Preparation of Modified Silane Composite Emulsion and Its Effect on Surface Properties of Cement-Based Materials

Abstract

:1. Introduction

2. Experiment

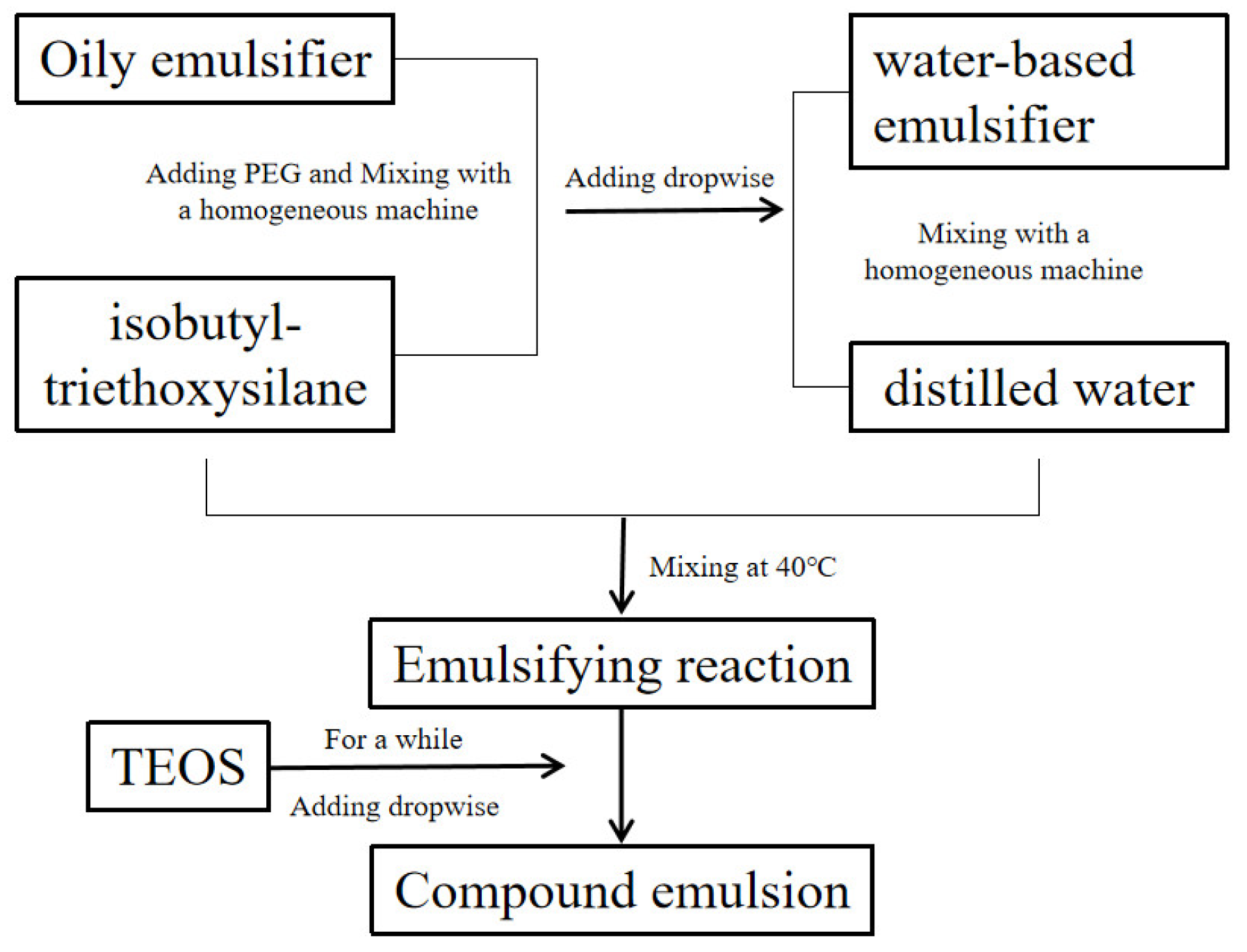

2.1. Preparation of TEOS/Isobutyl-Triethoxysilane Emulsion

2.1.1. Materials

2.1.2. Preparation Process

2.1.3. Effect of Emulsifiers on Compound Emulsion

2.1.4. Effect of Addition Time Period of TEOS on Compound Emulsion

2.1.5. Effect of Added Amount of TEOS on Compound Emulsion

2.2. Preparation of Cement-based Materials

3. Performance Characterization and Methods

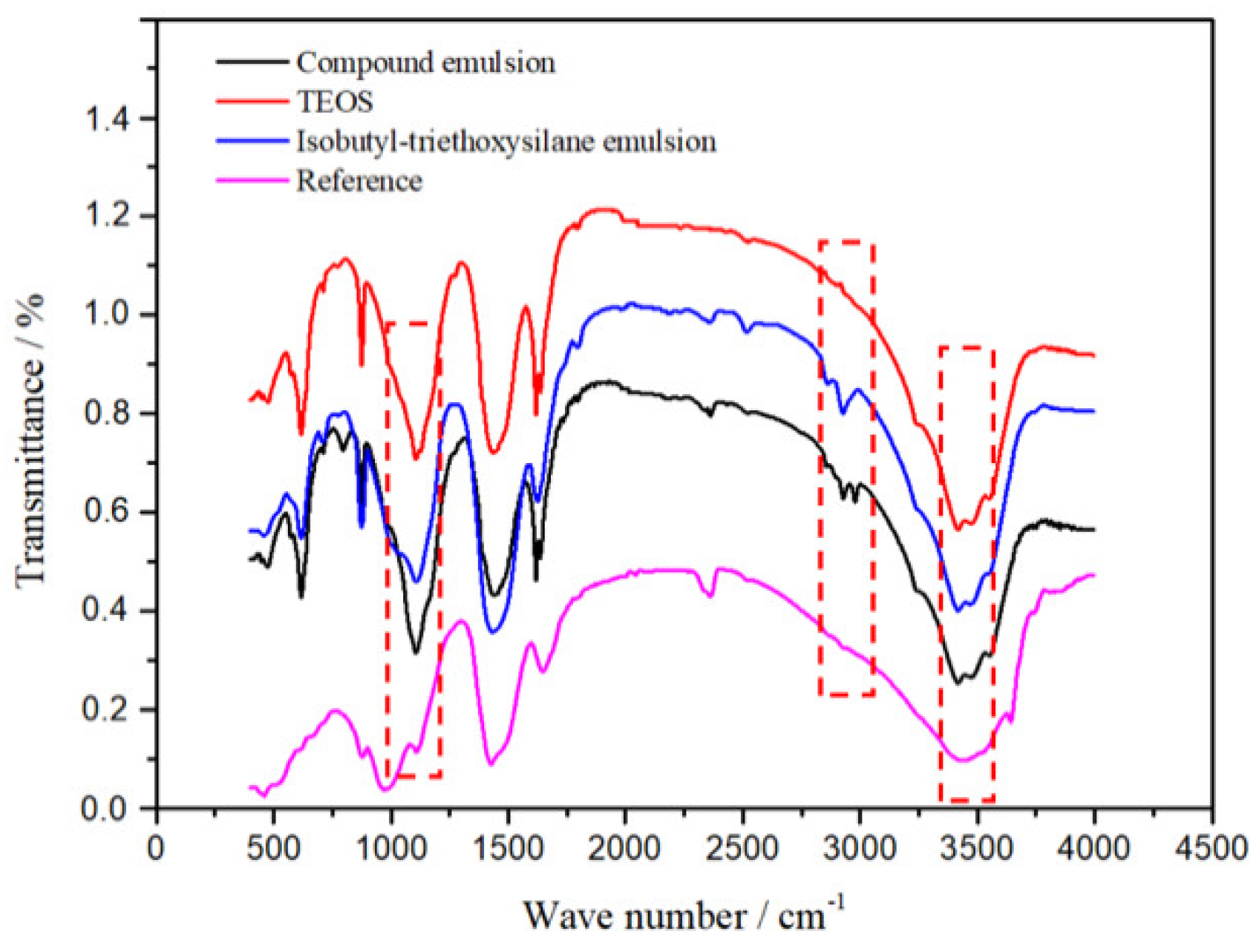

3.1. Fourier-Transform Infrared Spectroscopy

3.2. Thermogravimetric Analysis and Differential Scanning Calorimetry

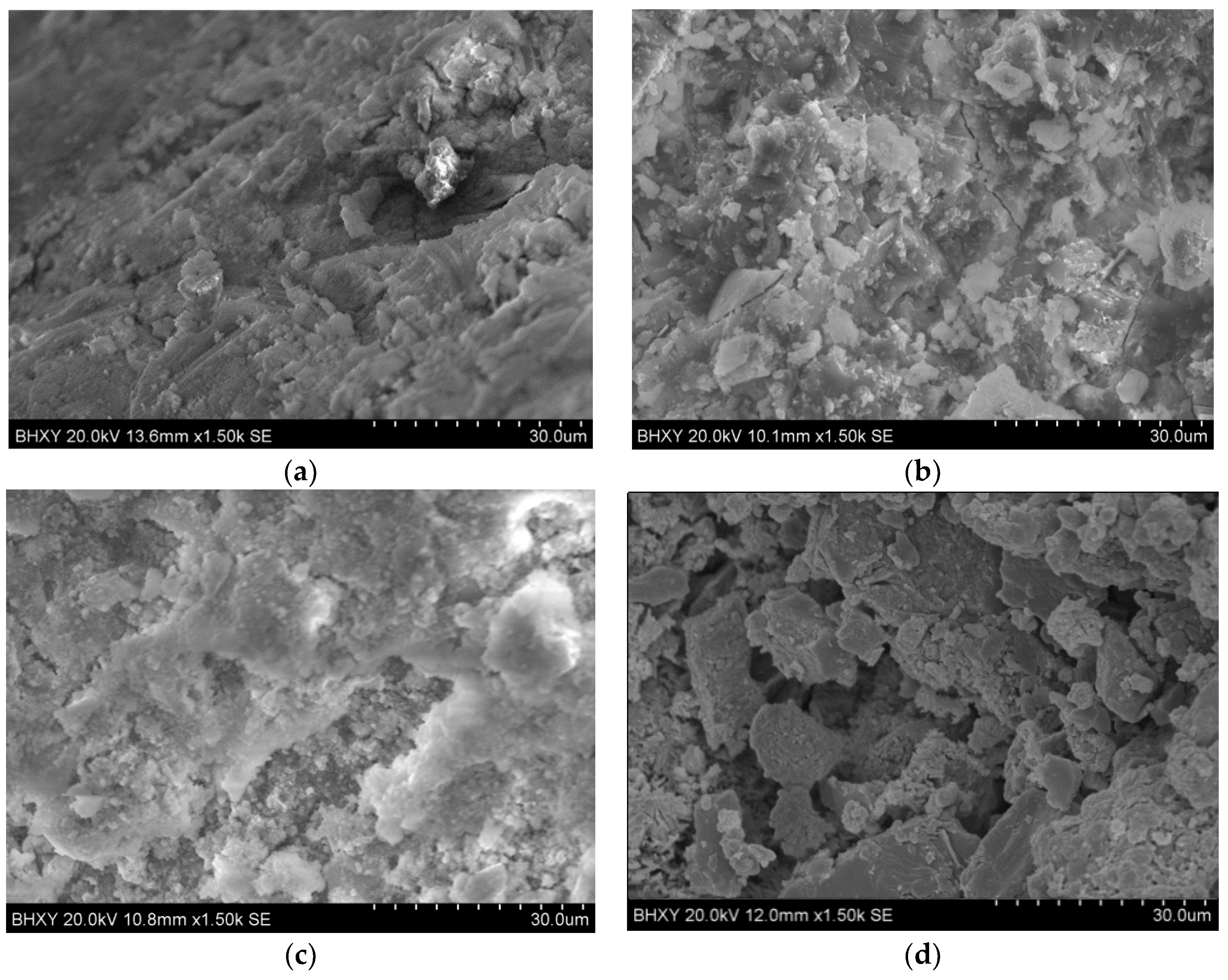

3.3. Scanning Electron Microscopy and Energy-Dispersive X-ray Spectroscopy

3.4. Particle-Size Measurements and Distributions

3.5. Capillary Water-Absorption Test

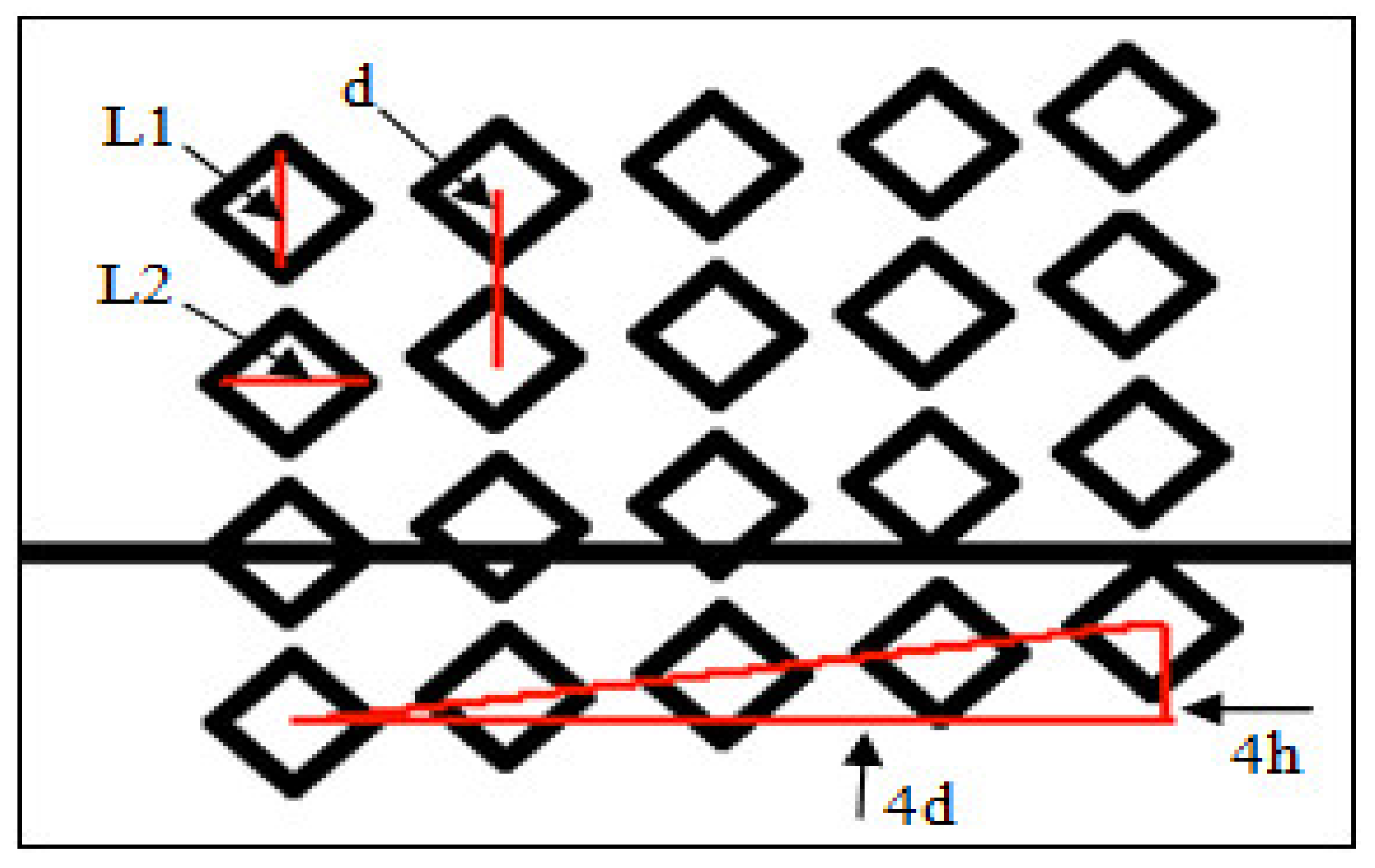

3.6. Gas Permeability Test

3.7. Microhardness Test

4. Results and Discussion

4.1. Chemical Characterization

4.2. Thermogravimetric Analysis of Silane Waterproofing Materials

4.3. SEM and EDS

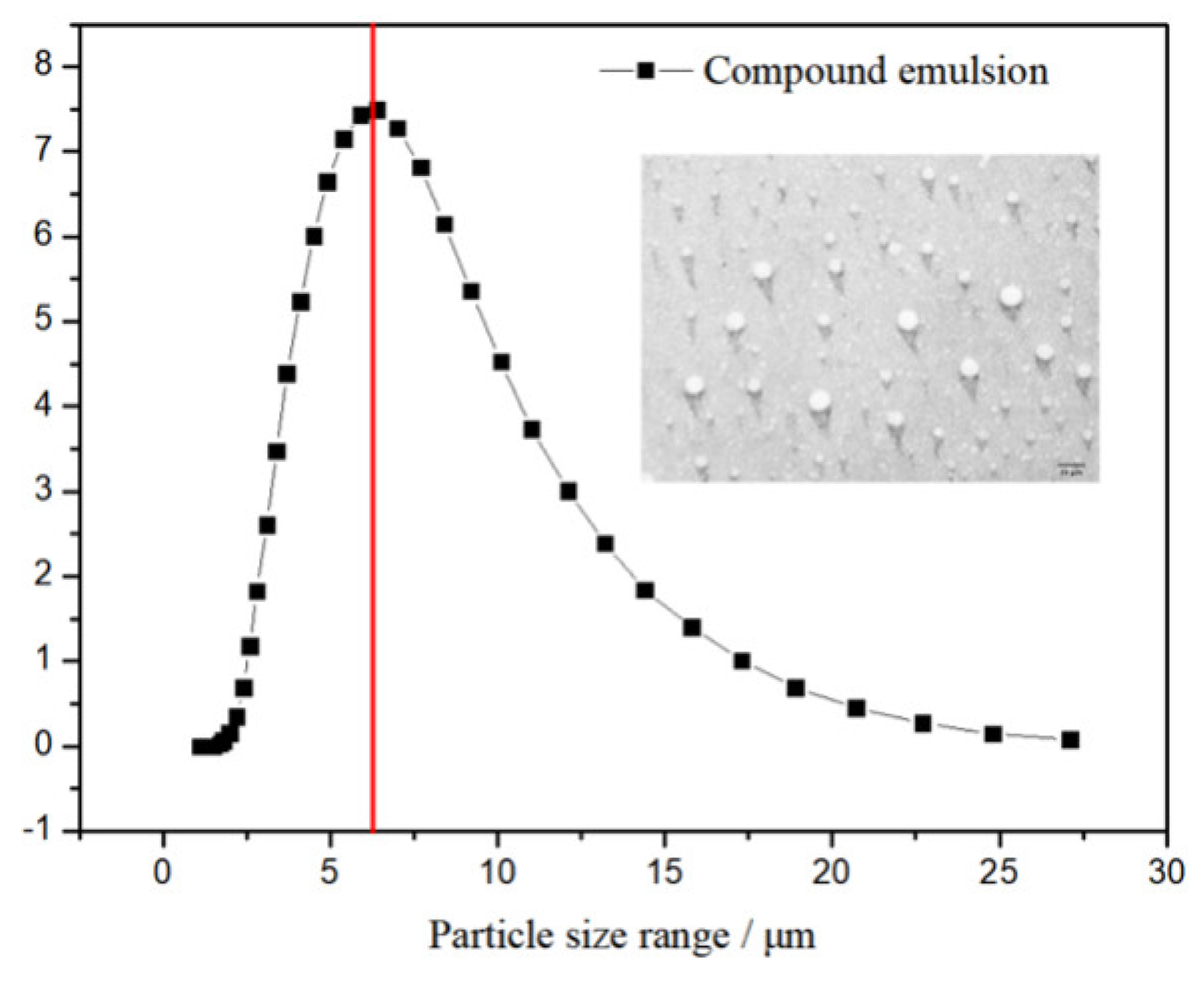

4.4. Particle-Size Analysis

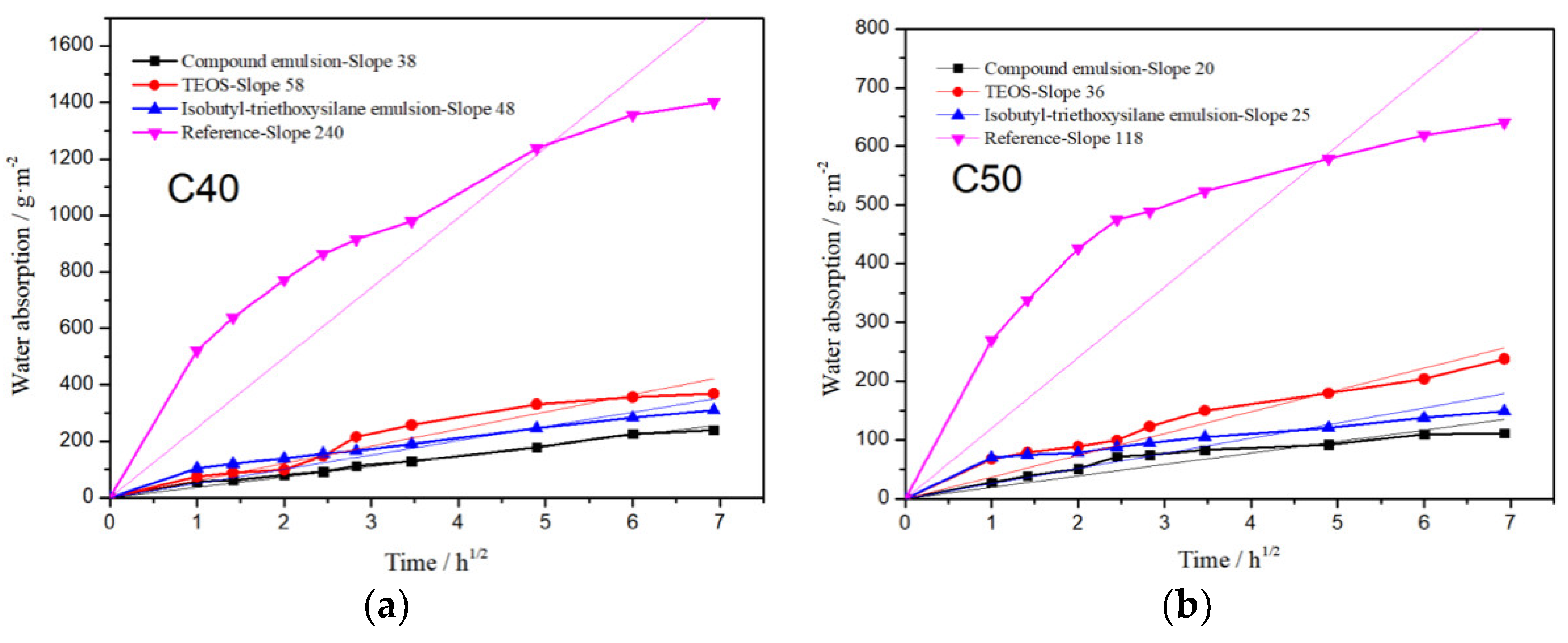

4.5. Effect on Capillary Water Absorption of Concrete

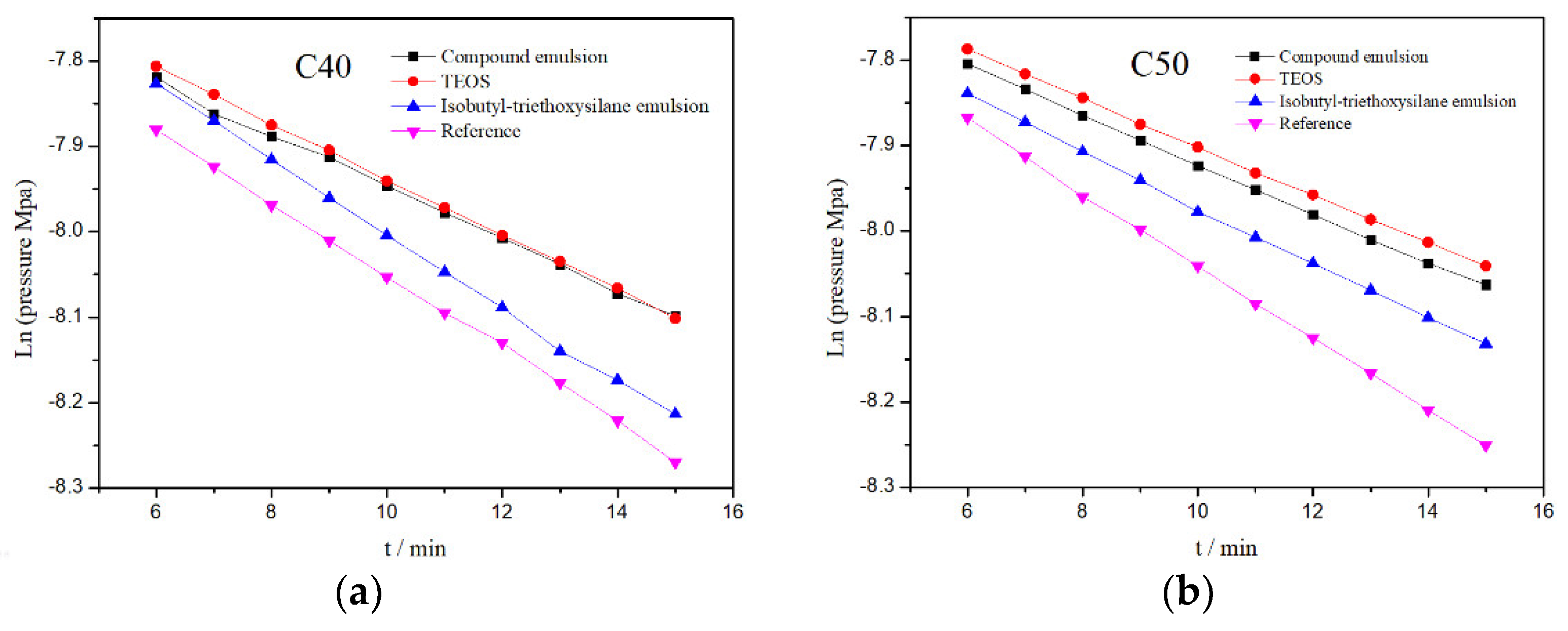

4.6. Gas Permeability Analysis

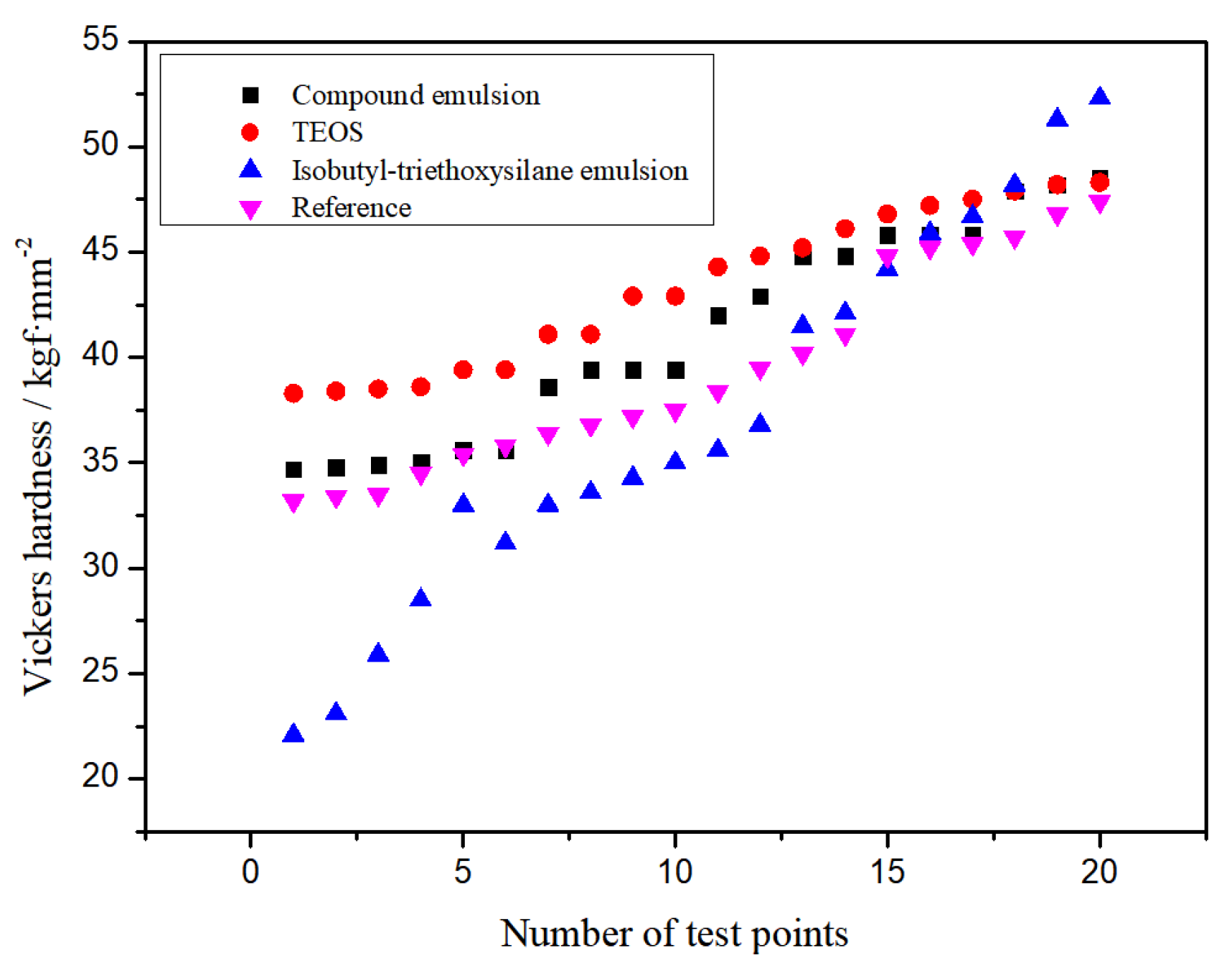

4.7. Microhardness Analysis

5. Conclusions

- The key points in the preparation of the composite emulsion were determined, including the type and amount of emulsifier (a mass ratio of Span80 to PPG O of 1:1), addition time (after an emulsion reaction period of 1 h), and amount of TEOS (accounting for 35% of the total solution mass), to ensure the stability of the composite emulsion.

- The composite emulsion was coated on the surface of cement-based materials, which formed a hydrophobic film on the surface of cement-based materials that can improve the waterproofing effect of cement-based materials without affecting its permeability.

- The surface hardness of the composite emulsion can be improved by coating it on the cement-based materials, due to the introduction of TEOS into the composite emulsion, which reduces the possibility of reducing the surface hardness of cement-based materials by the use of traditional silane materials.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Pan, Z.; Zhu, Y.; Zhang, D.; Chen, N.; Yang, Y.; Cai, X. Effect of expansive agents on the workability, crack resistance and durability of shrinkage-compensating concrete with low contents of fibers. Constr. Build. Mater. 2020, 259, 119768. [Google Scholar] [CrossRef]

- Zou, D.; Wang, Z.; Shen, M.; Liu, T.; Zhou, A. Improvement in freeze-thaw durability of recycled aggregate permeable concrete with silane modification. Constr. Build. Mater. 2021, 268, 121097. [Google Scholar] [CrossRef]

- Zhong, R.; Wille, K. Influence of matrix and pore system characteristics on the durability of pervious concrete. Constr. Build. Mater. 2018, 162, 132–141. [Google Scholar] [CrossRef]

- Ge, X.; Ge, Y.; Li, Q.; Cai, X.; Yang, W.; Du, Y. Effect of low air pressure on the durability of concrete. Constr. Build. Mater. 2018, 187, 830–838. [Google Scholar] [CrossRef]

- Zhu, P.; Hao, Y.; Liu, H.; Wang, X.; Gu, L. Durability evaluation of recycled aggregate concrete in a complex environment. J. Clean. Prod. 2020, 273, 122569. [Google Scholar] [CrossRef]

- Konečný, P.; Lehner, P. Durability assessment of concrete bridge deck considering waterproof membrane and epoxy-coated reinforcement. Perspect. Sci. 2016, 7, 222–227. [Google Scholar] [CrossRef] [Green Version]

- Matar, P.; Barhoun, J. Effects of waterproofing admixture on the compressive strength and permeability of recycled aggregate concrete. J. Build. Eng. 2020, 32, 101521. [Google Scholar] [CrossRef]

- Al-Rashed, R.; Jabari, M. Dual-crystallization waterproofing technology for topical treatment of concrete. Case Stud. Constr. Mater. 2020, 13, e00408. [Google Scholar] [CrossRef]

- Wang, R.; Gao, P.; Tian, M.; Dai, Y. Experimental study on mechanical and waterproof performance of lightweight foamed concrete mixed with crumb rubber. Constr. Build. Mater. 2019, 209, 655–664. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, S.; Zhang, W.; Chen, X.; Hou, D.; Zhao, T.; Li, X. Preparation and mechanism of graphene oxide/isobutyltriethoxysilane composite emulsion and its effects on waterproof performance of concrete. Constr. Build. Mater. 2019, 208, 343–349. [Google Scholar] [CrossRef]

- Tittarelli, F.; Moriconi, G. Comparison between surface and bulk hydrophobic treatment against corrosion of galvanized reinforcing steel in concrete. Cem. Concr. Res. 2011, 41, 609–614. [Google Scholar] [CrossRef]

- Zhang, B.; Li, Q.; Niu, X.; Yang, L.; Hu, Y.; Zhang, J. Influence of a novel hydrophobic agent on freeze–thaw resistance and microstructure of concrete. Constr. Build. Mater. 2021, 269, 121294. [Google Scholar] [CrossRef]

- Liu, B.; Shi, J.; Sun, M.; He, Z.; Xu, H.; Tan, J. Mechanical and permeability properties of polymer-modified concrete using hydrophobic agent. J. Build. Eng. 2020, 31, 101337. [Google Scholar] [CrossRef]

- Sakr, M.R.; Bassuoni, M.T. Silane and methyl-methacrylate based nanocomposites as coatings for concrete exposed to salt solutions and cyclic environments. Cem. Concr. Compos. 2021, 115, 103841. [Google Scholar] [CrossRef]

- Shen, L.; Jiang, H.; Wang, T.; Chen, K.; Zhang, H. Performance of silane -based surface treatments for protecting degraded historic concrete. Prog. Org. Coat. 2019, 129, 209–216. [Google Scholar] [CrossRef]

- Zhu, Y.-G.; Kou, S.-C.; Poon, C.-S.; Dai, J.-G.; Li, Q.-Y. Influence of silane-based water repellent on the durability properties of recycled aggregate concrete. Cem. Concr. Compos. 2013, 35, 32–38. [Google Scholar] [CrossRef]

- Zhang, X.; Li, S.; Zhao, T.; Jin, Z. Effffect of silane polymers and silane emulsions on carbonization and freezing-thawing cycle concrete resistance. Concrete 2015, 3, 69–73. [Google Scholar]

- Yoo, P.J.; Eom, B.S.; Park, K.S.; Kim, D.H. Aggregate pre-coating approach using rubber- and silane-coupled thermoset polymer and emulsion for warm-mix asphalt mixtures. Constr. Build. Mater. 2017, 152, 708–714. [Google Scholar] [CrossRef]

- Felekoğlu, B. A method for improving the early strength of pumice concrete blocks by using alkyl alkoxy silane (AAS). Constr. Build. Mater 2012, 28, 305–310. [Google Scholar] [CrossRef]

- Cai, Y.; Hou, P.; Duan, C.; Zhang, R.; Zhou, Z.; Cheng, X.; Shah, S. The use of tetraethyl orthosilicate silane (TEOS) for surface-treatment of hardened cement-based materials: A comparison study with normal treatment agents. Constr. Build. Mater. 2016, 117, 144–151. [Google Scholar] [CrossRef]

- Hou, P.; Zhang, R.; Cai, Y.; Cheng, X.; Shah, S.P. In situ Ca(OH)2 consumption of TEOS on the surface of hardened cement-based materials and its improving effects on the Ca-leaching and sulfate-attack resistivity. Constr. Build. Mater. 2016, 113, 890–896. [Google Scholar] [CrossRef]

- Binder, L.; Jatschka, J.; Baurecht, D.; Wirth, M.; Valenta, C. Novel concentrated water-in-oil emulsions based on a non-ionic silicone surfactant: Appealing application properties and tuneable viscoelasticity. Eur. J. Pharm. Biopharm. 2017, 120, 34–42. [Google Scholar] [CrossRef]

- Hong, I.K.; Kim, S.I.; Lee, S.B. Effects of HLB value on oil-in-water emulsions: Droplet size, rheological behavior, zeta-potential, and creaming index. J. Ind. Eng. Chem. 2018, 67, 123–131. [Google Scholar] [CrossRef]

- Zhang, X.Y.; Li, S.C.; Zhao, T.J.; Jin, Z.Q. Effect of Octyl-Triethoxysilane Emulsion on Protection of Concrete. Key Eng. Mater. 2014, 629, 504–509. [Google Scholar] [CrossRef]

- Chen, Y.; Liu, P.; Yu, Z. Study on degradation of macro performances and micro structure of concrete attacked by sulfate under artificial simulated environment. Constr. Build. Mater. 2020, 260, 119951. [Google Scholar] [CrossRef]

- Al-Ostaz, A.; Wu, W.; Cheng, A.D.; Song, C.R. A molecular dynamics and microporomechanics study on the mechanical properties of major constituents of hydrated cement. Compos. Part B Eng. 2010, 41, 543–549. [Google Scholar] [CrossRef]

- Stȩpkowska, E.T.; Perez-Rodriguez, J.L.; Justo, A.; Sanchez-Soto, P.J.; Aviles, M.A.; Bijen, J.M.J.M. Variations in water sorption and in thermogravimetry of a Portland cement. Thermochim. Acta 1993, 214, 97–102. [Google Scholar] [CrossRef]

- McGettigan, E. Silicon-based weatherproofifing materials. Concr. Int. 1992, 14, 52–56. [Google Scholar]

- Rosell, J.R.; Cantalapiedra, I.R. Simple method of dynamic Young’s modulus determination in lime and cement mortars. Matteriales Construcción 2011, 61, 39–48. [Google Scholar] [CrossRef]

- Sharif-Pakdaman, A.; Morshedian, J.; Jahani, Y. Effect of organoclay and silane grafting of polyethylene on morphology, barrierity, and rheological properties of HDPE/PA6 blends. J. Appl. Polym. Sci. 2013, 127, 1211–1220. [Google Scholar] [CrossRef]

- Jiang, Z.W.; Sun, Z.P.; Wang, P.M. Effects of silane on anti-corrosion properties of high-performance marine concrete. China Harb. Eng. 2005, 1, 26–27. [Google Scholar]

| Silicone Monomer | Molecular Formula | Manufacturer | Purity |

|---|---|---|---|

| Isobutyl-triethoxysilane | (CH3)2CHCH2Si(OC2H5)3 | Sigma (Shanghai, China) | Chemical level |

| TEOS | Si(OC2H5)4 | ||

| Span 80 | C24H44O6 | Shanghai Aibi Chemical Reagent Co., Ltd. (Shanghai, China) | |

| PPG O | RO-(CH2CH2O)n-HR | ||

| PEG | HO(C2H4O)nH | ||

| SLS | C12H25SO4Na | ||

| SDBS | C18H29NaO3S |

| Emulsifier | SLS | SDBS | Span 80 | PPG O |

|---|---|---|---|---|

| HLB | 40 | 10.6 | 4.3 | 16.5 |

| Compound Emulsifier | Dosage Ratio | Static Situation |

|---|---|---|

| Span 80 and SDS | 4:1 | Layered |

| Span 80 and SDBS | 1:9 | Layered |

| Span 80 and PPG O | 1:1 | Stable |

| Addition Time Period | Emulsion State |

|---|---|

| Stirring for 1 h | Stable |

| Stirring for 2 h | Layered |

| Stirring for 3 h | Layered |

| Stirring for 4 h | Layered |

| Mass Ratio of TEOS and Isobutyl-Triethoxysilane | Static Situation | Gelation Time |

|---|---|---|

| 1:2 | Stable | Approximately 2 months |

| 1:1 | Stable | Approximately 1 month |

| 2:1 | Layered | Approximately 15 days |

| Cement-Based Materials | Strength Grade | Mixing Ratio (kg/m3) | ||||

|---|---|---|---|---|---|---|

| Water–Cement RATIO | Cement | Sandstone | Aggregate | Water | ||

| Concrete | C40 | 0.5 | 320 | 653 | 1267 | 160 |

| C50 | 0.4 | 380 | 579 | 1269 | 152 | |

| Cement paste | - | 0.4 | 1350 | - | - | 540 |

| SiO2 | Al2O3 | Fe2O3 | CaO | MgO | SO3 | Na2O | f-CaO |

|---|---|---|---|---|---|---|---|

| 21.9 | 4.5 | 3.5 | 64.0 | 2.9 | 2.4 | 0.5 | 0.92 |

| Samples | 20–300 °C | 300–500 °C |

|---|---|---|

| Compound emulsion | 10.92 | 4.24 |

| TEOS | 11.59 | 4.14 |

| Isobutyl-triethoxysilane emulsion | 9.38 | 4.12 |

| Reference | 11.21 | 4.74 |

| Samples | Content of Silicon (at.%) | |

|---|---|---|

| Spot Scanning | Surface Scanning | |

| Compound emulsion | 14.12 | 10.23 |

| TEOS | 7.34 | 7.21 |

| Isobutyl-triethoxysilane emulsion | 11.64 | 8.28 |

| Reference | 4.04 | 4.81 |

| Silane Waterproofing Material | Average Particle Size (μm) |

|---|---|

| Isobutyl-triethoxysilane emulsion | 5.12 |

| Compound emulsion | 6.31 |

| Strength Grade | Compound Emulsion | TEOS | Isobutyl-Triethoxysilane Emulsion | Reference |

|---|---|---|---|---|

| C40 | 38 | 58 | 48 | 240 |

| C50 | 20 | 36 | 25 | 118 |

| Strength Grade | Compound Emulsion | TEOS | Isobutyl-triethoxysilane Emulsion | Reference |

|---|---|---|---|---|

| C40 | 0.0414 | 0.0305 | 0.0332 | 0.0438 |

| C50 | 0.0322 | 0.0287 | 0.0323 | 0.0432 |

| Samples | Average Vickers Hardness (MPa) |

|---|---|

| Compound emulsion | 41.2 |

| TEOS | 43.1 |

| Isobutyl-triethoxysilane emulsion | 37.2 |

| Reference | 39.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, X.; Geng, Y.; Li, S.; Hou, D.; Meng, S.; Gao, Y.; Zhang, P.; Ai, H. Preparation of Modified Silane Composite Emulsion and Its Effect on Surface Properties of Cement-Based Materials. Coatings 2021, 11, 272. https://doi.org/10.3390/coatings11030272

Chen X, Geng Y, Li S, Hou D, Meng S, Gao Y, Zhang P, Ai H. Preparation of Modified Silane Composite Emulsion and Its Effect on Surface Properties of Cement-Based Materials. Coatings. 2021; 11(3):272. https://doi.org/10.3390/coatings11030272

Chicago/Turabian StyleChen, Xu, Yongjuan Geng, Shaochun Li, Dongshuai Hou, Shuling Meng, Yan Gao, Ping Zhang, and Hongxiang Ai. 2021. "Preparation of Modified Silane Composite Emulsion and Its Effect on Surface Properties of Cement-Based Materials" Coatings 11, no. 3: 272. https://doi.org/10.3390/coatings11030272

APA StyleChen, X., Geng, Y., Li, S., Hou, D., Meng, S., Gao, Y., Zhang, P., & Ai, H. (2021). Preparation of Modified Silane Composite Emulsion and Its Effect on Surface Properties of Cement-Based Materials. Coatings, 11(3), 272. https://doi.org/10.3390/coatings11030272