The Influence of Drying Conditions of Clay-Based Polymer Coatings on Coated Paper Properties

Abstract

:1. Introduction

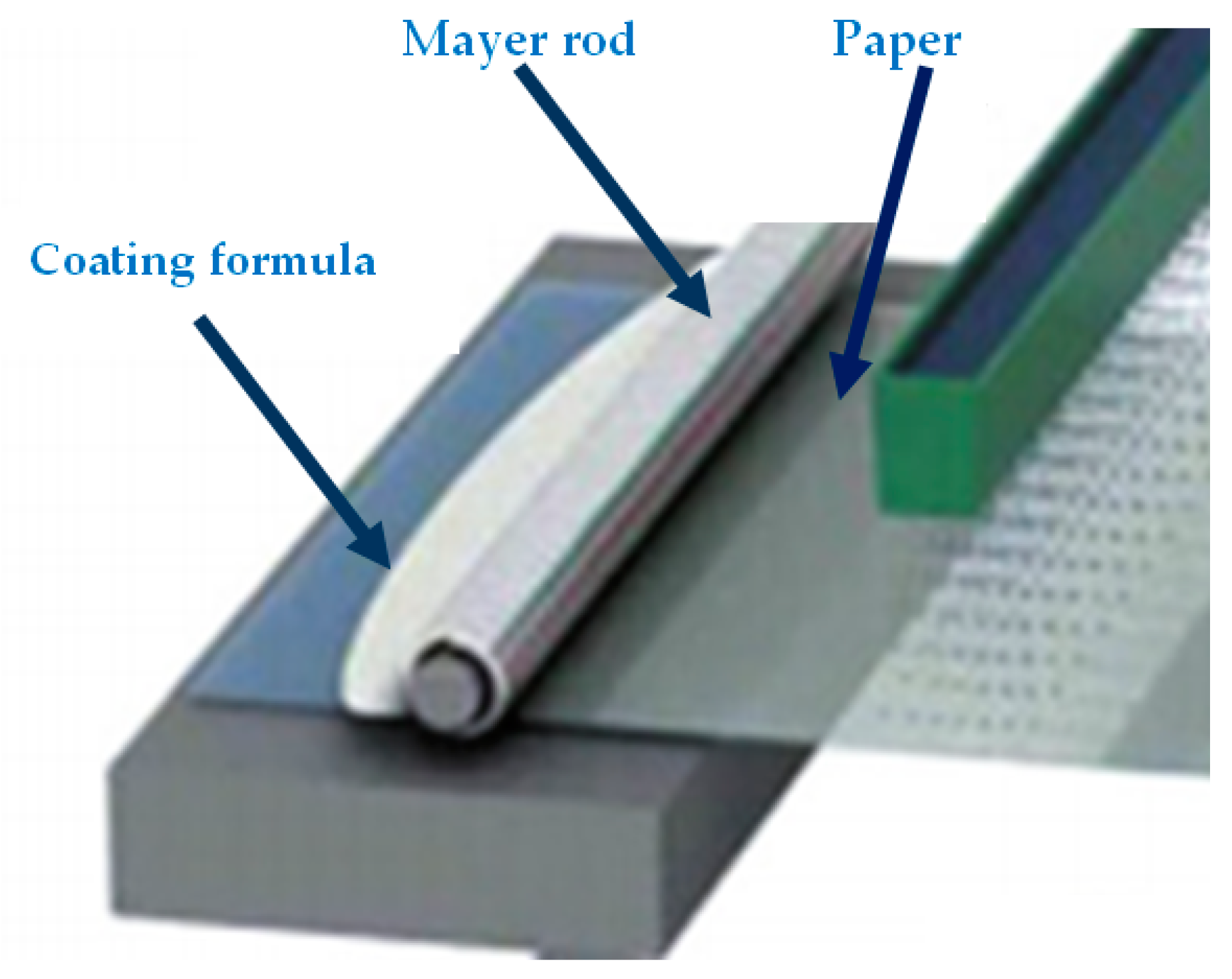

2. Materials and Methods

- Woil—the oil weight;

- ρoil—density of the silicon oil;

- A—the paper sample surface;

- p, L—pigment and latex;

- f—weight fraction of the component in the coating formula;

- Wc—the weight of coating layer per unit area;

- ρ—the density of each component.

- Vp—the volume of the oil absorbed in the base paper (calculated) with the Equation:

- f—fraction of fibers and filler in the base paper;

- W—the weight of fibres and filler per unit area;

- ρ—the density of fibres and filler;

- Va—the volume of air in the coating layer and the base paper.

3. Results and Discussion

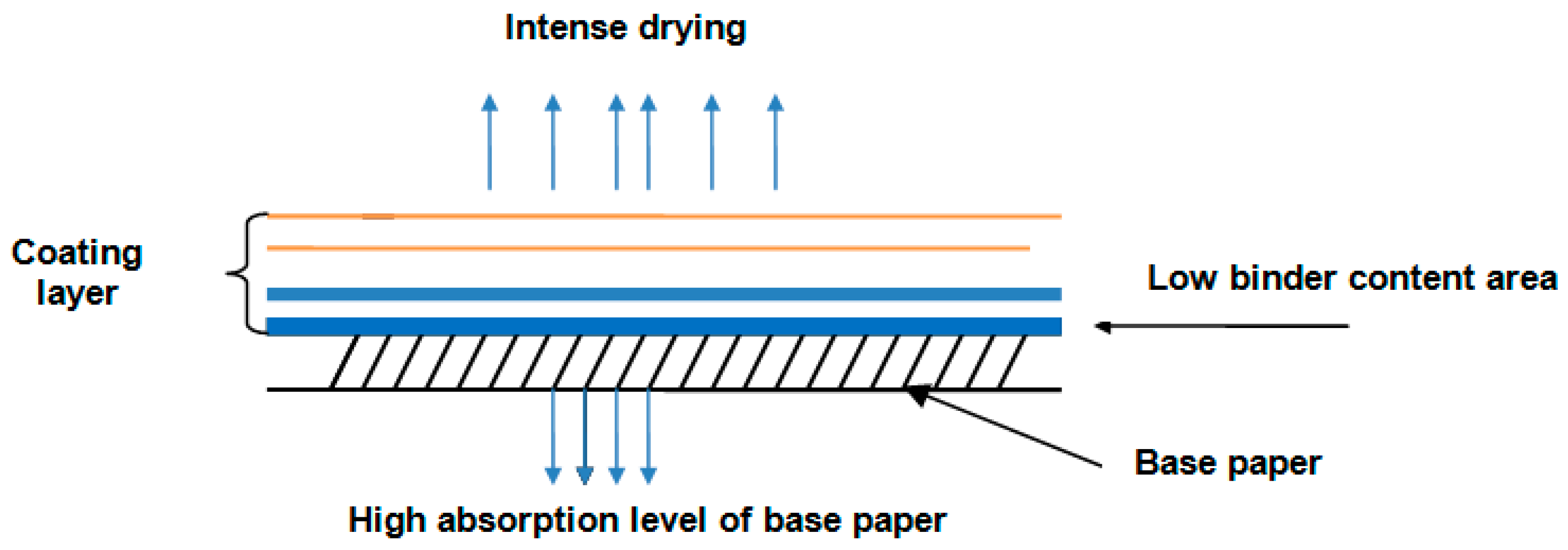

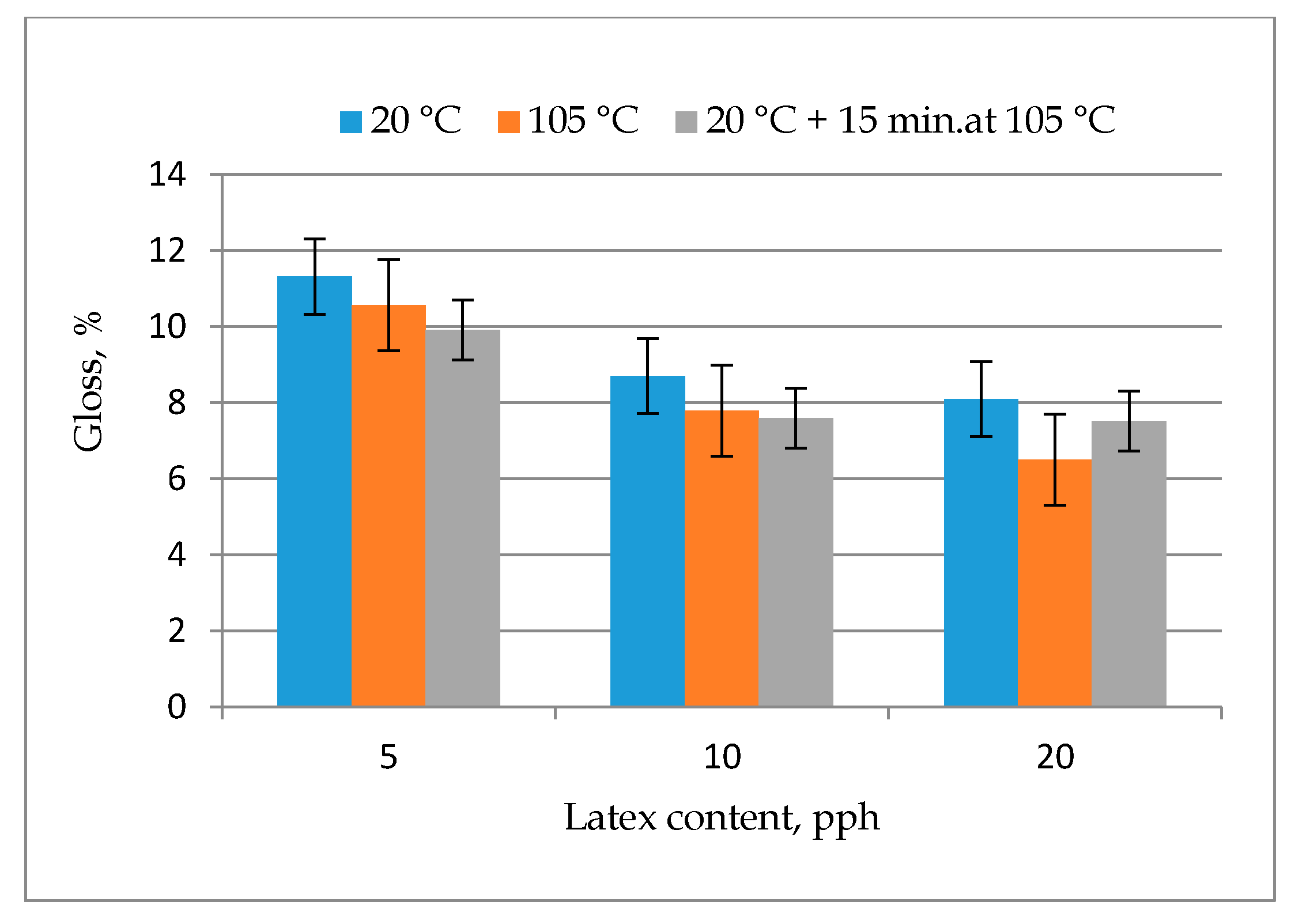

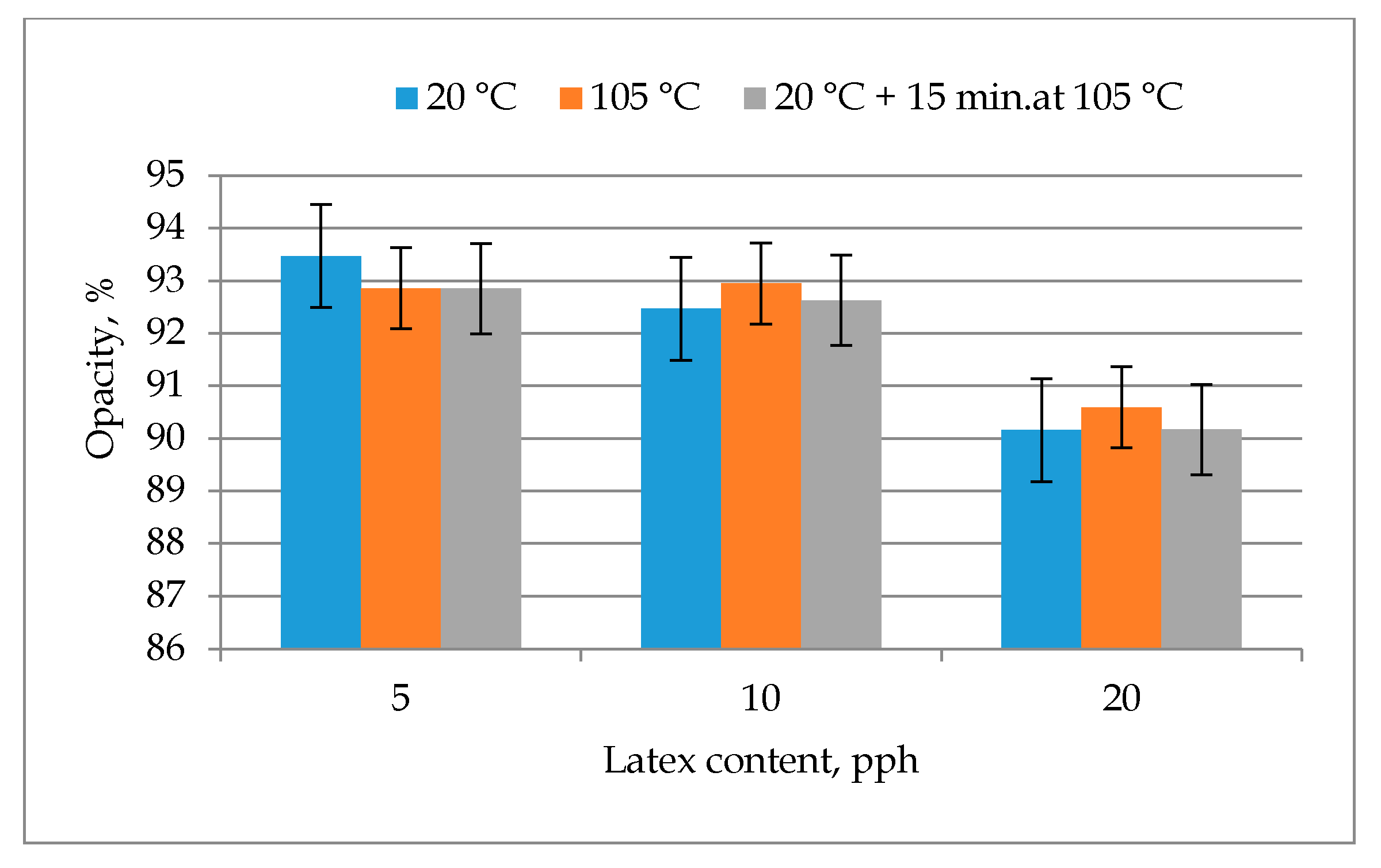

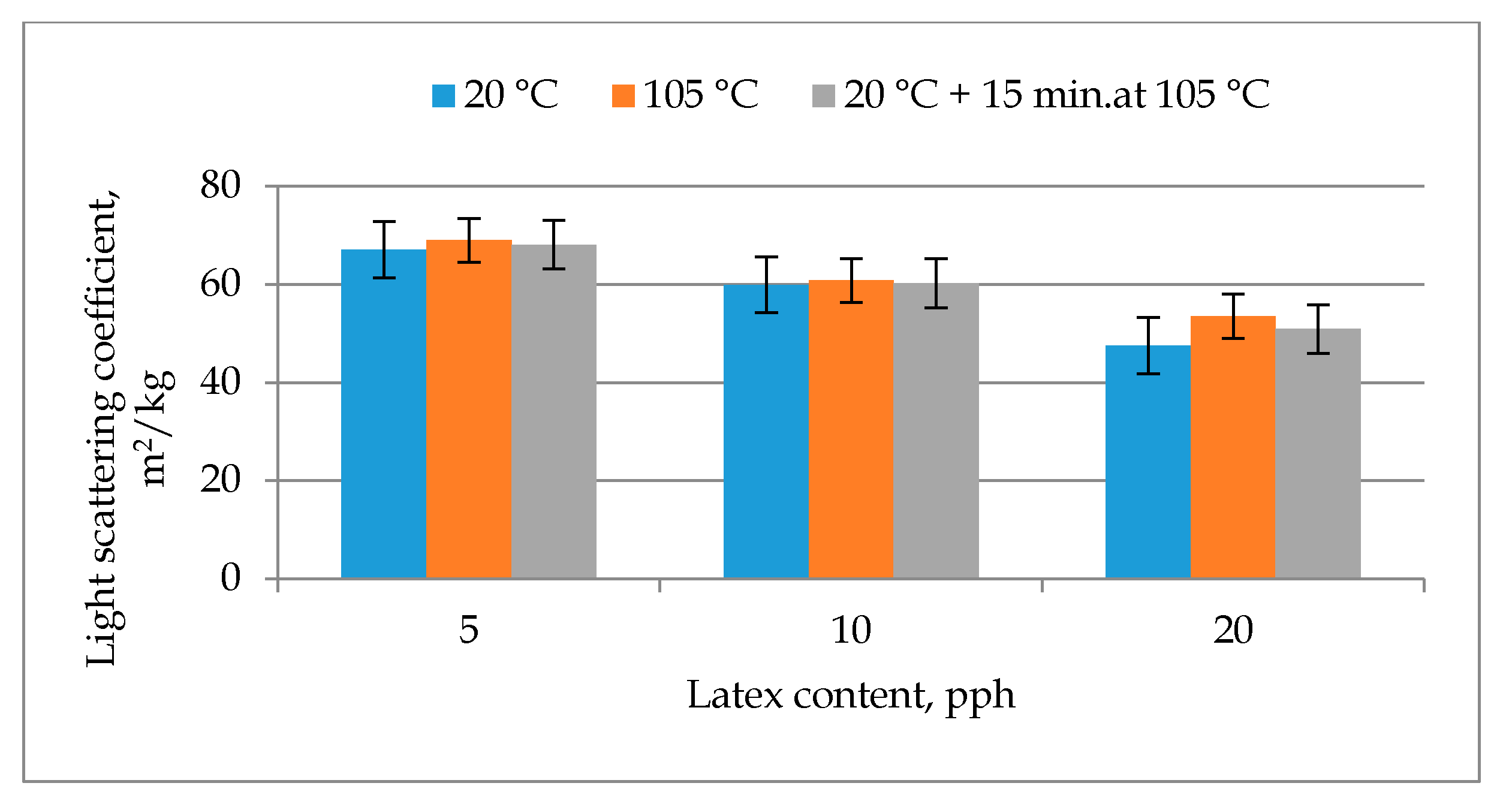

3.1. The Influence of Drying Conditions on the Optical Properties of Coating Layer

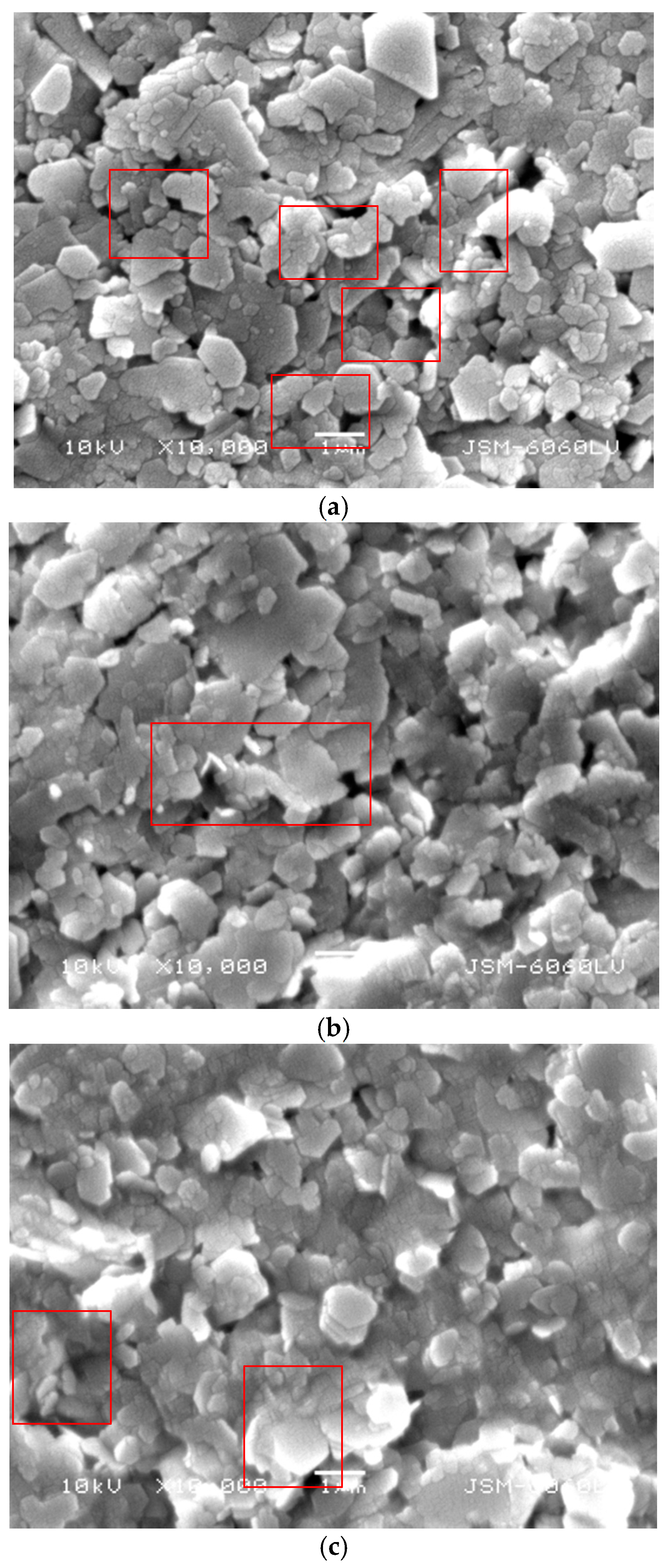

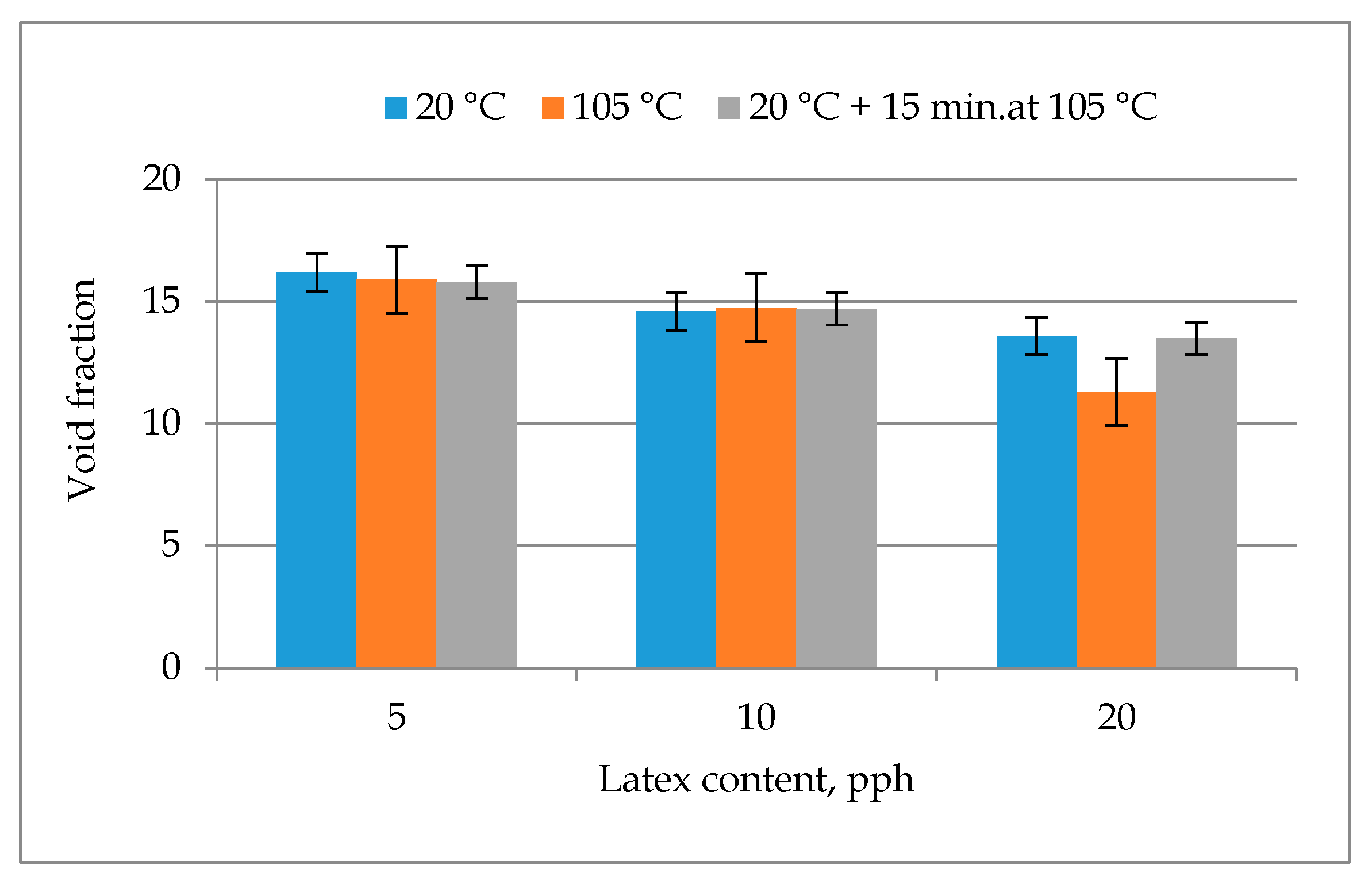

3.2. The Influence of Drying Conditions on the Structural Properties of Coating Layer

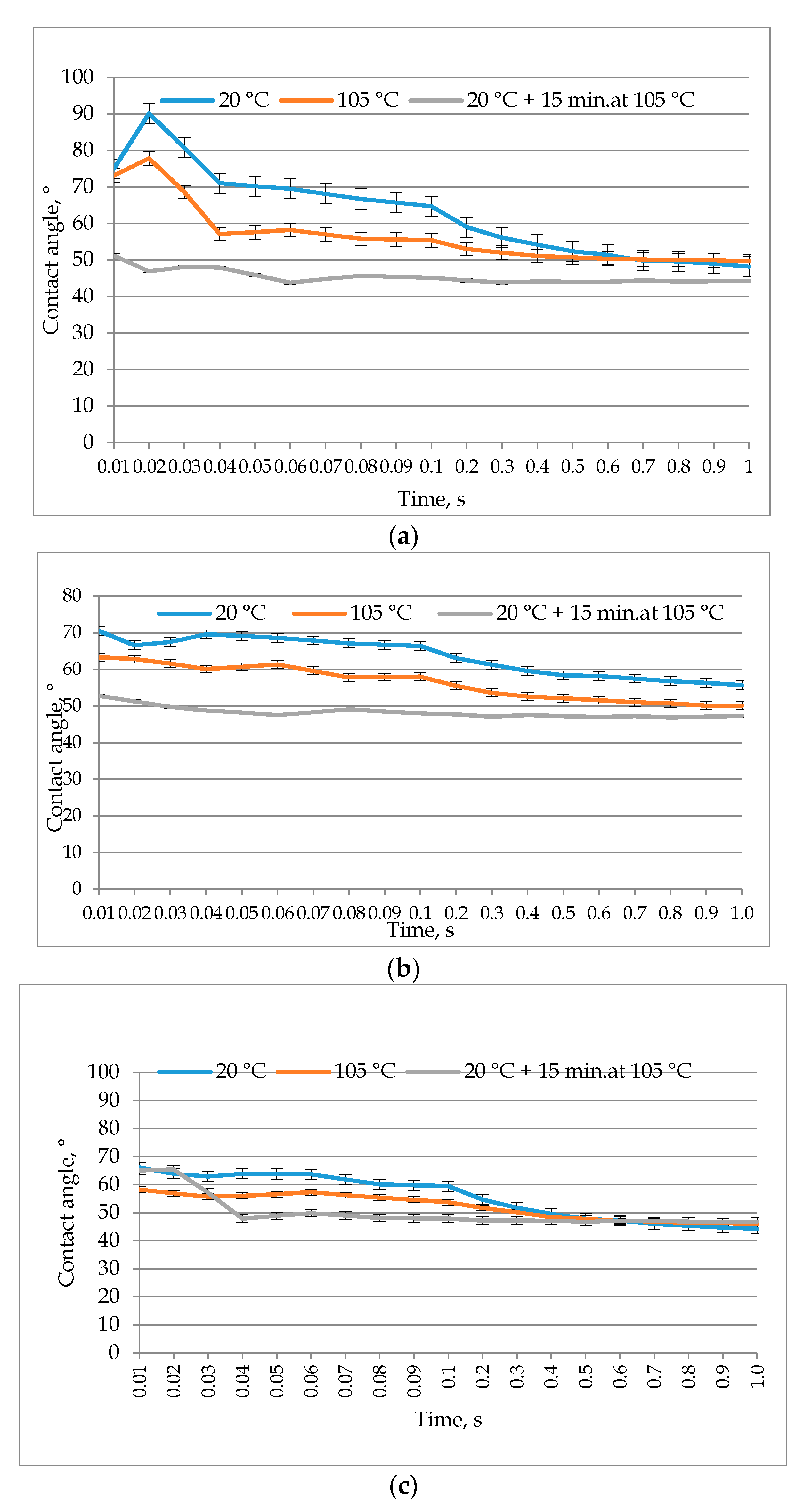

3.3. The Influence of Drying Conditions on the Water Absorption and Coating Layer Wettability

4. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

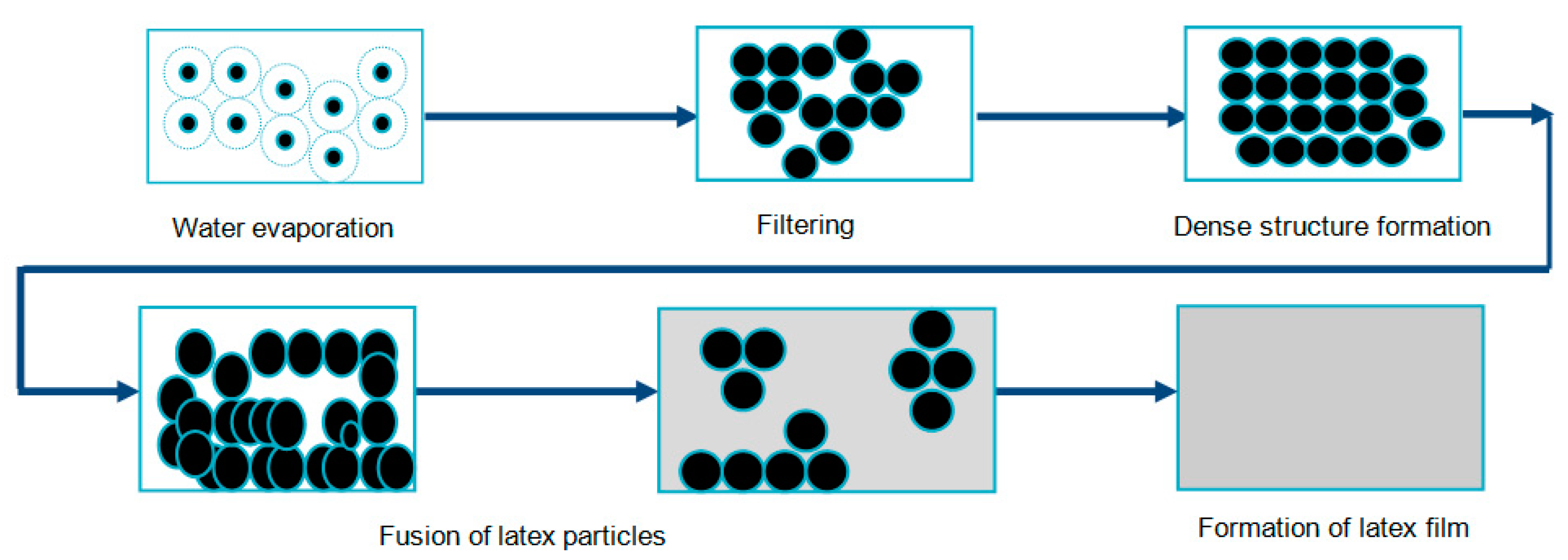

- Watanabe, J.; LePoutre, P. A mechanism for the consolidation of the structure of clay-latex coatings. J. Appl. Polym. Sci. 1982, 27, 4207–4219. [Google Scholar] [CrossRef]

- Walter, J.C. The Coating Processes; TAPP Press: Atlanta, GA, USA, 1993; pp. 71–131. [Google Scholar]

- LePoutre, P. The structure of paper coatings: An update. Prog. Org. Coat. 1989, 17, 89–106. [Google Scholar] [CrossRef]

- Stanislawska, A.; Lepoutre, P. Consolidation of pigmented coatings: Development of porous structure. Tappi J. 1996, 79, 117–125. [Google Scholar]

- Laudone, G.M.; Matthews, G.P.; Gane, P.A.C. Coating shrinkage during evaporation: Observation, measurement and modelling within a network structure. In Proceedings of the Advanced Coating Fundamentals Symposium, Norcross, GA, USA, 10–12 September 2003. [Google Scholar]

- Lee, J.-H.; Lee, H.L. Characterization of the paper coating structure using focused ion beam and field-emission scanning electron microscopy. 2. Structural variation depending on the glass transition temperature of an S/B latex. Ind. Eng. Chem. Res. 2018, 57, 16718–16726. [Google Scholar] [CrossRef]

- Lee, J.-H.; Oh, K.D.; Rajabi Abhari, A.; Lee, H.L. Characterization of paper coating structure using FIB and FE-SEM. 1. New Method for Image Analysis. Ind. Eng. Chem. Res. 2018, 57, 4237–4244. [Google Scholar] [CrossRef]

- Giuliano, M.; Laudone, G.; Peter, M. Observation of shrinkage during evaporative drying of water-based paper coatings. Ind. Eng. Chem. Res. 2004, 43, 712–719. [Google Scholar] [CrossRef]

- Francis, L.F.; McCormick, A.V.; Vaessen, D.M.; Payne, J.A. Development and measurement of stress in polymer coating. J. Mater. Sci. 2002, 37, 4717–4731. [Google Scholar] [CrossRef]

- Oh, K.; Lee, J.-H.; Im, W.; Rajabi Abhari, A.; Lee, H.L. Role of cellulose nanofibrils in structure formation of pigment coating layers. Ind. Eng. Chem. Res. 2017, 56, 9569–9577. [Google Scholar] [CrossRef]

- Oh, K.; Lee, J.-H.; Im, W.; Rajabi Abhari, A.; Lee, H.L. Stress development in a cellulose-nanofibril-containing pigment coating layer during drying. Ind. Eng. Chem. Res. 2019, 58, 18187–18196. [Google Scholar] [CrossRef]

- Lee, S.G.; Kim, S.; Lee, H.L. Effect of the glass-transition temperature of latexes on drying-stress development of latex films and inkjet coating layers. Nord. Pulp Paper Res. J. 2020, 35. [Google Scholar] [CrossRef]

- Salminen, P.J. Studies of Water Transport in Paper during Short Contact Times. Ph.D. Thesis, Abo Akademi University, Turku, Finland, 1988. [Google Scholar]

- Prinz, M.; Nikkanen, J.; Wille Bacher, N. Improving the quality of coated paper by optimization of the base paper and the coating color. Nord. Pulp Paper Res. J. 1998, 13, 123–140. [Google Scholar]

- Yaqiang, M.; Takamura, K.; Davis Ted, H.; Scrinen, L.E. Microstructure evolution in latex coatings. Tappi J. 1995, 78, 151–159. [Google Scholar]

- Hagen, K.G. A fundamental assessment of the effect of drying on coating quality. In Proceedings of the Tappi Coating Conference, Atlanta, GA, USA, 19–23 May 1985. [Google Scholar]

- Hagen, K.G. An assessment of the use of infra-red in coating drying. In Proceedings of the Tappi Coating Conference, Chicago, IL, USA, 14–17 May 1989. [Google Scholar]

- Hallajisani, A.; Shahbeig, H.; Hashemi, S.J.; Murray Douglas, W.J. An experimental simulation model for coated paper drying. Braz. J. Chem. Eng. 2013, 30, 563–573. [Google Scholar] [CrossRef]

- Sönmez, S.; Dölen, E.; Fleming, P.D. Binder effect on the crease-ability of pigment coated paper board. Asian J. Chem. 2011, 23, 1193–1197. [Google Scholar]

- El-Sherif, H.M.; Nasser, A.M.; Hussin, A.I.; Abd El-Wahab, H.; Ghazi, M.B.M.; Elsayed, A.E. Tailoring of mechanical properties and printability of coated recycled papers. Polym. Bull. 2019, 76, 2965–2990. [Google Scholar] [CrossRef]

- Du, Y.; Zang, Y.H.; Du, J. Effects of starch on latex migration and on paper coating properties. Ind. Eng. Chem. Res. 2011, 50, 9781–9786. [Google Scholar] [CrossRef]

- Ojala, K. Studies on Infrared Drying of Paper, Use of Integration Spheres in FTIR Measurements, and Heat and Mass Transfer Inside Paper; PB-94-136843/XAB; Helsinki University of Technology: Helsinki, Finland, 1993. [Google Scholar]

- Piette, P. Prediction of mottling and speed of ink immobilisation of offset papers with i-motto. In Proceedings of the 1st Symposium in the COST E32 Action, Characterisation of Paper Surfaces for Improved Printing Paper Grades, Madrid, Spain, 6–7 October 2005; p. 34. [Google Scholar]

- Herbert, S.; Richard, A. Careful choice of ir drying is required to meet rising demands for coating quality and production speed. Pulp Paper Eur. 1998, 54, 37. [Google Scholar]

- Alince, B.; Lepoutre, P. Porosity and optical properties of clay coatings. J. Coll. Int. Sci. 1980, 76, 439–444. [Google Scholar] [CrossRef]

- Basant, G.D. The Relationship between Rheology, Application Method, and Final Coating Structure. Master’s Thesis, Georgia Southern University, Statesboro, GA, USA, 1998. [Google Scholar]

- Standard Method Tappi T558 pm: Surface Wettability and Absorbency of Sheeted Materials Using an Automated Contact Angle Tester; TAPPI: Peachtree Corners, GA, USA, 2010.

- Standard Method SR 7775-91: Paper and Board. Method of Gloss Measuring at 75°; Romanian Association of Standardization: Bucharest, Romania, 1991.

- Standard Method SR ISO 2471:2001 Paper and Board. Determination of Opacity on a Paper Background. The Method of Reflection in Diffused Light; ASRO: București, Romania, 2001.

- Nechita, P. Research on Relations between Coating Layer Structure and Paper Product’s Quality. Doctoral Thesis, Gheorghe Asachi Technical University, Iasi, Romania, 2007. (In Romanian). [Google Scholar]

- Modaressi, H.; Garnier, G. Mechanism of wetting and absorption of water droplets on sized papers: Effect of chemical and physical heterogeneity. Langmuir 2002, 18, 642–649. [Google Scholar] [CrossRef]

- Wågberg, L. Spreading of droplets of different liquids on specially structured papers. Nord. Pulp Paper Res. J. 2000, 15, 598–606. [Google Scholar] [CrossRef] [Green Version]

- Gómez, N.; Quintana, E.; Villar, J. Effect of paper surface properties on coated paper wettability with different fountain solutions. BioResources 2014, 9, 4226–4241. [Google Scholar] [CrossRef] [Green Version]

| Properties | Values |

|---|---|

| Grammage, g/m2 | 54.8 |

| Density, g/cm3 | 0.78 |

| Water absorption, Cobb60, g/m2 | 22.6 |

| Smoothness, Bekk, s | 50 |

| Breaking length, m | 3703 |

| Brightness, R457/D65, % | 91.43 |

| Opacity, % | 83.44 |

| Gurley porosity, s | 4.5 |

| Components | Samples Codifications | ||

|---|---|---|---|

| U1 (20 °C) | U2 (105 °C) | U3 (20 °C + 105 °C 15 min) | |

| SPS Clay, pph | 100 | 100 | 100 |

| XNBR Latex, pph | 5 | 10 | 20 |

| Dry content, % | 45.16 | 44.98 | 45.1 |

| Brookfield viscosity, (20 °C, 60 rpm), cP | 120 | 225 | 260 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nechita, P. The Influence of Drying Conditions of Clay-Based Polymer Coatings on Coated Paper Properties. Coatings 2021, 11, 12. https://doi.org/10.3390/coatings11010012

Nechita P. The Influence of Drying Conditions of Clay-Based Polymer Coatings on Coated Paper Properties. Coatings. 2021; 11(1):12. https://doi.org/10.3390/coatings11010012

Chicago/Turabian StyleNechita, Petronela. 2021. "The Influence of Drying Conditions of Clay-Based Polymer Coatings on Coated Paper Properties" Coatings 11, no. 1: 12. https://doi.org/10.3390/coatings11010012

APA StyleNechita, P. (2021). The Influence of Drying Conditions of Clay-Based Polymer Coatings on Coated Paper Properties. Coatings, 11(1), 12. https://doi.org/10.3390/coatings11010012