Effect of Pulsing Configuration and Magnetic Balance Degree on Mechanical Properties of CrN Coatings Deposited by Bipolar-HiPIMS onto Floating Substrate

Abstract

:1. Introduction

2. Materials and Methods

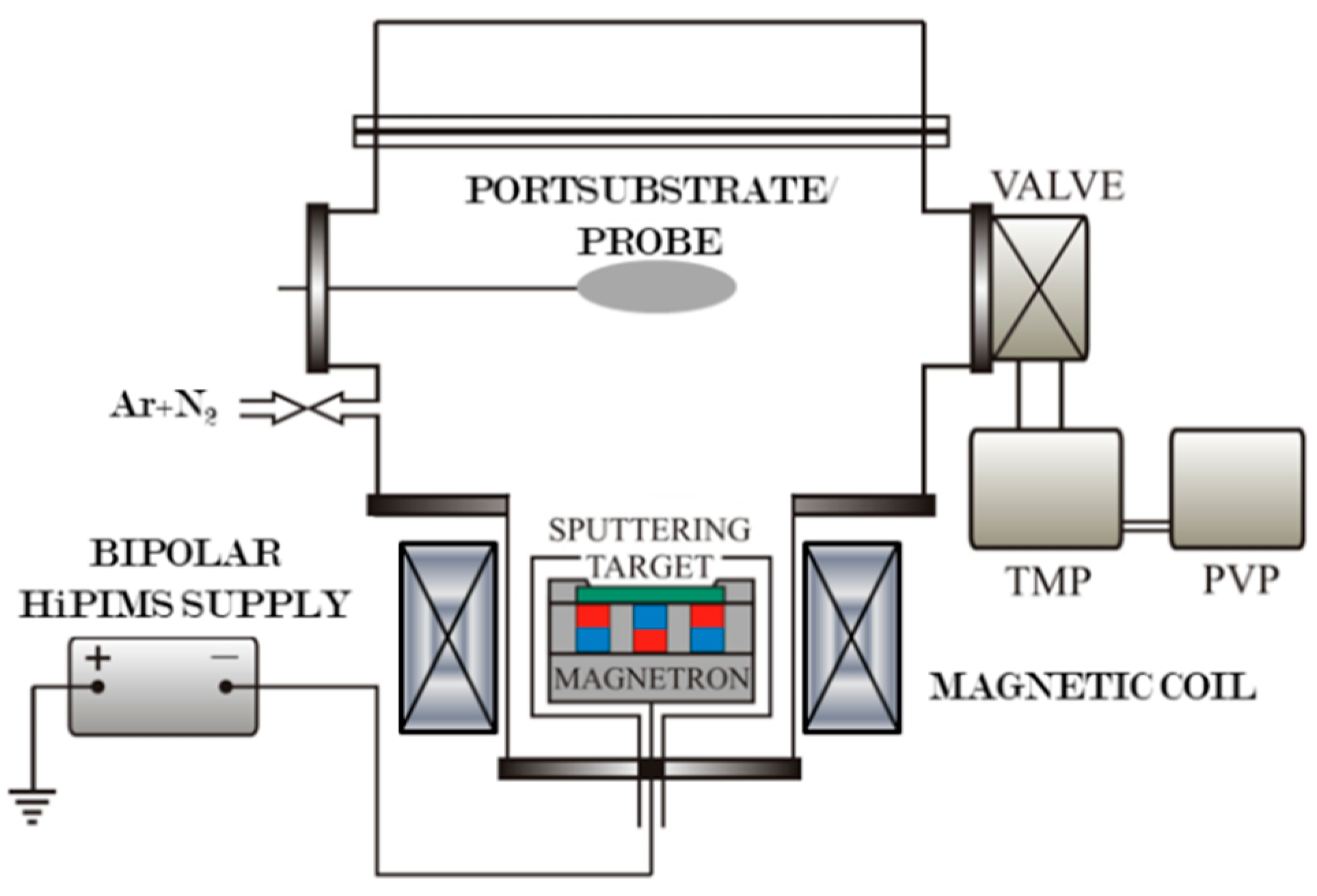

2.1. Films Deposition

2.2. Films Characterization

3. Results and Discussion

3.1. Control of CrN Thin Film Properties by Pulsing Configuration

3.1.1. Sputtering Condition. Pulse Duration Selection

3.1.2. Phase Composition and Microstructure

3.1.3. Mechanical Properties

3.2. Control of CrN Thin Film Properties by Magnetic Field Configuration

3.2.1. Sputtering Condition. Magnetic Balance Selection

3.2.2. Phase Composition and Microstructure

3.2.3. Mechanical Properties of Thin Film

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Petrov, I.; Adibi, F.; Greene, J.E.; Sproul, W.D.; Münz, W.-D. Use of an externally applied axial magnetic field to control ion/neutral flux ratios incident at the substrate during magnetron sputter deposition. J. Vac. Sci. Technol. A Vac. Surf. Film. 1992, 10, 3283. [Google Scholar] [CrossRef]

- Petrov, I.; Barna, P.B.; Hultman, L.; Greene, J.E. Microstructural evolution during film growth. J. Vac. Sci. Technol. A Vac. Surf. Film. 2003, 21, 117. [Google Scholar] [CrossRef]

- Balzer, M.; Fenker, M. Investigations on tailoring the deposition conditions in HIPIMS by varying the pulse durations and the argon partial pressure. In IOP Conference Series: Materials, Sciience and Engineering; IOP Publishing: Bristol, UK, 2012; Volume 39, p. 012002. [Google Scholar]

- Hurkmans, T.; Lewis, D.B.; Brooks, J.S.; Münz, W.-D. Chromium nitride coatings grown by unbalanced magnetron (UBM) and combined arc/unbalanced magnetron (ABS™) deposition techniques. Surf. Coat. Technol. 1996, 86–87, 192–199. [Google Scholar] [CrossRef]

- Lin, J.; Sproul, W.D.; Moore, J.J.; Wu, Z.L.; Lee, S.L. Effect of negative substrate bias voltage on the structure and properties of CrN films deposited by modulated pulsed power (MPP) magnetron sputtering. J. Phys. D Appl. Phys. 2011, 44, 425305. [Google Scholar] [CrossRef]

- Guimaraes, M.C.R.; de Castilho, B.C.N.M.; de Souza Nossa, T.; Avila, P.R.T.; Cucatti, S.; Alvarez, F.; Garcia, J.L.; Pinto, H.C. On the effect of substrate oscillation on CrN coatings deposited by HiPIMS and dcMS. Surf. Coat. Technol. 2018, 340, 112–120. [Google Scholar] [CrossRef]

- Biswas, B.; Purandare, Y.; Khan, I.; Hovsepian, P.E. Effect of substrate bias voltage on defect generation and their influence on corrosion and tribological properties of HIPIMS deposited CrN/NbN coatings. Surf. Coat. Technol. 2018, 344, 383–393. [Google Scholar] [CrossRef]

- Kouznetsov, V.; Macák, K.; Schneider, J.M.; Helmersson, U.; Petrov, I. A novel pulsed magnetron sputter technique utilizing very high target power densities. Surf. Coat. Technol. 1999, 122, 290–293. [Google Scholar] [CrossRef]

- Sarakinos, K.; Alami, J.; Konstantinidis, S. High power pulsed magnetron sputtering: A review on scientific and engineering state of the art. Surf. Coat. Technol. 2010, 204, 1661. [Google Scholar] [CrossRef]

- Gudmundsson, J.T.; Brenning, N.; Lundin, D.; Helmersson, U. High power impulse magnetron sputtering discharge. J. Vac. Sci. Technol. A Vac. Surf. Film. 2012, 30, 030801. [Google Scholar] [CrossRef] [Green Version]

- Hecimovic, A.; Burcalova, K.; Ehiasarian, A.P. Origins of ion energy distribution function (IEDF) in high power impulse magnetron sputtering (HIPIMS) plasma discharge. J. Phys. D Appl. Phys. 2008, 41, 095203. [Google Scholar] [CrossRef]

- Greczynski, G.; Hultman, L. Time and energy resolved ion mass spectroscopy studies of the ion flux during high power pulsed magnetron sputtering of Cr in Ar and Ar/N2 atmospheres. Vacuum 2010, 84, 1159–1170. [Google Scholar] [CrossRef] [Green Version]

- Velicu, I.-L.; Tiron, V.; Porosnicu, C.; Burducea, I.; Lupu, N.; Stoian, G.; Popa, G.; Munteanu, D. Enhanced properties of tungsten thin films deposited with a novel HiPIMS approach. Appl. Surf. Sci. 2017, 424, 397–406. [Google Scholar] [CrossRef]

- Wu, B.; Haehnlein, I.; Shchelkanov, I.; McLain, J.; Patel, D.; Uhlig, J.; Jurczyk, B.; Leng, Y.; Ruzic, D.N. Cu films prepared by bipolar pulsed high power impulse magnetron sputtering. Vacuum 2018, 150, 216. [Google Scholar] [CrossRef]

- Britun, N.; Michiels, M.; Godfroid, T.; Snyders, R. Ion density evolution in a high power sputtering discharge with bipolar pulsing. Appl. Phys. Lett. 2018, 112, 234103. [Google Scholar] [CrossRef] [Green Version]

- Keraudy, J.; Viloan, R.P.B.; Raadu, M.A.; Brenning, N.; Lundin, D.; Helmersson, U. Bipolar HiPIMS for tailoring ion energies in thin film deposition. Surf. Coat. Technol. 2019, 359, 433–437. [Google Scholar] [CrossRef]

- Hippler, R.; Cada, M.; Hubicka, Z. Time-resolved Langmuir probe diagnostics of a bipolar high power impulse magnetron sputtering discharge. Appl. Phys. Lett. 2020, 116, 064101. [Google Scholar] [CrossRef]

- Tiron, V.; Velicu, I.-L. Understanding the ion acceleration mechanism in bipolar HiPIMS: The role of the double layer structure developed in the after-glow plasma. Plasma Sources Sci. Technol. 2020, 29, 015003. [Google Scholar] [CrossRef]

- Velicu, I.-L.; Ianoş, G.-T.; Porosnicu, C.; Mihăilă, I.; Burducea, I.; Velea, A.; Cristea, D.; Munteanu, D.; Tiron, V. Energy-Enhanced Deposition of Copper Thin Films by Bipolar High Power Impulse Magnetron Sputtering. Surf. Coat. Technol. 2019, 259, 97–107. [Google Scholar] [CrossRef]

- Viloan, R.P.B.; Gu, J.; Boyd, R.; Keraudy, J.; Li, L.; Helmersson, U. Bipolar high power impulse magnetron sputtering for energetic ion-bombardment during TiN thin film growth without the use of a substrate bias. Thin Solid Film. 2019, 688, 137350. [Google Scholar] [CrossRef]

- Santiago, J.A.; Fernández-Martínez, I.; Kozák, T.; Capek, J.; Wennberg, A.; Molina-Aldareguia, J.M.; Bellido-González, V.; González-Arrabal, R.; Monclús, M.A. The influence of positive pulses on HiPIMS deposition of hard DLC coatings. Surf. Coat. Technol. 2019, 358, 43–49. [Google Scholar] [CrossRef]

- Viloan, R.P.B.; Zanáška, M.; Lundin, D.; Helmersson, U. Pulse length selection for optimizing the accelerated ion flux fraction of a bipolar HiPIMS discharge. Plasma Sources Sci. Technol. 2021, 29, 125013. [Google Scholar] [CrossRef]

- Tiron, V.; Ursu, E.-L.; Cristea, D.; Munteanu, D.; Bulai, G.; Ceban, A.; Velicu, I.-L. Overcoming the insulating materials limitation in HiPIMS: Ion-assisted deposition of DLC coatings using bipolar HiPIMS. Appl. Surf. Sci. 2019, 494, 871–879. [Google Scholar] [CrossRef]

- Du, H.; Zanáška, M.; Brenning, N.; Helmersson, U. Bipolar HiPIMS: The role of capacitive coupling in achieving ion bombardment during growth of dielectric thin films. Surf. Coat. Technol. 2021, 416, 127152. [Google Scholar] [CrossRef]

- Batková, S.; Čapek, J.; Rezek, J.; Čerstvý, R.; Zeman, P. Effect of positive pulse voltage in bipolar reactive HiPIMS on crystal structure, microstructure and mechanical properties of CrN films. Surf. Coat. Technol. 2020, 393, 125773. [Google Scholar] [CrossRef]

- Hippler, R.; Cada, M.; Stranak, V.; Hubicka, Z. Time-resolved optical emission spectroscopy of a unipolar and a bipolar pulsed magnetron sputtering discharge in an argon/oxygen gas mixture with a cobalt target. Plasma Sources Sci. Technol. 2019, 28, 115020. [Google Scholar] [CrossRef]

- Hippler, R.; Cada, M.; Hubicka, Z. Time-resolved diagnostics of a bipolar HiPIMS discharge. J. Appl. Phys. 2020, 127, 203303. [Google Scholar] [CrossRef]

- Kozák, T.; Pajdarová, A.D.; Čada, M.; Hubička, Z.; Mareš, P.; Čapek, J. Ion energy distributions at substrate in bipolar HiPIMS: Effect of positive pulse delay, length and amplitude. Plasma Sources Sci. Technol. 2020, 29, 065003. [Google Scholar] [CrossRef]

- Purandare, Y.P.; Ehiasarian, A.P.; Stack, M.M.; Hovsepian, P.E. CrN/NbN coatings deposited by HIPIMS: A preliminary study of erosion–corrosion performance. Surf. Coat. Technol. 2010, 204, 1158–1162. [Google Scholar] [CrossRef] [Green Version]

- Mayrhofer, P.H.; Tischler, G.; Mitterer, C. Microstructure and mechanical/thermal properties of CrN coatings deposited by reactive unbalanced magnetron sputtering. Surf. Coat. Technol. 2001, 142–144, 78–84. [Google Scholar] [CrossRef]

- Window, B.; Savvides, N. Charged particle fluxes from planar magnetron sputtering sources. J. Vac. Sci. Technol. A Vac. Surf. Film. 1986, 4, 196. [Google Scholar] [CrossRef]

- Tiron, V.; Bulai, G.; Costin, C.; Velicu, I.-L.; Dincă, P.; Iancu, D.; Burducea, I. Growth and characterization of W thin films with controlled Ne and Ar contents deposited by bipolar HiPIMS. Nucl. Mater. Energy 2021, 29, 101091. [Google Scholar] [CrossRef]

- Pelleg, J.; Zevin, L.Z.; Lungo, S.; Croitoru, N. Reactive-sputter-deposited TiN films on glass substrates. Thin Solid Film. 1991, 197, 117–128. [Google Scholar] [CrossRef]

- Waseda, Y.; Matsubara, E.; Shinoda, K. X-Ray Diffraction Crystallography; Springer: New York, NY, USA, 2011; p. 124. [Google Scholar]

- Lattemann, M.; Helmersson, U.; Greene, J.E. Fully dense, non-faceted 111-textured high power impulse magnetron sputtering TiN films grown in the absence of substrate heating and bias. Thin Solid Film. 2010, 518, 5978. [Google Scholar] [CrossRef] [Green Version]

- Haye, E.; Colaux, J.L.; Moskovkin, P.; Pireaux, J.J.; Lucas, S. Wide range investigation of duty cycle and frequency effects on bipolar magnetron sputtering of chromium nitride. Surf. Coat. Technol. 2018, 350, 84–94. [Google Scholar] [CrossRef]

- Sánchez-López, J.C.; Caro, A.; Alcalá, G.; Rojas, T.C. Tailoring CrNx stoichiometry and functionality by means of reactive HiPIMS. Surf. Coat. Technol. 2020, 401, 126235. [Google Scholar] [CrossRef]

- Barna, P.B.; Adamik, M. Fundamental structure forming phenomena of polycrystalline films and the structure zone models. Thin Solid Film. 1998, 317, 27–33. [Google Scholar] [CrossRef]

- Greczynski, G.; Jensen, J.; Hultman, L. CrNx films prepared by DC magnetron sputtering and high-power pulsed magnetron sputtering: A comparative study. IEEE Trans. Plasma Sci. 2010, 38, 3046–3056. [Google Scholar] [CrossRef] [Green Version]

- Pajdarová, A.D.; Kozák, T.; Hubička, Z.; Čada, M.; Mareš, P.; Čapek, J. Plasma parameters in positive voltage pulses of bipolar HiPIMS discharge determined by Langmuir probe with a sub-microsecond time resolution. Plasma Sources Sci. Technol. 2020, 29, 085016. [Google Scholar] [CrossRef]

- Lin, J.; Sproul, W.D.; Moore, J.J. Tribological behavior of thick CrN coatings deposited by modulated pulsed power magnetron sputtering. Surf. Coat. Technol. 2012, 206, 2474–2483. [Google Scholar] [CrossRef]

- Velicu, I.-L.; Tiron, V.; Rusu, B.-G.; Popa, G. Copper thin films deposited under different power delivery modes and magnetron configurations: A comparative study. Surf. Coat. Technol. 2017, 327, 192–199. [Google Scholar] [CrossRef]

- Tiron, V.; Velicu, I.-L.; Cristea, D.; Lupu, N.; Stoian, D.; Munteanu, D. Influence of ion-to-neutral flux ratio on the mechanical and tribological properties of TiN coatings deposited by HiPIMS. Surf. Coat. Technol. 2018, 352, 690–698. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tiron, V.; Ciolan, M.A.; Bulai, G.; Cristea, D.; Velicu, I.-L. Effect of Pulsing Configuration and Magnetic Balance Degree on Mechanical Properties of CrN Coatings Deposited by Bipolar-HiPIMS onto Floating Substrate. Coatings 2021, 11, 1526. https://doi.org/10.3390/coatings11121526

Tiron V, Ciolan MA, Bulai G, Cristea D, Velicu I-L. Effect of Pulsing Configuration and Magnetic Balance Degree on Mechanical Properties of CrN Coatings Deposited by Bipolar-HiPIMS onto Floating Substrate. Coatings. 2021; 11(12):1526. https://doi.org/10.3390/coatings11121526

Chicago/Turabian StyleTiron, Vasile, Mihai Alexandru Ciolan, Georgiana Bulai, Daniel Cristea, and Ioana-Laura Velicu. 2021. "Effect of Pulsing Configuration and Magnetic Balance Degree on Mechanical Properties of CrN Coatings Deposited by Bipolar-HiPIMS onto Floating Substrate" Coatings 11, no. 12: 1526. https://doi.org/10.3390/coatings11121526

APA StyleTiron, V., Ciolan, M. A., Bulai, G., Cristea, D., & Velicu, I.-L. (2021). Effect of Pulsing Configuration and Magnetic Balance Degree on Mechanical Properties of CrN Coatings Deposited by Bipolar-HiPIMS onto Floating Substrate. Coatings, 11(12), 1526. https://doi.org/10.3390/coatings11121526