Powder Diffraction Data of Aluminum-Rich FCC-Ti1−xAlxN Prepared by CVD

Abstract

:1. Introduction

2. Materials and Methods

2.1. Coating Deposition and Powder Preparation

2.2. Coating and Powder Analysis

3. Results and Discussion

3.1. Analysis of the Ti1−xAlxN Coating

3.1.1. Thickness of the Ti1−xAlxN Coating

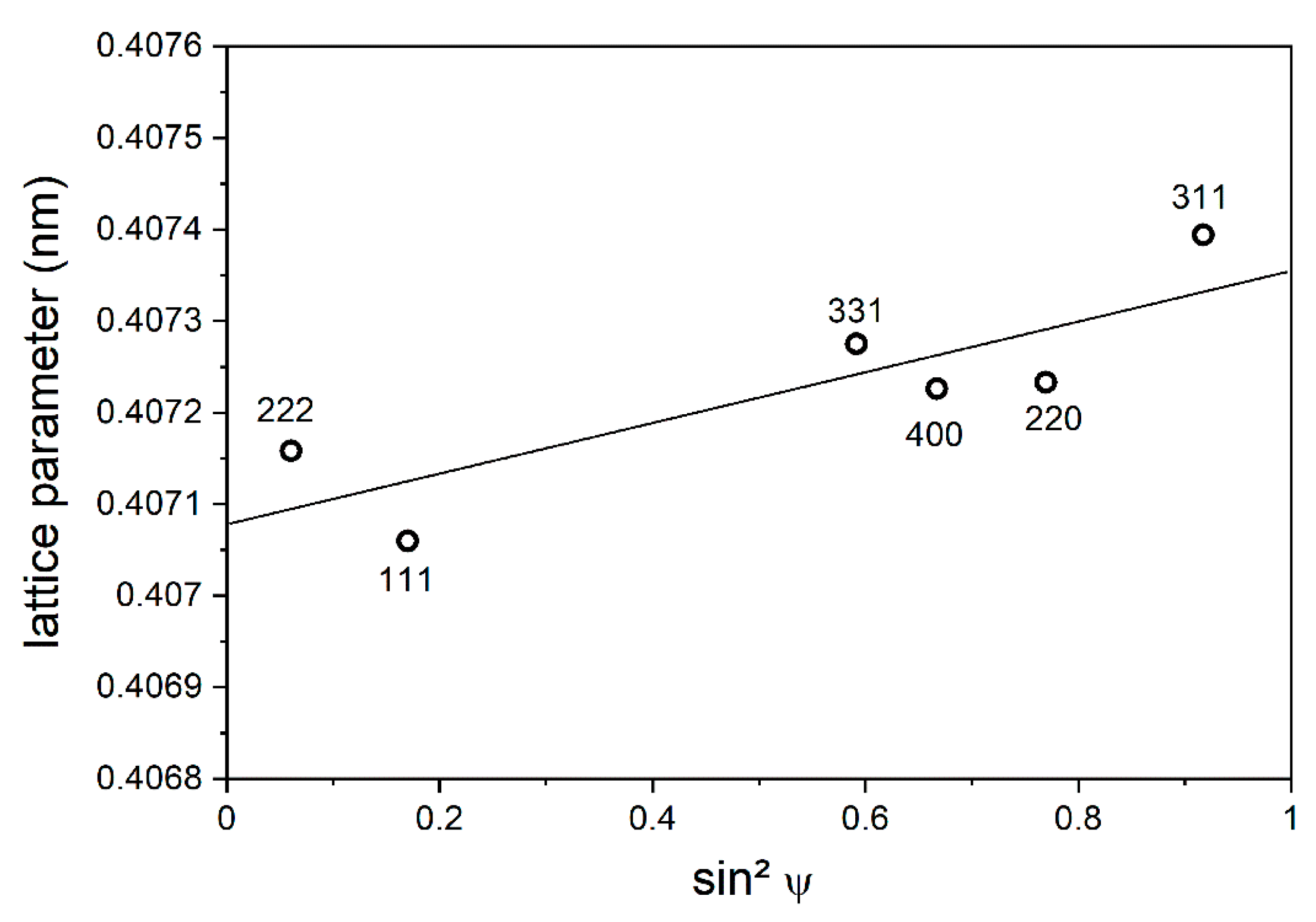

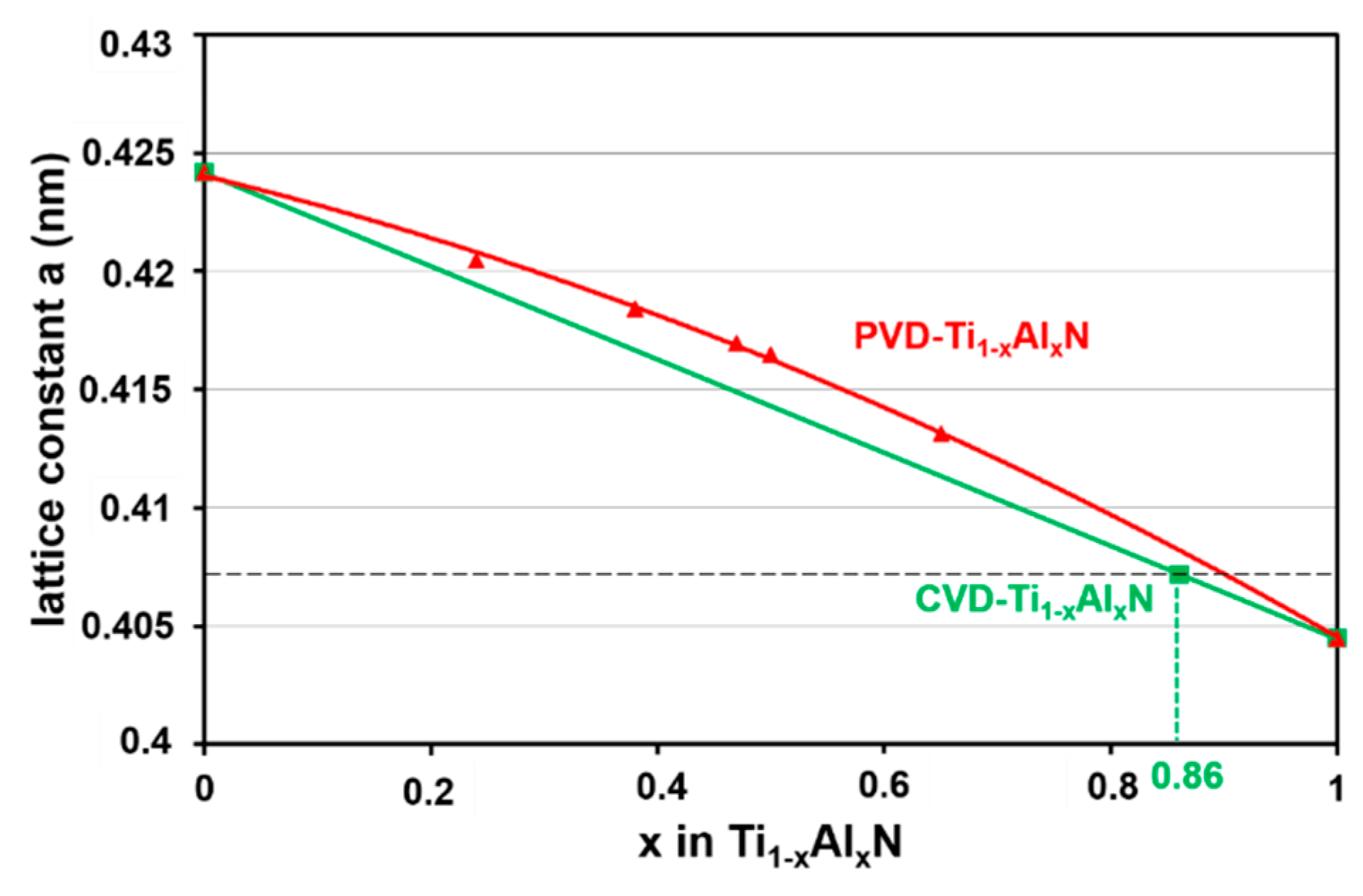

3.1.2. X-ray Analysis of the Ti1−xAlxN Coating

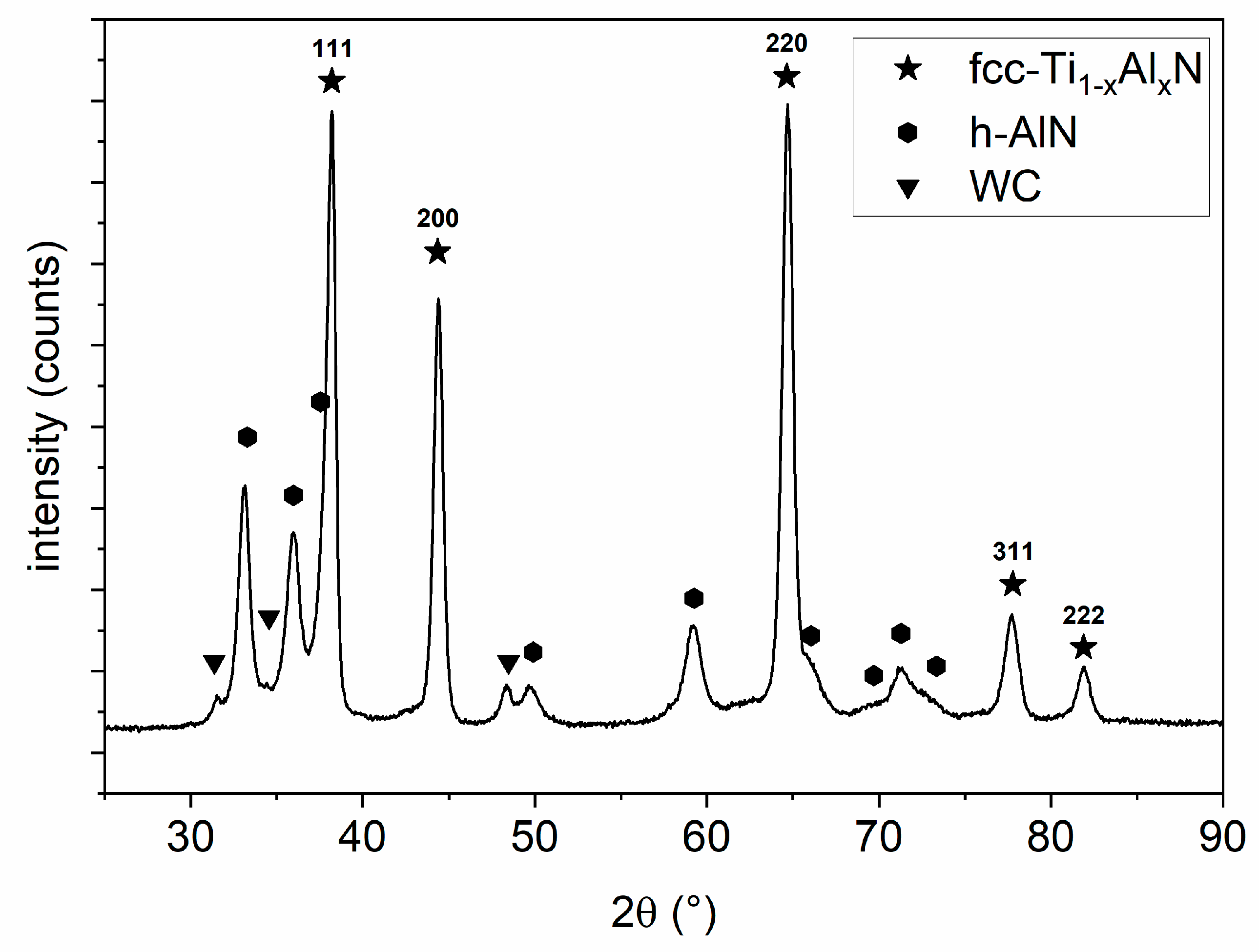

3.2. Microstructure, Composition and X-ray Analysis of the Ti1−xAlxN Powder

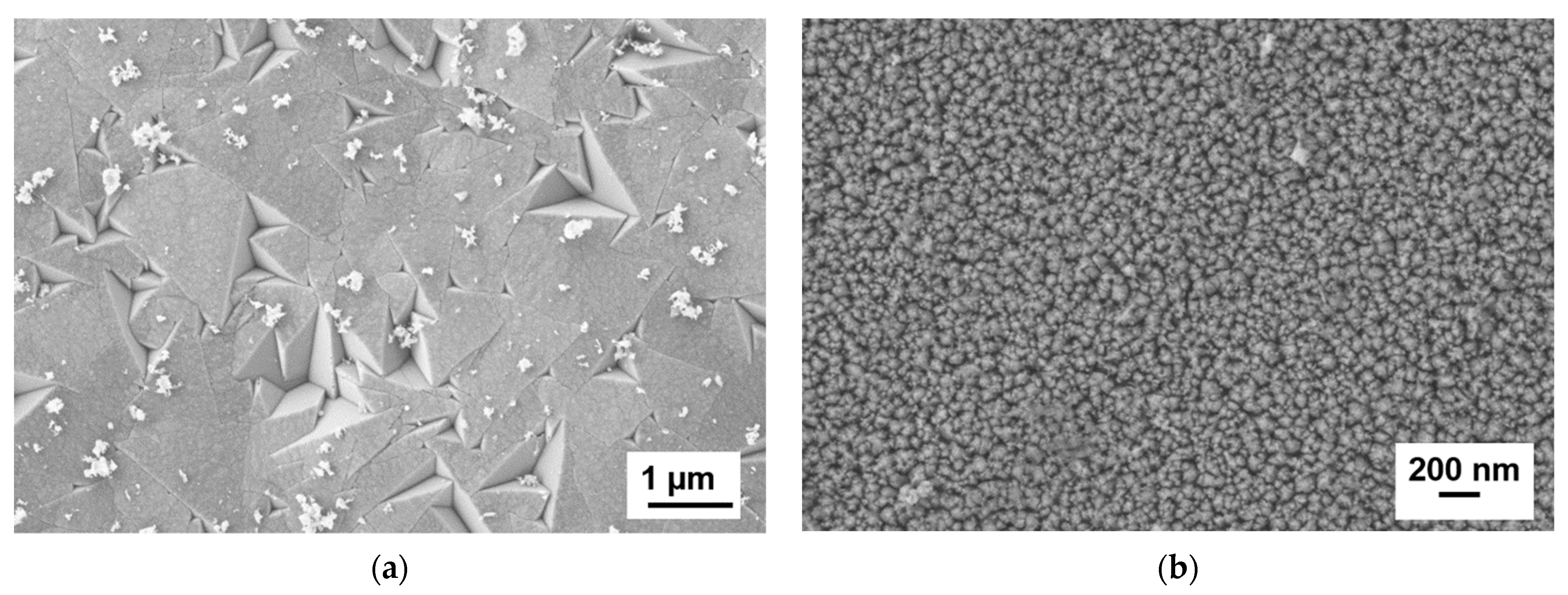

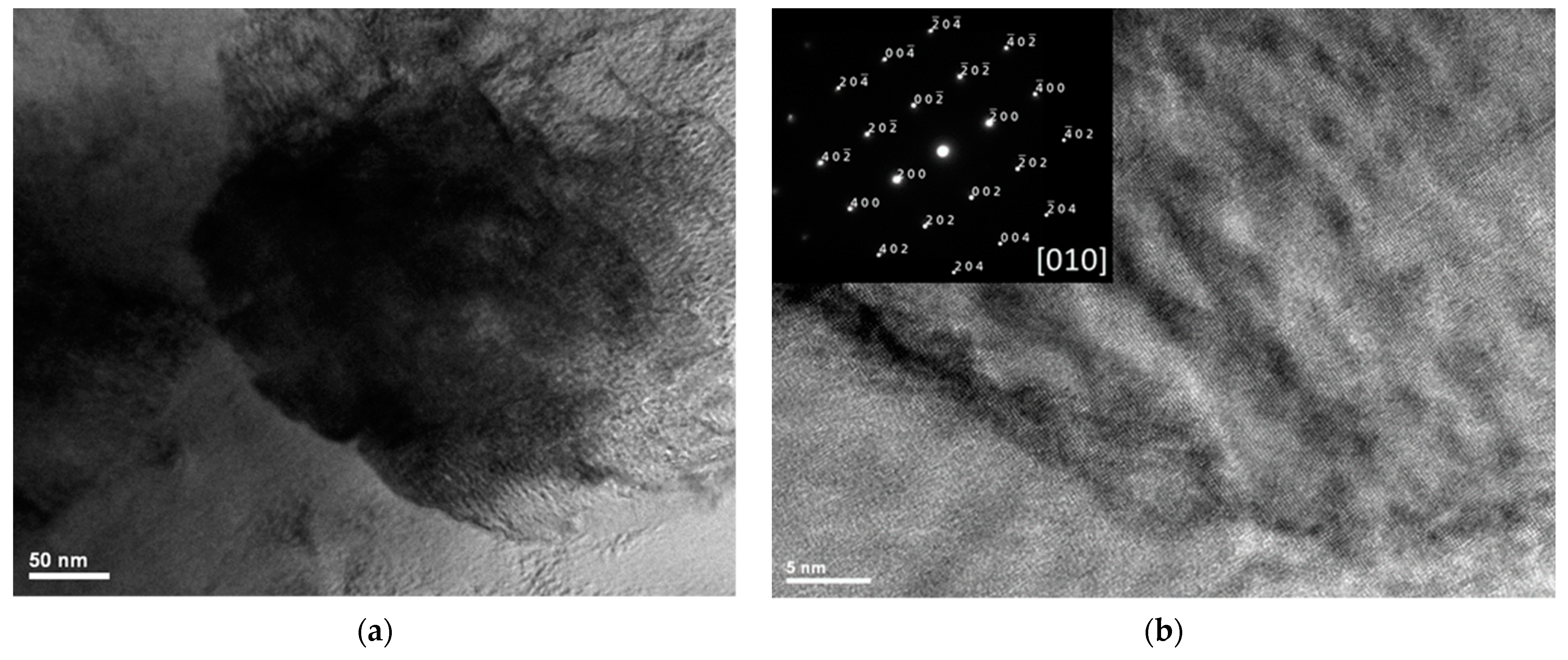

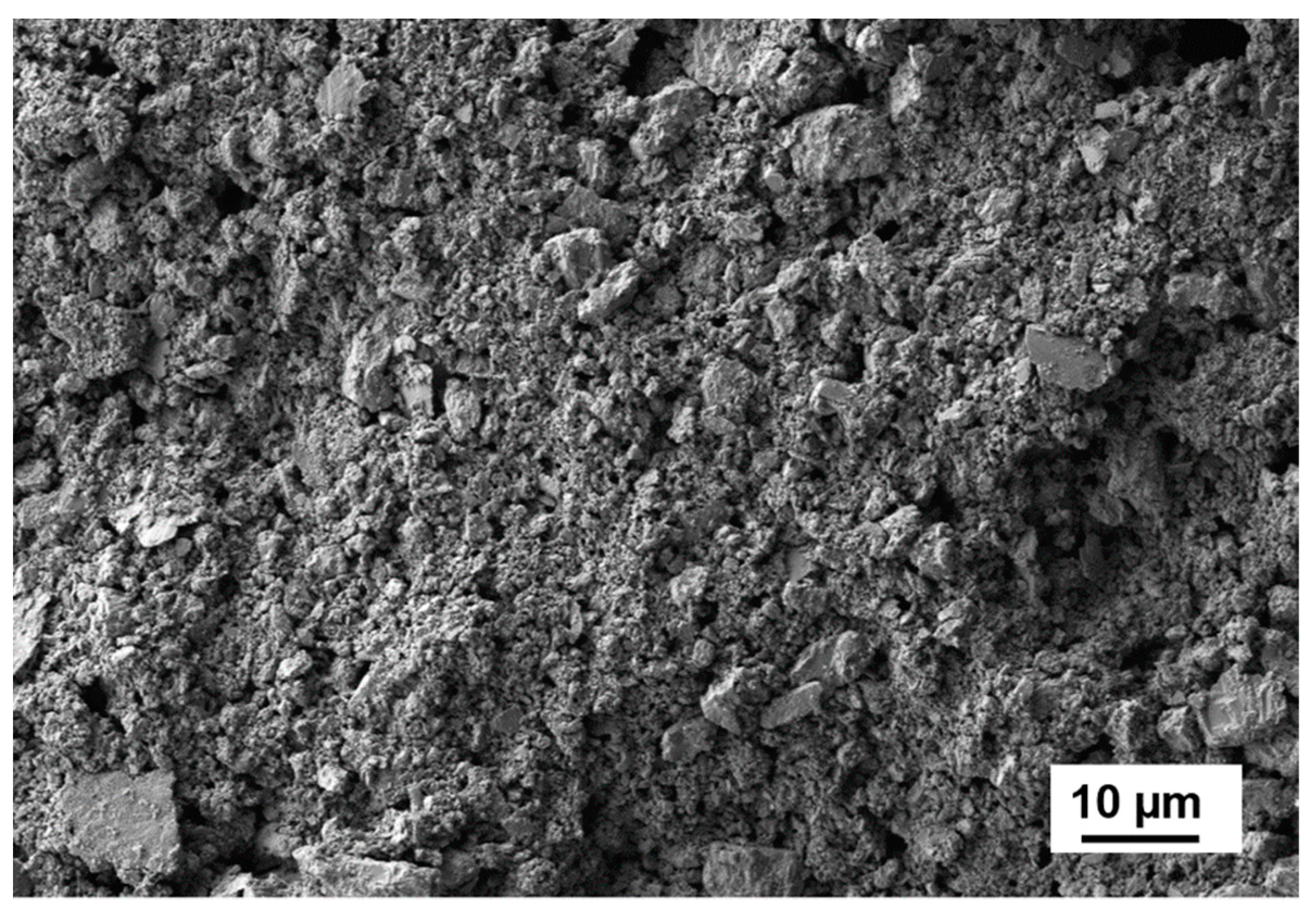

3.2.1. Microstructure of the Ti1−xAlxN Powder

3.2.2. Composition of the Ti1−xAlxN Powder

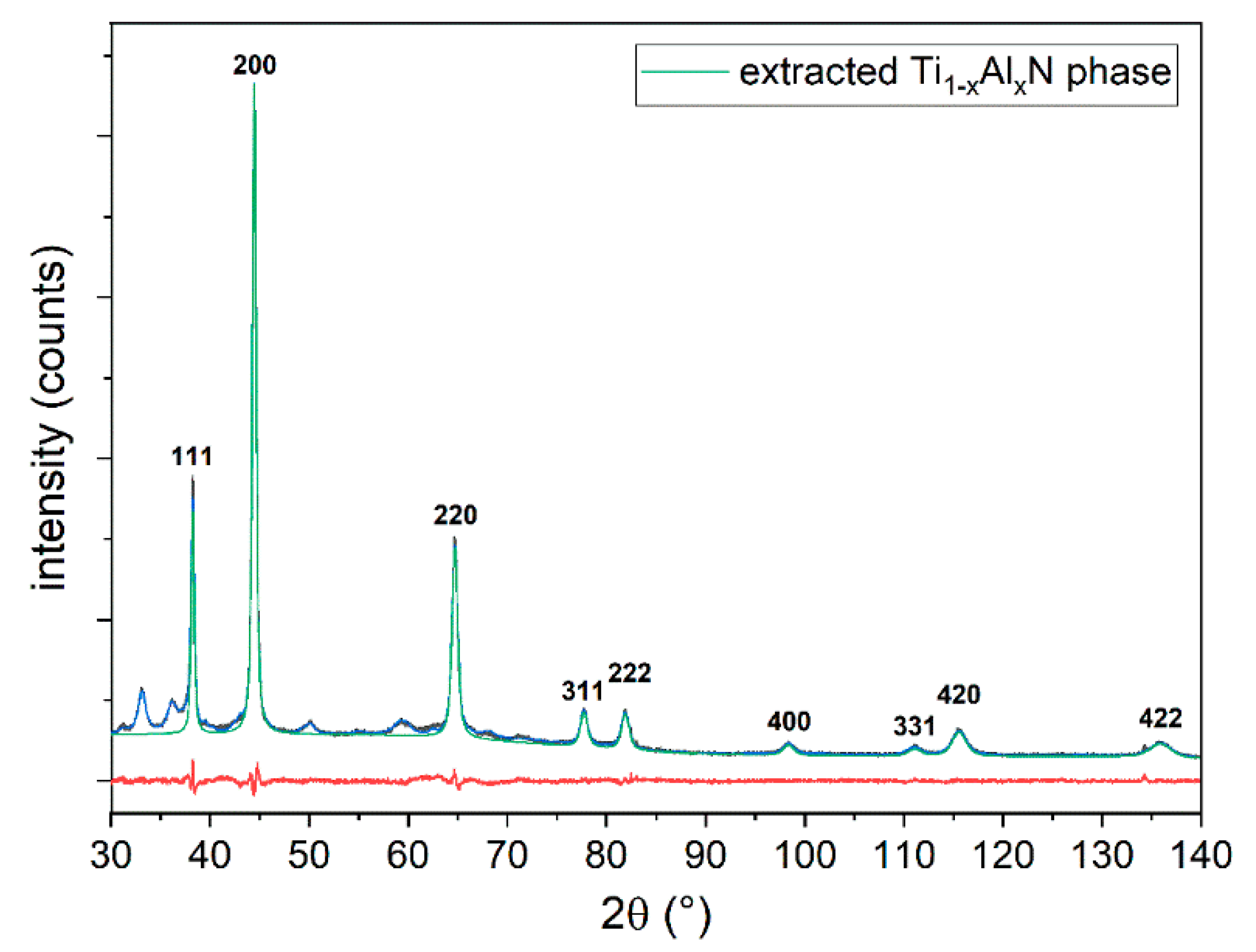

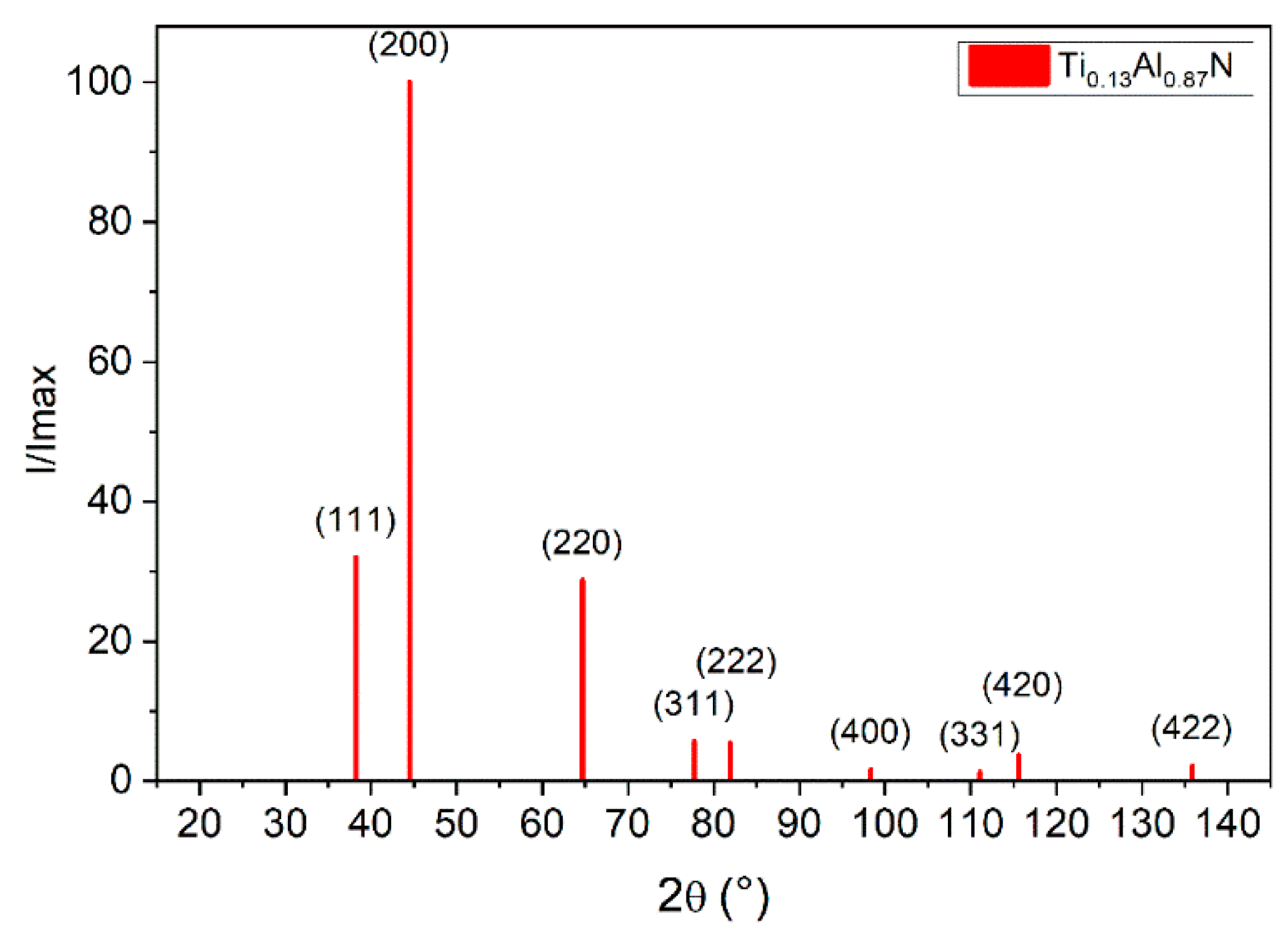

3.2.3. X-ray Analysis of the Ti1−xAlxN Powder

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Knotek, O.; Böhmer, M.; Leyendecker, T. On structure and properties of sputtered Ti and Al based hard compound films. J. Vac. Sci. Technol. A 1986, 4, 2695–2700. [Google Scholar] [CrossRef]

- PalDey, S.; Deevi, S.C. Single layer and multilayer wear resistant coatings of (Ti,Al)N: A review. Mat. Sci. Eng. A 2003, 342, 58–79. [Google Scholar] [CrossRef]

- Cremer, R.; Witthaut, M.; von Richthofen, A.; Neuschütz, D. Determination of the cubic to hexagonal structure transition in the metastable system TiN-AlN, Fresenius. J. Anal. Chem. 1998, 361, 642–645. [Google Scholar]

- Rafaja, D.; Šıma, M.; Klemm, V.; Schreiber, G.; Heger, D.; Havela, L.; Kužel, R. X-ray diffraction on nanocrystalline Ti1−xAlxN thin films. J. Alloys Comp. 2004, 378, 107–111. [Google Scholar] [CrossRef]

- Endler, I.; Höhn, M.; Herrmann, M.; Pitonak, R.; Ruppi, S.; Schneider, M.; van den Berg, H.; Westphal, H. Novel aluminum-rich Ti1−xAlxN coatings by LPCVD. Surf. Coat. Technol. 2008, 203, 530–533. [Google Scholar] [CrossRef]

- Pitonak, R.; Köpf, A.; Weißenbacher, R.; Keckes, J.; Stefenelli, M.; Todt, J.; Endler, I.; Höhn, M. Novel TiAlN coating by Medium Temperature Low Pressure CVD. In Proceedings of the 18th Plansee Seminar, Reutte, Austria, 3–7 June 2013. HM 37/1-37/12. [Google Scholar]

- Czettl, C.; Schleinkofer, U.; Schedle, F.; Wolf, C.; Lechleitner, M.; Holzschuh, H.; Bürgin, W. CVD TiAlN – Development and challenges for use in mass production History and development of CVD-TiAlN. In Proceedings of the 19th Plansee Seminar, Reutte, Austria, 29 May–2 June 2017. HM 45/1-45/13. [Google Scholar]

- PDF Database; The International Centre for Diffraction Data (ICDD): Newton Square, PA, USA.

- Gates-Rector, S.D.; Blanton, T.N. The powder diffraction file: A quality materials characterization database. Powder Diffr. 2019, 34, 352–360. [Google Scholar] [CrossRef] [Green Version]

- Powder Diffraction File, Int. Centre for Diffraction Data; Newton Square, PN, USA, 2011; file no. 00-025-1495.

- Powder Diffraction File, Int. Centre for Diffraction Data; Newton Square, PN, USA, 2019; file no. 00-046-1200.

- Vollstädt, H.; Ito, E.; Akaishi, M.; Akimoto, S.; Fukunaga, O. High pressure synthesis of rocksalt type of AlN. Proc. Jpn. Acad. Ser. B Phys. Biol. Sci. 1990, 66, 7–9. [Google Scholar] [CrossRef] [Green Version]

- Powder Diffraction File, Int. Centre for Diffraction Data; Newton Square, PN, USA, 2019; file no. 00-038-1420.

- Madan, A.; Kim, I.W.; Cheng, S.C.; Yashar, P.; Dravid, V.P.; Barn, S.A. Stabilization of cubic AlN in epitaxial AlN/TiN superlattices. Phys. Rev. Lett. 1997, 78, 1743–1746. [Google Scholar] [CrossRef]

- Schwarz, M.R.; Antlauf, M.; Schmerler, S.; Keller, K.; Schlothauer, T.; Kortus, J.; Heide, G.; Kroke, E. Formation and properties of rocksalt-type AlN and implications for high pressure phase relations in the system Si-Al-O-N. High. Press. Res. 2014, 34, 22–38. [Google Scholar] [CrossRef]

- Wüstefeld, C.; Rafaja, D.; Dopita, M.; Motylenko, M.; Baehtz, C.; Michotte, C.; Kathrein, M. Decomposition kinetics in Ti1−xAlxN coatings as studied by in-situ X-ray diffraction during annealing. Surf. Coat. Technol. 2011, 206, 1727–1734. [Google Scholar] [CrossRef]

- Rafaja, D.; Wüstefeld, C.; Baehtz, C.; Klemm, V.; Dopita, M.; Motylenko, M.; Michotte, C.; Kathrein, M. Effect of internal interfaces on hardness and thermal stability of nanocrystalline Ti0.5Al0.5N coatings. Metall. Mater. Trans. A 2011, 42A, 559–569. [Google Scholar] [CrossRef] [Green Version]

- Rogström, L.; Ullbrand, J.; Almer, J.; Hultman, L.; Jansson, B.; Odén, M. Strain evolution during spinodal decomposition of TiAlN thin films. Thin Solid Films 2012, 520, 5542–5549. [Google Scholar] [CrossRef] [Green Version]

| Sample | Al (WDS) at.% | Ti (WDS) at.% | N (EDS) at.% | O (WDS) at.% | x |

|---|---|---|---|---|---|

| Ti1−xAlxN flake top side | 43.7 | 5.8 | 49.9 | 0.6 | 0.88 |

| Ti1−xAlxN flake bottom side | 41.0 | 6.1 | 52.1 | 0.8 | 0.87 |

| h k l | D (Å) | 2θ (°, Cu Kα) | I/Imax (%) | M Multiplicity | N (h2 + k2 + l2) |

|---|---|---|---|---|---|

| 1 1 1 | 2.35079 | 38.256 | 32.0 | 8 | 3 |

| 2 0 0 | 2.03584 | 44.465 | 100.0 | 6 | 4 |

| 2 2 0 | 1.43956 | 64.701 | 28.7 | 12 | 8 |

| 3 1 1 | 1.22766 | 77.725 | 5.7 | 24 | 11 |

| 2 2 2 | 1.17539 | 81.893 | 5.5 | 8 | 12 |

| 4 0 0 | 1.01792 | 98.355 | 1.7 | 6 | 16 |

| 3 3 1 | 0.93411 | 111.103 | 1.2 | 24 | 19 |

| 4 2 0 | 0.91046 | 115.571 | 3.7 | 24 | 20 |

| 4 2 2 | 0.83113 | 135.886 | 2.2 | 24 | 36 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Endler, I.; Höhn, M.; Matthey, B.; Zálešák, J.; Keckes, J.; Pitonak, R. Powder Diffraction Data of Aluminum-Rich FCC-Ti1−xAlxN Prepared by CVD. Coatings 2021, 11, 683. https://doi.org/10.3390/coatings11060683

Endler I, Höhn M, Matthey B, Zálešák J, Keckes J, Pitonak R. Powder Diffraction Data of Aluminum-Rich FCC-Ti1−xAlxN Prepared by CVD. Coatings. 2021; 11(6):683. https://doi.org/10.3390/coatings11060683

Chicago/Turabian StyleEndler, Ingolf, Mandy Höhn, Björn Matthey, Jakub Zálešák, Jozef Keckes, and Reinhard Pitonak. 2021. "Powder Diffraction Data of Aluminum-Rich FCC-Ti1−xAlxN Prepared by CVD" Coatings 11, no. 6: 683. https://doi.org/10.3390/coatings11060683

APA StyleEndler, I., Höhn, M., Matthey, B., Zálešák, J., Keckes, J., & Pitonak, R. (2021). Powder Diffraction Data of Aluminum-Rich FCC-Ti1−xAlxN Prepared by CVD. Coatings, 11(6), 683. https://doi.org/10.3390/coatings11060683