A Dual Active-Passive Coating with Intumescent and Fire-Retardant Properties Based on High Molecular Weight Tannins

Abstract

:1. Introduction

2. Materials and Methods

2.1. Extraction and Characterization of the H-MWT

2.2. Optimization of Base Formulation and Effect of the Addition of H-MWT as a Carbon Source

2.3. Dual Coating Scheme with FR and IN Properties

2.4. Determination of the Mechanical, FR, and IN Properties of the Active–Passive Dual Coating

3. Results and Discussion

3.1. Chemical Characterization of H-MWT

3.2. Optimization of Base Formulation and Effect of H-MWT as a Complement to the Carbon Source

3.3. Evaluation of the Mechanical and Functional Properties of Active–Passive Coatings (IN-RF)

3.3.1. Evaluation of Flame Resistance of Coatings on Wood Substrates

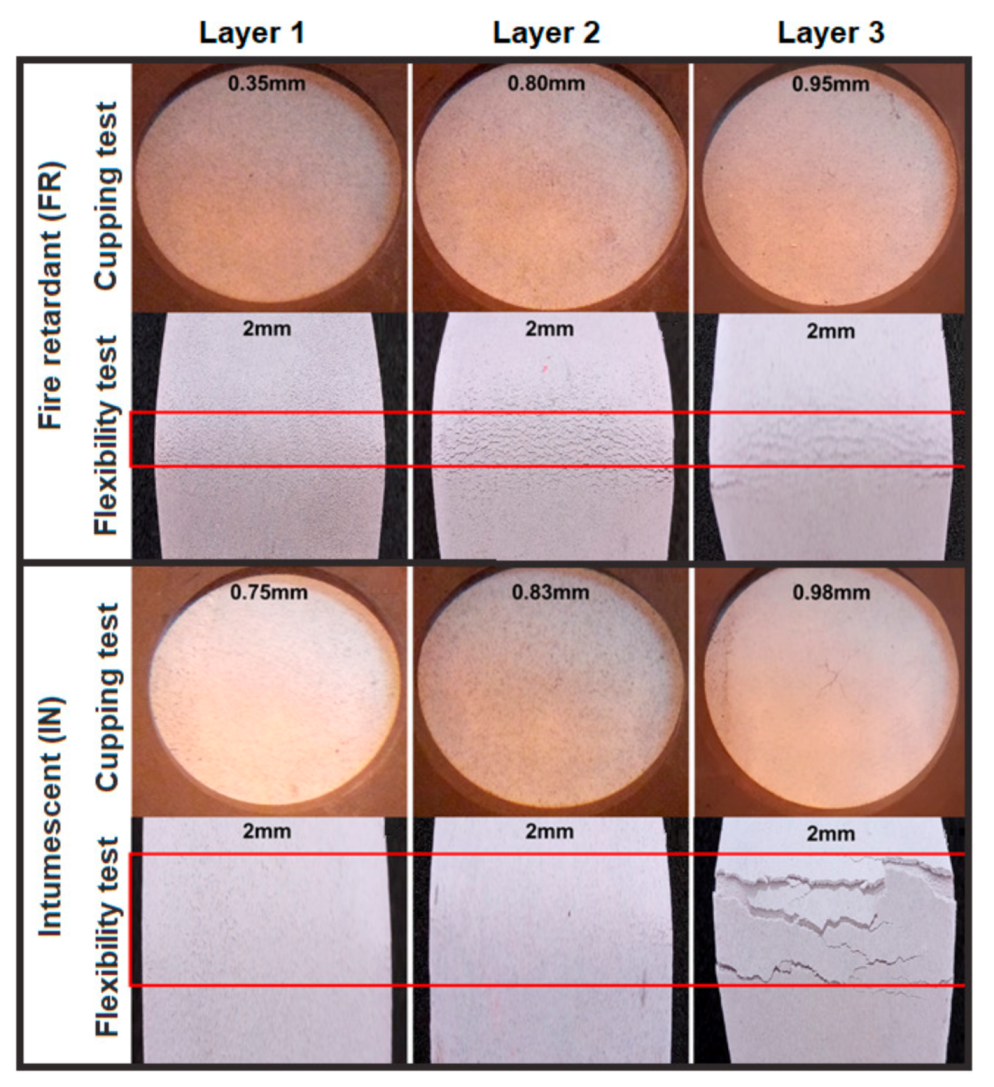

3.3.2. Evaluation of the Mechanical Properties of Coatings on Wood Substrates

3.3.3. Evaluation of Fire Resistance of Coatings on Metal Substrates

3.3.4. Evaluation of the Mechanical Properties of Coatings on Metal Substrates

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yew, M.C.; Sulong, N.R. Fire-resistive performance of intumescent flame-retardant coatings for steel. Mater. Des. 2012, 34, 719–724. [Google Scholar] [CrossRef]

- Jaramillo, A.; Díaz-Gómez, A.; Ramirez, J.; Berrio, M.; Cornejo, V.; Rojas, D.; Montoya, L.; Mera, A.; Melendrez, M. Eco-Friendly Fire-Resistant Coatings Containing Dihydrogen Ammonium Phosphate Microcapsules and Tannins. Prog. Org. Coat. 2021, 11, 280. [Google Scholar] [CrossRef]

- Liang, S.; Neisius, N.M.; Gaan, S. Recent developments in flame retardant polymeric coatings. Coatings 2013, 76, 1642–1665. [Google Scholar] [CrossRef]

- Baldissera, A.F.; Silveira, M.R.; Dornelles, A.C.; Ferreira, C.A. Assessment of lignin as a carbon source in intumescent coatings containing polyaniline. J. Coat. Technol. Res. 2020, 17, 1–11. [Google Scholar] [CrossRef]

- Lu, H.; Song, L.; Hu, Y. A review on flame retardant technology in China. Part II: Flame retardant polymeric nanocomposites and coatings. Polym. Adv. Technol. 2011, 22, 379–394. [Google Scholar] [CrossRef]

- Yew, M.; Sulong, N.R.; Amalina, M.; Johan, M. Influences of flame-retardant fillers on fire protection and mechanical properties of intumescent coatings. Prog. Org. Coat. 2015, 78, 59–66. [Google Scholar] [CrossRef]

- Wang, Z.; Han, E.; Ke, W. Effect of nanoparticles on the improvement in fire-resistant and anti-ageing properties of flame-retardant coating. Surf. Coat. Technol. 2006, 200, 5706–5716. [Google Scholar] [CrossRef]

- Weil, E.D. Fire-Protective and Flame-Retardant Coatings - A State-of-the-Art Review. J. Fire Sci. 2011, 29, 259–296. [Google Scholar] [CrossRef]

- Oliveira, R.B.R.; Junior, A.L.M.; Vieira, L.C.M. Intumescent paint as fire protection coating. Rev. IBRACON Estrut. Mater. 2017, 10, 220–231. [Google Scholar] [CrossRef] [Green Version]

- Shih, Y.; Cheung, F.; Koo, J. Theoretical Modeling of Intumescent Fire-Retardant Materials. J. Fire Sci. 1998, 16, 46–71. [Google Scholar] [CrossRef]

- Amaral-Labat, G.; Szczurek, A.; Fierro, V.; Stein, N.; Boulanger, C.; Pizzi, A.; Celzard, A. Pore structure and electrochemical performances of tannin-based carbon cryogels. Biomass-Bioenergy 2012, 39, 274–282. [Google Scholar] [CrossRef]

- Chou, C.-S.; Lin, S.-H.; Wang, C.-I. Preparation and characterization of the intumescent fire retardant coating with a new flame retardant. Adv. Powder Technol. 2009, 20, 169–176. [Google Scholar] [CrossRef]

- Chen, X.; Hu, Y.; Jiao, C.; Song, L. Preparation and thermal properties of a novel flame-retardant coating. Polym. Degrad. Stab. 2007, 92, 1141–1150. [Google Scholar] [CrossRef]

- Montoya, L.; Contreras, D.; Jaramillo, A.; Carrasco, C.; Fernández, K.; Schwederski, B.; Rojas, D.; Melendrez, M. Study of anticorrosive coatings based on high and low molecular weight polyphenols extracted from the Pine radiata bark. Prog. Org. Coat. 2019, 127, 100–109. [Google Scholar] [CrossRef]

- Jaramillo, A.; Montoya, L.; Prabhakar, J.M.; Sanhueza, J.; Fernández, K.; Rohwerder, M.; Rojas, D.; Montalba, C.; Melendrez, M. Formulation of a multifunctional coating based on polyphenols extracted from the Pine radiata bark and functionalized zinc oxide nanoparticles: Evaluation of hydrophobic and anticorrosive properties. Prog. Org. Coat. 2019, 135, 191–204. [Google Scholar] [CrossRef]

- Da Silveira, M.R.; Peres, R.S.; Moritz, V.F.; Ferreira, C.A. Intumescent Coatings Based on Tannins for Fire Protection. Mater. Res. 2019, 22, 22. [Google Scholar] [CrossRef]

- Chen, X.; Jiao, C. Thermal degradation characteristics of a novel flame retardant coating using TG-IR technique. Polym. Degrad. Stab. 2008, 93, 2222–2225. [Google Scholar] [CrossRef]

- Ji, W.; Hua, S.W.; Miao, Z.; Zhen, C. Study and Prediction for the Fire Resistance of Acid Corroded Intumescent Coating. Procedia Eng. 2014, 84, 524–534. [Google Scholar] [CrossRef] [Green Version]

- Bocalandro, C.; Sanhueza, V.; Gómez-Caravaca, A.M.; González-Álvarez, J.; Fernández, K.; Roeckel, M.; Rodríguez-Estrada, M.T. Comparison of the composition of Pinus radiata bark extracts obtained at bench- and pilot-scales. Ind. Crop. Prod. 2012, 38, 21–26. [Google Scholar] [CrossRef]

- Ma, W.; Waffo-Téguo, P.; Paissoni, M.A.; Jourdes, M.; Teissedre, P.-L. New insight into the unresolved HPLC broad peak of Cabernet Sauvignon grape seed polymeric tannins by combining CPC and Q-ToF approaches. Food Chem. 2018, 249, 168–175. [Google Scholar] [CrossRef]

- Yang, T.; Dong, M.; Cui, J.; Gan, L.; Han, S. Exploring the formaldehyde reactivity of tannins with different molecular weight distributions: Bayberry tannins and larch tannins. Holzforschung 2020, 74, 673–682. [Google Scholar] [CrossRef]

- Banach, M.; Makara, A. Thermal Decomposition of Sodium Phosphates. J. Chem. Eng. Data 2011, 56, 3095–3099. [Google Scholar] [CrossRef]

- Jiang, H.-C.; Lin, W.-C.; Hua, M.; Pan, X.-H.; Shu, C.-M.; Jiang, J.-C. Analysis of kinetics of thermal decomposition of melamine blended with phosphorous ionic liquid by green approach. J. Therm. Anal. Calorim. 2017, 131, 2821–2831. [Google Scholar] [CrossRef]

- Su, C.-H.; Chen, C.-C.; Liaw, H.-J.; Wang, S.-C. The Assessment of Fire Suppression Capability for the Ammonium Dihydrogen Phosphate Dry Powder of Commercial Fire Extinguishers. Procedia Eng. 2014, 84, 485–490. [Google Scholar] [CrossRef]

- Pardo, A.; Romero, J.; Ortiz, E. High-temperature behaviour of ammonium dihydrogen phosphate. J. Phys. Conf. Ser. 2017, 935, 935. [Google Scholar] [CrossRef] [Green Version]

- Venkitaraj, K.; Suresh, S. Experimental thermal degradation analysis of pentaerythritol with alumina nano additives for thermal energy storage application. J. Energy Storage 2019, 22, 8–16. [Google Scholar] [CrossRef]

- Venkitaraj, K.; Suresh, S. Experimental study on thermal and chemical stability of pentaerythritol blended with low melting alloy as possible PCM for latent heat storage. Exp. Therm. Fluid Sci. 2017, 88, 73–87. [Google Scholar] [CrossRef]

- Lim, W.P.; Mariatti, M.; Chow, W.; Mar, K. Effect of intumescent ammonium polyphosphate (APP) and melamine cyanurate (MC) on the properties of epoxy/glass fiber composites. Compos. Part B Eng. 2012, 43, 124–128. [Google Scholar] [CrossRef]

- Xia, Y.; Jin, F.; Mao, Z.; Guan, Y.; Zheng, A. Effects of ammonium polyphosphate to pentaerythritol ratio on composition and properties of carbonaceous foam deriving from intumescent flame-retardant polypropylene. Polym. Degrad. Stab. 2014, 107, 64–73. [Google Scholar] [CrossRef]

- Braghiroli, F.; Fierro, V.; Pizzi, A.; Rode, K.; Radke, W.; Delmotte, L.; Parmentier, J.; Celzard, A. Reaction of condensed tannins with ammonia. Ind. Crop. Prod. 2013, 44, 330–335. [Google Scholar] [CrossRef]

- Yang, T.-T.; Guan, J.-P.; Tang, R.-C.; Chen, G. Condensed tannin from Dioscorea cirrhosa tuber as an eco-friendly and durable flame retardant for silk textile. Ind. Crop. Prod. 2018, 115, 16–25. [Google Scholar] [CrossRef]

- Tudor, E.M.; Barbu, M.C.; Petutschnigg, A.; Réh, R. Added-value for wood bark as a coating layer for flooring tiles. J. Clean. Prod. 2018, 170, 1354–1360. [Google Scholar] [CrossRef]

- Puri, R.G.; Khanna, A. Effect of cenospheres on the char formation and fire protective performance of water-based intumescent coatings on structural steel. Prog. Org. Coat. 2016, 92, 8–15. [Google Scholar] [CrossRef]

- Yin, J.J.K.; Yew, M.C.; Saw, L.H.; Yew, M.K. Preparation of Intumescent Fire Protective Coating for Fire Rated Timber Door. Coatings 2019, 9, 738. [Google Scholar] [CrossRef] [Green Version]

| Component | (%) |

|---|---|

| Solvent | 43.5 |

| Polyol | 8.3 |

| Catalytic acid | 23.1 |

| Foaming agent | 7.4 |

| Complementary components | 8.3 |

| Polymeric matrix | 9.3 |

| Component | Variation Ratio (%) | ||||

|---|---|---|---|---|---|

| FT1 | FT2 | FT3 | FT4 | FT5 | |

| Ratio MAP/PER | 1.5 | 1.5 | 1.5 | 1.5 | 1.9 |

| MAP | 25.0 | 25.0 | 25.0 | 25.0 | 25.0 |

| PER | 15.0 | 15.0 | 15.0 | 15.0 | 15.0 |

| ME | 14.0 | 14.0 | 14.0 | 14.0 | 8.0 |

| H-MWT | 13.0 | 26.0 | 5.8 | 2.5 | 2.5 |

| Mass Loss (%) | |||||

|---|---|---|---|---|---|

| Wood | FT1 | FT2 | FT3 | FT4 | FT5 |

| 14.7 ± 0.1 | 7.3 ± 0.5 | 10.2 ± 0.2 | 11.7 ± 0.9 | 11.5 ± 0.7 | 9.3 ± 0.8 |

| Coating | Wood | Steel | |||||

|---|---|---|---|---|---|---|---|

| Thickness (µm) | Fire Resistance Time (s) | Substrate Back Side Temperature (°C) | Mass Loss (g) | Carbonization Index (%) | Thickness (µm) | Substrate Back Side Temperature (°C) | |

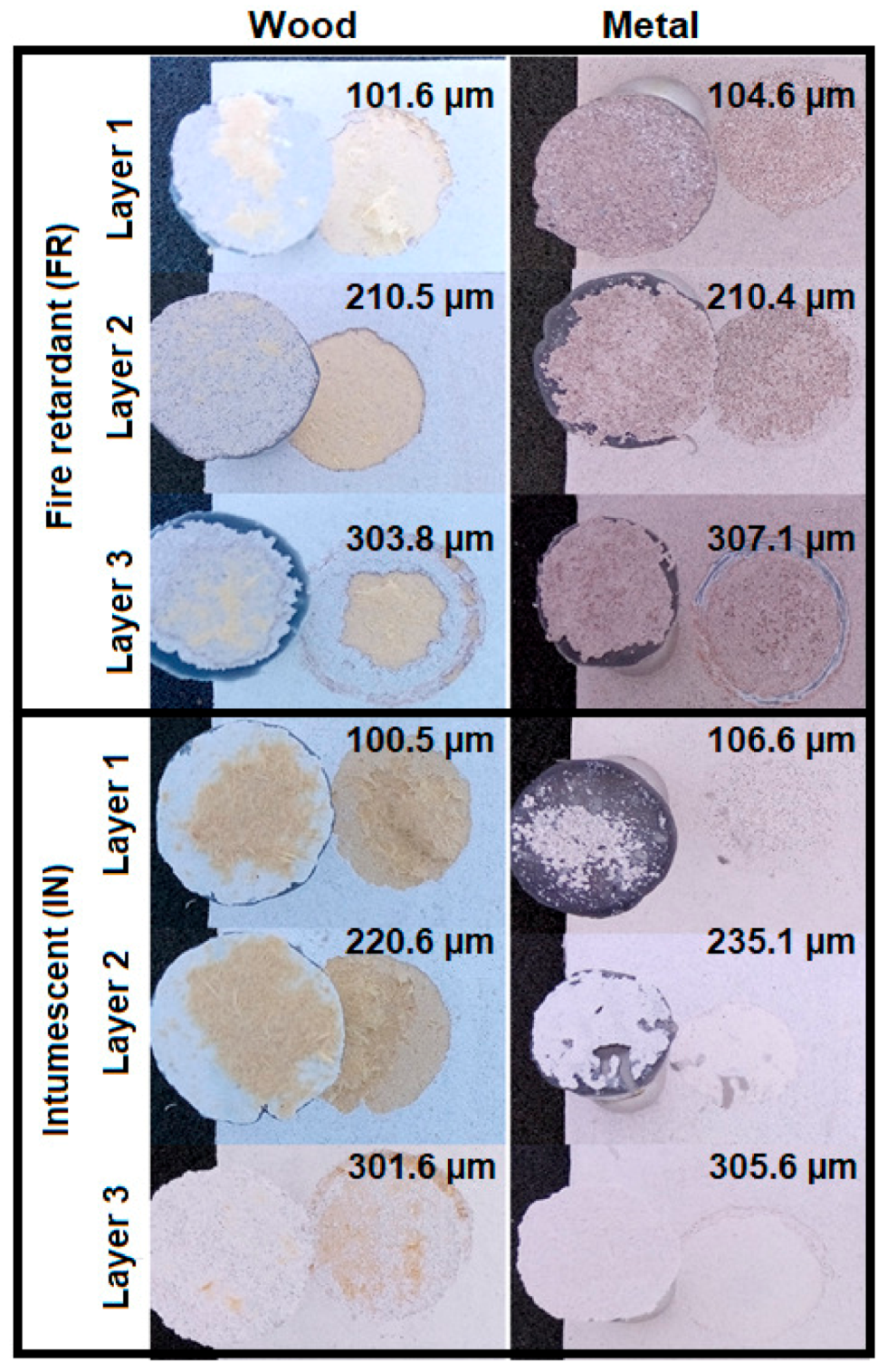

| FR1 | 101.6 ± 14.6 | 10.0 ± 0.1 | 16.2 ± 0.7 | 7.4 ± 0.6 | 37.1 ± 2.1 | 104.6 ± 15.3 | 189.1 ± 10.5 |

| FR2 | 210.5 ± 5.8 | 10.0 ± 0.1 | 16.3 ± 0.4 | 6.5 ± 0.5 | 33.1 ± 2.2 | 210.4 ± 11.9 | 187.0 ± 13.3 |

| FR3 | 303.8 ± 16.1 | 30.0 ± 0.1 | 14.7 ± 0.3 | 5.2 ± 0.6 | 23.7 ± 2.9 | 307.1 ± 12.7 | 165.9 ± 11.1 |

| IN1 | 100.5 ± 13.5 | 10.0 ± 0.1 | 39.1 ± 0.1 | 9.35 ± 0.5 | 41.9 ± 2.7 | 106.6 ± 19.0 | 387.9 ± 10.5 |

| IN2 | 220.6 ± 15.9 | 20.0 ± 0.1 | 14.8 ± 0.8 | 7.8 ± 0.6 | 22.7 ± 2.6 | 235.1 ± 10.4 | 225.1 ± 15.2 |

| IN3 | 301.6 ± 22.7 | 30.0 ± 0.1 | 13.9 ± 0.8 | 6.5 ± 0.7 | 19.6 ± 3.0 | 305.6 ± 11.5 | 181.2 ± 13.2 |

| C-IN | 317.1 ± 11.5 | 70.0 ± 0.1 | 26.9 ± 0.3 | 0.2 ± 0.1 | 4.6 ±0.7 | 310.1 ± 7.2 | 298.8 ± 55.6 |

| C-FR | 305.3 ± 7.6 | 29.8 ± 0.1 | 14.1 ± 0.2 | 7.4 ± 1.0 | 19.9 ± 1.9 | 300.4 ± 30.5 | 301.5 ± 68.9 |

| IN–FR Scheme | 612.1 ± 9.7 | 66.4 ± 0.1 | 12.6 ± 1.2 | 3.5 ± 0.3 | 20.0 ± 5.7 | 639.4 ± 54.6 | 147.4 ± 15.31 |

| Wood | - | 10.0 ± 0.1 | 20.0 ± 1.9 | 13.5 ± 1.2 | 52.5 ± 5.4 | - | - |

| C-IN | 650.3 ± 23.5 | 79.9 ± 0.0 | 5.8 ± 3.1 | 0.4 ± 0.3 | 9.2 ± 1.4 | 630.9 ± 55.6 | 238.9 ± 20.1 |

| Coating/No. Layers | Tensile Strength (MPa) | |||

|---|---|---|---|---|

| Wood | Type of Failure | Metal | Type of Failure | |

| FR1 | 1.48 ± 0.02 | 100% adhesive | 1.30 ± 0.06 | 100% cohesive |

| FR2 | 1.25 ± 0.43 | 100% adhesive | 1.13 ± 0.16 | 100% cohesive |

| FR3 | 0.79 ± 0.17 | 60% adhesive | 0.74 ± 0.02 | 100% cohesive |

| IN1 | 1.42 ± 0.05 | 100% adhesive | 1.70 ± 0.09 | 20% cohesive |

| IN2 | 1.31 ± 0.06 | 100% adhesive | 1.03 ± 0.06 | 80% cohesive |

| IN3 | 0.79 ± 0.01 | 100% cohesive | 0.87 ± 0.03 | 100% cohesive |

| Coating | Tensile Strength (MPa) | Type of Failure |

|---|---|---|

| IN-FR | 0.70 ± 0.14 | 25% cohesive IG/15% adhesive IG glue/60% cohesive IN |

| C-IG | 3.02 ± 0.32 | 30% adhesive IG primer/70% adhesive IG glue |

| C-IN | 0.98 ± 0.04 | 100% cohesive |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Solis-Pomar, F.; Díaz-Gómez, A.; Berrío, M.E.; Ramírez, J.; Jaramillo, A.F.; Fernández, K.; Rojas, D.; Melendrez, M.F.; Pérez-Tijerina, E. A Dual Active-Passive Coating with Intumescent and Fire-Retardant Properties Based on High Molecular Weight Tannins. Coatings 2021, 11, 460. https://doi.org/10.3390/coatings11040460

Solis-Pomar F, Díaz-Gómez A, Berrío ME, Ramírez J, Jaramillo AF, Fernández K, Rojas D, Melendrez MF, Pérez-Tijerina E. A Dual Active-Passive Coating with Intumescent and Fire-Retardant Properties Based on High Molecular Weight Tannins. Coatings. 2021; 11(4):460. https://doi.org/10.3390/coatings11040460

Chicago/Turabian StyleSolis-Pomar, Francisco, Andrés Díaz-Gómez, María Elizabeth Berrío, Jesús Ramírez, Andrés Felipe Jaramillo, Katherina Fernández, David Rojas, Manuel Francisco Melendrez, and Eduardo Pérez-Tijerina. 2021. "A Dual Active-Passive Coating with Intumescent and Fire-Retardant Properties Based on High Molecular Weight Tannins" Coatings 11, no. 4: 460. https://doi.org/10.3390/coatings11040460

APA StyleSolis-Pomar, F., Díaz-Gómez, A., Berrío, M. E., Ramírez, J., Jaramillo, A. F., Fernández, K., Rojas, D., Melendrez, M. F., & Pérez-Tijerina, E. (2021). A Dual Active-Passive Coating with Intumescent and Fire-Retardant Properties Based on High Molecular Weight Tannins. Coatings, 11(4), 460. https://doi.org/10.3390/coatings11040460