Self-Healing UV-Curable Acrylate Coatings for Wood Finishing System, Part 2: Impact of Monomer Structure and Self-Healing Parameters on Self-Healing Efficiency

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Coating Formulation and Application Procedure

2.3. Physicochemical and Mechanical Characterization

2.3.1. Fourier Transformation Infrared Spectroscopy Measurements (FTIR)

2.3.2. Dynamic Mechanical Analysis Measurements (DMA)

2.3.3. Hardness Characterizations

Pendulum Damping Tests

Indentation Measurements

2.3.4. Reverse Impact Resistance

2.4. Self-Healing Characterization

2.4.1. Self-Healing Characterization by Gloss Measurements

2.4.2. Self-Healing Characterization by Scratch Depth Measurements

3. Results and Discussion

3.1. Physicochemical and Mechanical Characterization

3.1.1. Fourier Transformation Infrared Spectroscopy

3.1.2. Dynamic Mechanical Analysis

3.1.3. Hardness

3.1.4. Impact Resistance

3.2. Self-Healing Characterization

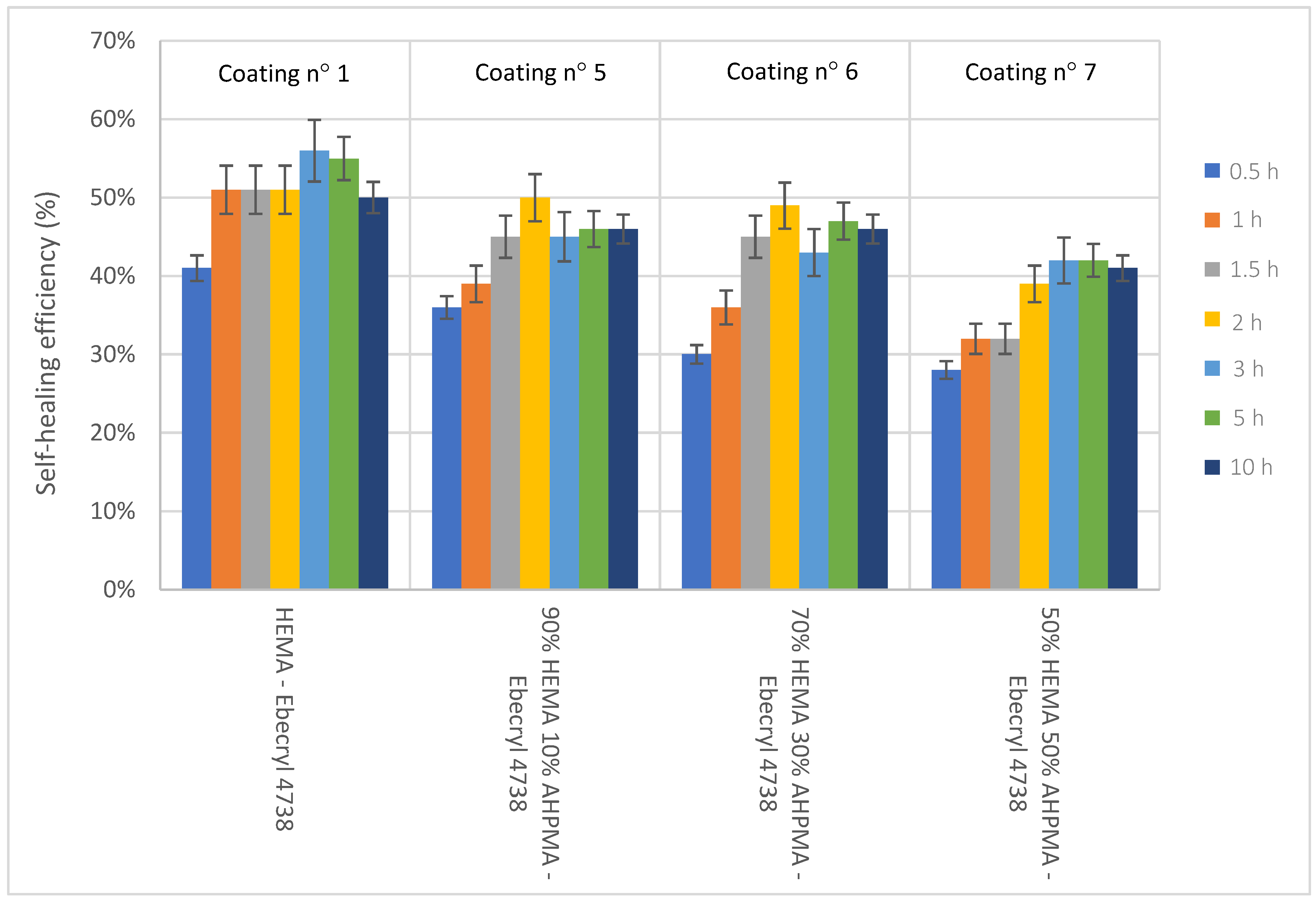

3.2.1. Self-healing Characterization by Gloss Measurements

3.2.2. Self-Healing Characterization by Scratch Depth Measurements

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yin, J.; Zhu, S.; MacNaughton, P.; Allen, J.G.; Spengler, J.D. Physiological and cognitive performance of exposure to biophilic indoor environment. Build. Environ. 2018, 132, 255–262. [Google Scholar] [CrossRef]

- Wilson, E.O. Biophilia; Harvard University Press: Cambridge, MA, USA, 1986; ISBN 978-0-674-04523-1. [Google Scholar]

- Nyrud, A.Q.; Bringslimark, T.; Bysheim, K. Benefits from wood interior in a hospital room: A preference study. Arch. Sci. Rev. 2013, 57, 125–131. [Google Scholar] [CrossRef]

- Stratégie d’utilisation du bois Dans la Construction. Available online: https://afsq.org/information-foret/amenagement/gestion-forestiere/foret-publique/regime-forestier-quebecois/ (accessed on 20 July 2021).

- Lamason, C.; Gong, M. Optimization of Pressing Parameters for Mechanically Surface-Densified Aspen. For. Prod. J. 2007, 57, 64–68. [Google Scholar]

- Triquet, J.; Blanchet, P.; Landry, V. Hardness of Chemically Densified Yellow Birch in Relation to Wood Density, Polymer Content and Polymer Properties. Available online: https://www-degruyter-com.acces.bibl.ulaval.ca/document/doi/10.1515/hf-2020-0076/html (accessed on 20 July 2021).

- Blaiszik, B.; Kramer, S.; Olugebefola, S.; Moore, J.; Sottos, N.; White, S. Self-Healing Polymers and Composites. Annu. Rev. Mater. Res. 2010, 40, 179–211. [Google Scholar] [CrossRef]

- Müller, B. Coatings Formulation; Vincentz Network: Hannover, Germany, 2011; ISBN 978-3-86630-891-6. [Google Scholar]

- Zhong, N.; Post, W. Self-repair of structural and functional composites with intrinsically self-healing polymer matrices: A review. Compos. Part A Appl. Sci. Manuf. 2015, 69, 226–239. [Google Scholar] [CrossRef] [Green Version]

- Herbst, F.; Döhler, D.; Michael, P.; Binder, W.H. Self-Healing Polymers via Supramolecular Forces. Macromol. Rapid Commun. 2013, 34, 203–220. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Dam, M.A.; Ono, K.; Mal, A.; Shen, H.; Nutt, S.R.; Sheran, K.; Wudl, F. A Thermally Re-mendable Cross-Linked Polymeric Material. Science 2002, 295, 1698–1702. [Google Scholar] [CrossRef] [PubMed]

- Murphy, E.B.; Bolanos, E.; Schaffner-Hamann, C.; Wudl, F.; Nutt, S.R.; Auad, M. Synthesis and Characterization of a Single-Component Thermally Remendable Polymer Network: Staudinger and Stille Revisited. Macromolecules 2008, 41, 5203–5209. [Google Scholar] [CrossRef]

- Jo, Y.Y.; Lee, A.S.; Baek, K.-Y.; Lee, H.; Hwang, S.S. Thermally reversible self-healing polysilsesquioxane structure-property relationships based on Diels-Alder chemistry. Polymer 2017, 108, 58–65. [Google Scholar] [CrossRef]

- Boyer, D.B.; Chalkley, Y.; Chan, K.C. Correlation between strength of bonding to enamel and mechanical properties of dental composites. J. Biomed. Mater. Res. 1982, 16, 775–783. [Google Scholar] [CrossRef] [PubMed]

- Paquet, C.; Schmitt, T.; Klemberg-Sapieha, J.E.; Morin, J.-F.; Landry, V. Self-Healing UV Curable Acrylate Coatings for Wood Finishing System, Part 1: Impact of the Formulation on Self-Healing Efficiency. Coatings 2020, 10, 770. [Google Scholar] [CrossRef]

- Chen, Y.; Kushner, A.M.; Williams, G.A.; Guan, Z. Multiphase design of autonomic self-healing thermoplastic elastomers. Nat. Chem. 2012, 4, 467–472. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Cao, J.; Zhou, Z.; Liu, R.; Yuan, Y.; Liu, X. Stiff Self-Healing Coating Based on UV-Curable Polyurethane with a “Hard Core, Flexible Arm” Structure. ACS Omega 2018, 3, 11128–11135. [Google Scholar] [CrossRef] [PubMed]

- Cortese, J.; Soulié-Ziakovic, C.; Tencé-Girault, S.; Leibler, L. Suppression of Mesoscopic Order by Complementary Interactions in Supramolecular Polymers. J. Am. Chem. Soc. 2012, 134, 3671–3674. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Liang, H.; Yang, H.; Xiong, L.; Zhou, J.; Huang, S.; Zhao, C.; Zhong, J.; Fan, X. UV-curable self-healing polyurethane coating based on thiol-ene and Diels-Alder double click reactions. Prog. Org. Coat. 2019, 137, 105282. [Google Scholar] [CrossRef]

- Fan, F.; Szpunar, J. The self-healing mechanism of an industrial acrylic elastomer. J. Appl. Polym. Sci. 2015, 132, 132. [Google Scholar] [CrossRef]

- Abdallh, M.; Hearn, M.T.W.; Simon, G.P.; Saito, K. Light triggered self-healing of polyacrylate polymers crosslinked with 7-methacryloyoxycoumarin crosslinker. Polym. Chem. 2017, 8, 5875–5883. [Google Scholar] [CrossRef]

- Furtak-Wrona, K.; Kozik-Ostrówka, P.; Jadwiszczak, K.; Maigret, J.; Aguié-Béghin, V.; Coqueret, X. Polyurethane acrylate networks including cellulose nanocrystals: A comparison between UV and EB- curing. Radiat. Phys. Chem. 2018, 142, 94–99. [Google Scholar] [CrossRef]

- ASTM D4366. Available online: https://www.astm.org/Standards/D4366.htm (accessed on 20 July 2021).

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Wilson, L.; Illanes, A.; Soler, L.; Henríquez, M.J. Effect of the degree of cross-linking on the properties of different CLEAs of penicillin acylase. Process. Biochem. 2009, 44, 322–326. [Google Scholar] [CrossRef]

- Kinetic Study of Free-Radical Polymerization of Multifunctional Acrylates and Methacrylates. Available online: http://www.imaging.org/site/PDFS/Papers/1997/IST-0-4/150.pdf (accessed on 1 October 2021).

- Interpretation of ASTM Testing 2009. Endura Paint. Available online: https://www.endurapaint.com/wp-content/uploads/pdf/astm.pdf (accessed on 1 October 2021).

| Name | Description | Molecular Weight (g/mol) | Viscosity (cP) | Supplier | Function |

|---|---|---|---|---|---|

| AHPMA | 3-(Acryloyloxy)-2-hydroxypropyl methacrylate | 214.2 | 44 | Sigma-Aldrich | Monomer |

| PETA | Pentaerythritol triacrylate | 298.3 | 1000 | Sigma-Aldrich | Monomer |

| HEMA | 2-Hydroxyethyl methacrylate | 130.1 | 6 | Sigma-Aldrich | Monomer |

| Ebecryl 4738 | Aliphatic urethane acrylate, hard resin | confidential | 35,000 | Allnex | Acrylated allophanate oligomer |

| HMPP | 2-Hydroxy-2-methylpropiophenone | 164.2 | 0 | Canlak | Photoinitiator absorbing at 240 nm |

| n° | Monomer | Oligomer | moligomer (g) | mHEMA (g) | m2nd monomer (g) | mphotoinitiator (g) | η (cP) |

|---|---|---|---|---|---|---|---|

| 1 | HEMA | Ebecryl 4738 | 82.5 | 17.5 | x | 3 | 2336 |

| 2 | 90% HEMA 10% PETA | 83.2 | 15.1 | 1.7 | 3.2 | 2285 | |

| 3 | 70% HEMA 30% PETA | 80.8 | 13.4 | 5.8 | 3 | 2407 | |

| 4 | 50% HEMA 50% PETA | 77.4 | 11.3 | 11.3 | 3.2 | 2271 | |

| 5 | 90% HEMA 10% AHPMA | 84.2 | 14.2 | 1.6 | 2.9 | 2301 | |

| 6 | 70% HEMA 30% AHPMA | 83.0 | 11.9 | 5.1 | 3.1 | 2174 | |

| 7 | 50% HEMA 50% AHPMA | 81.0 | 9.5 | 9.5 | 3.2 | 2350 |

| n° | Monomer | Oligomer | Average Functionality | Conversion (%) |

|---|---|---|---|---|

| 1 | HEMA | Ebecryl 4738 | 1.87 | 62 ± 1 |

| 2 | 90% HEMA 10% PETA | 1.97 | 53 ± 1 | |

| 3 | 70% HEMA 30% PETA | 2.08 | 57 ± 2 | |

| 4 | 50% HEMA 50% PETA | 2.22 | 65 ± 1 | |

| 5 | 90% HEMA 10% AHPMA | 1.98 | 61 ± 1 | |

| 6 | 70% HEMA 30% AHPMA | 2.06 | 64 ± 1 | |

| 7 | 50% HEMA 50% AHPMA | 2.13 | 63 ± 3 |

| n° | Monomer | Oligomer | Tg (°C) = max(E″) | Max tan(δ) (°C) | CLD (mol/m3) |

|---|---|---|---|---|---|

| 1 | HEMA | Ebecryl 4738 | 78 ± 2 | 100 ± 2 | 3268 ± 89 |

| 2 | 90% HEMA 10% PETA | 75 ± 1 | 98 ± 1 | 2869 ± 127 | |

| 3 | 70% HEMA 30% PETA | 76 ± 2 | 101 ± 1 | 3848 ± 257 | |

| 4 | 50% HEMA 50% PETA | 76 ± 2 | 108 ± 2 | 4935 ± 115 | |

| 5 | 90% HEMA 10% AHPMA | 74 ± 2 | 97 ± 1 | 3295 ± 122 | |

| 6 | 70% HEMA 30% AHPMA | 74 ± 2 | 100 ± 1 | 4062 ± 159 | |

| 7 | 50% HEMA 50% AHPMA | 75 ± 1 | 105 ± 1 | 4589 ± 184 |

| n° | Monomer | Oligomer | Hardness Pendulum (osc) |

|---|---|---|---|

| 1 | HEMA | Ebecryl 4738 | 81 ± 1 |

| 2 | 90% HEMA 10% PETA | 77 ± 3 | |

| 3 | 70% HEMA 30% PETA | 79 ± 2 | |

| 4 | 50% HEMA 50% PETA | 110 ± 7 | |

| 5 | 90% HEMA 10% AHPMA | 73 ± 2 | |

| 6 | 70% HEMA 30% AHPMA | 74 ± 3 | |

| 7 | 50% HEMA 50% AHPMA | 95 ± 3 |

| n° | Monomer | Oligomer | HIT (MPa) | E* (GPa) |

|---|---|---|---|---|

| 1 | HEMA | Ebecryl 4738 | 231 ± 10 | 6.2 ± 0.2 |

| 2 | 90% HEMA 10% PETA | 243 ± 8 | 6.0 ± 0.3 | |

| 3 | 70% HEMA 30% PETA | 291 ± 7 | 7.3 ± 0.3 | |

| 4 | 50% HEMA 50% PETA | 324 ± 5 | 7.2 ± 0.3 | |

| 5 | 90% HEMA 10% AHPMA | 238 ± 9 | 6.2 ± 0.2 | |

| 6 | 70% HEMA 30% AHPMA | 239 ± 7 | 5.9 ± 0.2 | |

| 7 | 50% HEMA 50% AHPMA | 248 ± 10 | 6.0 ± 0.2 |

| n° | Monomer | Oligomer | Reverse Impact Resistance (cm/kg) |

|---|---|---|---|

| 1 | HEMA | Ebecryl 4738 | 16.4 ± 1 |

| 2 | 90% HEMA 10% PETA | 9.1 ± 2 | |

| 3 | 70% HEMA 30% PETA | 10.9 ± 2 | |

| 4 | 50% HEMA 50% PETA | 10.0 ± 1 | |

| 5 | 90% HEMA 10% AHPMA | 15.5 ± 2 | |

| 6 | 70% HEMA 30% AHPMA | 15.5 ± 1 | |

| 7 | 50% HEMA 50% AHPMA | 13.7 ± 2 |

| n° | Monomer | Oligomer | Scratch Depth (µm) | Depth after Heating (µm) | Self-Healing (%) | Tukey Statistic |

|---|---|---|---|---|---|---|

| 1 | HEMA | Ebecryl 4738 | 5.3 ± 0.4 | 0.2 ± 0.1 | 96 ± 2 | A |

| 5 | 90% HEMA 10% AHPMA | 4.8 ± 0.3 | 0.4 ± 0.2 | 91 ± 5 | AB | |

| 6 | 70% HEMA 30% AHPMA | 4.5 ± 0.2 | 0.5 ± 0.1 | 90 ± 2 | B | |

| 7 | 50% HEMA 50% AHPMA | 4.3 ± 0.2 | 0.3 ± 0.2 | 93 ± 4 | AB |

| n° | Monomer | Oligomer | Scratch Depth at 8 N | Self-Healing at 8 N | Tukey Statistic | Maximum Depth Repaired at 100% | Produced Under |

|---|---|---|---|---|---|---|---|

| 1 | HEMA | Ebecryl 4738 | 14 ± 1 μm | 73 ± 6% | B | 3.9 μm | 6.7 N |

| 5 | 90% HEMA 10% AHPMA | 12 ± 2 μm | 77 ± 6% | B | 4.8 μm | 7.2 N | |

| 6 | 70% HEMA 30% AHPMA | 9 ± 2 μm | 96 ± 6% | A | 4.0 μm | 6.9 N | |

| 7 | 50% HEMA 50% AHPMA | 11 ± 1 μm | 68 ± 5% | B | 3.5 μm | 6.4 N |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Paquet, C.; Brown, S.; Klemberg-Sapieha, J.E.; Morin, J.-F.; Landry, V. Self-Healing UV-Curable Acrylate Coatings for Wood Finishing System, Part 2: Impact of Monomer Structure and Self-Healing Parameters on Self-Healing Efficiency. Coatings 2021, 11, 1328. https://doi.org/10.3390/coatings11111328

Paquet C, Brown S, Klemberg-Sapieha JE, Morin J-F, Landry V. Self-Healing UV-Curable Acrylate Coatings for Wood Finishing System, Part 2: Impact of Monomer Structure and Self-Healing Parameters on Self-Healing Efficiency. Coatings. 2021; 11(11):1328. https://doi.org/10.3390/coatings11111328

Chicago/Turabian StylePaquet, Chloé, Stephen Brown, Jolanta E. Klemberg-Sapieha, Jean-François Morin, and Véronic Landry. 2021. "Self-Healing UV-Curable Acrylate Coatings for Wood Finishing System, Part 2: Impact of Monomer Structure and Self-Healing Parameters on Self-Healing Efficiency" Coatings 11, no. 11: 1328. https://doi.org/10.3390/coatings11111328

APA StylePaquet, C., Brown, S., Klemberg-Sapieha, J. E., Morin, J.-F., & Landry, V. (2021). Self-Healing UV-Curable Acrylate Coatings for Wood Finishing System, Part 2: Impact of Monomer Structure and Self-Healing Parameters on Self-Healing Efficiency. Coatings, 11(11), 1328. https://doi.org/10.3390/coatings11111328