Thermally Sprayed Nickel-Based Repair Coatings for High-Pressure Turbine Blades: Controlling Void Formation during a Combined Brazing and Aluminizing Process

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Coating Equipment

2.3. Heat Treatment

2.4. Design of Experiments

2.5. Characterization of the Coatings

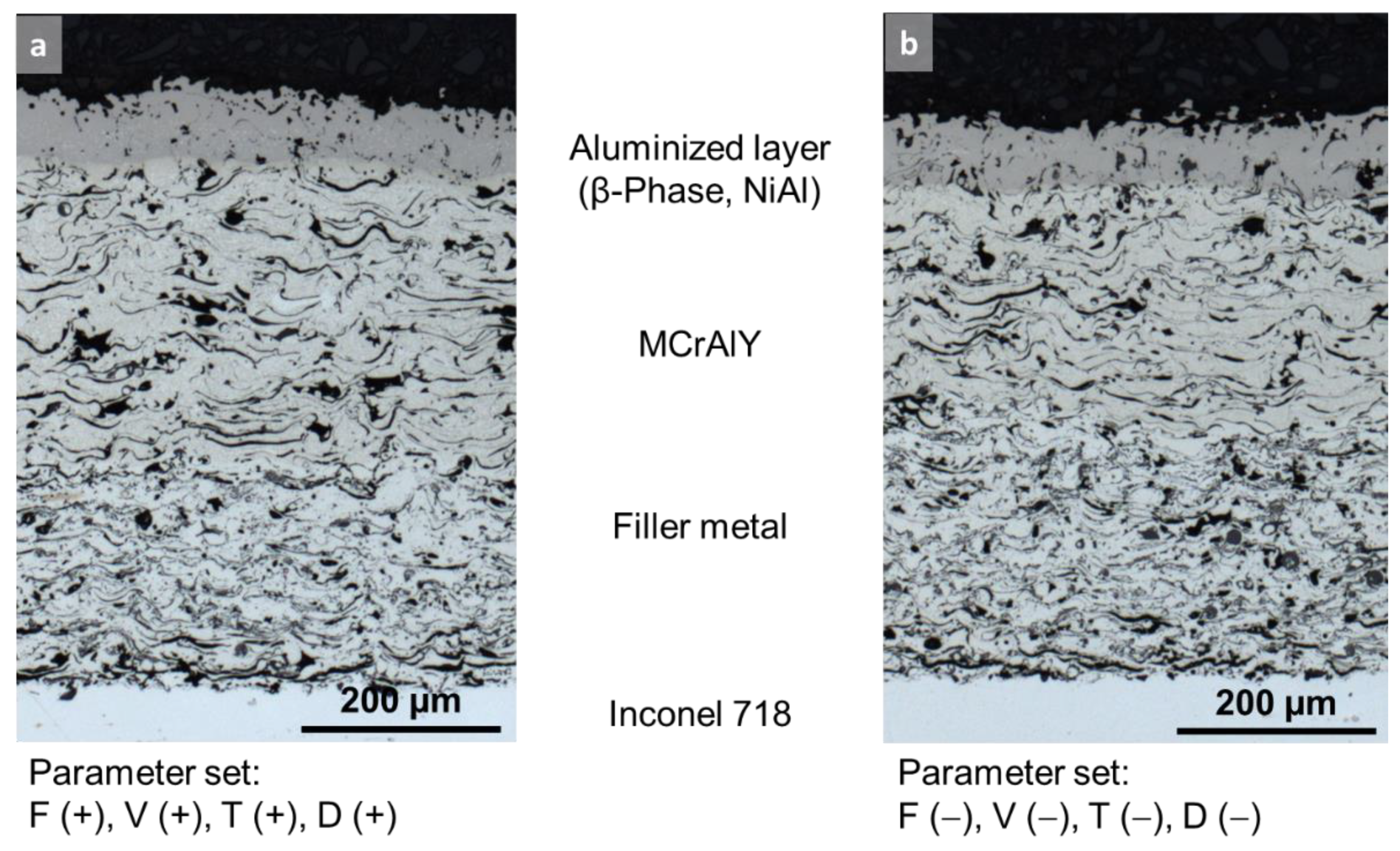

3. Results and Discussion

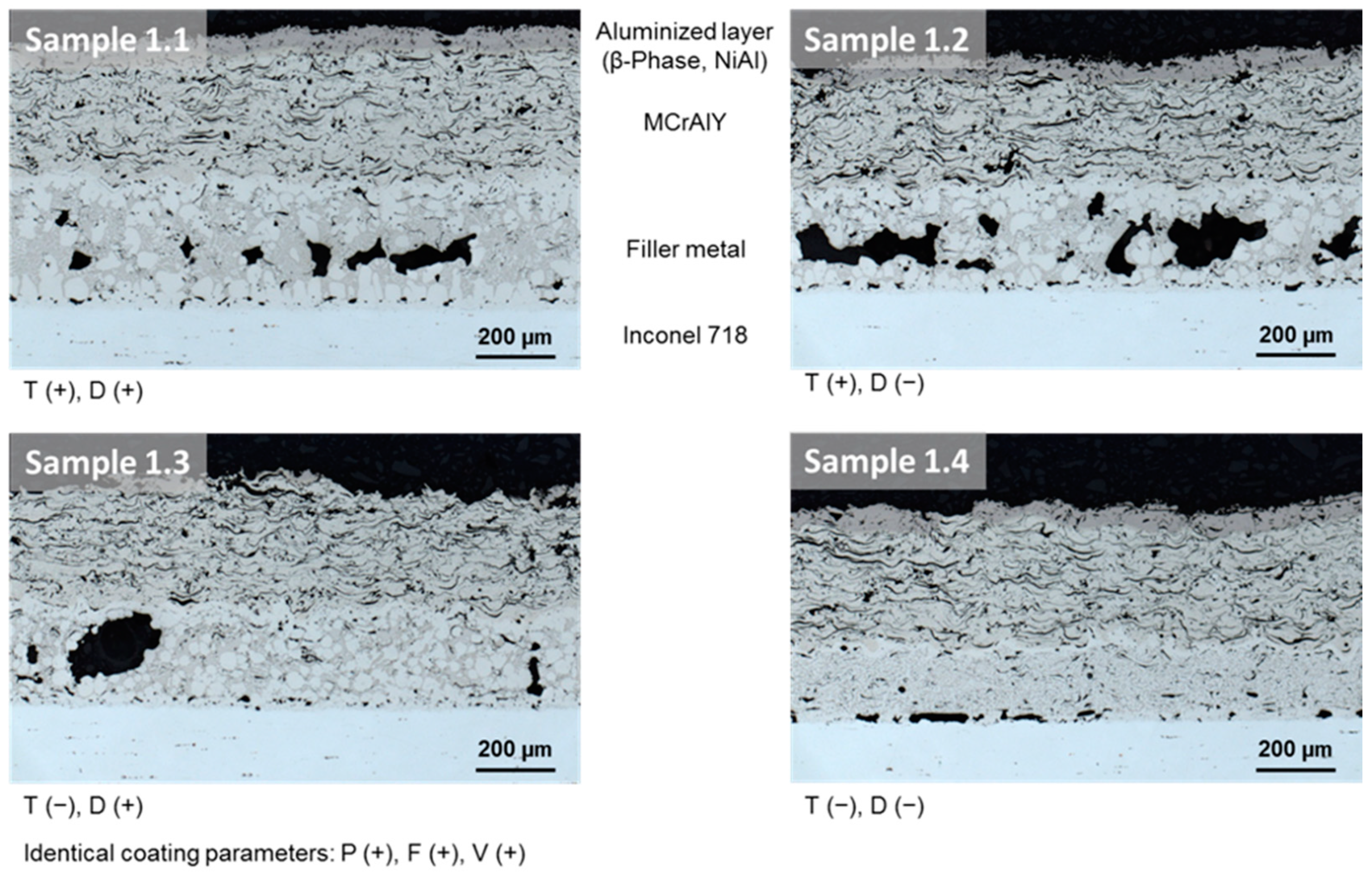

3.1. Fine Powder

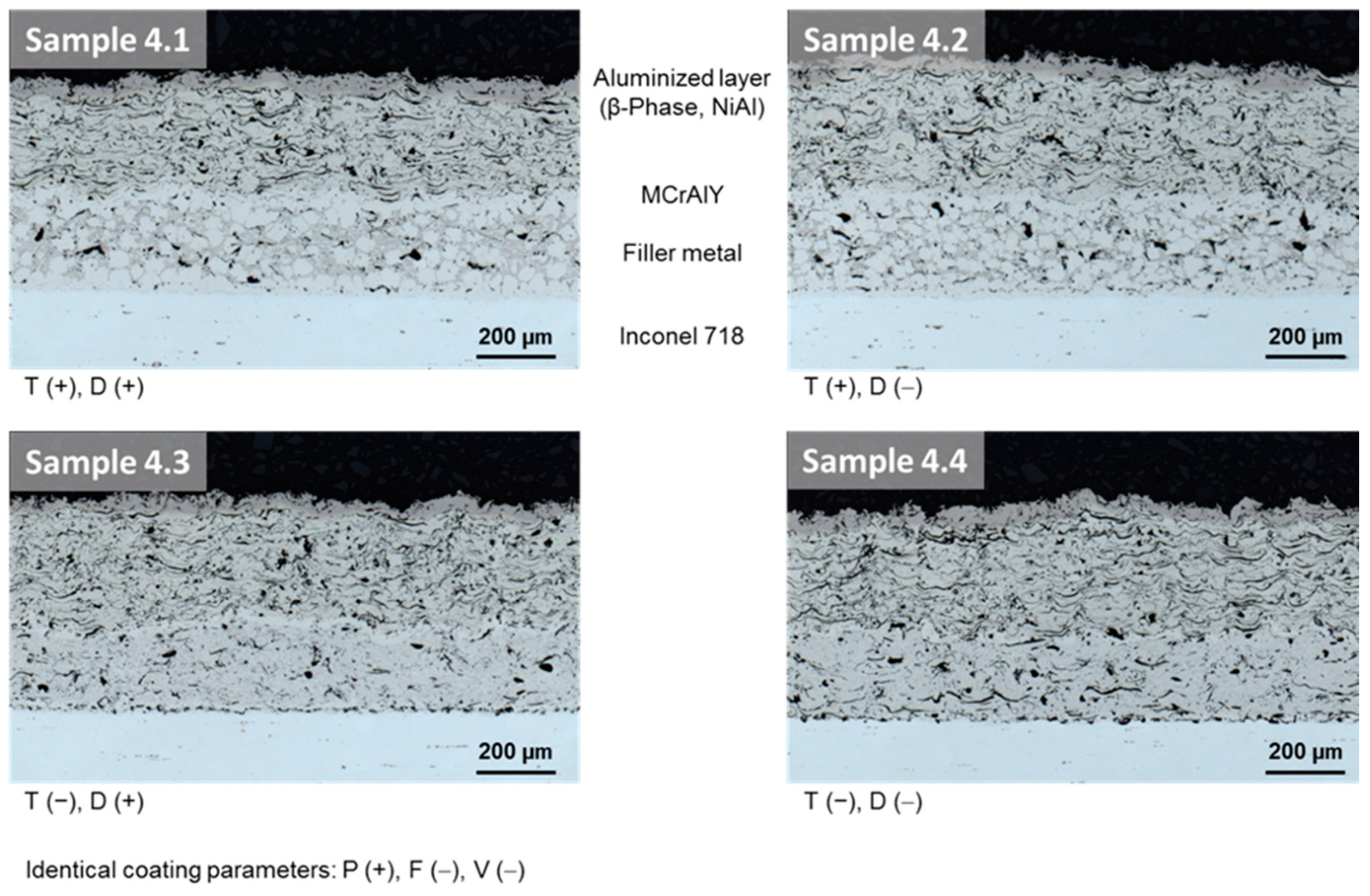

3.2. Coarse Powder

4. Conclusions

- When using fine powder particles (<63 µm) of the filler metal, these oxidize easily, and thus, flowability of the filler metal is reduced.

- The oxidation of the fine particles dominates the microstructural evolution. In turn, the effect of the heat treatment parameters on microstructure is only minor in this case.

- For coarser grained powder particles, the effect of oxidation diminishes, and heat treatment starts to have a significant impact on the resulting microstructures.

- In case of the coarser powder particles, the voids in the coating can be reduced via appropriate selection of heat treatment parameters. Specifically, the voids can be reduced by selecting a lowering brazing temperature and/or shorter dwell periods. This effect can be attributed to diminished diffusion and segregation processes along with the higher viscosity of the filler metal.

- Powder feed rate and the traverse velocity should be set to low values for obtaining a homogeneous distribution of the formed phases within the brazed seam.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Vardelle, A.; Moreau, C.; Akedo, J.; Ashrafizadeh, H.; Berndt, C.C.; Berghaus, J.O.; Boulos, M.; Brogan, J.; Bourtsalas, A.C.; Dolatabadi, A.; et al. The 2016 Thermal Spray Roadmap. J. Therm. Spray Technol. 2016, 25, 1376–1440. [Google Scholar] [CrossRef]

- Gérad, B. Application of thermal spraying in the automobile industry. Surf. Coat. Technol. 2006, 201, 2028–2031. [Google Scholar] [CrossRef]

- Brand, O.; Möhwald, K.; Reimche, W.; Bruchwald, O. Practical experiences using HVOF sprayed tungsten carbide coatings in the plastic foil industry. In Proceedings of the ITSC 2017 Conference Proceedings, Düsseldorf, Germany, 7–9 June 2017; DVS Media GmbH: Düsseldorf, Germany, 2017; pp. 360–363. [Google Scholar]

- Stolle, R. Conventional and Advanced Coatings for Turbine Airfoils, MTU Aero Engines Munich. 2004. Available online: http://www.academia.edu/7789702/Conventional_and_advanced_coatings_for_turbine_airfoils (accessed on 14 January 2021).

- Fayomi, O.S.I.; Agboola, O.; Akande, I.G.; Emmanuel, A.O. Challenges of coatings in aerospace, automobile and marine industries. AIP Conf. Proc. 2020, 2307, 020038. [Google Scholar]

- Naraparaju, R.; Schulz, U.; Mechnich, P.; Döbber, P.; Seidel, F. Degradation study of 7 wt.% yttria stabilised zirconia (7YSZ) thermal barrier coatings on aero-engine combustion chamber parts due to infiltration by different CaO–MgO–Al2O3–SiO2 variants. Surf. Coat. Technol. 2014, 260, 73–81. [Google Scholar] [CrossRef]

- Bakan, E.; Mack, D.E.; Mauer, G.; Vaßen, R.; Lamon, J.; Padture, N.P. High-temperature materials for power generation in gas turbines. In Advanced Ceramics for Energy Conversion and Storage, 1st ed.; Guillon, O., Ed.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 3–62. [Google Scholar]

- Huang, X.; Miglietti, W. Wide Gap Braze Repair of Gas Turbine Blades and Vanes—A Review. J. Eng. Gas Turbines Power 2011, 134, 010801. [Google Scholar] [CrossRef]

- Henderson, M.B.; Arrell, D.; Larsson, R.; Heobel, M.; Marchant, G. Nickel-based superalloy welding practices for industrial gas turbine applications. Sci. Technol. Weld. Join. 2004, 9, 13–21. [Google Scholar] [CrossRef]

- Migletti, W.; Summerside, I. Repair Process Technology Development & Experience For W501F Row 1 Hot Gas Path Blades. In Proceedings of the ASME Turbo Expo 2010: Power for Land, Sea and Air, Glasgow, UK, 14–18 June 2010. [Google Scholar]

- Bobzin, K.; Ernst, F.; Rösing, J.; Schlegel, A.; Rojas, Y. Hochtemperaturlöten als Reparaturverfahren zur Erweiterung der Lebensdauer einkristalliner Turbinenkomponenten. Schweißen und Schneiden 2007, 59, 249–252. [Google Scholar]

- Laux, B.; Piegert, S.; Rösler, J. Fast epitaxial high temperature brazing of single crystal-line nickel based superalloys. J. Eng. Gas Turbines Power 2009, 131, 032102. [Google Scholar] [CrossRef] [Green Version]

- Zhan, Z.; He, Y.; Li, L.; Liu, H.; Dai, Y. Low-temperature formation and oxidation resistance of ultrafine aluminide coatings on Ni-base superalloy. Surf. Coat. Technol. 2009, 203, 2337–2342. [Google Scholar] [CrossRef]

- Nicolaus, M.; Rottwinkel, B.; Alfred, I.; Möhwald, K.; Nölke, C.; Kaierle, S.; Maier, H.J.; Wesling, V. Future regeneration processes for high-pressure turbine blades. CEAS Aeronaut. J. 2018, 9, 85–92. [Google Scholar] [CrossRef]

- Nicolaus, M.; Möhwald, K.; Maier, H.J. A Combined Brazing and Aluminizing Process for Repairing Turbine Blades by Thermal Spraying Using the Coating System NiCrSi/NiCoCrAlY/Al. J. Therm. Spray Technol. 2017, 26, 1659–1668. [Google Scholar] [CrossRef]

- Brooks, J.W.; Bridges, P.J. Metallurgical Stability of Inconel Alloy 718. In Superalloys 1988; The Metallurgical Society, TMS: Pittsburgh, PA, USA, 1988; pp. 33–42. [Google Scholar]

- Schirra, J.J. Effect of Heat Treatment Variations on the Hardness and Mechanical Properties of Wrought Inconel 718. In Superalloys 718, 625, 706 and Various Derivatives; The Minerals, Metals & Materials Society, TMS: Pittsburgh, PA, USA, 1991; pp. 431–438. [Google Scholar]

- Rao, G.A.; Kumar, M.; Srinivas, M.; Sarma, D.S. Effect of Solution Treatment Temperature on the Microstructure and Tensile Properties of P/M (HIP) Processed Superalloy Inconel 718. In Superalloys 718, 625, 706 and Various Derivatives; The Minerals, Metals & Materials Society, TMS: Pittsburgh, PA, USA, 2001; pp. 605–616. [Google Scholar]

- Česnik, D.; Bratuš, V.; Kosec, B.; Rozman, J.; Bizjak, M. Heat treatment and fine-blankin Inconel 718. RMZ Mater. Geoenviron. 2008, 55, 163–172. [Google Scholar]

- Nakajima, H. The discovery and acceptance of the Kirkendall Effect: The result of a short research career. JOM 1997, 49, 15–19. [Google Scholar] [CrossRef]

- Babiak, Z.; Wenz, T. Grundlagen der thermischen Spritztechnik, Flamm- und Lichtbogenspritzen. In Moderne Beschichtungsverfahren; Bach, F.-W., Möhwald, K., Laarmann, A., Wenz, T., Eds.; Wiley-VCH: Weinheim, Germany, 2006; pp. 131–149. [Google Scholar]

- ImageJ. Image Processing and Analysis in Java. Available online: https://imagej.nih.gov/ij/ (accessed on 20 January 2021).

- Ansara, I.; Dupin, N.; Lukas, H.L.; Sundman, B. Thermodynamic assessment of the Al-Ni system. J. Alloys Compd. 1997, 247, 20–301. [Google Scholar] [CrossRef]

- Gupta, K.P. The Cr-Ni-Si (Chromium-Nickel-Silicon) System. J. Phase Equilibria Diffus. 2006, 27, 523–528. [Google Scholar] [CrossRef]

- Schuster, J.C.; Du, Y. Experimental Investigation and Thermodynamic Modeling of the Cr-Ni-Si System. Metall. Mater. Trans. A 2000, 31, 1795–1803. [Google Scholar] [CrossRef]

- Nash, P.; Nash, A. The Ni−Si (Nickel-Silicon) system. Bull. Alloy Phase Diagr. 1987, 8, 6–14. [Google Scholar] [CrossRef]

- Tung, S.K.; Lim, L.C.; Lai, M.O. Solidification phenomena in nickel base brazes containing boron and silicon. Scr. Mater. 1996, 34, 763–769. [Google Scholar] [CrossRef]

| Material | Inconel 718 | Ni650 (B-Ni5) | MCrAlY |

|---|---|---|---|

| Ni | 56.5 | 71.0 | 47.5 |

| Co | 19.0 | 23.0 | |

| Cr | 19.0 | 17.0 | |

| Si | 10.0 | ||

| Al | 0.5 | 12.0 | |

| Y | 0.5 | ||

| Fe | 18.0 | ||

| Nb + Ta | 5.1 | ||

| Ti | 1.0 |

| Parameter | Value |

|---|---|

| Current/A | 390 |

| Argon flowrate/L·min−1 | 40 |

| Hydrogen flowrate/L·min−1 | 10 |

| Nozzle distance/mm | 130 |

| Traverse velocity/m·s−1 | 0.9–1.8 |

| Spray angle/° | 90 |

| Powder size Ni650/µm | <106 |

| Powder size MCrAlY/µm | −75 + 38 |

| Powder size Al/µm | −90 + 45 |

| Powder feed rate/g·min−1 | 25–50 |

| Parameter | Unit | High (+) | Low (−) | |

|---|---|---|---|---|

| Powder particle size | P | µm | −106 + 63 | <63 |

| Powder feed rate | F | g·min−1 | 50 | 25 |

| Traverse velocity | V | m·s−1 | 1.8 | 0.9 |

| Brazing temperature | T | °C | 1190 | 1090 |

| Brazing dwell | D | min | 15 | 5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nicolaus, M.; Möhwald, K.; Maier, H.J. Thermally Sprayed Nickel-Based Repair Coatings for High-Pressure Turbine Blades: Controlling Void Formation during a Combined Brazing and Aluminizing Process. Coatings 2021, 11, 725. https://doi.org/10.3390/coatings11060725

Nicolaus M, Möhwald K, Maier HJ. Thermally Sprayed Nickel-Based Repair Coatings for High-Pressure Turbine Blades: Controlling Void Formation during a Combined Brazing and Aluminizing Process. Coatings. 2021; 11(6):725. https://doi.org/10.3390/coatings11060725

Chicago/Turabian StyleNicolaus, Martin, Kai Möhwald, and Hans Jürgen Maier. 2021. "Thermally Sprayed Nickel-Based Repair Coatings for High-Pressure Turbine Blades: Controlling Void Formation during a Combined Brazing and Aluminizing Process" Coatings 11, no. 6: 725. https://doi.org/10.3390/coatings11060725

APA StyleNicolaus, M., Möhwald, K., & Maier, H. J. (2021). Thermally Sprayed Nickel-Based Repair Coatings for High-Pressure Turbine Blades: Controlling Void Formation during a Combined Brazing and Aluminizing Process. Coatings, 11(6), 725. https://doi.org/10.3390/coatings11060725