Performance Evaluation of Road Pavement Green Concrete: An Application of Advance Decision-Making Approach before Life Cycle Assessment

Abstract

:1. Introduction

2. Materials and Methods

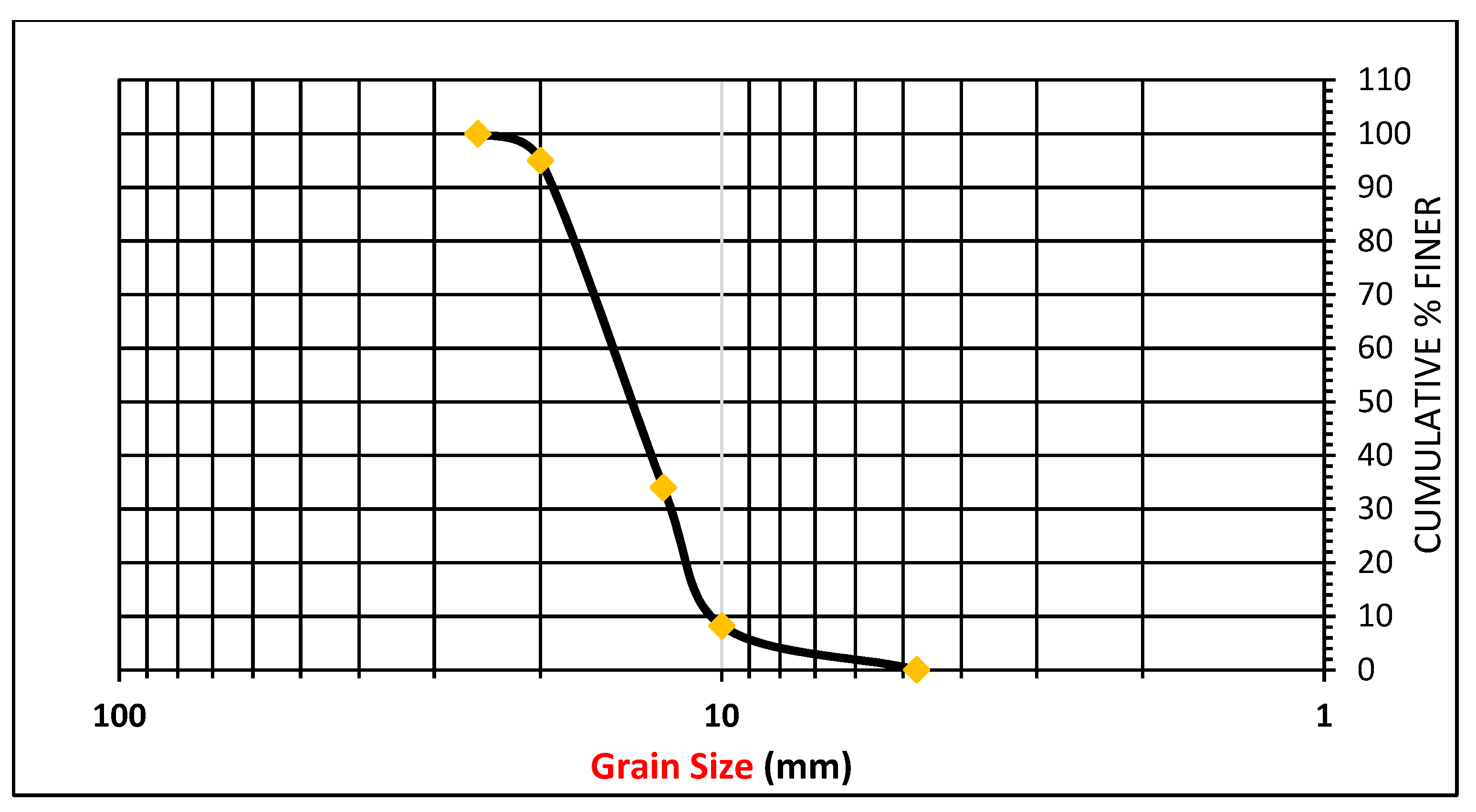

2.1. Basic Materials

2.2. Waste Materials

2.3. Mixing and Preparation of the Specimen

2.4. Specimen Testing Methods

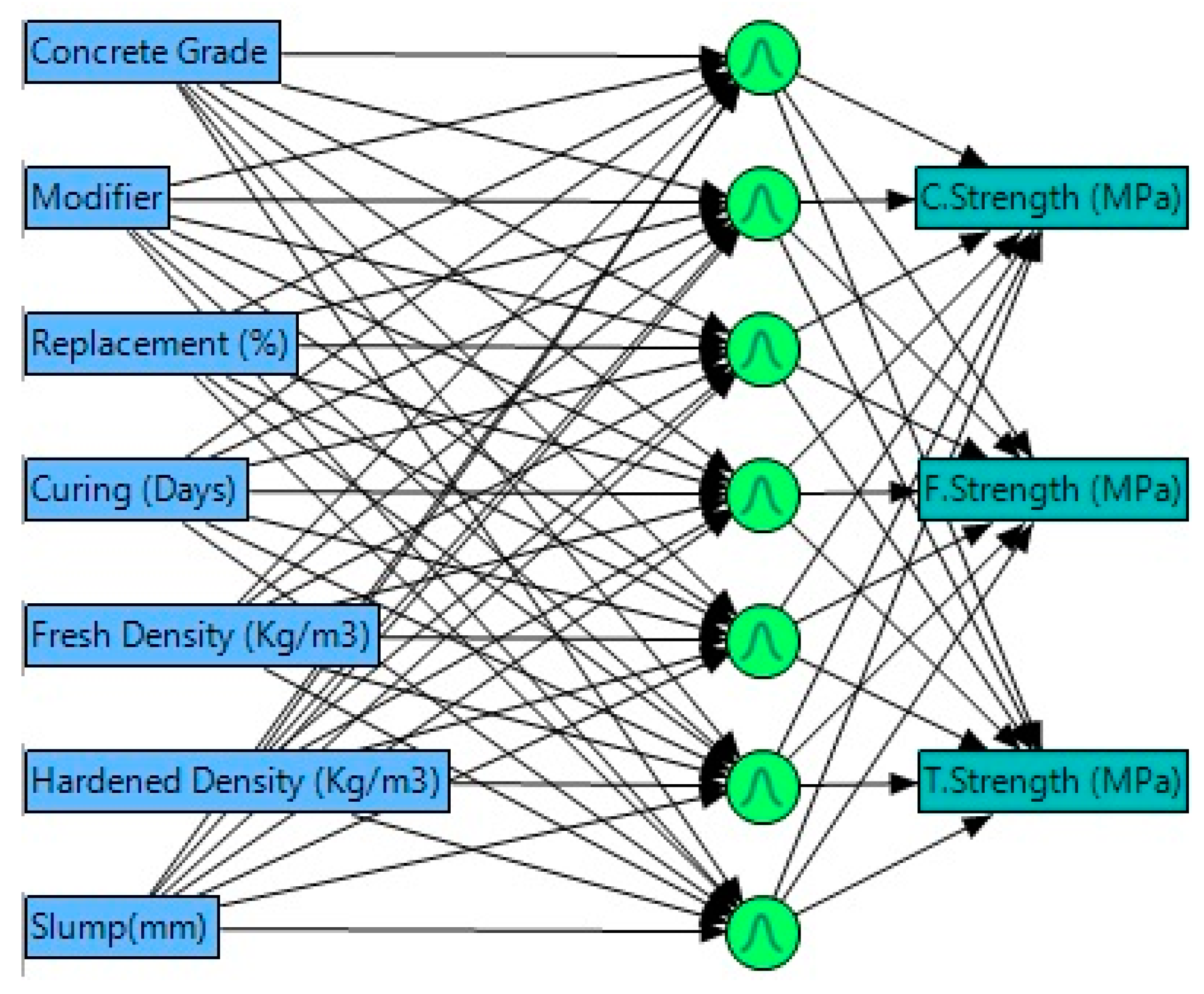

2.5. Application of Artificial Neural Networks Model

3. Results and Discussion

3.1. Mechanical Properties of Concrete

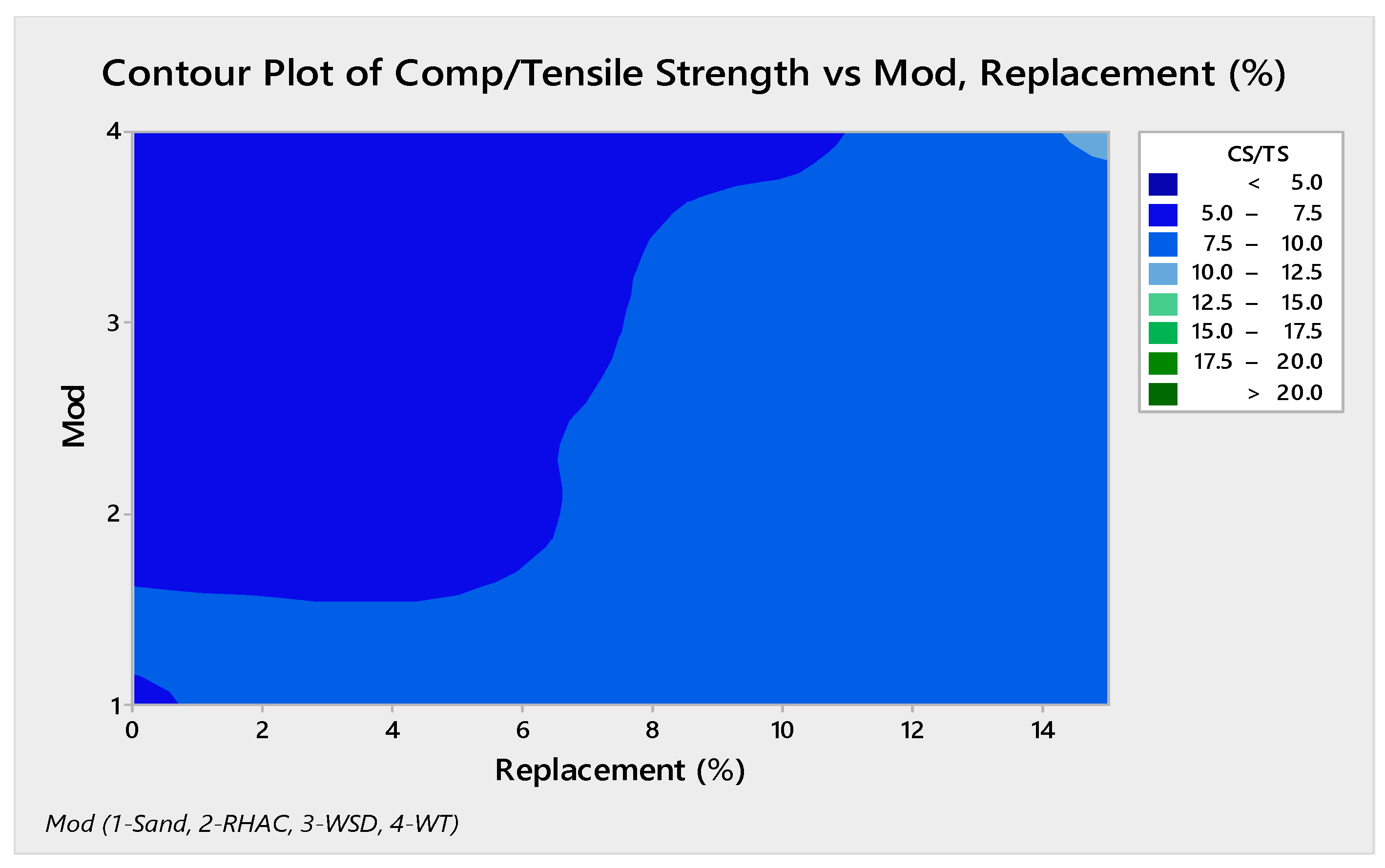

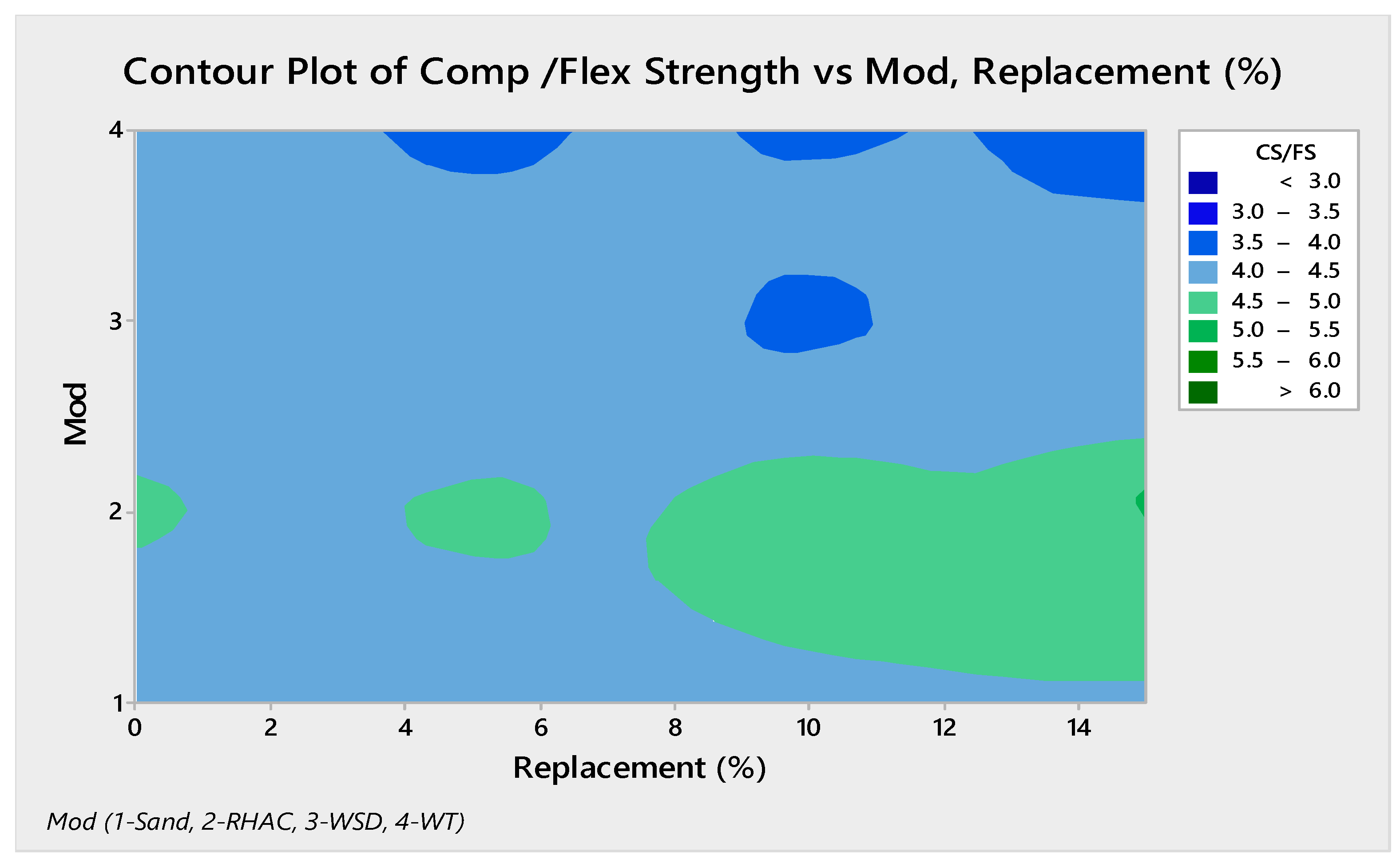

3.2. Relationship Analysis between Mechanical Properties

3.3. ANNs Model Performance

3.4. Prediction Profiler

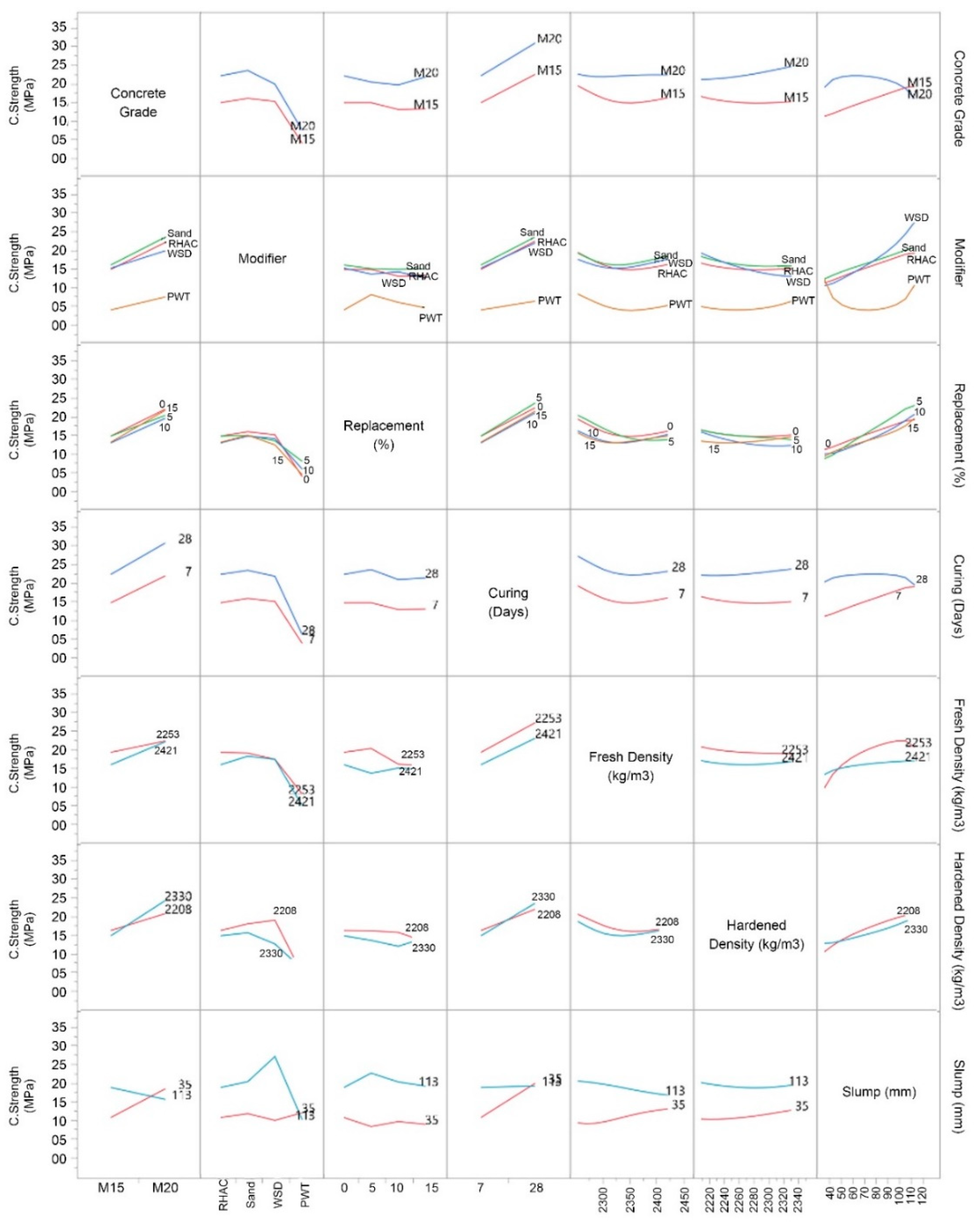

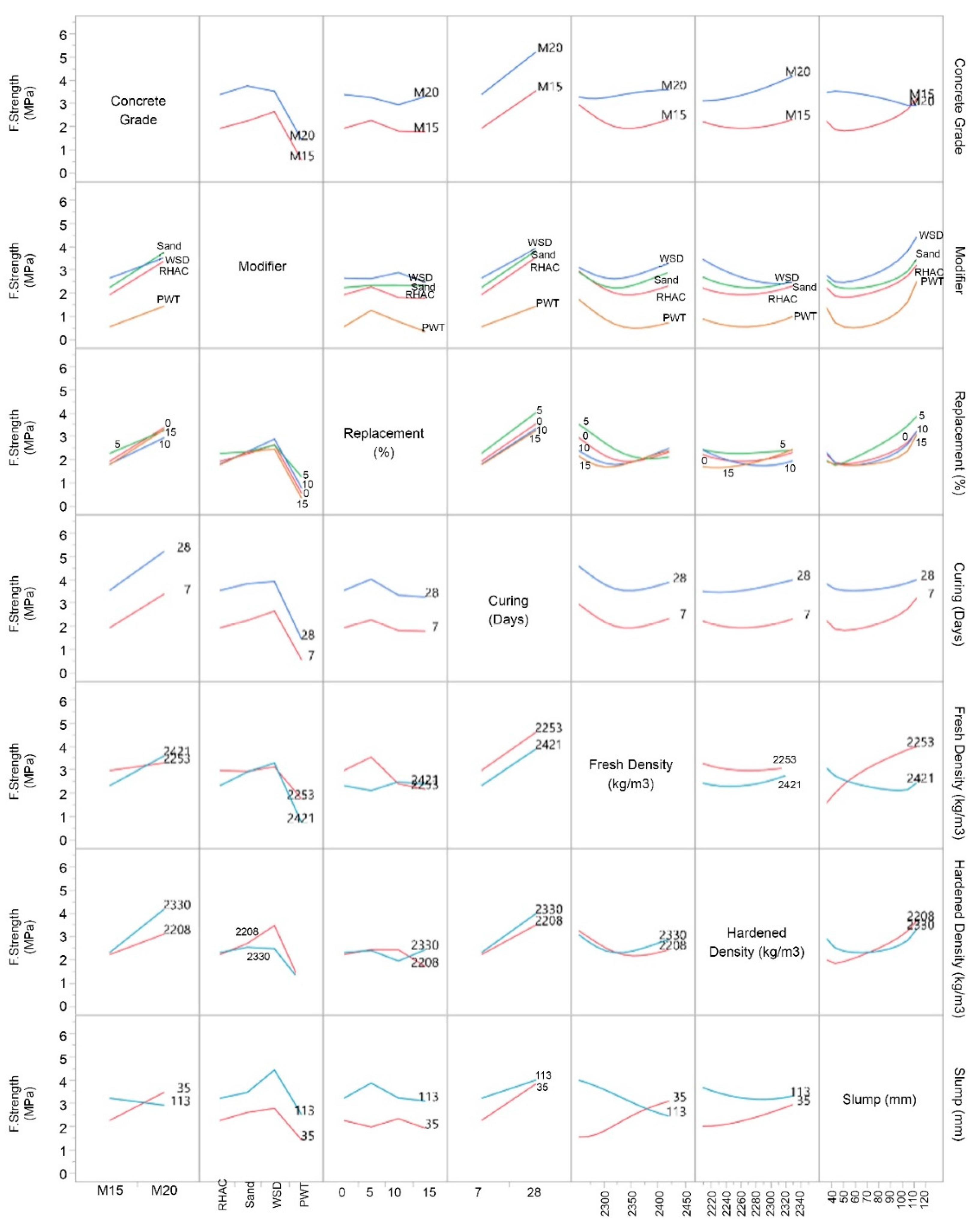

3.5. Interaction Profiler

3.6. Variable Importance Analysis

4. Conclusions

- Green concrete pavement was developed utilizing three waste products (rice husk ash (RHA), wood sawdust (WSD), and processes waste tea (PWT)) to develop the concrete for rigid pavement structures by replacing the sand, i.e., a filler material at different percentages (5%, 10% and 15%) using two mix design formations of M15 grade (ratio 1:2:4) and M20 grade (ratio 1:1.5:3);

- Performance analysis of developed green concrete is usually evaluated based on the performance of mechanical properties (i.e., compressive strength, tensile strength, and flexural strength;

- Compressive strength of developed green concrete also has been analyzed for two grades of concrete mix design formations of M15 grade (ratio 1:2:4) and M20 grade (ratio 1:1.5:3), and higher strength was observed for M20 grade. Furthermore, RHAC and WSD can be a good replacement at 5% replacement of sand if the grain size is kept at a similar level;

- Tensile strength of developed green concrete was analyzed for similar M15 grade (ratio 1:2:4) and M20 grade (ratio 1:1.5:3), and higher split tensile strength was observed for M20 grade using RHAC and WSD, which can be a good replacement at 5% replacement of sand if the grain size is kept at a similar level;

- Flexural strength of developed green concrete has additionally been analyzed for similar M15 grade (ratio 1:2:4) and M20 grade (ratio 1:1.5:3), and higher flexural strength was observed for M20 grade using WSD, which can be a good replacement at 5% replacement of sand if the grain size is kept at a similar level;

- As an advanced decision-making technique, artificial neural networks (ANNs) were utilized to predict the three mechanical properties that help in not only prediction but also develop a prediction profile to study the behavior of developed green concrete in one form of graphs.

5. Limitations of the Study

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Plati, C. Sustainability factors in pavement materials, design, and preservation strategies: A literature review. Constr. Build. Mater. 2019, 211, 539–555. [Google Scholar] [CrossRef]

- Inventory of US Greenhouse Gas Emissions and Sinks: 1990–2011; United States Environmental Protection Agency: Washington, DC, USA, 2013; p. 505.

- Alfalqi, S.; Alzaidi, J.; Lu, D.; Khater, M. On exact and approximate solutions of (2 + 1)-dimensional Konopelchenko-Dubrovsky equation via modified simplest equation and cubic B-spline schemes. Therm. Sci. 2019, 23, 349. [Google Scholar] [CrossRef] [Green Version]

- Lu, D.; Seadawy, A.R.; Khater, M.M. Structure of solitary wave solutions of the nonlinear complex fractional generalized Zakharov dynamical system. Adv. Differ. Equ. 2018, 2018, 266. [Google Scholar] [CrossRef] [Green Version]

- Thirupathi, N.; Naresh, T.; Harish, B. The behaviour of rigid pavement by nonlinear finite element method. J. Archit. Technol. 2019, 11, 1–5. [Google Scholar]

- Harwalkar, A.B.; Awanti, S. Laboratory and field investigations on high-volume fly ash concrete for rigid pavement. Transp. Res. Rec. 2014, 2441, 121–127. [Google Scholar] [CrossRef]

- Road Traffic, Vehicles and Networks-Environment at a Glance; OECD: Paris, France, 2013.

- Chandra, S. Flexible Pavement Versus Rigid Pavement. 2020. NBM&CW. Available online: https://www.nbmcw.com/tech-articles/roads-and-pavements/36977-flexible-pavement-versus-rigid-pavement.html (accessed on 10 August 2020).

- Kowalski, K.J.; Król, J.; Radziszewski, P.; Casado, R.; Blanco, V.; Pérez, D.; Viñas, V.M.; Brijsse, Y.; Frosch, M.; Le, D.M.; et al. Eco-friendly materials for a new concept of asphalt pavement. Transp. Res. Procedia. 2016, 14, 582–3591. [Google Scholar]

- Chore, H.S.; Joshi, M.P. Strength characterization of concrete using industrial waste as cement replacing materials for rigid pavement. Innov. Infrastruct. Solut. 2020, 5, 1–9. [Google Scholar] [CrossRef]

- Van Dam, T.J.; Harvey, J.; Muench, S.T.; Smith, K.D.; Snyder, M.B.; Al-Qadi, I.L.; Ozer, H.; Meijer, J.; Ram, P.; Roesler, J.R. Towards Sustainable Pavement Systems: A Reference Document; Federal Highway Administration: New York, NY, USA, 2015. [Google Scholar]

- Liu, X.; Cui, Q.; Schwartz, C. Greenhouse gas emissions of alternative pavement designs: Framework development and illustrative application. J. Environ. Manag. 2014, 132, 313–322. [Google Scholar] [CrossRef]

- Maisham, M.; Adnan, H.; Ismail, N.A.A.; Mahat, N.A.A. Developing a research methodology for life cycle costing framework for application in green projects. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Bristol, UK, 24–25 April 2019; p. 012066. [Google Scholar]

- Khater, M.M.; Seadawy, A.R.; Lu, D. Dispersive solitary wave solutions of new coupled Konno-Oono, Higgs field and Maccari equations and their applications. J. King Saud Univ.-Sci. 2018, 30, 417–423. [Google Scholar] [CrossRef]

- Singh, M.; Adhikari, A.; Maurya, M.K.; Srivastava, A.; Chhabra, R.S. Feasibility study on use of washed-reclaimed asphalt as a partial replacement of natural aggregate in dry-lean concrete as base course for rigid pavement. J. Mater. Civ. Eng. 2020, 32, 04020266. [Google Scholar] [CrossRef]

- Van Dam, T.; Taylor, P. Seven principles for sustainable concrete pavements. Concr. Int. 2011, 33, 49–52. [Google Scholar]

- Presti, D.L.; del Barco Carrión, A.J.; Airey, G.; Hajj, E. Towards 100% recycling of reclaimed asphalt in road surface courses: Binder design methodology and case studies. J. Clean. Prod. 2016, 131, 43–51. [Google Scholar] [CrossRef]

- Jamshidi, A.; Kurumisawa, K.; Nawa, T.; Hamzah, M.O. Analysis of structural performance and sustainability of airport concrete pavements incorporating blast furnace slag. J. Clean. Prod. 2015, 90, 195–210. [Google Scholar] [CrossRef]

- Buss, A.; Cascione, A.; Williams, R.C. Evaluation of warm mix asphalt containing recycled asphalt shingles. Constr. Build. Mater. 2014, 61, 1–9. [Google Scholar] [CrossRef]

- Yazoghli-Marzouk, O.; Vulcano-Greullet, N.; Cantegrit, L.; Friteyre, L.; Jullien, A. Recycling foundry sand in road construction–field assessment. Constr. Build. Mater. 2014, 61, 69–78. [Google Scholar] [CrossRef]

- Jamshidi, A.; Kurumisawa, K.; Nawa, T.; Igarashi, T. Performance of pavements incorporating waste glass: The current state of the art. Renew. Sustain. Energy Rev. 2016, 64, 211–236. [Google Scholar] [CrossRef]

- Mohammadinia, A.; Arulrajah, A.; Horpibulsuk, S.; Chinkulkijniwat, A. Effect of fly ash on properties of crushed brick and reclaimed asphalt in pavement base/subbase applications. J. Hazard. Mater. 2017, 321, 547–556. [Google Scholar] [CrossRef]

- Chen, M.-Z.; Lin, J.-T.; Wu, S.-P.; Liu, C.-H. Utilization of recycled brick powder as alternative filler in asphalt mixture. Constr. Build. Mater. 2011, 25, 1532–1536. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, K.; Liu, H.; Deng, Z. Key performance properties of asphalt mixtures with recycled concrete aggregate from low strength concrete. Constr. Build. Mater. 2016, 126, 711–719. [Google Scholar] [CrossRef]

- Reza, F.; Wilde, W.; Izevbekhai, B. Performance of recycled concrete aggregate pavements based on historical condition data. Int. J. Pavement Eng. 2020, 21, 677–685. [Google Scholar] [CrossRef]

- Ossa, A.; García, J.; Botero, E. Use of recycled construction and demolition waste (CDW) aggregates: A sustainable alternative for the pavement construction industry. J. Clean. Prod. 2016, 135, 379–386. [Google Scholar] [CrossRef]

- Aydin, E. Novel coal bottom ash waste composites for sustainable construction. Constr. Build. Mater. 2016, 124, 582–588. [Google Scholar] [CrossRef]

- Seadawy, A.R.; Lu, D.; Khater, M.M. Structure of optical soliton solutions for the generalized higher-order nonlinear Schrödinger equation with light-wave promulgation in an optical fiber. Opt. Quantum Electron. 2018, 50, 333. [Google Scholar] [CrossRef]

- Khater, M.M.; Seadawy, A.R.; Lu, D. Bifurcations of solitary wave solutions for (two and three)-dimensional nonlinear partial differential equation in quantum and magnetized plasma by using two different methods. Results Phys. 2018, 9, 142–150. [Google Scholar] [CrossRef]

- Khater, M.M. Solitary wave solutions for the generalized Zakharov Kuznetsov–Benjamin–Bona–Mahony nonlinear evolution equation. Global J. Sci. Front. Res. Phys. Space Sci 2016, 16, 4. [Google Scholar]

- Alsugair, A.M.; Al-Qudrah, A.A. Artificial neural network approach for pavement maintenance. J. Comput. Civ. Eng. 1998, 12, 249–255. [Google Scholar] [CrossRef]

- Amin, S.R.; Amador-Jiménez, L.E. Backpropagation Neural Network to estimate pavement performance: Dealing with measurement errors. Road Mater. Pavement Des. 2017, 18, 1218–1238. [Google Scholar] [CrossRef]

- Bayrak, M.B.; Ceylan, H. Neural network-based approach for analysis of rigid pavement systems using deflection data. Transp. Res. Rec. 2008, 2068, 61–70. [Google Scholar] [CrossRef] [Green Version]

- Ceylan, H.; Guclu, A.; Tutumluer, E.; Thompson, M.R. Backcalculation of full-depth asphalt pavement layer moduli considering nonlinear stress-dependent subgrade behavior. Int. J. Pavement Eng. 2005, 6, 171–182. [Google Scholar] [CrossRef]

- Choi, J.H.; Adams, T.M.; Bahia, H.U. Pavement roughness modeling using back-propagation neural networks. Comput. Aided Civ. Infrastruct. Eng. 2004, 19, 295–303. [Google Scholar] [CrossRef]

- Eldin, N.N.; Senouci, A.B. Use of neural networks for condition rating of jointed concrete pavements. Adv. Eng. Softw. 1995, 23, 133–141. [Google Scholar] [CrossRef]

- Debbarma, S.; Ransinchung RN, G.D. Using artificial neural networks to predict the 28-day compressive strength of roller-compacted concrete pavements containing RAP aggregates. Road Mater. Pavement Des. 2020, 1–19. [Google Scholar] [CrossRef]

- Ioannides, A.M.; Alexander, D.R.; Hammons, M.I.; Davis, C.M. Application of artificial neural networks to concrete pavement joint evaluation. Transp. Res. Rec. 1996, 1540, 56–64. [Google Scholar] [CrossRef]

- Nasly, M.; Yassin, A. Sustainable housing using an innovative interlocking block building system. In Proceedings of the Fifth National Conference on Civil Engineering (AWAM’09); Towards Sustainable Development: Kuala Lumpur, Malaysia; 2009; pp. 130–138. Available online: https://ccasistem.files.wordpress.com/2009/11/nasly_awam09.pdf (accessed on 10 January 2021).

- Madandoust, R.; Ranjbar, M.M.; Moghadam, H.A.; Mousavi, S.Y. Mechanical properties and durability assessment of rice husk ash concrete. Biosyst. Eng. 2011, 110, 144–152. [Google Scholar] [CrossRef]

- Jain, S.; Kumar, R. Processing of bamboo fiber reinforced plastic composites. Mater. Manuf. Process 1994, 9, 813–828. [Google Scholar] [CrossRef]

- Bruder-Hubscher, V.; Lagarde, F.; Leroy, M.; Coughanowr, C.; Enguehard, F. Utilisation of bottom ash in road construction: Evaluation of the environmental impact. Waste Manag. Res. 2001, 19, 545–556. [Google Scholar] [CrossRef]

- Mansoor, J.; Shah, S.; Khan, M.; Sadiq, A.; Anwar, M.; Siddiq, M.; Ahmad, H. Analysis of mechanical properties of self compacted concrete by partial replacement of cement with industrial wastes under elevated temperature. Appl. Sci. 2018, 8, 364. [Google Scholar] [CrossRef] [Green Version]

- Bignozzi, M.; Sandrolini, F. Tyre rubber waste recycling in self-compacting concrete. Cem. Concr. Res. 2006, 36, 735–739. [Google Scholar] [CrossRef]

- Ramesh, S.T.; Gandhimathi, R.; Nidheesh, P.V.; Rajakumar, S.; Prateepkumar, S. Use of furnace slag and welding slag as replacement for sand in concrete. Int. J. Energy Environ. Eng. 2013, 4, 3. [Google Scholar] [CrossRef] [Green Version]

- Arshad, H.; Mansoor, M.S.; Shah, S.A.R.; Khan, M.M.; Raza, S.S.; Imtiaz, S.; Mansoor, J. Study of mechanical properties of concrete developed using metamorphosed limestone powder (MLSP), burnt clay pozzolana (BCP) & wood ash (WA) as partial replacement of cement. In Proceedings of the 1st Conference on Sustainability in Civil Engineering, Islamabad, Pakistan, 1 August 2019. [Google Scholar]

- ASTM-C150-07: Standard Specification for Portland Cement; ASTM: West Conshohocken, PA, USA, 2007.

- ASTM.-C114-18: Standard Test Methods for Chemical Analysis of Hydraulic Cement; American Society for Testing of Materials: Philadelphia, PA, USA, 2004.

- ASTM-C187-16: Standard Test Method for Normal Consistency of Hydraulic Cement; ASTM: West Conshohocken, PA, USA, 2002.

- ASTM-C191-13: Standard Test Methods for Time of Setting of Hydraulic Cement by Vicat Needle; ASTM: West Conshohocken, PA, USA, 2013.

- ASTM-C188-17: Standard Test Method for Density of Hydraulic Cement; ASTM: West Conshohocken, PA, USA, 2009.

- BS-EN-196-3: Methods of Testing Cement–Part 3: Determination of Setting Times and Soundness; BSI: London, UK, 2005.

- ASTM-C-136: Standard Test Method for Sieve Analysis of Fine and Coarse Aggregates; Annual Book of Standards; ASTM: West Conshohocken, PA, USA, 2002; Volume 4.

- ASTM-C33-A: Standard Specification for Concrete Aggregates; American Society for Testing and Material; ASTM: West Conshohocken, PA, USA, 2004; pp. 1–11.

- ATSM-C29/C29M-07: Standard Test Method for Bulk Density (Unit Weight) and Voids in Aggregate; ASTM International: West Conshohocken, PA, USA, 2007.

- BS-812-112: Testing Aggregates. Method for Determination of Aggregate Impact Value (AIV); BSI: London, UK, 1990; p. 812-112.

- BS-812-110: Testing Aggregates—Methods for Determination of Aggregate Crushing Value (ACV); BSI: London, UK, 1990.

- ASTM-C131/C131M: Standard Test Method for Resistance to Degradation of Small-Size Coarse Aggregate by Abrasion and Impact in the Los Angeles Machine; ASTM International: West Conshohocken, PA, USA, 2008.

- ASTM-C127-01: Standard Test Method for Relative Density (Specific Gravity) and Absorption of Coarse Aggregate; ASTM: West Conshohocken, PA, USA, 2015.

- ASTM-C143/C-05a: Standard Test Method for Slump of Hydraulic-Cement Concrete; ASTM: Philadelphia, PA, USA, 2005.

- ASTM-C192/C192M-19: Standard Practice for Making and Curing Concrete Test Specimens in the Laboratory; ASTM International: West Conshohocken, PA, USA, 2016.

- ASTM-C39/C39M-20: Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens; ASTM International: West Conshohocken, PA, USA, 2014.

- ASTM-C496/C496M-17: Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens; ASTM: West Conshohocken, PA, USA, 2011.

- ASTM-C78/C78M-18: Standard Test Method for Flexural Strength of Concrete (Using Simple Beam with Third-Point Loading). In American Society for Testing and Materials; ASTM: West Conshohocken, PA, USA, 2016.

- Ali, F.; Khan, M.A.; Qurashi, M.A.; Shah, S.A.R.; Khan, N.M.; Khursheed, Z.; Rahim, H.S.; Arshad, H.; Farhan, M.; Waseem, M. Utilization of Pyrolytic Carbon Black Waste for the development of Sustainable Materials. Processes 2020, 8, 174. [Google Scholar] [CrossRef] [Green Version]

- Siddique, R.; Aggarwal, P.; Aggarwal, Y. Prediction of compressive strength of self-compacting concrete containing bottom ash using artificial neural networks. Adv. Eng. Softw. 2011, 42, 780–786. [Google Scholar] [CrossRef]

| Loss on Ignition | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | SO3 | K2O | Na2O |

|---|---|---|---|---|---|---|---|---|

| 3.78 | 20.17 | 5.04 | 2.94 | 66.42 | 1.71 | 3.09 | 0.79 | 0.55 |

| Property | Unit | Result | Standard |

|---|---|---|---|

| Cement-Basic Binder | |||

| Bulk density | kg/m3 | 1440.00 | ASTM C-188 |

| Normal consistency | % | 29.50 | ASTM C-187 |

| Fineness | % | 94.54 | ASTM C-184 |

| Initial setting time | mints | 139.00 | ASTM C-191 |

| Final setting time | mints | 185.00 | ASTM C-191 |

| Soundness | mm | 1.00 | BS 196–3 |

| Fine Aggregates (sand) | |||

| Fineness modulus | – | 2.21 | ASTM C-136 |

| Bulk density | kg/m3 | 1530.00 | ASTM C-29 |

| Processed Waste Tea (PWT) | |||

| Fineness modulus | – | 3.55 | ASTM C-136 |

| Bulk density | kg/m3 | 514 | ASTM C-29 |

| Wood Sawdust (WSD) | |||

| Fineness modulus | – | 2.92 | ASTM C-136 |

| Bulk density | kg/m3 | 677 | ASTM C-29 |

| Rice Husk Ash (RHA) | |||

| Fineness modulus | – | 1.66 | ASTM C-136 |

| Bulk density | kg/m3 | 152 | ASTM C-29 |

| Coarse Aggregates | |||

| Bulk density | kg/m3 | 1500.00 | ASTM C-29 |

| Aggregate impact value | % | 22.21 | BS 812-3 |

| Aggregate crushing value | % | 28.11 | BS 812-3 |

| Los Angeles abrasion | % | 30.00 | ASTM C-131 |

| Water absorption | % | 2.43 | ASTM C-127 |

| Mix ID | Grade | Details |

|---|---|---|

| P.C.C | M15 | M15 grade Concrete (1:2:4) |

| WSD | Replacement of sand with 5%, 10%, 15% wood sawdust | |

| RHA | Replacement of sand with 5%, 10%, 15% rice husk ash | |

| PWT | Replacement of sand with 5%, 10%, 15% processes waste tea | |

| P.C.C | M20 | M20 grade concrete (1:1.5:3) |

| WSD | Replacement of sand with 5%, 10%, 15% wood saw dust | |

| RHA | Replacement of sand with 5%, 10%, 15% rice husk ash | |

| PWT | Replacement of sand with 5%, 10%, 15% processes waste tea |

| Variable | Mean | St. Dev | Min. | Q1 | Median | Q3 | Max. |

|---|---|---|---|---|---|---|---|

| Replacement (%) | 9 | 4.92 | 0 | 5 | 10 | 15 | 15 |

| Curing (days) | – | – | 7 | 7 | – | 28 | 28 |

| Cement (kg/m3) | 354.5 | 37.66 | 317 | 317 | 354.5 | 392 | 392 |

| Sand (kg/m3) | 599.25 | 35.68 | 546 | 573 | 607 | 633.5 | 674 |

| Waste material (kg/m3) | 17.35 | 13.57 | 0 | 6.48 | 12.75 | 29.48 | 44.7 |

| Aggregate (kg/m3) | 1290.5 | 30.6 | 1260 | 1260 | 1290.5 | 1321 | 1321 |

| Water (kg/m3) | 198.5 | 23.6 | 175 | 175 | 198.5 | 222 | 222 |

| Fresh density (kg/m3) | 2336.1 | 34.2 | 2253 | 2311.5 | 2330.5 | 2355.8 | 2421 |

| Hardened density (kg/m3) | 2264.4 | 27.9 | 2208 | 2244.3 | 2264 | 2287.5 | 2330 |

| Slump (mm) | 67.4 | 17.32 | 35 | 53.25 | 66 | 78 | 113 |

| Compressive strength (MPa) | 12.52 | 6.348 | 2.27 | 7.396 | 11.944 | 16.817 | 27.78 |

| Flexural strength (MPa) | 2.907 | 1.357 | 0.643 | 1.775 | 2.85 | 3.928 | 6.14 |

| Tensile strength (MPa) | 1.6932 | 0.8903 | 0.1415 | 1.0303 | 1.6781 | 2.2597 | 3.51 |

| Measures | Training | Validation |

|---|---|---|

| Compressive Strength (MPa) | ||

| R2 | 0.969402 | 0.9575216 |

| RMSE | 1.1083706 | 1.2900781 |

| Sum freq | 96 | 24 |

| Tensile Strength (MPa) | ||

| R2 | 0.9746607 | 0.9772819 |

| RMSE | 0.1412995 | 0.13299 |

| Sum freq | 96 | 24 |

| Flexural Strength (MPa) | ||

| R2 | 0.9493726 | 0.9459538 |

| RMSE | 0.2944877 | 0.3492705 |

| Sum freq | 96 | 24 |

| Parameter | Main Effect | Total Effect | Profile |

|---|---|---|---|

| Overall | |||

| Modifier | 0.487 | 0.563 |  |

| Curing (days) | 0.195 | 0.24 |  |

| Concrete grade | 0.087 | 0.136 |  |

| Slump (mm) | 0.029 | 0.11 |  |

| Replacement (%) | 0.037 | 0.073 |  |

| Hardened density (kg/m3) | 0.035 | 0.06 |  |

| Fresh density (kg/m3) | 0.017 | 0.035 |  |

| Compressive Strength (MPa) | |||

| Modifier | 0.544 | 0.664 |  |

| Curing (days) | 0.15 | 0.198 |  |

| Slump (mm) | 0.03 | 0.148 |  |

| Concrete grade | 0.088 | 0.132 |  |

| Replacement (%) | 0.017 | 0.041 |  |

| Hardened density (kg/m3) | 0.014 | 0.03 |  |

| Fresh density (kg/m3) | 0.013 | 0.024 |  |

| Tensile Strength (MPa) | |||

| Modifier | 0.457 | 0.501 |  |

| Curing (days) | 0.212 | 0.252 |  |

| Concrete grade | 0.083 | 0.125 |  |

| Hardened density (kg/m3) | 0.066 | 0.101 |  |

| Replacement (%) | 0.057 | 0.096 |  |

| Slump (mm) | 0.03 | 0.086 |  |

| Fresh density (kg/m3) | 0.012 | 0.019 |  |

| Flexural Strength (MPa) | |||

| Modifier | 0.46 | 0.524 |  |

| Curing (days) | 0.224 | 0.27 |  |

| Concrete grade | 0.091 | 0.15 |  |

| Slump (mm) | 0.026 | 0.096 |  |

| Replacement (%) | 0.036 | 0.081 |  |

| Fresh density (kg/m3) | 0.026 | 0.063 |  |

| Hardened density (kg/m3) | 0.025 | 0.049 |  |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alhazmi, H.; Shah, S.A.R.; Basheer, M.A. Performance Evaluation of Road Pavement Green Concrete: An Application of Advance Decision-Making Approach before Life Cycle Assessment. Coatings 2021, 11, 74. https://doi.org/10.3390/coatings11010074

Alhazmi H, Shah SAR, Basheer MA. Performance Evaluation of Road Pavement Green Concrete: An Application of Advance Decision-Making Approach before Life Cycle Assessment. Coatings. 2021; 11(1):74. https://doi.org/10.3390/coatings11010074

Chicago/Turabian StyleAlhazmi, Hatem, Syyed Adnan Raheel Shah, and Muhammad Aamir Basheer. 2021. "Performance Evaluation of Road Pavement Green Concrete: An Application of Advance Decision-Making Approach before Life Cycle Assessment" Coatings 11, no. 1: 74. https://doi.org/10.3390/coatings11010074

APA StyleAlhazmi, H., Shah, S. A. R., & Basheer, M. A. (2021). Performance Evaluation of Road Pavement Green Concrete: An Application of Advance Decision-Making Approach before Life Cycle Assessment. Coatings, 11(1), 74. https://doi.org/10.3390/coatings11010074