Aluminum Powder Preparation for Additive Manufacturing Using Electrostatic Classification

Abstract

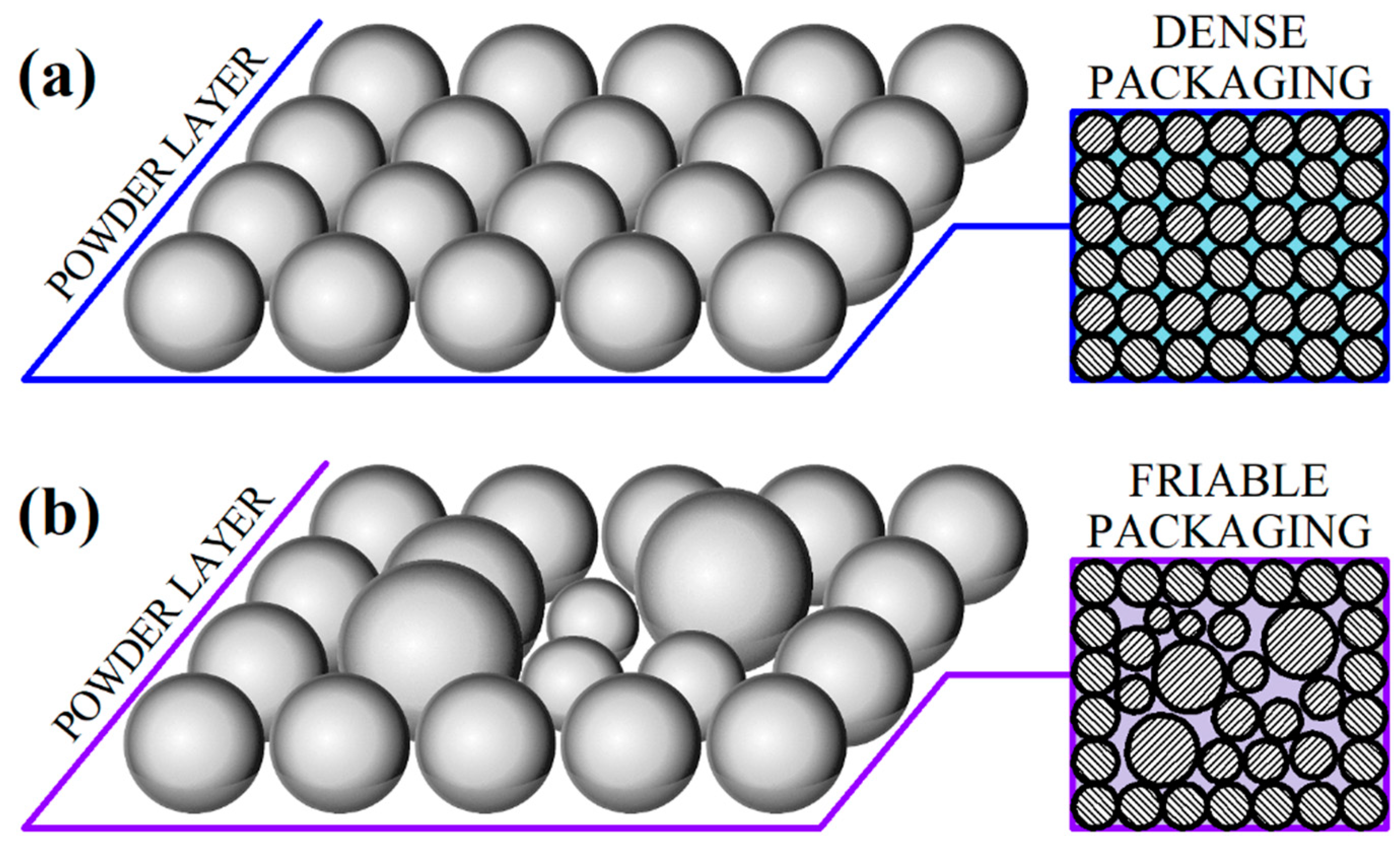

:1. Introduction

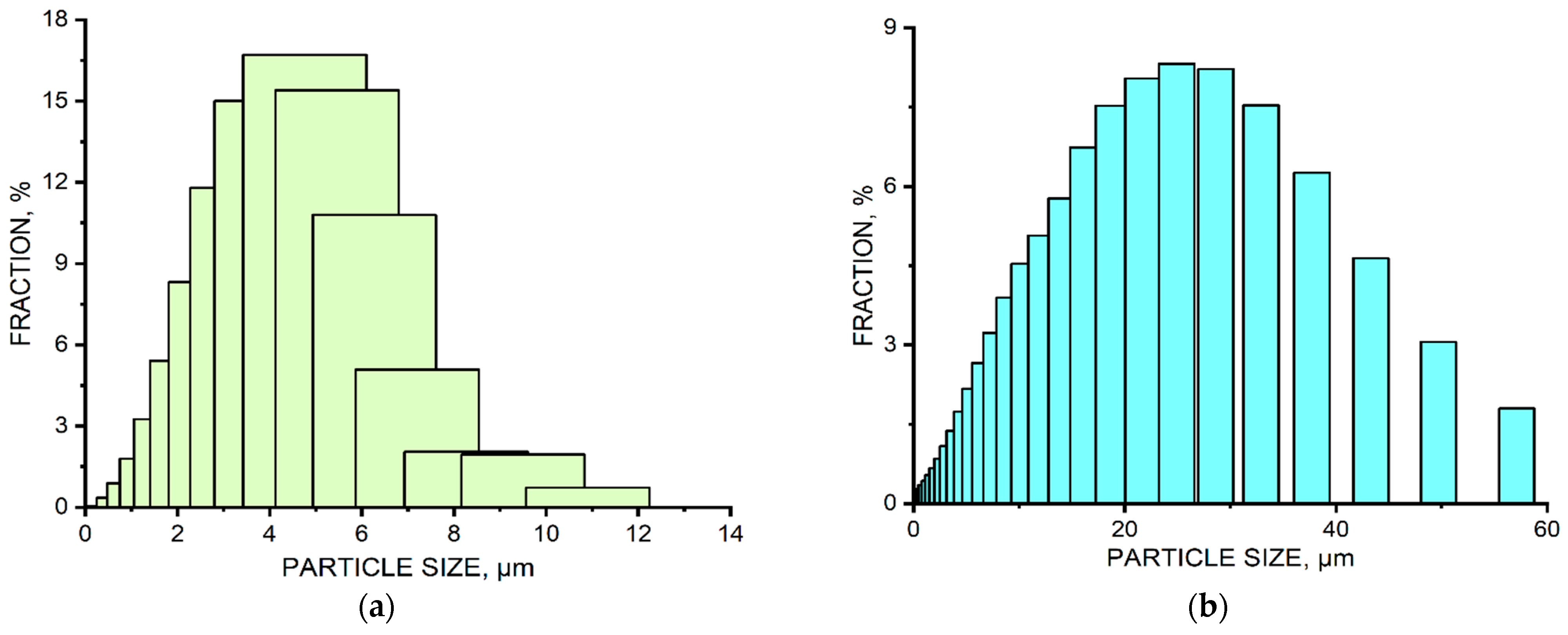

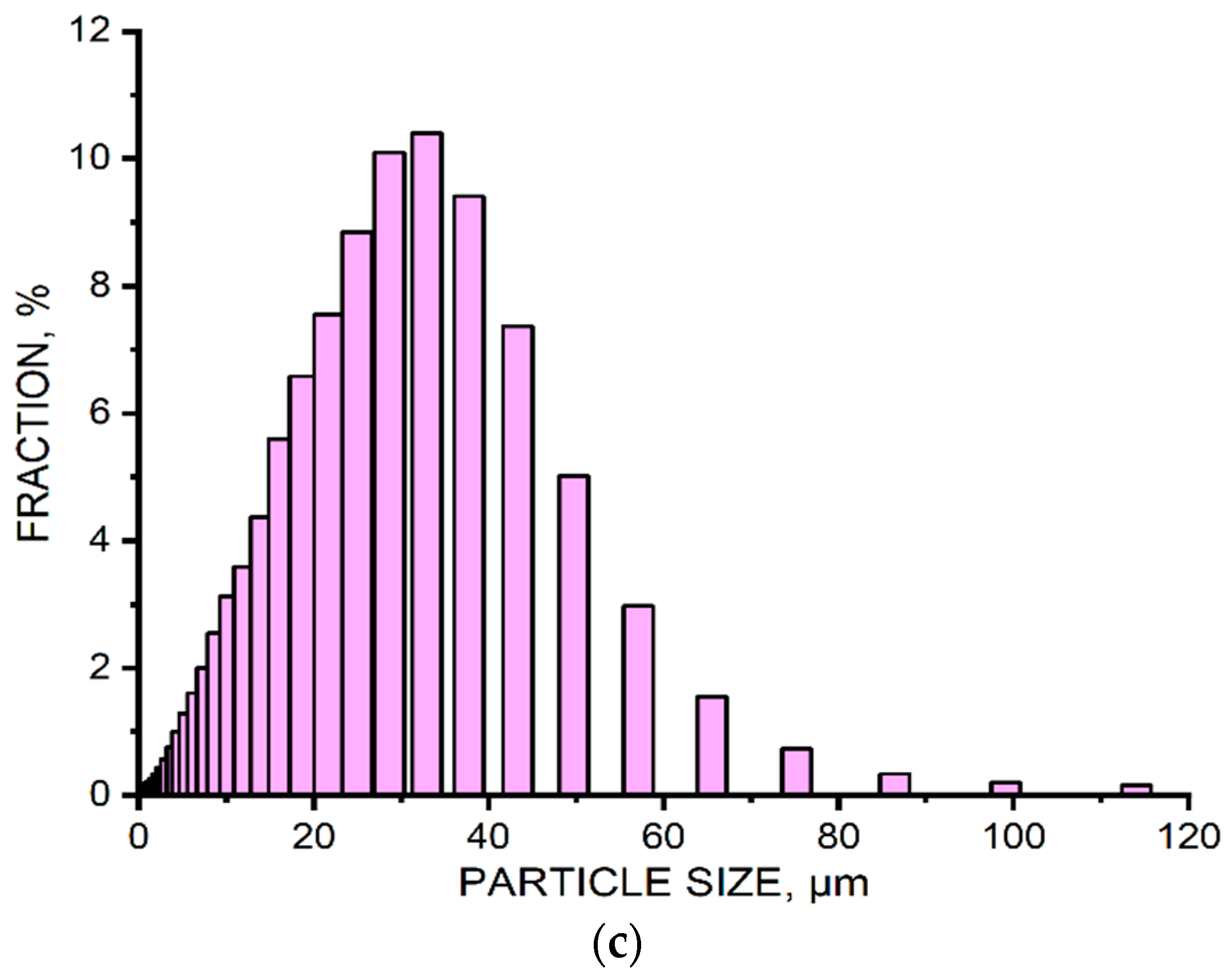

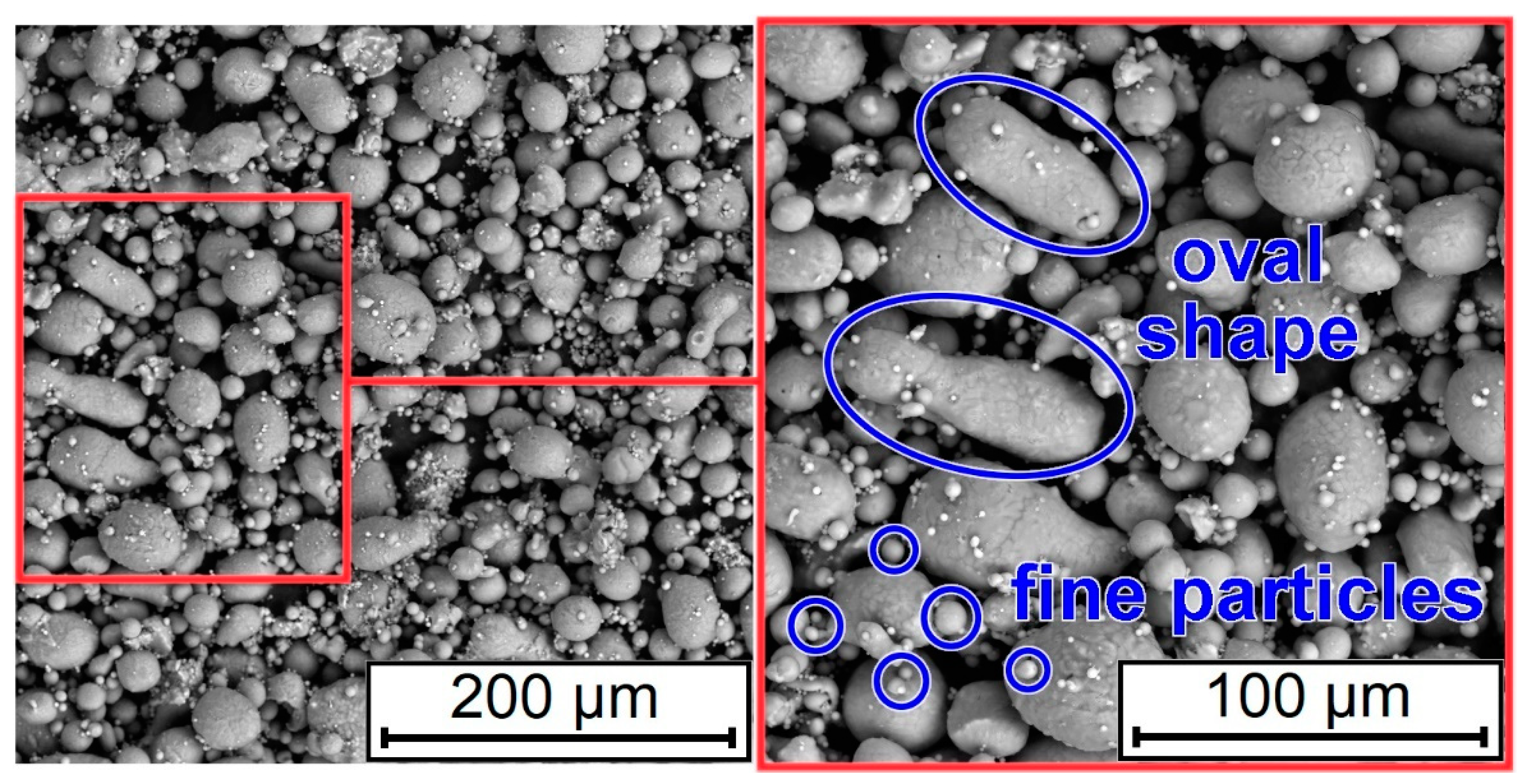

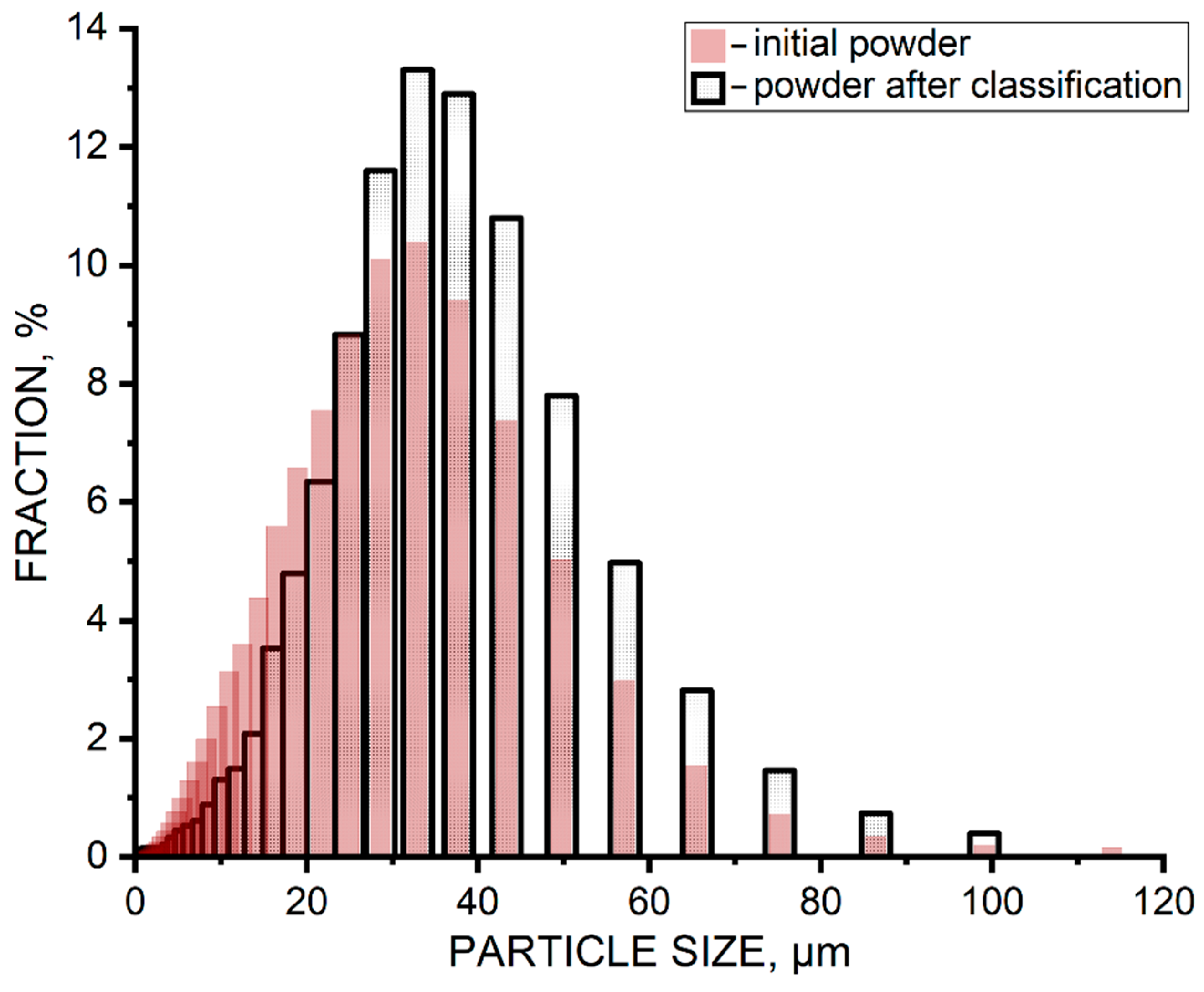

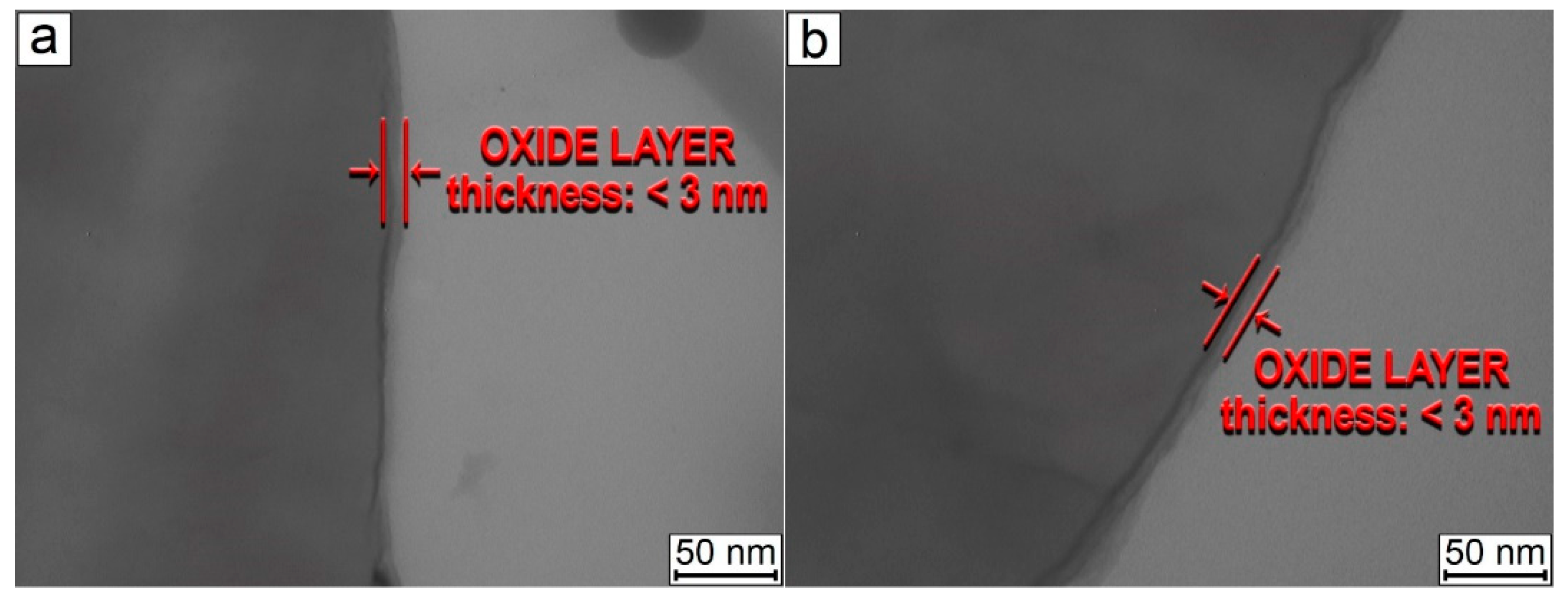

2. Materials and Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Khairallah, S.A.; Anderson, A.T.; Rubenchik, A.; King, W.E. Laser powder-bed fusion additive manufacturing: Physics of complex melt flow and formation mechanisms of pores, spatter, and denudation zones. Acta Mater. 2016, 108, 36–45. [Google Scholar] [CrossRef] [Green Version]

- Gu, D.; Meiners, W.; Wissenbach, K.; Poprawe, R. Laser additive manufacturing of metallic components: Materials, processes and mechanisms. Int. Mater. Rev. 2012, 57, 133–164. [Google Scholar] [CrossRef]

- Debroy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive manufacturing of metallic components—Process, structure and properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Attar, H.; Calin, M.; Zhang, L.; Scudino, S.; Eckert, J. Manufacture by selective laser melting and mechanical behavior of commercially pure titanium. Mater. Sci. Eng. A 2014, 593, 170–177. [Google Scholar] [CrossRef]

- Attar, H.; Ehtemam-Haghighi, S.; Kent, D.; Wu, X.; Dargusch, M.S. Comparative study of commercially pure titanium produced by laser engineered net shaping, selective laser melting and casting processes. Mater. Sci. Eng. A 2017, 705, 385–393. [Google Scholar] [CrossRef]

- Tolosa, I.; Garciandía, F.; Zubiri, F.; Zapirain, F.; Esnaola, A. Study of mechanical properties of AISI 316 stainless steel processed by “selective laser melting”, following different manufacturing strategies. Int. J. Adv. Manuf. Technol. 2010, 51, 639–647. [Google Scholar] [CrossRef]

- Kurzynowski, T.; Gruber, K.; Stopyra, W.; Kuźnicka, B.; Chlebus, E. Correlation between process parameters, microstructure and properties of 316 L stainless steel processed by selective laser melting. Mater. Sci. Eng. A 2018, 718, 64–73. [Google Scholar] [CrossRef]

- Zhang, J.; Song, B.; Wei, Q.; Bourell, D.; Shi, Y. A review of selective laser melting of aluminum alloys: Processing, microstructure, property and developing trends. J. Mater. Sci. Technol. 2019, 35, 270–284. [Google Scholar] [CrossRef]

- Buchbinder, D.; Schleifenbaum, H.; Heidrich, S.; Meiners, W.; Bültmann, J. High Power Selective Laser Melting (HP SLM) of aluminum parts. Phys. Procedia 2011, 12, 271–278. [Google Scholar] [CrossRef]

- Louvis, E.; Fox, P.; Sutcliffe, C.J. Selective laser melting of aluminium components. J. Mater. Process. Technol. 2011, 211, 275–284. [Google Scholar] [CrossRef]

- Rometsch, P.; Jia, Q.; Yang, K.V.; Wu, X. Aluminum alloys for selective laser melting—Towards improved performance. Addit. Manuf. Aerosp. Ind. 2019, 301–325. [Google Scholar] [CrossRef]

- Trevisan, F.; Calignano, F.; Lorusso, M.; Pakkanen, J.A.; Aversa, A.; Ambrosio, E.P.; Lombardi, M.; Fino, P.; Manfredi, D. On the Selective Laser Melting (SLM) of the AlSi10Mg alloy: Process, microstructure, and mechanical properties. Materials 2017, 10, 76. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.; Gu, D. Parametric analysis of thermal behavior during selective laser melting additive manufacturing of aluminum alloy powder. Mater. Des. 2014, 63, 856–867. [Google Scholar] [CrossRef]

- Yap, C.Y.; Chua, C.K.; Dong, Z.; Liu, Z.H.; Zhang, D.Q.; Loh, L.E.; Sing, S.L. Review of selective laser melting: Materials and applications. Appl. Phys. Rev. 2015, 2, 041101. [Google Scholar] [CrossRef]

- Jia, Q.; Rometsch, P.; Cao, S.; Zhang, K.; Wu, X. Towards a high strength aluminium alloy development methodology for selective laser melting. Mater. Des. 2019, 174, 107775. [Google Scholar] [CrossRef]

- Aboulkhair, N.T.; Simonelli, M.; Parry, L.; Ashcroft, I.; Tuck, C.; Hague, R. 3D printing of aluminium alloys: Additive manufacturing of aluminium alloys using selective laser melting. Prog. Mater. Sci. 2019, 106, 100578. [Google Scholar] [CrossRef]

- Aboulkhair, N.T.; Everitt, N.M.; Maskery, I.; Ashcroft, I.; Tuck, C. Selective laser melting of aluminum alloys. MRS Bull. 2017, 42, 311–319. [Google Scholar] [CrossRef]

- Yakout, M.; Elbestawi, M.A.; Veldhuis, S.C. On the characterization of stainless steel 316L parts produced by selective laser melting. Int. J. Adv. Manuf. Technol. 2018, 95, 1953–1974. [Google Scholar] [CrossRef]

- Li, R.; Shi, Y.; Wang, Z.; Wang, L.; Liu, J.; Jiang, W. Densification behavior of gas and water atomized 316L stainless steel powder during selective laser melting. Appl. Surf. Sci. 2010, 256, 4350–4356. [Google Scholar] [CrossRef]

- Baitimerov, R.; Lykov, P.; Zherebtsov, D.; Radionova, L.; Shultc, A.; Prashanth, K.G. Influence of powder characteristics on processability of AlSi12 alloy fabricated by selective laser melting. Materials 2018, 11, 742. [Google Scholar] [CrossRef] [Green Version]

- Muñiz-Lerma, J.A.; Nommeots-Nomm, A.; Waters, K.E.; Brochu, M. A Comprehensive approach to powder feedstock characterization for powder bed fusion additive manufacturing: A case study on AlSi7Mg. Materials 2018, 11, 2386. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Spierings, A.B.; Voegtlin, M.; Bauer, T.; Wegener, K. Powder flowability characterisation methodology for powder-bed-based metal additive manufacturing. Prog. Addit. Manuf. 2015, 1, 9–20. [Google Scholar] [CrossRef] [Green Version]

- Brika, S.E.; Letenneur, M.; Dion, C.A.; Brailovski, V. Influence of particle morphology and size distribution on the powder flowability and laser powder bed fusion manufacturability of Ti-6Al-4V alloy. Addit. Manuf. 2020, 31, 100929. [Google Scholar] [CrossRef]

- Tonelli, L.; Liverani, E.; Valli, G.; Fortunato, A.; Ceschini, L. Effects of powders and process parameters on density and hardness of A357 aluminum alloy fabricated by selective laser melting. Int. J. Adv. Manuf. Technol. 2019, 106, 371–383. [Google Scholar] [CrossRef]

- Garboczi, E.; Hrabe, N. Particle shape and size analysis for metal powders used for additive manufacturing: Technique description and application to two gas-atomized and plasma-atomized Ti64 powders. Addit. Manuf. 2020, 31, 100965. [Google Scholar] [CrossRef]

- Nalivaiko, A.Y.; Arnautov, A.N.; Zmanovsky, S.V.; A Gromov, A. Al–Si–Cu and Al–Si–Cu–Ni alloys for additive manufacturing: Composition, morphology and physical characteristics of powders. Mater. Res. Express 2019, 6, 086536. [Google Scholar] [CrossRef]

- Nalivaiko, A.Y.; Ozherelkov, D.Y.; Arnautov, A.N.; Zmanovsky, S.V.; Osipenkova, A.A.; Gromov, A.A. Selective laser melting of aluminum-alumina powder composites obtained by hydrothermal oxidation method. Appl. Phys. A 2020, 126, 871. [Google Scholar] [CrossRef]

- Lee, Y.; Gurnon, A.K.; Bodner, D.; Simunovic, S. Effect of particle spreading dynamics on powder bed quality in metal additive manufacturing. Integr. Mater. Manuf. Innov. 2020, 9, 410–422. [Google Scholar] [CrossRef]

- Engeli, R.; Etter, T.; Hövel, S.; Wegener, K. Processability of different IN738LC powder batches by selective laser melting. J. Mater. Process. Technol. 2016, 229, 484–491. [Google Scholar] [CrossRef]

- Cherkasova, M.V.; Samukov, A.D.; Dmitriev, S.V.; O Mezenin, A. Research and engineering by REC “Mechanobr-technika” of additive technologies. J. Phys. Conf. Ser. 2021, 1721, 012025. [Google Scholar] [CrossRef]

- Dmitriev, S.V.; Grigoryev, I.V. Prospects for the use of dielectric barrier discharge in electrostatic separation. Obogashchenie Rud 2018, 4, 34–37. [Google Scholar] [CrossRef]

- Mezenin, A.; Dmitriev, S.; Cherkasova, M. Vibration effects in conditioning of metal powders. Vibroeng. Procedia 2019, 25, 36–41. [Google Scholar] [CrossRef]

- Gromov, A.A.; Nalivaiko, A.Y.; Ambaryan, G.N.; Vlaskin, M.S.; Buryakovskaya, O.A.; Kislenko, S.A.; Zhuk, A.Z.; Shkolnikov, E.I.; Slyusarskiy, K.V.; Osipenkova, A.A.; et al. Aluminum–alumina composites: Part Ⅰ: Obtaining and characterization of powders. Materials 2019, 12, 3180. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Powder Type | ASP-30 | ASP-22 | ASP-5 |

|---|---|---|---|

| D10 (μm) | 9.8 | 6.9 | 3.0 |

| D50 (μm) | 28.0 | 21.9 | 4.9 |

| D90 (μm) | 51.4 | 45.4 | 7.3 |

| SPAN | 1.480 | 1.756 | 0.869 |

| 30 kV Voltage Applied | ||||

| Tray number | 1 | 2 | 3 | 4 |

| D10 (μm) | 10.0 | 17.1 | 6.09 | 15.6 |

| D50 (μm) | 23.3 | 34.9 | 16.9 | 31.9 |

| D90 (μm) | 46.9 | 58.5 | 36.4 | 54.1 |

| SPAN | 1.584 | 1.186 | 1.794 | 1.207 |

| 20 kV Voltage Applied | ||||

| Tray number | 1 | 2 | 3 | 4 |

| D10 (μm) | 13.30 | 12.5 | 14.4 | 9.7 |

| D50 (μm) | 34.60 | 32.0 | 33.8 | 25.1 |

| D90 (μm) | 58.60 | 56.3 | 56.7 | 47.00 |

| SPAN | 1.309 | 1.369 | 1.252 | 1.485 |

| 10 kV Voltage Applied | ||||

| Tray number | 1 | 2 | 3 | 4 |

| D10 (μm) | 10.4 | 11.2 | 10.9 | 9.7 |

| D50 (μm) | 30.1 | 31.3 | 29.9 | 25.5 |

| D90 (μm) | 55.5 | 55.4 | 53.9 | 47.3 |

| SPAN | 1.498 | 1.412 | 1.438 | 1.475 |

| 100 rpm Drum Rotation Speed | |||

| Tray number | 1 | 2 | – |

| D10 (μm) | 10.6 | 11.1 | – |

| D50 (μm) | 29.8 | 30.5 | – |

| D90 (μm) | 54.4 | 55.2 | – |

| SPAN | 1.470 | 1.446 | – |

| 200 rpm Drum Rotation Speed | |||

| Tray number | 1 | 2 | 3 |

| D10 (μm) | 11.9 | 13.1 | 9.6 |

| D50 (μm) | 31.5 | 33.0 | 26.5 |

| D90 (μm) | 54.9 | 55.9 | 49.2 |

| SPAN | 1.365 | 1.297 | 1.493 |

| 300 rpm Drum Rotation Speed | |||

| Tray number | 1 | 2 | 3 |

| D10 (μm) | 11.1 | 13.9 | 8.4 |

| D50 (μm) | 30.9 | 34.0 | 25.6 |

| D90 (μm) | 54.7 | 57.3 | 49.5 |

| SPAN | 1.411 | 1.276 | 1.604 |

| Separator Type | ELKOR | Zeus | ASP-30 Powder (Initial) |

|---|---|---|---|

| Voltage applied | 30 kV | No voltage | - |

| D10 (μm) | 17.1 | 13.9 | 9.8 |

| D50 (μm) | 34.9 | 34.0 | 28.0 |

| D90 (μm) | 58.5 | 57.3 | 51.4 |

| SPAN | 1.186 | 1.276 | 1.480 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shinkaryov, A.S.; Cherkasova, M.V.; Pelevin, I.A.; Ozherelkov, D.Y.; Chernyshikhin, S.V.; Kharitonova, N.A.; Gromov, A.A.; Nalivaiko, A.Y. Aluminum Powder Preparation for Additive Manufacturing Using Electrostatic Classification. Coatings 2021, 11, 629. https://doi.org/10.3390/coatings11060629

Shinkaryov AS, Cherkasova MV, Pelevin IA, Ozherelkov DY, Chernyshikhin SV, Kharitonova NA, Gromov AA, Nalivaiko AY. Aluminum Powder Preparation for Additive Manufacturing Using Electrostatic Classification. Coatings. 2021; 11(6):629. https://doi.org/10.3390/coatings11060629

Chicago/Turabian StyleShinkaryov, Alexander S., Margarita V. Cherkasova, Ivan A. Pelevin, Dmitriy Yu. Ozherelkov, Stanislav V. Chernyshikhin, Natalia A. Kharitonova, Alexander A. Gromov, and Anton Yu. Nalivaiko. 2021. "Aluminum Powder Preparation for Additive Manufacturing Using Electrostatic Classification" Coatings 11, no. 6: 629. https://doi.org/10.3390/coatings11060629

APA StyleShinkaryov, A. S., Cherkasova, M. V., Pelevin, I. A., Ozherelkov, D. Y., Chernyshikhin, S. V., Kharitonova, N. A., Gromov, A. A., & Nalivaiko, A. Y. (2021). Aluminum Powder Preparation for Additive Manufacturing Using Electrostatic Classification. Coatings, 11(6), 629. https://doi.org/10.3390/coatings11060629