On-Machine Measurement for Surface Flatness of Transparent and Thin Film in Laser Ablation Process

Abstract

:1. Introduction

2. Surface Flatness of Thin Film

2.1. Laser Ablation and Surface Flatness

2.2. Surface Flatness of Conductive Vacuum Chuck

2.3. Interplation of Surface Flatness of Thin Film

3. Experiment

3.1. Laser Ablation System

3.2. Interpolation and Surface Flatness

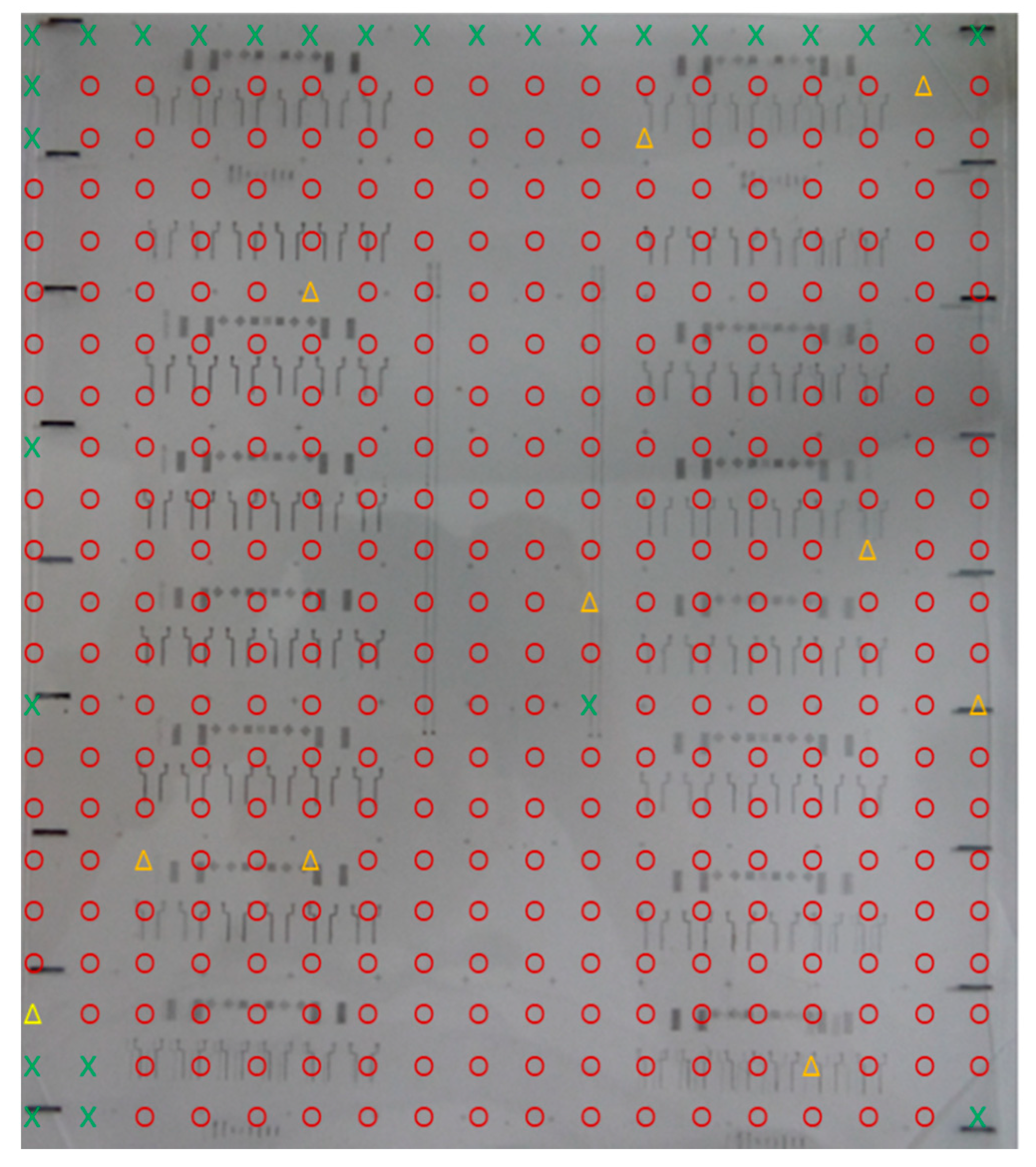

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A. Digital Focus Indices

| DFI | Formulation | Color |

| Brightness | - | |

| Contrast | - | |

| Variance | brown | |

| Squared Gradient (Δ = 1) | grey | |

| Brenner gradient (Δ = 2) | goldenrod | |

| Tenenbaum gradient | blue | |

| Energy Laplacian | dark green | |

| Histogram Entropy | - | |

| Thresholded Pixel Count | yellow | |

| Normalized Variance | - | |

| Derivative-based Correlation | lime | |

| Auto-correlation | - |

References

- Venkata Krishna, R.R.; Venkata Abhinav, K.; Kathik, P.S.; Surya Prakash, S. Conductive silver inks and their applications in printed and flexible electronics. RSC Adv. 2015, 2015, 77760–77790. [Google Scholar]

- Phillips, C.O.; Beynon, D.G.; Hamblyn, S.M.; Davies, G.R.; Gethin, D.T.; Claypole, T.C. A Study of the Abrasion of Squeegees Used in Screen Printing and Its Effect on Performance with Application in Printed Electronics. Coatings 2014, 4, 356–379. [Google Scholar] [CrossRef] [Green Version]

- Kang, D.; Kim, J.; Kim, I.; Choi, K.H.; Lee, T.M. Experimental Qualification of the Process of Electrostatic Spray Deposition. Coatings 2019, 9, 294. [Google Scholar] [CrossRef] [Green Version]

- Park, J.P.; Shin, K.; Lee, C. Roll-to-Roll Coating Technology and Its Applications: A Review. Int. J. Precis. Eng. Manuf. 2016, 17, 537–550. [Google Scholar] [CrossRef]

- Chen, S.; Chen, W.; Liu, J.; Chen, W. A roller posture adjustment device with remote-center-of-motion for roll-to-roll printed electronics. Precis. Eng. 2019, 56, 172–183. [Google Scholar] [CrossRef]

- Lu, B.H.; Lan, H.B.; Liu, H.Z. Additive manufacturing frontier: 3D printing electronics. Opto-Electron. Adv. 2018, 1, 170004. [Google Scholar] [CrossRef]

- Yu, J.H.; Kang, K.T.; Hwang, J.Y.; Lee, S.H.; Kang, H. Rapid Sintering of Copper Nano Ink Using a Laser in Air. Int. J. Precis. Eng. Manuf. 2014, 15, 1051–1054. [Google Scholar] [CrossRef]

- Kim, S.H.; Kang, H.; Kang, K.; Lee, S.H.; Cho, K.H.; Hwang, J.Y. Effect of Meniscus Damping Ratio on Drop-on-Demand Electrohydrodynamic Jetting. App. Sci. 2018, 8, 164. [Google Scholar] [CrossRef] [Green Version]

- Ram, O. Performance optimization of electronic circuits laser repair. In Proceedings of the SPIE LAMOM XIX, San Francisco, CA, USA, 1–6 February 2014; Volume 8967, p. 89671H. [Google Scholar]

- Seiler, A.L.; Chartier, I.; Laurent, J.Y.; Suhonen, R.; Hast, J.; Känsäkoski, M.; Petkov, P.; Blaudeck, T.; Baumann, R.R. Eximer laser ablation as industrial production tool for structuring ITO anodes for flexible OLEDs. In Proceedings of the LOPEC Conference, Frankfurt, Germany, 31 May–2 June 2010; pp. 1–4. [Google Scholar]

- Lee, K.; Ki, H. Fabrication and optimization of transparent conductive films using laser annealing and picosecond laser patterning. App. Surf. Sci. 2017, 420, 886–895. [Google Scholar] [CrossRef]

- IEC 62899-201 Edition 1.1 Printed Electronics—Part 201: Materials—Substrates. Available online: https://webstore.iec.ch/publication/64210 (accessed on 4 August 2020).

- Seong, J.; Kim, S.; Park, J.; Lee, D.; Shin, K.H. Online noncontact thickness measurement of printed conductive silver patterns in Roll-to-Roll gravure printing. Int. J. Precis. Eng. Manuf. 2015, 16, 2265–2270. [Google Scholar] [CrossRef]

- Choi, Y.M.; Yoo, H.; Kang, D. Large-area thickness measurement of transparent multi-layer films based on laser confocal reflection sensor. Measurement 2020, 153, 107390. [Google Scholar] [CrossRef]

- Bornemann, N.; Dörsam, E. A flatbed scanner for large-area thickness determination of ultra-thin layers in printed electronics. Opt. Exp. 2013, 21, 21897–21911. [Google Scholar] [CrossRef] [PubMed]

- Lee, C.; Kang, H.; Kim, H.; Nguyen, H.A.D.; Shin, K. Quality control with matching technology in roll to roll printed electronics. J. Mech. Sci. Technol. 2010, 24, 315–318. [Google Scholar] [CrossRef]

- Abbel, R.; Galagan, Y.; Groen, P. Roll-to-Roll Fabrication of Solution Processed Electronics. Adv. Eng. Mater. 2018, 20, 1701190. [Google Scholar] [CrossRef] [Green Version]

- Zou, X.; Zhao, X.; Li, G.; Li, Z.; Sun, T. Non-contact on-machine measurement using a chromatic confocal probe for an ultra-precision turning machine. Int. J. Adv. Manuf. Technol. 2017, 90, 2163–2172. [Google Scholar] [CrossRef]

- Xu, C.; Chen, L.; Yin, J. Method for absolute flatness measurement of optical surface. App. Opt. 2009, 48, 2536–2541. [Google Scholar] [CrossRef]

- Une, A.; Yoshitomi, K.; Mochida, M. Dynamic deformation of a wafer above a lift hole and influence on flatness due to chucking. Microelectron. Eng. 2011, 88, 2163–2166. [Google Scholar] [CrossRef]

- Mikkelson, A.; Engelstad, R.; Sohn, J.; Lovell, E. Effect of electrostatic chucking and film thickness uniformity on extreme ultraviolet lithography mask flatness. J. Vac. Sci. Technol. B 2004, 22, 3043. [Google Scholar] [CrossRef]

- Mane, V.V. An Effective Method to Reduce Smearing in Machining of Metallic Foams. Master’s Thesis, Iowa State University, Ames, IA, USA, 2016. [Google Scholar]

- Banhart, J. Manufacture, characterisation and application of cellular metals and metal foams. Prog. Mater. Sci. 2001, 46, 559–632. [Google Scholar] [CrossRef]

- Lee, C.C.; Huang, P.C.; Wang, K.S. Flexural Capability of Patterned Transparent Conductive Substrate by Performing Electrical Measurements and Stress Simulations. Materials 2016, 9, 850. [Google Scholar] [CrossRef] [Green Version]

- Kuwahara, K.; Taguchi, R.; Masayuki, K.; Akamatsu, N.; Tokumitsu, K.; Shishido, A. Experimental and theoretical analyses of curvature and surface strain in bent polymer films. Appl. Phys. Express 2020, 13, 056502. [Google Scholar] [CrossRef] [Green Version]

- Li, X.; Fan, B.; Jiang, H.; Zhao, H. Non-contact large-scale separated surfaces flatness measurement by using laser beam and laser distance sensor. In Proceedings of the SPIE icOPEN, Singapore, 14–16 April 2015; Volume 9524, p. 95241N. [Google Scholar]

- Hilfiker, J.N.; Stadermann, M.; Sun, J.; Tiwald, T.; Hale, J.S.; Miller, P.E.; Aracne-Ruddle, C. Determining thickness and refractive index from free-standing ultra-thin polymer films with spectroscopic ellipsometry. App. Surf. Sci. 2017, 421(Pt. B), 508–512. [Google Scholar] [CrossRef]

- Giusca, C.L.; Claverly, J.D.; Sun, W.; Leach, R.K.; Helmli, F.; Chavigner, M.P.J. Practical estimation of measurement noise and flatness deviation on focus variation microscopes. CIRP Ann. 2014, 63, 545–548. [Google Scholar] [CrossRef]

- Kim, H.T.; Cho, K.Y.; Kim, J.; Jin, K.C.; Kim, S.T. Robust Parameter Design of Derivative Optimization Methods for Image Acquisition Using a Color Mixer. J. Imaging 2017, 3, 31. [Google Scholar] [CrossRef]

- Yao, Y.; Abidi, B.; Doggaz, N.; Abidi, M. Evaluation of Sharpness Measures and Search Algorithms for the Auto-Focusing of High Magnification Images. In Proceedings of the SPIE Visual Information Processing XV, Orlando, FL, USA, 17–21 April 2006; Volume 6246, p. 6246G. [Google Scholar]

- Raghynanda, R.; Venkateswara Rao, P. Selection of sampling points for accurate evaluation of flatness error using coordinate measuring machine. J. Mater. Process. Technol. 2008, 202, 240–245. [Google Scholar] [CrossRef]

- Press, W.H.; Teukolsky, S.A.; Vetterling, W.T.; Flannery, B.P. Numerical Recipes in C—The Art of Scientific Computing, 2nd ed.; Cambridge University Press: Cambridge, UK, 1992; pp. 123–124. [Google Scholar]

- Chen, H.C.; Wang, W.J. Fuzzy-adapted linear interpolation algorithm for image zooming. Signal. Process. 2009, 89, 2490–2502. [Google Scholar] [CrossRef]

- Chen, L.W.; Yin, Y.M.; Li, Y.; Hong, M.H. Multifunctional inverse sensing by spatial distribution characterization of scattering photons. Opto-Electron. Adv. 2019, 2, 190019. [Google Scholar] [CrossRef] [Green Version]

| Components | Contents | Values |

|---|---|---|

| Linear stage | axis stroke (x/y/z) speed (x/y/z) accuracy (x/y/z) vacuum chuck size | 3 (dual x, y, z) 450/400/100 mm 500/500/100 mm ±2/±2/±2 μm 200 mm × 200 mm |

| Ablation head | image size frame rate FOV focus depth ablation depth mount camera interface light source | 1624 × 1236 pixels 50 frames/s 0.8 mm × 0.6 mm 10 μm 30 μm C-mount GigE RGBW mixing |

| Optical distance sensor | measuring range resolution measuring rate light source interface | 0–10 mm 0.15 μm 20 kHz 650 nm laser diode Ethernet |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, H.; Moon, Y.J.; Kang, H.; Hwang, J.Y. On-Machine Measurement for Surface Flatness of Transparent and Thin Film in Laser Ablation Process. Coatings 2020, 10, 885. https://doi.org/10.3390/coatings10090885

Kim H, Moon YJ, Kang H, Hwang JY. On-Machine Measurement for Surface Flatness of Transparent and Thin Film in Laser Ablation Process. Coatings. 2020; 10(9):885. https://doi.org/10.3390/coatings10090885

Chicago/Turabian StyleKim, HyungTae, Yoon Jae Moon, Heuiseok Kang, and Jun Yong Hwang. 2020. "On-Machine Measurement for Surface Flatness of Transparent and Thin Film in Laser Ablation Process" Coatings 10, no. 9: 885. https://doi.org/10.3390/coatings10090885

APA StyleKim, H., Moon, Y. J., Kang, H., & Hwang, J. Y. (2020). On-Machine Measurement for Surface Flatness of Transparent and Thin Film in Laser Ablation Process. Coatings, 10(9), 885. https://doi.org/10.3390/coatings10090885