Chemical Solution Deposition of YBCO Films with Gd Excess

Abstract

:1. Introduction

2. Materials and Methods

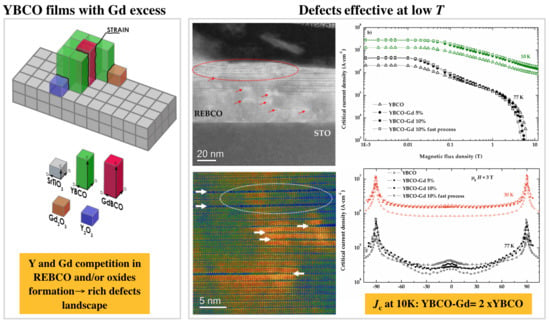

3. Results and Discussion

3.1. Structural Properties and Morphology

3.2. Superconducting Properties

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Erbe, M.; Cayado, P.; Freitag, W.; Ackermann, K.; Langer, M.; Meledin, A.; Hänisch, J.; Holzapfel, B. Comparative study of CSD-grown REBCO films with different rare earth elements: Processing windows and Tc. Supercond. Sci. Technol. 2020. [Google Scholar] [CrossRef]

- Lao, M.; Willa, R.; Meledin, A.; Rijckaert, H.; Chepikov, V.; Lee, S.; Petrykin, V.; Driessche, I.V.; Molodyk, A.; Holzapfel, B.; et al. In-field performance and flux pinning mechanism of pulsed laser deposition grown BaSnO3/GdBa2Cu3O7−$\updelta$ nanocomposite coated conductors by SuperOx. Supercond. Sci. Technol. 2019, 32, 094003. [Google Scholar] [CrossRef]

- Wang, Y.; Xu, D.; Li, Y.; Liu, L. Dependencies of microstructure and stress on the thickness of GdBa2Cu3O7 −δ thin films fabricated by RF sputtering. Nanoscale Res. Lett. 2013, 8, 304. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Oh, W.-J.; Park, I.; Lee, J.-H.; Lee, H.; Moon, S.-H.; Shinde, K.; Chung, K.; Yoo, S.-I. The post-annealing effect on the pinning properties of GdBa2Cu3O7−δ coated conductors via RCE-DR. IEEE Trans. Appl. Supercond. 2018, 28, 1–5. [Google Scholar] [CrossRef]

- Cayado, P.; Mundet, B.; Eloussifi, H.; Vallés, F.; Coll, M.; Ricart, S.; Gázquez, J.; Palau, A.; Roura, P.; Farjas, J.; et al. Epitaxial superconducting GdBa2Cu3O7−δ/Gd2O3 nanocomposite thin films from advanced low-fluorine solutions. Supercond. Sci. Technol. 2017, 30, 125010. [Google Scholar] [CrossRef] [Green Version]

- Erbe, M.; Hänisch, J.; Hühne, R.; Freudenberg, T.; Kirchner, A.; Molina-Luna, L.; Damm, C.; Van Tendeloo, G.; Kaskel, S.; Schultz, L.; et al. BaHfO3 artificial pinning centres in TFA-MOD-derived YBCO and GdBCO thin films. Supercond. Sci. Technol. 2015, 28, 114002. [Google Scholar] [CrossRef]

- Pop, C.; Villarejo, B.; Pino, F.; Mundet, B.; Ricart, S.; de Palau, M.; Puig, T.; Obradors, X. Growth of all-chemical high critical current YBa2Cu3O7−$\updelta$ thick films and coated conductors. Supercond. Sci. Technol. 2018, 32, 015004. [Google Scholar] [CrossRef]

- Lee, J.-W.; Choi, S.-M.; Song, J.-H.; Lee, J.-H.; Moon, S.-H.; Yoo, S.-I. Stability phase diagram of GdBa2Cu3O7−δ in low oxygen pressures. J. Alloy. Compd. 2014, 602, 78–86. [Google Scholar] [CrossRef]

- Iguchi, T.; Araki, T.; Yamada, Y.; Hirabayashi, I.; Ikuta, H. Fabrication of Gd Ba Cu O films by the metal organic deposition method using trifluoroacetates. Supercond. Sci. Technol. 2002, 15, 1415–1420. [Google Scholar] [CrossRef]

- Cayado, P.; Erbe, M.; Kauffmann-Weiss, S.; Bühler, C.; Jung, A.; Hänisch, J.; Holzapfel, B. Large critical current densities and pinning forces in CSD-grown superconducting GdBa2Cu3O7−x-BaHfO3 nanocomposite films. Supercond. Sci. Technol. 2017, 30, 094007. [Google Scholar] [CrossRef]

- Sun, M.J.; Liu, W.Q.; He, K.; Liu, Z.Y.; Chen, S.G.; Cai, C.B. Orientation behavior and mechanism of Ag-doped GdBa2Cu3O7−δ superconducting thin films derived by metal organic deposition. J. Supercond. Nov. Magn. 2018, 31, 3159–3162. [Google Scholar] [CrossRef]

- Xu, A.; Delgado, L.; Khatri, N.; Liu, Y.; Selvamanickam, V.; Abraimov, D.; Jaroszynski, J.; Kametani, F.; Larbalestier, D.C. Strongly enhanced vortex pinning from 4 to 77 K in magnetic fields up to 31 T in 15 mol.% Zr-added (Gd, Y)-Ba-Cu-O superconducting tapes. APL Mater. 2014, 2, 046111. [Google Scholar] [CrossRef] [Green Version]

- Miura, M.; Kato, T.; Yoshizumi, M.; Yamada, Y.; Izumi, T.; Hirayama, T.; Shiohara, Y. Rare earth substitution effects and magnetic field dependence of critical current in Y1−xRExBa2Cu3Oy coated conductors with nanoparticles (RE=Sm, Gd). Appl. Phys. Express 2009, 2, 023002. [Google Scholar] [CrossRef]

- Nakaoka, K.; Yoshida, R.; Sato, M.; Ibi, A.; Machi, T.; Izumi, T. Optimization of interim heat-treatment condition on TFA-MOD process for fabrication of Y0.77Gd0.23Ba2Cu3Oy coated conductors with BaHfO3. J. Phys. Conf. Ser. 2019, 1293, 012035. [Google Scholar] [CrossRef]

- Dong, Z.; Ding, F.; Zhang, H.; Shang, H.; Huang, D.; Xu, W.; Li, T.; Zou, Q.; Gu, H. Preparation of high performance YGdBCO films by low fluorine TFA-MOD process. J. Rare Earths 2020, 38, 755–762. [Google Scholar] [CrossRef]

- Jian, H.; Shao, D.; Yang, Z.; Zhu, X.; Sun, Y. Jc enhancement and flux pinning in Y1−xGdxBCO and (Gd, Eu) codoped Y0.9−yEuyGd0.1BCO thin films by TFA-MOD. Phys. C Supercond. 2013, 488, 39–45. [Google Scholar] [CrossRef]

- Miura, M.; Maiorov, B.; Baily, S.A.; Haberkorn, N.; Willis, J.O.; Marken, K.; Izumi, T.; Shiohara, Y.; Civale, L. Mixed pinning landscape in nanoparticle-introduced YGdBa2Cu3Oy films grown by metal organic deposition. Phys. Rev. B 2011, 83, 184519. [Google Scholar] [CrossRef]

- Cayado, P.; Erbe, M.; Kauffmann-Weiss, S.; Jung, A.; Hänisch, J.; Holzapfel, B. Chemical solution deposition of Y1−xGdxBa2Cu3O7−δ–BaHfO3 nanocomposite films: Combined influence of nanoparticles and rare-earth mixing on growth conditions and transport properties. RSC Adv. 2018, 8, 42398–42404. [Google Scholar] [CrossRef] [Green Version]

- Xu, S.; Wu, X.S.; Ma, G.B.; Wang, Z.H.; Gao, J. Effects of Gd2O3 addition in YBa2Cu3O7−δ on the critical current density. J. Appl. Phys. 2008, 103, 07C714. [Google Scholar] [CrossRef]

- Li, C.S.; Jin, L.H.; Yu, Z.M.; Zhang, S.N.; Lu, Y.F.; Feng, J.Q.; Wang, Y.; Zhang, P.X. Enhanced flux pinning in YGdBCO film grown by sol–gel approach. J. Sol-Gel Sci. Technol. 2014, 70, 67–71. [Google Scholar] [CrossRef]

- Cayado, P. Multifunctional Nanostructured Superconductors by Chemical Routes: Towards High Current Conductors. Ph.D. Thesis, Barcelona Autonomous University, Barcelona, Spain, 2016. [Google Scholar]

- Obradors, X.; Puig, T.; Li, Z.; Pop, C.; Mundet, B.; Chamorro, N.; Vallés, F.; Coll, M.; Ricart, S.; Vallejo, B.; et al. Epitaxial YBa2Cu3O7−x nanocomposite films and coated conductors from Ba M O3 (M = Zr, Hf) colloidal solutions. Supercond. Sci. Technol. 2018, 31, 044001. [Google Scholar] [CrossRef] [Green Version]

- De Keukeleere, K.; Cayado, P.; Meledin, A.; Vallès, F.; De Roo, J.; Rijckaert, H.; Pollefeyt, G.; Bruneel, E.; Palau, A.; Coll, M.; et al. Superconducting YBa2Cu3O7−δ nanocomposites using preformed ZrO2 nanocrystals: Growth mechanisms and vortex pinning properties. Adv. Electron. Mater. 2016, 2, 1600161. [Google Scholar] [CrossRef] [Green Version]

- Coll, M.; Guzman, R.; Garcés, P.; Gazquez, J.; Rouco, V.; Palau, A.; Ye, S.; Magen, C.; Suo, H.; Castro, H.; et al. Size-controlled spontaneously segregated Ba2YTaO6 nanoparticles in YBa2Cu3O7 nanocomposites obtained by chemical solution deposition. Supercond. Sci. Technol. 2014, 27, 044008. [Google Scholar] [CrossRef]

- Prado, F.; Caneiro, A.; Serquis, A. High temperature thermodynamic properties, orthorhombic/tetragonal transition and phase stability of GdBa2Cu3Oy and related R123 compounds. Phys. C Supercond. Appl. 1998, 295, 235–246. [Google Scholar] [CrossRef]

- Adachi, G.; Imanaka, N. The Binary Rare Earth Oxides. Chem. Rev. 1998, 98, 1479–1514. [Google Scholar] [CrossRef] [PubMed]

- Eyring, L. Chapter 27 The binary rare earth oxides. In Handbook on the Physics and Chemistry of Rare Earths; Elsevier: Amsterdam, The Netherlands, 1979; Volume 3, pp. 337–399. ISBN 978-0-444-85215-1. [Google Scholar]

- Meledin, A.; Turner, S.; Cayado, P.; Mundet, B.; Solano, E.; Ricart, S.; Ros, J.; Puig, T.; Obradors, X.; Van Tendeloo, G. Unique nanostructural features in Fe, Mn-doped YBCO thin films. Supercond. Sci. Technol. 2016, 29, 125009. [Google Scholar] [CrossRef] [Green Version]

- Pinto, V.; Lamanna, R.; Vannozzi, A.; Angrisani Armenio, A.; De Marzi, G.; Augieri, A.; Piperno, L.; Sotgiu, G.; Celentano, G. Solution Refining for MOD-YBCO Optimization: An NMR Study. IEEE Trans. Appl. Supercond. 2018, 28, 1–5. [Google Scholar] [CrossRef]

- Anthony, M.T. Spectrometer calibration. In Practical Surface Analysis by Auger and X-ray Photoelectron Spectroscopy; Briggs, D., Seah, M.P., Eds.; John Wiley and Sons: Hoboken, NJ, USA, 1983; pp. 429–435. [Google Scholar]

- Kovács, A.; Schierholz, R.; Tillmann, K. FEI Titan G2 80-200 CREWLEY. J. Large-Scale Res. Facil. JLSRF 2016, 2, 43. [Google Scholar] [CrossRef] [Green Version]

- Heggen, M.; Luysberg, M.; Tillmann, K. FEI Titan 80-300 STEM. J. Large-Scale Res. Facil. JLSRF 2016, 2, 42. [Google Scholar] [CrossRef] [Green Version]

- Bean, C.P. Magnetization of High-Field Superconductors. Rev. Mod. Phys. 1964, 36, 31–39. [Google Scholar] [CrossRef]

- Santoni, A.; Rondino, F.; Piperno, L.; Armenio Angrisani, A.; Pinto, V.; Mancini, A.; Augieri, A.; Frolova, A.; Rufoloni, A.; Vannozzi, A.; et al. Zirconium distribution in solution-derived BaZrO3-YBa2Cu3O7−δ epitaxial thin films studied by X-ray photoelectron spectroscopy. Thin Solid Films 2019, 669, 531–536. [Google Scholar] [CrossRef]

- Mote, V.; Purushotham, Y.; Dole, B. Williamson-Hall analysis in estimation of lattice strain in nanometer-sized ZnO particles. J. Theor. Appl. Phys. 2012, 6, 2–9. [Google Scholar] [CrossRef] [Green Version]

- Piperno, L.; Vannozzi, A.; Pinto, V.; Angrisani Armenio, A.; Rondino, F.; Santoni, A.; Mancini, A.; Rufoloni, A.; Augieri, A.; Tortora, L.; et al. Interaction between untreated SrTiO3 substrates and solution-derived YBa2Cu3O7-δ films. Appl. Surf. Sci. 2020, 528, 146402. [Google Scholar] [CrossRef]

- Barreca, D.; Gasparotto, A.; Milanov, A.; Tondello, E.; Devi, A.; Fischer, R.A. Gd2O3 Nanostructured Thin Films Analyzed by XPS. Surf. Sci. Spectra 2007, 14, 60–67. [Google Scholar] [CrossRef]

- Jeon, S.; Hwang, H. Effect of hygroscopic nature on the electrical characteristics of lanthanide oxides (Pr2O3, Sm2O3, Gd2O3, and Dy2O3). J. Appl. Phys. 2003, 93, 6393–6395. [Google Scholar] [CrossRef]

- Santoni, A.; Pinto, V.; Masi, A.; Cayado, P.; Celentano, G. Gd nanoinclusions in epitaxial YBCO thin films studied by X-ray Photoelectron Spectroscopy. 2020; in press. [Google Scholar]

- Guzman, R.; Gazquez, J.; Mundet, B.; Coll, M.; Obradors, X.; Puig, T. Probing localized strain in solution-derived YBa2Cu3O7−δ nanocomposite thin films. Phys. Rev. Mater. 2017, 1, 024801. [Google Scholar] [CrossRef]

- Gazquez, J.; Guzman, R.; Mishra, R.; Bartolomé, E.; Salafranca, J.; Magén, C.; Varela, M.; Coll, M.; Palau, A.; Valvidares, S.M.; et al. Emerging Diluted Ferromagnetism in High-Tc Superconductors Driven by Point Defect Clusters. Adv. Sci. 2016, 3, 1500295. [Google Scholar] [CrossRef] [Green Version]

- Palau, A.; Vallès, F.; Rouco, V.; Coll, M.; Li, Z.; Pop, C.; Mundet, B.; Gàzquez, J.; Guzman, R.; Gutierrez, J.; et al. Disentangling vortex pinning landscape in chemical solution deposited superconducting YBa2Cu3O7−x films and nanocomposites. Supercond. Sci. Technol. 2018, 31, 034004. [Google Scholar] [CrossRef]

- Bartolomé, E.; Alcalà, J.; Vallès, F.; Puig, T.; Obradors, X.; Pompeo, N.; Alimenti, A.; Torokhtii, K.; Rizzo, F.; Augieri, A.; et al. Vortex pinning properties at dc and microwave frequencies of YBa2Cu3O7−x films with nanorods and nanoparticles. Supercond. Sci. Technol. 2020, 33, 074006. [Google Scholar] [CrossRef]

- Li, Z.; Coll, M.; Mundet, B.; Chamorro, N.; Vallès, F.; Palau, A.; Gazquez, J.; Ricart, S.; Puig, T.; Obradors, X. Control of nanostructure and pinning properties in solution deposited YBa2Cu3O7−x nanocomposites with preformed perovskite nanoparticles. Sci. Rep. 2019, 9, 5828. [Google Scholar] [CrossRef]

- MacManus-Driscoll, J.L.; Foltyn, S.R.; Jia, Q.X.; Wang, H.; Serquis, A.; Maiorov, B.; Civale, L.; Lin, Y.; Hawley, M.E.; Maley, M.P.; et al. Systematic enhancement of in-field critical current density with rare-earth ion size variance in superconducting rare-earth barium cuprate films. Appl. Phys. Lett. 2004, 84, 5329–5331. [Google Scholar] [CrossRef]

- Civale, L.; Maiorov, B.; Serquis, A.; Willis, J.O.; Coulter, J.Y.; Wang, H.; Jia, Q.X.; Arendt, P.N.; MacManus-Driscoll, J.L.; Maley, M.P.; et al. Angular-dependent vortex pinning mechanisms in YBa2Cu3O7 coated conductors and thin films. Appl. Phys. Lett. 2004, 84, 2121–2123. [Google Scholar] [CrossRef] [Green Version]

- Rouco, V.; Palau, A.; Guzman, R.; Gazquez, J.; Coll, M.; Obradors, X.; Puig, T. Role of twin boundaries on vortex pinning of CSD YBCO nanocomposites. Supercond. Sci. Technol. 2014, 27, 125009. [Google Scholar] [CrossRef]

- Hayashi, M.; Araki, T.; Ishii, H.; Nishijima, G.; Matsumoto, A. Atom-replaced pins in a Y-based superconductor—Single-crystalline perovskite structure including both PrBa2Cu3O7−x and YBa2Cu3O7−y. Supercond. Sci. Technol. 2018, 31, 055013. [Google Scholar] [CrossRef]

- Pinto, V.; Celentano, G.; Tomellini, M. Heterogeneous nucleation of YBCO via fluorine based MOD process: thermodynamic and kinetic approach. Supercond. Sci. Technol. 2020, 33, 115006. [Google Scholar] [CrossRef]

| Lattice Parameter | YBCO | GdBCO | Y2O3 | Gd2O3 |

|---|---|---|---|---|

| a (Å) | 3.8230 (5) | 3.8416 (4) | 10.6021 | 10.8122 |

| b (Å) | 3.8857 (5) | 3.8984 (4) | - | - |

| c (Å) | 11.680 (2) | 11.707 (1) | - | - |

| V (Å3) | 173.5 | 175.32 | 1192 | 1264 |

| Sample | Process | Lattice Parameter c (Å) 1 | Grain Size (nm) | ε (%) |

|---|---|---|---|---|

| YBCO | Standard | 11.67 ± 0.01 | 77 ± 7 | 0.05 ± 0.01 |

| YBCO-Gd 5% | 11.67 ± 0.01 | 77 ± 3 | 0.07 ± 0.01 | |

| YBCO-Gd 10% | 11.67 ± 0.01 | 70 ± 5 | 0.07 ± 0.01 | |

| YBCO | 11.67 | 100 | 0.08 | |

| YBCO-Gd 5% | Fast | 11.68 | 80 | 0.06 |

| YBCO-Gd 10% | 11.67 | 80 | 0.09 |

| Temperature (K) | Applied Field (T) | Jc | YBCO 2 (MA·cm−2) | YBCO-Gd 5% (MA·cm−2) | YBCO-Gd 10% (MA·cm−2) |

|---|---|---|---|---|---|

| 77 | 0 | VSM I-V | 1.80 ± 0.59 2.26 ± 0.93 | 3.23 4.57 | 2.71 4.27 |

| 1 | VSM I-V | 0.10 ± 0.03 0.15 ± 0.04 | 0.11 0.16 | 0.10 0.16 | |

| 3 | VSM I-V | 0.02 ± 0.01 0.04 ± 0.01 | 0.03 0.04 | 0.01 0.03 | |

| 65 | 0 | VSM I-V | 3.81 ± 1.31 4.37 ± 1.76 | 6.69 9.22 | 6.05 8.94 |

| 1 | VSM I-V | 0.40 ± 0.12 0.55 ± 0.15 | 0.53 0.77 | 0.47 0.70 | |

| 3 | VSM I-V | 0.17 ± 0.05 0.25 ± 0.07 | 0.23 0.35 | 0.21 0.31 | |

| 9 | VSM I-V | 0.04 ± 0.02 0.08 ± 0.03 | 0.05 0.08 | 0.03 0.06 | |

| 10 | 0 | I-V | 13.3 ± 1.2 | 28.4 | 27.2 |

| 1 | I-V | 3.27 ± 0.42 | 5.47 | 5.73 | |

| 3 | I-V | 1.91 ± 0.44 | 2.97 | 3.04 | |

| 9 | I-V | 1.20 ± 0.32 | 1.70 | 1.65 |

| Sample | Tc (K)1 | H* (mT) | α | Fpmax (GN·m−3) | Hmax (T) | Hirr (T) | H* (mT) | α |

|---|---|---|---|---|---|---|---|---|

| 77 K | 10 K | |||||||

| YBCO | 90.2 ± 0.4 | 17.7 | 0.6 | 2.0 | 1.6 | 6.7 | 39 | 0.5 |

| YBCO-Gd 5% | 90.6 ± 0.2 | 13.7 | 0.6 | 1.8 | 1.5 | 6.5 | 31 | 0.5 |

| YBCO-Gd 10% | 90.3 ± 0.1 | 14.7 | 0.7 | 1.6 | 1.3 | 6.4 | 46 | 0.6 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pinto, V.; Vannozzi, A.; Angrisani Armenio, A.; Rizzo, F.; Masi, A.; Santoni, A.; Meledin, A.; Ferrarese, F.M.; Orlanducci, S.; Celentano, G. Chemical Solution Deposition of YBCO Films with Gd Excess. Coatings 2020, 10, 860. https://doi.org/10.3390/coatings10090860

Pinto V, Vannozzi A, Angrisani Armenio A, Rizzo F, Masi A, Santoni A, Meledin A, Ferrarese FM, Orlanducci S, Celentano G. Chemical Solution Deposition of YBCO Films with Gd Excess. Coatings. 2020; 10(9):860. https://doi.org/10.3390/coatings10090860

Chicago/Turabian StylePinto, Valentina, Angelo Vannozzi, Achille Angrisani Armenio, Francesco Rizzo, Andrea Masi, Antonino Santoni, Alexander Meledin, Fabrizio Mario Ferrarese, Silvia Orlanducci, and Giuseppe Celentano. 2020. "Chemical Solution Deposition of YBCO Films with Gd Excess" Coatings 10, no. 9: 860. https://doi.org/10.3390/coatings10090860

APA StylePinto, V., Vannozzi, A., Angrisani Armenio, A., Rizzo, F., Masi, A., Santoni, A., Meledin, A., Ferrarese, F. M., Orlanducci, S., & Celentano, G. (2020). Chemical Solution Deposition of YBCO Films with Gd Excess. Coatings, 10(9), 860. https://doi.org/10.3390/coatings10090860