Effects of Wollastonite on Fire Properties of Particleboard Made from Wood and Chicken Feather Fibers

Abstract

:1. Introduction

- (i)

- Nanoclays(layered aluminosilicates). It has been reported that montmorillonite, a variety of bentonite clays, is the most effective and promising among layered silicates. Its main characteristic is its ability to split into individual nanosized plates [22].

- (ii)

- Nano-oxides. Nanoparticles of titanium have been applied for this purpose [23]. They create a fire retardant barrier on wood surfaces which retard flame spread and suppress smoke generation. Additionally, during the fire, they produce water and gases which provide a cooling effect by snuffing out the oxygen. At the same time, char is created, which in turn protects the wood surface from combustion [24]. Another nano-oxide with promising potential is ZnO [25].

- (iii)

- Nanosilicasol and silicon compounds. Nano-SiO2 was impregnated into the wood by the sol–gel method and demonstrated great potential [26].

- (iv)

- Nanostructured carbon materials. The information oncarbon nanotubes and graphenes as potential materials for fire retardants is limited.

2. Materials and Methods

2.1. Panel Production and Specimen Preparation

2.2. Wollastonite Application

2.3. Fire-Retardant Testing Device

2.4. Statistical Analysis

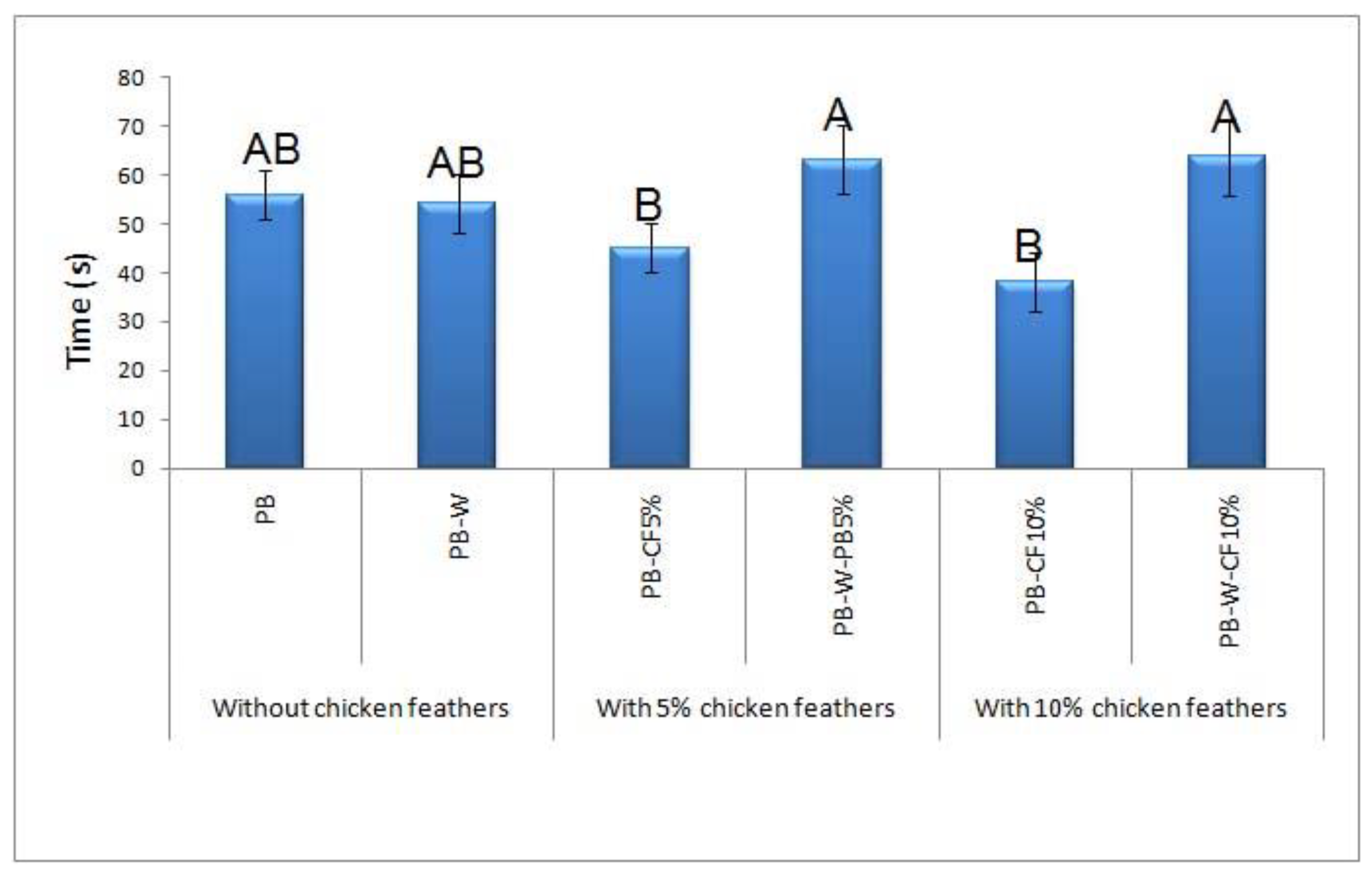

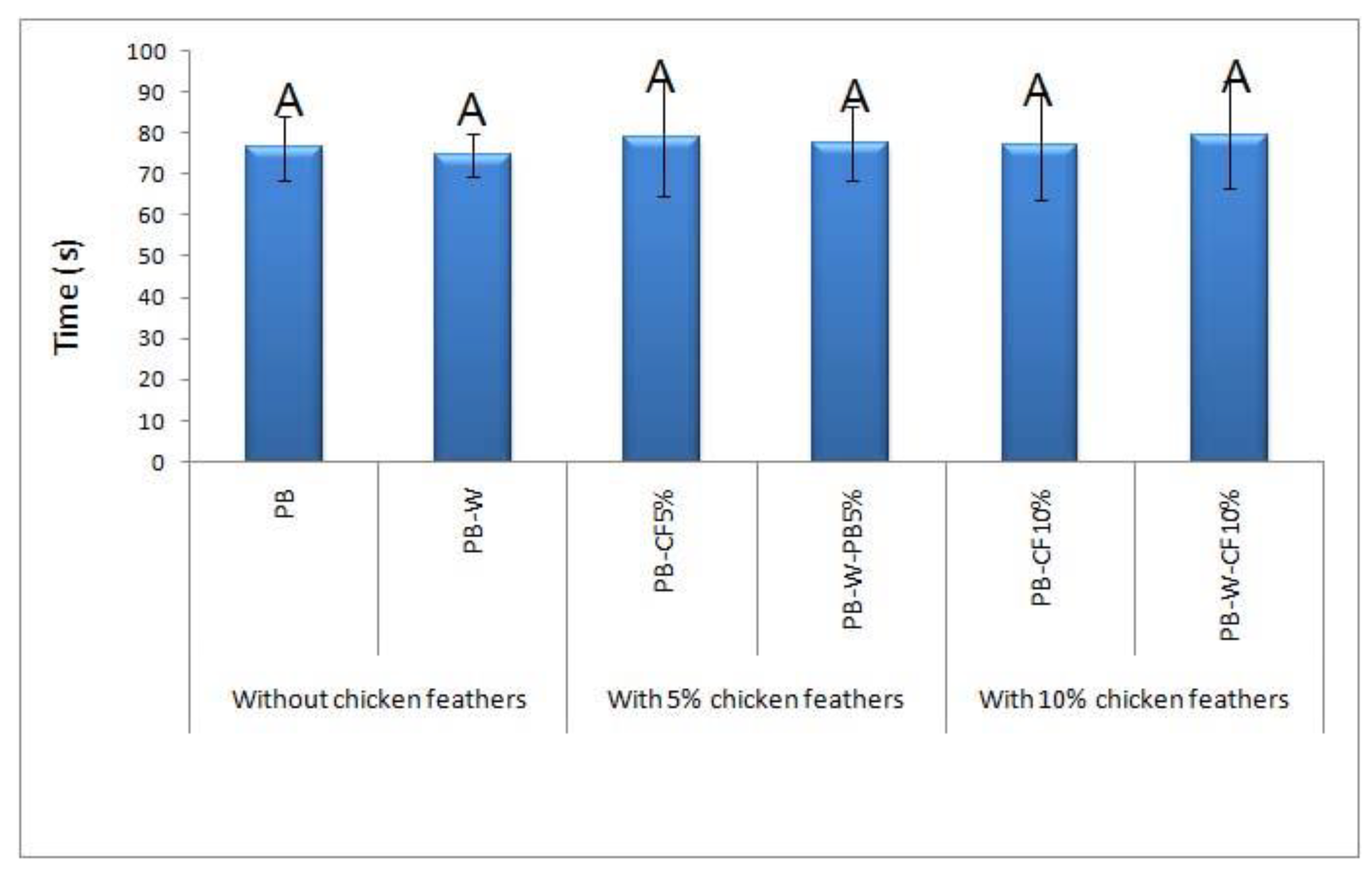

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Singh, T.; Singh, A.P. A review on natural products as wood protectant. Wood Sci. Technol. 2012, 46, 851–870. [Google Scholar] [CrossRef]

- Papadopoulos, A.N.; Avtzis, D.; Avtzis, N. The biological effectiveness of wood modified with linear chain carboxylic acid anhydrides against the subterranean termites Reticulitermes flavipes. Holz Roh Werkst. 2003, 66, 249–252. [Google Scholar] [CrossRef]

- Papadopoulos, A.N.; Taghiyari, H.R. Innovative Wood Surface Treatments Based on Nanotechnology. Coatings 2019, 9, 886. [Google Scholar] [CrossRef] [Green Version]

- Mantanis, G.; Papadopoulos, A.N. Reducing the thickness swelling of wood based panels by applying a nanotechnology compound. Eur. J. Wood Wood Prod. 2010, 68, 237–239. [Google Scholar] [CrossRef] [Green Version]

- Taghiyari, H.R.; Norton, J.; Tajvidi, M. Effects of Nano-materials on Different Properties of Wood-Composite Materials—Chapter 14. In Bio-Based Wood Adhesives: Protection, Characterization, and Testing; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar]

- Taghiyari, H.R.; Tajvidi, M.; Taghiyari, R.; Mantanis, G.I.; Esmailpour, A.; Hosseinpourpia, R. Nanotechnology for wood quality improvement and protection—Chapter 19. In Nanomaterials for Agriculture and Forestry Application; Elsevier: Amstedam, The Netherlands, 2020. [Google Scholar] [CrossRef]

- White, R.H.; Dietenberger, M.A. Wood Handbook, Chapter 17: Fire Safety; Forest Products Laboratory; Gen. Tech. Rep. FPL–GTR–113; Department of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 1999; 463p. [Google Scholar]

- Igaz, R.; Kristak, L.; Ruziak, I.; Gajtanska, M.; Kucerka, M. Thermophysical properties of OSB Boards versus Equilibrium Moisture Content. Bioresources 2017, 12, 8106–8118. [Google Scholar]

- Taghiyari, H.R. Fire-Retarding Properties of Nano-Silver in Solid Woods. Wood Sci. Technol. 2012, 46, 939–952. [Google Scholar] [CrossRef]

- Pizzi, A.; Papadopoulos, A.; Policardi, F. Wood Compositesand Their Polymer Binders. Polymers 2020, 12, 1115. [Google Scholar] [CrossRef] [PubMed]

- Gašparík, M.; Osvaldová, L.; Čekovská, H.; Potůček, D. Flammability characteristics of thermally modified oak wood treated with a fire retardant. Bioresources 2017, 12, 8451–8467. [Google Scholar]

- Winandy, J.E. Techline, Properties and Use of Wood, Composites, and Fiber Products, Durability of Fire-Retardant-Treated Wood; VL-5, Issued 01/98; United States Department of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 1998. [Google Scholar]

- Taghiyari, H.R.; Esmailpour, A.; Majidi, R.; Morrell, J.J.; Mallaki, M.; Militz, H.; Papadopoulos, A.N. Potential use of wollatonite as a filler in UF resin based medium-density fiberboard (MDF). Polymers 2020, 12, 1435. [Google Scholar] [CrossRef]

- Taghiyari, H.R.; Soltani, A.; Esmailpour, Α.; Hassani, V.; Gholipour, H.; Papadopoulos, A.N. Improving Thermal Conductivity Coefficient in Oriented Strand Lumber (OSL) using Sepiolite. Nanomaterials 2020, 10, 599. [Google Scholar] [CrossRef] [Green Version]

- Taghiyari, H.R.; Tajvidi, Μ.; Soltani, Α.; Esmailpour, Α.; Khodadoosti, G.; Jafarzadeh, H.; Militz, H.; Papadopoulos, A.N. Improving fire retardancy of unheated and heat-treated fir wood by nano-sepiolite. Eur. J. Wood Prod. 2021. [Google Scholar] [CrossRef]

- Esmailpour, A.; Majidi, R.; Taghiyari, H.R.; Ganjkhani, M.; Mohseni, M.; Papadopoulos, A.N. Improving fire retardancy of beech wood by graphene. Polymers 2020, 12, 303. [Google Scholar] [CrossRef] [Green Version]

- Maloney, T.M. Modern Particleboard and Dry Process Fibreboard Manufacturing; Hal Leonard Corporation: Milwaukee, WI, USA, 1993. [Google Scholar]

- Walker, J.C.F. Primary Wood Processing: Principles and Practice; Springer: Dordrecht, The Netherlands, 2006. [Google Scholar]

- Huuskonen, M.S.; Jarvisalo, J.; Koskinen, H.; Nickels, J.; Rasanen, J.; Asp, S. Preliminary results from a cohort of workers exposed to wollastonite in a Finish limestone quarry. Scand. J. Work. Health 1983, 9, 169–175. [Google Scholar] [CrossRef] [PubMed]

- Huuskonen, M.S.; Tossavainen, A.; Koskinen, H.; Zitting, A.; Korhonen, O.; Nickels, J.; Korhonen, K.; Vaaranen, V. Wollastonite exposure and lung fibrosis. Environ. Res. 1983, 30, 291–304. [Google Scholar] [CrossRef]

- Taghiyari, H.R.; Majidi, R.; Esmailpour, A.; Sarvari Samadi, Y.; Jahangiri, A.; Papadopoulos, A.N. Engineering composites made from wood and chicken feather bonded with UF resin fortified with wollastonite: A novel approach. Polymers 2020, 12, 857. [Google Scholar] [CrossRef] [Green Version]

- Vakhitova, L.N. Fire retardant nanocoating for wood protection. In Nanotechnology in Eco-Efficient Construction; Woodhead Publishing: Cambridge, UK, 2019. [Google Scholar]

- Wu, H.; La Parola, V.; Pantaleo, G.; Puleo, F.; Venezia, A.M.; Liotta, L.F. Ni-based catalysts for low temperature methane steam reforming: Recent results on Ni-Au and comparison with other bimetallic systems. Catalysts 2013, 3, 563–583. [Google Scholar] [CrossRef] [Green Version]

- Weichelt, F.; Emmler, R.; Flyunt, R.; Beyer, E.; Buchmeiser, M.R.; Beyer, M. ZnO-Based UV Nanocomposites for Wood Coatings in Outdoor Applications. Macromol. Mater. Eng. 2010, 29, 130–136. [Google Scholar] [CrossRef]

- Bueno, A.B.F.; Banon, M.V.N.; Morentín, L.; García, M.J.M. Treatment of natural woodveneers with nanooxides to improve their fire behaviour. In Proceedings of the 2nd International Conference on Structural Nano Composites, Madrid, Spain, 20–21 May 2014; Series: Materials Science and Engineering. Institute of Physics: Bristol, UK, 2014. [Google Scholar]

- Malthig, B.; Swaboda, C.; Roessler, A.; Bottcher, H. Functionalising wood by nanosol application. J. Mater. Chem. 2008, 18, 3180–3192. [Google Scholar] [CrossRef]

- Yeniocak, M.; Göktas¸, O.; Erdil, Y.Z.; Özen, E. Investigating the use of vine pruning stalks (Vitis Vinifera, L. CV. Sultani) as raw material for particleboard manufacturing. Wood Res. 2014, 59, 167–176. [Google Scholar]

- Klimek, P.; Meinlschimidt, P.; Wimmer, R.; Plinke, B. Using sunflower (Helianthus annuus L.), topinambour (Helianthus tuberosus L.) and cup-plant (Silphium perfoliatum L.) stalks as alternative raw materials for particleboards. Ind. Crop. Prod. 2016, 92, 157–164. [Google Scholar] [CrossRef]

- Nazerian, M.; Beyki, Z.; Gargari, R.; Kool, F. Theeffectofsometechnologicalproductionvariablesonmechanicalandphysicalpropertiesofparticleboardmanufacturedfromcottonstalks. Maderas Cienc. Technol. 2016, 18, 167–178. [Google Scholar]

- Papadopoulos, A.N.; Hill, C.A.S.; Gkaraveli, A.; Ntalos, G.; Karastergiou, S. Bamboo chips (Bambusa vulgaris) as an alternative lignocellulosic raw material for particleboard manufacture. Holz Als Roh-Und Werkst. 2004, 62, 36–39. [Google Scholar] [CrossRef]

- Papadopoulos, A.N.; Traboulay, E.; Hill, C.A.S. One layer Experimental Particleboard from Coconut Chips (Cocos nucifera L.). Holz Als Roh-Und Werkst. 2002, 60, 394–396. [Google Scholar] [CrossRef]

- Kord, B.; Zare, H.; Hosseinzabeh, A. Evaluation of the mechanical and physical properties of particleboard manufactured from canola straws. Maderas Cienc. Technol. 2016, 18, 9–18. [Google Scholar] [CrossRef] [Green Version]

- Küçüktüvek, M.; Kasal, A.; Kuşkun, T.; Erdil, Y. Utilizing poppy husk-based particleboards as an alternative material in case furniture construction. BioResources 2017, 12, 839–852. [Google Scholar] [CrossRef] [Green Version]

- Li, X.; Cai, Z.; Winandy, J.; Basta, A. Selected properties of particleboard panels manufactured from rice straws of different geometries. Biores. Technol. 2010, 101, 4662–4666. [Google Scholar] [CrossRef]

- Ntalos, G.A.; Grigoriou, A.H. Characterization and utilisation of vine prunings as a wood substitute for particleboard production. Ind. Crop. Prod. 2002, 16, 59–68. [Google Scholar] [CrossRef]

- Tudor, E.M.; Dettendorfer, A.; Kain, G.; Barbu, M.C.; Réh, R.; Krišťák, Ľ. Sound-Absorption Coefficient of Bark-Based Insulation Panels. Polymers 2020, 12, 1012. [Google Scholar] [CrossRef]

- Papadopoulos, A.N.; Hague, J.R.B. The potential use of Linum usitatissimun (flax) chips as a raw lignocellulosic material for particleboards. Ind. Crop. Prod. 2003, 17, 143–147. [Google Scholar] [CrossRef]

- Papadopoulos, A.N. Banana chips (Musa acuminate) as an alternative lignocellulosic raw material for particleboard manufacture. Maderas Cienc. Technol. 2018, 20, 395–402. [Google Scholar]

- Papadopoulos, A.N.; Kyzas, G.Z.; Mitropoulos, A.C. Lignocellulosic composites from acetylated sunflower stalks. Appl. Sci. 2019, 9, 646. [Google Scholar] [CrossRef] [Green Version]

- Rammou, E.; Mitani, A.; Ntalos, G.; Koutsianitis, D.; Taghiyari, H.R.; Papadopoulos, A.N. The Potential Use of Seaweed (Posidonia oceanica) as an Alternative Lignocellulosic Raw Material for Wood Composites Manufacture. Coatings 2021, 11, 69. [Google Scholar] [CrossRef]

- Kock, J.W. Physical and Mechanical Properties of Chicken Feather Materials. Master’s Thesis, School of Civil Environmental Engineering, Georgia Institute of Technology, Atlanta, GA, USA, 2006. [Google Scholar]

- Tesfaye, T.; Sithole, B.B.; Ramjugernath, D. Valorisation of chicken feathers: A review and recovery route—Current status and future prospects. Clean Technol. Environ. Policy 2017, 19, 2363–2378. [Google Scholar] [CrossRef]

- Tesfaye, T.; Sithole, B.B.; Ramjugernath, D. Valorisation of chicken feathers: Recycling and recovery routes. In Proceedings of the Sardinia 2017–16th International Waste Management & Landfill Symposium, Santa Margherita di Pula, Cagilari, Italy, 2–6 October 2017; p. 10. [Google Scholar]

- Figueroa, M.; Bustos, C.; Dechent, P.; Reyes, L.; Cloutier, A.; Giuliano, M. Analysis of rheological and thermo-hygro-mechanical behaviour of stress-laminated timber bridge deck in variable environmental conditions. Maderas Cienc. Y Tecnol. 2012, 14, 303–319. [Google Scholar]

- ISO 11925-3:1997. Cor. 1: 1998. Reaction to Fire Tests. Ignitability of Building Products Subjected to Direct Impingement of Flame. Part III: Multi-Source Test; BSI: London, UK, 1998; ISBN 0580292258. [Google Scholar]

- Taghiyari, H.R.; Morrell, J.J.; Papadopoulos, A.N. Wollastonite to improve fire properties in medium-density fiberboard made from wood and chicken feather fibers. Appl. Sci. 2021, 11, 3070. [Google Scholar] [CrossRef]

- Esmailpour, A.; Taghiyari, H.R.; Majidi, R.; Babaali, S.; Morrell, J.J.; Mohammadpanah, B. Effects of adsorption energy on air and liquid permeability of nanowollastonite-treated medium-density fiberboard. IEEE Trans. Instrum. Meas. 2021, 70. [Google Scholar] [CrossRef]

- Taghiyari, H.R.; Majidi, R.; Mohseni Armaki, S.M.; Haghighatparast, M. Graphene as reinforcing filler in polyvinyl acetate resin. Int. J. Adhes. Adhes. 2021, accepted. [Google Scholar]

- Hassani, V.; Taghiyari, H.R.; Schmidt, O.; Maleki, S.; Papadopoulos, A.N. Mechanical and physical properties of oriented strand lumber (OSL): The effect of fortification level of nanowollastonite on UF resin. Polymers 2019, 11, 1884. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Esmailpour, A.; Taghiyari, H.R.; Nouri, P.; Jahangiri, A. Fire-retarding properties of nanowollastonite in particleboard. Fire Mater. 2018, 42, 306–315. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Taghiyari, H.R.; Militz, H.; Antov, P.; Papadopoulos, A.N. Effects of Wollastonite on Fire Properties of Particleboard Made from Wood and Chicken Feather Fibers. Coatings 2021, 11, 518. https://doi.org/10.3390/coatings11050518

Taghiyari HR, Militz H, Antov P, Papadopoulos AN. Effects of Wollastonite on Fire Properties of Particleboard Made from Wood and Chicken Feather Fibers. Coatings. 2021; 11(5):518. https://doi.org/10.3390/coatings11050518

Chicago/Turabian StyleTaghiyari, Hamid R., Holger Militz, Petar Antov, and Antonios N. Papadopoulos. 2021. "Effects of Wollastonite on Fire Properties of Particleboard Made from Wood and Chicken Feather Fibers" Coatings 11, no. 5: 518. https://doi.org/10.3390/coatings11050518

APA StyleTaghiyari, H. R., Militz, H., Antov, P., & Papadopoulos, A. N. (2021). Effects of Wollastonite on Fire Properties of Particleboard Made from Wood and Chicken Feather Fibers. Coatings, 11(5), 518. https://doi.org/10.3390/coatings11050518