1. Introduction

Hot mix asphalts (HMAs) of road pavements are composed of different combinations of aggregates and bituminous binders. Aggregates can vary depending on their origin (natural, artificial, and recycled), lithology (usually constituted by SiO

2, CaO, and MgO), and size [

1]. From the physical point of view, bitumen gives rise to a multi-phase system characterized by asphaltenes, resins, and oil. The asphaltenes are largely responsible for the behavior of bitumen as a viscous body with plasticity and elasticity. The resins confer flexibility and are important for interfacial adhesion and ductility of the flooring [

2]. The malthenes represent the fluid bituminous components, which are essentially composed of carbon (80–87%), hydrogen (9–11%), oxygen (2–8%), nitrogen, sulfur compounds and trace metals (0–1%) [

3]. Different factors determine the response and behavior of an asphalt, including the temperature and loading time. The compound is liquid or solid at high or low temperatures, respectively. This property of asphalt as a pavement causes it to crack at low temperatures or suffer rutting at high temperatures. Factors such as oxygen, ultraviolet (UV) sunlight, and heat affect both the physical properties and the asphalt chemical structure and cause the phenomenon called aging [

4]. Another antagonist of the asphalt binder is moisture. The moisture damage of asphalt mixtures is defined as the progressive loss of functionality of the material due to a drop of the adhesive bond between the asphalt binder and the aggregate surface. The premature deterioration of asphalt pavements caused by moisture in asphalt mixtures is related to stripping, raveling, and hydraulic scour [

5].

The adhesion between bituminous mixtures’ constituents is essential for the endurance of an asphalt pavement [

6]. For these reasons, specific laboratory analyses are available to quantify the affinity between aggregate and bitumen. In particular, the European Standard EN 12697-11 methodology [

7], “Bituminous mixtures—Test methods for hot mix asphalt—Part 11”, specifies procedures for the determination of the affinity between aggregate and bitumen and its influence on the susceptibility of the combination to stripping. The susceptibility to stripping is an indirect measure of the power of a binder to adhere to various aggregates, or vice versa [

7]. The control method provided by the affinity tests according to the methodology [

7] is included in the standard tender documents for procurement of roads works, becoming a prescriptive method between client and supplier for the use of certain aggregates in road constructions.

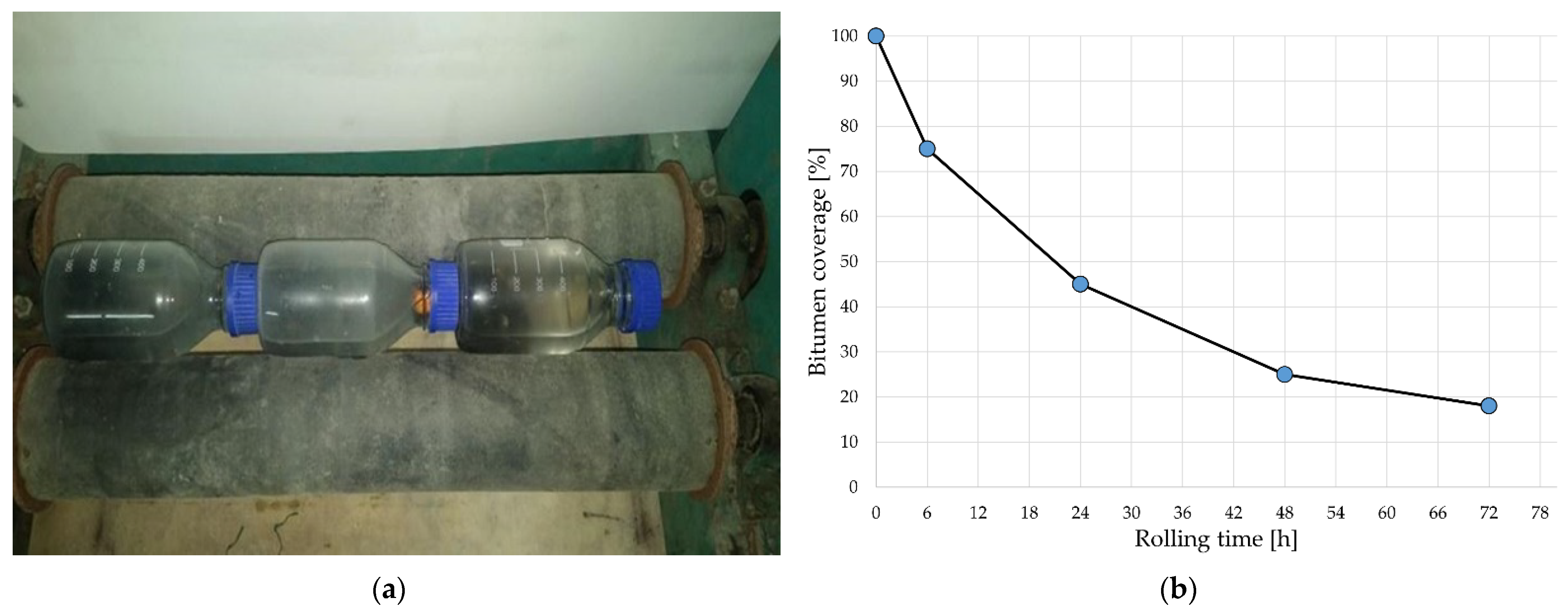

The most widely used standard procedures are the rolling-bottle test, the static test, and the boiling water stripping test. In the rolling-bottle test, the affinity is expressed as the degree of bitumen coverage on uncompacted bitumen-coated mineral aggregate particles after the influence of a mechanical stirring action in the presence of water. In the static test, affinity is measured in terms of the degree of bitumen coverage on uncompacted bitumen-coated mineral aggregate particles after storage in water. For both tests, affinity is determined by the operator via visual inspection. As mentioned in the standard specifications, the rolling-bottle test and the static test are simple and suitable for routine testing and for high polished stone value aggregates. The shortcoming is that they are subjective. Furthermore, the static test is generally less precise. In the boiling water stripping test, the affinity is expressed by determining the degree of bitumen-coverage on uncompacted bitumen-coated aggregates after immersion in water under specific conditions. The boiling water stripping test is an objective test characterized by high precision. However, it requires greater operator skills compared to the other tests, and, because of its use of chemicals as reagents, extra safety requirements must be employed [

7]. For its simplicity, the rolling-bottle test is the most used procedure.

Recent advancements in spectrometry and digital imaging processing (DIP) techniques can make it possible to overcome the subjectivity of the rolling-bottle test. In the literature, different ways to detect chemical and physical properties of bituminous mixtures can be found and, specifically, the use of different techniques to quantify the degree of bitumen’s aggregate coverage are described. As is known, due to both natural and artificial degradation processes, bituminous mixtures lose superficial bitumen, and the exposure of the aggregate compounds modifies their spectral response [

8,

9]. The absorption of silicates and hydrocarbons affects the short-wave infrared (SWIR) region, especially at 1750 nm and after 2100 nm [

10,

11], while bitumen loss causes a slope change in the visible (VIS) region [

12]. The use of spectroscopy can be helpful in quantifying bitumen removal on aggregate surfaces. For this reason, several studies have focused on the adoption of imaging techniques to objectivize the bitumen removal on them. Recently, spectroscopy and DIP techniques have been employed for bituminous mixtures analysis in both field and laboratory environments. In [

13], the bitumen coverage of asphalt mixture surfaces is retrieved using the 2D distribution of remote sensing data via the asphalt-line computation. At the same time, digital pictures are employed to quantify bituminous pavement cover using the geologic classification of Shvetsov (1954) [

14].

In recent years, DIP has been widely used in engineering studies to retrieve some physical parameters in unbiased and fast ways. In engineering, this kind of analysis is promising for the detection of the morphometric characteristics of aggregates in both loose and specimen forms [

15] and in the reconstruction of grain size curves starting from specimens [

16] or thin sections [

17]. Images are used to retrieve parameters related to the road macro-texture by road surface modeling [

16,

18] for calculating the binder/aggregate ratio and grading curve retrieval by digital imaging segmentation [

17] or aggregates’ characterization [

15]. Different authors focused on the application of DIP for bitumen removal using field and laboratory samples. As shown in [

19,

20], spectral data and DIP of bituminous mixtures make it possible to find a spectral model for the objective quantification of superficial bitumen removal. This analysis is performed by the computation of the exposed aggregate index (EAI). Considering that the brightness of new asphalt is lower than that of older ones, spoliation effects can be linked to colorimetric variation in the visible range, and a sensitivity analysis of the tested model demonstrates the robustness of the identified relation.

Two semi-automatic methods that reliably replace the subjective assessment are presented in [

21,

22]. The first one is based on gray level thresholding (GLT), while the second one on entropy-based image segmentation (EIS). The GLT method is adopted to recognize brightness and shadows on the digital image of asphalt mixtures, while the EIS method is used to assess the roughness of the texture.

According to the authors of [

23], the computerized analysis technique is based on the digital representation of the bitumen–aggregate system after the lamination process and the classification of the characteristic color zones by means of commercial software. As a side effect, there is a reduction in the labor required for the test analysis. The bituminous coverage of the stones using two different methods of digital image analysis is evaluated in [

24]. This method works for stones of any color because bitumen reflects light much better than rough stones.

A 2D image analysis is employed to evaluate the results of the rolling-bottle test in [

25]. To demonstrate its applicability to a wide range of materials, this procedure is applied to both light and dark aggregates, mixed with a wax-modified binder. The mixing temperature is varied to evaluate the influence of the binder’s viscosity on adhesion. Visual and semi-automatic estimations are compared through confusion matrices, and it is demonstrated that the proposed method leads to far better results. In [

26], the degree of coverage of bitumen is measured with digital image processing methods by using a professional camera and an ordinary smartphone. Image J is used to process images.

In [

27], a vision-based algorithm and a low-cost light enhancement system is developed as an alternative to visual inspection. The system processes images of samples captured under a controlled lighting condition and then applies contrast-limited adaptive histogram equalization to enhance the contrast intensity of the image. In addition, the system uses inpainting to reconstruct the specular highlights in the image, and then classifies the regions on the image, i.e., the coated and stripped areas, using combinations of K-means clustering, K-nearest neighbors, and support vector machines classifiers.

Fourier transform infrared (FTIR) has also been used to achieve this result. In [

28], the bitumen overlay of aggregates with reference to FTIR microscopy in attenuated total reflectance (ATR) mode is investigated. This method is a promising alternative to trace heterogeneous areas within the coating compared to methods that require extraction and recovery of the bitumen. In [

29], several types of mineral aggregates are characterized in detail by optical microscopy and X-ray powder diffraction in order to investigate the potentiality of the boiling test and the contact angle method to detect the level of bitumen/aggregate affinity.

The above-mentioned techniques show that DIP and some other imaging techniques represent useful tools to quantify the bitumen coverage of several aggregates. In this study, VIS–NIR and SWIR imaging spectrometers and a high-resolution digital camera were set in a multi-sensor platform to investigate their potentiality for bitumen removal quantification. A hyperspectral system has been employed in different applications such as the identification of vegetation diseases [

30,

31], the detection of marine plastic litters [

32], and plastics separation [

33,

34]. Different approaches were investigated to extrapolate the degree of bitumen coverage in the rolling-bottle test at 6, 24, 48 and 72 h. To achieve this goal, samples of trachytic and limestone mixtures were tested at different temporal steps with supervised (parallelepiped) and unsupervised (iterative self-organizing data analysis technique (ISODATA)) algorithms and finally compared with several operators’ visual observations.

Remarkably, by comparing the different techniques, this study demonstrated that, by means of both VIS–NIR and SWIR spectrometers and a digital camera, an objective quantification of the bitumen loss caused by the stripping process can be obtained and inaccuracies related to visual inspection overcome.

3. Results

3.1. Rolling-Bottle Data Analysis

The adhesion tests were carried out at four different time steps: 6, 24, 48 and 72 h. For each step, three replicates were arranged for a total number of samples equal to 12. A bitumen-free sample and one totally coated sample completed the dataset. This combination was repeated for both limestone and trachytic aggregates for a total of 28 samples.

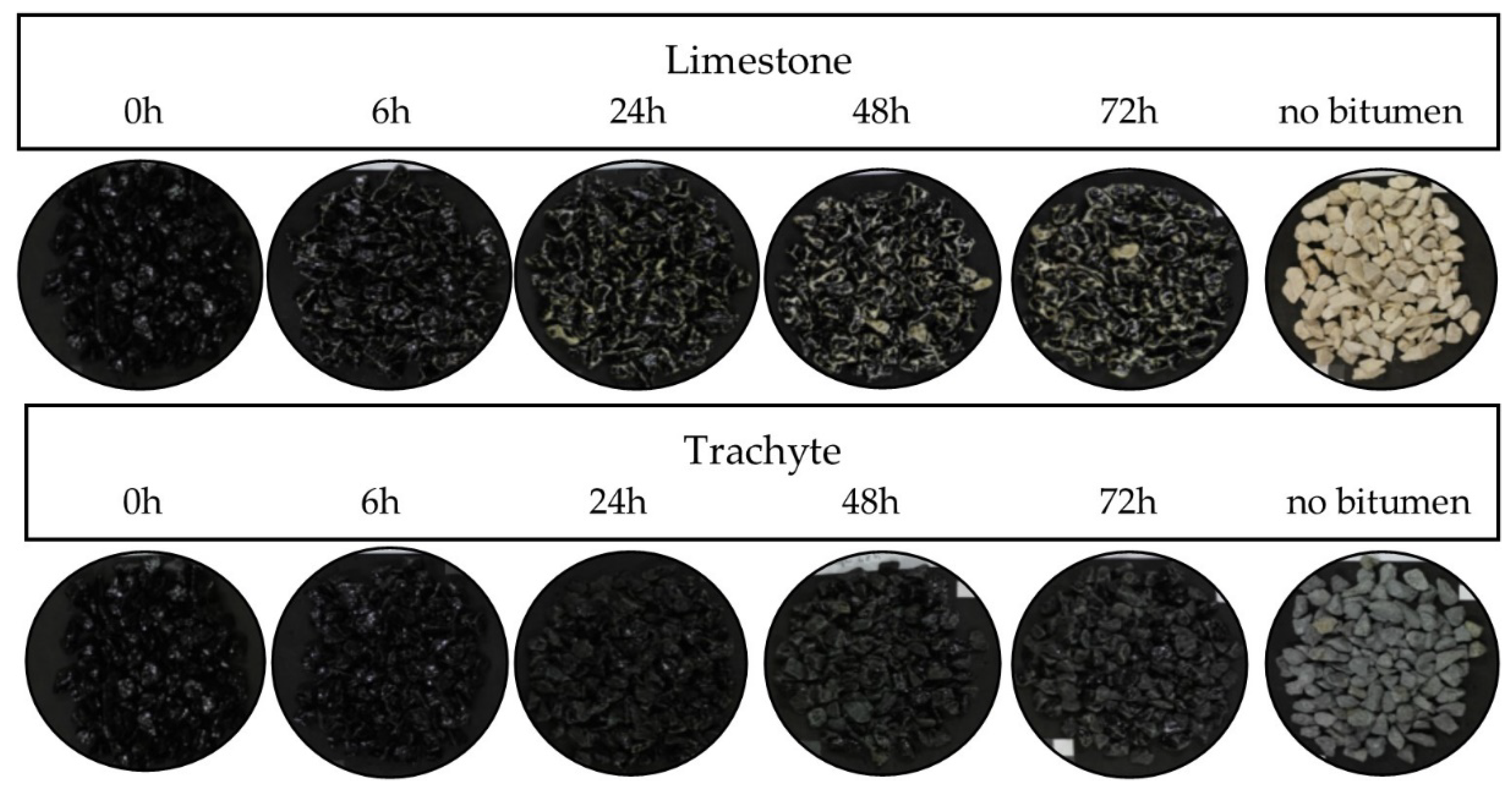

Figure 3 shows photographs of the dataset of the materials obtained after the adhesion tests.

At the end of each time step, the specimens obtained were analyzed via operators’ visual inspection to estimate the percentage of bitumen coverage. To extend the statistical dataset, 16 operators were employed instead of the two required by the UNI EN 12697-11 [

7] standard.

Figure 4 shows the large differences between the evaluations for each time step in terms of discrepancies between the minimum and maximum bitumen coverage values observed by the operators if compared to the averaged values. Standard deviations highlight discrepancies for trachytic samples, but, for both kinds of aggregates, a higher precision was obtained for the initial time steps.

The maximum and minimum values found within the evaluation forms show high heterogeneity. This fact was accentuated when the standard deviations were calculated for each sample and time step.

Figure 4 shows the increase in these values from the evaluations carried out for trachyte (from 10.2 to 30.5) and limestone (from 6.7 to 11.6). On average, the standard deviations calculated for limestone and trachytic aggregates are 9.7 and 24.7, respectively, while the overall average considering both kinds of aggregates is 17.2. Lower standard deviations are related to the limestone samples while higher ones are related to trachyte ones. Because of the lower brightness difference between bitumen and trachytic aggregates, operators showed a greater difficulty in carrying out the quantification of bitumen coverage over aggregates.

To further highlight the high variability of such evaluations, the comparison of mean, median, and mode calculated for each sample shows how these values tend to coincide for the limestone samples while they tend to differ for the trachyte samples. In fact, the average standard deviations for trachyte and limestone samples are, respectively, 9.9 and 2.7.

3.2. Digital Imaging Processing

Digital pictures were acquired for each sample at every time step. An AOI, consisting of 743 rows × 761 columns (565,423 pixels), was fixed in the middle of each picture (dimensions 4928 × 3264 pixels) matching with the GIFOV of the spectrometers. All images were classified by applying the parallelepiped and the ISODATA algorithms. The classification of these images allowed obtaining an image with four classes: aggregates not coated by bitumen (exposed aggregates), aggregates coated by bitumen (not exposed aggregates), shadows, and reflections. The classification allowed quantifying the number of pixels corresponding to the four classes, which can be expressed as a percentage of the known area of 565,423 pixels. From each image classification, only the number of “exposed aggregates” was considered because of the major influence on the “not exposed aggregates” class of reflections and shadows. Separability analysis was performed to evaluate if such classes are easily separable. For each mixture, Jeffries–Matusita (JM) and transformed divergence (TD) values were calculated for “aggregates” and “bitumen” classes as ROIs. Limestone and trachyte aggregates showed respectively 1.97 and 1.21 for JM and 1.98 and 1.31 for TD separability measurements. As presented in [

42], these measures can show values between 2 (completely separable) and 0 (no separability). Separability results corroborate a higher separability of limestone compared to trachytic aggregates.

The influence of shadows is minimized by a homogeneous illumination. Nevertheless, this influence must be considered as a limit of this kind of bi-dimensional analysis that does not allow considering the aggregate exposure of each aggregate in three dimensions.

Considering the above evidence, the values obtained from these classifications were expressed in terms of the exposed aggregate index. Finally, the BIT index was computed to achieve the percentage of bitumen coverage.

Figure 5 shows the results obtained with the two algorithms. The average values of the two methods tend to remain similar at the initial test stages but highly differ with the increase of the temporal steps. This was caused by the increase of the sample heterogeneity and the brightness variability of limestone or trachytic samples. These modifications affected the classification results obtained with the two algorithms, which used different criteria to define each class. Generally, values obtained for limestone aggregates show similar results for samples from each of the first three-time steps. Conversely, trachyte samples show a great variability. This evidence is better appreciated with the calculation of standard deviations and confusion matrices (overall accuracy and k-coefficient) of each image classification.

The parallelepiped method shows lower standard deviation values (1.38 for trachyte and 0.68 for limestone) than those obtained using the ISODATA method (16.80 for trachyte and 3.91 for limestone). For limestone mixtures, confusion matrices show the average overall accuracy (sum of the number of correctly classified values divided by the total number of values) and k-coefficient (measurement of the agreement between truth values and classification) for all rolling-bottle steps of 94.7% (k = 0.91) and 99.1% (k = 0.98) for ISODATA and parallelepiped, respectively. For trachytic mixtures, confusion matrices show average overall accuracy and k-coefficient of 79.7% (k = 0.72) and 98.3% (k = 0.97), respectively. The parallelepiped algorithm seems the most suitable technique to assess the BIT value for trachytic aggregates, while both techniques show remarkable results for both kinds of aggregates. Generally, higher overall accuracies are obtained for both aggregates with the parallelepiped algorithm.

3.3. Spectroscopy

The two VIS–NIR spectrometers were used to acquire spectral images of trachyte and limestone mixtures at 6, 24, 48 and 72 h. Once the dataset was developed, the hyperspectral cube was computed to manage and classify images. The number of images acquired by each camera was different because the frame rate of the two cameras was set to two different values, therefore more images were acquired by the sensor camera (frame rate equal to 50 fps) than by the Falcon camera (frame rate equal to 25 fps). By positioning the VIS spectrometer scan line perpendicular to the advancement direction of each sample, an image was obtained where each row (or column for NIR camera) represents the section of the scanned surface at a given wavelength. Through the initial step of the geometric calibration, a wavelength λ could be associated with each column of the image. The hyperspectral cube was processed using the ENVI® (Environment for Visualizing Images, L3Harris Geospatial, Boulder, CO, USA) software program for visualization, analysis, and classification of digital images.

Radiometric calibration was performed to remove the dependence of the spectra on the measuring instruments. In fact, the acquisition system did not record the reflectance of the material but the radiance value, i.e., the part of the radiation reflected by the material that reaches the sensor and has sufficient energy to be recorded. Absolute reflectance can only be calculated if the radiation incident on the material is known. Since halogen lamps were used as the light source, it was not possible to calculate the incident radiation at each point of the scene. Thus, the relative reflectance was calculated, obtained by comparing the radiance of the materials with the reference spectrum of a suitably chosen material. A Halon tile of 10 cm side was used as a reference object, which was analyzed under the same lighting conditions and with the same experimental setup. The FF method was used for radiometric image calibration. This method considers the background noise associated with the sensor measurements and takes it into account by introducing the dark current, i.e., the radiance recorded through closed-objective measurements. The relation for the calculation of the reflectance ρ

λ is:

where

Rλ is the radiance of the material at the wavelength λ,

Dλ is the value of the dark current, and

Wλ is the radiance of the reference white (Halon tile).

At this stage, the cube presents spectral information along the x and y axes, which allows the identification of every single pixel of the image, and the spectral curve can be used to characterize and recognize the different materials. Spectral signatures of the various materials were extracted from the images by defining ROIs in the NIR and VIS images. The average spectral signature of a sample was then obtained by averaging the curves of all the pixels included within the sample area.

As done for digital pictures, separability analysis from aggregate to bitumen was performed for each mixture by JM and TD calculations. Trachyte and limestone aggregates showed for both spectrometers averaged values of 1.94and 2.00 for JM and 1.99 and 2.00 for TD, respectively. These data allowed supposing the suitability of both spectrometers, although the coarse pixel resolution of NIR spectrometer could represent a limitation for spatial accuracies.

Similar to the analyses carried out by DIP, the hyperspectral images were classified by the ISODATA and parallelepiped algorithms. These classifications were first used to calculate the EAI index and compute the BIT index for the bitumen coating over aggregates.

Figure 6 shows trachyte and limestone samples after the rolling-bottle tests, while

Figure 7 indicates BIT values at the different temporal steps for the two classifiers.

For trachytic mixtures, both techniques present remarkable accuracies for the VIS spectrometer, while the worst results were obtained with the NIR spectrometer. The results show no evident decrease of bitumen coverage at 48 and 72 h (about 77–71%), while the VIS spectrometer provides similar results (63% and 48%), and a decreasing trend can be observed. In addition, the accuracies reflect this discrepancy, showing lower values for the NIR ranges. This tendency is also evident for limestone aggregates, while a decreasing trend is more visible. In addition, in this case, accuracy values are higher for the VIS spectrometer. Generally, a good consistency of classification results was observed for ISODATA using the VIS spectrometer because of its higher spatial resolution.

The accuracy values were calculated through the application of the confusion matrix, which makes it possible, using reference ROIs for validation, to obtain the overall accuracy and kappa coefficient values, as done for digital images. For trachytic aggregates and VIS spectrometer data, the classification by ISODATA provides accuracy values of 94.3% and a kappa value of 0.88, while, in the NIR range, the accuracy is equal to 77.5% and the kappa is 0.50. For limestone aggregates and VIS spectrometer data, the classification by ISODATA provides accuracy values of 97.4% and a kappa value of 0.93, while, in the NIR range, the accuracy is equal to 91.4% and the kappa is 0.81. Therefore, accuracy tends to decrease from the VIS data to the NIR data. Furthermore, in the VIS range, the average standard deviation is 2.47 for trachyte and 1.15 for limestone, while, in the NIR region, it is 4.09 for trachyte and 3.03 for limestone. Therefore, for ISODATA, NIR-classified data generally seem to be less reliable than those obtained by classification in the VIS region.

The parallelepiped algorithm provides accuracy values of 87.4% and kappa equal to 0.74 in the VIS (standard deviation: 4.19), while these values are 70.8% and 0.35 in the NIR region for trachytic mixtures (standard deviation: 6.87). For limestone mixtures, the accuracy in the VIS region is 95.7% and the kappa is 0.90 (standard deviation: 3.47) while these values are 87.3% and 0.7 in the NIR range (standard deviation: 7.65). Generally, accuracies are higher for the VIS spectrometer (and standard deviations are higher in the NIR region). The accuracies obtained by ISODATA are generally higher than those obtained through the application of the parallelepiped method.

4. Discussion

The European Standard EN 12697-11 [

7] focuses on different procedures for the determination of the affinity between aggregate and bitumen and its influence on the susceptibility of the combination to stripping. The bitumen coverage percentage over aggregates is evaluated by calculating the BIT index. In this study, the values calculated by DIP and VIS–NIR spectrometers were compared at each temporal step of the rolling-bottle test.

Therefore, the whole imaging classification dataset was compared for a better comprehension of the most suitable technique for bitumen coverage quantification. The dataset is composed of six different analyses, consisting of the application of ISODATA and parallelepiped algorithms to digital imagery and VIS/NIR hyperspectral cubes.

Figure 8 shows a decreasing trend of bitumen removal during the rolling-bottle test for each mentioned technique. Similar BIT values were observed at 6 and 24 h test steps, while, for longer temporal tests (48 and 72 h), a higher heterogeneity is prevalent. For each kind of classification technique, a lower reliability of measurements for longer tests was observed.

Figure 9 highlights this trend by showing the standard deviation of the classification of both aggregate mixtures: at 6 and 24 h, standard deviations show lower values (1.50) than those obtained at 48 and 72 h (2.66). More specifically, for all the imaging algorithms, the variation of the average standard deviations of trachytic aggregates shows higher values (1.78 at 6/24 h and 3.34 at 48/72 h) when compared with those of limestone aggregates (1.22 at 6/24 h and 1.97 at 48/72 h).

The pie chart presented in

Figure 10 summarizes the results of the different techniques, reporting the standard deviations (external ring) and the overall accuracies (internal ring) of each combination of processing technique, sensor, and aggregate type. Better results to retrieve the bitumen percentage coverage are differentiated for limestone and trachytic aggregates.

For limestone aggregates, higher results are reached with the use of VIS-spectrometer (97.4%) and digital pictures (99.1%), respectively, using ISODATA and parallelepiped techniques. For trachytic aggregates, overall accuracies are generally lower but, similar to limestone aggregates, better accuracies are reached using VIS spectrometer (94.3%) and digital pictures (98.3%), respectively, using ISODATA and parallelepiped techniques.

For both kinds of aggregates, the parallelepiped technique applied to digital pictures provides better results. These results are also expressed by the average standard deviations, which show values of 0.68 and 1.38, respectively, for limestone and trachyte.

In general, limestone mixtures show a lower standard deviation for the tested techniques, confirming the repeatability of the procedures. These results highlight the significance of spatial resolution rather than spectral resolution of the spectrometers used and the need of an initial start-up step defined by the user (supervised technique).

Figure 11 schematically represents the accuracies of each temporal test step obtained through the ISODATA and parallelepiped algorithms applied to both digital and hyperspectral images. Generally, higher accuracies are reached for limestone aggregates, but good results are also obtained for trachytic aggregates by using the VIS spectrometer (ISODATA) and digital picture (parallelepiped).

Considering the high subjectivity of each operator to determine the bitumen coverage percentage over aggregates and considering the high variability of the schematic reference scheme provided by the UNI EN 12697-11 [

7] standard, the use of alternative and rapid methods seems to be crucial. In particular, the reference schemes refer to a detail of 5% among the evaluation classes for high-level covered samples and of the order of 10–20% for those with low-level cover.

Instead of the higher spectral resolution of the VIS spectrometer, the spatial resolution seems to be more efficient for this kind of analysis. Better pixel resolution of the VIS spectrometer should provide higher accuracies and might be more efficient for the bitumen coverage evaluation. At the same time, considering the minor costs of the photographic system compared to the spectrometers, the technique could be more cost-effective and therefore considered available in the UNI EN 12697-11 [

7] as a smart standardized methodology. The elaboration of digital imaging can therefore represent an effective added value for a more rigorous determination of the affinity between aggregate and bitumen and its influence on the susceptibility of the combination to stripping. In addition, this kind of analysis allows simplifying the laboratory data processing operations and reduces subjective operator errors.

Further analyses will be focused on the use of different equipment and different aggregate and bitumen mixtures, with and without additives.