High Stability of Liquid-Typed White Light-Emitting Diode with Zn0.8Cd0.2S White Quantum Dots

Abstract

:1. Introduction

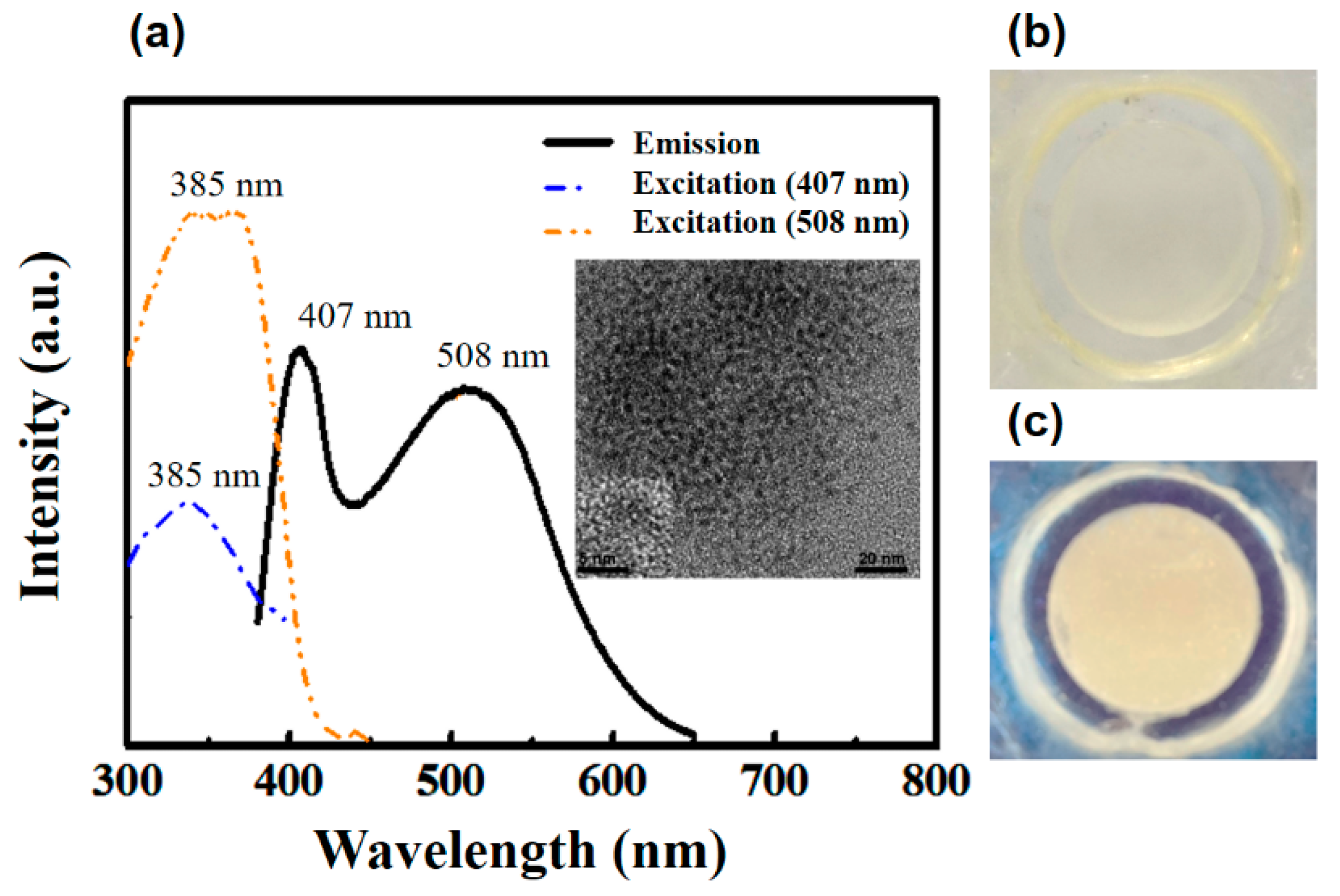

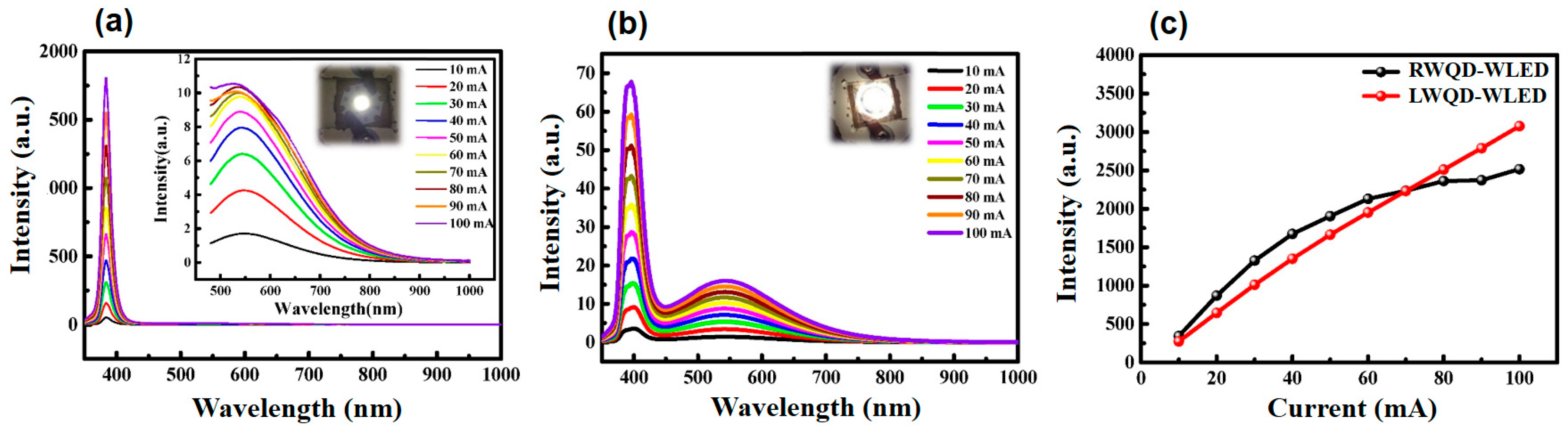

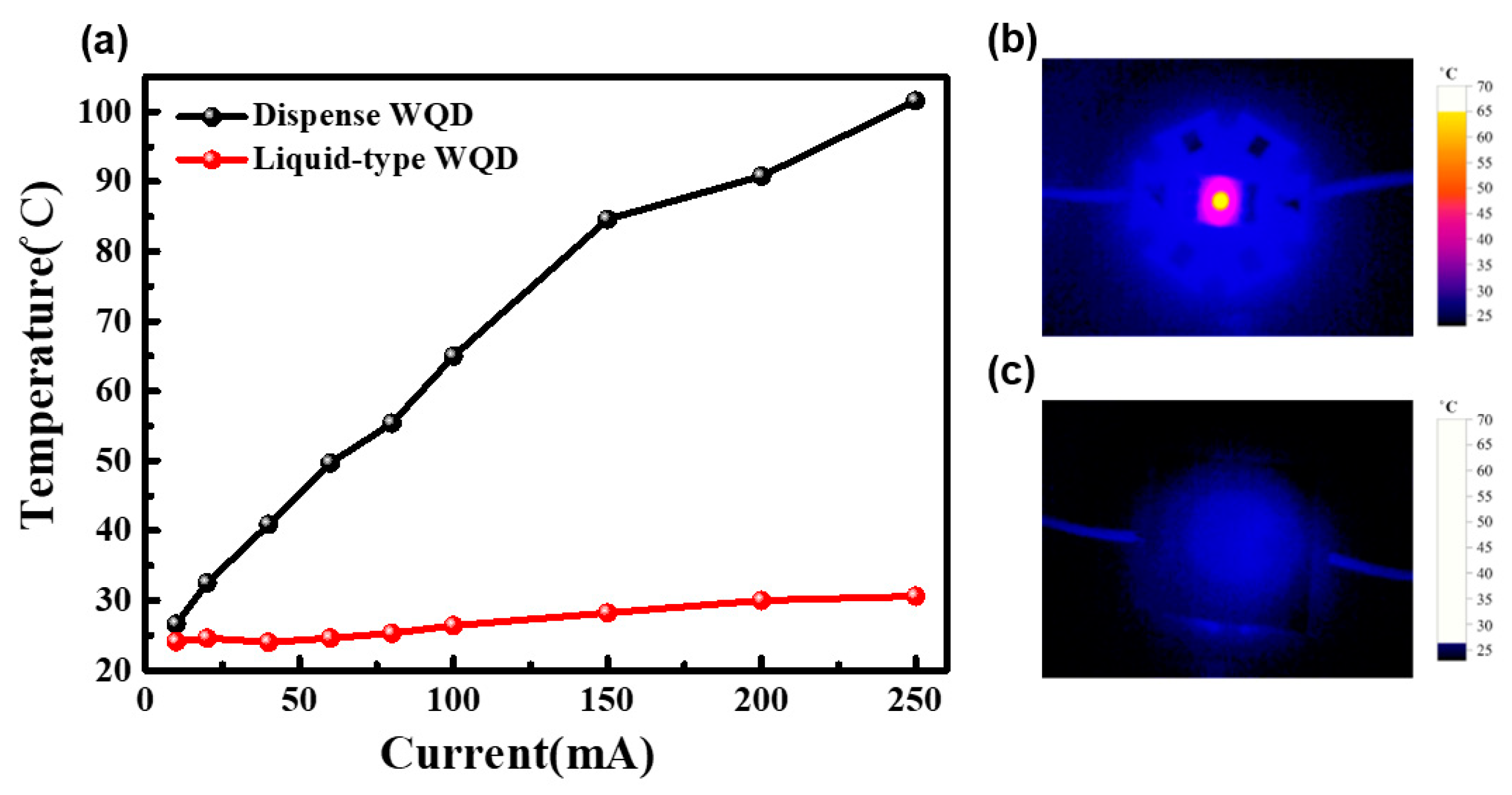

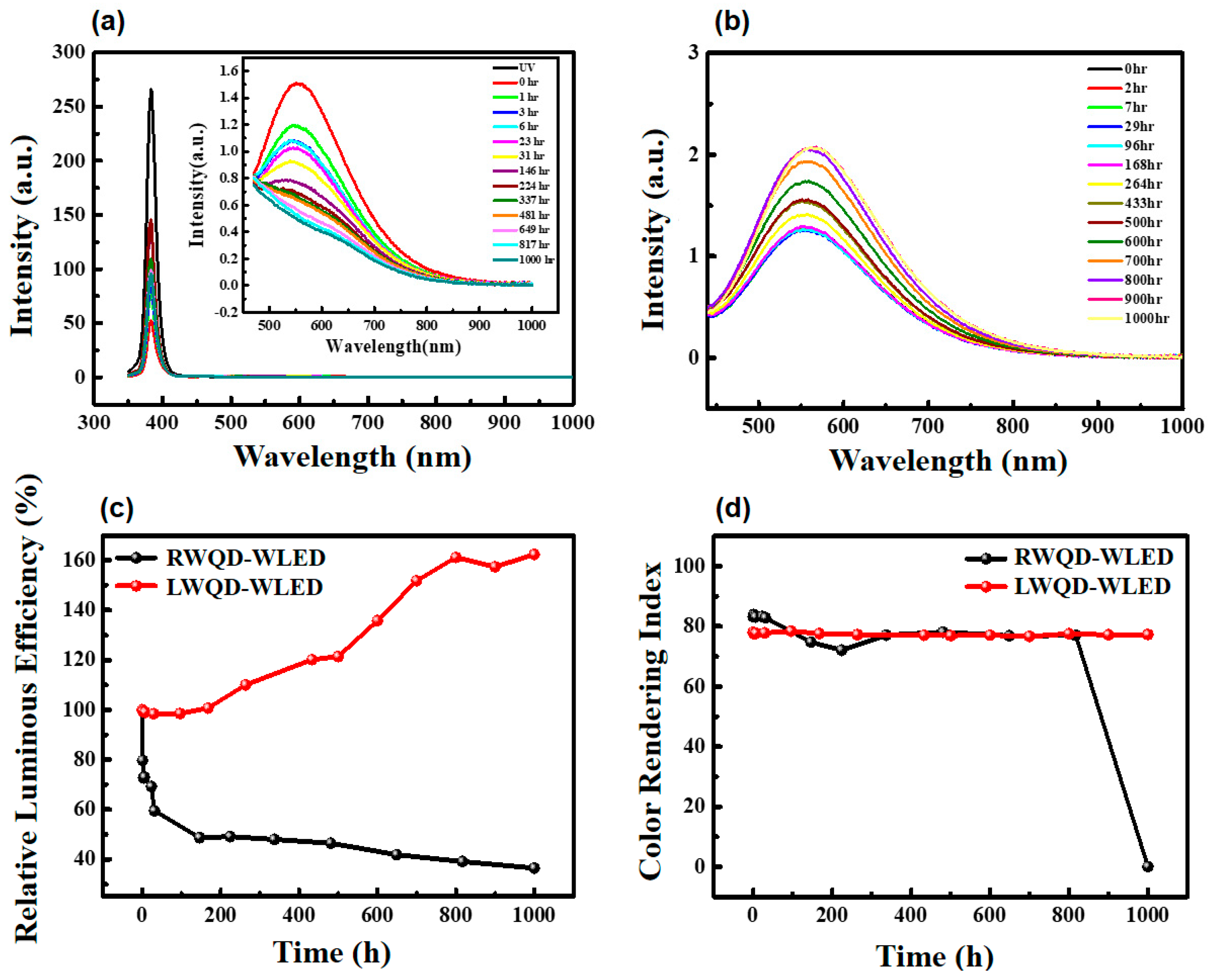

2. Experiment

3. Measurement and Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chen, K.J.; Chen, H.C.; Tsai, K.A.; Lin, C.C.; Tsai, H.H.; Chien, S.H.; Cheng, B.S.; Hsu, Y.J.; Shih, M.H.; Tsai, C.H.; et al. Resonant-enhanced full-color emission of quantum-dot-based display technology using a pulsed spray method. Adv. Func. Mater. 2012, 22, 5138–5143. [Google Scholar] [CrossRef]

- Gu, P.; Zhang, Y.; Feng, Y.; Zhang, T.; Chu, H.; Cui, T.; Wang, Y.; Zhao, J.; Yu, W.W. Real-time and on-chip surface temperature sensing of GaN LED chips using PbSe quantum dots. Nanoscale 2013, 5, 10481–10486. [Google Scholar] [CrossRef] [PubMed]

- Jang, H.S.; Yang, H.; Kim, S.W.; Han, J.Y.; Lee, S.G.; Jeon, D.Y. White light-emitting diodes with excellent color rendering based on organically capped CdSe quantum dots and Sr3SiO5:Ce3+,Li+ Phosphors. Adv. Mater. 2008, 20, 2696–2702. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.; Sundar, V.C.; Heine, J.R.; Bawendi, M.G.; Jensen, K.F. Full color emission from II–VI semiconductor quantum dot–polymer composites. Adv. Mater. 2000, 12, 1102–1105. [Google Scholar] [CrossRef]

- Clapp, A.R.; Medintz, I.L.; Uyeda, H.T.; Fisher, B.R.; Goldman, E.R.; Bawendi, M.G.; Mattoussi, H. Quantum dot-based multiplexed fluorescence resonance energy transfer. J. Am. Chem. Soc. 2005, 127, 18212–18221. [Google Scholar] [CrossRef]

- Reiss, P.; Bleuse, J.; Pron, A. Highly luminescent CdSe/ZnSe core/shell nanocrystals of low size dispersion. Nano Lett. 2002, 2, 781–784. [Google Scholar] [CrossRef]

- Shirasaki, Y.; Supran, G.J.; Bawendi, M.G.; Bulovic, V. Emergence of colloidal quantum-dot light-emitting technologies. Nat. Photon. 2013, 7, 13–23. [Google Scholar] [CrossRef]

- Jang, E.; Jun, S.; Jang, H.; Lim, J.; Kim, B.; Kim, Y. White-light-emitting diodes with quantum dot color converters for display backlights. Adv. Mater. 2010, 22, 3076–3080. [Google Scholar] [CrossRef]

- Nizamoglu, S.; Ozel, T.; Sari, E.; Demir, H.V. White light generation using CdSe/ZnS core-shell nanocrystals hybridized with InGaN/GaN light emitting diodes. Nanotechnology 2007, 18, 065709. [Google Scholar] [CrossRef]

- Nizamoglu, S.; Zengin, G.; Demir, H.V. Color-converting combinations of nanocrystal emitters for warm-white light generation with high color rendering index. Appl. Phys. Lett. 2008, 92, 031102. [Google Scholar] [CrossRef] [Green Version]

- Chung, W.; Park, K.; Yu, H.J.; Kim, J.; Chun, B.H.; Kim, S.H. White emission using mixtures of CdSe quantum dots and PMMA as a phosphor. Opt. Mater. 2010, 32, 515–521. [Google Scholar] [CrossRef]

- Lin, H.Y.; Wang, S.W.; Lin, C.C.; Chen, K.J.; Han, H.V.; Tu, Z.Y.; Tu, H.H.; Chen, T.M.; Shih, M.H.; Lee, P.T.; et al. Excellent color quality of white-light-emitting diodes by embedding quantum dots in polymers material. IEEE J. Sel. Top. Quan. Elect. 2016, 22, 35–41. [Google Scholar] [CrossRef]

- Nizamoglu, S.; Erdem, T.; Sun, X.W.; Demir, H.V. Warm-white light-emitting diodes integrated with colloidal quantum dots for high luminous efficacy and color rendering. Opt. Lett. 2010, 35, 3372–3374. [Google Scholar] [CrossRef] [Green Version]

- Nizamoglu, S.; Mutlugun, E.; Özel, T.; Demir, H.V.; Sapra, S.; Gaponik, N.; Eychmüller, A. Dual-color emitting quantum-dot-quantum-well CdSe-ZnS heteronanocrystals hybridized on InGaN/GaN light emitting diodes for high-quality white light generation. Appl. Phys. Lett. 2008, 92, 113110. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.; Li, W.; Sun, K. Stable efficient CdSe/CdS/ZnS core/multi-shell nanophosphors fabricated through a phosphine-free route for white light-emitting-diodes with high color rendering properties. J. Mater. Chem. 2011, 21, 8558–8565. [Google Scholar] [CrossRef]

- Siao, C.B.; Wang, K.W.; Chen, H.S.; Su, Y.S.; Chung, S.R. Ultra high luminous efficacy of white ZnxCd1−xS quantum dots-based white light emitting diodes. Opt. Mater. Express 2016, 6, 749–758. [Google Scholar] [CrossRef]

- Hsu, S.C.; Chen, Y.H.; Tu, Z.Y.; Han, H.V.; Lin, S.L.; Chen, T.M.; Kuo, H.C.; Lin, C.C. Highly stable and efficient hybrid quantum dot light-emitting diodes. IEEE Photonics J. 2015, 7, 1–10. [Google Scholar] [CrossRef]

- Chen, Y.C.; Siao, C.B.; Chen, H.S.; Wang, K.W.; Chung, S.R. The application of Zn0.8Cd0.2S nanocrystals in white light emitting diodes devices. RSC Adv. 2015, 5, 87667–87671. [Google Scholar] [CrossRef]

- Bowers, M.J.; McBride, J.R.; Rosenthal, S.J. White-light emission from magic-sized cadmium selenide nanocrystals. J. Am. Chem. Soc. 2005, 127, 15378–15379. [Google Scholar] [CrossRef]

- Schreuder, M.A.; Gosnell, J.D.; Smith, N.J.; Warnement, M.R.; Weiss, S.M.; Rosenthal, S.J. Encapsulated white-light CdSe nanocrystals as nanophosphors for solid-state lighting. J. Mater. Chem. 2008, 18, 970–975. [Google Scholar] [CrossRef]

- Kshirsagar, A.; Pickering, S.; Xu, J.; Ruzyllo, J. Light emitting diodes formed using mist deposition of colloidal solution of CdSe nanocrystalline quantum dots. ECS Trans. 2011, 35, 71–77. [Google Scholar] [CrossRef]

- Huang, H.T.; Tsai, C.C.; Huang, Y.P. Conformal phosphor coating using pulsed spray to reduce color deviation of white LEDs. Opt. Express 2010, 18, A201–A206. [Google Scholar] [CrossRef]

- Chen, Y.C.; Chen, H.S.; Chung, S.R.; Chang, J.K.; Wang, K.W. The effect of surface structures and compositions on the quantum yields of highly effective Zn0.8Cd0.2S nanocrystals. J. Mater. Chem. C 2015, 3, 5881–5884. [Google Scholar] [CrossRef]

- Chen, H.S.; Chung, S.R.; Chen, Y.C.; Chen, T.Y.; Liu, C.Y.; Wang, K.W. The structure-dependent quantum yield of ZnCdS nanocrystals. Cryst. Eng. Comm. 2015, 17, 5032–5037. [Google Scholar] [CrossRef]

- Sher, C.W.; Lin, C.H.; Lin, H.Y.; Lin, C.C.; Huang, C.H.; Chen, K.J.; Li, J.R.; Wang, K.Y.; Tu, H.H.; Fu, C.C.; et al. A high quality liquid-type quantum dot white light-emitting diode. Nanoscale 2016, 8, 1117–1122. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.S.; Chung, S.R.; Chen, T.Y.; Wang, K.W. Graphene-supported Pt and PtPd nanorods with enhanced electrocatalytic performance for the oxygen reduction reaction. J. Mater. Chem. C 2014, 2, 2664–2667. [Google Scholar] [CrossRef]

- Chen, H.S.; Wang, K.W.; Chen, S.S.; Chung, S.R. ZnxCd1−xS quantum dots-based white light-emitting diodes. Opt. Lett. 2013, 38, 2080–2082. [Google Scholar] [CrossRef] [PubMed]

- Chen, K.J.; Chen, H.C.; Shih, M.H.; Wang, C.H.; Kuo, M.Y.; Yang, Y.C.; Lin, C.C.; Kuo, H.C. The influence of the thermal effect on CdSe/ZnS quantum dots in light-emitting diodes. J. Lightwave Technol. 2012, 30, 2256–2261. [Google Scholar] [CrossRef]

- Erdem, T.; Nizamoglu, S.; Demir, H.V. Computational study of power conversion and luminous efficiency performance for semiconductor quantum dot nanophosphors on light-emitting diodes. Opt. Express 2012, 20, 3275–3295. [Google Scholar] [CrossRef] [Green Version]

- Incropera, F.P.; DeWitt, D.P.; Bergman, T.L.; Lavine, A.S. Fundamentals of Heat and Mass Transfer, 6th ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2005; Volume 4, pp. 58–66. [Google Scholar]

- Kim, K.; Woo, J.Y.; Jeong, S.; Han, C.S. Photoenhancement of a quantum dot nanocomposite via UV annealing and its application to white LEDs. Adv. Mater. 2011, 23, 911–914. [Google Scholar] [CrossRef]

- Kimura, J.; Uematsu, T.; Maenosono, S.; Yamaguchi, Y. Photoinduced fluorescence enhancement in CdSe/ZnS quantum dot submonolayers sandwiched between insulating layers: Influence of dot proximity. J. Phys. Chem. B 2004, 108, 13258–13264. [Google Scholar] [CrossRef]

- Zhang, T.; Zhao, H.; Riabinina, D.; Chaker, M.; Ma, D. Concentration-dependent photoinduced photoluminescence enhancement in colloidal PbS quantum dot solution. J. Phys. Chem. C 2010, 114, 10153–10159. [Google Scholar] [CrossRef]

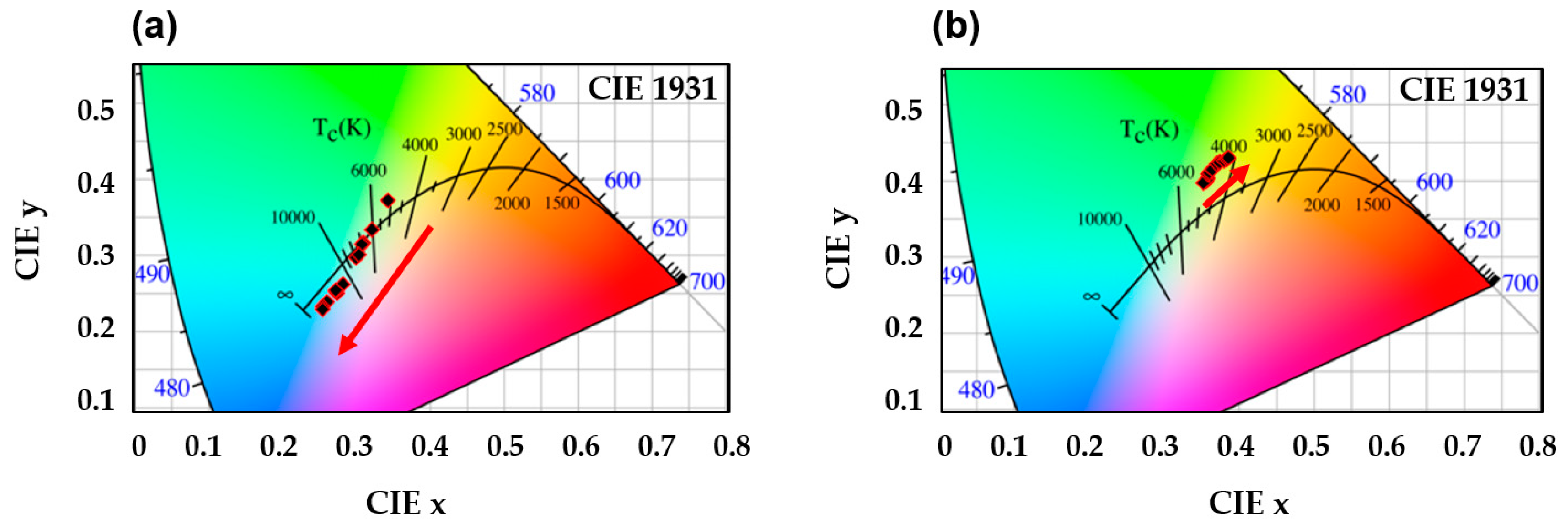

| Device | Operating Current | CCT (K) | CRI |

|---|---|---|---|

| RWQD-WLED | 100 mA | 5750 | 84 |

| LWQD-WLED | 100 mA | 5757 | 80 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, C.-C.; Chu, K.-H.; Sher, C.-W.; Lin, C.-L.; Su, Y.-K.; Sun, C.-W.; Kuo, H.-C. High Stability of Liquid-Typed White Light-Emitting Diode with Zn0.8Cd0.2S White Quantum Dots. Coatings 2021, 11, 415. https://doi.org/10.3390/coatings11040415

Huang C-C, Chu K-H, Sher C-W, Lin C-L, Su Y-K, Sun C-W, Kuo H-C. High Stability of Liquid-Typed White Light-Emitting Diode with Zn0.8Cd0.2S White Quantum Dots. Coatings. 2021; 11(4):415. https://doi.org/10.3390/coatings11040415

Chicago/Turabian StyleHuang, Chin-Chuan, Kuo-Hsiung Chu, Chin-Wei Sher, Chun-Liang Lin, Yan-Kuin Su, Chia-Wei Sun, and Hao-Chung Kuo. 2021. "High Stability of Liquid-Typed White Light-Emitting Diode with Zn0.8Cd0.2S White Quantum Dots" Coatings 11, no. 4: 415. https://doi.org/10.3390/coatings11040415

APA StyleHuang, C.-C., Chu, K.-H., Sher, C.-W., Lin, C.-L., Su, Y.-K., Sun, C.-W., & Kuo, H.-C. (2021). High Stability of Liquid-Typed White Light-Emitting Diode with Zn0.8Cd0.2S White Quantum Dots. Coatings, 11(4), 415. https://doi.org/10.3390/coatings11040415