Passive Layers and Corrosion Resistance of Biomedical Ti-6Al-4V and β-Ti Alloys

Abstract

:1. Introduction

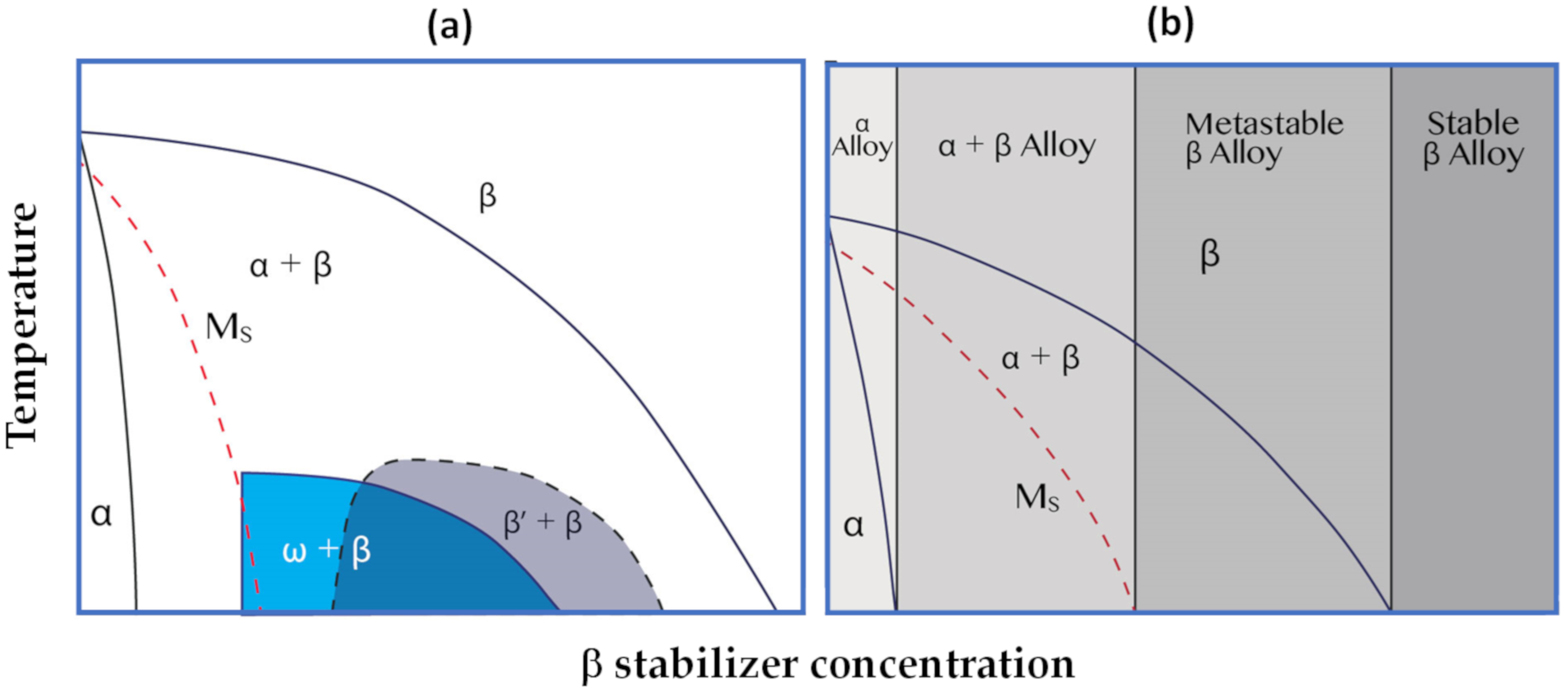

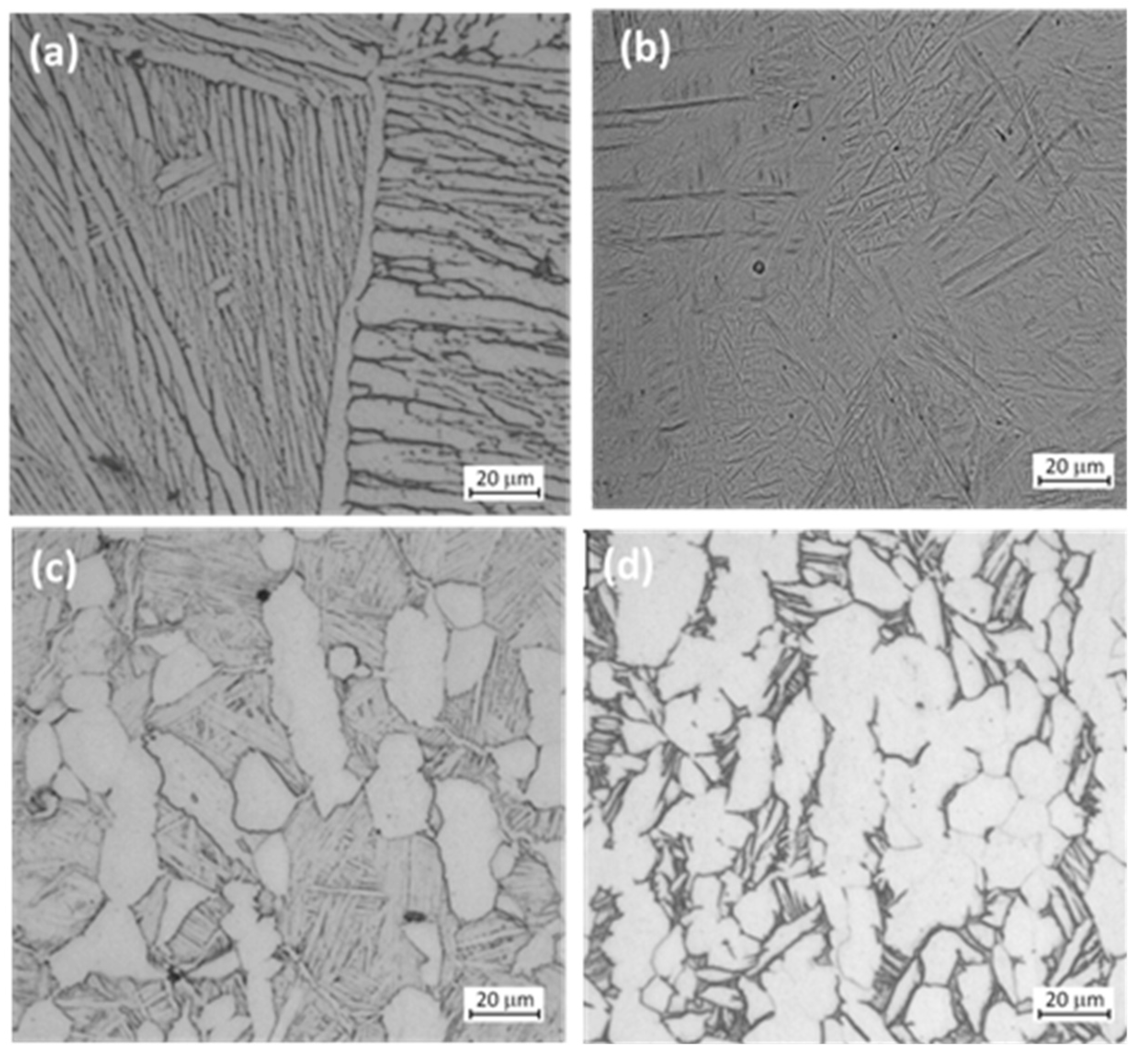

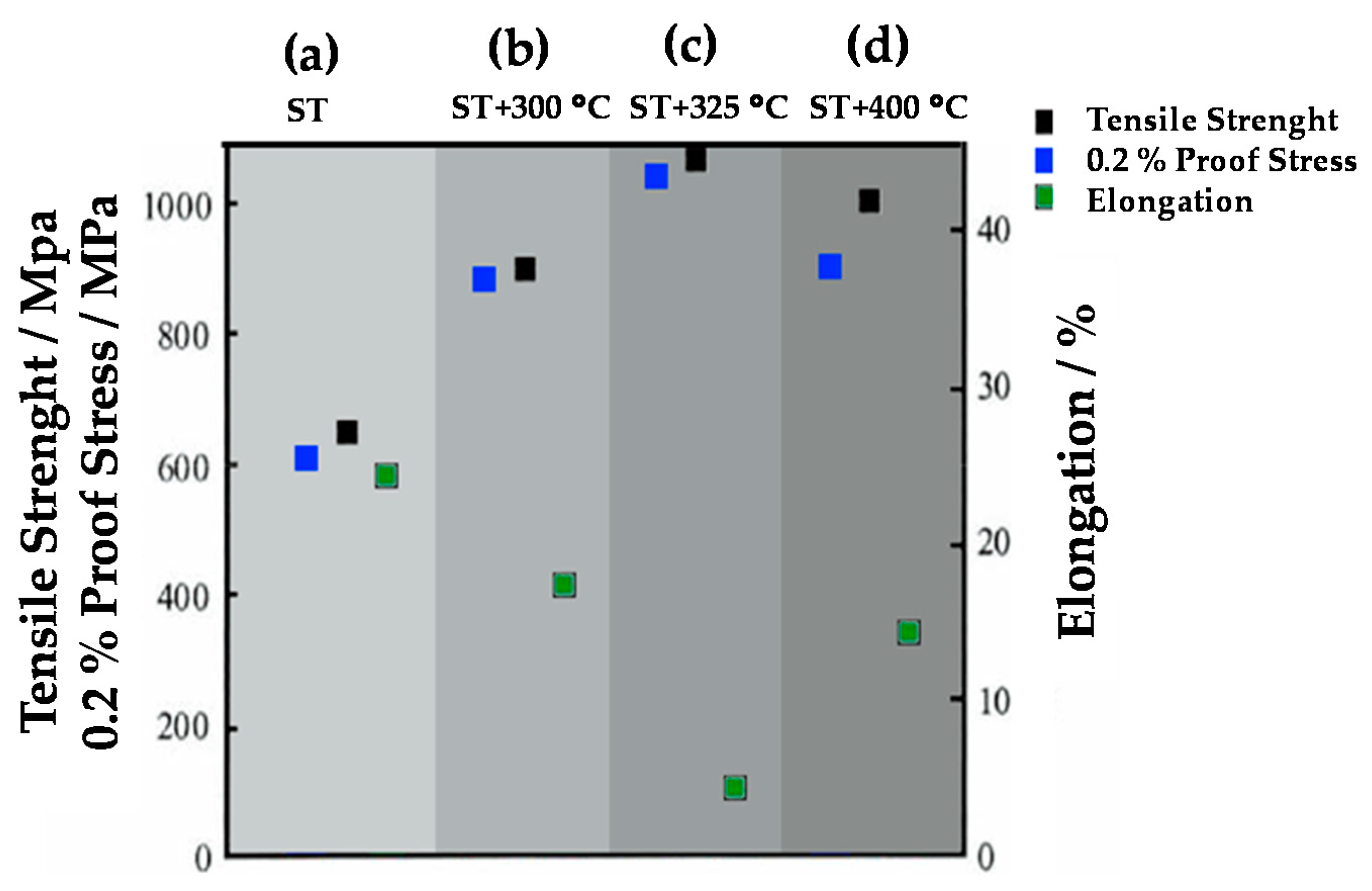

2. Biomedical Titanium Alloys

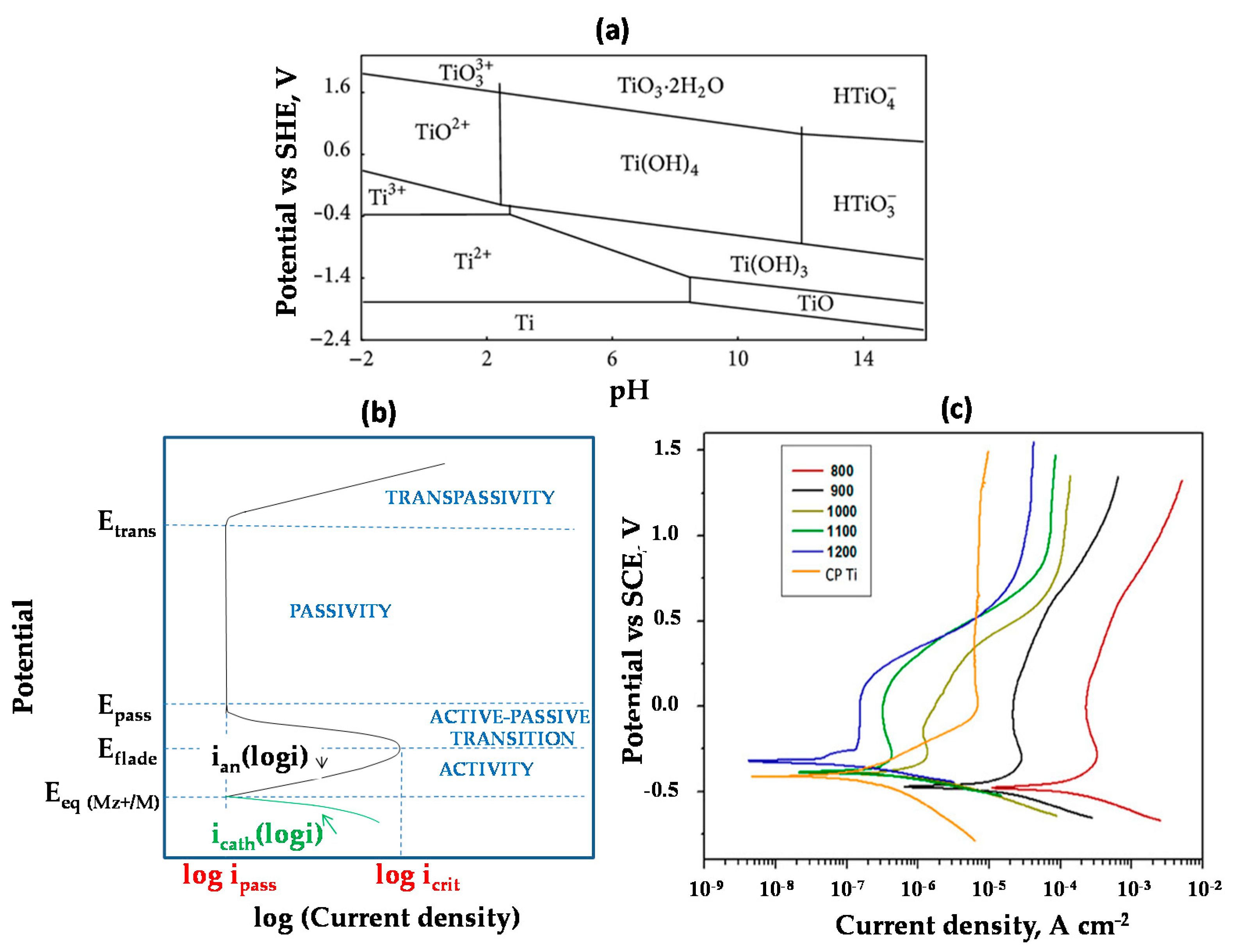

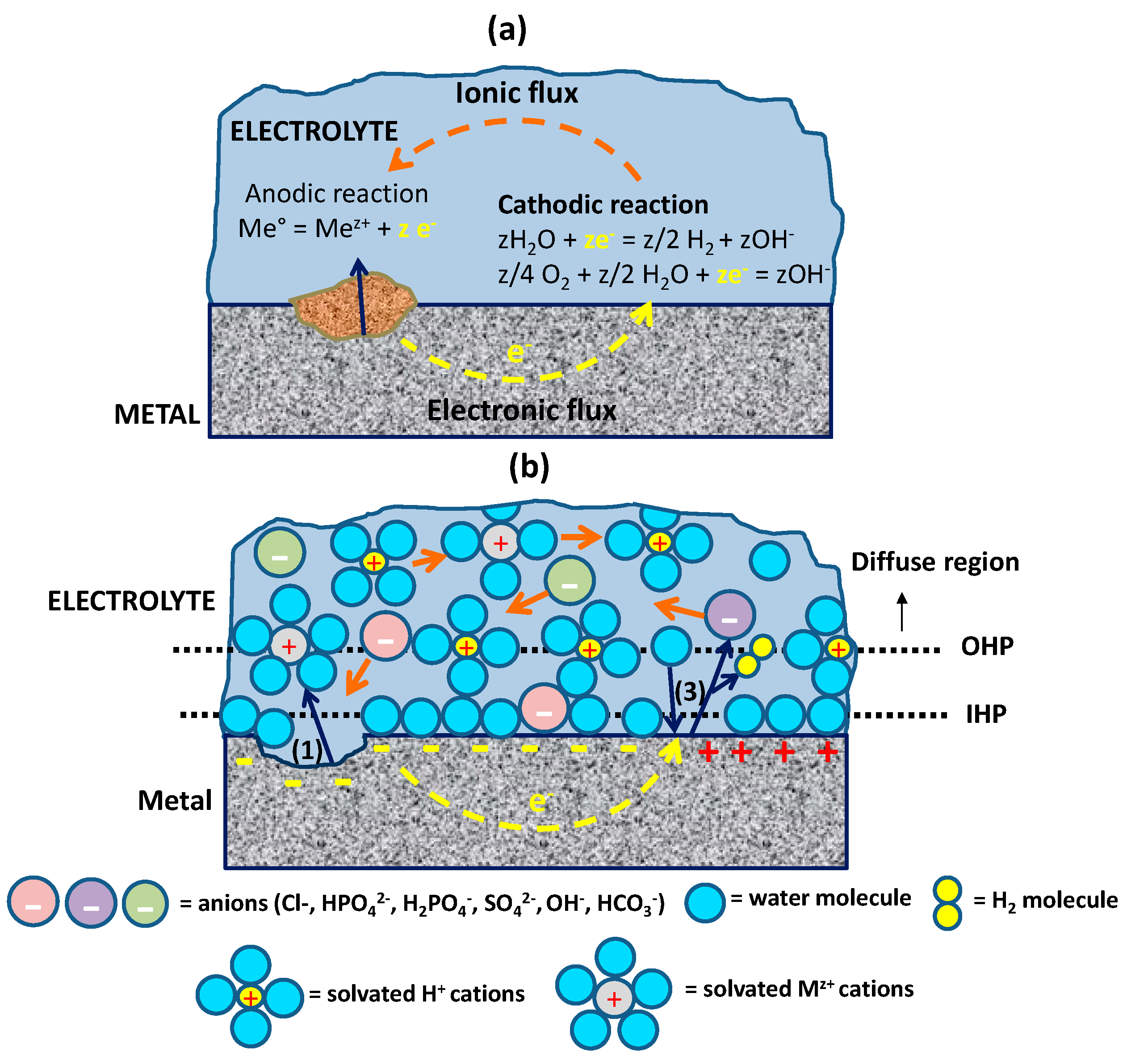

3. Electrochemical Corrosion of Ti Alloys in a Biological Environment: Overview

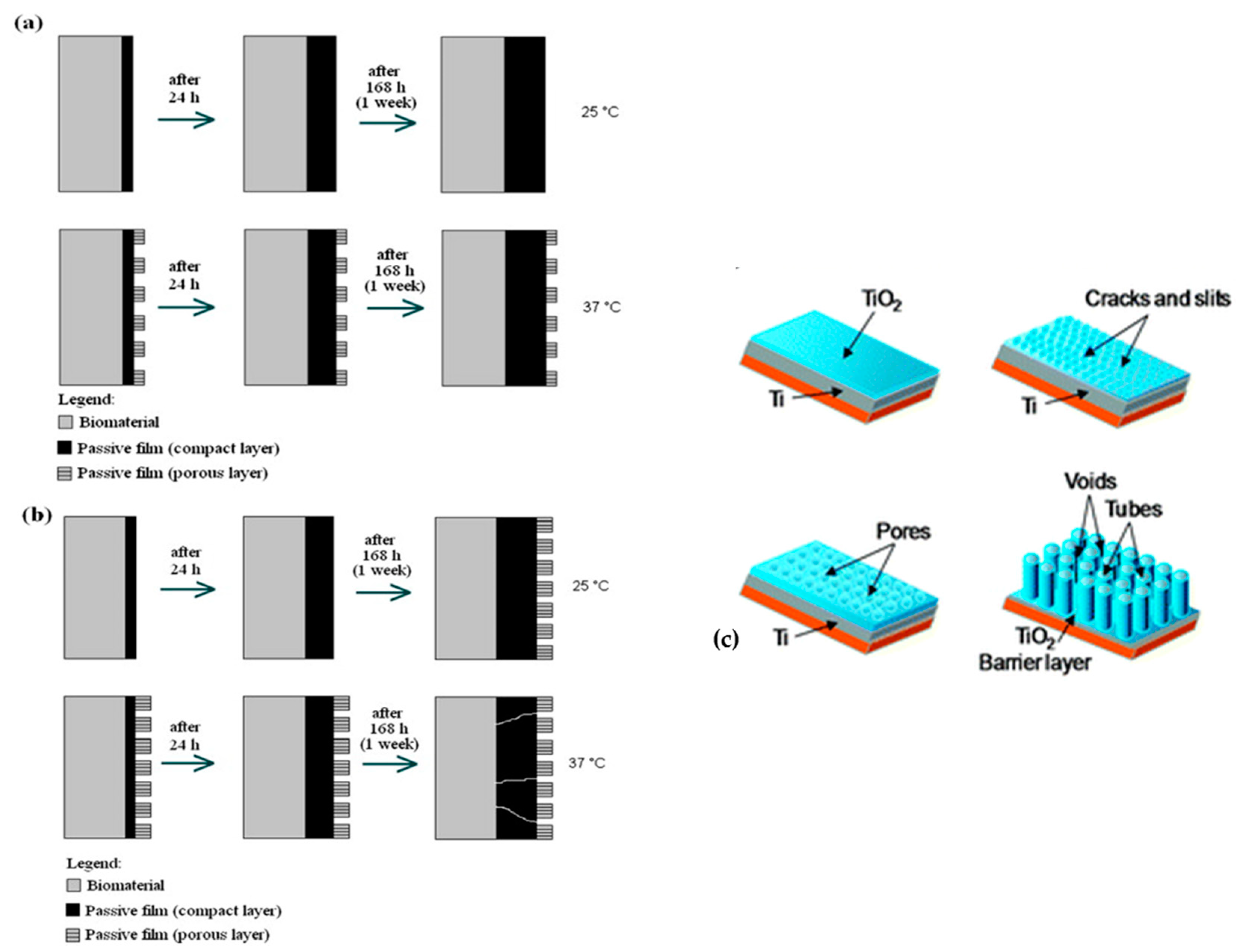

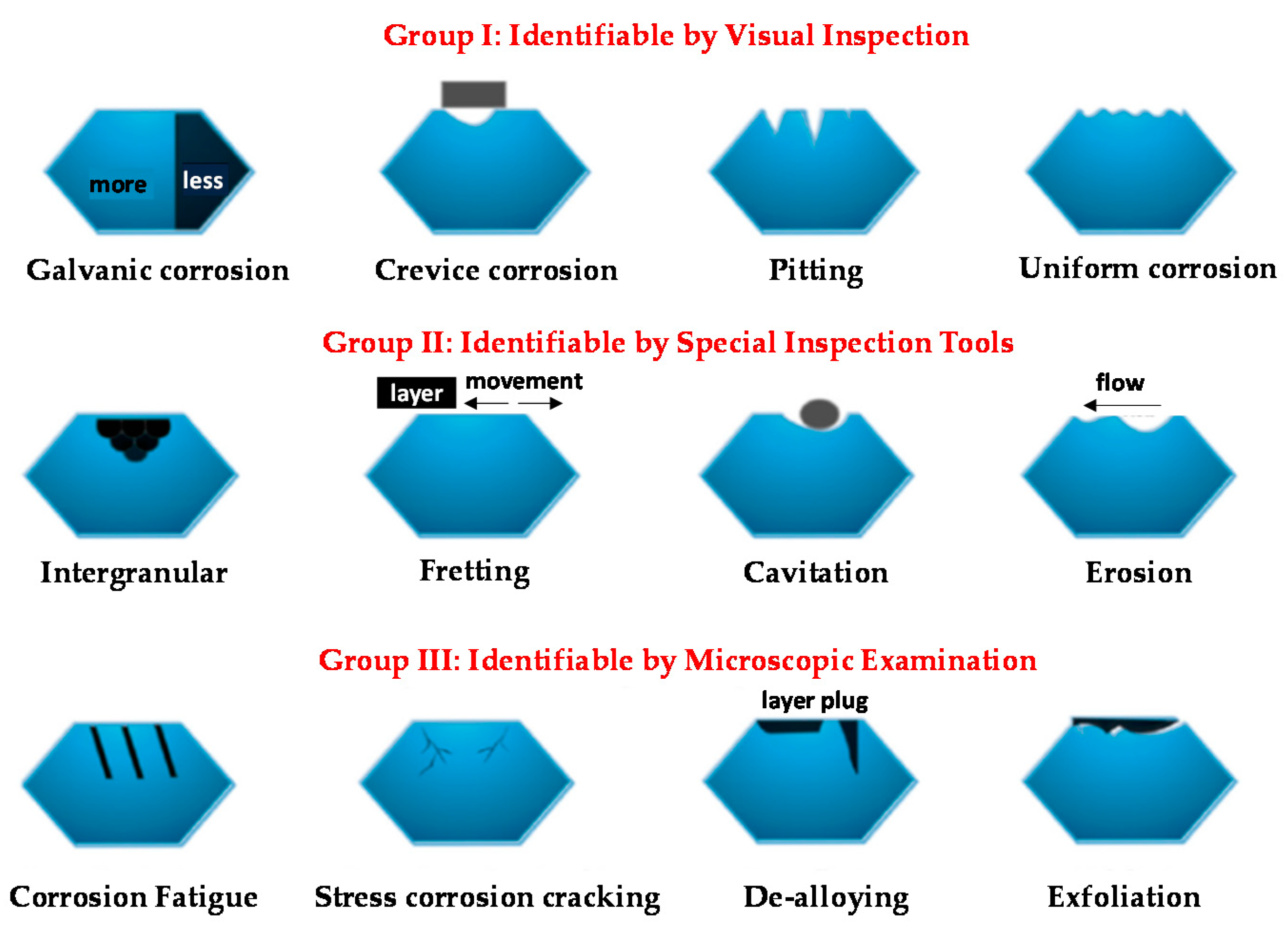

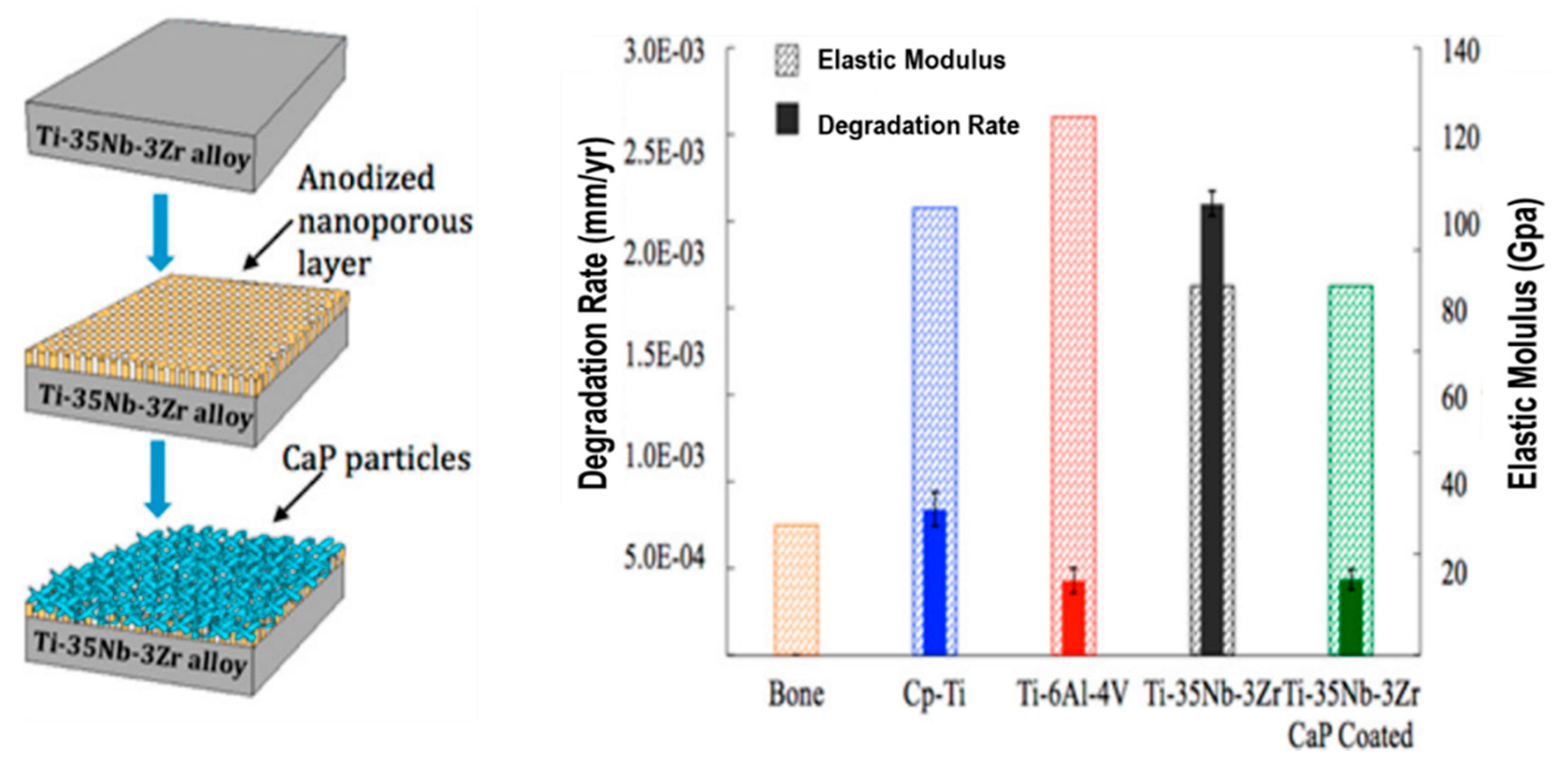

4. Passive Layers on Biomedical Ti-6Al-4V and β-Ti Alloys

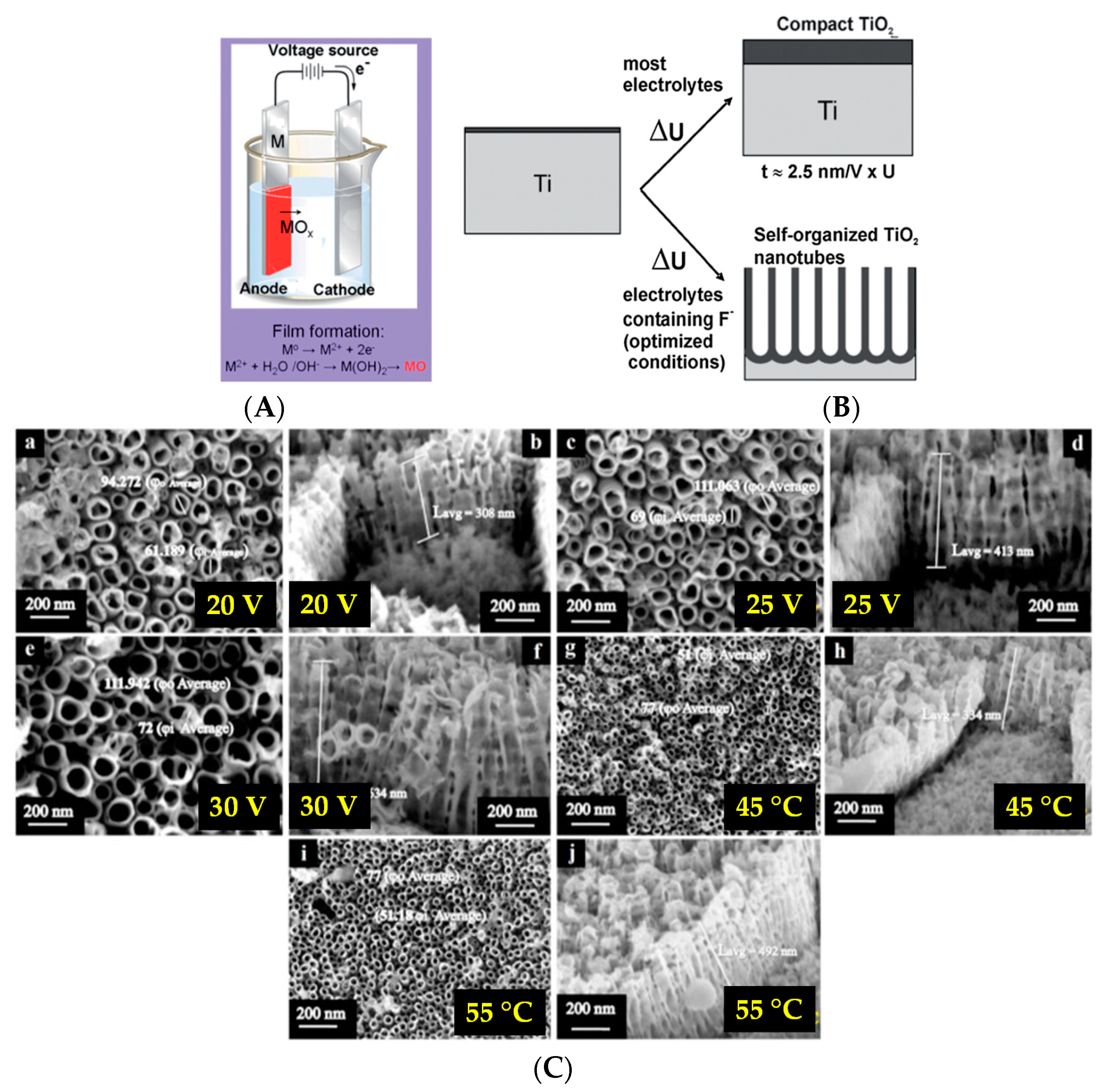

4.1. Electrochemical Passivation

4.2. Thermal Oxidation

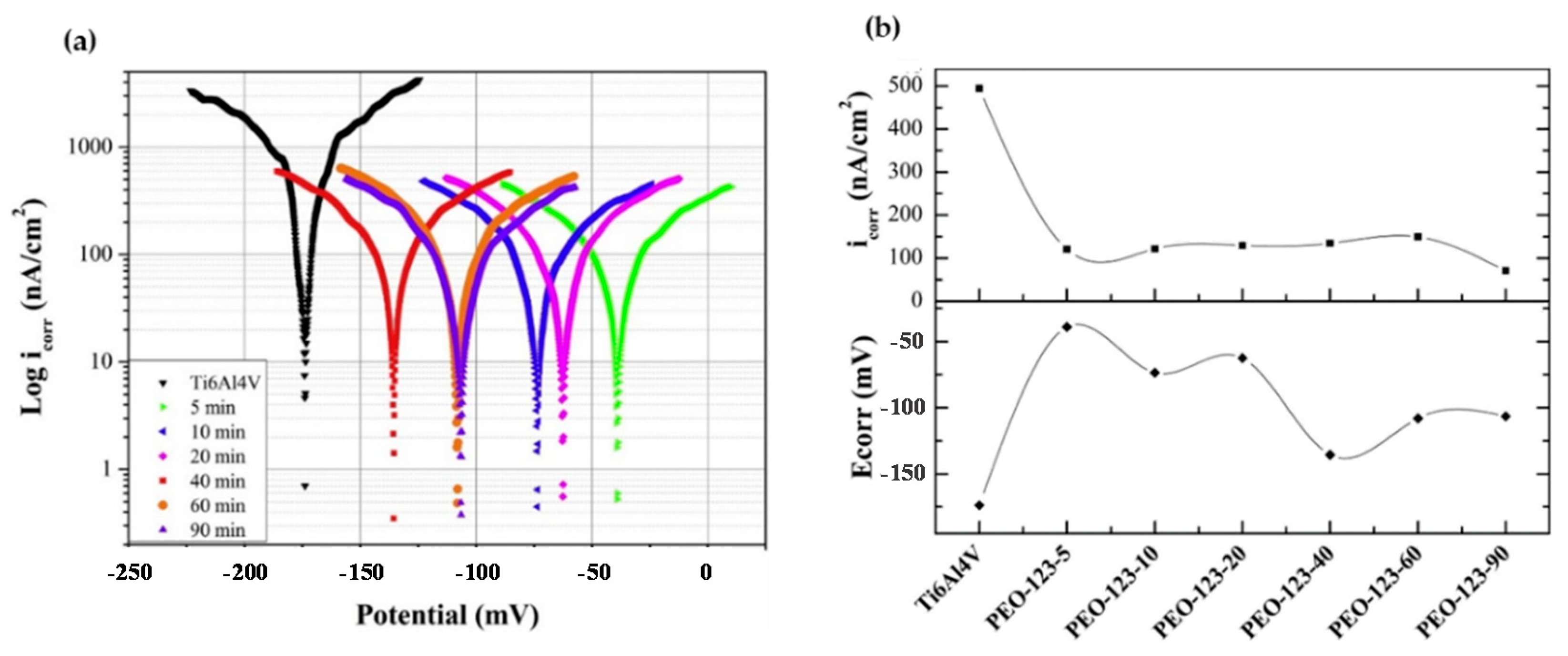

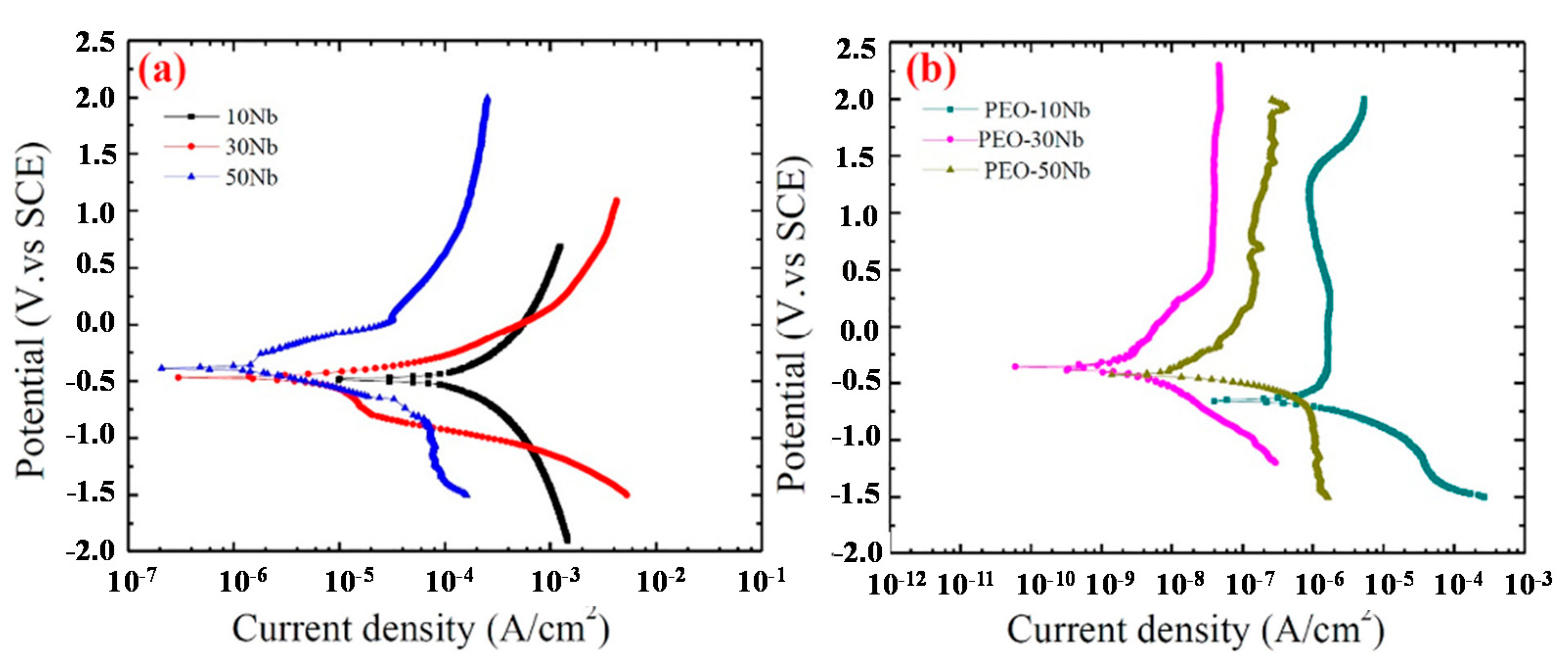

4.3. Plasma Electrolytic Oxidation

5. Electrochemical Biocorrosion of Passive Coatings on Ti-6Al-4V and β-Ti Alloys

5.1. Methods

5.2. Overview

5.3. Biochemical Environments Encouraging Ti-Alloy Passive Layer Corrosion

5.4. Electrochemical Biocorrosion of Passive Coatings on Ti-6Al-4V

5.5. Electrochemical Biocorrosion of Passive Coatings on β-Ti Alloys

6. Outlook and Future Perspectives

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Dini, C.; Costa, R.C.; Sukotjo, C.; Takoudis, C.G.; Mathew, M.T.; Barão, V.A.R. Progression of Bio-Tribocorrosion in Implant Dentistry. Front. Mech. Eng. 2020, 6, 1–14. [Google Scholar] [CrossRef]

- Apaza-Bedoya, K.; Tarce, M.; Benfatti, C.A.M.; Henriques, B.; Mathew, M.T.; Teughels, W.; Souza, J.C.M. Synergistic interactions between corrosion and wear at titanium-based dental implant connections: A scoping review. J. Periodontal Res. 2017, 52, 946–954. [Google Scholar] [CrossRef] [PubMed]

- Mehkri, S.; Abishek, N.R.; Sumanth, K.S.; Rekha, N. Study of the Tribocorrosion occurring at the implant and implant alloy Interface: Dental implant materials. Mater. Today Proc. 2020. [Google Scholar] [CrossRef]

- Cordeiro, J.M.; Barão, V.A.R. Is there scientific evidence favoring the substitution of commercially pure titanium with titanium alloys for the manufacture of dental implants? Mater. Sci. Eng. C 2017, 71, 1201–1215. [Google Scholar] [CrossRef]

- Zhang, L.; Chen, L. A Review on Biomedical Titanium Alloys: Recent Progress and Prospect. Adv. Eng. Mater. 2019, 21, 1801215. [Google Scholar] [CrossRef] [Green Version]

- Noronha Oliveira, M.; Schunemann, W.V.H.; Mathew, M.T.; Henriques, B.; Magini, R.S.; Teughels, W.; Souza, J.C.M. Can degradation products released from dental implants affect peri-implant tissues? J. Periodontal Res. 2017, 6, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Mombelli, A.; Hashim, D.; Cionca, N. What is the impact of titanium particles and biocorrosion on implant survival and complications? A critical review. Clin. Oral Implant. Res. 2018, 29 (Suppl. 18), 37–53. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.-C.; Chen, L.-Y.; Wang, L. Surface Modification of Titanium and Titanium Alloys: Technologies, Developments, and Future Interests. Adv. Eng. Mater. 2020, 22, 1901258. [Google Scholar] [CrossRef]

- Dias Corpa Tardelli, J.; Bolfarini, C.; Cândido Dos Reis, A. Comparative analysis of corrosion resistance between beta titanium and Ti-6Al-4V alloys: A systematic review. J. Trace Elem. Med. Biol. 2020, 62, 126618. [Google Scholar] [CrossRef]

- Dias Corpa Tardelli, J.; Lima da Costa Valente, M.; Theodoro de Oliveira, T.; Cândido dos Reis, A. Influence of chemical composition on cell viability on titanium surfaces: A systematic review. J. Prosthet. Dent. 2021, 125, 421–425. [Google Scholar] [CrossRef]

- Sharma, A.; Oh, M.C.; Kim, J.T.; Srivastava, A.K.; Ahn, B. Investigation of electrochemical corrosion behavior of additive manufactured Ti–6Al–4V alloy for medical implants in different electrolytes. J. Alloys Compd. 2020, 830, 154620. [Google Scholar] [CrossRef]

- Peñarrieta-Juanito, G.; Sordi, M.B.; Henriques, B.; Dotto, M.E.R.; Teughels, W.; Silva, F.S.; Magini, R.S.; Souza, J.C.M. Surface damage of dental implant systems and ions release after exposure to fluoride and hydrogen peroxide. J. Periodontal Res. 2018, 54, 46–52. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Contu, F.; Elsener, B.; Böhni, H. A study of the potentials achieved during mechanical abrasion and the repassivation rate of titanium and Ti6Al4V in inorganic buffer solutions and bovine serum. Electrochim. Acta 2004, 50, 33–41. [Google Scholar] [CrossRef]

- Mischler, S. Triboelectrochemical techniques and interpretation methods in tribocorrosion: A comparative evaluation. Tribol. Int. 2008, 41, 573–583. [Google Scholar] [CrossRef]

- Ribeiro, A.R.; Gemini-Piperni, S.; Travassos, R.; Lemgruber, L.; Silva, R.C.; Rossi, A.L.; Farina, M.; Anselme, K.; Shokuhfar, T.; Shahbazian-Yassar, R. Trojan-Like Internalization of Anatase Titanium Dioxide Nanoparticles by Human Osteoblast. Cells Sci. Rep. 2016, 6, 23615. [Google Scholar] [CrossRef]

- Mano, S.S.; Kanehira, K.; Taniguchi, A. Comparison of cellular uptake and inflammatory response via toll-like receptor 4 to lipopolysaccharide and titanium dioxide nanoparticles. Int. J. Mol. Sci. 2013, 14, 13154–13170. [Google Scholar] [CrossRef] [Green Version]

- Okuda-Shimazaki, J.; Takaku, S.; Kanehira, K.; Sonezaki, S.; Taniguchi, A. Effects of titanium dioxide nanoparticle aggregate size on gene expression. Int. J. Mol. Sci. 2010, 11, 2383–2392. [Google Scholar] [CrossRef] [Green Version]

- Chen, L.-Y.; Cui, Y.-W.; Zhang, L.-C. Recent Development in Beta Titanium Alloys for Biomedical Applications. Metals 2020, 10, 1139. [Google Scholar] [CrossRef]

- Kolawole, S.K.; Hai, W.; Zhang, S.; Sun, Z.; Siddiqui, M.A.; Ullah, I.; Song, W.; Witte, F.; Yang, K. Preliminary study of microstructure, mechanical properties and corrosion resistance of antibacterial Ti-15Zr-xCu alloy for dental application. J. Mater. Sci. Technol. 2020, 50, 31–43. [Google Scholar] [CrossRef]

- Kazemi, M.; Ahangarani, S.; Esmailian, M.; Shanaghi, A. Investigation on the corrosion behavior and biocompatibility of Ti-6Al-4V implant coated with HA/TiN dual layer for medical applications. Surf. Coat. Technol. 2020, 397, 126044. [Google Scholar] [CrossRef]

- Guo, W.Y.; Sun, J.; Wu, J.S. Electrochemical and XPS studies of corrosion behavior of Ti–23Nb–0.7Ta–2Zr–O alloy in Ringer’s solution. Mater. Chem. Phys. 2009, 113, 816–820. [Google Scholar] [CrossRef]

- Shukla, K.A.; Balasubramaniam, R. Effect of surface treatment on electrochemical behavior of CP Ti, Ti–6Al–4V and Ti–13Nb–13Zr alloys in simulated human body fluid. Corros. Sci. 2006, 48, 1696–1720. [Google Scholar] [CrossRef]

- Zhou, Y.L.; Niinomi, M.; Akahori, T.; Fukui, H.; Toda, H. Corrosion resistance and biocompatibility of Ti–Ta alloys for biomedical applications. Mater. Sci. Eng. A 2005, 398, 28–36. [Google Scholar] [CrossRef]

- Oliveira, T.T.; Reis, A.C. Fabrication of dental implants by the additive manufacturing method: A systematic review. J. Prosthet. Dent. 2019, 122, 270–274. [Google Scholar] [CrossRef]

- Kaseem, M.; Choe, H.C. Simultaneous improvement of corrosion resistance and bioactivity of a titanium alloy via wet and dry plasma treatments. J. Alloys Compd. 2021, 851, 156840. [Google Scholar] [CrossRef]

- Xie, L.; Liu, C.; Song, Y.; Guo, H.; Wang, Z.; Hua, L.; Wang, L.; Zhang, L.C. Evaluation of microstructure variation of TC11 alloy after electroshocking treatment. J. Mater. Res. Technol. 2020, 9, 2455–2466. [Google Scholar] [CrossRef]

- Pérez, D.A.G.; Jorge Junior, A.M.; Roche, V.; Lepretre, J.C.; Afonso, C.R.M.; Travessa, D.N.; Asato, G.H.; Bolfarini, C.; Botta, W.J. Severe plastic deformation and different surface treatments on the biocompatible Ti13Nb13Zr and Ti35Nb7Zr5Ta alloys: Microstructural and phase evolutions, mechanical properties, and bioactivity analysis. J. Alloys Compd. 2020, 812. [Google Scholar] [CrossRef]

- Konovalov, S.; Komissarova, I.; Ivanov, Y.; Gromov, V.; Kosinov, D. Structural and phase changes under electropulse treatment of fatigue-loaded titanium alloy VT1-0. J. Mater. Res. Technol. 2019, 8, 1300–1307. [Google Scholar] [CrossRef]

- Brammer, K.S.; Oh, S.; Cobb, C.J.; Bjursten, L.M.; van der Heyde, H. Improved bone-forming functionality on diameter-controlled TiO2 nanotube surface. Acta Biomater. 2009, 5, 3215–3223. [Google Scholar] [CrossRef]

- Antunes, A.R.; De Oliveira, L.C.M. Corrosion fatigue of biomedical metallic alloys: Mechanisms and mitigation. Acta Biomater. 2012, 8, 937–962. [Google Scholar] [CrossRef]

- Yazdi, R.; Ghasemi, M.H.; Wang, C.; Neville, A. Bio-corrosion behaviour of oxygen diffusion layer on Ti-6Al-4V during tribocorrosion. Corros. Sci. 2017, 128, 23–32. [Google Scholar] [CrossRef] [Green Version]

- Lutjering, G.; Williams, C.J. Titanium, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 2007. [Google Scholar]

- Attanasio, A.; Gelfi, M.; Pola, A.; Ceretti, E.; Giardini, C. Influence of Material Microstructures in Micromilling of Ti6Al4V Alloy. Materials 2013, 6, 4268–4283. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Geetha, M.; Singh, K.A.; Asokamani, R.; Gogia, K.A. Ti based biomaterials, the ultimate choice for orthopaedic implants—A review. Prog. Mater. Sci. 2009, 54, 397–425. [Google Scholar] [CrossRef]

- Sidambe, T.A. Biocompatibility of Advanced Manufactured Titanium Implants—A Review. Materials 2014, 7, 8168–8188. [Google Scholar] [CrossRef] [Green Version]

- Cvijović-Alagić, I.; Cvijović, Z.; Mitrović, S.; Panić, V.; Rakin, M. Wear and corrosion behaviour of Ti–13Nb–13Zr and Ti–6Al–4V alloys in simulated physiological solution. Corros. Sci. 2011, 53, 796–808. [Google Scholar] [CrossRef]

- Atapour, M.; Pilchak, A.; Frankel, S.G.; Williams, C.J.; Fathi, H.M.; Shamanian, M. Corrosion Behavior of Ti-6Al-4V with Different Thermomechanical Treatments and Microstructures. Corrosion 2010, 66, 065004. [Google Scholar] [CrossRef]

- Cvijović-Alagić, I.; Cvijović, Z.; Bajat, J.; Rakin, M. Composition and processing effects on the electrochemical characteristics of biomedical titanium alloys. Corrs. Sci. 2014, 83, 245–254. [Google Scholar] [CrossRef]

- Luiz de Assis, S.; Wolynec, S.; Costa, I. Corrosion characterization of titanium alloys by electrochemical techniques. Electrochim. Acta 2006, 51, 1815–1819. [Google Scholar] [CrossRef]

- Milošev, I.; Metikoš-Hukovic´, M.; Strehblow, H.H. Passive film on orthopaedic TiAlV alloy formed in physiological solution investigated by X-ray photoelectron spectroscopy. Biomaterials 2000, 21, 2103–2113. [Google Scholar] [CrossRef]

- Metikoš-Hukovic, M.; Kwokal, A.; Piljac, J. The influence of niobium and vanadium on passivity of titanium-based implants in physiological solution. Biomaterials 2003, 24, 3765–3775. [Google Scholar] [CrossRef]

- Marino, C.E.; Biaggio, S.R.; Rocha-Filho, R.C.; Bocchi, N. Voltammetric stability of anodic films on the Ti6Al4V alloy in chloride medium. Electrochim. Acta 2006, 51, 6580–6583. [Google Scholar]

- Mirza, A.; King, A.; Troakes, C.; Exley, C. Aluminium in brain tissue in familial Alzheimer’s disease. J. Trace Elem. Med. Biol. 2017, 40, 30–36. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Moretti, B.; Pesce, V.; MacCagnano, G.; Vicenti, G.; Lovreglio, P.; Soleo, L.; Apostoli, P. Peripheral neuropathy after hip replacement failure: Is vanadium the culprit? Lancet 2012, 379. [Google Scholar] [CrossRef]

- Akahori, T.; Niinomi, M.; Fukui, H.; Suzuki, A.; Hattori, Y.; Niwa, S. Ti-2003, Science and Technology; Wiley-VCH: Weinheim, Germany, 2004; p. 3181. [Google Scholar]

- Qazi, J.I.; Tsakiris, V.; Marquard, B.; Rack, H.J. Ti-2003, Science and Technology; WileyVCH: Weinheim, Germany, 2004; p. 1651. [Google Scholar]

- Qazi, J.; Rack, H. Metastable Beta Titanium Alloys for Orthopedic Applications. Adv. Eng. Mater. 2005, 7, 993–998. [Google Scholar] [CrossRef]

- Atapour, M.; Pilchak, L.A.; Frankel, S.G.; Williams, C.J. Corrosion behavior of β titanium alloys for biomedical applications. Mater. Sci. Eng. C 2011, 31, 885–891. [Google Scholar] [CrossRef]

- Pourbaix, M. Atlas of Electrochemical Equilibria in Aqueous Solution, 2nd ed.; National Association of Corrosion Engineers: Houston, TX, USA, 1974; p. 219. [Google Scholar]

- Kurup, A.; Dhatrak, P.; Khasnis, N. Surface modification techniques of titanium and titanium alloys for biomedical dental applications: A review. Mater. Today Proc. 2021, 39, 84–90. [Google Scholar] [CrossRef]

- Chen, P.C.; Hsieh, S.J.; Chen, C.C.; Zou, J. The Microstructure and Capacitance Characterizations of Anodic Titanium Based Alloy Oxide Nanotube. J. Nanomater. 2013, 2013, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Pedeferri, P. Corrosion Science and Engineering; Lazzari, L., Pedeferri, M.P., Eds.; Springer Nature Switzerland AG: Cham, Switzerland, 2018. [Google Scholar]

- Hussein, M.A.; Kumar, M.; Drew, R.; Al-Aqeeli, N. Electrochemical Corrosion and In Vitro Bioactivity of Nano-Grained Biomedical Ti-20Nb-13Zr Alloy in a Simulated Body Fluid. Materials 2018, 11, 26. [Google Scholar] [CrossRef] [Green Version]

- FKing, F.; Shoesmith, D. 13—Nuclear waste canister materials, corrosion behaviour and long-term performance in geological repository systems. In Woodhead Publishing Series in Energy, Geological Repository Systems for Safe Disposal of Spent Nuclear Fuels and Radioactive Waste; Ahn, J., Michael, J.A., Eds.; Woodhead Publishing: Cambridge, UK, 2010; pp. 379–420. [Google Scholar] [CrossRef]

- Tschernitschek, H.; Borchers, L.; Geurtsen, W. Nonalloyed titanium as a bioinert metal–A review. Quintessence Int. 2005, 36, 523–530. [Google Scholar] [CrossRef]

- Jacobs, J.J.; Gilbert, J.L.; Urban, R.M. Corrosion of metal orthopaedic implants. J. Bone Jt. Surg. 1998, 80-A, 268. [Google Scholar] [CrossRef]

- Gilbert, J.L.; Buckley, C.A.; Jacobs, J.J. In vivo corrosion of modular hip prothesis components in mixed and similar metal combinations. The effect of crevice, stress, motion, and alloy coupling. J. Biomed. Mater. Res. 1993, 27, 1533. [Google Scholar] [CrossRef]

- Grosgogeat, B.; Reclaru, L.; Lissac, M.; Dalard, F. Measurement and evaluation of galvanic corrosion between titanium/Ti6Al4V implants and dental alloys by electrochemical techniques and auger spectrometry. Biomaterials 1999, 20, 933. [Google Scholar] [CrossRef]

- Noumbissi, S.; Scarano, A.; Gupta, S. A Literature Review Study on Atomic Ions Dissolution of Titanium and Its Alloys in Implant Dentistry. Materials 2019, 12, 368. [Google Scholar] [CrossRef] [Green Version]

- Virtanen, S. Corrosion of biomedical implant materials. Corros. Rev. 2008, 26, 147–171. [Google Scholar] [CrossRef]

- Manivasagam, G.; Dhinasekaran, D.; Rajamanickam, A. Biomedical implants: Corrosion and its prevention—A review. Recent Patents Corros. Sci. 2010, 2, 40–54. [Google Scholar] [CrossRef] [Green Version]

- Gilbert, J.L.; Mali, S. Medical implant corrosion: Electrochemistry at metallic biomaterial surfaces. In Degradation of Implant Materials; Chapter 1; Eliaz, N., Ed.; Springer: New York, NY, USA, 2012; pp. 1–28. [Google Scholar]

- Virtanen, S. Degradation of titanium and its alloys. In Degradation of Implant Materials; Chapter 2; Eliaz, N., Ed.; Springer: New York, NY, USA, 2012; pp. 29–55. [Google Scholar]

- Witte, F.; Eliezer, A. Biodegradable metals. In Degradation of Implant Materials; Chapter 5; Eliaz, N., Ed.; Springer: New York, NY, USA, 2012; pp. 93–109. [Google Scholar]

- Pound, B.G. Corrosion behavior of metallic materials in biomedical applications. I. Ti and its alloys. Corros. Rev. 2014, 32, 1–20. [Google Scholar] [CrossRef]

- Eliaz, N. Corrosion of Metallic Biomaterials: A Review. Materials 2019, 12, 407. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Han, Y.; Xu, K. Photoexcited formation of bone apatite-like coatings on micro-arc oxidazed titanium. J. Biomed. Mater. Res. 2004, 71A, 608–614. [Google Scholar] [CrossRef]

- Landolt, D. (Ed.) Corrosion and Surface Science; CRC Press Taylor and Francis Group: Boca Raton, FL, USA, 2007; p. 33487. [Google Scholar]

- Lohrengel, M.M. Formation of ionic space charge layers in oxide films on valve metals. Electrochim. Acta 1994, 39, 1265–1271. [Google Scholar] [CrossRef]

- Tinghua, L.; Chongjian, D.; Yupeng, L.; Jun, W.; Xia, Z.; Xiaowei, G.; Wei, Z.; Daoai, W.; Donglai, Z. An Anodized Titanium/Sol-Gel Composite Coating with Self-Healable Superhydrophobic and Oleophobic Property. Front. Mater. 2021, 8, 64. [Google Scholar] [CrossRef]

- Milosev, I.; Popa, M. Electrochemical properties, chemical composition and thickness of passive film formed on novel Ti–20Nb–10Zr–5Ta alloy. Electrochim. Acta 2013, 99, 176–189. [Google Scholar] [CrossRef]

- Jarosz, M.; Grudzień, J.; Kapusta-Kołodziej, J.; Chudecka, A.; Sołtys, M.; Sulka, G.D. Chapter seven-Anodization of titanium alloys for biomedical applications. In Micro and Nano Technologies, Nanostructured Anodic Metal Oxides; Sulka, G.D., Ed.; Elsevier: Krakow, Poland, 2020; Volume 7, pp. 211–275. [Google Scholar]

- Zwilling, V.; Aucouturier, M.; Darque-Ceretti, E. Anodic oxidation of titanium and TA6V alloy in chromic media. An electrochemical approach. Electrochim. Acta. 1999, 45, 921–929. [Google Scholar] [CrossRef]

- Cheng, Y.; Yang, H.; Yang, Y.; Huang, J.; Wu, K.; Chen, Z.; Wang, X.; Lin, C.; Lai, Y. Progress in TiO2 nanotube coatings for biomedical applications: A review. J. Mater. Chem. B 2018, 6, 1862–1886. [Google Scholar] [CrossRef] [PubMed]

- Lin, N.; Li, D.; Zou, J.; Xie, R.; Wang, Z.; Tang, B. Surface Texture-Based Surface Treatments on Ti6Al4V Titanium Alloys for Tribological and Biological Applications: A Mini Review. Materials 2018, 11, 487. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Michalska-Domańska, M.; Łazińska, M.; Łukasiewicz, J.; Mol, J.M.C.; Durejko, T. Self-Organized Anodic Oxides on Titanium Alloys Prepared from Glycol- and Glycerol-Based Electrolytes. Materials 2020, 13, 4743. [Google Scholar] [CrossRef]

- Gulati, K.; Sinn Aw, M.; Findlay, D.; Losic, D. Local drug delivery to the bone by drug-releasing implants: Perspectives of nano-engineered titania nanotube arrays. Ther. Deliv. 2012, 3, 857–873. [Google Scholar] [CrossRef]

- Luz, A.R.; Santos, L.S.; Lepienski, C.M.; Kuroda, P.B.; Kuromoto, N.K. Characterization of the morphology, structure and wettability of phase dependent lamellar and nanotube oxides on anodized Ti-10Nb alloy. Appl. Surf. Sci. 2018, 448, 30–40. [Google Scholar] [CrossRef] [Green Version]

- Dikicia, T.; Erola, M.; Toparlia, M.; Celika, E. Characterization and photocatalytic properties of nanoporous titanium dioxide layer fabricated on pure titanium substrates by the anodic oxidation process. Ceram. Int. 2014, 40, 1587–1591. [Google Scholar] [CrossRef]

- Gao, A.; Hang, R.; Bai, L.; Tang, B.; Chu, P.K. Electrochemical surface engineering of titanium-based alloys for biomedical application. Electrochim. Acta 2018, 271, 699–718. [Google Scholar] [CrossRef]

- Indira, K.; Kamachi Mudali, U.; Nishimura, T.; Rajendran, N. A Review on TiO2 Nanotubes: Influence of Anodization Parameters, Formation Mechanism, Properties, Corrosion Behavior, and Biomedical Applications. J. Biol. Tribo-Corros. 2015, 1, 28. [Google Scholar] [CrossRef] [Green Version]

- Macak, M.J.; Tsuchiya, H.; Ghicov, A.; Yasuda, K.; Hahn, R.; Bauer, S.; Schmuki, P. TiO2 nanotubes: Self-organized electrochemical formation, properties and applications. Curr. Opin. Solid State Mater. Sci. 2007, 11, 3–18. [Google Scholar] [CrossRef]

- Poddar, S.; Bit, A.; Sinha, S.K. A study on influence of anodization on the morphology of titania nanotubes over Ti6Al4V alloy in correlation to hard tissue engineering application. Mater. Chem. Phys. 2020, 254, 123457. [Google Scholar] [CrossRef]

- Sarraf, M.; Nasiri-Tabrizi, B.; Yeong, C.H.; Madaah Hosseini, H.R.; Saber-Samandari, S.; Basirun, W.J.; Tsuzuki, T. Mixed oxide nanotubes in nanomedicine: A dead-end or a bridge to the future? Ceram. Int. 2021, 47, 2917–2948. [Google Scholar] [CrossRef]

- Rajyalakshmi, A.; Ercan, B.; Balasubramanian, K.; Webster, T.J. Reduced adhesion of macrophages on anodized titanium with select nanotube surface features. Int. J. Nanomed. 2011, 6, 1765–1771. [Google Scholar] [CrossRef] [Green Version]

- Tsuchiya, H.; Macak, J.M.; Muller, L.; Kunze, J.; Muller, F. Hydroxyapatite growth on anodic TiO2 nanotubes. J. Biol. Mater. Res. Part A 2006, 77A, 534–541. [Google Scholar] [CrossRef]

- von Wilmowsky, C.; Bauer, S.; Roedl, S.; Neukam, F.W.; Schmuki, P. The diameter of anodic TiO2 nanotubes affects bone formation and correlates with the bone morphogenetic protein-2 expression in vivo. Clin. Oral. Implant. Res. 2012, 23, 359–366. [Google Scholar] [CrossRef] [PubMed]

- Simchi, A.; Tamjid, E.; Pishbin, F.; Boccaccini, A.R. Recent progress in inorganic and composite coatings with bactericidal capability for orthopaedic applications. Nanomed. Nano Biol. Med. 2011, 7, 22–39. [Google Scholar] [CrossRef]

- Swain, S.; Misra, R.D.K.; You, C.K.; Rautray, T.R. TiO2 nanotubes synthesised on Ti-6Al-4V ELI exhibits enhanced osteogenic activity: A potential next-generation material to be used as medical implants. Mater. Technol. 2020. [Google Scholar] [CrossRef]

- Minagar, S.; Berndt, C.C.; Wang, J.; Ivanova, E.; Wen, C. A review of the application of anodization for the fabrication of nanotubes on metal implant surfaces. Acta Biol. 2012, 8, 2875–2888. [Google Scholar] [CrossRef]

- Tsuchiya, H.; Akaki, T.; Nakata, J.; Terada, D.; Tsuji, N.; Koizumi, Y.; Minamino, Y.; Schmuki, P.; Fujimoto, S. Anodic oxide nanotube layers on Ti–Ta alloys: Substrate composition, microstructure and self-organization on two-size scales. Corros. Sci. 2009, 51, 1528–1533. [Google Scholar] [CrossRef]

- Martínez, C.; Guerra, C.; Silva, D.; Cubillos, M.; Briones, F.; Muñoz, L.; Páez, M.A.; Aguilar, C.; Sancy, M. Effect of porosity on mechanical and electrochemical properties of Ti-6Al-4V alloy. Electrochim. Acta 2020, 338, 135858. [Google Scholar] [CrossRef]

- Assis, S.L.; Wolynec, S.; Costa, I. The electrochemical behaviour of Ti–13Nb–13Zr alloy in various solutions. Mater. Corros. 2008, 59, 739–743. [Google Scholar] [CrossRef]

- Popa, M.V.; Raducanu, V.; Vasilescu, E.; Drob, P.; Cojocaru, D.; Vasilescu, C.; Ivanescu, S.; Mirza Rosca, J.C. Mechanical and corrosion behaviour of a Ti–Al–Nb alloy after deformation at elevated temperatures. Mater. Corros. 2008, 59, 919–928. [Google Scholar] [CrossRef]

- Li, L.; Yu, K.; Zhang, K.; Liu, Y. Study of Ti–6Al–4V alloy spectral emissivity characteristics during thermal oxidation process. Int. J. Heat Mass Transf. 2016, 101, 699–706. [Google Scholar] [CrossRef]

- Jamesh, M.; Sankara Narayanan, T.S.N.; Chu, P.K. Thermal oxidation of titanium: Evaluation of corrosion resistance as a function of cooling rate. Mater. Chem. Phys. 2013, 138, 565–572. [Google Scholar] [CrossRef]

- Liu, X.; Chu, P.K.; Ding, C. Surface modification of titanium, titanium alloys, and related materials for biomedical applications. Mater. Sci. Eng. R Rep. 2004, 47, 49–121. [Google Scholar] [CrossRef] [Green Version]

- Ma, K.; Zhang, R.; Sun, J.; Liu, C. Oxidation Mechanism of Biomedical Titanium Alloy Surface and Experiment. Int. J. Corros. 2020, 1678615. [Google Scholar] [CrossRef]

- Zheng, L.; Qian, S.; Liu, X. Enhanced osteogenic activity and bacteriostatic effect of TiO2 coatings via hydrogen ion implantation. Mater. Lett. 2019, 253, 95–98. [Google Scholar] [CrossRef]

- Li, L.; Kong, Y.; Kim, H.; Kim, Y.; Kim, H.; Heo, S.; Koak, J. Improved biological performance of Ti implants due to surface modification by micro-arc oxidation. Biomaterials 2004, 25, 2867–2875. [Google Scholar] [CrossRef]

- Song, W.H.; Jun, Y.K.; Han, Y.; Hong, S.H. Biomimetic apatite coatings on micro-arc oxidized titania. Biomaterials 2004, 25, 3341. [Google Scholar] [CrossRef]

- Fadl-allah, S.A.; Mohsen, Q. Characterization of native and anodic oxide films formed on commercial pure titanium using electrochemical properties and morphology techniques. Appl. Surf. Sci. 2010, 256, 5849–5855. [Google Scholar] [CrossRef]

- Bundy, J.K. Corrosion and other electrochemical aspects of biomaterials. Crit. Rev. Biomed. Eng. 1993, 22, 139–251. [Google Scholar]

- Rogers, S.D.; Howie, D.W.; Graves, S.E.; Pearcy, M.J.; Haynes, D.R. In vitro human monocyte response to wear particles of titanium alloy containing vanadium or niobium. J. Bone Jt. Surg. 1997, 79, 311–315. [Google Scholar] [CrossRef]

- Bigi, A.; Nicoli-Aldini, N.; Bracci, B.; Zavan, B.; Boanini, E.; Sbaiz, F.; Panzavolta, S.; Zorzato, G.; Giardino, R.; Facchini, A.; et al. In vitro culture of mesenchymalcellsontonanocrystallinehydroxyapatite-coated Ti13Nb13Zr alloy. J. Biomed. Mater. Res. Part A 2007, 213–221. [Google Scholar] [CrossRef] [PubMed]

- Hernández-López, J.M.; Conde, A.; De Damborenea, J.; Arenas, M.A. Correlation of the nanostructure of the anodic layers fabricated on Ti-13Nb-13Zr with the electrochemical impedance response. Corros. Sci. 2015, 94, 61–69. [Google Scholar] [CrossRef]

- Hao, Y.Q.; Li, S.J.; Hao, Y.L.; Zhao, Y.L.; Ai, H.J. Effect of nanotube diameters on bioactivity of multifunctional titanium alloy. Appl. Surf. Sci. 2013, 268, 44–51. [Google Scholar] [CrossRef]

- Mendonça, G.; Mendonça, D.B.; Simões, L.G.; Araújo, A.L.; Leite, E.R.; Duarte, W.R.; Aragão, F.; Cooper, L. The effects of implant surface nanoscale features on osteoblast specific gene expression. Biomaterials 2009, 30, 4053–4062. [Google Scholar] [CrossRef]

- Yamazoe, M. Study of corrosion of combinations of titanium/Ti-6Al-4V implants and dental alloys. Dent. Mater. J. 2010, 29, 542–553. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chen, X.; Shah, K.; Dong, S.; Peterson, L.; Callagon La Plante, E.; Sant, G. Elucidating the corrosion-related degradation mechanisms of a Ti-6Al-4V dental implant. Natl. Library Med. 2020, 36, 431–441. [Google Scholar] [CrossRef]

- Wheelis, S.E.; Gindri, I.M.; Valderrama, P.; Wilson, T.G.; Huang, J.; Rodrigues, D.C. Effects of decontamination solutions on the surface of titanium: Investigation of surface morphology, composition, and roughness. Clin. Oral Implant. Res. 2016, 27, 329–340. [Google Scholar] [CrossRef]

- Souza, J.C.; Barbosa, S.L.; Ariza, E.A.; Henriques, M.; Teughels, W.; Ponthiaux, P.; Rocha, L.A. How do titanium and Ti6Al4V corrode in fluoridated medium as found in the oral cavity? An in vitro study. Mater. Sci. Eng. C 2015, 47, 384–393. [Google Scholar] [CrossRef] [Green Version]

- Nakagawa, M.; Matsuya, S.; Udoh, K. Effects of fluoride and dissolved oxygen concentrations on the corrosion behavior of pure titanium and titanium alloys. Dent. Mater. J. 2002, 21, 83–92. [Google Scholar] [CrossRef] [Green Version]

- Faverani, L.P.; Barao, V.A.; Ramalho-Ferreira, G.; Ferreira, M.B.; Garcia-Junior, I.R.; Assuncao, W.G. Effect of bleaching agents and soft drink on titanium surface topography. J. Biomed. Mater. Res. Part B Appl. Biomater. 2013, 102, 22–30. [Google Scholar] [CrossRef]

- Yu, F.; Addison, O.; Davenport, A.J. A synergistic effect of albumin and H2O2 accelerates corrosion of Ti6Al4V. Acta Biomater. 2015, 26, 355–365. [Google Scholar] [CrossRef] [Green Version]

- Romesburg, J.W.; Wasserman, P.L.; Schoppe, C.H. Metallosis and metal- induced synovitis following total knee arthroplasty: Review of radiographic and CT findings. J. Radiol. Case Rep. 2010, 4, 7–17. [Google Scholar] [CrossRef]

- Alves, V.A.; Reis, R.Q.; Santos, I.C.B.; Souza, D.G.; Gonçalves, T.D.F.; Pereira-Da-Silva, M.A.; Rossi, A.; Silva, L.A.D. In Situ impedance spectroscopy study of the electrochemical corrosion of Ti and Ti–6Al–4V in simulated body fluid at 25 °C and 37 °C. Corros. Sci. 2009, 51, 2473–2482. [Google Scholar] [CrossRef]

- Costa, B.C.; Tokuhara, C.K.; Rocha, L.A.; Oliveira, R.C.; Lisboa-Filho, P.N.; Pessoa, J.C. Vanadium ionic species from degradation of Ti-6Al-4V metallic implants: In vitro cytotoxicity and speciation evaluation. Mater. Sci. Eng. C 2019, 96, 730–739. [Google Scholar] [CrossRef]

- Pan, J.; Thierry, D.; Leygraf, C. Electrochemical and XPS studies of titanium for biomaterial application with respect to the effect of hydrogen peroxide. J. Biomed. Mater. Res. 1994, 28, 113–122. [Google Scholar] [CrossRef]

- Galstyan, V.; Vomiero, A.; Comini, E.; Faglia, G.; Sberveglieri, G. TiO2 nanotubular and nanoporous arrays by electrochemical anodization on different substrates. RSC Adv. 2011, 1, 1038–1044. [Google Scholar] [CrossRef]

- Ibriş, N.; Mirza Rosca, J.C. EIS study of Ti and its alloys in biological media. J. Electroanal. Chem. 2002, 526, 53–62. [Google Scholar] [CrossRef]

- Tamilselvi, S.; Raman, V.; Rajendran, N. Corrosion behaviour of Ti-6Al-7Nb and Ti-6Al-4V ELI alloys in the simulated body fluid solution by electrochemical impedance spectroscopy. Electrochim. Acta 2006, 52, 839–846. [Google Scholar] [CrossRef]

- Nabavi, F.H.; Aliofkhazraei, M. Morphology, composition and electrochemical properties of bioactive-TiO2/HA on CP-Ti and Ti6Al4V substrates fabricated by alkali treatment of hybrid plasma electrolytic oxidation process (estimation of porosity from EIS. Surf. Coat. Technol. 2019, 375, 266–291. [Google Scholar] [CrossRef]

- Orazem, E.N.; Tribollet, B. Electrochemical Impedance Spectroscopy; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2017. [Google Scholar]

- Attabi, S.; Mokhtari, M.; Taibi, Y.; Abdel-Rahman, I.; Hafez, B.; Elmsellem, H. Electrochemical and Tribological behavior of surface-treated titanium alloy Ti-6Al-4V. J. Bio- Tribo-Corros. 2019, 5, 2. [Google Scholar] [CrossRef]

- Fraoucene, H.; Sugiawati, V.A.; Hatem, D.; Vacandio, F.; Eyraud, M.; Pasquinelli, M.; Djenizian, T. Optical and Electrochemical Properties of Self-Organized TiO2 Nanotube Arrays From Anodized Ti-6Al-4V Alloy. Front. Chem. 2019, 7, 66. [Google Scholar] [CrossRef] [Green Version]

- Dimah, K.M.; Albeza, F.; Borrás, A.V.; Muñoz, I. Study of the biotribocorrosion behaviour of titanium biomedical alloys in simulated body fluids by electrochemical techniques. Wear 2012, 294, 409–418. [Google Scholar] [CrossRef]

- Durdu, S.; Usta, M.; Berkem, S.A. Bioactive coatings on Ti6Al4V alloy formed by plasma electrolytic oxidation. Surf. Coat. Technol. 2016, 301, 85–93. [Google Scholar] [CrossRef]

- Souza, M.E.P.; Ballester, M.; Freire, C.M.A. EIS characterisation of Ti anodic oxide porous films formed using modulated potential. Surf. Coat. Technol. 2007, 201, 7775–7780. [Google Scholar] [CrossRef]

- Nabavi, H.F.; Aliofkhazraei, M.; Rouhaghdam, A.S. Electrical characteristics and discharge properties of hybrid plasma electrolytic oxidation on titanium. J. Alloys Compd. 2017, 728, 464–475. [Google Scholar] [CrossRef]

- Lario, J.; Viera, M.; Vicente, A.; Igual, A.; Amigó, V. Corrosion behaviour of Ti-6Al-4V ELI nanotubes for biomedical applications. J. Mater. Sci. Technol. 2019, 8, 5548–5556. [Google Scholar] [CrossRef]

- Saha, S.K.; Park, Y.J.; Cho, S.O. Fabrication of highly ordered nanoporous oxide layer on Ti6Al4V surfaces for improved corrosion resistance property. J. Mol. Struct. 2021, 1223, 129244. [Google Scholar] [CrossRef]

- Hussein, A.H.; Gepreel, M.A.H.; Gouda, M.K.; Hefnawy, A.M.; Kandil, S.H. Biocompatibility of new Ti–Nb–Ta base alloys. Mater. Sci. Eng. C 2016, 61, 574–578. [Google Scholar] [CrossRef] [PubMed]

- Milosev, I.; Kosec, T.; Strehblow, H.-H. XPS and EIS study of the passive film formed on orthopaedic Ti–6Al–7Nb alloy in Hank’s physiological solution. Electrochim. Acta 2008, 53, 3547–3558. [Google Scholar] [CrossRef]

- Wei, T.; Huang, J.; Chao, C.Y.; Wei, L.; Tsai, M.; Chen, Y. Microstructure and elastic modulus evolution of TiTaNb alloys. J. Mech. Behav. Biomed. Mater. 2018, 86, 224–231. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.H.; Chuang, W.S.; Huang, J.C.; Wang, X.; Chou, H.S.; Lai, Y.J.; Lin, P.H. On the bio-corrosion and biocompatibility of TiTaNb medium entropy alloy films. Appl. Surf. Sci. 2020, 508, 145307. [Google Scholar] [CrossRef]

- Kim, S.; Choe, H. Highly ordered nanotube formation on beta typed Ti–xTa alloy surface. J. Nanosci. Nanotechnol. 2020, 20, 5791–5795. [Google Scholar] [CrossRef] [PubMed]

- Choe, H.-C. Nanotubular surface and morphology of Ti-binary and Ti-ternary alloys for biocompatibility. Thin Solid Films 2011, 519, 4652–4657. [Google Scholar] [CrossRef]

- Feng, X.; Macak, J.M.; Schmuki, P. Flexible self-organization of two size-scales oxide nanotubes on Ti45Nb alloy. Electrochem. Commun. 2007, 9, 2403–2407. [Google Scholar] [CrossRef]

- Jang, S.-H.; Choe, H.-C.; Ko, Y.-M.; Brantley, W.A. Electrochemical characteristics of nanotubes formed on Ti–Nb alloys. Thin Solid Films 2009, 517, 5038–5043. [Google Scholar] [CrossRef]

- Saji, V.S.; Choe, H.C.; Brantley, W.A. An electrochemical study on self-ordered nanoporous and nanotubular oxide on Ti–35Nb–5Ta–7Zr alloy for biomedical applications. Acta Biomater. 2009, 5, 2303–2310. [Google Scholar] [CrossRef]

- Choe, H.-C.; Kim, W.-G.; Jeong, Y.-H. Surface characteristics of HA coated Ti–30Ta–xZr and Ti–30Nb–xZr alloys after nanotube formation. Surf. Coat. Technol. 2010, 205, S305–S311. [Google Scholar] [CrossRef]

- Kim, E.-S.; Jeong, Y.-H.; Choe, H.-C.; Brantley, W.A. Formation of titanium dioxide nanotubes on Ti–30Nb–xTa alloys by anodizing. Thin Solid Films 2013, 549, 141–146. [Google Scholar] [CrossRef]

- Wang, P.; Li, H.; Zhang, Y.; Liu, H.; Guo, Y.; Liu, Z.; Zhao, S.; Yin, J.; Guo, Y. Morphology of nanotube arrays grown on Ti–35Nb–2Ta–3Zr alloys with different deformations. Appl. Surf. Sci. 2014, 290, 308–312. [Google Scholar] [CrossRef]

- Navarro-Laboulais, J.; Amigó-Mata, J.; Amigó-Borrás, V.; Igual-Muñoz, A. Electrochemical characterization and passivation behaviur of new beta-titanium alloys (Ti35Nb10Ta-xFe). Electrochim. Acta 2017, 227, 410–418. [Google Scholar] [CrossRef]

- Bocchetta, P.; Sunseri, C.; Masi, R.; Piazza, S.; Di Quarto, F. Influence of initial treatments of aluminium on the morphological features of electrochemically formed alumina membranes. Mater. Sci. Eng. C 2003, 23, 1021–1026. [Google Scholar] [CrossRef]

- Pawlik, A.; Rehman, M.A.U.; Nawaz, Q.; Bastan, E.F.; Sulka, D.G.; Boccaccini, A.R. Fabrication and characterization of electrophoretically deposited chitosan-hydroxyapatite composite coatings on anodic titanium dioxide layers. Electrochim. Acta 2019, 307, 465–473. [Google Scholar] [CrossRef]

- Kunze, J.; Müller, L.; Macak, J.M.; Greil, P.; Schmuki, P.; Müller, F.A. Time-dependent growth of biomimetic apatite on anodic TiO2 nanotubes. Electrochim. Acta 2008, 53, 6995–7003. [Google Scholar] [CrossRef]

- Sarraf, M.; Razak, B.A.; Crum, R.; Gámez, C.; Ramirez, B.; Noor Hayaty Binti Abu, K.; Bahman, N.-T.; Vijay, G.; Nazatul Liana, S.; Wan, J.B. Adhesion measurement of highly-ordered TiO2 nanotubes on Ti-6Al-4V alloy. In Processing and Application of Ceramics; National Library of Serbia: Belgrade, Serbia, 2017; Volume 11, pp. 311–321. [Google Scholar]

- Fojt, J.; Hybasek, V.; Jarolimova, P.; Pruchova, E.; Joska, L.; Malek, J. Corrosion behaviour of the titanium beta alloy nanotubular surface in the presence of fluoride ions. Koroze a Ochr. Mater. 2019, 63, 72–78. [Google Scholar] [CrossRef] [Green Version]

- Fojt, J.; Filip, V.; Joska, L. On the increasing of adhesive strength of nanotube layers on beta titanium alloys for medical applications. Appl. Surf. Sci. 2015, 355, 52–58. [Google Scholar] [CrossRef]

- Carobolante, J.P.A.; Silva, K.B.; Munoz Chaves, J.A.; Dias, M.F.; Netipanyj, K.; Popat, C.; Alves Claro, S.P.R. Nanoporous layer formation on the Ti10Mo8Nb alloy surface using anodic oxidation. Surf. Coat. Tech. 2020, 386, 125467. [Google Scholar] [CrossRef]

- Kim, W.-G.; Choe, H.-C. Nanostructure and corrosion behaviors of nanotube formed Ti-Zr alloy. Trans. Nonferrous Metals Soc. China 2009, 19, 1005–1008. [Google Scholar] [CrossRef]

- Yu, W.-Q.; Qiu, J.; Xu, L.; Zhang, F.-Q. Corrosion behaviors of TiO2 nanotube layers on titanium in Hank’s solution. Biomed. Mater. 2009, 4, 012–065. [Google Scholar] [CrossRef] [PubMed]

- Ossowska, A.; Sobieszcyk, S.; Supernak, M.; Zielinski, A. Morphology and properties of nanotubular oxide layer on the “Ti-13Zr-13Nb” alloy. Surf. Coat. Technol. 2014, 58, 1239–1248. [Google Scholar] [CrossRef]

- Kaseem, M.; Choe, H. Electrochemical and bioactive characteristics of the porous surface formed on Ti-xNb alloys via plasma electrolytic oxidation. Surf. Coat. Technol. 2019, 379, 125027. [Google Scholar] [CrossRef]

- Cordeiro, M.J.; Nagay, B.E.; Ribeiro, A.L.; da Cruz, N.; Rangel, E.; Fais, L.M.G.; Vaz, G.L.; Barao, R.A. Functionalization of an experimental Ti-Nb-Zr-Ta alloy with a biomimetic coating produced by plasma electrolytic oxidation. J. Alloys Compd. 2019, 770, 1038–1048. [Google Scholar] [CrossRef]

- Say, W.C.; Chen, C.C.; Shiu, Y.H. Monitoring the effects of growing titania nanotubes on titanium substrate by electrochemical impedance spectroscopy measurement. Jpn. J. Appl. Phys. 2009, 48, 004–035. [Google Scholar] [CrossRef]

- Guo, Y.; Chen, D.; Lu, W.; Jia, Y.; Wang, L.; Zhang, X. Corrosion resistance and in vitro response of a novel Ti35Nb2Ta3Zr alloy with a low Young’s modulus. Biomed. Mater. 2013, 8, 055004. [Google Scholar] [CrossRef]

- Marques, I.D.S.V.; Barão, V.A.R.; da Cruz, N.C.; Yuan, J.C.-C.; Mesquita, M.F.; Ricomini-Filho, A.P.; Sukotjo, C.; Mathew, M.T. Electrochemical behavior of bioactive coatings on cp-Ti surface for dental application. Corros. Sci. 2015, 100, 133–146. [Google Scholar] [CrossRef] [Green Version]

- Beline, T.; da Silva Vieira Marques, I.; Matos, A.O.; Ogawa, E.S.; Ricomini-Filho, A.P.A.P.; Rangel, E.C.; da Cruz, N.C.; Sukotjo, C.; Mathew, M.T.; Landers, R.; et al. Production of a biofunctional titanium surface using plasma electrolytic oxidation and glow-discharge plasma for biomedical applications. Biointerphases 2016, 11, 11013. [Google Scholar] [CrossRef] [Green Version]

- Wen, L.; Wang, Y.; Zhou, Y.; Guo, L.; Ouyang, H.J. Microstructure and corrosion resistance of modified 2024 Al alloy using surface mechanical attrition treatment combined with microarc oxidation process. Corros. Sci. 2011, 53, 473–480. [Google Scholar] [CrossRef]

- Mazigi, O.; Kannan, B.M.; Xu, J.; Choe, C.H.; Ye, Q. Biocompatibility and degradation of a low elastic modulus Ti-35Nb-3Zr alloy: Nanosurface engineering for enhanced degradation resistance. ACS Biomater. Sci. Eng. 2017, 3, 509–517. [Google Scholar] [CrossRef] [PubMed]

- Jáquez-Muñoz, J.M.; Tiburcio, C.G.; Miramontes, J.; Ángel, C.; López, F.E.; Robledo, P.Z.; Acuña, R.A.S.; Calderon, F.A. Electrochemical Behavior of Titanium Alloys Using Potentiodynamic Polarization. ECS Trans. 2021, 101, 173–178. [Google Scholar] [CrossRef]

- Jáquez-Muñoz, J.M.; Gaona-Tiburcio, C.; Cabral-Miramontes, J.; Nieves-Mendoza, D.; Maldonado-Bandala, E.; Olguín-Coca, J.; López-León, L.D. Flores-De los Rios, J.P.; Almeraya-Calderón, F. Electrochemical Noise Analysis of the Corrosion of Titanium Alloys in NaCl and H2SO4 Solutions. Metals 2021, 11, 105. [Google Scholar] [CrossRef]

- Zhou, H.; Li, F.; He, B.; Wang, J.; Sun, B. Air Plasma Sprayed Thermal Barrier Coatings on Titanium Alloy Substrates. Surf. Coat. Technol. 2007, 201, 7360–7367. [Google Scholar] [CrossRef]

- Zherebtsov, S.; Salishchev, G.; Łojkowski, W. Strengthening of a Ti-6Al-4V Titanium Alloy by Means of Hydrostatic Extrusion and other Methods. Mater. Sci. Eng. A 2009, 515, 43–48. [Google Scholar] [CrossRef]

- Liu, Y.Z.; Zu, X.T.; Wang, L.; Qiu, S.Y. Role of Aluminum Ion Implantation on Microstructure, Microhardness and Corrosion Properties of Titanium Alloy. Vacuum 2008, 83, 444–447. [Google Scholar] [CrossRef]

- Wang, Y.M.; Guo, L.X.; Ouyang, J.H.; Zhou, Y.; Jia, D.C. Interface Adhesion Properties of Functional Coatings on Titanium Alloy Formed by Microarc Oxidation Method. Appl. Surf. Sci. 2009, 255, 6875–6880. [Google Scholar] [CrossRef]

- Vadiraj, A.; Kamaraj, M. Effect of Surface Treatments on Fretting Fatigue Damage of Biomedical Titanium Alloys. Tribol. Int. 2007, 40, 82–88. [Google Scholar] [CrossRef]

- He, Z.Y.; Wang, Z.X.; Wang, W.B.; Fan, A.L.; Xu, Z. Surface Modification of Titanium Alloy Ti6Al4V by Plasma Niobium Alloying Process. Surf. Coat. Technol. 2007, 201, 5705–5709. [Google Scholar] [CrossRef]

- Cassar, G.; Avelar-Batista Wilson, J.C.; Banfield, S.; Housden, J.; Matthews, A.; Leyland, A. A Study of the Reciprocating-Sliding Wear Performance of Plasma Surface Treated Titanium Alloy. Wear 2010, 269, 60–70. [Google Scholar] [CrossRef]

- Singh, A.V.; Rosenkranz, D.; Ansari, M.H.D.; Singh, R.; Kanase, A.; Singh, S.P.; Johnston, B.; Tentschert, J.; Laux, P.; Luch, A. Artificial Intelligence and Machine Learning Empower Advanced Biomedical Material Design to Toxicity Prediction. Adv. Intell. Syst. 2020, 2, 2000084. [Google Scholar] [CrossRef]

- Ye, D.; Wang, W.; Xu, Z.; Yin, C.; Zhou, H.; Li, Y. Prediction of Thermal Barrier Coatings Microstructural Features Based on Support Vector Machine Optimized by Cuckoo Search Algorithm. Coatings 2020, 10, 704. [Google Scholar] [CrossRef]

- Singh, A.V.; Jahnke, T.; Wang, S.; Xiao, Y.; Alapan, Y.; Kharratian, S.; Onbasli, M.C.; Kozielski, K.; David, H.; Richter, G.; et al. Anisotropic Gold Nanostructures: Optimization via in Silico Modeling for Hyperthermia. ACS Appl. Nano Mater. 2018, 1, 6205–6216. [Google Scholar] [CrossRef]

- Karballaeezadeh, N.; Mohammadzadeh, S.D.; Moazemi, D.; Band, S.S.; Mosavi, A.; Reuter, U. Smart Structural Health Monitoring of Flexible Pavements Using Machine Learning Methods. Coatings 2020, 10, 1100. [Google Scholar] [CrossRef]

- Richard, C.; Kowandy, C.; Landoulsi, J.; Geetha, M.; Ramasawmy, H. Corrosion and Wear Behavior of Thermally Sprayed Nano Ceramic Coatings on Commercially Pure Titanium and Ti–13Nb–13Zr Substrates. Int. J. Refract. Met. Hard Mater. 2010, 28, 115–123. [Google Scholar] [CrossRef]

| Materials | σ0.2 [MPa] | σUTS [MPa] | E [GPa] | ɛmax [%]. |

|---|---|---|---|---|

| α-type | - | - | - | - |

| CP-Ti grade 1 | 170 | 240 | 105 | 24 |

| CP-Ti grade 2 | 275 | 345 | 105 | 2.20 |

| CP-Ti grade 3 | 380 | 445 | 105 | 18 |

| CP-Ti grade 4 | 480 | 550 | 105 | 15 |

| (α + β)-type | - | - | - | - |

| T-6Al-4V (annealed) | 825–869 | 895–930 | 110–114 | 6–10 |

| T-6Al-4V ELI (mil annealed) | 795–875 | 960–965 | 101–110 | 10–15 |

| T-6Al-4V | 795 | 860 | 105 | 10 |

| T-6Al-4V | 820 | 900 | 110 | 6 |

| T-6Al-4V | 585 | 690 | 100 | 15 |

| β-type | - | - | - | - |

| Ti-13Nb-13Zr (aged) | 836–908 | 973–1037 | 79–84 | 42–44 |

| Ti-12Mo-6Zr-2Fe (annealed) | 1000–1060 | 1060–1100 | 74–85 | 18–22 |

| Ti-15Mo (annealed) | 544 | 874 | 78 | 21 |

| Ti-15Mo-5Zr-3Al (annealed) | 838 | 852 | 80 | 25 |

| Ti-15Mo-5Zr-3Al (ST) | 1000–1060 | 1060–1100 | - | 18–22 |

| Ti-15Mo-2.8Nb-0.2Si-0.260 (annealed) | 945–987 | 979–999 | 83 | 16–18 |

| Ti-16Nb-10Hf | 736 | 851 | 81 | 10 |

| Ti-35.5Nb-7.3-Zr-5.7-Ta | 793 | 827 | 55–66 | 20 |

| Ti-29Nb-13Ta-4.6Zr (aged) | 864 | 911 | 80 | 13.2 |

| Ti-24Nb-4Zr-8Sn (Hot rolled) | 700 | 830 | 46 | 15.0 |

| Ti-24Nb-4Zr-8Sn (hot forged) | 570 | 755 | 55 | 13.0 |

| Ti-9Mn | 1023 | 1048 | 94 | 19.0 |

| Ti-6Mn-4Mo | 1090 | 1105 | 89 | 15.0 |

| Ti-10Fe-10Ta-4Zr | 960 | 1092 | - | 6.0 |

| Ti-12Cr | - | 760 | 65 | 18.5 |

| Ti-36Mb-2Ta-3Zr-0.3O | 670–1150 | 835–1180 | 32 | 6.5–12.9 |

| Ti-24Nb-0.5O | 665 | 810 | 54 | 22 |

| Ti-24Nb-0.5N | 665 | 665 | 43 | 13 |

| Ti23Nb-0.7Ta-2Zr | 280 | 400 | 55 | 33 |

| Ti-23Nb-0.7Ta-2Zr-1.2O | 830 | 880 | 60 | 14 |

| Bone | Age | N | n | σUTS [MPa] | E [GPa] | ɛ max [%] | ρ [g cm3] |

|---|---|---|---|---|---|---|---|

| Fibula | 41.5 | 17 | 20 | 100 | 19.2 | 2.10 | 1.91 |

| Fibula | 71 | 17 | 16 | 80 | 15.2 | 1.19 | 1.73 |

| Humerus * | 15–89 | 64 | 27 | 149 | 15.6 | 2.20 | 1.77 |

| Humerus ** | 15–89 | 64 | 16 | 151 | 16.1 | 1.90 | 1.72 |

| Tibia | 41.5 | 17 | 67 | 106 | 18.9 | 1.76 | 1.96 |

| Tibia | 71 | 17 | 34 | 84 | 16.2 | 1.56 | 1.83 |

| Tibia | 20–89 | 28 | 123 | 156 | 23.8 | 3.09 | – |

| Femur | 41.5 | 17 | 35 | 102 | 14.9 | 1.32 | 1.91 |

| Femur | 71 | 17 | 35 | 68 | 13.6 | 1.07 | 1.85 |

| Femur * | 15–89 | 64 | 29 | 141 | 15.2 | 2.00 | 1.90 |

| Femur * | 15–89 | 64 | 30 | 134 | 15.0 | 1.80 | 1.80 |

| Femur | 20–89 | 33 | 178 | 132 | 16.8 | 2.83 | – |

| Ti-Alloy | Passive Layer Formation (In Situ/Pre-Grown) | Biological Solution, T (°C), tIMM* (h) | Corrosion Current Density/μA cm−2 | Corrosion Potential/V vs. Ag/AgCl | Main Conclusions in Terms of Corrosion Resistance | Ref. |

|---|---|---|---|---|---|---|

| Ti6Al4V | − | NaCl, 25 | 0.043 | −0.538 | Unstable passive layer. | [165] |

| Ti6Al4V | in situ, NTs | Hank’s, 25, 168 Hank´s, 37, 168 | 0.104 0.164 | −0.297 −0.304 | At 25 °C: Ti and Ti6Al4V are similar. At 37 °C: corrosion resistance Ti–6Al–4V decreases due to passive film dissolution. | [117] |

| Ti6Al4V | in situ | PBS, 25, 0.33 PBS/BSA, 25, 0.33 | 0.18 0.75 | −0.497 −0.495 | Ti6Al4V alloy is better than Ti grade2 in PBS and PBS/BSA. In PBS/BSA, icorr increases for Ti6Al4V and decreases for Ti Grade 2. | [127] |

| Ti35Nb2Ta3Zr | − | Hank´s, 37, 2 | 0.101 | −0.320 | The high corrosion resistance and satisfactory biocompatibility make the novel Ti35Nb3Zr2Ta alloy a promising biomaterial for surgical implants. | [159] |

| Cp-Ti | PEO | AS, 37, 0.16 | 5.6 × 10−5 | −0.0546 | PEO surface treatment confers better electrochemical behavior to Ti alloys. | [160] |

| Cp-Ti | PEO 5 μm thick, porous oxide | AS at different pH (3.0, 6.5, and 9.0), SBF, 37, 0.16 | PEO AS(0.00019) SBF (0.00014) | PEO AS(0.15) SBF (0.081) | PEO improves surface properties and electrochemical stability of Cp-Ti surface due to Anatase/Rutile formation, while increasing protein adsorption. | [161] |

| Ti6Al4V | PEO | SBF, 25, 336 | 0.488 | −0.118 | Long times of PEO increase pore size and facilitate the penetration of ions; the passivation range is reduced. | [123] |

| Ti6Al4V ELI | EA TiO2 NTs | NaCl, 25 | 0.009 | 0.13 | EA permits the growth of a thick oxide compact layer at the base of TiO2 NTs array guaranteeing high corrosion resistance. | [131] |

| Ti-Nb-Zr-Ta | PEO | SBF, 37, 0.16 | 0.24 | 0.265 | Electrochemical behavior similar to Ti6Al4V, but with less tendency to transport ions across the oxide film. | [157] |

| Ti-xNb | PEO | SBF, 37, 24 | 0.006 | −0.353 | PEO coating made on the Ti-30Nb alloy gives great corrosion resistance and good bioactivity | [156] |

| Ti6Al4V | EA TiO2 NTs | NaCl, 25, 0.25 | 0.058 | 80.28 | Ti6Al4V covered by TiO2 NTs passive layer has higher corrosion resistance compared to the bare Ti6Al4V. | [132] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bocchetta, P.; Chen, L.-Y.; Tardelli, J.D.C.; Reis, A.C.d.; Almeraya-Calderón, F.; Leo, P. Passive Layers and Corrosion Resistance of Biomedical Ti-6Al-4V and β-Ti Alloys. Coatings 2021, 11, 487. https://doi.org/10.3390/coatings11050487

Bocchetta P, Chen L-Y, Tardelli JDC, Reis ACd, Almeraya-Calderón F, Leo P. Passive Layers and Corrosion Resistance of Biomedical Ti-6Al-4V and β-Ti Alloys. Coatings. 2021; 11(5):487. https://doi.org/10.3390/coatings11050487

Chicago/Turabian StyleBocchetta, Patrizia, Liang-Yu Chen, Juliana Dias Corpa Tardelli, Andréa Cândido dos Reis, Facundo Almeraya-Calderón, and Paola Leo. 2021. "Passive Layers and Corrosion Resistance of Biomedical Ti-6Al-4V and β-Ti Alloys" Coatings 11, no. 5: 487. https://doi.org/10.3390/coatings11050487

APA StyleBocchetta, P., Chen, L.-Y., Tardelli, J. D. C., Reis, A. C. d., Almeraya-Calderón, F., & Leo, P. (2021). Passive Layers and Corrosion Resistance of Biomedical Ti-6Al-4V and β-Ti Alloys. Coatings, 11(5), 487. https://doi.org/10.3390/coatings11050487