Indium Tin Oxide Thin Film Deposition by Magnetron Sputtering at Room Temperature for the Manufacturing of Efficient Transparent Heaters

Abstract

1. Introduction

2. Materials and Methods

3. Results

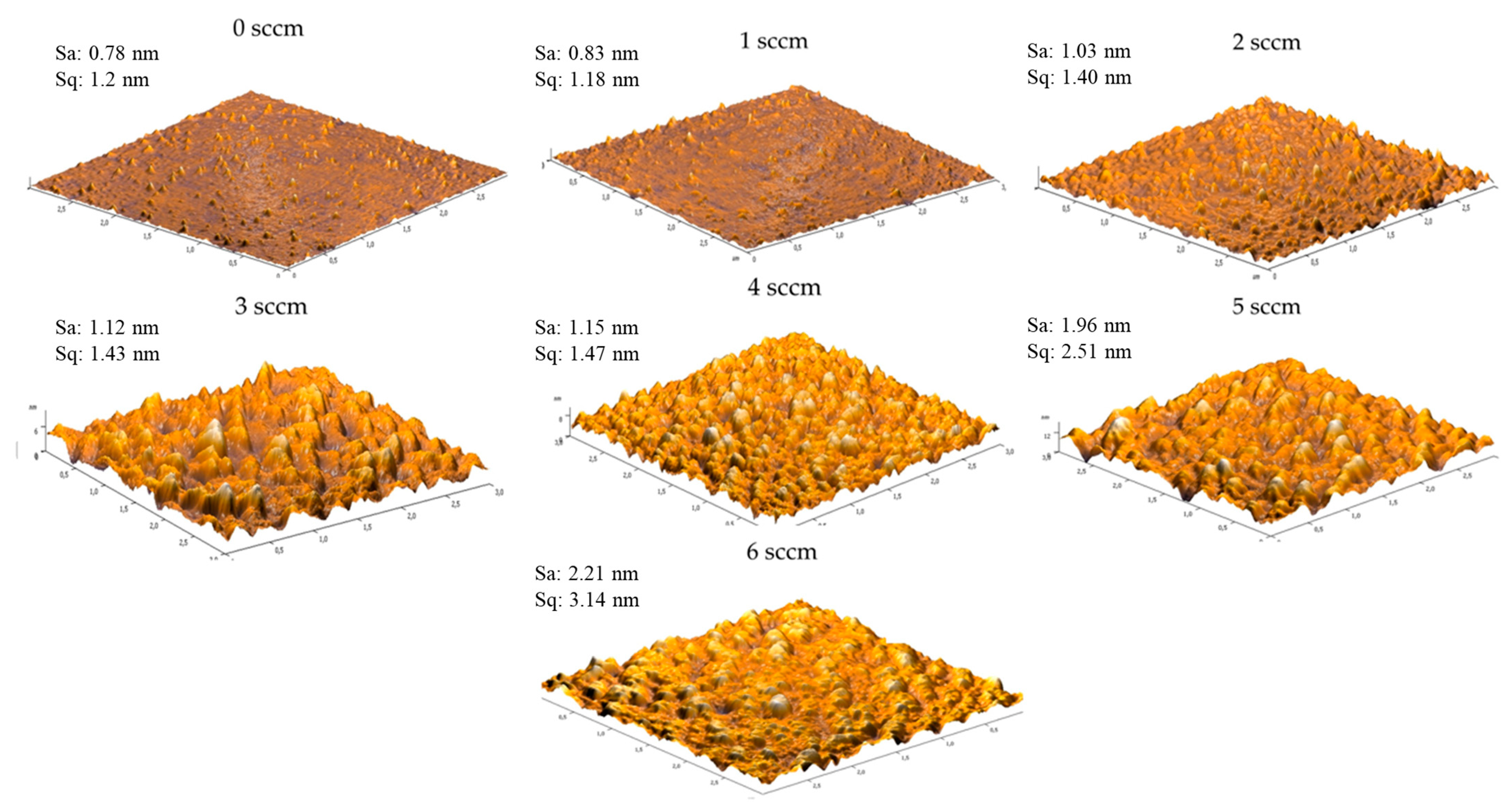

3.1. Effects of Oxygen Flow on the Morphology of ITO Thin Films

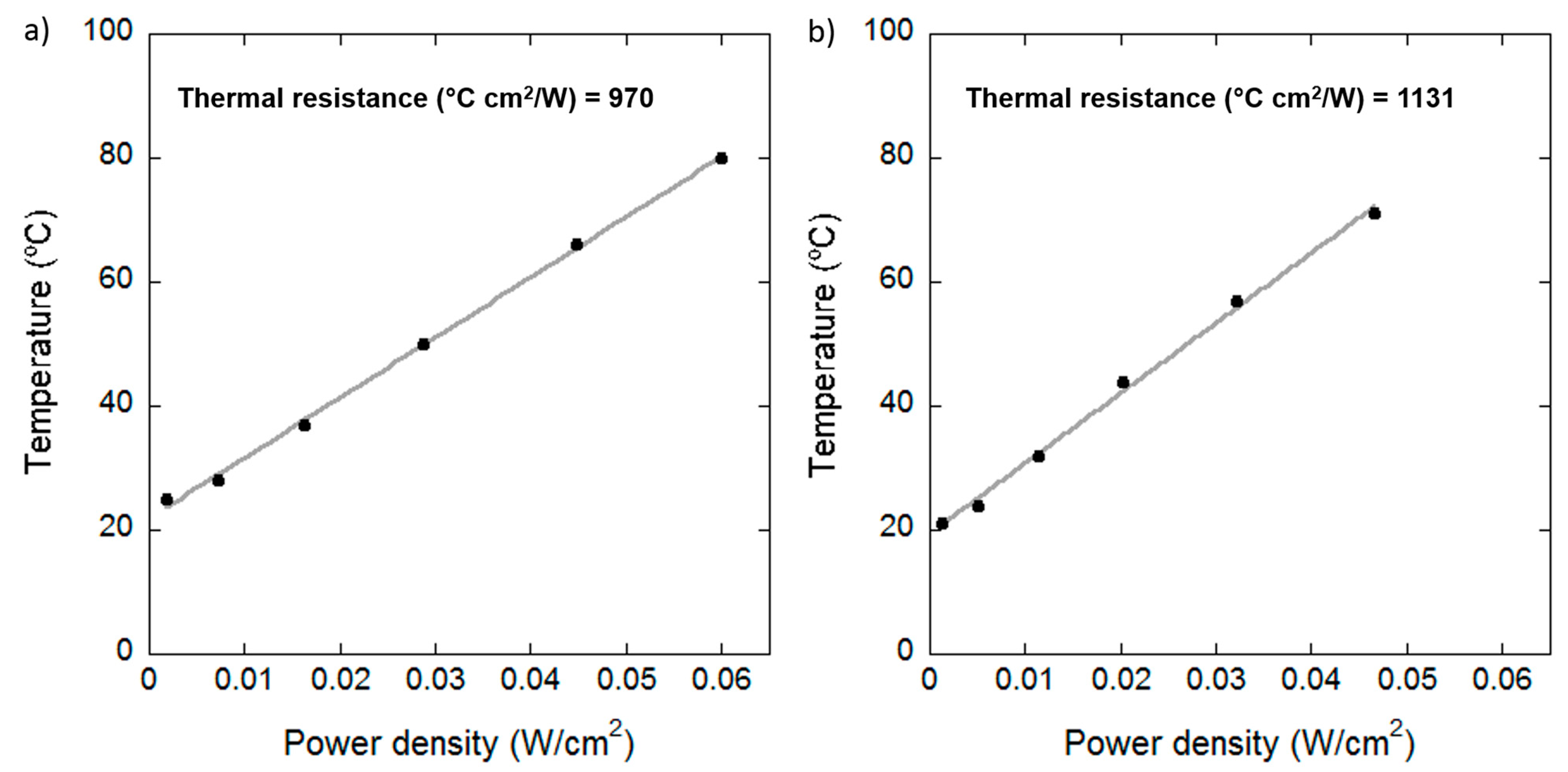

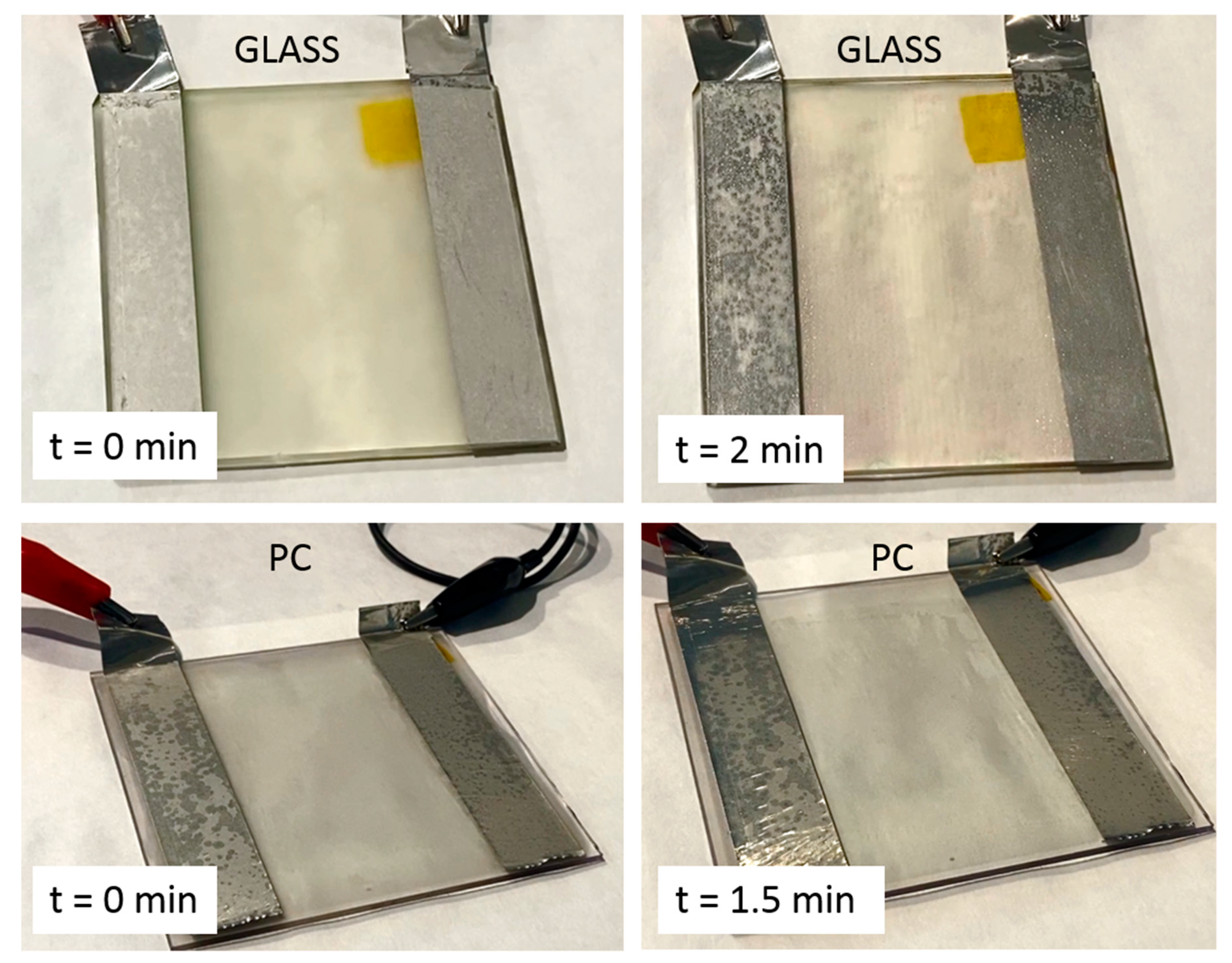

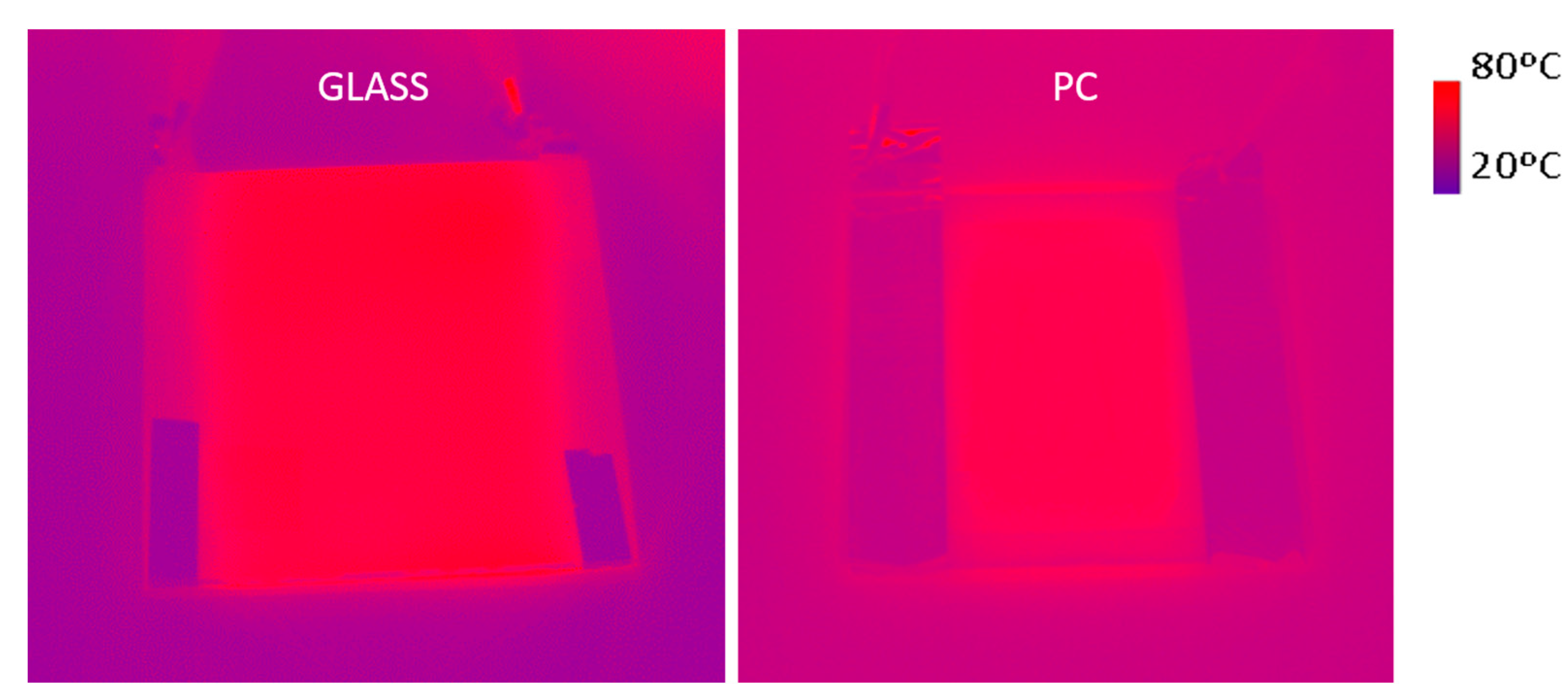

3.2. Manufacturing of Transparent ITO Heaters

4. Discussion

4.1. Effects of Oxygen Flow on Microstructural and Optoelectronic Properties of ITO Thin Films

4.1.1. Low Oxygen Region or Suboxide Region (0–1 sccm)

4.1.2. Medium Oxygen—Optimum Region (2–5 sccm)

4.1.3. High Oxygen or Oxygen Excess Region (up to 6 sccm)

4.2. Manufacturing of Transparent ITO Heaters

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Granqvist, C.G.; Hultåker, A. Transparent and conducting ITO films: New developments and applications. Thin Solid Films 2002, 411, 1–5. [Google Scholar] [CrossRef]

- Hotovy, J.; Hüpkes, J.; Böttler, W.; Marins, E.; Spiess, L.; Kups, T.; Smirnov, V.; Hotovu, I.; Kovác, J. Sputtered ITO for applications in thin-film silicon solar cells: Relationship between structural and electrical properties. Appl. Surf. Sci. 2013, 269, 81–87. [Google Scholar] [CrossRef]

- Maniyara, R.A.; Mkhitaryan, V.K.; Chen, T.L.; Ghosh, D.S.; Pruneri, V. An antireflection transparent conductor with ultralow optical loss (<2%) and electrical resistance. Nat. Commun. 2016, 7, 13771. [Google Scholar] [CrossRef] [PubMed]

- Papanastasiou, D.T.; Schultheiss, A.; Muñoz-Rojas, D.; Cell, C.; Carella, A.; Simonato, J.P.; Bellet, D. Transparent heaters: A review. Adv. Funct. Mater. 2020, 30, 1910225. [Google Scholar] [CrossRef]

- Oxyzoglou, I.; Tejero, A. Prediction of condensation forming in automotive headlights using CFD. Tech. Rep. TOYOTA Motor Eur. 2018. [Google Scholar] [CrossRef]

- Szyszka, B.; Dewald, W.; Gurram, S.K.; Pflug, A.; Schulz, C.; Siemers, M.; Sittinger, V.; Ulrich, S. Recent developments in the field of transparent conductive oxide films for spectral selective coatings, electronics and photovoltaics. Curr. Appl. Phys. 2012, 12, S2–S11. [Google Scholar] [CrossRef]

- Elhalawaty, S.; Sivaramakrishnan, K.; Theodore, N.D.; Alford, T.L. The effect of sputtering pressure on electrical optical and structure properties of indium tin oxide on glass. Thin Solid Films 2010, 518, 3326–3331. [Google Scholar] [CrossRef]

- Park, C.H.; Lee, J.H.; Choi, B.H. Effects of the surface treatment of ITO anode layer patterned with shadow mask technology on characteristics of organic light-emitting diodes. Org. Electron. 2013, 14, 3172–3179. [Google Scholar] [CrossRef]

- Yang, C.; Lee, S.; Lin, T.; Chen, S. Electrical and optical properties of indium tin oxide films prepared on plastic substrate by radio frequency magnetron sputtering. Thin Solid Films 2008, 516, 1984–1991. [Google Scholar] [CrossRef]

- Sato, Y.; Taketomo, M.; Ito, N.; Miyamura, A.; Shigestao, Y. Comparative study on early stages of film growth for transparent conductive oxide films deposited by dc magnetron sputtering. Thin Solid Films 2008, 516, 4598–4602. [Google Scholar] [CrossRef]

- Fallah, H.R.; Ghasemi, M.; Vahid, M.J. Substrate temperature effect on transparent heat reflecting nanocrystalline IOT films prepared by electron beam evaporation. Renew. Energy 2009, 35, 1527–1530. [Google Scholar] [CrossRef]

- Viespe, C.; Nicolae, I.; Sima, C.; Grigoriu, C.; Medianu, R. ITO films deposited by advanced pulsed laser deposition. Thin Solid Films 2007, 515, 8771–8775. [Google Scholar] [CrossRef]

- Rozati, M.; Ganj, T. Transparent conductive Sn-doped indium oxide thin film deposited by spray pyrolysis techniques. Renew. Energy 2004, 29, 1671–1676. [Google Scholar] [CrossRef]

- Kurdesau, F.; Khripunov, G.; da Cunha, A.F.; Kaelin, M.; Tiwari, A.N. Comparative study of ITO layers deposited by DC and RF magnetron sputtering at room temperature. J. Non-Crystall. Solids 2006, 352, 1466–1470. [Google Scholar] [CrossRef]

- Bhagwat, S.; Howson, R.P. Use of the magnetron-sputtering technique for the control of the properties of indium tin oxide thin films. Surf. Coat. Technol. 1999, 111, 163–171. [Google Scholar] [CrossRef]

- Guillén, C.; Herrero, J. Influence of oxygen in the deposition and annealing atmosphere on the characteristic on ITO thin film prepared but sputtering at room temperature. Thin Solid Films 2005, 480–481, 129–132. [Google Scholar]

- Guillén, C.; Herrero, J. Polycrystalline growth and recrystallinization process in sputtering ITO thin films. Thin Solid Films 2006, 510, 260–264. [Google Scholar] [CrossRef]

- Morikawa, H.; Fujita, M. Crystallization and electrical property change on the annealing of amorphous indium-oxide and indium tin oxide films. Thin Solid Films 2000, 359, 61–67. [Google Scholar] [CrossRef]

- Gui, Y.; Miscuglio, M.; Ma, Z.; Tahersima, M.H.; Sun, S.; Amin, R.; Dalir, H.; Sorger, V.J. Towards integrated mecatronics: A holistic approach on precise optical and electrical properties of Indium Tin Oxide. Sci. Rep. 2019, 9, 11279. [Google Scholar] [CrossRef]

- Mudryi, A.; Ivaniukovich, A.V.; Ulyashin, A. Deposition by magnetron sputtering and characterization of indium tin oxide thin films. Thin Solid Films 2007, 515, 6489–6492. [Google Scholar] [CrossRef]

- Ghorannevis, Z.; Akbarnejad, E.; Ghoranneviss, M. Structural and morphological properties of ITO thin films grown by magnetron sputtering. Theor. Appl. Phys. 2015, 9, 285–290. [Google Scholar] [CrossRef]

- Tien, C.-L.; Lin, H.-Y.; Chang, C.-K.; Tang, C.-J. Effect of Oxygen Flow Rate on the Optical, Electrical, and Mechanical Properties of DC Sputtering ITO Thin Films. Adv. Condens. Matter Phys. 2018, 2018, 1–6. [Google Scholar] [CrossRef]

- Im, K.; Cho, K.; Kim, J.; Kim, S. Transparent heaters based on solution-processed indium tin oxide nanoparticles. Thin Solid Films 2010, 518, 3960–3963. [Google Scholar] [CrossRef]

- Kim, C.; Park, J.W.; Kim, J.; Hong, S.J.; Lee, M.J. A highly efficient indium tin oxide nanoparticles (ITO-NPs) transparent heater based on solution-process optimized with oxygen vacancy control. J. Alloys Compd. 2017, 726, 712–719. [Google Scholar] [CrossRef]

- Moon, C.S.; Han, J.G. Low temperature synthesis of ITO thin film on polymer in Ar2/H2 plasm by pulsed DC magnetron sputtering. Thin Solid Films 2008, 516, 6560–6564. [Google Scholar] [CrossRef]

- Bouroushian, M. Characterization of Thin Films by Low Incidence X-Ray Diffraction. Cryst. Struct. Theory Appl. 2012, 1, 35–39. [Google Scholar] [CrossRef]

- Coating of Glass Optical Elements (Anti-Reflection). Military Specification, MIL-C-675C. 1980. Available online: https://www.irdglass.com/wp-content/uploads/2016/07/MIL-C-675C-AR-coatings.pdf (accessed on 14 January 2021).

- Dutta, J.; Ray, S. Variation in structural and electrical properties of magnetron-sputtered Indium Tin Oxide films with deposition parameters. Thin Solid Films 1988, 162, 119–127. [Google Scholar] [CrossRef]

- Haacke, G.J. New figure of merit for transparent conductors. J. Appl. Phys. 1976, 47, 4086. [Google Scholar] [CrossRef]

- Xian, S.; Nie, L.; Qin, J.; Kang, T.; Li, C.; Xie, J.; Deng, L.; Lei, B. Effect of oxygen stoichiometry on the structure, optical and epsilon-near-zero properties of indium tin oxide films. Opt. Express 2019, 27, 28618–28628. [Google Scholar] [CrossRef]

- Munir, M.M.; Iskandar, F.; Yun, K.M.; Okuyama, K.; Abdullah, M. Optical and electrical properties of indium tin oxide nanofibers prepared by electrospinning. Nanotechnology 2008, 19, 145603. [Google Scholar] [CrossRef]

- Buchanan, M.; Webb, J.B.; Williams, D.F. Preparation of conducting and transparent thin films of tin-doped indium oxide by magnetron sputtering. Appl. Phys. Lett. 1980, 37, 213–215. [Google Scholar] [CrossRef]

- Hoshi, Y.; Kato, H.; Funatsu, K. Structure and electrical properties of ITO thin films deposited at high rate by facing target sputtering. Thin Solid Films 2003, 445, 245–250. [Google Scholar] [CrossRef]

- Vink, T.J.; Walrave, W.; Daams, J.L.C.; Baarslag, P.C.; van den Meerakker, J.E.A.M. On the homogeneity of sputter-deposited ITO films Part I. Stress and microstructure. Thin Solid Films 1995, 266, 145–151. [Google Scholar] [CrossRef]

- Fan, J.C.C.; Goodenough, J.B. X-ray photoemission spectroscopy studies of Sn-doped indium-oxide films. J. Appl. Phys. 1977, 48, 3524–3531. [Google Scholar] [CrossRef]

- Masis, M.M.; De Wolf, S.; Woods-Robinson, R.; Ager, J.W.; Ballif, C. Transparent Electrodes for Efficient Optoelectronic. Adv. Electron. Mater. 2017, 3, 1600529. [Google Scholar] [CrossRef]

- Wong, F.L.; Fung, M.K.; Tong, S.W.; Lee, C.S.; Lee, S.T. Flexible organic light-emitting device based on magnetron sputtered indium-tin-oxide on plastic substrate. Thin Solid Films 2004, 466, 225–230. [Google Scholar] [CrossRef]

- Kim, J.; Shrestha, S.; Souri, M.; Connell, J.G.; Park, S.; Seo, A. High-temperature optical properties of indium tin oxide thin-films. Nat. Res. Sci. Rep. 2020, 10, 12486. [Google Scholar] [CrossRef]

- Lee, H.C.; Ok Park, O. Behaviours of carrier concentrations and mobilities in indium-tin oxide thin films by DC magnetron sputtering at various oxygen flow rates. Vacuum 2004, 77, 69–77. [Google Scholar] [CrossRef]

- Khaligh, H.H.; Xu, L.; Khosropour, A.; Madeira, A.; Romano, M.; Pradére, C.; Tréguer-Delapierre, M.; Servant, L.; Pope, M.A.; Goldthorpe, I.A. The Joule heating problem in silver nanowire transparent electrodes. Nanotechnology 2017, 28, 425703. [Google Scholar] [CrossRef]

| Oxygen Flow (sccm) | T (%) | µ (cm2/Vs) | n (/cm3) | SR (Ω/sq) | ρ (Ω·cm) | FoM ϕVIS (Ω−1) |

|---|---|---|---|---|---|---|

| 0 | 57.7 ± 0.7 | 1.7 ± 0.2 | (4.12 ± 0.03) × 1020 | 680 ± 50 | (9.2 ± 0.5) × 10−3 | 0.85 × 10−3 |

| 1 | 65.8 ± 0.4 | 5.97 ± 0.06 | (4.7 ± 0.2) × 1020 | 170 ± 10 | (2.2 ± 0.1) × 10−3 | 3.87 × 10−3 |

| 2 | 75 ± 1 | 11.7 ± 0.4 | (5.4 ± 0.8) × 1020 | 79 ± 9 | (1.0 ± 0.1) × 10−3 | 9.49 × 10−3 |

| 3 | 79.2 ± 0.9 | 18 ± 1 | (4.2 ± 0.2) × 1020 | 63 ± 5 | (8.3 ± 0.7) × 10−4 | 12.6·× 10−3 |

| 4 | 80.8 ± 0.3 | 28.7 ± 0.9 | (2.4 ± 0.3) × 1020 | 77 ± 6 | (7.9 ± 0.8) × 10−4 | 10.5·× 10−3 |

| 5 | 81.7 ± 0.6 | 36 ± 1 | (1.5 ± 0.2) × 1020 | 95 ± 9 | (1.2 ± 0.1) × 10−3 | 8.60 × 10−3 |

| 6 | 82.9 ± 0.5 | 26 ± 1 | (4.2 ± 0.1) × 1019 | 428 ± 15 | (5.6 ± 0.1) × 10−3 | 1.94·× 10−3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Txintxurreta, J.; G-Berasategui, E.; Ortiz, R.; Hernández, O.; Mendizábal, L.; Barriga, J. Indium Tin Oxide Thin Film Deposition by Magnetron Sputtering at Room Temperature for the Manufacturing of Efficient Transparent Heaters. Coatings 2021, 11, 92. https://doi.org/10.3390/coatings11010092

Txintxurreta J, G-Berasategui E, Ortiz R, Hernández O, Mendizábal L, Barriga J. Indium Tin Oxide Thin Film Deposition by Magnetron Sputtering at Room Temperature for the Manufacturing of Efficient Transparent Heaters. Coatings. 2021; 11(1):92. https://doi.org/10.3390/coatings11010092

Chicago/Turabian StyleTxintxurreta, Jago, Eva G-Berasategui, Rocío Ortiz, Oihane Hernández, Lucía Mendizábal, and Javier Barriga. 2021. "Indium Tin Oxide Thin Film Deposition by Magnetron Sputtering at Room Temperature for the Manufacturing of Efficient Transparent Heaters" Coatings 11, no. 1: 92. https://doi.org/10.3390/coatings11010092

APA StyleTxintxurreta, J., G-Berasategui, E., Ortiz, R., Hernández, O., Mendizábal, L., & Barriga, J. (2021). Indium Tin Oxide Thin Film Deposition by Magnetron Sputtering at Room Temperature for the Manufacturing of Efficient Transparent Heaters. Coatings, 11(1), 92. https://doi.org/10.3390/coatings11010092