Hydrothermal Synthesis and Microwave Absorption Properties of Nickel Ferrite/Multiwalled Carbon Nanotubes Composites

Abstract

:1. Introduction

2. Experimental

2.1. Materials

2.2. In-Situ Synthesis of NiFe2O4/ MWCNTs Hybrids

2.3. Characterizations

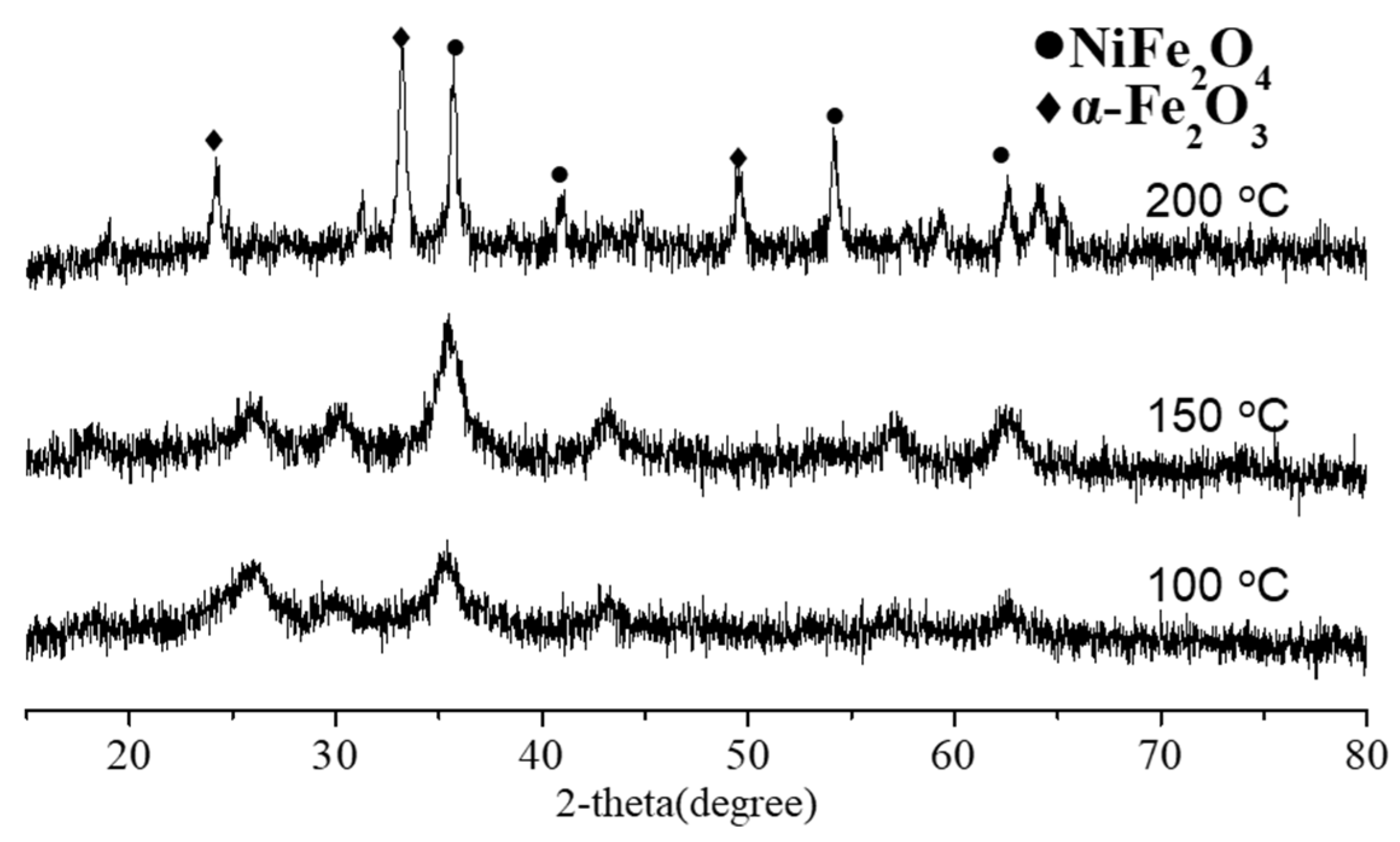

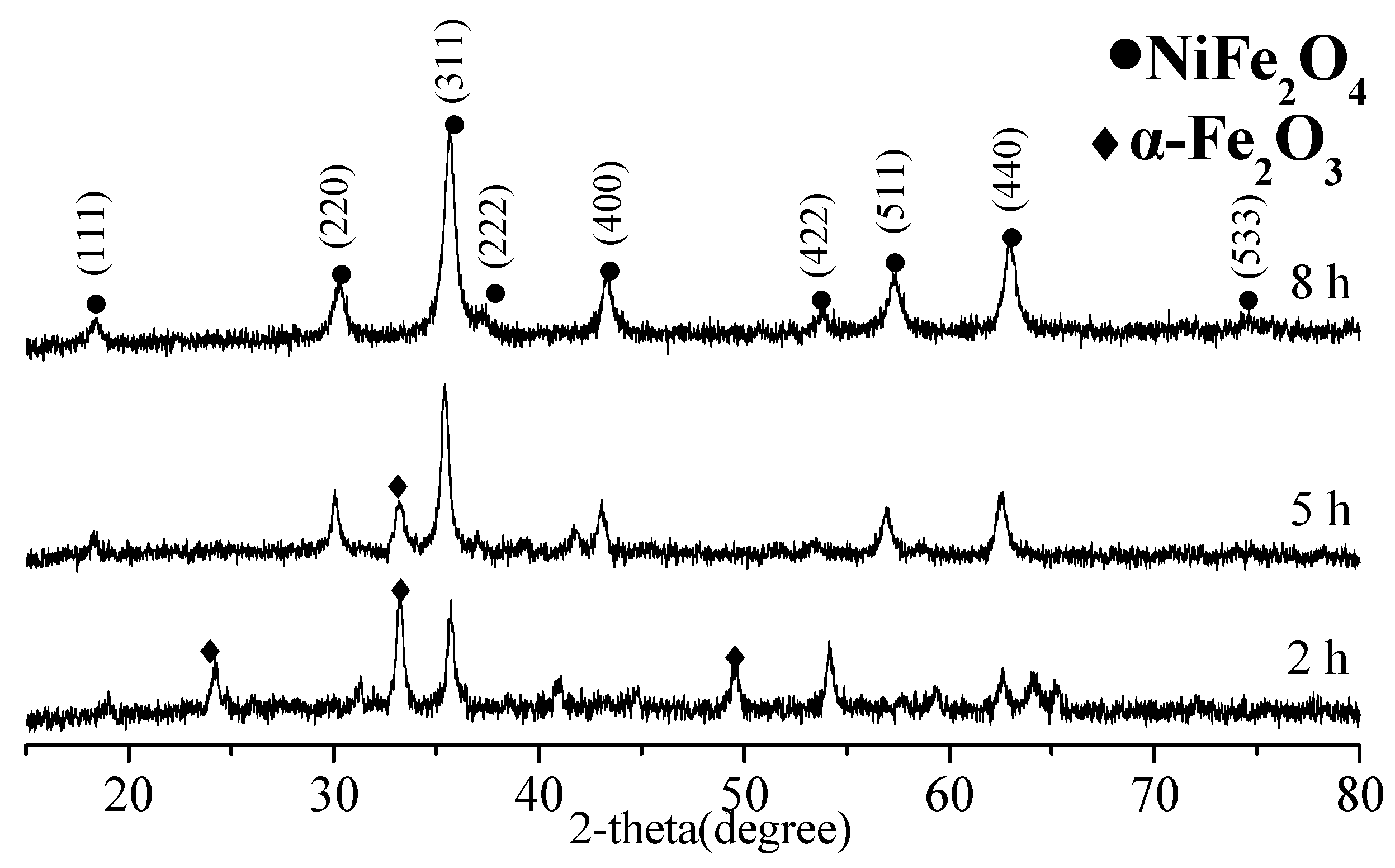

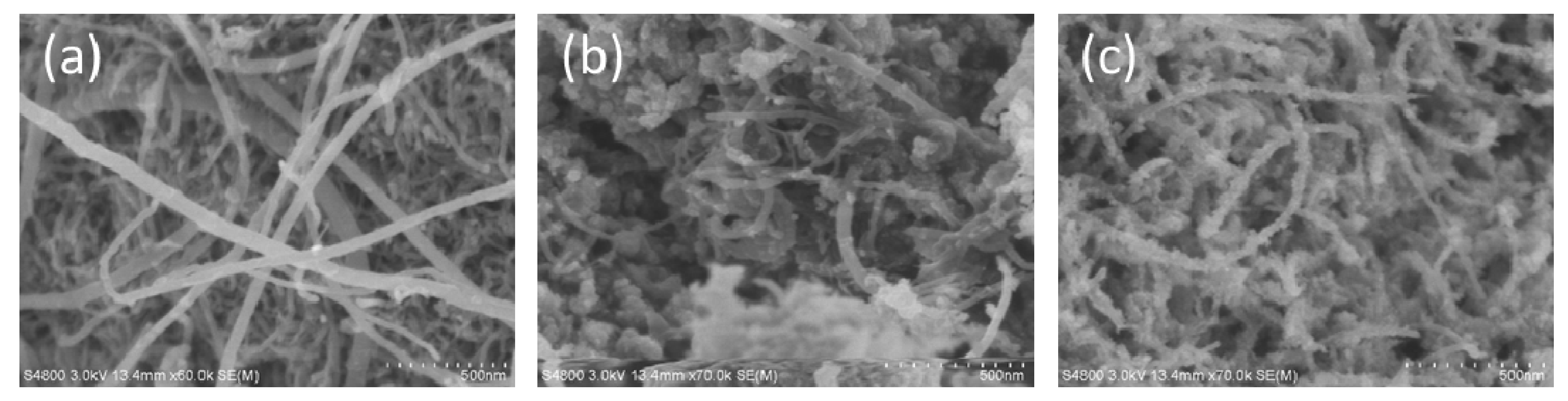

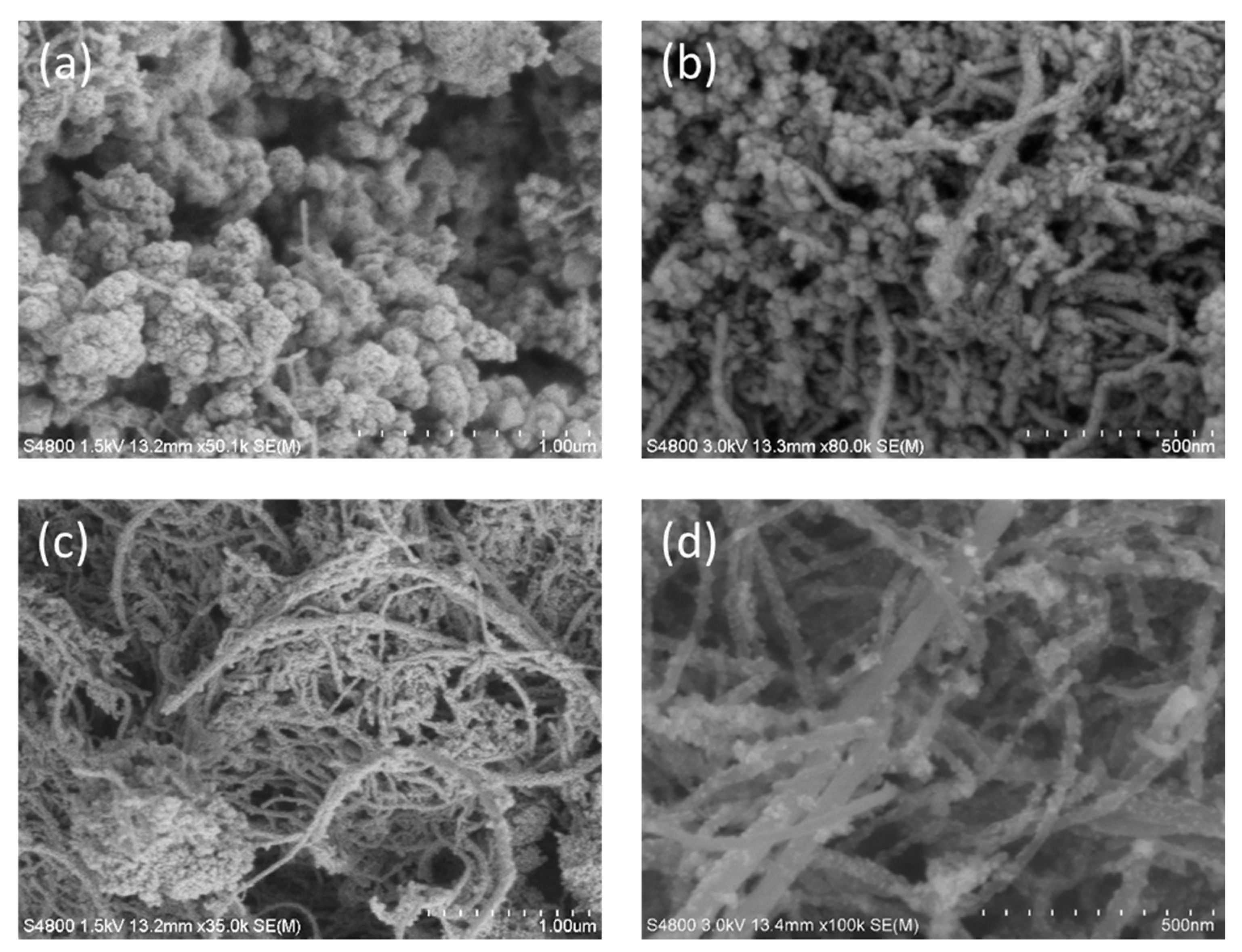

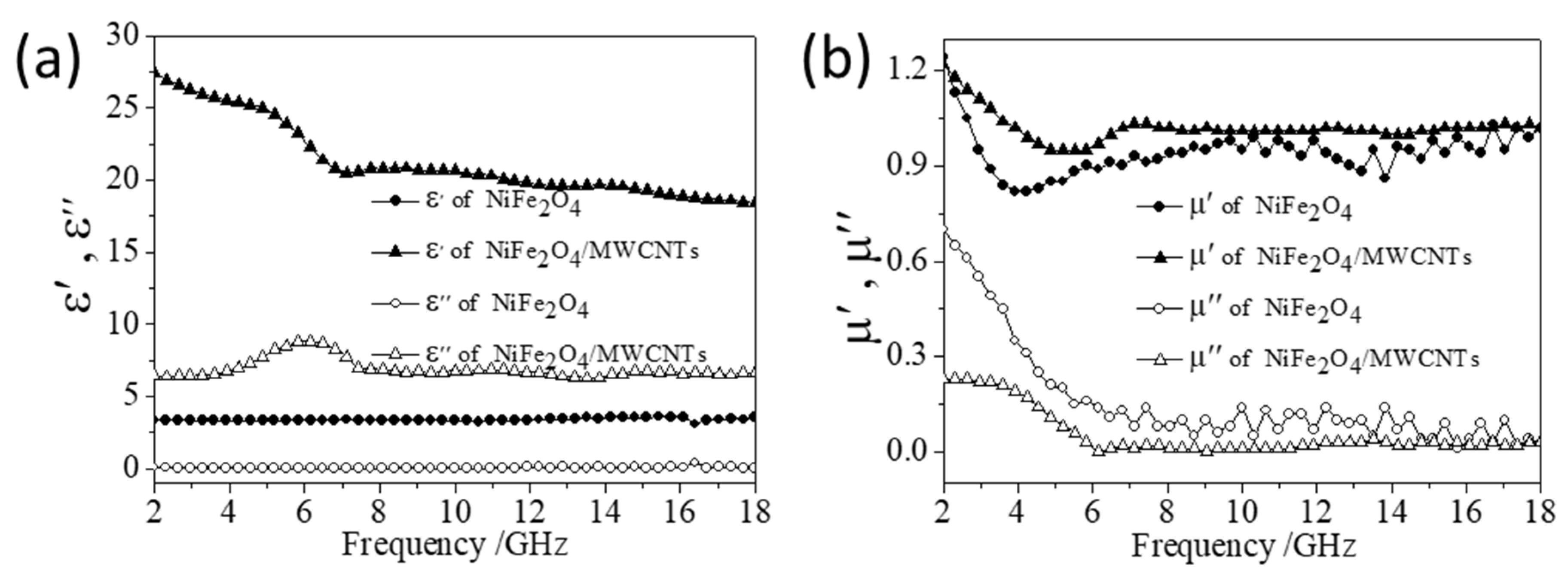

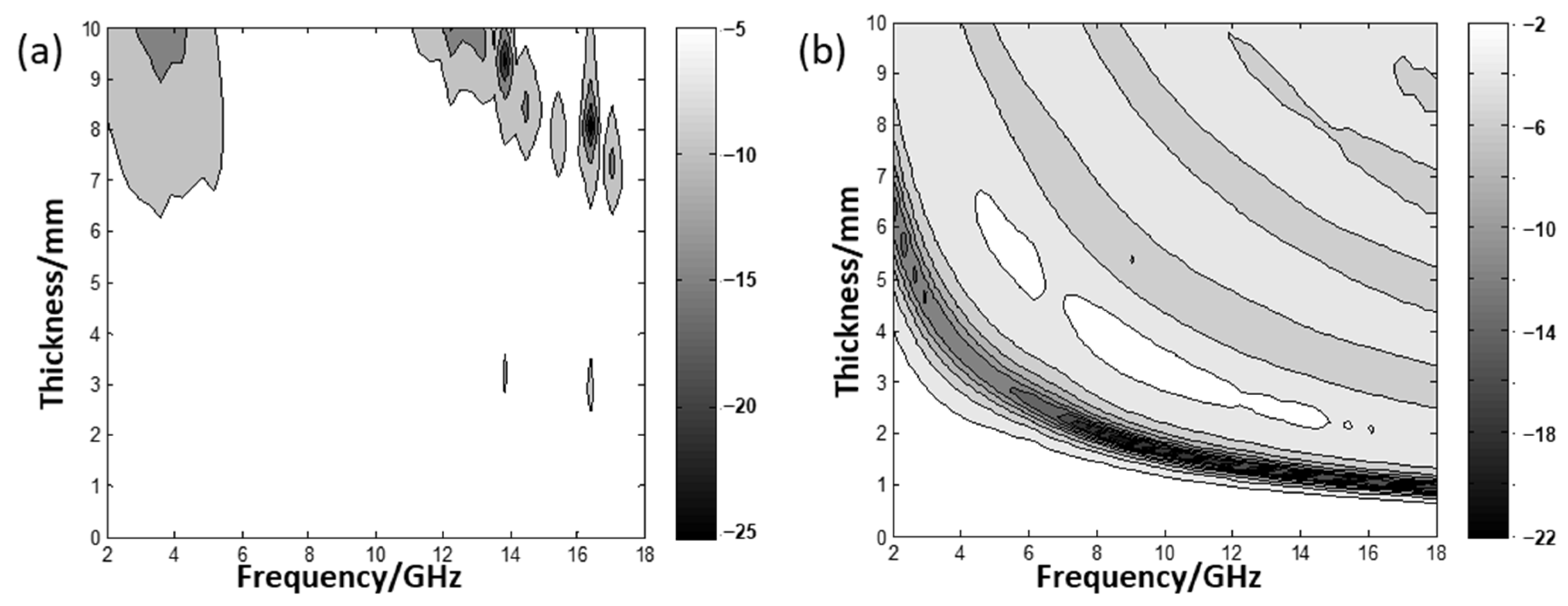

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lv, H.; Guo, Y.; Yang, Z.; Cheng, Y.; Wang, L.P.; Zhang, B.; Zhao, Y.; Xu, Z.J.; Ji, G. A Brief introduction to the fabrication and synthesis of graphene based composites for the realization of electromagnetic absorbing materials. J. Mater. Chem. C 2017, 5, 491–512. [Google Scholar] [CrossRef]

- Zhang, K.; Gao, X.; Zhang, Q.; Li, T.; Chen, H.; Chen, X. Synthesis, characterization and electromagnetic wave absorption properties of asphalt carbon coated graphene/magnetic NiFe2O4 modified multi-wall carbon nanotube composites. J. Alloys Compd. 2017, 721, 268–275. [Google Scholar] [CrossRef]

- Meng, F.; Wang, H.; Huang, F.; Guo, Y.; Wang, Z.; Hui, D.; Zhou, Z. Graphene-based microwave absorbing composites: A review and prospective. Compos. Part B Eng. 2018, 137, 260–277. [Google Scholar] [CrossRef]

- Hu, J.; Zhao, T.; Peng, X.; Yang, W.; Ji, X.; Li, T. Growth of coiled amorphous carbon nanotube array forest and its electromagnetic wave absorbing properties. Compos. Part B Eng. 2018, 134, 91–97. [Google Scholar] [CrossRef]

- Guan, B.; Liu, J.; Zhao, H.; Wu, J.; Liu, J.; Yang, F. Investigation of the microwave absorption of asphalt mixtures containing magnetite powder. Coatings 2019, 9, 813. [Google Scholar] [CrossRef] [Green Version]

- Bhattacharyya, R.; Prakash, O.; Roy, S.; Singh, A.P.; Bhattacharya, T.K.; Maiti, P.; Bhattacharyya, S.; Das, S. Graphene oxide-ferrite hybrid framework as enhanced broadband absorption in gigahertz frequencies. Sci. Rep. 2019, 9, 12111. [Google Scholar] [CrossRef]

- Zhang, J.; Shu, R.; Guo, C.; Sun, R.; Chen, Y.; Yuan, J. Fabrication of nickel ferrite microspheres decorated multi-walled carbon nanotubes hybrid composites with enhanced electromagnetic wave absorption properties. J. Alloys Compd. 2019, 784, 422–430. [Google Scholar] [CrossRef]

- Lu, D.; Ramzan, M.; Ahmad, S.; Shafee, A.; Suleman, M. Impact of nonlinear thermal radiation and entropy optimization coatings with hybrid nanoliquid flow past a curved stretched surface. Coatings 2018, 8, 430. [Google Scholar] [CrossRef] [Green Version]

- Zhao, T.; Jin, W.; Wang, Y.; Ji, X.; Yan, H.; Xiong, C.; Lou, X.; Dang, A.; Li, H.; Li, T. In situ synthesis and electromagnetic wave absorbing properties of sandwich microstructured graphene/la-doped barium ferrite nanocomposite. RSC Adv. 2017, 7, 37276–37285. [Google Scholar] [CrossRef] [Green Version]

- Zhao, T.; Jin, W.; Ji, X.; Yan, H.; Jiang, Y.; Dong, Y.; Yang, Y.; Dang, A.; Li, H.; Li, T. Synthesis of sandwich microstructured expanded graphite/barium ferrite connected with carbon nanotube composite and its electromagnetic wave absorbing properties. J. Alloys Compd. 2017, 712, 59–68. [Google Scholar] [CrossRef] [Green Version]

- Li, J.; Xie, Y.; Lu, W.; Chou, T.-W. Flexible electromagnetic wave absorbing composite based on 3D RGO-CNT-Fe3O4 ternary films. Carbon 2018, 129, 76–84. [Google Scholar] [CrossRef]

- Hong, X.; Xie, Y.; Wang, X.; Li, M.; Le, Z.; Gao, Y.; Huang, Y.; Qin, Y.; Ling, Y. A novel ternary hybrid electromagnetic wave-absorbing composite based on BaFe11.92(LaNd)0.04 O19 -titanium dioxide/multiwalled carbon nanotubes/polythiophene. Compos. Sci. Technol. 2015, 117, 215–224. [Google Scholar] [CrossRef]

- Vinetsky, Y.; Jambu, J.; Mandler, D.; Magdassi, S. Cnt-based solar thermal coatings: Absorptance vs. emittance. Coatings 2020, 10, 1101. [Google Scholar] [CrossRef]

- Rodríguez-Salinas, J.; Hernández, M.B.; Cruz, L.G.; Martínez-Romero, O.; Ulloa-Castillo, N.A.; Elías-Zúñiga, A. Enhancing electrical and thermal properties of Al6061 parts by electrophoresis deposition of multi-walled carbon nanotubes. Coatings 2020, 10, 656. [Google Scholar] [CrossRef]

- Li, J.; Lu, W.; Suhr, J.; Chen, H.; Xiao, J.Q.; Chou, T.W. Superb electromagnetic wave-absorbing composites based on large-scale graphene and carbon nanotube films. Sci. Rep. 2017, 7, 2349. [Google Scholar] [CrossRef]

- Zhao, T.; Ji, X.; Jin, W.; Guo, S.; Zhao, H.; Yang, W.; Wang, X.; Xiong, C.; Dang, A.; Li, H. Electromagnetic wave absorbing properties of aligned amorphous carbon nanotube/BaFe12O19 nanorod composite. J. Alloys Compd. 2017, 703, 424–430. [Google Scholar] [CrossRef] [Green Version]

- Lu, S.; Xu, W.; Xuhai, X.; Ma, K.; Wang, X. Preparation, magnetism and microwave absorption performance of ultra-thin Fe3O4/carbon nanotube sandwich buckypaper. J. Alloys Compd. 2014, 606, 171–176. [Google Scholar] [CrossRef]

- Hou, C.-l.; Li, T.-h.; Zhao, T.-k.; Liu, H.-g.; Liu, L.-h.; Zhang, W.-j. Electromagnetic wave absorbing properties of multi-wall carbon nanotube/Fe3O4 hybrid materials. New Carbon Mater. 2013, 28, 184–190. [Google Scholar] [CrossRef]

- Li, Y.; Wu, T.; Jin, K.; Qian, Y.; Qian, N.; Jiang, K.; Wu, W.; Tong, G. Controllable synthesis and enhanced microwave absorbing properties of Fe3O4/NiFe2O4/Ni heterostructure porous rods. Appl. Surf. Sci. 2016, 387, 190–201. [Google Scholar] [CrossRef]

- Fu, H.; Du, Z.-j.; Zou, W.; Li, H.-q.; Zhang, C. Simple fabrication of strongly coupled cobalt ferrite/carbon nanotube composite based on deoxygenation for improving lithium storage. Carbon 2013, 65, 112–123. [Google Scholar] [CrossRef]

- Zhou, G.; Wang, D.-W.; Yin, L.-C.; Li, N.; Li, F.; Cheng, H.-M. Oxygen bridges between NiO nanosheets and graphene for improvement of lithium storage. ACS Nano 2012, 6, 3214–3223. [Google Scholar] [CrossRef] [PubMed]

- Liu, W.; Shao, Q.; Ji, G.; Liang, X.; Cheng, Y.; Quan, B.; Du, Y. Metal–organic-frameworks derived porous carbon-wrapped ni composites with optimized impedance matching as excellent lightweight electromagnetic wave absorber. Chem. Eng. J. 2017, 313, 734–744. [Google Scholar] [CrossRef]

- Feng, J.; Zong, Y.; Sun, Y.; Zhang, Y.; Yang, X.; Long, G.; Wang, Y.; Li, X.; Zheng, X. Optimization of porous FeNi3/N-GN composites with superior microwave absorption performance. Chem. Eng. J. 2018, 345, 441–451. [Google Scholar] [CrossRef]

- Zhao, H.; Sun, X.; Mao, C.; Du, J. Preparation and microwave–absorbing properties of NiFe2O4-polystyrene composites. Phys. B Condens. Matter 2009, 404, 69–72. [Google Scholar] [CrossRef]

- Chakradhary, V.K.; Akhtar, M.J. Absorption properties of CNF mixed cobalt nickel ferrite nanocomposite for radar and stealth applications. J. Magn. Magn. Mater. 2021, 525, 167592. [Google Scholar] [CrossRef]

- Fu, M.; Jiao, Q.; Zhao, Y. Preparation of NiFe2O4 nanorod–graphene composites via an ionic liquid assisted one-step hydrothermal approach and their microwave absorbing properties. J. Mater. Chem. A 2013, 1, 5577–5586. [Google Scholar] [CrossRef]

- Shu, R.; Zhang, G.; Wang, X.; Gao, X.; Wang, M.; Gan, Y.; Shi, J.; He, J. Fabrication of 3D net-like MWCNTs/ZnFe2O4 hybrid composites as high-performance electromagnetic wave absorbers. Chem. Eng. J. 2018, 337, 242–255. [Google Scholar] [CrossRef]

- Wen, B.; Cao, M.-S.; Hou, Z.-L.; Song, W.-L.; Zhang, L.; Lu, M.-M.; Jin, H.-B.; Fang, X.-Y.; Wang, W.-Z.; Yuan, J. Temperature dependent microwave attenuation behavior for carbon-nanotube/silica composites. Carbon 2013, 65, 124–139. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, L.; He, Y.; Chen, D.; Du, B.; Cao, W.; Lv, Y.; Ding, Z. Hydrothermal Synthesis and Microwave Absorption Properties of Nickel Ferrite/Multiwalled Carbon Nanotubes Composites. Coatings 2021, 11, 534. https://doi.org/10.3390/coatings11050534

Guo L, He Y, Chen D, Du B, Cao W, Lv Y, Ding Z. Hydrothermal Synthesis and Microwave Absorption Properties of Nickel Ferrite/Multiwalled Carbon Nanotubes Composites. Coatings. 2021; 11(5):534. https://doi.org/10.3390/coatings11050534

Chicago/Turabian StyleGuo, Lei, Yusong He, Dong Chen, Bin Du, Wei Cao, Yadong Lv, and Zhijun Ding. 2021. "Hydrothermal Synthesis and Microwave Absorption Properties of Nickel Ferrite/Multiwalled Carbon Nanotubes Composites" Coatings 11, no. 5: 534. https://doi.org/10.3390/coatings11050534