1. Introduction

Green composites have less environmental impact at the production, use, and post-use stages than in the case of composites based on chemical fibers [

1]. As filling material for producing biocomposites, the natural fibers of wood, cork, horsehair, nettle, leaves, paper cut in a shredder, chicken feather calamus cut into small cubes, fine sawdust, and straw are usually used [

2,

3,

4,

5,

6,

7]. As the matrix material, among others, polylactide, poly-hydroxybutyrate, starch, chitosan, gum Arabic, and green epoxy resin are used [

1,

8]. Nowadays, different kinds of natural materials are investigated for the reinforcement of sound-absorbing composites because of their cheap production cost, eco-friendly composition, and their relevant properties related to the application of interest [

9]. The results of the sound absorption of composites based on natural filling materials and biopolymers are promising, and present the high potential of such materials as sound absorbers. These composites exhibit different sound absorption depending not only on the type of filling/reinforcing material, but also on the sound frequency range. Usually, however, high sound absorption is observed at frequencies above 2000 Hz [

1,

2,

10]. Sound absorption of selected frequency ranges depends on the structure, density, and thickness of the absorber. The results for pineapple leaf/epoxy composite show that for a given material density, by increasing its thickness, we extend the absorption range towards lower frequencies [

11].

Among various forms of the filling component, the fibers are the most beneficial from the point of view of the mechanical properties of the composite [

12]. The tensile strength of a composite based on flax fibers is much higher than those reinforced with particles. It can be about 20 times the strength of the cork-based composite, and about 3.6 times the strength of the straw-based composite [

1]. Fibrous products are increasingly used as a sound-absorbing material. New structures with the participation of natural or synthetic fibers are still being developed, and the literature on the subject contains research results concerning the use of fibers that differ in terms of raw material, dimensions, arrangement, and specific surface area [

13,

14,

15]. Mamtaz et al. stated that synthetic fibers, due to their thinner diameter and antifungal quality, are a better sound absorptive material than natural fibers; unfortunately, they also have a greater impact on the environment [

16]. However, when talking about the acoustic properties of the fibers, many factors should be taken into account, such as their thinness, the shape of their cross-section, and the bulk density of the material. For example, the sound absorption of fabrics made from 3 denier polyester fibers is 5 times greater than that of the material from 15 denier fibers [

17]. The polyester fibers with octalobal or trilobal cross-sections are better as sound insulators than round fibers because of their higher total surface area [

17]. The absorption of glass fibers with a bulk density of 54 kg/m

3 is higher than that of kapok fibers, with a bulk density of 10 kg/m

3, but lower than those fibers with a density of 15 kg/m

3 [

18].

The microscopic structure and surface morphology of natural fibers such as flax, bamboo, kenaf, kapok, coir, cotton, broom, giant reeds, cane, coconut, hemp, etc. are conducive to sound absorption [

18,

19,

20,

21,

22]. Natural fibers, due to their unique hollow and multi scale structures, show better sound absorption compared to high-modulus fibers such as glass or carbon, especially at frequencies above 1000 Hz. The ramie, jute, and flax fibers are characterized by a noise reduction coefficient at the level of 0.6–0.65, while glass fibers are at the level of 0.35, and carbon fibers at 0.45 [

23]. The literature reports indicate that, for example, natural kapok fibers show sound absorption comparable to the widely used reinforcing glass fibers [

18,

24]. They are also characterized by a much lower density, which is of great importance in the design of lightweight composites. Yang and Li stated that composites made of natural fibers, such as jute, ramie, flax, and epoxy resin can exhibit similar or even better sound absorption than composites based on high-modulus fibers such as glass or carbon, which is important for aeronautical applications [

23]. Mohanty and Fatima presented natural rubber-based jute composites manufactured by a compression molding process as biodegradable soundproofing materials for noise control applications, e.g., in home appliances, building construction, and cars [

25]. Ersoy and Kucuk proposed that biodegradable tea leaf-fibers, as a product of renewable bio-resources, can be used as a sound absorber. The backing of these fibers with a cotton fabric layer gives sound absorption comparable to nonwoven polypropylene [

26]. According to Zulkifli et al., an even better effect can be obtained by using coconut fibers [

27]. The sound absorption of composite materials is also positively influenced by the addition of ultra-short/ultra-fine fibers obtained from natural fibers, e.g., flax fibers. Such fibers obtained by an enzymatic process and mechanical treatment, due to the larger total fiber surface, give greater interaction with sound waves, and thus increase the sound absorption of the material [

28,

29]. Research has shown that urea formaldehyde resin fiber boards made of various fibers, such as bagasse, banana, bamboo, coir, and corn husk, are characterized by better sound absorption if they have a lower density [

30].

Much attention is also paid to fibrous layered products, as increasing the thickness and density of the sound-absorbing layer promotes sound absorption at the mid-to-high frequency ranges [

10]. Layer systems where the layers differ in the type of fibers and in the textile structure are described. The most commonly used structures are nonwovens, woven fabrics, knitted fabrics, or nanofiber membranes. Sometimes fibrous layers are combined with other materials, such as cork [

31,

32], foam [

33], or a honeycomb grid [

34]. The use of several fibrous layers differing in apparent density favors increased sound absorption and widened absorption bands. The same is true in the case of laminated composites based on textiles. The use of a system of textile layers differing in structure allows for obtaining a composite that has a lower thickness than the system of textile layers, and a comparable absorption [

28,

29,

35]. By using layers that differ in structure, one can control the dependence of the sound absorption on the sound frequency [

36]. Each material absorbs and reflects sound waves to some extent. The proportions between the energy of the reflected and absorbed waves can vary depending on the frequency of the sound. Soft, porous materials are good sound absorbing materials. Hard and smooth materials absorb sound waves very poorly. However, for some applications, it is necessary that at least the surfaces of the material should be hard and smooth. The structure of the material can be created in the process of its production [

37].

Much attention is also paid to the importance of the material shape for its acoustic performance. Sharma et al. presented an analytical framework for a metasurface with a lattice of closely spaced spherical cavities embedded in a thin, soft medium. The strong resonance of the cavities was confirmed, and it has been shown that the high sound absorption of the metasurface is due to the strong multiple scattering of waves between the cavities and the conversion of longitudinal waves into shear waves dissipated then in the elastic medium [

38]. Azad et al. investigated the effects of large-scale pyramidal and convex-shaped diffusers in an empty non-diffuse room on its acoustical parameters. The statistical analysis and measurement results showed that the influence of diffuser type on the room acoustic characteristics is significant, especially at high frequencies [

39]. Recently, a growing interest in practical applications has been enjoyed by sonic crystals, i.e., finite arrays of periodically distributed scatterers for which very little sound transmission occurs in certain frequency bands. It is caused by the destructive interference of scattered waves in the latttice structure. These bands depend on the shape of the scatterers, the distance between the scatterers as a lattice constant, and the filling fraction. The center frequencies of these bands can be predicted from Bragg’s law, and, for a greater lattice constant, they are at lower frequencies. The literature gives results for rigid diffusers in the form of steel cylinders or trees. Measurement results indicated that if the diffusers are arranged in a lattice configuration, they can more effectively attenuate certain low frequency bands. The attenuation level depends on the filling fraction, and the attenuation frequencies depend on the type of lattice pattern and the angle of sound incidence on the barrier [

40,

41].

In the case of thermoplastic composites, both the reinforcing component and the thermoplastic polymer can be used in the form of fibers. Having fibers, they can be used in the form of a hybrid structure, e.g., a needle-punched nonwoven. This structure allows for a high degree of mixing of both components, necessary to ensure good wettability of the reinforcement by the matrix. Nonwovens provide a number of functional benefits, including thermal and acoustic insulation. The most important advantages of the needle-punching technology include high production efficiency, the possibility of obtaining structures of high thickness, and the possibility of joining layers with different fiber orientation. The literature reports present the results of the research on sound absorption by nonwovens in terms of nonwoven technology and the aspect of web orientation angle. The effect of the web orientation angle on the sound absorption properties for thermally bonded nonwovens of multiangle layered webs was tested by Lee et al. [

29].

The present work concerns research on the possibilities of producing green composite materials of various layered structures and different profiling from nonwovens, and determining the impact of these factors on the sound absorption by the composite [

23,

42].

2. Materials and Methods

To obtain green composites, flax fibers (LI), from Safilin Ltd., Milakowo, Poland, were used as a reinforcement. The dimensions and quality of waste short flax fibers, the so-called noils, were very diverse,

Figure 1. The length of the flax fibers ranged from a few mm up to 115 mm, and the transverse dimensions were from 16 μm to 560 μm. As a matrix material, biodegradable polylactide fibers (PLA) were used [

43,

44]. These commercial thermoplastic fibers, Ingeo Fiber type SLN2660D (linear density 6.7 dtex, length 64 mm), with a melting point in the range of 165–170 °C and finished with polylactide resin without any hazardous substances, were delivered by Far Eastern Textile Ltd., Taipei, Taiwan. In order to obtain a homogeneous composite material, it was necessary to perfectly blend the fibers in the nonwoven fabric. The mixing process consisted of passing the fibers twice through the carding machine. The fleece with a parallel system of fiber arrangement was obtained. Then, the needle-punching process of the fleece layer was carried out on an Asselin needle-punching machine (France). The following technological parameters were used: type of needles—15 × 18 × 40 × 3

1/

2 RB (Groz-Beckert

®, Albstadt, Germany); number of needles punching—40/cm

2; depth of needle-punching—12 mm. The needle-punched nonwoven was thus obtained.

Composites were formed from textile multilayer structures in a hydraulic press machine, Hydromega, Gdynia, Poland, with heated top and bottom plates and a water cooling system. A multilayer structure of nonwovens, sandwiched between two layers of Teflon foil, was put into the press mold. The mold was then closed and the heating was turned on. After reaching the pressing temperature, i.e., the melting point of the thermoplastic fibers, the consolidation stage was carried out under a pressure of 0.58 MPa for 5 min. Finally, the heating was turned off and the water cooling system was turned on to bring the temperature down to room temperature. For profiling the composites, a Teflon plate with holes was used (during pressing it was placed under the multilayer structure of nonwovens), and a tool with a spherical tip was used to obtain concavities in the composite plates,

Figure 2.

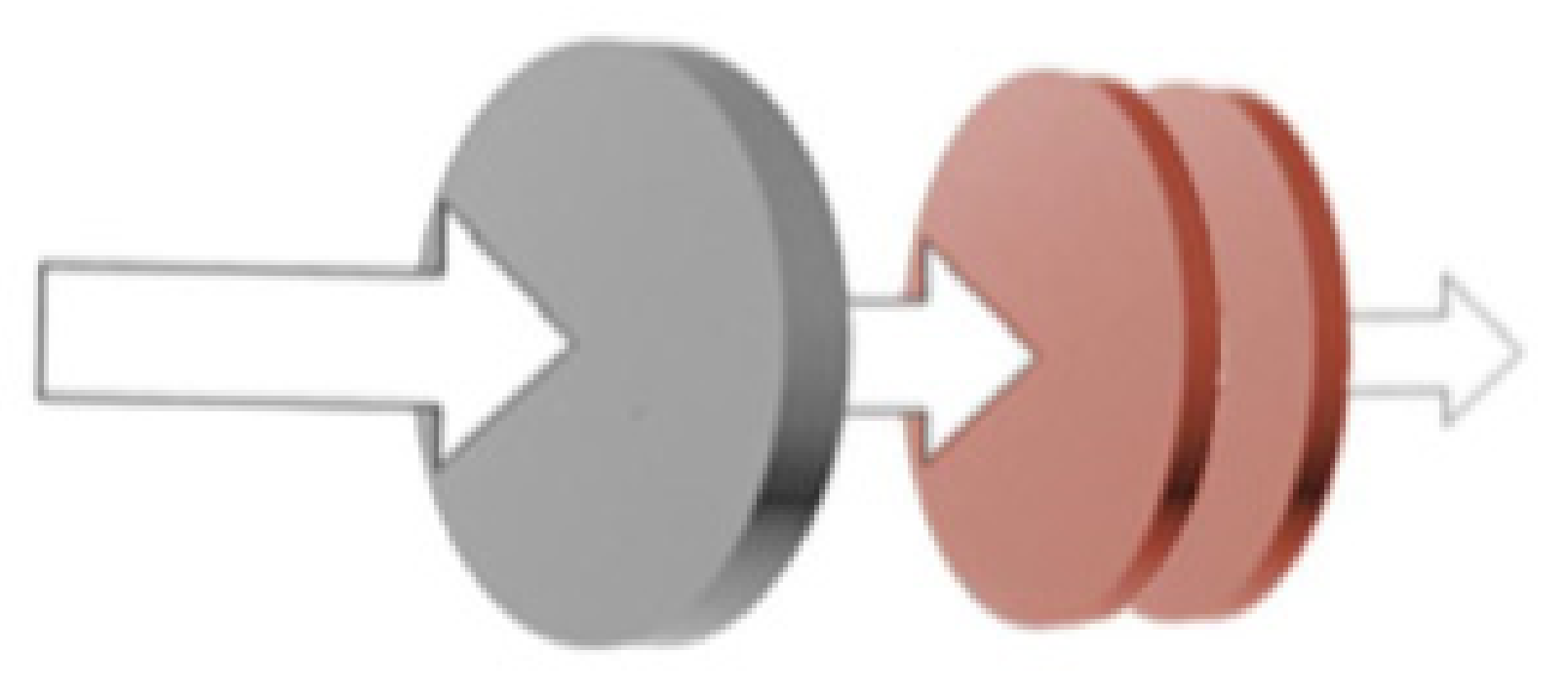

The acoustic properties of the composites were determined by means of a small-sized impedance tube, type 4206 (Bruel&Kjaer, Denmark) using two ¼-inch condenser microphones, type 4187,

Figure 3. The physical sound absorption coefficient (a quotient of acoustic energy absorbed by the given material to the energy of the acoustic incident wave) was determined for each sample by the method using the coefficient of a standing wave, according to the standard procedure: PN-EN ISO 10534-2 in the frequency range of 500–6400 Hz. This range of sound frequencies is adequate and sufficient to observe the sound absorbing behavior of the tested materials [

2,

12,

28]. In this method, using a Kundt tube, the sound wave coming from sound source is directed perpendicularly at the surface of tested material. The acoustic pressure is measured by microphones at two locations on the wall of the tube. Then, the signals are transferred to analyzer. In this method, the impedance tube is connected to the sound source on one side, and on the opposite side the test sample is placed. The noise source generates plane waves in the tube directed perpendicular to the sample surface. The sound pressure is measured thanks to the two microphones in fixed positions in the tube wall. Then, the signals are transferred to the analyzer and the interference distribution of the field is determined. Based on this, the sound absorption coefficient is calculated. Before the measurement, the instrument was calibrated each time the sample material was changed. The samples with a diameter of 29 mm were cut with a punch. Three samples were tested for each variant.

3. Results

Comparatively, the pre-pressed nonwovens, the composites made of nonwovens, and the layered systems composed of pre-pressed nonwovens and composites were used for the acoustic measurements.

3.1. Nonwovens

Nonwovens were obtained with an area weight of 180 g/m2, differing in fiber composition:

fiber composition I—20% LI fibers and 80% PLA fibers, mixed together—“LI/PLA”,

fiber composition II—100% PLA fibers—“PLA”.

3.2. Pre-Pressed Nonwovens

The obtained LI/PLA nonwoven was pre-pressed on the nonwoven press machine at different conditions. The parameters of the pre-pressing process and the characteristics of the nonwoven sound-absorbing materials obtained after the pre-pressing process are presented in

Table 1.

The dependence of the sound absorption coefficient on the sound frequency for individual variants of the pre-pressed nonwovens is shown in

Figure 4. For single, very thin layers of pre-pressed nonwovens, 0.8 to 1.75 mm thick, an increase in sound absorption is observed with increasing sound frequency. In the case of sounds with frequencies up to 4800 Hz, the highest similar values of sound absorption coefficient were obtained for the 2N and 3N pre-pressed nonwovens. Higher frequency sounds are better absorbed by the 1.08 mm thick 3N pre-pressed nonwoven, presenting an almost plastic structure, than by the 1.75 mm thick 2N pre-pressed nonwoven with a compact fibrous and rigid structure. Nonwoven 3N shows the highest value of the sound absorption coefficient, i.e., 0.44 at the sound frequency of 6400 Hz. The other three pre-pressed nonwovens show a lower absorption. In all frequency ranges, the dependence of the sound absorption coefficient on the sound frequency is similar for these three nonwovens. The maximum value of the sound absorption coefficient, obtained at 6400 Hz, is 0.23 for 1.55 mm thick 1N nonwoven with a fibrous structure, 0.20 for 1.24 mm thick 5N nonwoven with a compact/fibrous structure, and 0.17 for 0.8 mm thick 4N nonwoven with an almost plastic structure but with a mesh surface.

The combination of successive nonwovens with each other causes the thickness of the resulting absorbent systems to be greater than that of the individual layers, but does not mean adding up their individual sound absorption. It can be seen from

Figure 5 that adding three nonwovens, i.e., 2N, 3N, and 4N, to the nonwoven 1N successively increases the value of the absorption coefficient by a value corresponding to the individual nonwovens in a given frequency range. The addition of another layer, i.e., a 5N nonwoven, no longer increases the sound absorption by a value corresponding to this nonwoven, but rather only slightly. The contribution of the next added layer with specific sound absorption characteristics to the increase of a system’s sound absorption coefficient depends on the resulting system structure and sound frequency. The same layer can show a different absorption as a separate layer, and a different one to the arrangement with another layer, because then, a new structure is created, which constitutes different conditions for attenuating the energy of the acoustic wave. As a consequence, the sound absorption of the system is different from that resulting from adding up the absorption of both layers.

Table 2 shows that the tested pre-pressed nonwovens, very thin and with low absorption, can be combined into multilayer systems in order to increase sound absorption in the frequency range of 2500–5500 Hz in relation to the total absorption of the individual layers. The share of each next added nonwoven layer characterized by a specific sound absorption in the increase in the system’s sound absorption coefficient depends on the sound frequency and on the sound absorption of the system without this layer.

If both previous graphs,

Figure 4 and

Figure 5, are compared, it is possible to observe that the shapes of the curves for individual nonwovens are completely different when the nonwovens are together. For individual nonwovens, the curves are practically flat, with an important increase for high frequencies. However, for the nonwovens together, the curves are concave, more similar than a composite curve, which have higher values for a wider range of frequencies.

In the case of sound-absorbing porous materials, a low-frequency sound absorption is higher if the material is thicker. A homogeneous material of high thickness or a layered material with layers of different structure can be used. Homogeneous material can be used with a thick material layer or a different layer structure.

However, joining the layers of nonwovens, the thickness of the material can increase up to several cm, which is why, in this work, pre-pressed nonwovens were used. However, combining layers of nonwovens causes an increase in the material thickness of up to several cm, so, in this research work, the pre-pressed nonwovens were proposed.

The multilayer structures consist of several pre-pressed nonwoven layers with different acoustic characteristics, and are a promising material for noise reduction. Thanks to such acoustic systems, it is possible to increase the level of absorption and extend the frequency range of high absorption.

3.3. Composites

Variants of the composites obtained from LI/PLA and PLA nonwovens are presented in

Table 3.

Composites obtained according to variants 1, 2, and 3 were made of a nonwoven under conditions differing in system temperature, and this factor influenced the structure of the composite. By changing the temperature of the pressing process in the range from 165 to 180 °C, we changed the structure of the composite from fibrous to plastic. Differences in the sound absorption of the composites produced resulted from their structure. The values of the sound absorption coefficient for the individual sound frequencies are presented in

Figure 6,

Figure 7 and

Figure 8.

For each sample, two different curves, depending on the receptor surface of the sound waves (two composite sides), are presented. For composite 1,

Figure 6, the sound absorption coefficient is higher for middle and low frequencies than for the composites 2 and 3. It is more advantageous if the sound wave strikes the composite from the plastic side than the fibrous side. The highest values of sound absorption coefficient are above 0.9 at 6000–6400 Hz. The results for composite 2,

Figure 7, show a clear difference between the sound absorption of surface 1 and 2. Surface 1, more plastic, presents a better structure for sound absorption at higher frequencies than surface 2, porous plastic. In low frequencies the difference is not so big. This sample is interesting because the maximum coefficient value of the plastic surface receptor is very high at 6400 Hz, between 0.9 and 1. For composite 3,

Figure 8, the values of the sound absorption coefficient are similar, regardless of which the side of the composite faces the sound wave. This fact results from the similar structure of both surfaces of the composite. The maxim coefficient is lower than for sample 2’s maxim coefficient. Generally, composites with a different structure for both surfaces give better sound absorption, and if the plastic surface is directed to the sound, the values of the sound absorption coefficient are higher.

Another important parameter of the composite is the profiling. Composite 4 was made on the basis of a blended nonwoven, but located between layers of PLA nonwoven, which, after compression, gives rigid, smooth plastic surfaces. Then, the modifications were used to profile the composite 4 plate, as shown in

Figure 9. The results below show the influence of the surface profiling on the sound-absorption properties. Four samples were analyzed. The schematic view of the samples is shown below. The dependence of the sound absorption coefficient on the sound frequency for the profiled composite is shown in the diagrams in

Figure 10,

Figure 11,

Figure 12 and

Figure 13. The composite plates were tested with the left side and right side facing the sound wave, respectively. From assessing the effects of profiling the composite plate, it can be seen that the proposed modifications have a beneficial effect on sound absorption. A two-sided flat plate shows the lowest values of the sound absorption coefficient in the entire tested frequency range,

Figure 10. However, profiling a concave in the plate and directing it with its front face to the sound wave causes an increase in sound absorption,

Figure 11.

Taking into account the published results of previous studies [

21], which indicated the validity of the use of convexity on the back of the composite plate, which was confirmed in

Figure 12, the absorption of the plate with concavity was measured comparatively. The results showed that convexity on the plate is more advantageous than concavity,

Figure 11 and

Figure 12. In the case of a plate with convexity, the flat side facing the sound wave achieves the greatest sound absorption among the tested profiled plates, and the value of the absorption coefficient is equal to 1 for sounds with a frequency above 5500 Hz,

Figure 12,

Table 4. Among the tested profiled samples, a plate with convexity on one side has the greatest thickness over the entire area. This favors an increase in sound absorption. In addition, when such a sample is positioned with the flat side to the sound wave, and there is a convexity on the other side, an air space is created between the sample and the wall of the measuring tube in which resonance may occur. Under the conditions of use, such an orientation of the sample with a convexity in relation to the wall will be most advantageous. In the case of a concave–convex plate (

Figure 13), where it does not matter which side it faces the sound wave, the values of the sound absorption coefficient are higher than for a concave–flat, flat–concave plate (

Figure 11), or convex–flat plate (

Figure 12), and lower than for a flat–convex plate (

Figure 12).

The homogeneous porous material is not a good and practical low frequency sound absorber, as it would have to be extremely thick or very far from the back boundary surface. For example, at 500 Hz, the total wavelength is 0.688 m, so the porous material would need to be approximately 0.172 m from the back boundary surface to meet the 1/4 wavelength requirement for significant sound absorption. The lower the sound frequencies, the greater the material thickness/distance should be. In order to improve the sound absorption at low frequencies, the material thickness can be compensated for by air space in the rear. In studied porous composites, periodic inclusions have been employed to significantly enhance the sound wave manipulation abilities,

Figure 2 and

Figure 9. The 4c and 4d profiled composites having the convexities at the rear provide just such an air space at the rear on the stiff wall side, and therefore exhibit better sound absorption towards lower frequencies than composites that are flat on both sides or flat–concave. Taking into account the front surface of the composite, when the back surface is flat, the best sound absorption is provided by the surface with convexities, then with concavities, and the worst by a flat surface. Sound absorption, apart from the thickness of the material, is also influenced by the surface area of interaction with the sound wave, the largest surface area is provided by convexity, then concavity, and the smallest one by a flat surface. The porosity of the material is also an important factor, and the convexity promotes increased porosity. A detailed presentation of the influence of individual factors on the obtained effect of sound absorption requires model considerations, which, in the case of fiber-based materials, and especially natural waste fibers with wide variation in thinness and length, and the sophisticated profiling of the composite plate, is an extremely complex issue [

38,

45,

46]. It is known that resonant inclusions embedded in the soft matrix are conducive to the effective conversion of long longitudinal sound waves into short shear waves, which are subsequently absorbed. The literature reports that in the case of a periodically voided viscoelastic coating made of soft rubber embedded with a layer of cylindrical voids of infinite length, uncertainty in the geometric parameters has greater impact on the resonance frequency of the voids and sound transmission through the coating than the uncertainty in the material properties [

47].

3.4. Pre-Pressed Nonwovens and Composites

In order to verify the possibility of obtaining an increase in sound absorption, systems consisting of pre-pressed nonwovens and composites in various combinations were tested. Composite 3 (described in

Table 2 as “8xLI/PLA”) was joined in a two-layer system successively with individual pre-pressed nonwovens. Successive material samples were stacked on top of each other without space between them, and put together into the measuring tube. The scheme of the arrangement of layers, where a nonwoven is situated on the side of the sound wave, and the composite on the back, is shown in

Figure 14, and the sound absorption of such a system is shown in

Figure 15. The scheme of the arrangement of layers, where the composite is situated on the side of the sound wave, and the pre-pressed nonwoven on the back, is shown in

Figure 16, and the sound absorption of such a system is shown in

Figure 17.

The graphs of the dependence of the sound absorption coefficient on the sound frequency,

Figure 4,

Figure 15 and

Figure 17, show that the combined systems show greater absorption than the individual layers separately, which results from the increase in the thickness of the final absorbing material and depends on the structure and, in consequence, on the absorption of the component layers. In the “pre-pressed nonwoven + composite” system, the 1N nonwoven and the 2N nonwoven provide the best effects. In such a system, the layer on the side of the sound wave is more fibrous, and on the other side, the layer is a porous composite. In the case of the “composite + pre-pressed nonwoven” system, the 2N nonwoven also provides the best effect. As shown in

Figure 4, among the nonwovens tested, this nonwoven, next to the 3N nonwoven, shows the highest sound absorption in the sound frequency range up to 4800 Hz. The composite layer forms a better sound-absorbing system with a more fibrous and compact layer than with a more plastic layer. The comparison of the sound absorption coefficient for both systems, with the example of composite 3 and 2N pre-pressed nonwoven, i.e., 3-2N and 2N-3, is shown in

Table 5. The results show that it is more advantageous to position the composite layer from the sound wave side, and the nonwoven as the back layer. Then, the absorptive surface of the system is plastic and the back is fibrous, and as shown in the earlier

Figure 6 and

Figure 7, this structure, with more plastic surface, promotes sound absorption [

48].

Composite 3, with a thickness of 5.5 mm, shows a sound absorption very similar to that presented by Hao et.al. [

49] for kenaf/polypropylene nonwoven composites with a thickness of 6 mm. The values of the sound absorption coefficient of these composites at high frequencies are high, about 0.9 at 6400 Hz. The addition of a pre-pressed nonwoven, with a thickness in the range from 0.8 mm to 1.75 mm, to the tested composite has the effect of increasing the sound absorption in a wide sound frequency range. For both two-layer systems, the values of the sound absorption coefficient increase with increasing sound frequency, and begin to stabilize at about 6000 Hz. The results of absorption are very good (above 0.7) at higher values of the tested frequency range, i.e., from 3750–4230 Hz to 6400 Hz for the “pre-pressed nonwoven + composite” systems, and from 3340–4000 Hz to 6400 Hz for the “composite + pre-pressed nonwoven” systems. Separate composite 3 reaches a value of sound absorption coefficient of 0.7 at frequencies from 4600 Hz to 6400 Hz. At the highest sound frequencies, the sound absorption coefficient for both kinds of systems is around 0.9 or even higher. At the lower sound frequency range, the absorption of the system increases by a value approximate to the absorption of the added layer; the higher the frequency, the smaller the increase in absorption.

An increase in the sound absorption level can be obtained by combining a fibrous material, e.g., a pre-pressed nonwoven, with a composite plate acting as a rigid membrane, which can also extend the range of high absorption. The absorber then consists of two types of material, and there are probably two mechanisms for damping the sound wave in different frequency ranges. A composite layering sequence in a multilayer structure also plays an important role, the most absorptive are the systems where the composite as a rigid material is on the side of the incident sound wave, and the more porous is on the back. All proposed layers differing only in pressing conditions are produced on the basis of the same LI/PLA nonwoven fabric, which simplifies the production process and makes it more economical.

In order to improve the results for low frequencies, the next tests were made with a combination of composite and pre-pressed nonwoven layers. The scheme of the arrangement of the layers, where the composite is located on the side of the sound wave and the individual nonwovens are placed on the back, is shown in

Figure 18, and the sound absorption of such a system is shown in

Figure 19. The values of the sound absorption coefficient increase as the frequency increases, and then stabilize. As more nonwoven layers are added, the results of absorption increase, but less and less. This is because the total thickness increases, and the values of the absorption coefficient of the final multilayer system result from the structure, and consequently from the absorption of the individual layers. Sound absorption of 0.9 for the system (3-1N-2N-3N-4N-5N) with a total thickness of only 11.92 mm occurs in the frequency range from 2700 Hz to 6400 Hz, and 0.7 from 1850 Hz to 6400 Hz, which is a very good result. The literature [

50] states that, for bilayered nonwoven composite with the thickness of 12.02 mm, the absorption is 0.92 at a peak at 1500 Hz, and 0.7 in the range of about 1000–3500 Hz. The more layers the system has, the more its absorption is close to 1.0 and the range of highest absorption is extended towards lower frequencies. This means that this combination will have a good absorption for almost all frequencies. Then, this material could be used in a wide variety of applications. Adding the next layers to the system increases the maximum sound absorption and extends its frequency range. A nonwoven, more fibrous, and more open structure absorbs better low frequency sound, and a composite, more plastic, and rigid structure absorbs better high frequency sound, [

51]. Combining such structures into one system extends the range of high sound absorption.

4. Conclusions

The combination of successive pre-pressed nonwovens with each other causes the thickness of the resulting sound-absorbing systems to be greater than that of the individual layers. The contribution of the next added layer with specific sound absorption characteristics to the increase of a system’s sound absorption coefficient depends on the resulting system structure and sound frequency.

Thermoplastic composites with different structures of both surfaces give better sound absorption than composites with the same surfaces. If the more plastic surface of the composite is directed to the sound, the values of the sound absorption coefficient are higher.

Shaping the composite plate has a positive effect on its sound absorption. In the case of a one-sided concave, it is better to position the plate with the concave side facing the sound and the flat side on the back. In the case of a one-sided convexity, it is better to place the plate with its flat side facing the sound, and the convex side at the back, then the absorption is the highest among the tested variants of profiled composites. For a composite plate with opposite profiles, i.e., concavity and convexity, no difference in absorption is related to the orientation of the plate relative to the sound.

The addition of a pre-pressed nonwoven to the composite, regardless of whether it is on the side of the incident sound wave or on the back, increases the sound absorption coefficient in the entire tested frequency range. However, it is preferable to have a composite on the sound side and a nonwoven on the back. Increasing the number of differentiated nonwoven layers in terms of structure means increasing the value of the sound absorption coefficient and broadening the frequency range of sounds most absorbed. The presented research is part of the work on sound absorbing composites on the basis of natural materials, and will be continued towards identifying the optimal composite structure. The proposed materials containing natural waste fibers will be an environmentally friendly, cheaper, and more sustainable alternative to traditional sound-absorbing materials. They could be used in the walls and partitions of vehicles, in buildings, or in door panels.