Tribological Behaviour and Lubricating Mechanism of Tire Pyrolysis Oil

Abstract

1. Introduction

2. System Description and Methodology

2.1. Refining and Production of Tire Pyrolysis Oil

2.2. Test Arrangement

2.3. Test Method

2.3.1. Friction Assessment

2.3.2. Wear Assessment

2.3.3. Flash Temperature Parameter Assessment

3. Result and Discussion

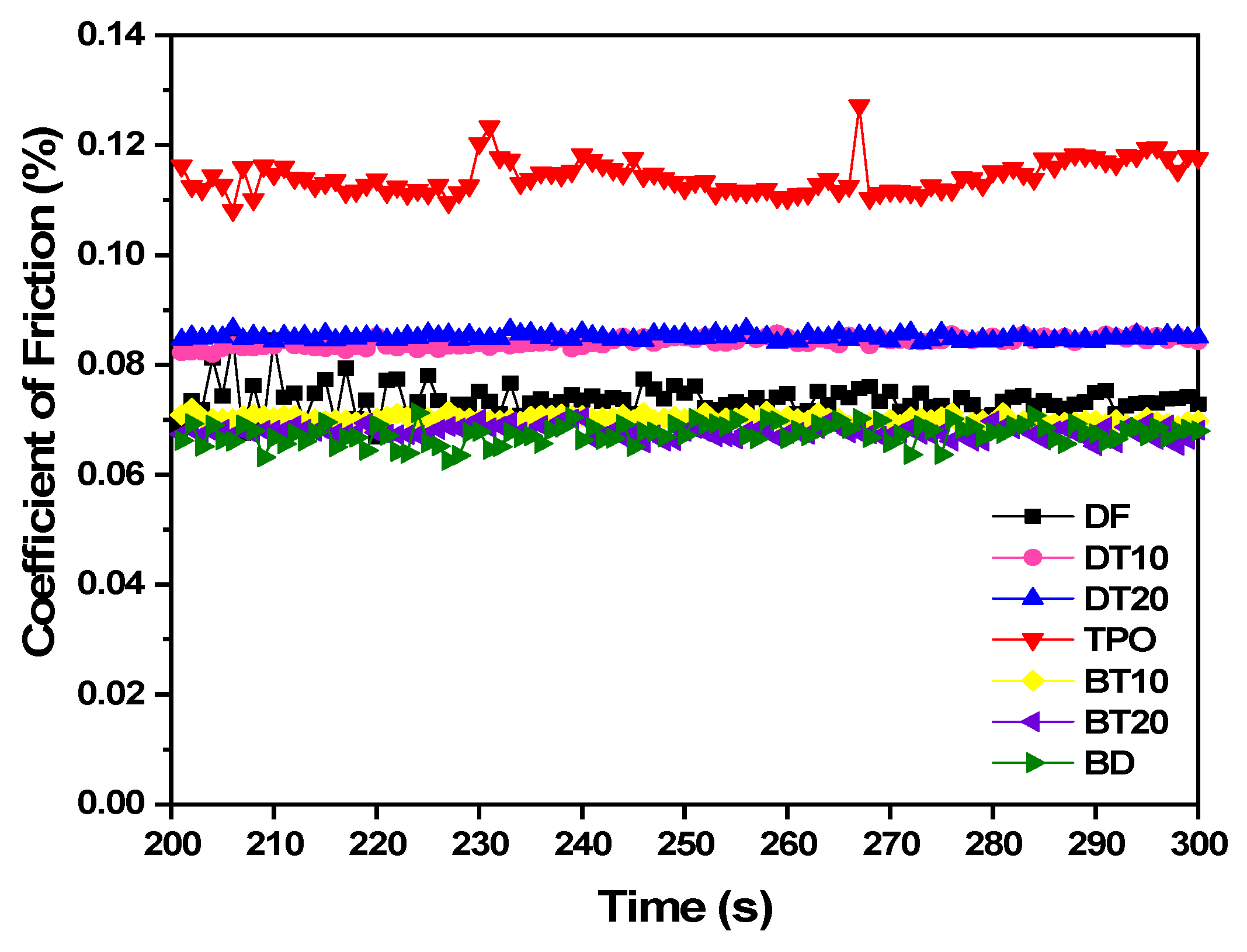

3.1. Friction Performance

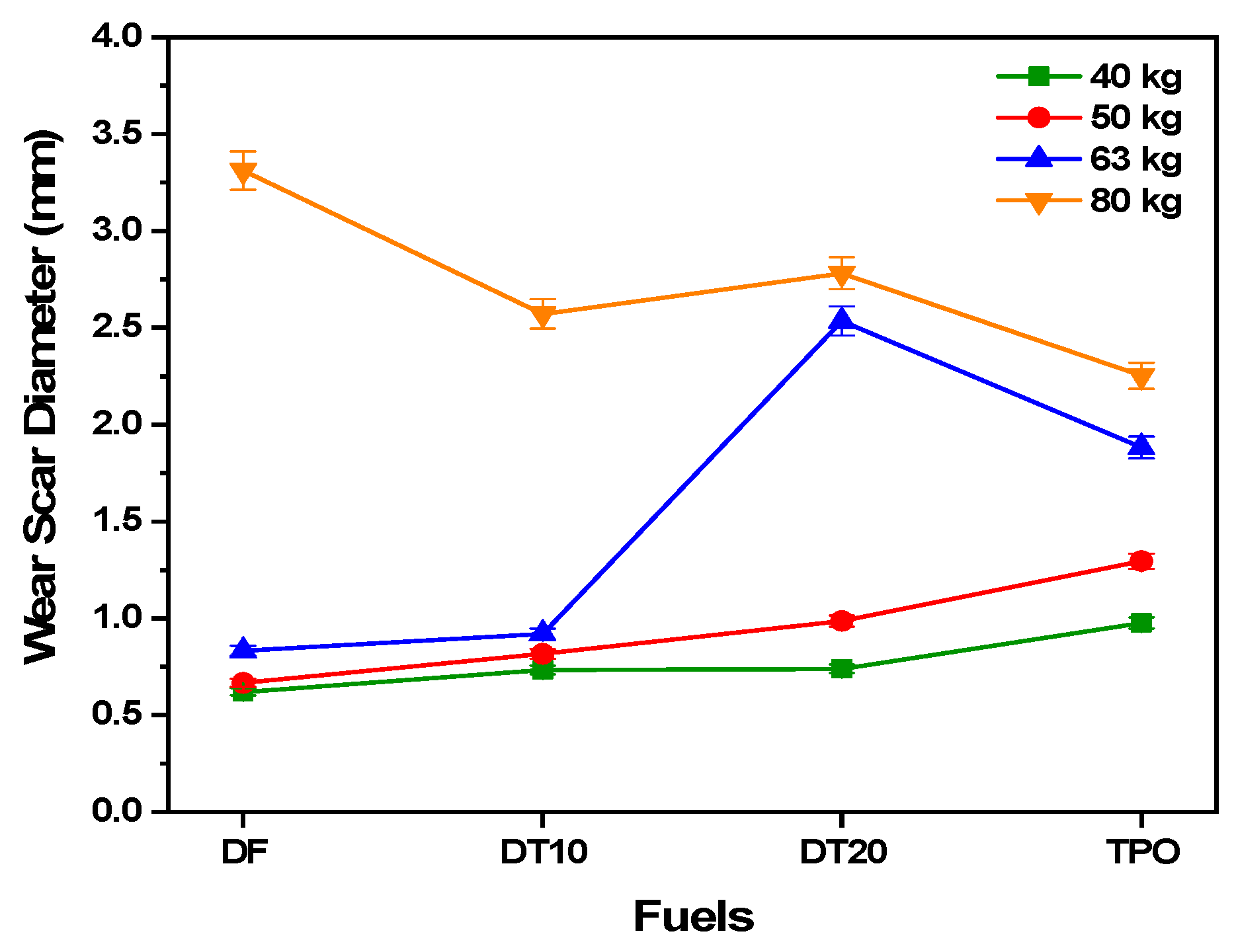

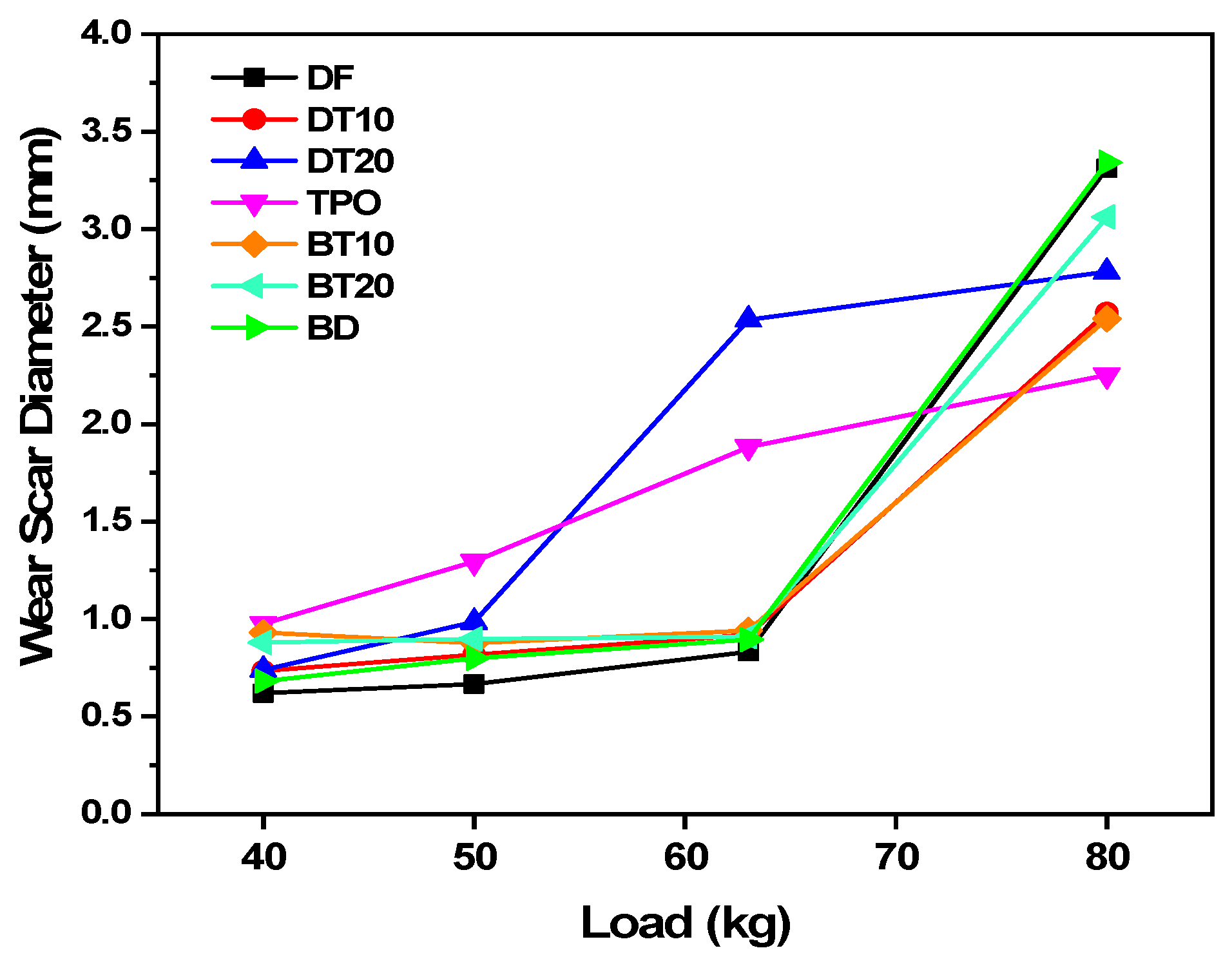

3.2. Wear Performance

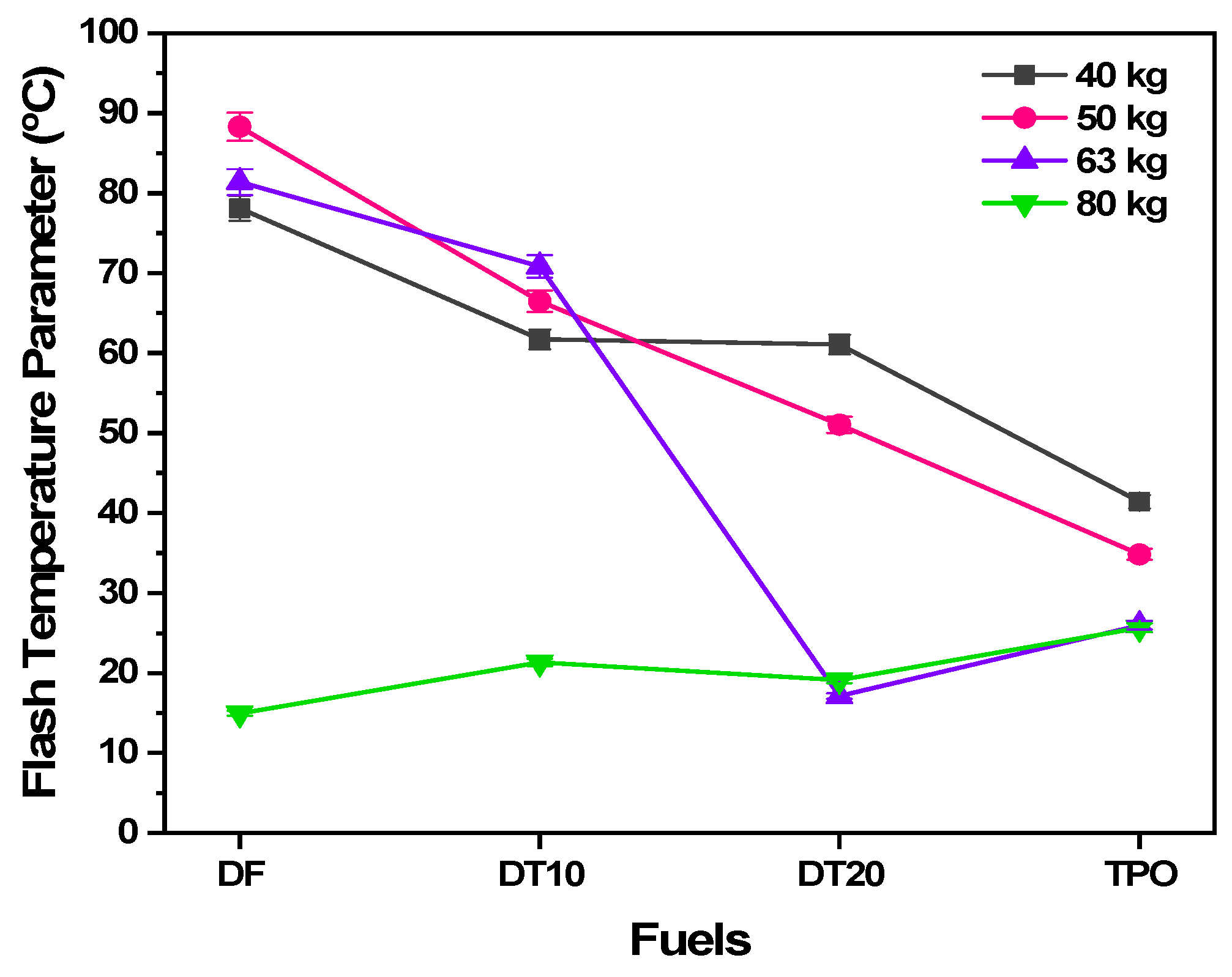

3.3. Flash Temperature Parameter

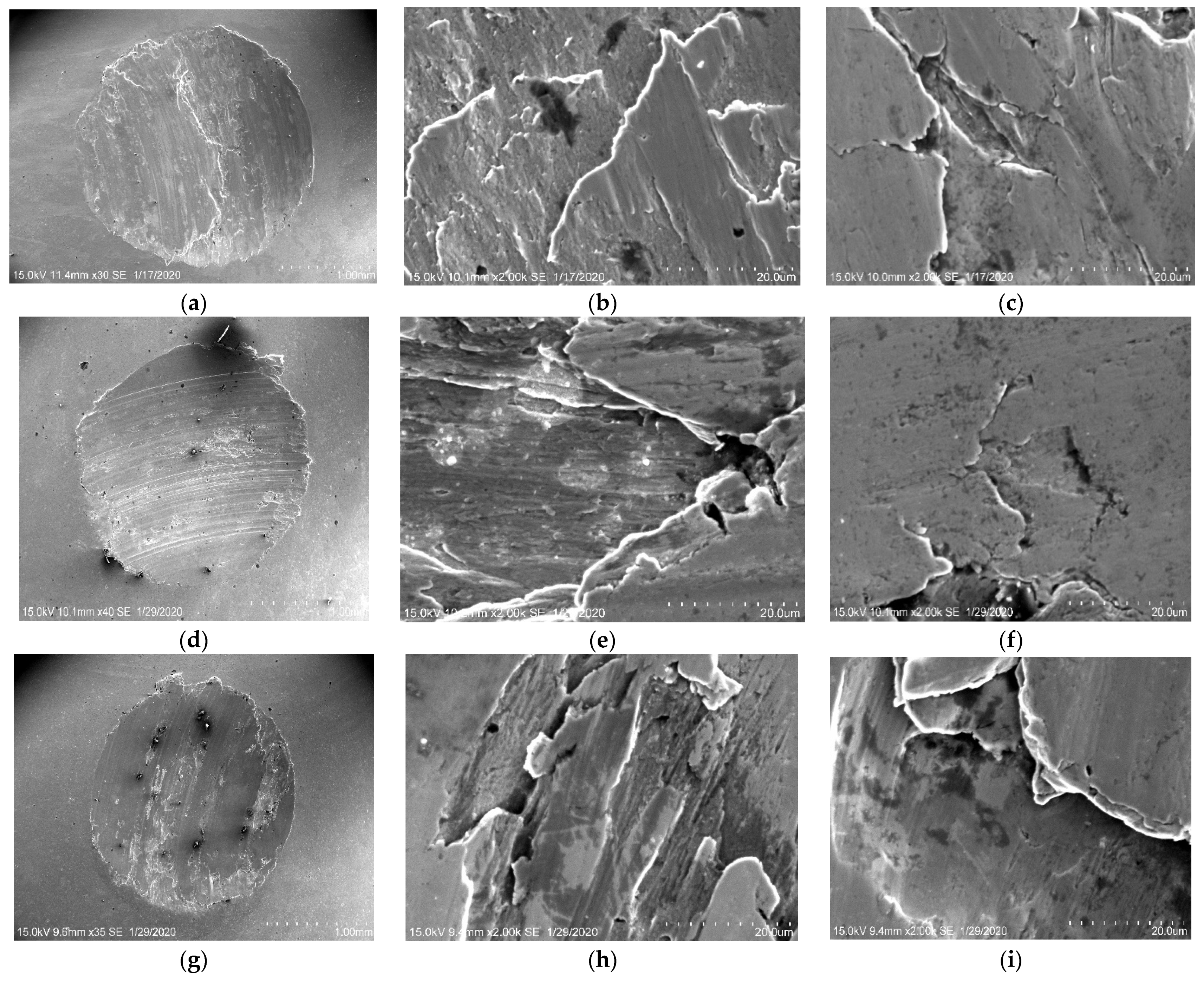

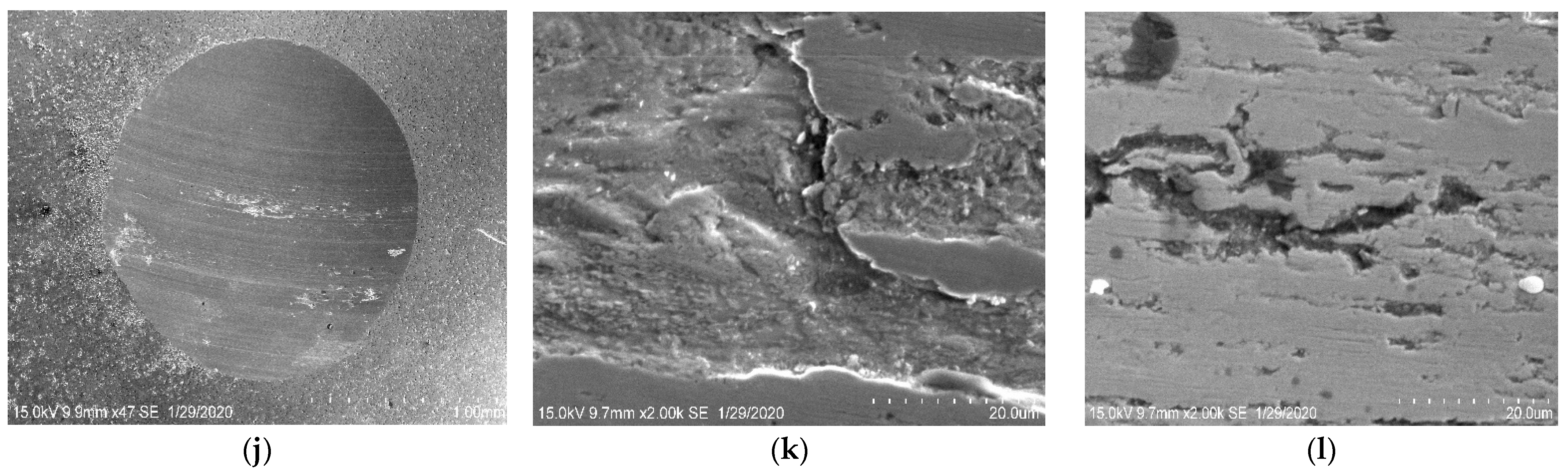

3.4. SEM Analysis

4. Conclusions

- Diesel fuel showed 49.9%, 28.71%, and 20.9% higher unsteady friction coefficients than TPO, DT10, and DT20, respectively. DT10 and DT20 displayed smooth behaviour of the steady-state friction coefficient compared to diesel’s fluctuating performance.

- DT10 exhibited better wear behaviour relative to diesel, TPO, and DT20 at low and high loads. The WSD of DT10, DT20, and TPO were 22.35, 16.01, and 31.99%, respectively, smaller than diesel at the load of 80 kg.

- TPO showed a higher load-carrying capacity, which shows its potential to use at higher loads and in extreme pressure conditions.

- The wear behaviours of considered blends showed that a reasonable friction behaviour and a greater load-holding capability could be obtained for a specific use.

- TPO displayed the highest flash temperature parameter of 25.67 °C at 80 kg load compared to other fuels. DT10 displayed the better flash temperature parameter results, close to the diesel fuel at low loads. However, the lowest flash temperature parameter value was credited to diesel fuel (14.96 °C).

- The SEM micrographs revealed that the TPO and DT10 display lower metal extrusion than DT20 and diesel fuel.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ASTM | American society for testing and materials |

| BD | Biodiesel |

| BT10 | TPO 10%, Biodiesel 90% |

| BT20 | TPO 20%, Biodiesel 80% |

| CIB | Calophyllum inophyllum biodiesel |

| CI | Compression ignition |

| COF | Coefficient of friction |

| DF | Diesel fuel |

| DT10 | TPO 10%, Diesel 90% |

| DT20 | TPO 20%, Diesel 80% |

| EDX | Energy dispersive X-ray |

| EU | European Union |

| FBT | Four ball tribometer |

| FTP | Flash temperature parameter |

| GC-MS | Gas chromatography-mass spectroscopy |

| MO | Mongongo-oil |

| PB | Palm oil biodiesel |

| PCT | Passenger car type |

| SEM | Scanning electron microscope |

| TPO | Tire pyrolysis oil |

| TT | Truck tire |

| WSD | Wear scar diameter |

References

- Yaqoob, H.; Teoh, Y.H.; Jamil, M.A.; Gulzar, M. Potential of tire pyrolysis oil as an alternate fuel for diesel engines: A review. J. Energy Inst. 2021, 96, 1–17. [Google Scholar] [CrossRef]

- Rashid, T.; Ali, S.; Taqvi, A.; Sher, F.; Rubab, S.; Thanabalan, M.; Bilal, M. Enhanced lignin extraction and optimisation from oil palm biomass using neural network modelling. Fuel 2021, 293, 120485. [Google Scholar] [CrossRef]

- Sher, F.; Yaqoob, A.; Saeed, F.; Zhang, S.; Jahan, Z.; Klemeš, J.J. Torrefied biomass fuels as a renewable alternative to coal in co-firing for power generation. Energy 2020, 209, 118444. [Google Scholar] [CrossRef]

- Murugesan, A.; Umarani, C.; Subramanian, R.; Nedunchezhian, N. Bio-diesel as an alternative fuel for diesel engines—A review. Renew. Sustain. Energy Rev. 2009, 13, 653–662. [Google Scholar] [CrossRef]

- Dhar, A.; Agarwal, A.K. Performance, emissions and combustion characteristics of Karanja biodiesel in a transportation engine. Fuel 2014, 119, 70–80. [Google Scholar] [CrossRef]

- Yaqoob, H.; Teoh, Y.H.; Goraya, T.S.; Sher, F.; Jamil, M.A.; Rashid, T.; Yar, K.A. Energy evaluation and environmental impact assessment of transportation fuels in Pakistan. Case Stud. Chem. Environ. Eng. 2021, 3, 100081. [Google Scholar] [CrossRef]

- Qaisrani, M.A.; Wei, J.; Khan, L.A. Potential and transition of concentrated solar power: A case study of China. Sustain. Energy Technol. Assess. 2021, 44, 101052. [Google Scholar] [CrossRef]

- Lam, M.K.; Tan, K.T.; Lee, K.T.; Mohamed, A.R. Malaysian palm oil: Surviving the food versus fuel dispute for a sustainable future. Renew. Sustain. Energy Rev. 2009, 13, 1456–1464. [Google Scholar] [CrossRef]

- Duan, P.; Jin, B.; Xu, Y.; Wang, F. Co-pyrolysis of microalgae and waste rubber tire in supercritical ethanol. Chem. Eng. J. 2015, 269, 262–271. [Google Scholar] [CrossRef]

- Yaqoob, H.; Teoh, Y.H.; Sher, F.; Jamil, M.A.; Murtaza, D.; Al Qubeissi, M.; Hassan, M.U.I.; Mujtaba, M.A. Current status and potential of tire pyrolysis oil production as an alternative fuel in developing countries. Sustainability 2021, 13, 3214. [Google Scholar] [CrossRef]

- Mokhtar, N.M.; Omar, R.; Idris, A. Microwave pyrolysis for conversion of materials to energy: A brief review. Energy Sources Part A Recovery Util. Environ. Eff. 2012, 34, 2104–2122. [Google Scholar] [CrossRef]

- Verma, P.; Zare, A.; Jafari, M.; Bodisco, T.A.; Rainey, T.; Ristovski, Z.D.; Brown, R.J. Diesel engine performance and emissions with fuels derived from waste tyres. Sci. Rep. 2018, 8, 2457. [Google Scholar] [CrossRef]

- Ameen, M.; Zamri, N.M.; May, S.T.; Azizan, M.T.; Aqsha, A.; Sabzoi, N.; Sher, F. Effect of acid catalysts on hydrothermal carbonization of Malaysian oil palm residues (leaves, fronds, and shells) for hydrochar production. Biomass Convers. Biorefinery 2021. [Google Scholar] [CrossRef]

- Al-Juboori, O.; Sher, F.; Hazafa, A.; Khan, M.K.; Chen, G.Z. The effect of variable operating parameters for hydrocarbon fuel formation from CO2 by molten salts electrolysis. J. CO2 Util. 2020, 40, 101193. [Google Scholar] [CrossRef]

- Zhang, Y.; Ran, Z.; Jin, B.; Zhang, Y.; Zhou, C.; Sher, F. Simulation of particle mixing and separation in multi-component fluidized bed using Eulerian-Eulerian method: A review. Int. J. Chem. React. Eng. 2019, 17, 1–27. [Google Scholar] [CrossRef]

- ACEA. ACEA Pocket Guide—European Automobile Manufacturers’ Association; ACEA: Brussels, Belgium, 2016. [Google Scholar]

- Voelcker, J. 1.2 Billion Vehicles on World’s Roads Now, 2 Billion by 2035: Report. Available online: https://www.greencarreports.com/news/1093560_1-2-billion-vehicles-on-worlds-roads-now-2-billion-by-2035-report (accessed on 18 October 2018).

- Shulman, V.L. Tyre Recycling, Rapra Review Reports; Smithers Rapra Press: Shrewsbury, UK, 2004. [Google Scholar]

- Li, W.; Huang, C.; Li, D.; Huo, P.; Wang, M.; Han, L.; Chen, G.; Li, H.; Li, X.; Wang, Y.; et al. Derived oil production by catalytic pyrolysis of scrap tires. Chin. J. Catal. 2016, 37, 526–532. [Google Scholar] [CrossRef]

- Khan, M.Z.; Hossain, M.I.; Halder, P.K.; Hasan, M.R.; Al-Mamun, M.R. Fuel properties of pyrolytic tyre oil and its blends with diesel fuel—Towards waste management. Int. J. Environ. Waste Manag. 2016, 18, 335–348. [Google Scholar] [CrossRef]

- García-Contreras, R.; Martínez, J.D.; Armas, O.; Murillo, R.; García, T. Study of a residential boiler under start-transient conditions using a tire pyrolysis liquid (TPL)/diesel fuel blend. Fuel 2015, 158, 744–752. [Google Scholar] [CrossRef]

- Pinto, G.M.; De Souza, T.A.Z.; Coronado, C.J.R.; Flôres, L.F.V.; Chumpitaz, G.R.A.; Silva, M.H. Experimental investigation of the performance and emissions of a diesel engine fuelled by blends containing diesel S10, pyrolysis oil from used tires and biodiesel from waste cooking oil. Environ. Prog. Sustain. Energy 2019, 38, 13199. [Google Scholar] [CrossRef]

- Karagoz, M.; Uysal, C.; Agbulut, U.; Saridemir, S. Energy, exergy, economic and sustainability assessments of a compression ignition diesel engine fueled with tire pyrolytic oil−diesel blends. J. Clean. Prod. 2020, 264, 121724. [Google Scholar] [CrossRef]

- Pote, R.N.; Patil, R.K. Combustion and emission characteristics analysis of waste tyre pyrolysis oil. Sn Appl. Sci. 2019, 294. [Google Scholar] [CrossRef]

- Uyumaz, A.; Aydoğan, B.; Solmaz, H.; Yılmaz, E.; Hopa, D.Y.; Bahtli, T.A.; Solmaz, Ö.; Aksoy, F. Production of waste tyre oil and experimental investigation on combustion, engine performance and exhaust emissions. J. Energy Inst. 2019, 92, 1406–1418. [Google Scholar] [CrossRef]

- Sharma, A.; Murugan, S. Potential for using a tyre pyrolysis oil-biodiesel blend in a diesel engine at different compression ratios. Energy Convers. Manag. 2015, 93, 289–297. [Google Scholar] [CrossRef]

- Singh, D.; Soni, S.L.; Sharma, D.; Kumari, D. Waste tyre oil as alternative fuel in CI engine: A review. Int. J. Adv. Res. Innov. Ideas Educ. 2017, 3, 577–585. [Google Scholar]

- Quek, A.; Balasubramanian, R. Liquefaction of waste tires by pyrolysis for oil and chemicals—A review. J. Anal. Appl. Pyrolysis 2013, 101, 1–16. [Google Scholar] [CrossRef]

- Silva e Mello, V.; Do Vale Souza, E.R.; De Araújo Oliveira, M.V.; Alves, S.M. Effect of desulfurization of diesel and its blends with biodiesel on metallic contact. Mater. Res. 2014, 17, 82–88. [Google Scholar] [CrossRef][Green Version]

- Murugan, S.; Sundaramoorthi, H.; Nagarajan, G.; Horak, B. A comparative study on some methods to use tyre pyrolysis oil as an alternative fuel in a DI diesel engine. In Exergy for A Better Environment and Improved Sustainability 2: Applications; Aloui, F., Dincer, I., Eds.; Springer International Publishing: Cham, Switzerland, 2018; pp. 405–420. ISBN 978-3-319-62575-1. [Google Scholar]

- Yaqoob, H.; Teoh, Y.H.; Jamil, M.A.; Rasheed, T.; Sher, F. An experimental investigation on tribological behaviour of tire-derived pyrolysis oil blended with biodiesel fuel. Sustainability 2020, 12, 9975. [Google Scholar] [CrossRef]

- Habibullah, M.; Masjuki, H.H.; Kalam, M.A.; Zulkifli, N.W.; Masum, B.M.; Arslan, A.; Gulzar, M. Friction and wear characteristics of Calophyllum inophyllum biodiesel. Ind. Crop. Prod. 2015, 76, 188–197. [Google Scholar] [CrossRef]

- Mosarof, M.H.; Kalam, M.A.; Masjuki, H.H.; Alabdulkarem, A.; Habibullah, M.; Arslan, A.; Monirul, I.M. Assessment of friction and wear characteristics of Calophyllum inophyllum and palm biodiesel. Ind. Crop. Prod. 2016, 83, 470–483. [Google Scholar] [CrossRef]

- Mujtaba, M.A.; Muk Cho, H.; Masjuki, H.H.; Kalam, M.A.; Farooq, M.; Soudagar, M.E.M.; Gul, M.; Ahmed, W.; Afzal, A.; Bashir, S.; et al. Effect of alcoholic and nano-particles additives on tribological properties of diesel–palm–sesame–biodiesel blends. Energy Rep. 2020, 7, 1162–1171. [Google Scholar] [CrossRef]

- Sharul, M.; Awang, N.; Wahidah, N.; Zulkifli, M.; Abbass, M.M.; Zulkifli, S.A.; Nur, M.; Mohd, A. Effect of blending local plastic pyrolytic oil with diesel fuel on lubricity. J. Tribol. 2020, 27, 143–157. [Google Scholar]

- ASTM D6079-18, Standard Test Method for Evaluating Lubricity of Diesel Fuels by the High-Frequency Reciprocating Rig (HFRR); ASTM International: West Conshohocken, PA, USA, 2018.

- Chauhan, B.S.; Kumar, N.; Cho, H.M. A study on the performance and emission of a diesel engine fueled with Jatropha biodiesel oil and its blends. Energy 2012, 37, 616–622. [Google Scholar] [CrossRef]

- Fayaz, H.; Mujtaba, M.A.; Soudagar, M.E.M.; Razzaq, L.; Nawaz, S.; Nawaz, M.A.; Farooq, M.; Afzal, A.; Ahmed, W.; Khan, T.M.Y.; et al. Collective effect of ternary nano fuel blends on the diesel engine performance and emissions characteristics. Fuel 2021, 293, 120420. [Google Scholar] [CrossRef]

- Tung, S.C.; McMillan, M.L. Automotive tribology overview of current advances and challenges for the future. Tribol. Int. 2004, 37, 517–536. [Google Scholar] [CrossRef]

- Serrano, L.M.; Câmara, R.M.; Carreira, V.J.; Da Silva, M.G. Performance study about biodiesel impact on buses engines using dynamometer tests and fleet consumption data. Energy Convers. Manag. 2012, 60, 2–9. [Google Scholar] [CrossRef]

- Sarvi, A.; Fogelholm, C.-J.; Zevenhoven, R. Emissions from large-scale medium-speed diesel engines: 2. Influence of fuel type and operating mode. Fuel Process. Technol. 2008, 89, 520–527. [Google Scholar] [CrossRef]

- Thangavelu, S.K.; Arthanarisamy, M. Experimental investigation on engine performance, emission, and combustion characteristics of a DI CI engine using tyre pyrolysis oil and diesel blends doped with nanoparticles. Environ. Prog. Sustain. Energy 2020, 39, 1–7. [Google Scholar] [CrossRef]

- Vihar, R.; Seljak, T.; Rodman Oprešnik, S.; Katrašnik, T. Combustion characteristics of tire pyrolysis oil in turbo charged compression ignition engine. Fuel 2015, 150, 226–235. [Google Scholar] [CrossRef]

- Hamzah, M.H.; Alias, A.; Mamat, R.; Abdullah, A.A.; Sudrajad, A.; Ramlan, N.A.; Jaharudin, N.F. Performance analysis of diesel engine running with tyre-derived fuel. Iop Conf. Ser. Mater. Sci. Eng. 2019, 469, 12017. [Google Scholar] [CrossRef]

- Hürdoğan, E.; Ozalp, C.; Kara, O.; Ozcanli, M. Experimental investigation on performance and emission characteristics of waste tire pyrolysis oil–diesel blends in a diesel engine. Int. J. Hydrogen Energy 2017, 42, 23373–23378. [Google Scholar] [CrossRef]

- Murillo, R.; Aylo, E.; Navarro, M.V.; Calle, M.S.; Aranda, A.; Mastral, A.M. The application of thermal processes to valorise waste tyre. Fuel Process. Technol. 2006, 87, 143–147. [Google Scholar] [CrossRef]

- Frigo, S.; Seggiani, M.; Puccini, M.; Vitolo, S. Liquid fuel production from waste tyre pyrolysis and its utilisation in a diesel engine. Fuel 2014, 116, 399–408. [Google Scholar] [CrossRef]

- ASTM D240-19, Standard Test Method for Heat of Combustion of Liquid Hydrocarbon Fuels by Bomb Calorimeter; ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM D7042-21, Standard Test Method for Dynamic Viscosity and Density of Liquids by Stabinger Viscometer (and the Calculation of Kinematic Viscosity); ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM D4052-18a, Standard Test Method for Density, Relative Density, and API Gravity of Liquids by Digital Density Meter; ASTM International: West Conshohocken, PA, USA, 2018.

- ASTM D2266-01, Standard Test Method for Wear Preventive Characteristics of Lubricating Grease (Four-Ball Method); ASTM International: West Conshohocken, PA, USA, 2015.

- ASTM D4172-20, Standard Test Method for Wear Preventive Characteristics of Lubricating Fluid (Four-Ball Method); ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM F1372-93, Standard Test Method for Scanning Electron Microscope (SEM) Analysis of Metallic Surface Condition for Gas Distribution System Components; ASTM International: West Conshohocken, PA, USA, 2020.

- IP-239, Determination of Extreme Pressure and Anti-Wear Properties of Lubricating Fluids and Greases—Four Ball Method (European Conditions); Energy Institute: London, UK, 1986.

- Zulkifli, N.W.M.; Kalam, M.A.; Masjuki, H.H.; Al Mahmud, K.A.H.; Yunus, R. The effect of palm oil trimethylolpropane ester on extreme pressure lubrication. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2014, 228, 160–169. [Google Scholar] [CrossRef]

- Zulkifli, N.W.M.; Azman, S.S.N.; Kalam, M.A.; Masjuki, H.H.; Yunus, R.; Gulzar, M. Lubricity of bio-based lubricant derived from different chemically modified fatty acid methyl ester. Tribol. Int. 2016, 93, 555–562. [Google Scholar] [CrossRef]

- Wain, K.S.; Perez, J.M.; Chapman, E.; Boehman, A.L. Alternative and low sulfur fuel options: Boundary lubrication performance and potential problems. Tribol. Int. 2005, 38, 313–319. [Google Scholar] [CrossRef]

- Nikanjam, M.; Henderson, P.T. Lubricity of low sulfur diesel fuels. SAE Tech. Pap. 1993, 1–9. [Google Scholar] [CrossRef]

- Knothe, G.; Steidley, K.R. Kinematic viscosity of biodiesel fuel components and related compounds. Influence of compound structure and comparison to petrodiesel fuel components. Fuel 2005, 84, 1059–1065. [Google Scholar] [CrossRef]

- Habibullah, M.; Masjuki, H.H.; Kalam, M.A.; Gulzar, M.; Arslan, A.; Zahid, R. Tribological characteristics of calophyllum inophyllum–based TMP (trimethylolpropane) ester as energy-saving and biodegradable lubricant. Tribol. Trans. 2015, 58, 1002–1011. [Google Scholar] [CrossRef]

- Tsuchiya, T.; Shiotani, H.; Goto, S.; Sugiyama, G.; Maeda, A. Japanese standards for diesel fuel containing 5% fame: Investigation of acid generation in fame blended diesel fuels and its impact on corrosion. SAE Tech. Pap. 2006, 776–790. [Google Scholar] [CrossRef]

| Tested Samples | Density (kg/m3) (15 °C) | Kinematic Viscosity (mm2/s) (40 °C) | Lower Heating Value (MJ/kg) | Cetane Index |

|---|---|---|---|---|

| DF | 845.3 | 3.36 | 44.49 | 51.72 |

| DT10 | 849 | 3.17 | 44.81 | 51.71 |

| DT20 | 854 | 2.98 | 44.68 | 51.68 |

| TPO | 946 | 2.23 | 41.81 | 51.65 |

| Properties/Instruments | Standard/Mode | Apparatus | Made | Model | Accuracy |

|---|---|---|---|---|---|

| Calorific value | ASTM D240 [48] | Bomb Calorimeter | IKA, Oxford, UK | C2000 | ±0.1% MJ/kg |

| Kinematic viscosity | ASTM D7042 [49] | Stabinger viscometer | Anton Paar, St Albans, UK | SVM 3000 | ±0.35% |

| Density | ASTM D4052 [50] | Stabinger viscometer | Anton Paar, St Albans, UK | SVM 3000 | ±0.1 kg/m3 |

| Wear and friction | ASTM D2266 [51] | Four-ball testers | DUCOM, Karnataka, India | TR-30L-IAS | – |

| Wear scar diameter (WSD) | ASTM D4172 [52] | Optical microscope | IKA, Oxford, UK | C2000 | ±0.01 mm |

| Scanning Electron Microscope (SEM) | X30/X2000 [53] | Scanning electron microscope | Hitachi, Tokyo, Japan | S3400N | 3.0 nm at 30 kV |

| Specification | Units | Detail | Accuracy |

|---|---|---|---|

| Model | – | Make: DUCOMTR-30L-IAS | – |

| Speed | RPM | 300–3000 | 1 |

| Oil Temperature | °C | Ambient temperature to 100 | 0.5 |

| Maximum axial load | N | 10,000 | 0.5 |

| Scar range | μm | 100–4000 | 0.5 |

| Test ball diameter | mm | 12.7 | – |

| Power | V/Hz/VA | 380/50/3/2000 | – |

| Image measuring system | – | Microscope220 V, 50 Hz | – |

| Image acquisition system | – | Web camera, 12 MP (Megapixels) | – |

| Software | – | Winducom 2010 | – |

| Test Conditions | Units | Details |

|---|---|---|

| Standard | – | ASTM D2266 [51] |

| Load | kg | 40, 50, 63, and 80 |

| Speed | rpm | 1800 |

| Temperature of Fuel | °C | 27 |

| Test period | s | 300 |

| Test ball materials | – | Carbon–chromium steel (SKF) |

| Material composition | – | 0.12% P; 0.45% Si; 1.46% Cr; 0.06% Ni; 2.15% Zn; 0.07% S; 0.42% Mn; 10.2% C; and 85.06% Fe; |

| Ball diameter | mm | 12.7 |

| Ball material hardness (HRc) | – | 62 |

| Ball material surface roughness | μm | 0.1 C.L. A |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yaqoob, H.; Teoh, Y.H.; Sher, F.; Jamil, M.A.; Nuhanović, M.; Razmkhah, O.; Erten, B. Tribological Behaviour and Lubricating Mechanism of Tire Pyrolysis Oil. Coatings 2021, 11, 386. https://doi.org/10.3390/coatings11040386

Yaqoob H, Teoh YH, Sher F, Jamil MA, Nuhanović M, Razmkhah O, Erten B. Tribological Behaviour and Lubricating Mechanism of Tire Pyrolysis Oil. Coatings. 2021; 11(4):386. https://doi.org/10.3390/coatings11040386

Chicago/Turabian StyleYaqoob, Haseeb, Yew Heng Teoh, Farooq Sher, Muhammad Ahmad Jamil, Mirza Nuhanović, Omid Razmkhah, and Begum Erten. 2021. "Tribological Behaviour and Lubricating Mechanism of Tire Pyrolysis Oil" Coatings 11, no. 4: 386. https://doi.org/10.3390/coatings11040386

APA StyleYaqoob, H., Teoh, Y. H., Sher, F., Jamil, M. A., Nuhanović, M., Razmkhah, O., & Erten, B. (2021). Tribological Behaviour and Lubricating Mechanism of Tire Pyrolysis Oil. Coatings, 11(4), 386. https://doi.org/10.3390/coatings11040386