steel during and after immersion in acid. Corrosion 1948, 5, 1–16. [Google Scholar] [CrossRef]

- Kirkland, N.T.; Schiller, T.; Medhekar, N.; Birbilis, N. Exploring graphene as a corrosion protection barrier. Corros. Sci. 2012, 56, 1–4. [Google Scholar] [CrossRef]

- Ahmad, Z. Corrosion Kinetics. In Principles of Corrosion Engineering and Corrosion Control; Elsevier: Amsterdam, The Netherlands, 2006; pp. 57–119. [Google Scholar]

- Bunjongpru, W.; Porntheeraphat, S.; Somwang, N.; Khomdet, P.; Hruanun, C.; Poyai, A.; Nukeaw, J. Oxygen control on nanocrystal-AlON Films by reactive gas-timing technique RF magnetron sputtering and annealing effect. Adv. Mater. Res. 2008, 55–57, 573–576. [Google Scholar] [CrossRef]

- Cachet, H.; Debiemme-Chouvy, C.; Deslouis, C.; Lagrini, A.; Vivier, V. Correlation between electrochemical reactivity and surface chemistry of amorphous carbon nitride films. Surf. Interface Anal. 2006, 38, 719–722. [Google Scholar] [CrossRef]

- Park, I.T.; Kim, W.; Kim, E.J.; Bae, S.E.; Kim, J.Y.; Shin, H.C. Electrochemical reactivity of chemically roughened tungsten electrodes. Asian J. Chem. 2013, 25, 7037–7040. [Google Scholar] [CrossRef]

- Gira, M.J.; Tkacz, K.P.; Hampton, J.R. Physical and electrochemical area determination of electrodeposited Ni, Co, and NiCo thin films. Nano Converg. 2016, 3, 6. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sivakumar, B.; Pathak, L.C.; Singh, R. Role of surface roughness on corrosion and fretting corrosion behaviour of commercially pure titanium in Ringer’s solution for bio-implant application. Appl. Surf. Sci. 2017, 401, 385–398. [Google Scholar] [CrossRef]

- Rocha, L.A.; Ariza, E.; Ferreira, J.; Vaz, F.; Ribeiro, E.; Rebouta, L.; Alves, E.; Ramos, A.R.; Goudeau, P.; Rivière, J.P. Structural and corrosion behaviour of stoichiometric and substoichiometric TiN thin films. Surf. Coat. Technol. 2004, 180–181, 158–163. [Google Scholar] [CrossRef]

- Subramanian, B.; Ananthakumar, R.; Jayachandran, M. Structural and tribological properties of DC reactive magnetron sputtered titanium/titanium nitride (Ti/TiN) multilayered coatings. Surf. Coat. Technol. 2011, 205, 3485–3492. [Google Scholar] [CrossRef]

- Patel, N.S.; Menghani, J.; Pai, K.B.; Totlani, M.K. Corrosion behavior of Ti2N thin films in various corrosive environments. J. Mater. Environ. Sci. 2010, 1, 34–43. [Google Scholar]

- Li, S.; Fu, J. Improvement in corrosion protection properties of TiO2 coatings by chromium doping. Corros. Sci. 2013, 68, 101–110. [Google Scholar] [CrossRef]

- Hassannejad, H.; Shahrabi, T.; Malekmohammadi, F.; Shanaghi, A.; Aliofkhazraei, M.; Oskuie, A. Effect of cerium doping on corrosion resistance of amorphous silica-titanium sol-gel coating. Curr. Appl. Phys. 2010, 10, 1022–1028. [Google Scholar] [CrossRef]

- Sedira, S.; Achour, S.; Avci, A.; Eskizeybek, V. Physical deposition of carbon doped titanium nitride film by DC magnetron sputtering for metallic implant coating use. Appl. Surf. Sci. 2014, 295, 81–85. [Google Scholar] [CrossRef]

- Cicek, V. Corrosion Engineering; Tata McGraw-Hill Education: New York, NY, USA, 2014; ISBN 9781118720837. [Google Scholar]

- Hua, L.; Hou, H. Electrochemical migration behaviors of lead-free 64Sn-35Bi-1Ag solder on FR-4 PCB board plated with Cu. Wuhan Univ. J. Nat. Sci. 2012, 17, 79–85. [Google Scholar] [CrossRef]

- Mansour, S.F.; El-Dek, S.I.; Ahmed, M.K. Physico-mechanical and morphological features of zirconia substituted hydroxyapatite nano crystals. Sci. Rep. 2017, 7, 43202. [Google Scholar] [CrossRef] [Green Version]

- Qin, L.Y.; Lian, J.S.; Jiang, Q. Effect of grain size on corrosion behavior of electrodeposited bulk nanocrystalline Ni. Trans. Nonferrous Met. Soc. China 2010, 20, 82–89. [Google Scholar] [CrossRef]

- Escobar, C.A.; Caicedo, J.C.; Aperador, W. Corrosion resistant surface for vanadium nitride and hafnium nitride layers as function of grain size. J. Phys. Chem. Solids 2014, 75, 23–30. [Google Scholar] [CrossRef]

- Kinumoto, T.; Sou, Y.; Ono, K.; Matsuoka, M.; Arai, Y.; Tsumura, T.; Toyoda, M. Preparation of fibrous titania oxynitride—Carbon catalyst and oxygen reduction reaction analysis in both acidic and alkaline media. J. Power Sources 2015, 273, 136–141. [Google Scholar] [CrossRef] [Green Version]

| Substrate/Coating | Elemental Composition (at.%) | (O + N)/Ti | ||

|---|---|---|---|---|

| Ti | N | O | ||

| SS /TiN | 49.6 ± 1.2 | 50.4 ± 1.3 | – | 1.00 ± 0.05 |

| SS /TiNO | 49.7 ± 1.3 | 43.0 ± 1.0 | 7.3 ± 0.2 | 0.98 ± 0.08 |

| SS /TiN/TiNO | 49.4 ± 1.3 | 44.9 ± 1.2 | 5.7 ± 0.2 | 1.03 ± 0.08 |

| SS /TiNO/TiN | 49.3 ± 1.3 | 49.5 ± 1.3 | 1.2 ± 0.1 | 1.03 ± 0.09 |

| Coating | d (nm) |

|---|---|

| SS/TiN | 23.8 |

| SS/TiNO | 16.3 |

| SS/TiN/TiNO | 19.9 |

| SS/TiNO/TiN | 22.1 |

| Substrate/Coating | Eoc (mV) | Ecorr (mV) | icorr (µA/cm2) | Rp (k·Ω) | P | Pe (%) |

|---|---|---|---|---|---|---|

| SS | 18 | 34 | 14.689 | 1.703 | – | – |

| SS/TiN | 205 | 101 | 7.734 | 5.981 | 0.247 | 47.3 |

| SS/TiNO | 227 | 164 | 3.385 | 12.150 | 0.107 | 77.0 |

| SS/TiN/TiNO | 243 | 126 | 3.723 | 7.170 | 0.196 | 74.7 |

| SS/TiNO/TiN | 214 | 123 | 6.630 | 6.450 | 0.219 | 54.9 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pana, I.; Braic, V.; Dinu, M.; Mouele, E.S.M.; Parau, A.C.; Petrik, L.F.; Braic, M. In Vitro Corrosion of Titanium Nitride and Oxynitride-Based Biocompatible Coatings Deposited on Stainless Steel. Coatings 2020, 10, 710. https://doi.org/10.3390/coatings10080710

Pana I, Braic V, Dinu M, Mouele ESM, Parau AC, Petrik LF, Braic M. In Vitro Corrosion of Titanium Nitride and Oxynitride-Based Biocompatible Coatings Deposited on Stainless Steel. Coatings. 2020; 10(8):710. https://doi.org/10.3390/coatings10080710

Chicago/Turabian StylePana, Iulian, Viorel Braic, Mihaela Dinu, Emile S. Massima Mouele, Anca C. Parau, Leslie F. Petrik, and Mariana Braic. 2020. "In Vitro Corrosion of Titanium Nitride and Oxynitride-Based Biocompatible Coatings Deposited on Stainless Steel" Coatings 10, no. 8: 710. https://doi.org/10.3390/coatings10080710

APA StylePana, I., Braic, V., Dinu, M., Mouele, E. S. M., Parau, A. C., Petrik, L. F., & Braic, M. (2020). In Vitro Corrosion of Titanium Nitride and Oxynitride-Based Biocompatible Coatings Deposited on Stainless Steel. Coatings, 10(8), 710. https://doi.org/10.3390/coatings10080710