Employing Nanosilver, Nanocopper, and Nanoclays in Food Packaging Production: A Systematic Review

Abstract

:1. Introduction

2. Methods

2.1. Search Strategy

2.2. Study Selection

3. Results

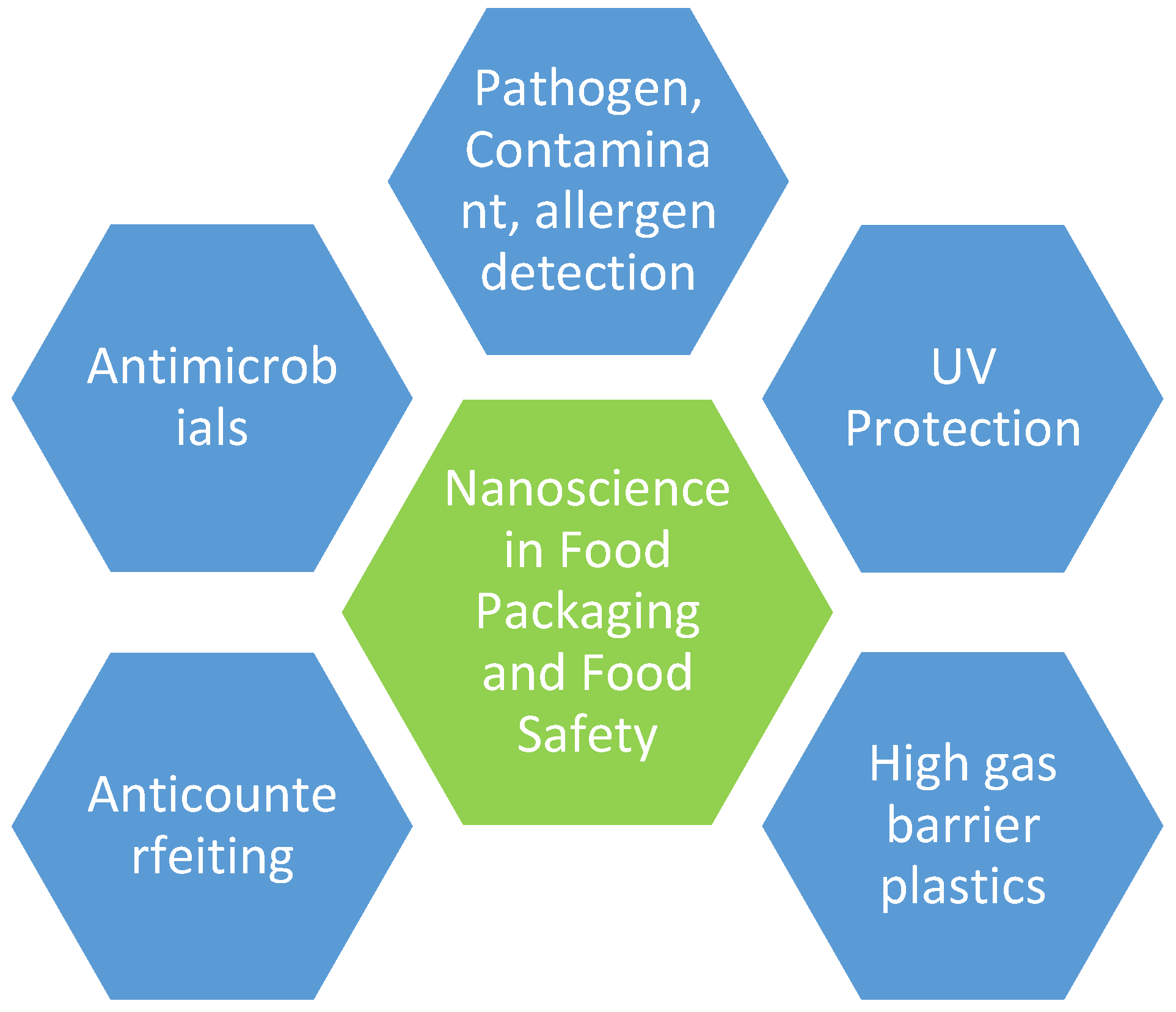

3.1. Nanomaterials in Food Packaging: Definition, Characteristics, and Types

3.2. Inorganic and Metal Oxide Nanomaterials

3.2.1. Silver-Based Nanoparticles

3.2.2. Copper-Based Nanoparticles

3.2.3. Titanium Dioxide-Based Nanoparticles

3.2.4. Zinc Oxide-Based Nanoparticles

3.2.5. Silicon Dioxide-Based Nanoparticles

3.2.6. Nano Clays

3.2.7. Montmorillonite Nanomaterials (MMT)

3.2.8. Organic Polymer-Based Nanomaterials

4. Natural Biopolymers

4.1. Synthetic Polymers

4.2. Polylactic Acid (PLA)

4.3. Polyhydroxyalkanoates (PHAs)

4.4. Polyamine Polyacid (PPA)

4.5. Starch Nanocrystals

4.6. Chitin/chitosan Nanoparticles

4.7. Protein Nanocomposites

5. Effects of Migration of Nanoparticles in Foods on Human Health Situation

6. Environmentally Friendly Nano Packaging in Food

7. Improvement in Barrier Properties of Polymers by Nanoparticles in Food Packaging

8. Discussion

9. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| Silver | Ag |

| Copper | Cu |

| Gold | Au |

| Iron oxide | (Fe3O4) |

| Copper oxide | CuO |

| Titanium oxide | TiO2 |

| Zinc oxide | ZnO |

| Magnesium oxide | MgO |

| Calcium oxide | CaO |

| Reactive oxygen species | ROS |

| Water vapor transmission rate | WVTR |

| Molecularly imprinted polymer | MIP |

| Starch nanocrystals | SNCs |

| Methacrylic acid | MAA |

| Electroless nickel plating | ENP |

| Nanoparticles | NPs |

| Silicon dioxide or silica | nSiO2 |

| Chitosan-tripolyphosphate | CS-TPP |

| Carbon nanotubes | CNTs |

| Polyvinyl pyrrolidone | PVP |

| Thyme essential oil | TEO |

| Salmonella Typhi | S. Typhi |

| Escherichia coli | E. coli |

| Staphylococcus aureus | S. aureus |

| Listeria monocytogenes | L. monocytogenes |

| Crohn’s disease | CD |

| Pseudomonas aeruginosa | P. aeruginosa |

| Montmorillonite | MMT |

| Total microbial count | CFU |

| Low-density polyethylene | LDPE |

| Polypropylene | PP |

| Polyurethane | PU |

| Polyvinyl chloride | PVC |

| Polylactic acid | PLA |

| -ε-Caprolactone | PCL |

| Polybutylene succinate | PBS |

| And polyvinyl alcohol | PVA |

| Polyamine polyacid | PPA |

| Polyhydroxyalkanoates | PHAs |

References

- Azeredo, H.M.C.d. Nanocomposites for food packaging applications. Food Res. Int. 2009, 42, 1240–1253. [Google Scholar] [CrossRef] [Green Version]

- Roco, M.C. The long view of nanotechnology development: The National Nanotechnology Initiative at 10 years. J. Nanoparticle Res. 2011, 13, 427–445. [Google Scholar] [CrossRef] [Green Version]

- Insights, F.B. 2021. Available online: https://www.fortunebusinessinsights.com/industry-reports/food-packaging-market-101941 (accessed on 16 April 2021).

- Paul, P.; Rhim, J.-W. Nano and Nanocomposite Antimicrobial Materials for Food Packaging Applications; Future Medicine: London, UK, 2014; pp. 34–48. [Google Scholar]

- Ahari, H. The Use of Innovative Nano emulsions and Nano-Silver Composites Packaging for anti-bacterial properties: An article review. IJAAH 2017, 3, 61–73. [Google Scholar] [CrossRef] [Green Version]

- Naik, K.; Kowshik, M. Anti-quorum sensing activity of AgCl-TiO2 nanoparticles with potential use as active food packaging material. J. Appl. Microbiol. 2014, 117, 972–983. [Google Scholar] [CrossRef]

- Ebrahimi, Y.; Peighambardoust, S.J.; Peighambardoust, S.H.; Karkaj, S.Z. Development of Antibacterial Carboxymethyl Cellulose-Based Nanobiocomposite Films Containing Various Metallic Nanoparticles for Food Packaging Applications. J. Food Sci. 2019, 84, 2537–2548. [Google Scholar] [CrossRef]

- Song, H.; Li, B.; Lin, Q.; Wu, H.; Chen, Y. Migration of silver from nanosilver-polyethylene composite packaging into food simulants. Food Addit. Contam. Part A Chem. Anal. Control. Expo. Risk Assess. 2011, 28, 1758–1762. [Google Scholar] [CrossRef] [PubMed]

- Becaro, A.A.; Puti, F.C.; Correa, D.S.; Paris, E.C.; Marconcini, J.M.; Ferreira, M.D. Polyethylene Films Containing Silver Nanoparticles for Applications in Food Packaging: Characterization of Physico-Chemical and Anti-Microbial Properties. J. Nanosci. Nanotechnol. 2015, 15, 2148–2156. [Google Scholar] [CrossRef]

- Sarwar, M.S.; Niazi, M.B.K.; Jahan, Z.; Ahmad, T.; Hussain, A. Preparation and characterization of PVA/nanocellulose/Ag nanocomposite films for antimicrobial food packaging. Carbohydr. Polym. 2018, 184, 453–464. [Google Scholar] [CrossRef] [PubMed]

- Vishnuvarthanan, M.; Rajeswari, N. Preparation and characterization of carrageenan/silver nanoparticles/Laponite nanocomposite coating on oxygen plasma surface modified polypropylene for food packaging. J. Food Sci. Technol. 2019, 56, 2545–2552. [Google Scholar] [CrossRef]

- Gallocchio, F.; Cibin, V.; Biancotto, G.; Roccato, A.; Muzzolon, O.; Carmen, L.; Simone, B.; Manodori, L.; Fabrizi, A.; Patuzzi, I.; et al. Testing nano-silver food packaging to evaluate silver migration and food spoilage bacteria on chicken meat. Food Addit. Contam. Part A Chem. Anal. Control. Expo. Risk Assess. 2016, 33, 1063–1071. [Google Scholar] [CrossRef] [PubMed]

- Longano, D.; Ditaranto, N.; Cioffi, N.; di Niso, F.; Sibillano, T.; Ancona, A.; Conte, A.; del Nobile, M.A.; Sabbatini, L.; Torsi, L. Analytical characterization of laser-generated copper nanoparticles for antibacterial composite food packaging. Anal. Bioanal. Chem. 2012, 403, 1179–1186. [Google Scholar] [CrossRef] [PubMed]

- Saravanakumar, K.; Sathiyaseelan, A.; Mariadoss, A.V.A.; Xiaowen, H.; Wang, M. Physical and bioactivities of biopolymeric films incorporated with cellulose, sodium alginate and copper oxide nanoparticles for food packaging application. Int. J. Biol. Macromol. 2020, 153, 207–214. [Google Scholar] [CrossRef]

- Rhim, J.W.; Ng, P.K. Natural biopolymer-based nanocomposite films for packaging applications. Crit. Rev. Food Sci. Nutr. 2007, 47, 411–433. [Google Scholar] [CrossRef] [PubMed]

- Ebrahimiasl, S.; Rajabpour, A. Synthesis and characterization of novel bactericidal Cu/HPMC BNCs using chemical reduction method for food packaging. J. Food Sci. Technol. 2015, 52, 5982–5988. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Beltrán, A.; Valente, A.J.M.; Jiménez, A.; Garrigós, M.C. Characterization of poly(ε-caprolactone)-based nanocomposites containing hydroxytyrosol for active food packaging. J. Agric. Food Chem. 2014, 62, 2244–2252. [Google Scholar] [CrossRef] [Green Version]

- Abolghasemi-Fakhri, L.; Ghanbarzadeh, B.; Dehghannya, J.; Abbasi, F.; Adun, P. Styrene monomer migration from polystyrene based food packaging nanocomposite: Effect of clay and ZnO nanoparticles. Food Chem. Toxicol. 2019, 129, 77–86. [Google Scholar] [CrossRef]

- Han, C.; Zhao, A.; Varughese, E.; Sahle-Demessie, E. Evaluating Weathering of Food Packaging Polyethylene-Nano-clay Composites: Release of Nanoparticles and their Impacts. NanoImpact 2017, 9, 61–71. [Google Scholar] [CrossRef]

- Echegoyen, Y.; Rodríguez, S.; Nerín, C. Nanoclay migration from food packaging materials. Food Addit. Contam. Part A Chem. Anal. Control. Expo. Risk Assess. 2016, 33, 530–539. [Google Scholar] [CrossRef]

- Busolo, M.; Fernandez, P.; Ocio, M.J.; Lagaron, J.M. Novel Silver-based Nanoclay as an Antimicrobial in Polylactic Acid Food Packaging Coatings. Food Addit. Contam. Part A Chem. Anal. Control. Expo. Risk Assess. 2010, 27, 1617–1626. [Google Scholar] [CrossRef]

- Scarfato, P.; di Maio, L.; Milana, M.R.; Giamberardini, S.; Denaro, M.; Incarnato, L. Study of performance properties, lactic acid specific migration and swelling by simulant of biodegradable poly(lactic acid)/nanoclay multilayer films for food packaging. Food Addit. Contam. Part A 2017, 34, 1730–1742. [Google Scholar] [CrossRef]

- Maisanaba, S.; Guzman-Guillen, R.; Puerto, M.; Gutierrez-Praena, D.; Ortuno, N.; Jos, A. In vitro toxicity evaluation of new silane-modified clays and the migration extract from a derived polymer-clay nanocomposite intended to food packaging applications. J. Hazard Mater. 2018, 341, 313–320. [Google Scholar] [CrossRef]

- Iamareerat, B.; Singh, M.; Sadiq, M.B.; Anal, A.K. Reinforced cassava starch based edible film incorporated with essential oil and sodium bentonite nanoclay as food packaging material. J. Food Sci. Technol. 2018, 55, 1953–1959. [Google Scholar] [CrossRef]

- Sharma, R.; Jafari, S.M.; Sharma, S. Antimicrobial bio-nanocomposites and their potential applications in food packaging. Food Control. 2020, 112, 107086. [Google Scholar] [CrossRef]

- Vasile, C.; Rapua, M.; Cstefan, M.; Stan, M.; Macavei, S.; Darie-Nictua, R.N.; Barbu-Tudoran, L.; Vodnar, D.C.; Popa, E.E.; Cstefan, R.; et al. New PLA/ZnO: Cu/Ag bionanocomposites for food packaging. Express Polym. Lett. 2017, 11, 531–544. [Google Scholar] [CrossRef]

- Meira, S.M.M.; Zehetmeyer, G.; Scheibel, J.M.; Werner, J.O.; Brandelli, A. Starch-halloysite nanocomposites containing nisin: Characterization and inhibition of Listeria monocytogenes in soft cheese. LWT Food Sci. Technol. 2016, 68, 226–234. [Google Scholar] [CrossRef]

- Emamifar, A.; Kadivar, M.; Shahedi, M.; Soleimanian-Zad, S. Evaluation of nanocomposite packaging containing Ag and ZnO on shelf life of fresh orange juice. Innov. Food Sci. Emerg. Technol. 2010, 11, 742–748. [Google Scholar] [CrossRef]

- Li, H.; Li, F.; Wang, L.; Sheng, J.; Xin, Z.; Zhao, L.; Xiao, H.; Zheng, Y.; Hu, Q. Effect of nano-packing on preservation quality of Chinese jujube (Ziziphus jujuba Mill. var. inermis (Bunge) Rehd). Food Chem. 2009, 114, 547–552. [Google Scholar] [CrossRef]

- Llorens, A.; Lloret, E.; Picouet, P.A.; Trbojevich, R.; Fernandez, A. Metallic-based micro and nanocomposites in food contact materials and active food packaging. Trends Food Sci. Technol. 2012, 24, 19–29. [Google Scholar] [CrossRef]

- Fernandez, A.; Picouet, P.; Lloret, E. Reduction of the spoilage-related microflora in absorbent pads by silver nanotechnology during modified atmosphere packaging of beef meat. J. Food Protect. 2010, 73, 2263–2269. [Google Scholar] [CrossRef]

- Jin, T.; Gurtler, J.B. Inactivation of Salmonella in liquid egg albumen by antimicrobial bottle coatings infused with allyl isothiocyanate, nisin and zinc oxide nanoparticles. J. Appl. Microbiol. 2011, 110, 704–712. [Google Scholar] [CrossRef] [PubMed]

- Nobile, M.D.; Cannarsi, M.; Altieri, C.; Sinigaglia, M.; Iacoviello, C.; D’Agostino, R. Effect of Ag-containing nano-composite active packaging system on survival of Alicyclobacillus acidoterrestris. J. Food Sci. 2004, 69, E379–E383. [Google Scholar] [CrossRef]

- Gorrasi, G.; Bugatti, V. Edible bio-nano-hybrid coatings for food protection based on pectins and LDH-salicylate: Preparation and analysis of physical properties. LWT Food Sci. Technol. 2016, 69, 139–145. [Google Scholar] [CrossRef]

- López, O.V.; Castillo, L.A.; Garcia, M.A.; Villar, M.A.; Barbosa, S.E. Food packaging bags based on thermoplastic corn starch reinforced with talc nanoparticles. Food Hydrocoll. 2015, 43, 18–24. [Google Scholar] [CrossRef]

- Nagarajan, M.; Benjakul, S.; Prodpran, T.; Songtipya, P. Effects of pHs on properties of bio-nanocomposite based on tilapia skin gelatin and Cloisite Na+. Int. J. Biol. Macromol. 2015, 75, 388–397. [Google Scholar] [CrossRef]

- Sanuja, S.; Agalya, A.; Umapathy, M.J. Synthesis and characterization of zinc oxide–neem oil–chitosan bionanocomposite for food packaging application. Int. J. Biol. Macromol. 2015, 74, 76–84. [Google Scholar] [CrossRef]

- Dervisevic, M.; Custiuc, E.; Ccevik, E.; Csenel, M. Construction of novel xanthine biosensor by using polymeric mediator/MWCNT nanocomposite layer for fish freshness detection. Food Chem. 2015, 181, 277–283. [Google Scholar] [CrossRef]

- Jiang, T.; Feng, L.; Wang, Y. Effect of alginate/nano-Ag coating on microbial and physicochemical characteristics of shiitake mushroom (Lentinus edodes) during cold storage. Food Chem. 2013, 141, 954–960. [Google Scholar] [CrossRef]

- Mohammed Fayaz, A.; Balaji, K.; Girilal, M.; Kalaichelvan, P.T.; Venkatesan, R. Mycobased synthesis of silver nanoparticles and their incorporation into sodium alginate films for vegetable and fruit preservation. J. Agric. Food Chem. 2009, 57, 6246–6252. [Google Scholar] [CrossRef]

- Akbar, A.; Anal, A.K. Zinc oxide nanoparticles loaded active packaging, a challenge study against Salmonella typhimurium and Staphylococcus aureus in ready-to-eat poultry meat. Food Control. 2014, 38, 88–95. [Google Scholar] [CrossRef]

- Severino, R.; Ferrari, G.; Vu, K.D.; Donsi, F.; Salmieri, S.; Lacroix, M. Antimicrobial effects of modified chitosan based coating containing nanoemulsion of essential oils, modified atmosphere packaging and gamma irradiation against Escherichia coli O157: H7 and Salmonella Typhimurium on green beans. Food Control. 2015, 50, 215–222. [Google Scholar] [CrossRef]

- Youssef, A.M.; El-Sayed, S.M.; Salama, H.H.; El-Sayed, H.S.; Dufresne, A. Evaluation of bionanocomposites as packaging material on properties of soft white cheese during storage period. Carbohydr. Polym. 2015, 132, 274–285. [Google Scholar] [CrossRef]

- Wakai, M.; Almenar, E. Effect of the presence of montmorillonite on the solubility of whey protein isolate films in food model systems with different compositions and pH. Food Hydrocoll. 2015, 43, 612–621. [Google Scholar] [CrossRef]

- Kumar, P.; Sandeep, K.P.; Alavi, S.; Truong, V.D.; Gorga, R.E. Preparation and characterization of bio-nanocomposite films based on soy protein isolate and montmorillonite using melt extrusion. J. Food Eng. 2010, 100, 480–489. [Google Scholar] [CrossRef]

- Fernández, A.; Picouet, P.; Lloret, E. Cellulose-silver nanoparticle hybrid materials to control spoilage-related microflora in absorbent pads located in trays of fresh-cut melon. Int. J. Food Microbiol. 2010, 142, 222–228. [Google Scholar] [CrossRef] [PubMed]

- An, J.; Zhang, M.; Wang, S.; Tang, J. Physical, chemical and microbiological changes in stored green asparagus spears as affected by coating of silver nanoparticles-PVP. LWT Food Sci. Technol. 2008, 41, 1100–1107. [Google Scholar] [CrossRef]

- Li, X.; Li, W.; Jiang, Y.; Ding, Y.; Yun, J.; Tang, Y.; Zhang, P. Effect of nano-ZnO-coated active packaging on quality of fresh-cut ‘Fuji’apple. Int. J. Food Sci. Technol. 2011, 46, 1947–1955. [Google Scholar] [CrossRef]

- Issa, A.; Ibrahim, S.A.; Tahergorabi, R. Impact of sweet potato starch-based nanocomposite films activated with thyme essential oil on the shelf-life of baby spinach leaves. Foods 2017, 6, 43. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Terefe, N.S.; Yang, Y.H.; Knoerzer, K.; Buckow, R.; Versteeg, C. High pressure and thermal inactivation kinetics of polyphenol oxidase and peroxidase in strawberry puree. Innov. Food Sci. Emerg. Technol. 2010, 11, 52–60. [Google Scholar] [CrossRef]

- Zhou, L.; Lv, S.; He, G.; He, Q.; Shi, B.I. Effect of pe/ag2o nano-packaging on the quality of apple slices. J. Food Q. 2011, 34, 171–176. [Google Scholar] [CrossRef]

- Nalwa, H.S. Handbook of Nanostructured Materials and Nanotechnology; Academic Press: San Diego, CA, USA, 2000; Volume 3. [Google Scholar]

- Erdogan, O.; Kara, M. Analytical approach to the waste management of nanomaterials in developing countries. Front. Drug Chem. Clin. Res. 2019, 2, 1–5. [Google Scholar]

- Bumbudsanpharoke, N.; Choi, J.; Ko, S. Applications of Nanomaterials in Food Packaging. J. Nanosci. Nanotechnol. 2015, 15, 6357–6372. [Google Scholar] [CrossRef]

- Singh, T.; Shukla, S.; Kumar, P.; Wahla, V.; Bajpai, V.K.; Rather, I.A. Application of Nanotechnology in Food Science: Perception and Overview. Front. Microbiol. 2017, 8. [Google Scholar] [CrossRef] [Green Version]

- Jane Selia, R.C.; Jose, A. Teixeira Active and Intelligent Packaging for Milk and Milk Products; CRC Press: Boca Raton, FA, USA, 2009; pp. 175–199. [Google Scholar]

- Cheeseman, S.; Christofferson, A.J.; Kariuki, R.; Cozzolino, D.; Daeneke, T.; Crawford, R.J.; Truong, V.K.; Chapman, J.; Elbourne, A. Antimicrobial Metal Nanomaterials: From Passive to Stimuli-Activated Applications. Adv. Sci. 2020, 7, 1902913. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Singh, P.; Garg, A.; Pandit, S.; Mokkapati, V.R.S.S.; Mijakovic, I. Antimicrobial Effects of Biogenic Nanoparticles. Nanomaterials 2018, 8, 1009. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Blecher, K.; Nasir, A.; Friedman, A. The growing role of nanotechnology in combating infectious disease. Virulence 2011, 2, 395–401. [Google Scholar] [CrossRef] [Green Version]

- Pelgrift, R.Y.; Friedman, A.J. Nanotechnology as a therapeutic tool to combat microbial resistance. Adv. Drug Deliv. Rev. 2013, 65, 1803–1815. [Google Scholar] [CrossRef]

- Wang, L.; Hu, C.; Shao, L. The antimicrobial activity of nanoparticles: Present situation and prospects for the future. Int. J. Nanomed. 2017, 12, 1227–1249. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Memar, M.Y.; Ghotaslou, R.; Samiei, M.; Adibkia, K. Antimicrobial use of reactive oxygen therapy: Current insights. Infect. Drug Resist. 2018, 11, 567–576. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Khan, M.M.; Adil, S.F.; Al-Mayouf, A. Metal oxides as photocatalysts. J. Saudi Chem. Soc. 2015, 19, 462–464. [Google Scholar] [CrossRef] [Green Version]

- Pereda, M.; Marcovich, N.E.; Ansorena, M.R. Nanotechnology in Food Packaging Applications: Barrier Materials, Antimicrobial Agents, Sensors, and Safety Assessment. In Handbook of Ecomaterials; Martínez, L.M.T., Kharissova, O.V., Kharisov, B.I., Eds.; Springer International Publishing: Cham, Switzerland, 2017; pp. 1–22. [Google Scholar]

- Sridhar, L.; Gupta, R.; Bhardwaj, M. Barrier Properties of Polymer Nanocomposites. Ind. Eng. Chem. Res. 2006, 45, 8282–8289. [Google Scholar] [CrossRef]

- Vasile, C. Polymeric Nanocomposites and Nanocoatings for Food Packaging: A Review. Materials 2018, 11, 1834. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Luzi, F.; Torre, L.; Kenny, J.M.; Puglia, D. Bio-and fossil-based polymeric blends and nanocomposites for packaging: Structure–property relationship. Materials 2019, 12, 471. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Fernández-Menéndez, T.; Garcia-Lopez, D.; Arguelles, A.; Fernandez, A.; Vina, J. Industrially produced PET nanocomposites with enhaced properties for food packaging applications. Polym. Test. 2020, 90, 106729. [Google Scholar] [CrossRef]

- Dallas, P.; Sharma, V.K.; Zboril, R. Silver polymeric nanocomposites as advanced antimicrobial agents: Classification, synthetic paths, applications, and perspectives. Adv. Colloid Interface Sci. 2011, 166, 119–135. [Google Scholar] [CrossRef]

- Feldman, D. Polymer Nanocomposite Barriers. J. Macromol. Sci. Part A 2013, 50, 441–448. [Google Scholar] [CrossRef]

- Carrera, M.C.; Erdmann, E.; Destéfanis, H.A. Barrier Properties and Structural Study of Nanocomposite of HDPE/Montmorillonite Modified with Polyvinylalcohol. J. Chem. 2013, 2013, 679567. [Google Scholar] [CrossRef]

- Dufresne, A. Processing of polymer nanocomposites reinforced with polysaccharide nanocrystals. Molecules 2010, 15, 4111–4128. [Google Scholar] [CrossRef] [Green Version]

- Fotie, G.; Limbo, S.; Piergiovanni, L. Manufacturing of Food Packaging Based On Nanocellulose: Current Advances and Challenges. Nanomaterials 2020, 10, 1726. [Google Scholar] [CrossRef]

- Aulin, C.; Karabulut, E.; Tran, A.; Wågberg, L.; Lindström, T. Transparent nanocellulosic multilayer thin films on polylactic acid with tunable gas barrier properties. ACS Appl. Mater. Interfaces 2013, 5, 7352–7359. [Google Scholar] [CrossRef]

- Park, H.-M.; Lee, W.; Park, C.; Cho, W.; Ha, C. Environmentally friendly polymer hybrids Part I Mechanical, thermal, and barrier properties of thermoplastic starch/clay nanocomposites. J. Mater. Sci. 2003, 38, 909–915. [Google Scholar] [CrossRef]

- Trifol, J.; Plackett, D.; Sillard, C.; Szabo, P.; Bras, J.; Daugaard, A.E. Hybrid poly(lactic acid)/nanocellulose/nanoclay composites with synergistically enhanced barrier properties and improved thermomechanical resistance. Polym. Int. 2016, 65, 988–995. [Google Scholar] [CrossRef] [Green Version]

- Mahmoodi, A.; Ghodrati, S.; Khorasani, M. High-Strength, Low-Permeable, and Light-Protective Nanocomposite Films Based on a Hybrid Nanopigment and Biodegradable PLA for Food Packaging Applications. ACS Omega 2019, 4, 14947–14954. [Google Scholar] [CrossRef] [Green Version]

- Caon, T.; Martelli, S.M.; Fakhouri, F.M. 18—New trends in the food industry: Application of nanosensors in food packaging. In Nanobiosensors; Grumezescu, A.M., Ed.; Academic Press: Cambridge, MA, USA, 2017; pp. 773–804. [Google Scholar]

- Fuertes, G.; Soto, I.; Carrasco, R.; Vargas, M.; Sabattin, J.; Lagos, C. Intelligent Packaging Systems: Sensors and Nanosensors to Monitor Food Quality and Safety. J. Sens. 2016, 2016, 4046061. [Google Scholar] [CrossRef] [Green Version]

- Kumar, V.; Guleria, P.; Mehta, S.K. Nanosensors for food quality and safety assessment. Environ. Chem. Lett. 2017, 15, 165–177. [Google Scholar] [CrossRef]

- Silina, Y.E.; Gernaey, K.V.; Semenova, D.; Iatsunskyi, I. Application of Organic-Inorganic Hybrids in Chemical Analysis, Bio- and Environmental Monitoring. Appl. Sci. 2020, 10, 1458. [Google Scholar] [CrossRef] [Green Version]

- Rosi, N.L.; Mirkin, C.A. Nanostructures in biodiagnostics. Chem. Rev. 2005, 105, 1547–1562. [Google Scholar] [CrossRef] [PubMed]

- Bülbül, G.; Hayat, A.; Andreescu, S. Portable Nanoparticle-Based Sensors for Food Safety Assessment. Sensors 2015, 15, 30736–30758. [Google Scholar] [CrossRef] [PubMed]

- Razavilar, V.; Ahari, H.; Adergani, B.A.; Anvar, A.A. A central composite face-centered design for optimizing the detection of Salmonella typhi with a fluorescence nanobiosensor using the microcontact method. Int. J. Environ. Sci. Technol. 2019, 16, 4637–4646. [Google Scholar] [CrossRef]

- Huang, Y.; Mei, L.; Chen, X.; Wang, Q. Recent Developments in Food Packaging Based on Nanomaterials. Nanomaterials 2018, 8, 830. [Google Scholar] [CrossRef] [Green Version]

- Carbone, M.; Donia, D.T.; Sabbatella, G.; Antiochia, R. Silver nanoparticles in polymeric matrices for fresh food packaging. J. King Saud. Univ. Sci. 2016, 28, 273–279. [Google Scholar] [CrossRef] [Green Version]

- Youssef, A.; Abelaziz, M. Preparation of Polystyrene Nanocomposites Based on Silver Nanoparticles Using Marine Bacterium for Packaging. Polym. Plast. Technol. Eng. 2013, 52, 607–613. [Google Scholar] [CrossRef]

- Durán, N.; Marcato, P.D.; Conti, R.d.; Alves, O.L.; Costa, F.; Brocchi, M. Potential use of silver nanoparticles on pathogenic bacteria, their toxicity and possible mechanisms of action. J. Brazil. Chem. Soc. 2010, 21, 949–959. [Google Scholar] [CrossRef]

- Sharma, S.; Sanpui, P.; Chattopadhyay, A.; Ghosh, S.S. Fabrication of Antibacterial Silver Nanoparticle–Sodium Alginate-Chitosan Composite Films. RSC Adv. 2012, 2, 5837–5843. [Google Scholar] [CrossRef]

- Yildirim, S.; Rocker, B.; Pettersen, M.K.; Nilsen-Nygaard, J.; Ayhan, Z.; Rutkaite, R.; Radusin, T.; Suminska, P.; Marcos, B.; Coma, V. Active Packaging Applications for Food. Compr. Rev. Food Sci. Food Saf. 2018, 17, 165–199. [Google Scholar] [CrossRef] [Green Version]

- Lotfi, S.; Ahari, H.; Sahraeyan, R. The effect of silver nanocomposite packaging based on melt mixing and sol–gel methods on shelf life extension of fresh chicken stored at 4 °C. J. Food Saf. 2019, 39, e12625. [Google Scholar] [CrossRef]

- Madhumitha, G.; Fowsiya, J.; Mohana Roopan, S.; Thakur, V.K. Recent advances in starch–clay nanocomposites. Int. J. Polym. Anal. Character. 2018, 23, 331–345. [Google Scholar] [CrossRef]

- Abreu, A.S.; Oliveira, M.; de Sa, A.; Rodrigues, R.M.; Cerqueira, M.A.; Vicente, A.A.; Machado, A.V. Antimicrobial nanostructured starch based films for packaging. Carbohydr. Polym. 2015, 129, 127–134. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gawande, M.B.; Goswami, A.; Felpin, F.; Asefa, T.; Huang, X.; Silva, R.; Zou, X.; Zboril, R.; Varma, R.S. Cu and Cu-Based Nanoparticles: Synthesis and Applications in Catalysis. Chem. Rev. 2016, 116, 3722–3811. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kasana, R.; Panwar, N.R.; Kaul, R.K.; Kumar, P. Copper Nanoparticles in Agriculture: Biological Synthesis and Antimicrobial Activity; Springer: Cham, Switzerland, 2017; pp. 129–143. [Google Scholar]

- Ren, G.; Hu, D.; Cheng, E.W.C.; Vargas-Reus, M.A.; Reip, P.; Allaker, R.P. Characterisation of copper oxide nanoparticles for antimicrobial applications. Int. J. Antimicrob. Agents 2009, 33, 587–590. [Google Scholar] [CrossRef] [PubMed]

- Muthuvel, A.; Jothibas, M.; Manoharan, C. Synthesis of copper oxide nanoparticles by chemical and biogenic methods: Photocatalytic degradation and in vitro antioxidant activity. Nanotechnol. Environ. Eng. 2020, 5, 14. [Google Scholar] [CrossRef]

- Mirhosseini, M.; Marvasti, S.H. Antibacterial Activities of Copper Oxide (CuO) Nanoparticles in Combination With Nisin and Ultrasound Against Foodborne Pathogens. Iran. J. Med. Microbiol. 2017, 11, 125–135. [Google Scholar]

- Gerba, C.P. Titanium Dioxide as Disinfectant. In Encyclopedia of Metalloproteins; Kretsinger, R.H., Uversky, V.N., Permyakov, E.A., Eds.; Springer: New York, NY, USA, 2013; pp. 2242–2247. [Google Scholar]

- Othman, S.; Abd Salam, N.R.; Zainal, N.; Kadir Basha, R.; Talib, R.A. Antimicrobial Activity of TiO2 Nanoparticle-Coated Film for Potential Food Packaging Applications. Int. J. Photoenergy 2014, 2014, 1–6. [Google Scholar] [CrossRef] [Green Version]

- Zimbone, M.; Buccheri, M.A.; Cacciato, G.; Sanz, R.; Rappazzo, G.; Boninelli, S.; Reitano, R.; Romano, L.; Privitera, V.; Grimaldi, M.G. Photocatalytical and antibacterial activity of TiO2 nanoparticles obtained by laser ablation in water. Appl. Catal. B Environ. 2015, 165, 487–494. [Google Scholar] [CrossRef]

- Haghi, M.; Hekmatafshar, M.; Janipour, M.B.; Gholizadeh, S.S.; Faraz, M.K.; Sayyadifar, F.; Ghaedi, M. Antibacterial effect of TiO2 nanoparticles on pathogenic strain of E. coli. IJABR 2012, 3, 621–624. [Google Scholar]

- Kubacka, A. Understanding the antimicrobial mechanism of TiO2-based nanocomposite films in a pathogenic bacterium. Sci. Rep. 2014, 4, 4134. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mohammadi, H.; Anvar, A.A.; Qajarbeygi, P.; Ahari, H.; Abdi, F. Comparison of the Antifungal Activity of Titanium Dioxide Based Nano-Silver Packaging and Conventional Polyethylene Packaging in Consumed Bread. Appl. Food Biotechnol. 2014, 2, 45–51. [Google Scholar]

- Espitia, P.; Otoni, C.; Soares, N. Zinc Oxide Nanoparticles for Food Packaging Applications. In Antimicrobial Food Packaging; Academic Press: Cambridge, MA, USA, 2016; pp. 425–431. [Google Scholar]

- Espitia, P.J.P.; Soares, N.d.F.; dos Reis Coimbra, J.S.; de Andrade, N.J.; Cruz, R.S.; Medeiros, E.A.A. Zinc Oxide Nanoparticles: Synthesis, Antimicrobial Activity and Food Packaging Applications. Food Bioprocess. Technol. 2012, 5, 1447–1464. [Google Scholar] [CrossRef]

- Wu, C.; Zhang, M.Q.; Rong, M.Z.; Friedrich, K. Silica Nanoparticles Filled Polypropylene: Effects of Particle Surface Treatment, Matrix Ductility and Particle Species on Mechanical Performance of the Composites. Composites Sci. Technol. 2005, 65, 635–645. [Google Scholar] [CrossRef]

- Xiong, H.; Tang, S.; Tang, H.; Zou, P. The structure and properties of a starch-based biodegradable film. Carbohydr. Polym. 2008, 71, 263–268. [Google Scholar] [CrossRef]

- Vladimirov, V.; Betchev, C.; Vassiliou, A.; Papageorgiou, G.; Bikiaris, D. Dynamic mechanical and morphological studies of isotactic polypropylene/fumed silica nanocomposites with enhanced gas barrier properties. Composites Sci. Technol. 2006, 66, 2935–2944. [Google Scholar] [CrossRef]

- Jia, X.; Li, Y.; Cheng, Q.; Zhang, S.; Zhang, B. Preparation and properties of poly(vinyl alcohol)/silica nanocomposites derived from copolymerization of vinyl silica nanoparticles and vinyl acetate. Eur. Polym. J. 2007, 43, 1123–1131. [Google Scholar] [CrossRef]

- Uddin, F. Clays, Nanoclays, and Montmorillonite Minerals. Metal. Mater. Trans. A 2008, 39, 2804–2814. [Google Scholar] [CrossRef]

- Bumbudsanpharoke, N.; Ko, S. Nanoclays in Food and Beverage Packaging. J. Nanomater. 2019, 2019, 8927167. [Google Scholar] [CrossRef] [Green Version]

- Jawaid, M.; Qaiss, A.; Bouhfid, R. Nanoclay Reinforced Polymer Composites; Springer: Singapore, 2016. [Google Scholar]

- Müller, K.; Bugnicourt, E.; Latorre, M.; Jorda, M.; Echegoyen Sanz, Y.; Lagaron, J.M.; Miesbauer, O.; Bianchin, A.; Hankin, S.; Bolz, U. Review on the Processing and Properties of Polymer Nanocomposites and Nanocoatings and Their Applications in the Packaging, Automotive and Solar Energy Fields. Nanomaterials 2017, 7, 74. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Elmore, A.R. Final Report on the Safety Assessment of Aluminum Silicate, Calcium Silicate, Magnesium Aluminum Silicate, Magnesium Silicate, Magnesium Trisilicate, Sodium Magnesium Silicate, Zirconium Silicate, Attapulgite, Bentonite, Fuller’s Earth, Hectorite, Kaolin, Lithium Magnesium Silicate, Lithium Magnesium Sodium Silicate, Montmorillonite, Pyrophyllite, and Zeolite. Int. J. Toxicol. 2003, 22, 37–102. [Google Scholar] [PubMed]

- Sinha Ray, S.; Okamoto, M. Polymer/Layered Silicate Nanocomposites: A Review from Preparation to Processing. Prog. Polym. Sci. 2003, 28. [Google Scholar] [CrossRef]

- Demetrakakes, P. Nanocomposites raise barriers, but also face them: Clay based additives increase the barrier qualities of plastics, but obstacles to commercialization must be overcome. Food Drug Packag. Nanocomposite Mater. 2002.

- Mangaraj, S.; Yadav, A.; Bal, L.M.; Dash, S.K.; Mahanti, N.K. Application of Biodegradable Polymers in Food Packaging Industry: A Comprehensive Review. J. Packag. Technol. Res. 2018, 3, 77–96. [Google Scholar] [CrossRef]

- Priyadarshi, R. Food Packaging. Nat. Synthetic Biopolym. 2018, 7, 1325–1342. [Google Scholar]

- Valdés, A.; Mellinas, A.C.; Ramos, M.; Garrigos, M.C.; Jimenez, A. Natural additives and agricultural wastes in biopolymer formulations for food packaging. Front. Chem. 2014, 2, 6. [Google Scholar] [CrossRef] [Green Version]

- Mellinas, C.; Valdes, A.; Ramos, M.; Burgos, N.; Garrigos, M.d.; Jimenez, A. Active edible films: Current state and future trends. J. Appl. Polym. Sci. 2016, 133, 42631. [Google Scholar] [CrossRef] [Green Version]

- Kumar, N.; Kaur, P.; Bhatia, S. Advances in bio-nanocomposite materials for food packaging: A review. Nutr. Food Sci. 2017, 47, 591–606. [Google Scholar] [CrossRef]

- Luangapai, F.; Peanparkdee, M.; Iwamoto, S. Biopolymer films for food industries: Properties, applications, and future aspects based on chitosan. Rev. Agric. Sci. 2019, 7, 59–67. [Google Scholar] [CrossRef] [Green Version]

- Cortés-Rodríguez, M.; Villegas-Yepez, C.; Gonzalez, J.H.G.; Rodriguez, P.E.; Ortega-Toro, R. Development and evaluation of edible films based on cassava starch, whey protein, and bees wax. Heliyon 2020, 6, e04884. [Google Scholar] [CrossRef] [PubMed]

- Jafarzadeh, S.; Ariffin, F.; Mahmud, S.; Najafi, A. Preparation and characterization of bionanocomposite films reinforced with nano kaolin. J. Food Sci. Technol. 2016, 53, 1111–1119. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Othman, S. Bio-nanocomposite Materials for Food Packaging Applications: Types of Biopolymer and Nano-sized Filler. Agric. Agric. Sci. Proc. 2014, 2, 296–303. [Google Scholar] [CrossRef] [Green Version]

- Yunus, K.S. Anotube/Biopolymer Nanocomposites; Sanyang, J.M., Ed.; Springer: Cham, Switzerland, 2019. [Google Scholar]

- Silva-Weiss, A.; Ihl, M.; Sobral, P.J.d.A.; Gomez-Guillen, M.C.; Bifani, V. Natural Additives in Bioactive Edible Films and Coatings: Functionality and Applications in Foods. Food Eng. Rev. 2013, 5, 200–216. [Google Scholar] [CrossRef]

- Shah, U.; Naqash, F.; Gani, A.; Masoodi, F.A. Art and Science behind Modified Starch Edible Films and Coatings: A Review. Compr. Rev. Food Sci. Food Safety 2016, 15. [Google Scholar] [CrossRef]

- Jiang, T.; Duan, Q.; Zhu, J.; Liu, H.; Yu, L. Starch-based biodegradable materials: Challenges and opportunities. Adv. Ind. Eng. Polym. Res. 2020, 3, 8–18. [Google Scholar] [CrossRef]

- Shah, U.; Gani, A.; Ashwar, B.A.; Shah, A.; Ahmad, M.; Gani, A.; Wani, I.A.; Masoodi, F.A. A review of the recent advances in starch as active and nanocomposite packaging films. Cogent Food Agric. 2015, 1, 1115640. [Google Scholar] [CrossRef]

- Avella, M.; De Vlieger, j.; Errico, M.E.; Fischer, S.; Vacca, P.; Volpe, M.G. Biodegradable Starch/Clay Nanocomposite Films for Food Packaging Applications. Food Chem. 2005, 93, 467–474. [Google Scholar] [CrossRef]

- Amirthalingam, T. Preparation of Biodegradable Starch-Clay Nanocomposites Film for Food Packaging. Carbohydr. Polym. 2012, 463–472. [Google Scholar]

- Melo, C.d.; Garcia, P.S.; Grossmann, M.V.E.; Yamashita, F.; Dall’Antonia, L.H.; Mali, S. Properties of extruded xanthan-starch-clay nanocomposite films. Brazil. Arch. Biol. Technol. 2011, 54, 1223–1333. [Google Scholar] [CrossRef] [Green Version]

- Vanaraja, M.; Karthika, M.; Kumar, V.S.R.P.; Boomadevi, S.; Jeyadheepan, K.; Karn, R.K.; Balaguru, R.J.B.; Pandiyan, S.K. Synthesis of ZnO Nanoparticles using Carboxymethyl Cellulose Hydrogel. Asian J. Appl. Sci. 2014, 7, 798–803. [Google Scholar]

- Arora, A.; Padua, G.W. Review: Nanocomposites in Food Packaging. J. Food Sci. 2010, 75, R43–R49. [Google Scholar] [CrossRef]

- Vroman, I.; Tighzert, L. Biodegradable Polymers. Materials 2009, 2, 307–344. [Google Scholar] [CrossRef]

- Koller, M. Poly(hydroxyalkanoates) for Food Packaging: Application and Attempts towards Implementation. Appl. Food Biotechnol. 2014, 1, 3–15. [Google Scholar]

- Silva, I.D.d.L.; de Andrade, M.F.; Caetano, V.F.; Hallwass, F.; Brito, A.M.S.S.; Vinhas, G.M. Development of active PHB/PEG antimicrobial films incorporating clove essential oil. Polímeros 2020, 30. [Google Scholar] [CrossRef]

- Zhang, M.; Thomas, N.L. Preparation and properties of polyhydroxybutyrate blended with different types of starch. J. Appl. Polym. Sci. 2010, 116, 688–694. [Google Scholar] [CrossRef]

- Oz, A.; Süfer, Ö.; Sezer, Y.C. Poly (Lactic Acid) Films in Food Packaging Systems. Food Sci. Nutr. Technol. 2017, 2, 208. [Google Scholar]

- Lagaron, J.M. Polylactic Acid (PLA) Nanocomposites for Food Packaging Applications; Woodhead Publishing: Sawston, UK, 2011; pp. 485–497. [Google Scholar]

- Sha, L.; Chen, Z.; Chen, Z.; Zhang, A.; Yang, Z. Polylactic Acid Based Nanocomposites: Promising Safe and Biodegradable Materials in Biomedical Field. Int. J. Polym. Sci. 2016, 2016, 6869154. [Google Scholar] [CrossRef] [Green Version]

- Thellen, C.; Orroth, C.; Froio, D.; Ziegler, D.; Lucciarini, J.; Farrell, R.; D’Souza, N.A.; Ratto, J.A. Influence of montmorillonite layered silicate on plasticized poly(L-lactide) blown films. Polymer 2005, 46, 11716–11727. [Google Scholar] [CrossRef]

- González, R.M.; Villanueva, M.P. 19—Starch-based polymers for food packaging. In Multifunctional and Nanoreinforced Polymers for Food Packaging; Lagarón, J.-M., Ed.; Woodhead Publishing: Sawston, UK, 2011; pp. 527–570. [Google Scholar]

- Kristo, E.; Biliaderis, C. Physical properties of starch nanocrystal reinforced pullulan film. Carbohydr. Polym. 2007, 68, 146–158. [Google Scholar] [CrossRef]

- Chen, Y.; Cao, X.; Chang, P.R.; Huneault, M.A. Comparative Study on the Films of Poly (vinyl alcohol)/Pea Starch Nanocrystals and Poly (Vinyl Alcohol)/Native Pea Starch. Carbohydr. Polym. 2008, 73, 8–17. [Google Scholar] [CrossRef]

- Sriupayo, J.; Supaphol, P.; Blackwell, J.; Rujiravanit, R. Preparation and characterization of ??-chitin whisker-reinforced chitosan nanocomposite films with or without heat treatment. Carbohydr. Polym. 2005, 62, 130–136. [Google Scholar] [CrossRef]

- Du, J.; Zhang, S.; Sun, R.; Zhang, L.; Xiong, C.; Peng, Y. Novel polyelectrolyte carboxymethyl konjac glucomannan–chitosan nanoparticles for drug delivery. II. Release of albumin in vitro. J. Biomed. Mater. Res. Part B Appl. Biomater. 2005, 72B, 299–304. [Google Scholar] [CrossRef] [PubMed]

- Márcia, R.; de Moura, F.A.A.; Roberto, J.; Avena-Bustillos, T.H.; McHugh, J.M.; Krochta, L.; Mattoso, H.C. Improved barrier and mechanical properties of novel hydroxypropyl methylcellulose edible films with chitosan/tripolyphosphate nanoparticles. J. Food Eng. 2009, 92, 448–453. [Google Scholar]

- Bhat, Z.F.; Kumar, S.; Bhat, H.F. Bioactive peptides of animal origin: A review. J. Food Sci. Technol. 2015, 52, 5377–5392. [Google Scholar] [CrossRef] [Green Version]

- Chen, H.; Wang, J.; Cheng, Y.; Wang, C.; Liu, H.; Bian, H.; Pan, Y.; Sun, J.; Han, W. Application of Protein-Based Films and Coatings for Food Packaging: A Review. Polymers 2019, 11, 2039. [Google Scholar] [CrossRef] [Green Version]

- Janjarasskul, T.; Krochta, J. Edible Packaging Materials. Ann. Rev. Food Sci. Technol. 2010, 1, 415–448. [Google Scholar] [CrossRef]

- Sothornvit, R.; Krochta, J. Plasticizers in edible films and coatings. In Innovations in Food Packaging; Academic Press: Cambridge, MA, USA, 2005; pp. 403–433. [Google Scholar]

- Zhou, J.J.; Wang, S.; Gunasekaran, S. Preparation and Characterization of Whey Protein Film Incorporated with TiO2 Nanoparticles. J. Food Sci. 2009, 74, N50–N56. [Google Scholar] [CrossRef] [PubMed]

- Uyama, H.; Kuwabara, M.; Tsujimoto, T.; Nakano, M.; Usuki, A.; Kobayashi, S. Green Nanocomposites from Renewable Resources: Plant Oil−Clay Hybrid Materials. Chem. Mater. 2003, 15, 2492–2494. [Google Scholar] [CrossRef]

- Reddy, M.; Mohanty, A.; Misra, M. Thermoplastics from Soy Protein: A Review on Processing, Blends and Composites. J. Biobased Mater. Bioenergy 2010, 4, 298–316. [Google Scholar] [CrossRef]

- Echeverria, I.; Eisenberg, P.; Mauri, A. Nanocomposites films based on soy proteins and montmorillonite processed by casting. J. Membrane Sci. 2013, 449, 15–26. [Google Scholar] [CrossRef]

- Winters, E.P.; Deardorff, D.L. Zein as a film-type coating for medicinal tablets. J. Am. Pharm. Assoc. 1958, 47, 608–612. [Google Scholar] [CrossRef] [PubMed]

- Ryu, S.; Rhim, J.W.; Roh, H.J.; Kim, S.S. Preparation and Physical Properties of Zein-Coated High-Amylose Corn Starch Film. Lebensm. Wiss. Technol. 2002, 35, 680–686. [Google Scholar] [CrossRef]

- Souza, V.G.L.; Fernando, A.L. Nanoparticles in food packaging: Biodegradability and potential migration to food—A review. Food Packag. Shelf Life 2016, 8, 63–70. [Google Scholar] [CrossRef]

- Martirosyan, A.; Schneider, Y.-J. Engineered nanomaterials in food: Implications for food safety and consumer health. Int. J. Environ. Res. Public Health 2014, 11, 5720–5750. [Google Scholar] [CrossRef] [Green Version]

- Ahari, H.; Lahijani, L.K. Migration of Silver and Copper Nanoparticles from Food Coating. Coatings 2021, 11, 380. [Google Scholar] [CrossRef]

- Manke, A.; Wang, L.; Rojanasakul, Y. Mechanisms of nanoparticle-induced oxidative stress and toxicity. BioMed Res. Int. 2013, 2013, 1–15. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Huang, Y.-W.; Wu, C.-H.; Aronstam, R.S. Toxicity of Transition Metal Oxide Nanoparticles: Recent Insights from in vitro Studies. Materials 2010, 3, 4842–4859. [Google Scholar] [CrossRef] [Green Version]

- Fahmy, H.M.; Eldin, R.E.S.; Serea, E.S.A.; Gomaa, N.M.; AboElmagd, G.M.; Salem, S.A.; Elsayed, Z.A.; Edrees, A.; Shams-Eldin, E.; Shalan, A.E. Advances in nanotechnology and antibacterial properties of biodegradable food packaging materials. RSC Adv. 2020, 10, 20467–20484. [Google Scholar] [CrossRef]

- Cushen, M.; Kerry, J.; Morris, M.; Cruz-Romero, M.; Cummins, E. Nanotechnologies in the food industry–Recent developments, risks and regulation. Trends Food Sci. Technol. 2012, 24, 30–46. [Google Scholar] [CrossRef]

- Alina Martirosyan, M.P.; Alexandra Bazes, T.S.; Schneider, Y.V. Food Nanoparticles and Intestinal Inflammation: A Real Risk? Inflamm. Bowel Disease 2012, 259–282. [Google Scholar]

- Senchukova, M. A Brief Review about the Role of Nanomaterials, Mineral-Organic Nanoparticles, and Extra-Bone Calcification in Promoting Carcinogenesis and Tumor Progression. Biomedicines 2019, 7, 65. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Störmer, A.; Bott, J.; Kemmer, D.; Franz, R. Critical review of the migration potential of nanoparticles in food contact plastics. Trends Food Sci. Technol. 2017, 63, 39–50. [Google Scholar] [CrossRef]

- Hannon, J.C.; Kerry, J.P.; Cruz-Romero, M.; Azlin-Hasim, S.; Morris, M.; Cummins, E. Migration assessment of silver from nanosilver spray coated low density polyethylene or polyester films into milk. Food Packag. Shelf Life 2018, 15, 144–150. [Google Scholar] [CrossRef]

- Shit, S.C.; Shah, P.M. Edible Polymers: Challenges and Opportunities. J. Polym. 2014, 2014, 427259. [Google Scholar] [CrossRef] [Green Version]

- Vaidya, U.R.; Bhattacharya, M. Properties of blends of starch and synthetic polymers containing anhydride groups. J. Appl. Polym. Sci. 1994, 52, 617–628. [Google Scholar] [CrossRef]

- Khajavi, M.Z.; Ebrahimi, A.; Yousefi, M.; Ahmadi, S.; Farhoodi, M.; Alizadeh, A.M.; Taslikh, M. Strategies for producing improved oxygen barrier materials appropriate for the food packaging sector. Food Eng. Rev. 2020, 12, 346–363. [Google Scholar] [CrossRef]

- Arrieta, M.P.; Peponi, L.; Lopez, D.; Lopez, J.; Kenny, J.M. An overview of nanoparticles role in the improvement of barrier properties of bioplastics for food packaging applications. Food Packag. 2017, 391–424. [Google Scholar] [CrossRef]

- Megahed, M.; Abd El-baky, M.A.; Alsaeedy, A.M.; Alshorbagy, A.E. Improvement of impact and water barrier properties of GLARE by incorporation of different types of nanoparticles. Fibers Polym. 2020, 21, 840–848. [Google Scholar] [CrossRef]

- Wolf, C.; Angellier-Coussy, H.; Gontard, N.; Doghieri, F.; Guillard, V. How the shape of fillers affects the barrier properties of polymer/non-porous particles nanocomposites: A review. J. Membrane Sci. 2018, 556, 393–418. [Google Scholar] [CrossRef]

- Pavlidou, S.; Papaspyrides, C.D. A review on polymer–layered silicate nanocomposites. Prog. Polym. Sci. 2008, 33, 1119–1198. [Google Scholar] [CrossRef]

- Patel, N.P.; Miller, A.C.; Spontak, R.J. Highly CO2-Permeable and Selective Polymer Nanocomposite Membranes. Adv. Mater. 2003, 15, 729–733. [Google Scholar] [CrossRef]

- Duncan, T.V. Applications of nanotechnology in food packaging and food safety: Barrier materials, antimicrobials and sensors. J. Colloid Interface Sci. 2011, 363, 1–24. [Google Scholar] [CrossRef] [PubMed]

- Rashidi, L.; Khosravi-Darani, K. The Applications of Nanotechnology in Food Industry. Crit. Rev. Food Sci. Nutr. 2011, 51, 723–730. [Google Scholar] [CrossRef]

- Nesic, A.R.; Seslija, S.I. 19—The influence of nanofillers on physical–chemical properties of polysaccharide-based film intended for food packaging. In Food Packaging; Grumezescu, A.M., Ed.; Academic Press: Cambridge, MA, USA, 2017; pp. 637–697. [Google Scholar]

- Jamróz, E.; Kulawik, P.; Kopel, P. The Effect of Nanofillers on the Functional Properties of Biopolymer-based Films: A Review. Polymers 2019, 11, 675. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Beyth, N.; Houri-Haddad, Y.; Domb, A.; Khan, W.; Hazan, R. Alternative Antimicrobial Approach: Nano-Antimicrobial Materials. Evid. Based Complement. Altern. Med. 2015, 2015, 246012. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gatoo, M.A.; Naseem, S.; Arfat, M.Y.; Mahmood Dar, A.; Qasim, K.; Zubair, S. Physicochemical Properties of Nanomaterials: Implication in Associated Toxic Manifestations. BioMed. Res. Int. 2014, 2014, 498420. [Google Scholar] [CrossRef]

- Jeong, Y.; Lim, D.W.; Choi, J. Assessment of Size-Dependent Antimicrobial and Cytotoxic Properties of Silver Nanoparticles. Adv. Mater. Sci. Eng. 2014, 2014, 763807. [Google Scholar] [CrossRef] [Green Version]

- Yamamoto, O. Influence of particle size on the antibacterial activity of zinc oxide. Int. J. Inorg. Mater. 2001, 3, 643–646. [Google Scholar] [CrossRef]

- Echegoyen, Y.; Nerín, C. Nanoparticle release from nano-silver antimicrobial food containers. Food Chem. Toxicol. 2013, 62, 16–22. [Google Scholar] [CrossRef] [PubMed]

- Anvar, A.; Haghighat Kajavi, S.; Ahari, H.; Sharifan, A.; Motallebi, A.; Kakoolaki, S.; Paidari, S. Evaluation of the antibacterial effects of Ag-Tio2 nanoparticles and optimization of its migration to sturgeon caviar (Beluga). Iran. J. Fisher. Sci. 2019, 18, 954–967. [Google Scholar]

- Bankier, C.; Matharu, R.K.; Cheong, Y.K.; Ren, G.G.; Cloutman-Green, E.; Ciric, L. Synergistic Antibacterial Effects of Metallic Nanoparticle Combinations. Sci. Rep. 2019, 9, 16074. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Barani, S.; Ahari, H.; Bazgir, S. Increasing the shelf life of pikeperch (Sander lucioperca) fillets affected by low-density polyethylene/Ag/TiO2 nanocomposites experimentally produced by sol-gel and melt-mixing methods. Int. J. Food Prop. 2018, 21, 1923–1936. [Google Scholar] [CrossRef] [Green Version]

| Type of Bio-Nanocomposite | Food Product | Antimicrobial Results | References |

|---|---|---|---|

| PLA/ZnO:Cu/Ag | Food simulant: (distilled water)—simulant A, ethanol 10% (v/v) in aqueous solution—simulant B and acetic acid 3% (w/v) in aqueous solution—simulant C | Good mechanical, thermal and barrier properties to ultraviolet light, water vapor, oxygen and carbon dioxide; antibacterial activity and low migration of NPs into food simulants. | [26] |

| Starch/halloysite/nisin | Soft cheese | Improved mechanical properties with halloysite addition; antimicrobial activity against Listeria monocytogenes (L. monocytogenes), Clostridium perfringens, and Staphylococcus aureus (S. aureus) | [27] |

| Low-density polyethylene (LDPE)/Ag, ZnO | Orange juice | A significant decrease of the yeast and mold counts without disrupting juice relevant quality attributes; significant reduction in the growth rate of Lactobacillus plantarum | [28] |

| PE/Ag, titanium oxide (TiO2), kaolin | Chinese jujube | Firmer, heavier, less decay, less browning, slower ripening, decrease in senescence and climacteric evolution | [29] |

| Cellulose absorber/Cu | Melon and pineapple juices | Excellent antifungal activity, reducing spoilage-related yeasts and molds | [30] |

| Absorbent pad/Ag | Poultry meat | Confirmed antimicrobial effect against Escherichia coli (E. coli) and S. aureus | [31] |

| Allyl isothiocyanate, nisin/ZnO absorber/Ag | Liquid egg albumen Kiwi and melon juices | Effective inactivation of Salmonella Reduced counts of total viable microorganisms, yeasts and molds | [32] |

| PE/Ag | Apple juice | High bactericide capacity against Alicyclobacillus acidoterrestris | [33] |

| Pectin/nanohybrid-layered double-hydroxide salicylate | Fresh apricots | Improved elongation at a breakpoint for pectin; improved water vapor barrier properties; extended shelf life | [34] |

| Corn starch/talc NPs | Tomatoes | Reduction in water vapor and oxygen permeability | [35] |

| Gelatin/ethanolic extract from coconut husk/Cloisite Na + nanoclay | Meat powder | Lower lipid oxidation products; Increased moisture barrier properties; extended shelf life | [36] |

| Nanozinc oxide–neem oil–chitosan | Carrots | Good inhibition effect as antibacterial activity against E. coli | [37] |

| Poly(glycidyl methacrylate covinyl ferrocene)/graphene oxide/iron oxide NPs, and poly(glycidylmethacrylate-covinylferrocene)/MWCNT | Fish | Fish meat freshness control | [38] |

| Alginate/nano-Ag | Shiitake mushroom | Spoilage reduction, improvement of sensory attributes, lower weight loss | [39] |

| Sodium alginate solution containing Ag NPs | Carrot and pear | Antibacterial film effective against the test strains, E. coli ATCC 8739 and S. aureus ATCC 6538 | [40] |

| Calcium alginate film loaded with ZnO NPs | Ready-to-eat poultry meat | Shelf life increase of carrots and pears Reduction of microbial load of Salmonella typhimurium and E. coli | [41] |

| Nanoemulsion coating of chitosan and mandarin essential oil | Green beans | Reduction in the population of L. monocytogenes | [42] |

| Chitosan/poly(vinyl alcohol)/TiO2 NPs | Soft white cheese | Antibacterial activity against Gram-positive (S. aureus), Gram-negative (Pseudomonas aeruginosa (P. aeruginosa), E. coli) bacteria and fungi (Candida albicans); extension of shelf life | [43] |

| Whey protein isolate (WPI)/ montmorillonite (MMT) | Food models (water, 3% acetic acid, 15% ethanol, olive oil) | Increased tensile strength of the WPI film and swelling of the WPI film | [44] |

| Soy protein isolate–MMT | Fresh fruits and vegetables | Improvement in mechanical properties, thermal stability, and water vapor permeability with the addition of MMT | [45] |

| Ag NPs-based cellulose absorbent pads | Fresh-cut melons | Retarding the senescence rate of the fresh-cut melons; reduction in antibacterial activity | [46] |

| Edible coating of polyvinyl pyrrolidone (PVP) containing Ag NPs | Asparagus | Inhibiting the growth of psychotropic microorganisms; lowering weight loss, greener color, and tender textures | [47] |

| Nano-ZnO-coated poly(vinyl chloride) | Fresh-cuts of “Fuji” apples | Preservation of quality indicators, such as ascorbic acid and polyphenol content; Lower counts of typical altering microorganisms | [48] |

| Thyme essential oil (TEO) and MMT-based sweet potato starch films | Baby spinach leaves | Incorporation of TEO in the film reduced the population of E. coli and Salmonella Typhi (S. Typhi) on fresh baby spinach leaves | [49] |

| LDPE/Ag, TiO2, kaolin | Strawberries | Decelerated decay rate | [50] |

| LDPE/Ag2O | Apple slices | Decreased microbial spoilage, delayed browning and weight loss | [51] |

| Nanomaterial | Nanoparticle Size (nm) | Preparation Method | Analytical Techniques | Migration Test Conditions | Migration Results | Antimicrobial Activity Assay | Antimicrobial Activity Results | References |

|---|---|---|---|---|---|---|---|---|

| AgCl- TiO2 NPs (ATNPs) | 6–7 | Low-temperature-based one-pot sol–gel method | SEM | Disc diffusion assay for measuring anti-quorum-sensing activity of ATNPs (100–500 µg/mL) | Increase in inhibition of QS in Chromobacterium violaceum Inhibition of biofilm formation by ATNPs at 20 µg/mL | [6] | ||

| Carboxymethyl cellulose nanobiocomposites containing metal NPs (ZnO, CuO, and Ag | ZnO: 20–30 CuO: 35 Ag: <50 | Solution-casting method | SEM, EDXA, WVP, UV-vis, and tensile tests | Agar diffusion method | Ag and ZnO: high antibacterial activity against S. aureus and E. coli CuO: antibacterial activity against E. coli | [7] | ||

| Nanosilver-polyethylene composite | 7 | Nanosilver–polyethylene composite film was purchased (Anson Nanotechnology Co., Ltd., Zhuhai, China) | ICP-MS | 20 °C for 1, 2, 3, 4, 5, 6, 7, 8 and 9 h. 40 °C for 1, 2, 3, 4, 5, 6, 7, 8 and 9 h. 70 °C for 1, 2, 3, 4, 5, 6, 7, 8 and 9 h. | Ag migration in 3% aqueous acetic acid: 1.70%, 3.0% and 5.6% at 20, 40 and 70 °C. Ag migration in 95% aqueous ethanol: 0.24%, 0.23% and 0.22% at 20, 40 and 70 °C | [8] | ||

| Low-density polyethylene (LDPE) film containing AgNPs | Not mentioned by the authors | Extrusion method | SEM, XRD, TGA, FTIR, DSC | Japanese industrial standard (JIS) method | Intense antimicrobial properties against E. coli and S. aureus by polyethylene nanocomposites containing AgNPs | [9] | ||

| PVA nanocomposite films containing nanocellulose (NC) and AgNPs | Not mentioned by the authors | Solution-casting method | SEM, EDX, FTIR, TGA, XRD, MRC, WVTR | Disc diffusion method | Maximum inhibition of E. coli was at 0.5 g AgNPs with 12 wt % NC. Maximum inhibition of S. aureus was at 0.3 g Ag NPs for 16 wt % NC. The highest antibacterial activity was observed for E. coli | [10] | ||

| Carrageenan/ AgNPs/laponite nanocomposite | Not mentioned by the authors | Green synthesis method from the Digitalis purpurea plant | SEM, XRD, FTIR, WVTR | Agar disk diffusion method | Strong antimicrobial activity against the E. coli and S. aureus | [11] | ||

| AgNPs | 20 | FreshLonger™ plastic storage bags contained AgNPs, and produced by Sharper Image Corporation (San Francisco, CA, USA) were purchased | SEM, ICP-MS, AAS, EDS | EU regulation 10/2011 | No Ag migration into chicken meat | Total microbial count (CFU) | Bags containing AgNPs had no effect on levels of the three types of spoilage bacteria, including TMC, Enterobacteriaceae and Pseudomonas spp. | [12] |

| Cu NPs (CuNPs) embedded in polylactic acid (CuNPs-PLA) | Not mentioned by the authors | Pulsed-laser ablation | TEM, UV-vis, XPS, ETAAS | Cu release from the nanocomposites into an aqueous contact solution was carried out by atomic absorption analyses 24 h after putting coating in saline solution | Release kinetics of Cu from CuNPs-C-PLA nanocomposite was described according to first-order kinetic profile | JIS method | Cell load of P. aeruginosa in CuNPs- C-PLA sample was lower (6.0 log CFU/mL) than the blank PLA sample (7.4 Log CFU/mL) | [13] |

| Biopolymeric films (SA-CNW-CuNPs) containing cellulose, sodium alginate and CuO NPs | Not mentioned by the authors | Antibacterial polymeric film (APF) were prepared by using the three types of the components such as CuONPs, SA and CNW at different ratios | SEM, FTIR, EDS, XRD | Disc diffusion method | CNW (0.5%)-SA (3%)-CuO NPs (5 mM) films showed a higher zone of inhibition against S. aureus, E. coli, Salmonella spp., C. albicans and Trichoderma spp. | [14] | ||

| Carbohydrate-based composite films incorporated with CuONPs | Not mentioned by the authors | Solvent-casting method | SEM, FTIR, XRD, UV-vis, WVP | Total microbial count (CFU) | Nanocomposite films with CuONPs exhibited strong antibacterial activity against foodborne pathogenic bacteria, L. monocytogenes, and E. coli. | [15] | ||

| Cu/HPMC bionanocomposites (hydroxypropyl methylcellulose (HPMC) matrix incorporated with CuNPs)) | 30 | Chemical-reduction method | SEM, XRD, WVP | Disk diffusion method | CuNPs in HPMC suspension had high antibacterial activity against Gram-positive bacteria but not against Gram-negative bacteria | [16] | ||

| Poly (ε-caprolactone)-based nanocomposites containing hydroxytyrosol (HT) and cloisite30B (nanoclay) | Not mentioned by the authors | Melt-blending | DSC, TGA, SEM, TEM, XRD | Evaluation of the release rate of HT from the film for samples immersed in methanol. The extracts were analyzed by UV-vis spectroscopy | Presence of the nanoclay produced a decrease in the HT release from films | [17] | ||

| Polystyrene nanocomposites containing organoclay and ZnONPs | 20 | Melt-mixing | AFM, GC-FID | 5 °C for 10 days, 40 °C for 24 h, 100 °C for 30 min | Organoclay and ZnONPs could significantly hinder the release of styrene monomers (SM) from nanocomposites to food simulants | [18] | ||

| Nanoclay-loaded low-density polyethylene (LDPE) composite | 2–8 | Spherilene technology | XRD, TGA, CL, FTIR, AFM, SEM, TEM, ICP-OES | Ultraviolet (UV) irradiation and low concentration of ozone at 40 °C | The presence of nanoclay accelerated in degradation of the LDPE and enhanced the release of clay particles | [19] | ||

| LDPE nanocomposite | Variable | Debbie Meyer BreadBags and Aisaika Everfresh bag as two models of nanoclay food containers were studied | ICP-MS, SEM-EDX | EU regulation 10/2011 40 °C for 10 days and 70 °C for 2 h | Migration value of nanoclay from LDPE into acetic acid 3% for 10 days at 40 °C was higher than ethanol 10% | [20] | ||

| Polylactic acid (PLA) biocomposites containing Ag-based nanoclay | 20 | Solution-casting method | WAXS, TEM, DSC, WVP | The norm UNE-ENV 13130-1 | The migration levels of Ag was found within the specific migration levels referenced by the European Food Safety Agency (EFSA) | Total microbial count (CFU) | Ag-based nanoclay showed strong antimicrobial activity against Gram-negative Salmonella spp. | [21] |

| PLA/clay nanocomposite | Not mentioned by the authors | Blown film co-extrusion | TEM, DSC, XRD, WVTR, SEM | EU regulation 10/2011 | Lactic acid migration values in 50% ethanol remained well below the former generic specific migration limit of 60 mg/kg food (10 mg/dm2) of the reg. EU 10/2011 | [22] | ||

| Nanocomposites of polypropylene (PP) + Clay | Not mentioned by the authors | Extrusion method | TGA, FTIR, WAXD, ICP-MS | European Standard UNE-EN 1186 | Migration of the PP-Clay was 0.0 ± 0.4 and 2.0 ± 0.4 mg/dm2, with no significant differences, compared to the controls; migration rate was below those established by the EU regulation | [23] | ||

| Cassava starch films incorporated with cinnamon essential oil and sodium bentonite clay NPs | Not mentioned by the authors | Solution-casting method | Film thickness, WVP, TS | MIC | Cassava starch films incorporated with sodium bentonite and cinnamon oil showed significant antibacterial potential against E. coli, Salmonella typhimurium and Staphylococcus aureus. | [24] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahari, H.; Anvar, A.A.; Ataee, M.; Naeimabadi, M. Employing Nanosilver, Nanocopper, and Nanoclays in Food Packaging Production: A Systematic Review. Coatings 2021, 11, 509. https://doi.org/10.3390/coatings11050509

Ahari H, Anvar AA, Ataee M, Naeimabadi M. Employing Nanosilver, Nanocopper, and Nanoclays in Food Packaging Production: A Systematic Review. Coatings. 2021; 11(5):509. https://doi.org/10.3390/coatings11050509

Chicago/Turabian StyleAhari, Hamed, Amir Ali Anvar, Maryam Ataee, and Mohammad Naeimabadi. 2021. "Employing Nanosilver, Nanocopper, and Nanoclays in Food Packaging Production: A Systematic Review" Coatings 11, no. 5: 509. https://doi.org/10.3390/coatings11050509