High Performance Accelerated Tests to Evaluate Hard Cr Replacements for Hydraulic Cylinders

Abstract

:1. Introduction

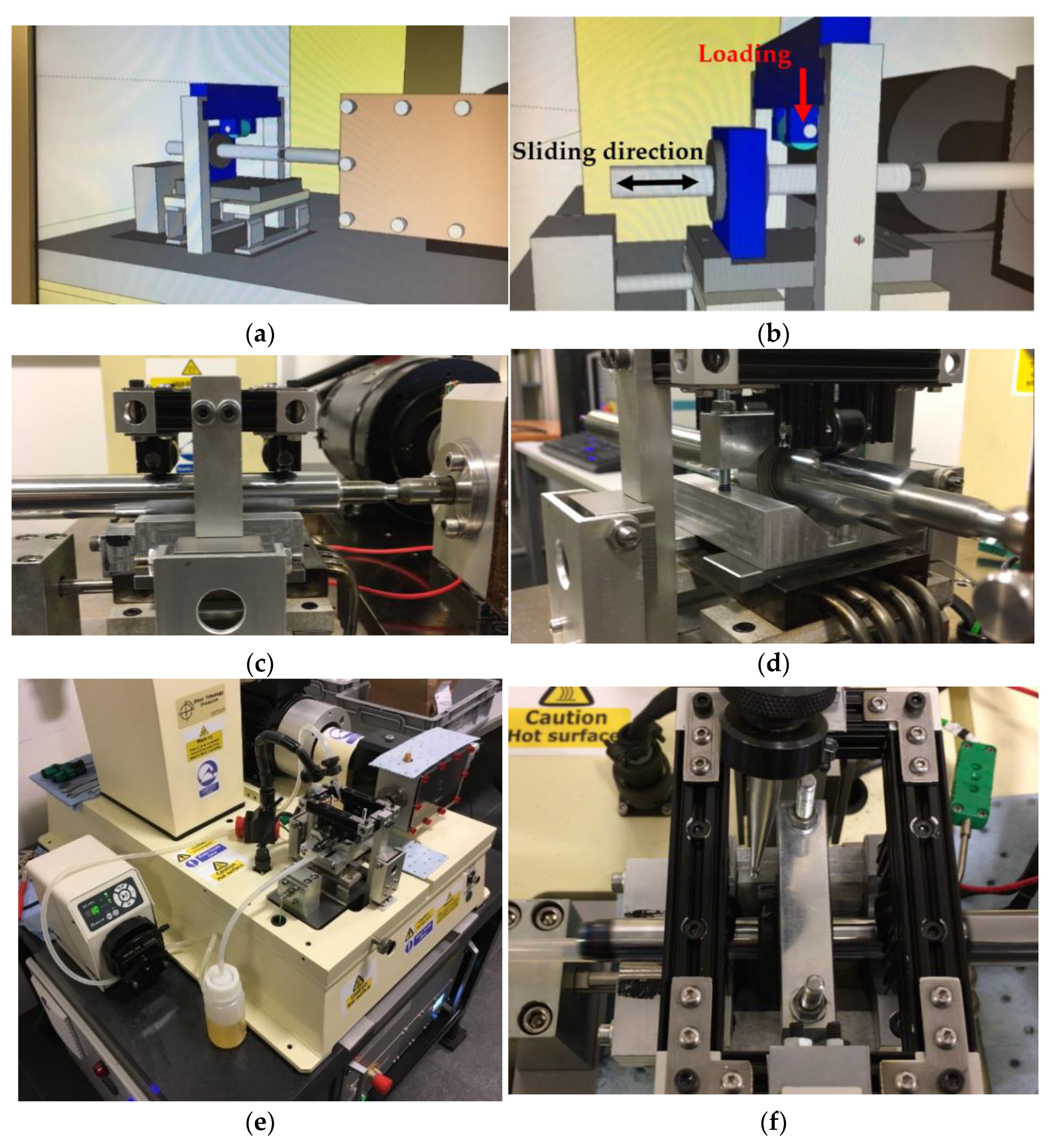

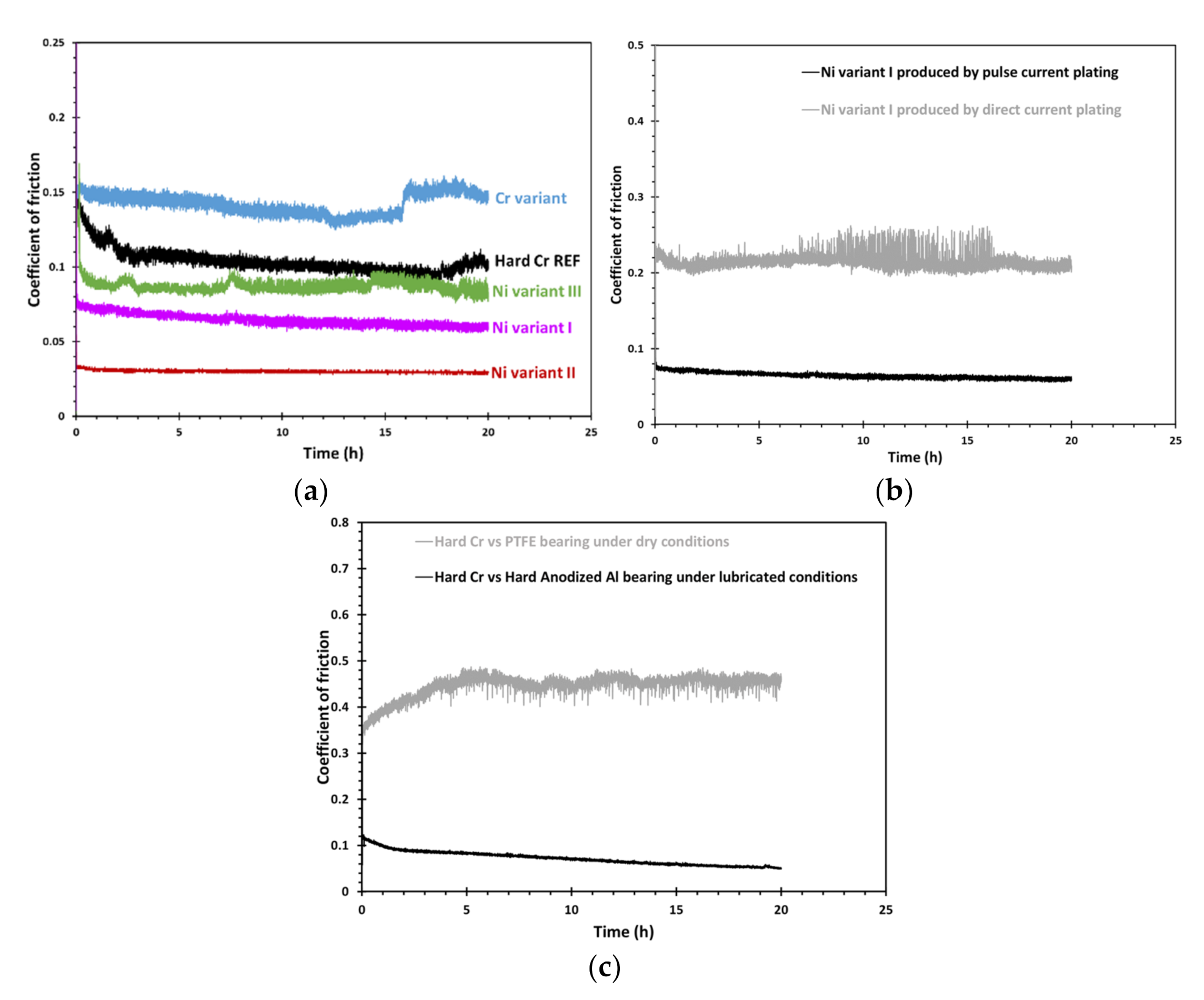

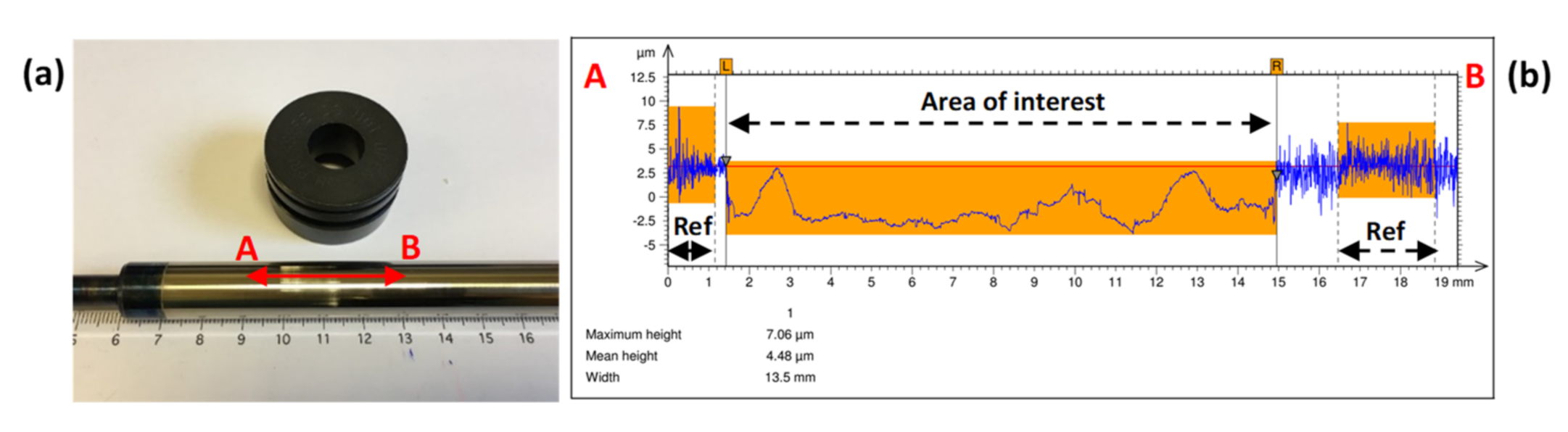

2. Materials and Methods

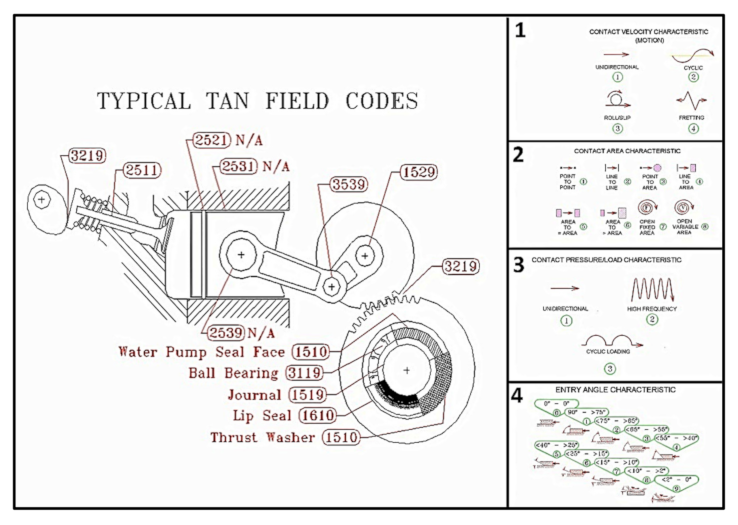

- The motion is reciprocating sliding.

- The contact geometry is area to area.

- A unidirectional lateral load is applied.

- A monolayer of oil is pushed into the tribo-contact.

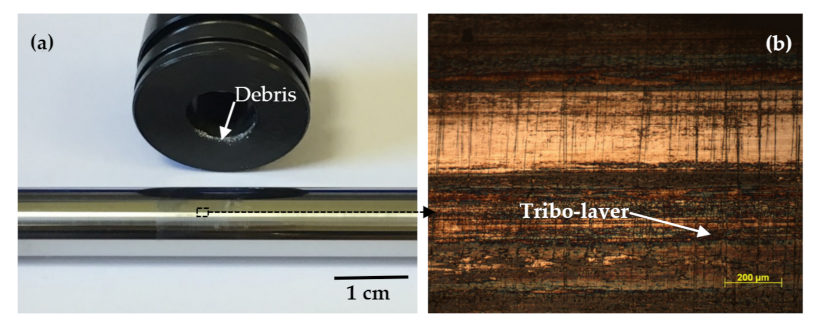

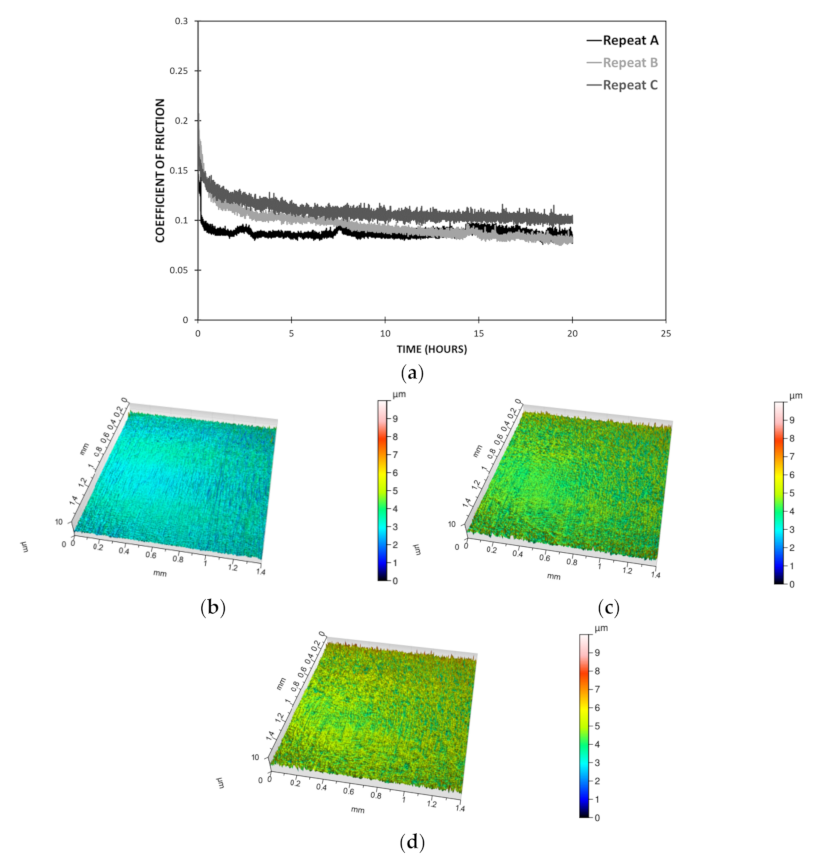

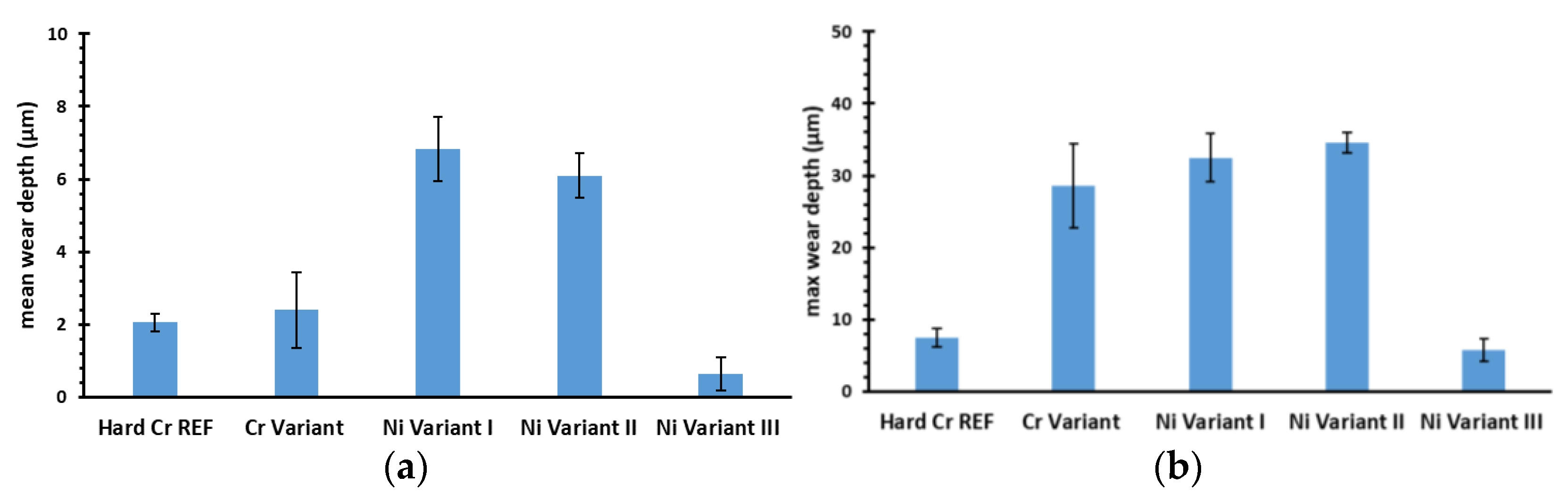

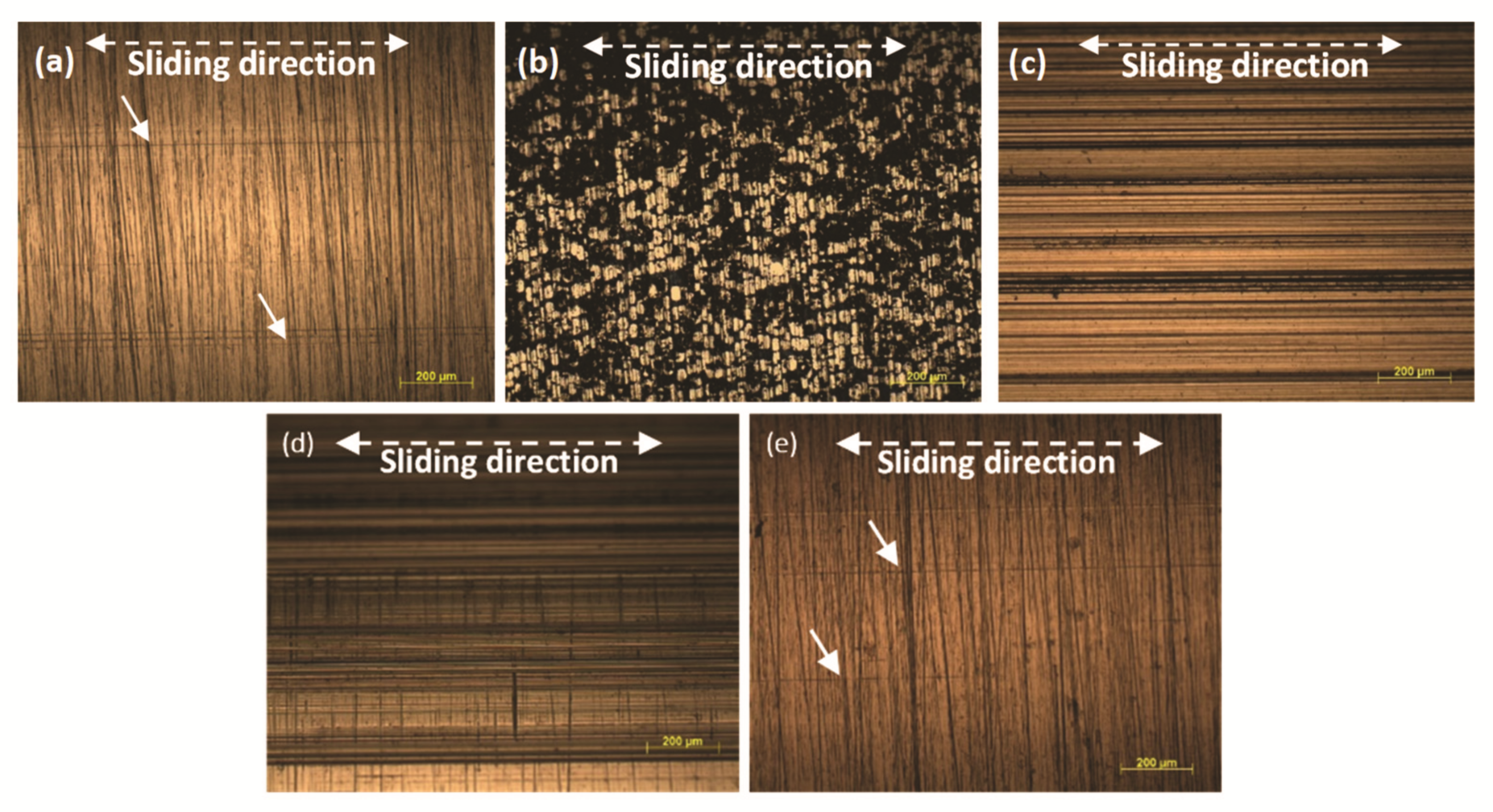

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dixon, J.C. The Shock Absorber Handbook, 2nd ed.; John Wiley & Sons Ltd.: West Sussex, UK, 2007. [Google Scholar]

- National Bureau of Statistics. Statistical Communiqué of the 2017 National Economic and Social Development of the People’s Republic of China; China Stat: Beijing, China, 2018; pp. 7–20. [Google Scholar]

- Guffie, R.K. The Handbook of Hard Chromium Plating, 1st ed.; Gardner Publications: Cincinnati, OH, USA, 1986. [Google Scholar]

- Cotell, C.M.; Sprague, J.A.; Smidt, F.A. Handbook of Metals, Surface Engineering; ASM International: Cleveland, OH, USA, 1994; Volume 5. [Google Scholar]

- Zarogiannis, P. Environmental Risk Reduction Strategy and Analysis of Advantages and Drawbacks for Hexavalent Chromium; Risk & Policy Analysts Ltd.: Norwich, UK, 2005. [Google Scholar]

- Jeong, D.H.; Erb, U.; Aust, K.T.; Palumbo, G. The relationship between hardness and abrasive wear resistance of electrodeposited nanocrystalline Ni–P coatings. Scr. Mater. 2008, 48, 1067–1072. [Google Scholar] [CrossRef]

- Ma, C.; Wang, S.C.; Wang, L.P.; Walsh, F.C.; Wood, R.J.K. The role of a tribofilm and wear debris in the tribological behaviour of nanocrystalline Ni–Co electrodeposits. Wear 2013, 306, 296–303. [Google Scholar] [CrossRef]

- Wasekar, N.P.; Sundararajan, G. Sliding wear behavior of electrodeposited Ni–W alloy and hard chrome coatings. Wear 2015, 342, 340–348. [Google Scholar] [CrossRef]

- Georgiou, E.P.; Van der Donck, T.; Celis, J.-P. Electrodeposition and structural characteristics of intermetallic nickel-tin based coatings. Trans. Inst. Met. Finish. 2017, 95, 301–307. [Google Scholar] [CrossRef]

- Georgiou, E.P.; Kwee, I.S.K.; Van der Donck, T.; Drees, D.; Celis, J.-P. Synthesis, characterization and tribological behavior of electrodeposited nanostructured Co–23 wt.% Sn coatings. Wear 2019, 430, 290–298. [Google Scholar] [CrossRef]

- Weston, D.P.; Shipway, P.H.; Harris, S.J.; Cheng, M.K. Friction and sliding wear behaviour of electrodeposited cobalt and cobalt–tungsten alloy coatings for replacement of electrodeposited chromium. Wear 2009, 88, 934–943. [Google Scholar] [CrossRef]

- Ma, C.; Wang, S.C.; Wang, L.P.; Walsh, F.C.; Wood, R.J.K. The electrodeposition and characterisation of low-friction and wear-resistant Co-Ni-P coatings. Surf. Coat. Technol. 2013, 235, 495–505. [Google Scholar] [CrossRef]

- Vlaic, C.A.; Kurniawan, M.; Peipmann, R.; Lalău, C.C.; Stich, M.; Schmidt, U.; Bund, A. Improved wear resistance of alternating amorphous and crystalline layers in electrodeposited Ni-P multilayers. Surf. Coat. Technol. 2020, 386, 125470. [Google Scholar] [CrossRef]

- Bernasconi, R.; Allievi, F.; Sadeghi, H.; Magagnin, L. Codeposition of nickel–phosphorus alloys reinforced with boron carbide microparticles: Direct and pulse plating. Trans. Inst. Met. Finish. 2017, 95, 52–59. [Google Scholar] [CrossRef]

- Wang, S.; Ma, C.; Walsh, F.C. Alternative tribological coatings to electrodeposited hard chromium: A critical review. Trans. Inst. Met. Finish. 2020, 98, 173–185. [Google Scholar] [CrossRef]

- Lizarraga, J.; Biera, J.; Sala, J.A. Modelling of friction phenomena in sliding conditions in suspension shock absorbers. Veh. Syst. Dyn. 2008, 46, 751–764. [Google Scholar] [CrossRef]

- Zach, C.; Mack, W.; Fruhmann, G.; Tieber, W. On the performance of rheological shock absorber models in full vehicle simulation. Veh. Syst. Dyn. 2007, 45, 981–999. [Google Scholar] [CrossRef]

- Gracia, A.G.; Jimenez, F.; Páez, J.; Narváez, A. Theoretical and experimental analysis to determine the influence of the ageing process of the shock-absorber on safety. Int. J. Vehicle Des. 2006, 40, 15–35. [Google Scholar] [CrossRef]

- Ryabov, I.V.; Novikov, V.V.; Pozdeev, A.V. Efficiency of shock absorber in vehicle suspension. Procedia Eng. 2016, 150, 354–362. [Google Scholar] [CrossRef]

- Zhao, X.; Wang, J. Pump-back effect analysis and wear feature extraction for hydraulic cylinder piston seal based on multi-sensor monitoring. IEEE Trans. Ind. Electron. 2019, 66, 7270–7280. [Google Scholar] [CrossRef]

- Kato, S.; Sasaki, S. Effects of hydraulic oil and lubricant additives on dynamic friction properties under various reciprocating sliding conditions. Friction 2020, 8, 471–480. [Google Scholar] [CrossRef] [Green Version]

- Ryabov, I.M.; Pozdeev, A.V.; Erontaev, V.V.; Danilov, S.V.; Omarova, Z.K.; Kovalev, A.M.; Silchenkov, D.D. Method for determining the shock absorber effectiveness in the vehicle suspension to ensure its active and operational safety. IOP Conf. Ser. Mater. Sci. Eng. 2019, 632, 012060. [Google Scholar] [CrossRef]

- Basso, R. Experimental characterization of damping force in shock absorbers with constant velocity excitation. Veh. Syst. Dyn. 1998, 30, 431–442. [Google Scholar] [CrossRef]

- Sheleg, V.K.; Levantsevich, M.A.; Maksimchenko, N.N.; Pilipchuk, E.V.; Yurut, E.L.; Kalach, V.N. Evaluating the applicability of electrodeformation placing technology by a flexible tool for chromeing hydrocilindes. J. Frict. Wear. 2019, 40, 207–212. [Google Scholar] [CrossRef]

- ASTM. Standard Test Method for Linearly Reciprocating Ball-on-Flat Sliding Wear; ASTM International: West Conshohocken, PA, USA, 2005. [Google Scholar]

- ASTM. The Use of Tribological Aspect Numbers in Bench Test Selection; ASTM International: West Conshohocken, PA, USA, 2001. [Google Scholar]

- Georgiou, E.P.; Lopes, L.M.; De Bilde, M.; Drees, D. How can we measure sliding wear in an efficient way? Wear 2020, 458, 203414. [Google Scholar] [CrossRef]

- Wu, Y.C.; Li, G.H.; Zhang, L. Wear resistance of electroless deposited Ni–P and Ni–P/SiC composite coatings on low alloy cast iron. Surf. Eng. 2013, 16, 506–510. [Google Scholar] [CrossRef]

- Soleimani, R.; Mahboubi, F.; Kazemi, M.; Arman, S.Y. Corrosion and tribological behaviour of electroless Ni–P/nano-SiC composite coating on aluminium 6061. Surf. Eng. 2015, 31, 714–721. [Google Scholar] [CrossRef]

- Franco, M.; Sha, W.; Malinov, S.; Liu, H. Micro-scale wear characteristics of electroless Ni–P/SiC composite coating under two different sliding conditions. Wear 2014, 317, 254–264. [Google Scholar] [CrossRef] [Green Version]

| Rod | Rod Guide | Load (N) | Frequency (Hz) | Stroke (mm) | Test Time (h) | Lubrication (mL/min) |

|---|---|---|---|---|---|---|

| Hard Cr | Anodized Al | 20 | 10 | 21 | 20 | 1 |

| Cr variant | Anodized Al | 20 | 10 | 21 | 20 | 1 |

| Ni variant I | Anodized Al | 20 | 10 | 21 | 20 | 1 |

| Ni variant II | Anodized Al | 20 | 10 | 21 | 20 | 1 |

| Ni variant III | Anodized Al | 20 | 10 | 21 | 20 | 1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Georgiou, E.P.; Drees, D.; Timmermans, G.; Zoikis-Karathanasis, A.; Pérez-Fernández, M.; Magagnin, L.; Celis, J.-P. High Performance Accelerated Tests to Evaluate Hard Cr Replacements for Hydraulic Cylinders. Coatings 2021, 11, 1511. https://doi.org/10.3390/coatings11121511

Georgiou EP, Drees D, Timmermans G, Zoikis-Karathanasis A, Pérez-Fernández M, Magagnin L, Celis J-P. High Performance Accelerated Tests to Evaluate Hard Cr Replacements for Hydraulic Cylinders. Coatings. 2021; 11(12):1511. https://doi.org/10.3390/coatings11121511

Chicago/Turabian StyleGeorgiou, Emmanuel P., Dirk Drees, Greet Timmermans, Alexandros Zoikis-Karathanasis, Marta Pérez-Fernández, Luca Magagnin, and Jean-Pierre Celis. 2021. "High Performance Accelerated Tests to Evaluate Hard Cr Replacements for Hydraulic Cylinders" Coatings 11, no. 12: 1511. https://doi.org/10.3390/coatings11121511