Tribological Properties of a Mesh-Like Nanostructured Diamond-Like Carbon (DLC) Lubricated with a Fully Formulated Oil at DLC/Steel Contacts under Boundary Lubrication

Abstract

1. Introduction

2. Materials and Methods

2.1. Characterization of Materials

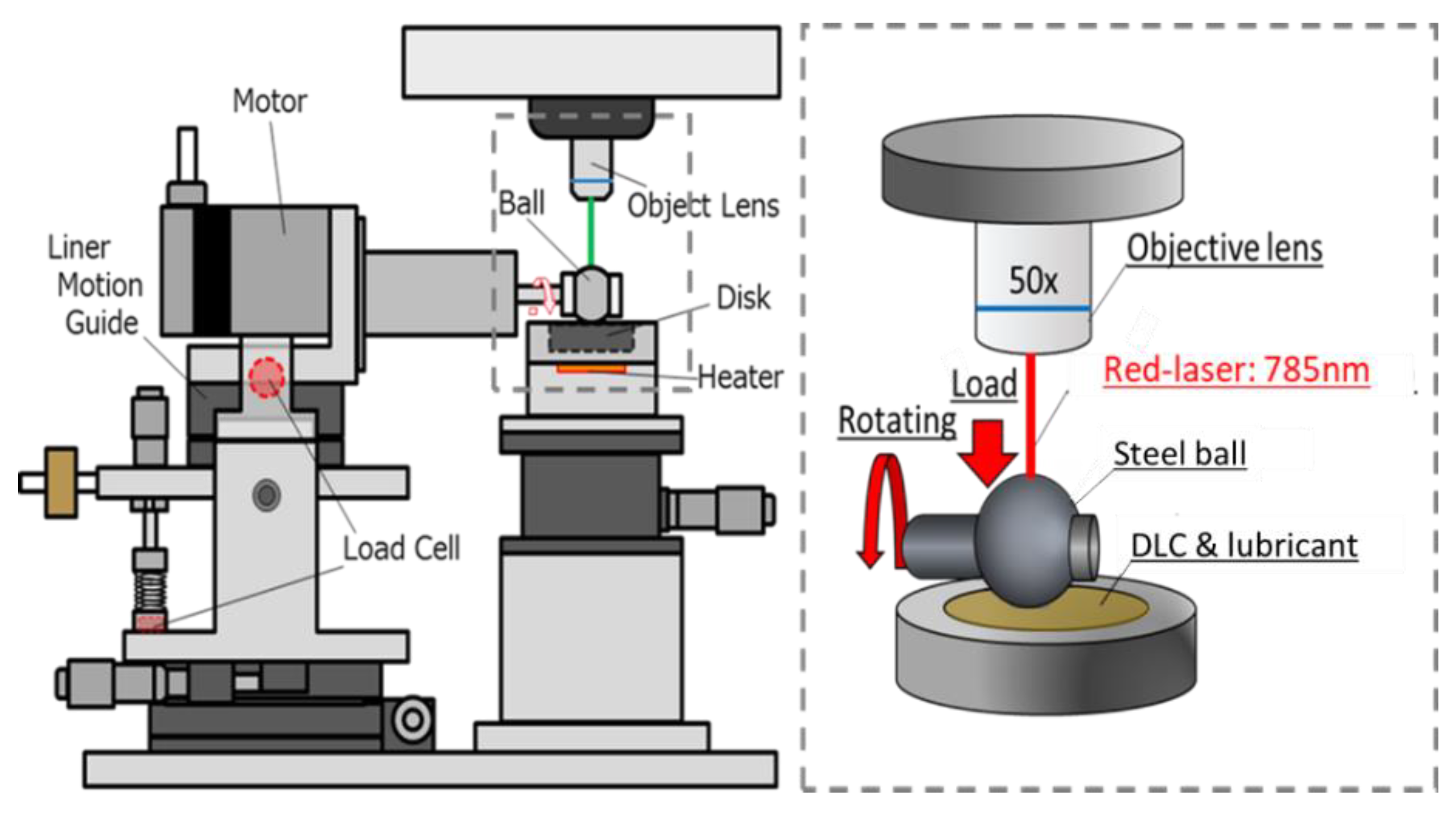

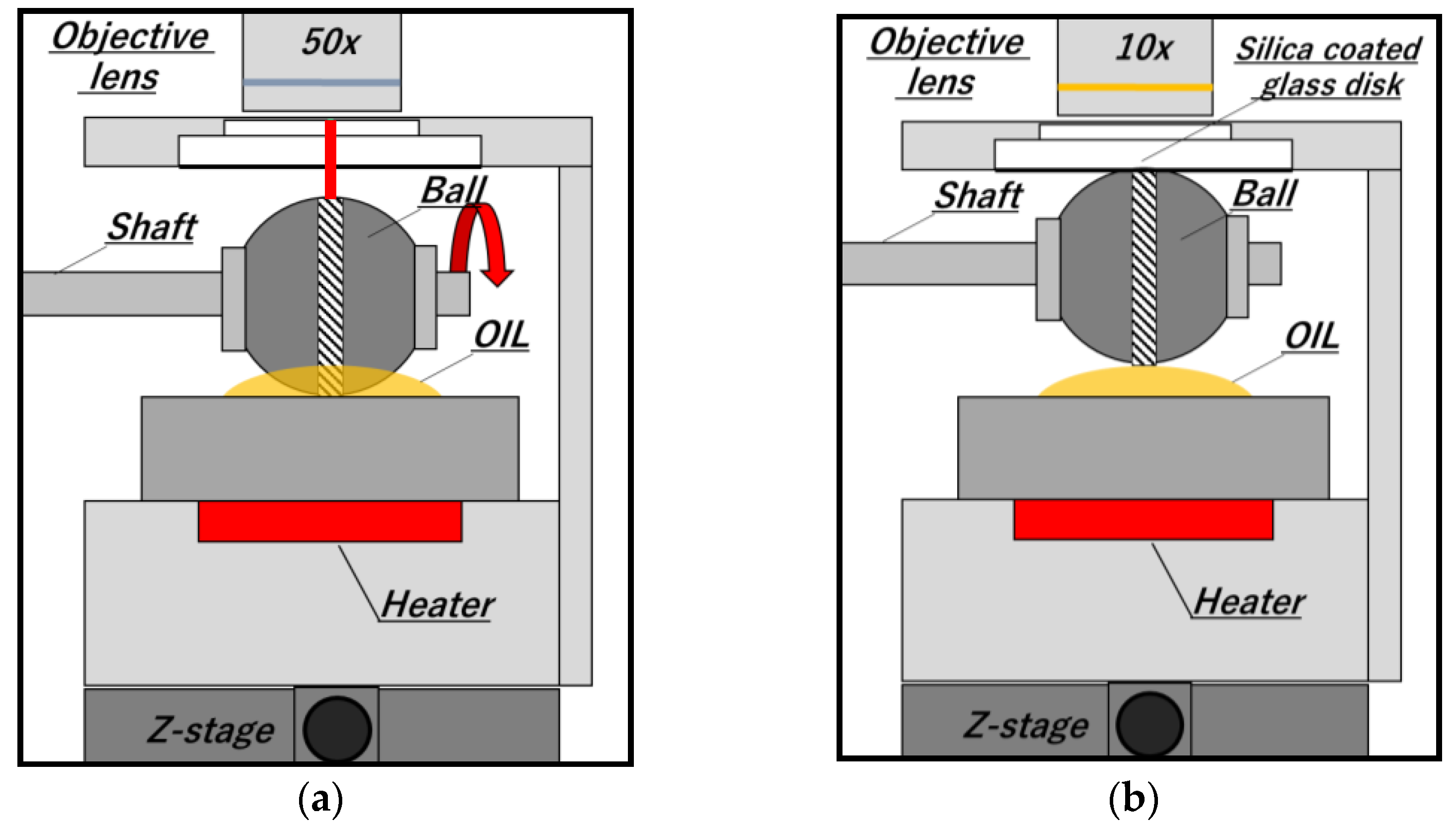

2.2. Friction Test and Raman-SLIM Analyses

2.3. Chemical Analysis for Tribofilms

3. Results

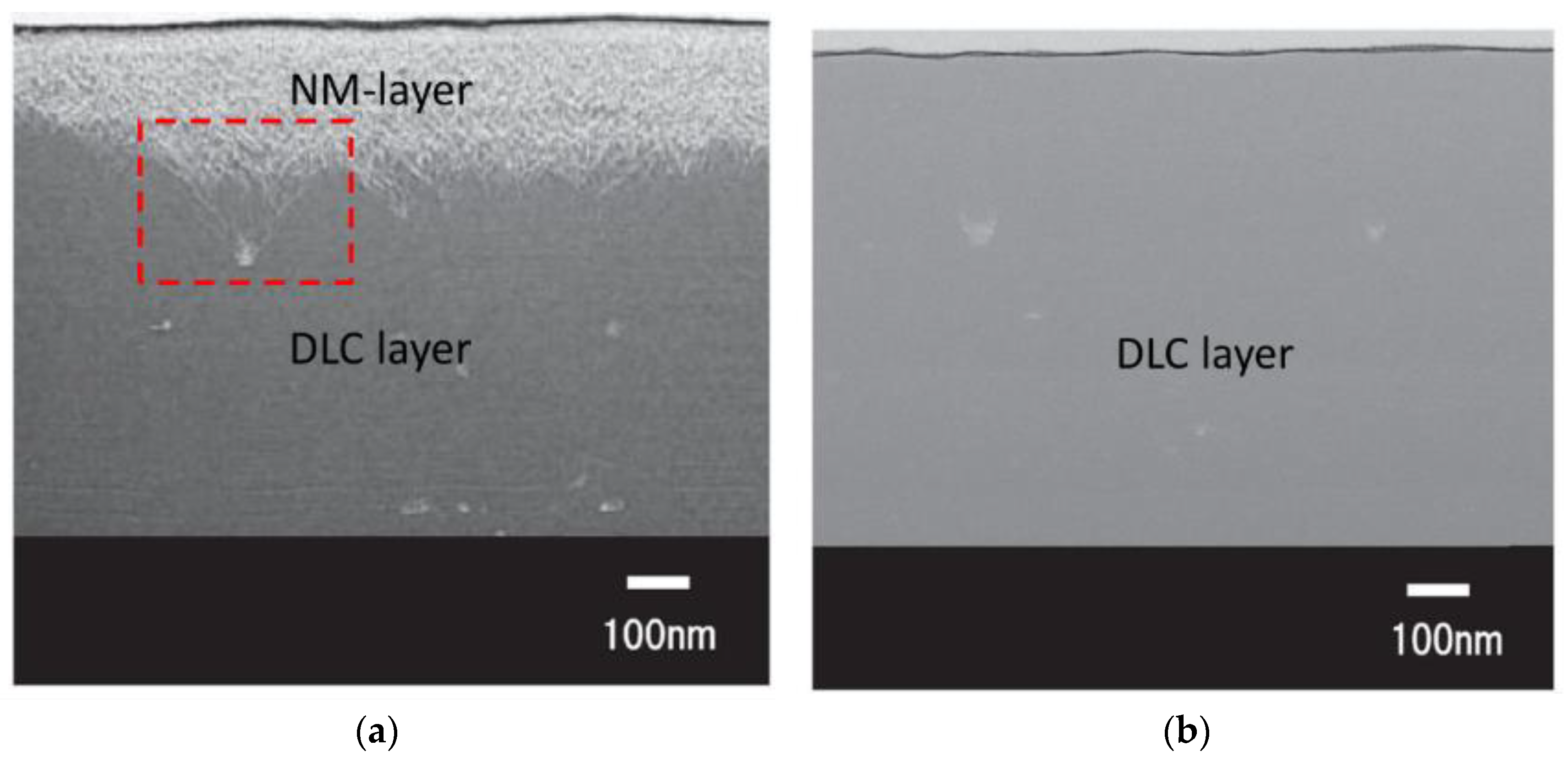

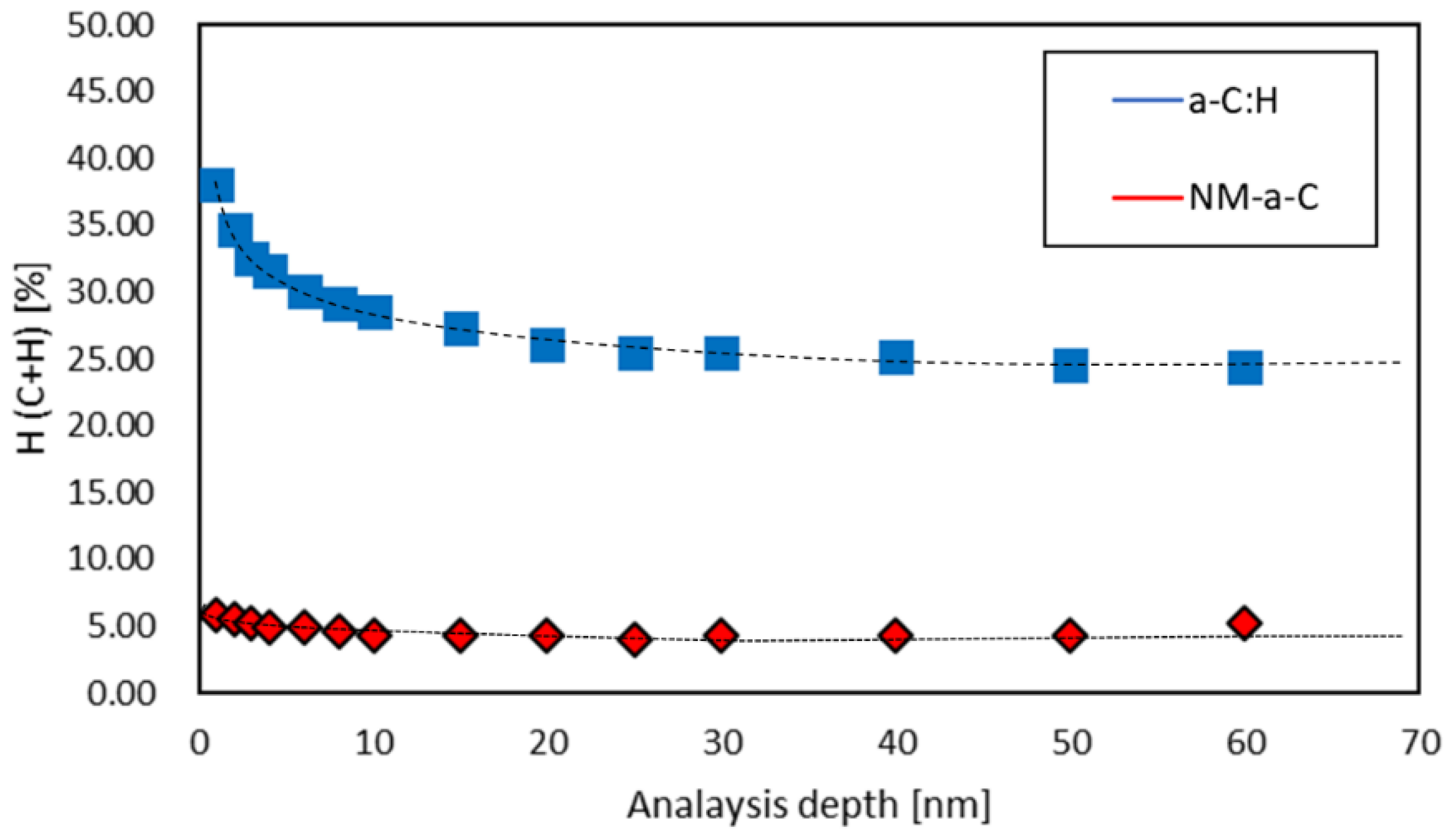

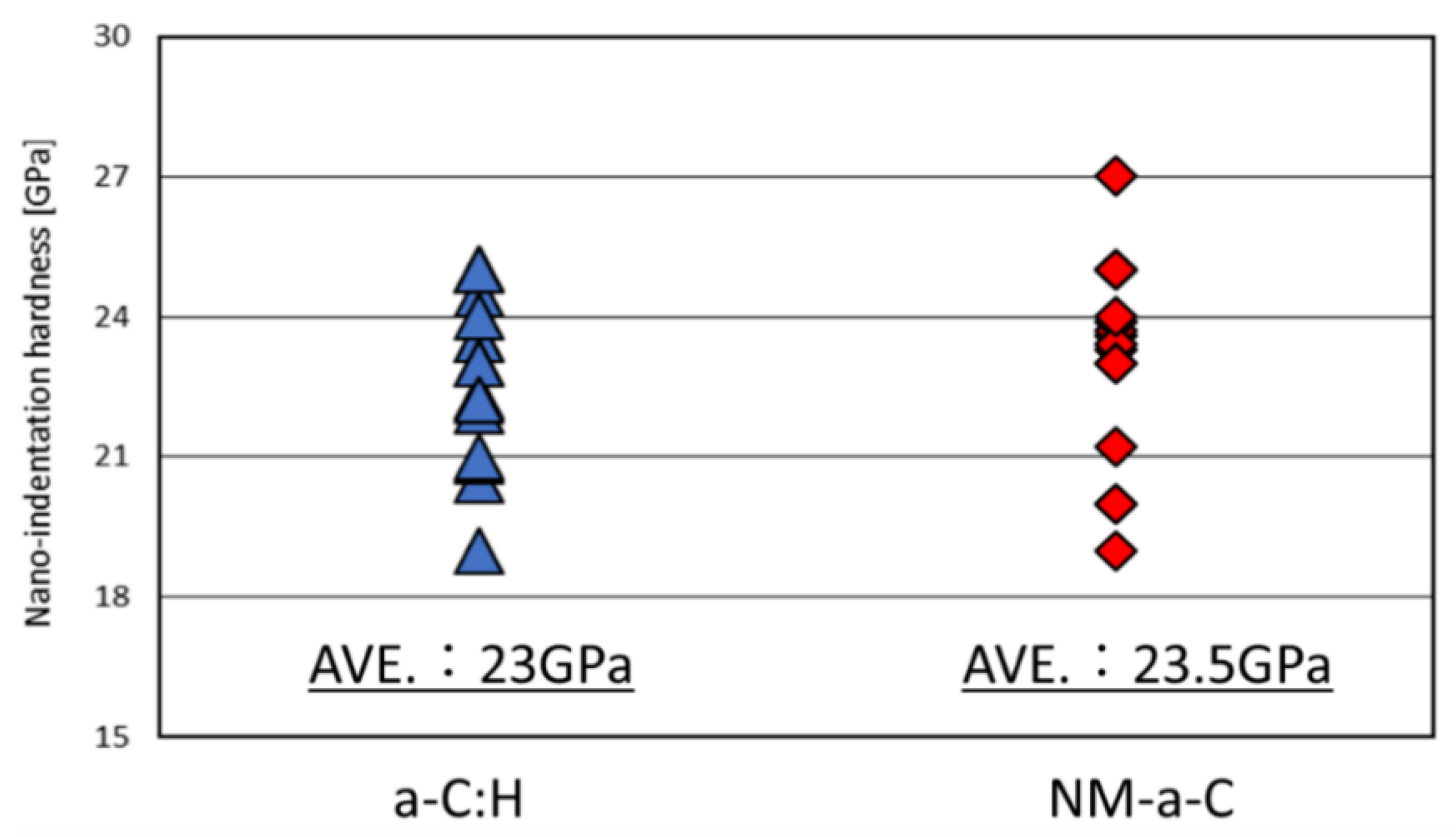

3.1. Characterization of the DLC films

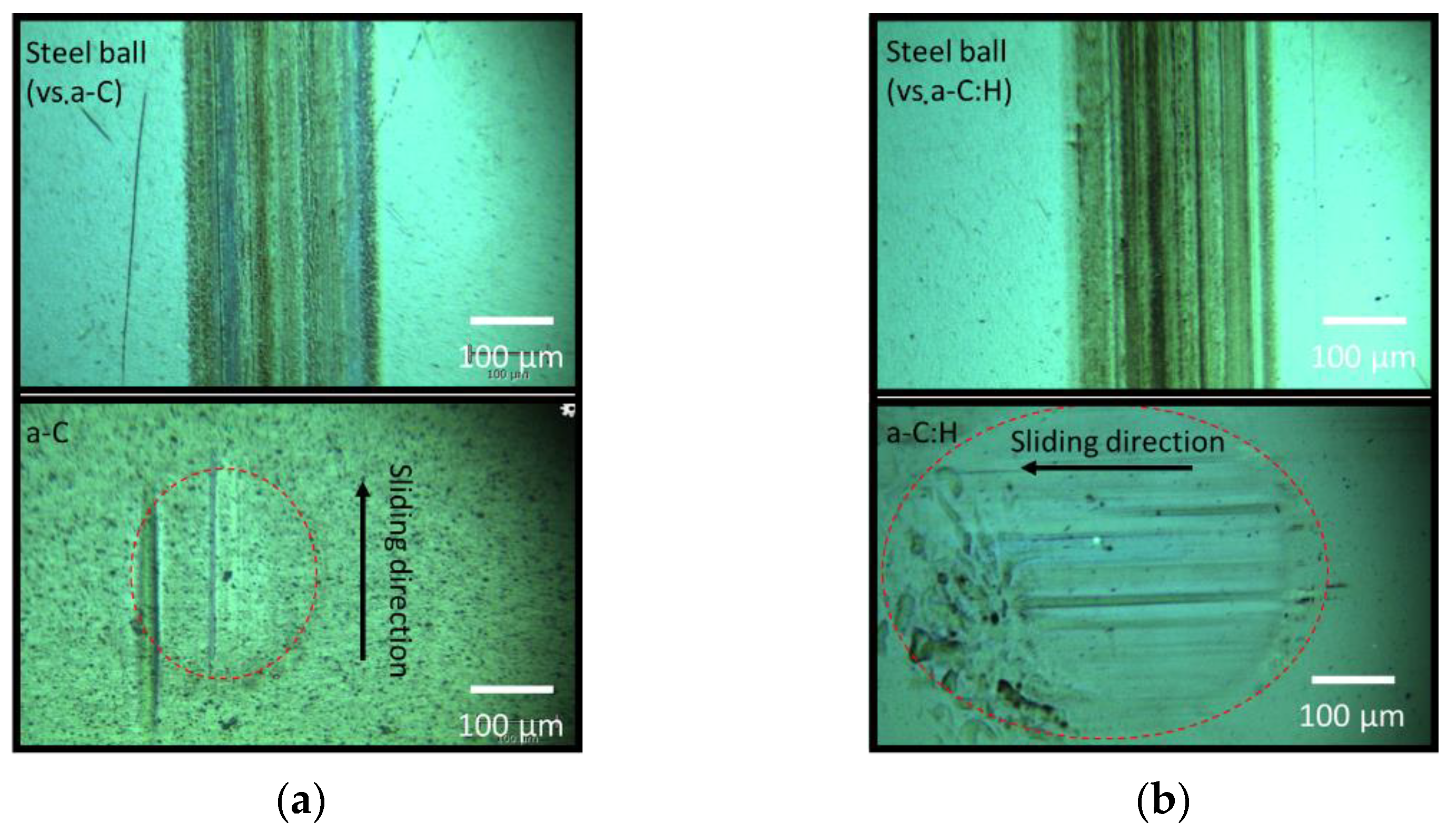

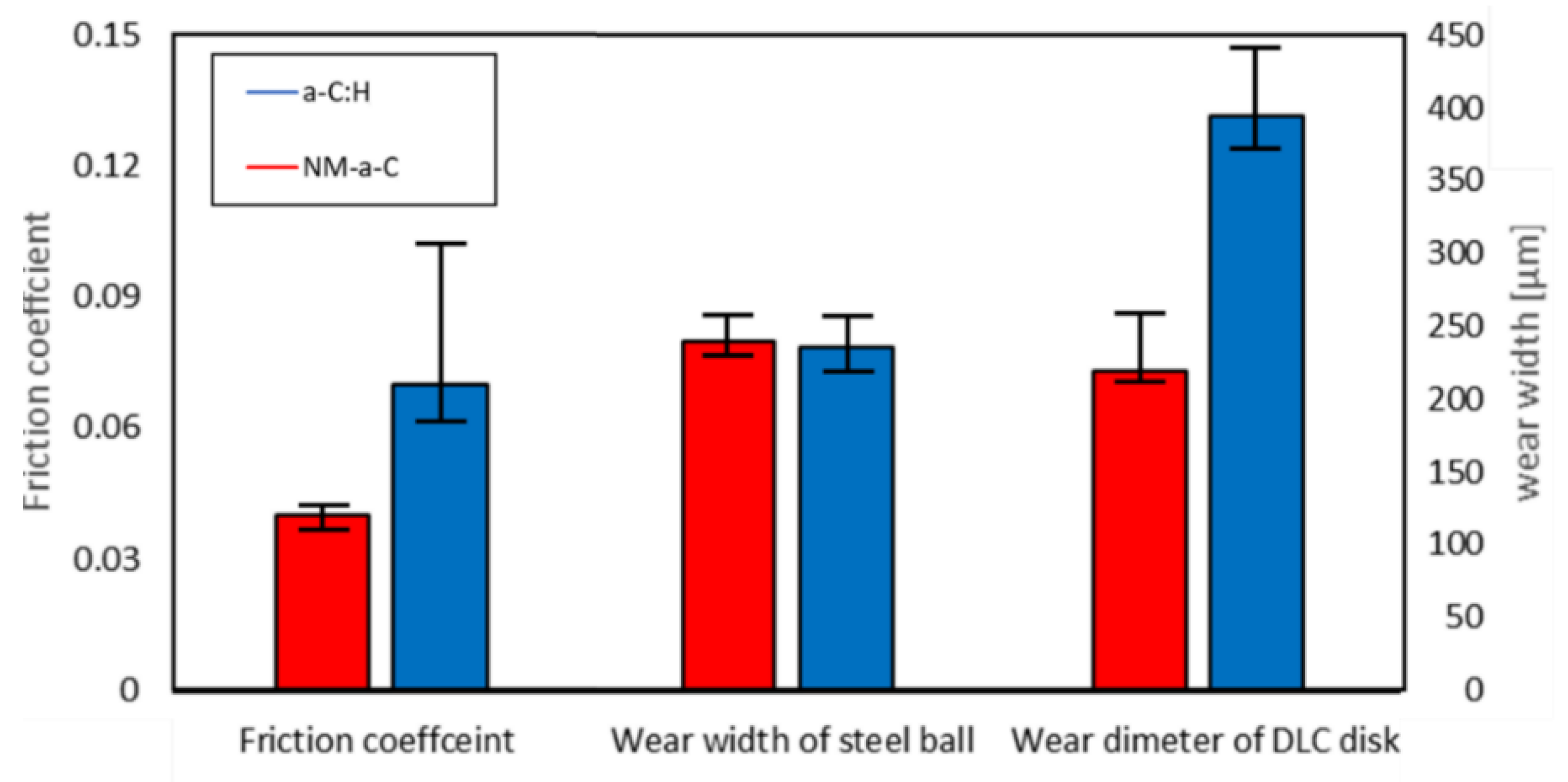

3.2. Friction and Wear Results

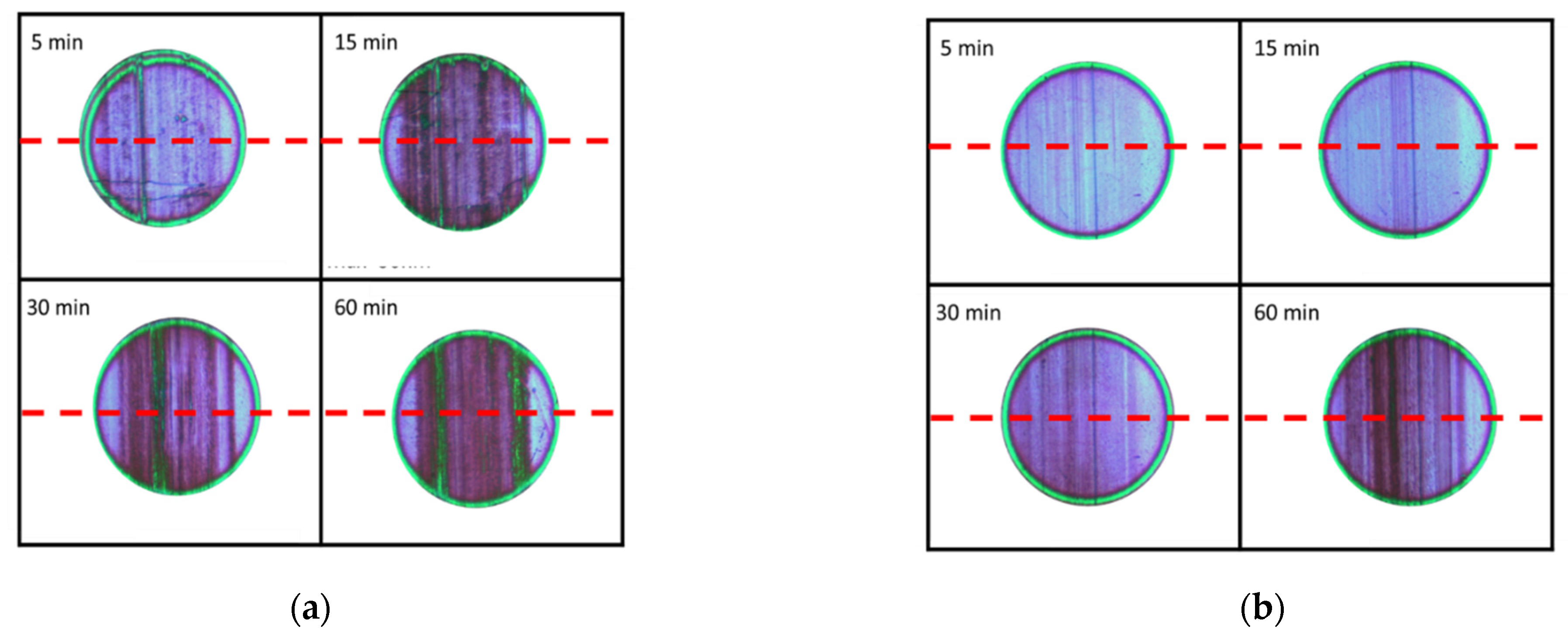

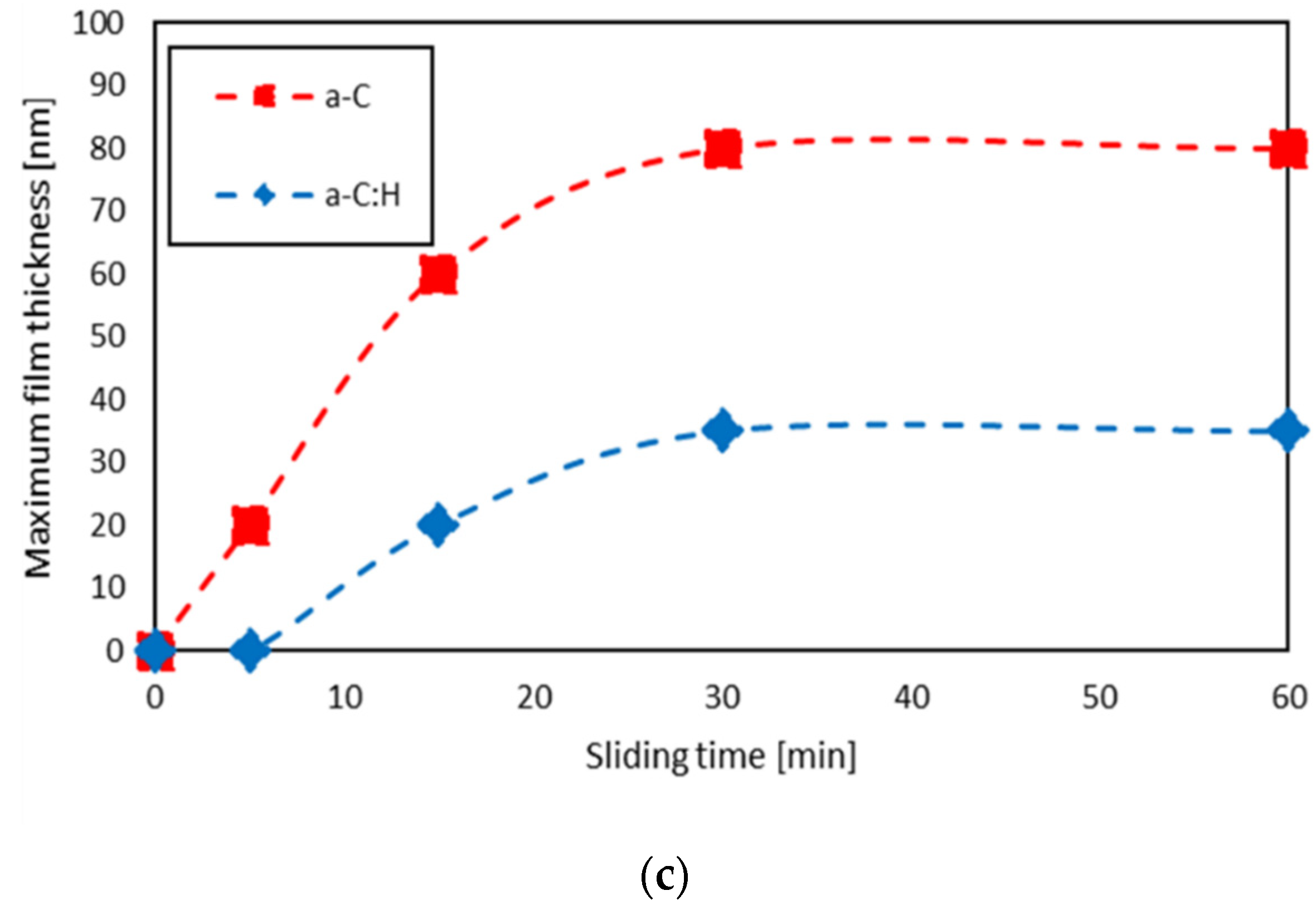

3.3. SLIM Analysis Results

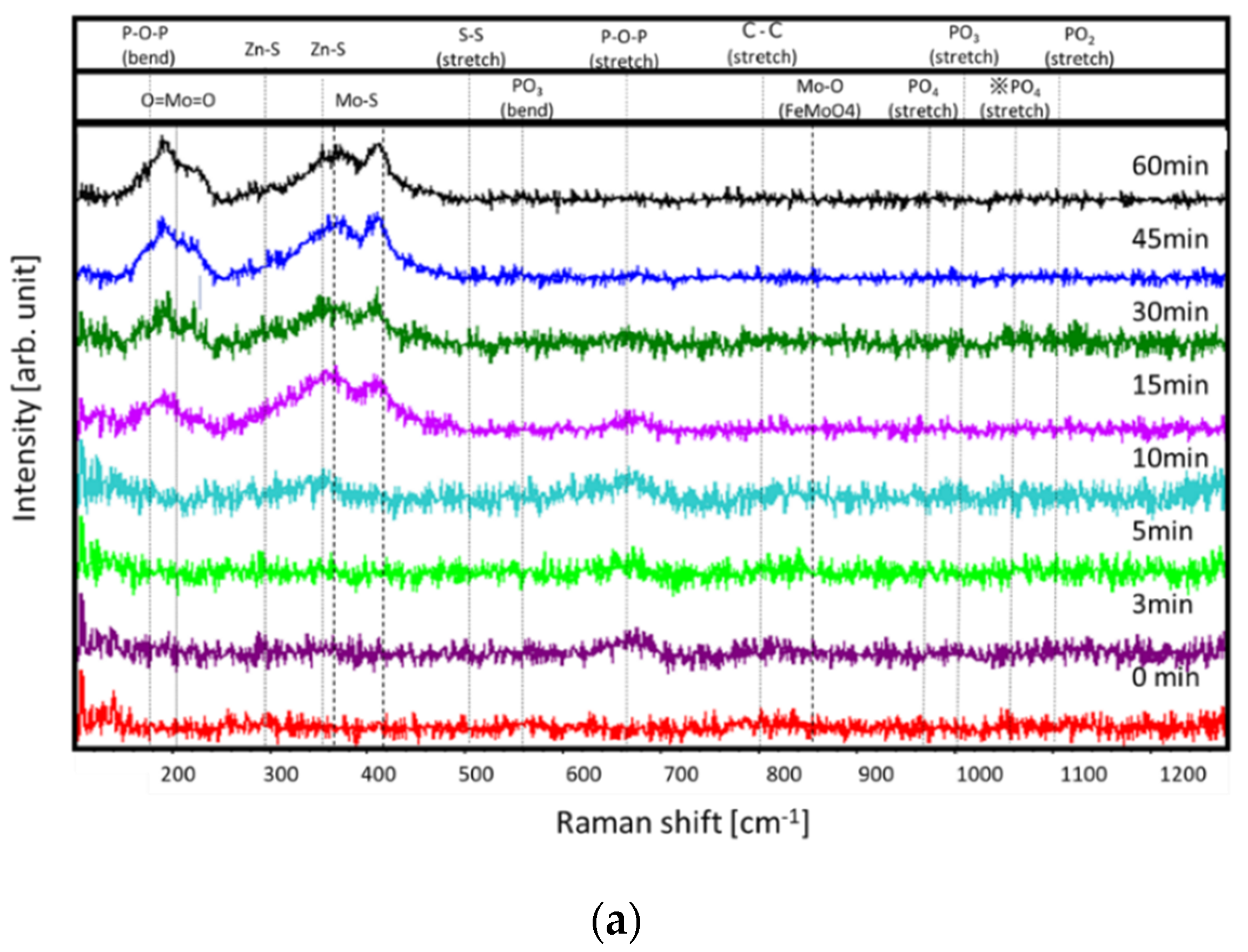

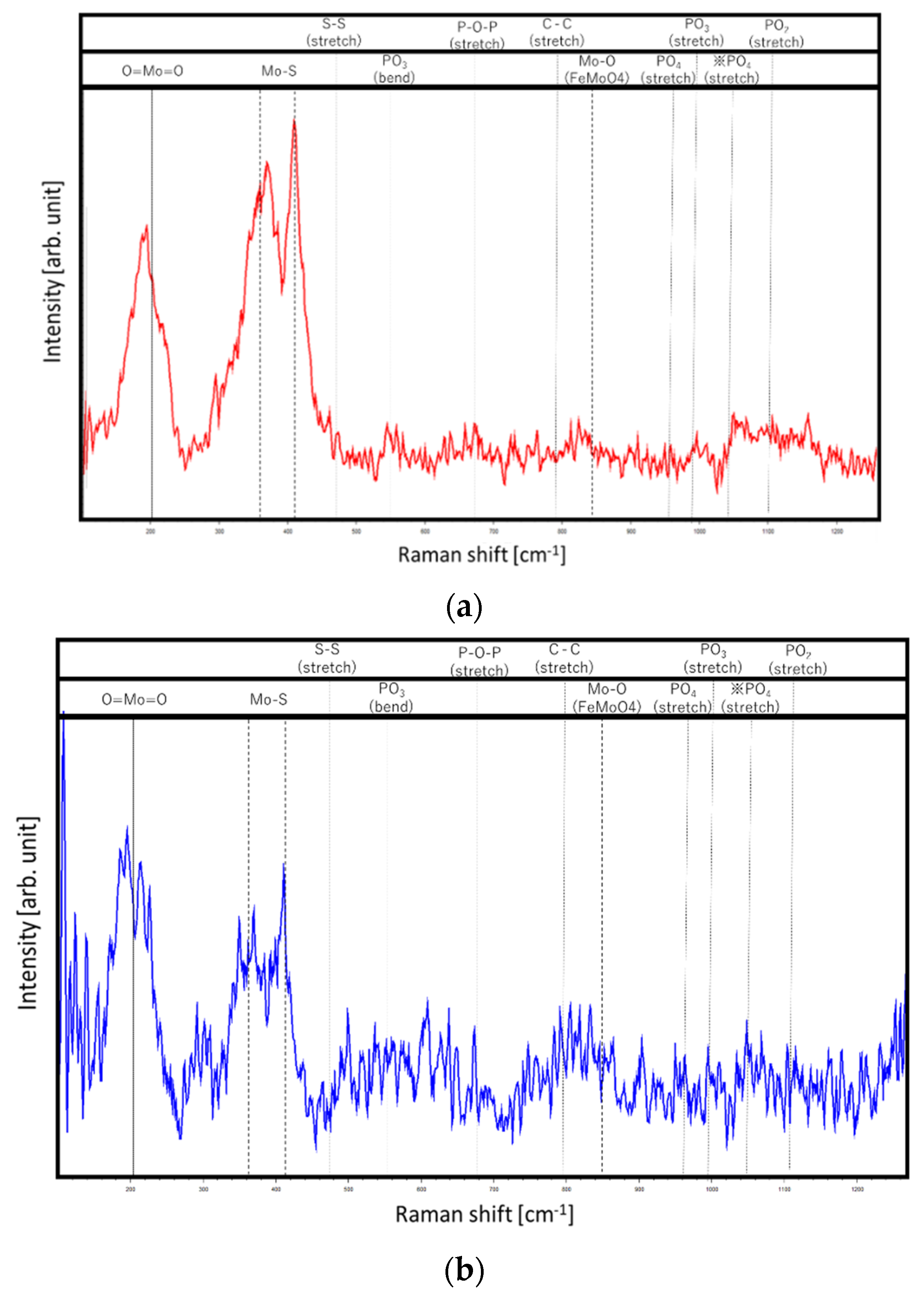

3.4. Raman Analysis Results

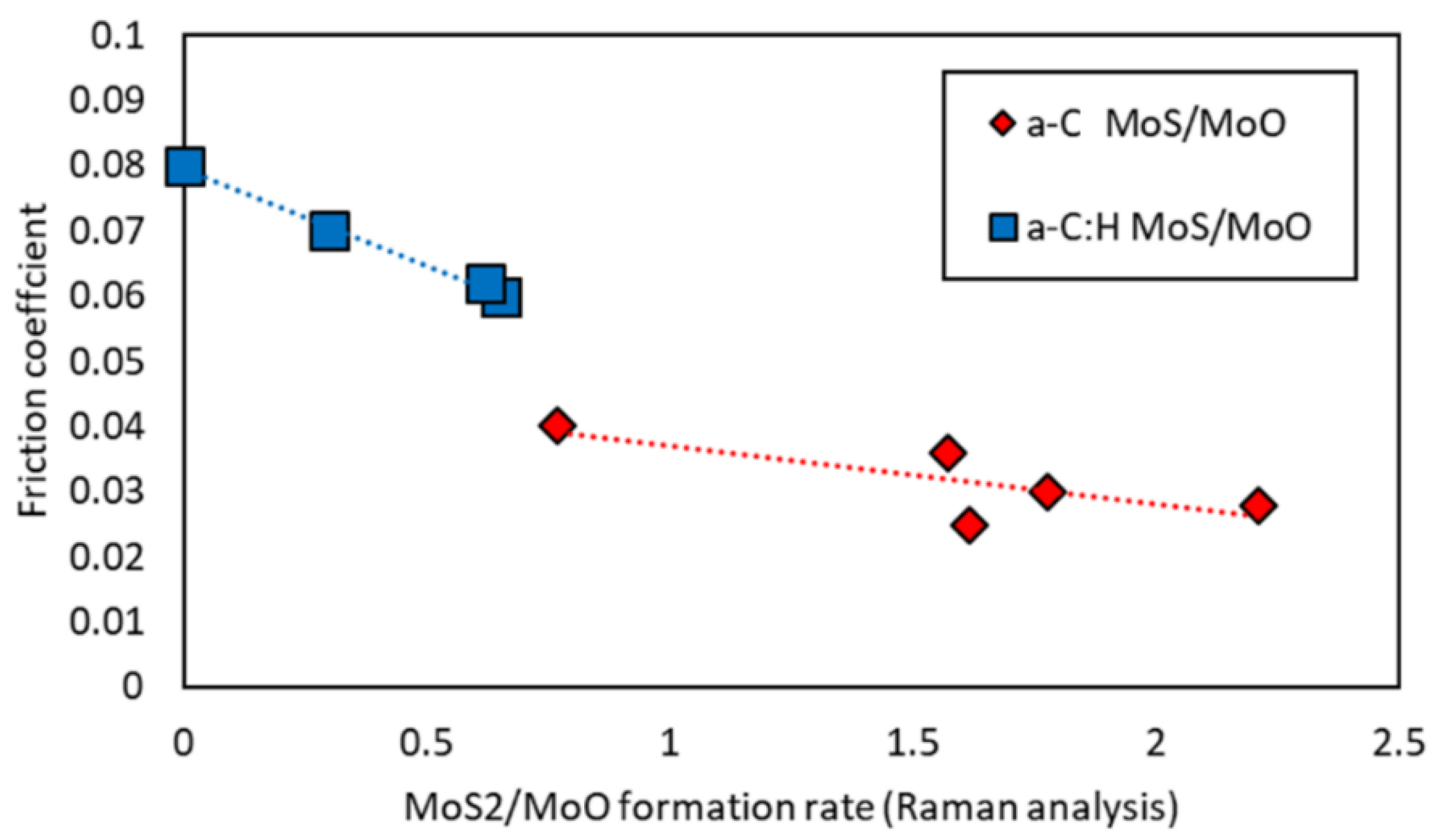

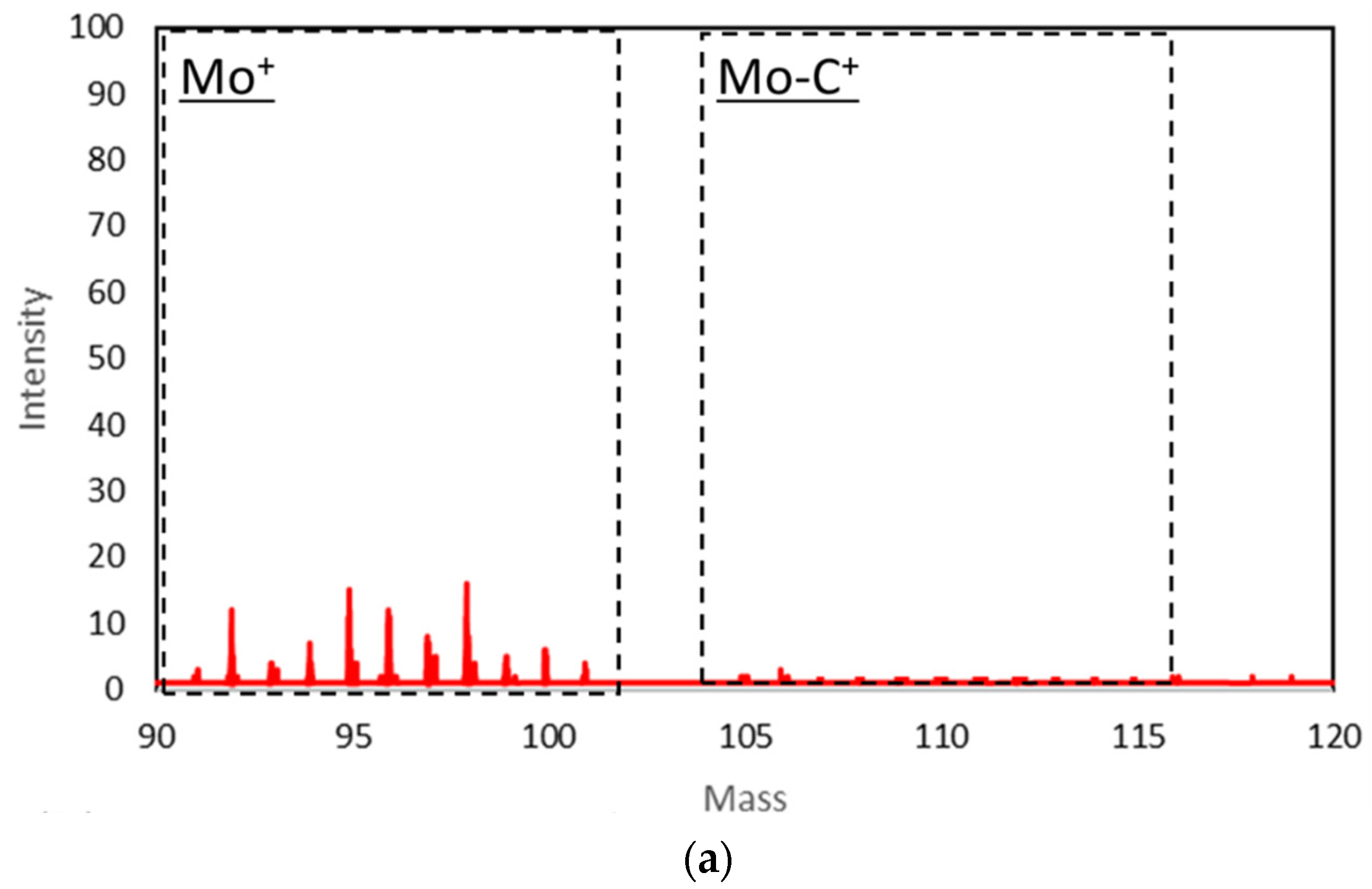

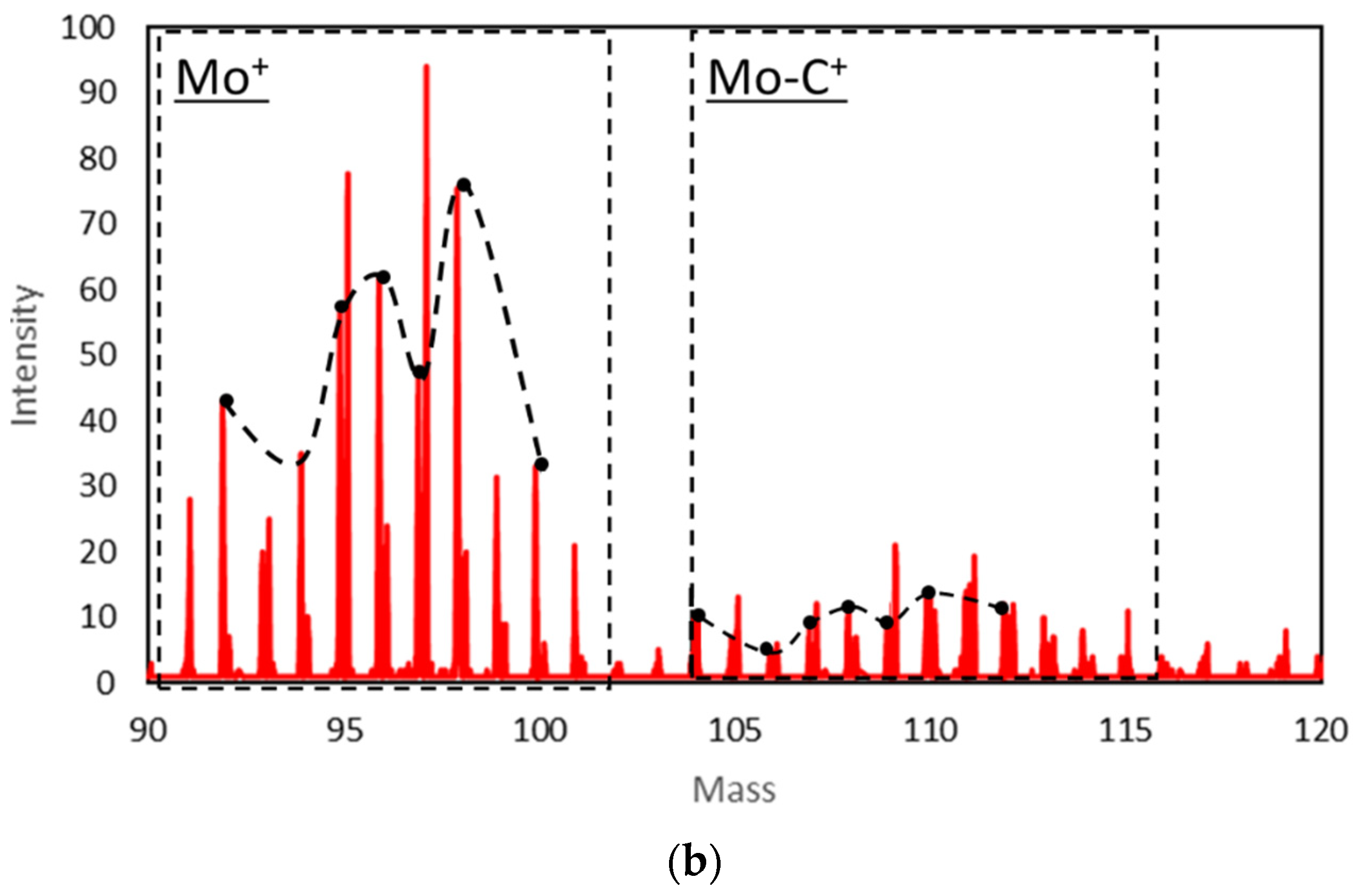

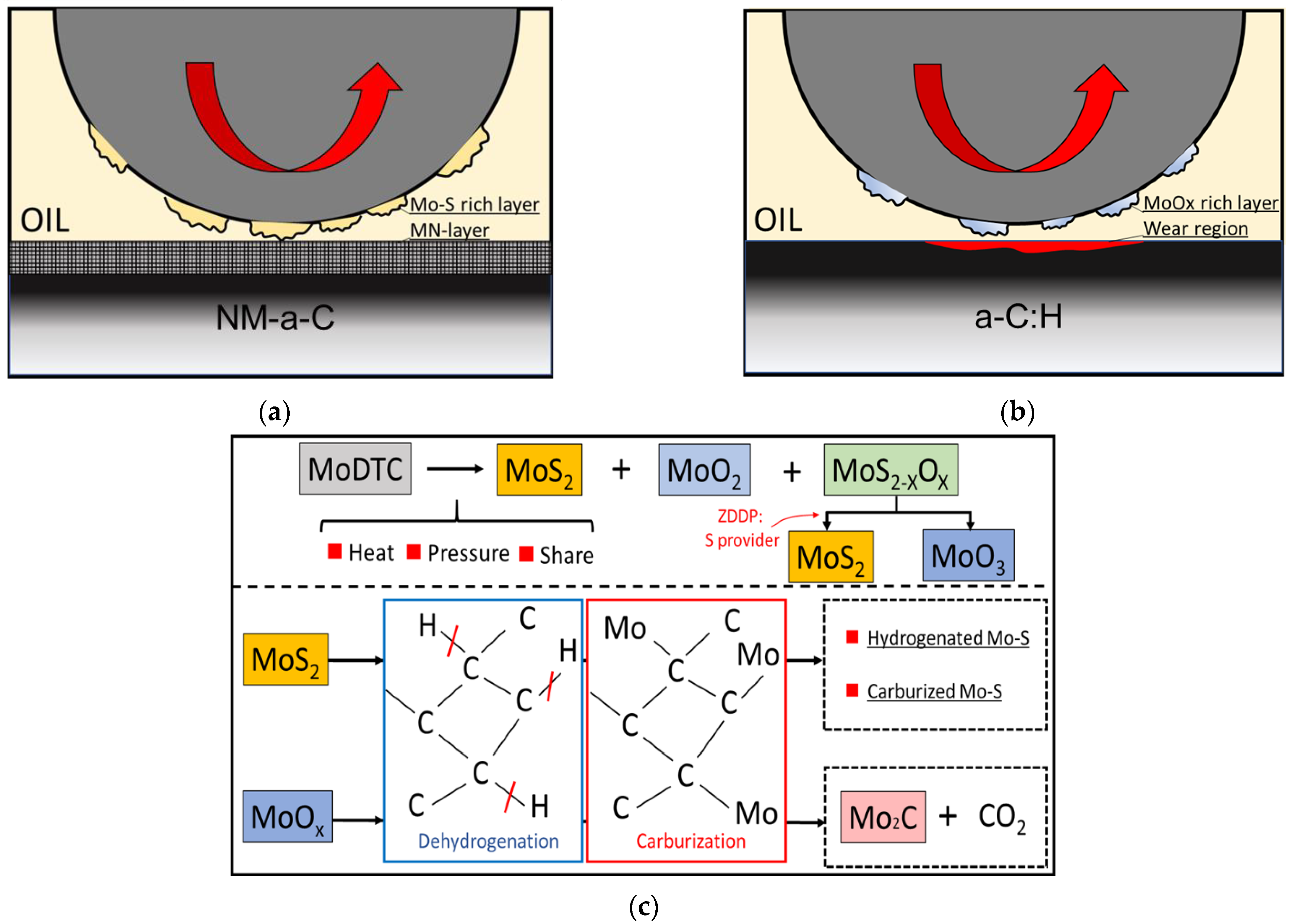

3.5. Lubrication Mechanism of the NM-a-C Film Lubricated with the Fully Formulated Oil

4. Conclusions

- From our SEM, ERDA, and XPS analyses, the NM-a-C film is characterized as non-hydrogenated amorphous carbon, and possesses a nano-mesh-like structured layer at the outermost surface.

- The results of our friction tests indicate that the NM-a-C exhibited lower friction and higher wear resistance than the a-C:H under lubrication with a fully formulated oil containing MoDTC and ZDDP.

- The in situ Raman-SLIM and ToF-SIMS results indicated that thicker MoS2-rich tribofilms form on the counter-face steel surface as opposed to the NM-a-C film. Additionally, the NM-a-C and steel interface inhibited the formation of Mo-carbides, contributing to DLC wear.

- Differences in the tribological properties between the NM-a-C/steel and the a-C:H/steel tribopairs can be explained by the difference between the tribofilms within DLC films, caused by dehydrogenation and carburization between MoDTC decompositions and the DLC surface. The NM-a-C film was observed to be mostly inert to MoDTC-derived Mo-compounds at tribological contacts. Due to the inhibition of the dehydrogenation and carburization processes, tribofilms with low frictional MoS2-rich layers survive and develop at the NM-a-C/steel tribological contacts, resulting in both low friction and high-wear-resistance performance under boundary lubrication regimes.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Holmberg, K.; Erdemier, A. Influence of tribology on global energy consumption, costs and emissions. Friction 2017, 5, 263–284. [Google Scholar] [CrossRef]

- De Barros’Bouchet, M.I.; Martin, J.M.; Le-Mogne, T.; Vacher, B. Boundary lubrication mechanisms of carbon coatings by MoDTC and ZDDP additives. Tribol. Int. 2005, 38, 257–264. [Google Scholar] [CrossRef]

- Haque, T.; Morina, A.; Neville, A.; Kapadia, R.; Arrowsmith, S. Non-ferrous coating/lubricant interactions in tribological contacts: Assessment of tribo-films. Tribol. Int. 2007, 40, 1603–1612. [Google Scholar] [CrossRef]

- Miyake, S.; Saito, T.; Yasuda, Y.; Okamoto, Y.; Kano, M. Improvement of boundary lubrication properties of Diamond-Like Carbon (DLC) films due to metal addition. Tribol. Int. 2004, 37, 751–761. [Google Scholar] [CrossRef]

- Okubo, H.; Sasaki, S.; Lancon, D.; Jarnias, F.; Thiébaut, B. Tribo-Raman-SLIM observation for diamond-like carbon lubricated with fully formulated oils with different wear levels at DLC/steel contacts. Wear 2020, 454–455, 203326. [Google Scholar] [CrossRef]

- Vengudusamy, B.; Green, J.H.; Lamb, G.D.; Spikes, H.A. Behaviour of MoDTC in DLC/DLC and DLC/Steel contacts. Tribol. Int. 2012, 54, 68–76. [Google Scholar] [CrossRef]

- Vengudusamy, B.; Green, J.H.; Lamb, G.D.; Spikes, H.A. Tribological properties of tribofilms formed from ZDDP in DLC/DLC and DLC/steel contacts. Tribol. Int. 2011, 44, 165–174. [Google Scholar] [CrossRef]

- Mabuchi, Y.; Higuchi, T.; Weihnacht, V. Effect of sp2/sp3 Bonding ratio and nitrogen content on friction properties of hydrogen-free DLC coatings. Tribol. Int. 2013, 62, 130–140. [Google Scholar] [CrossRef]

- Aisenberg, S.; Chabot, R. Ion-beam deposition of thin films of diamondlike carbon. J. Appl. Phys. 1971, 42, 2953–2958. [Google Scholar] [CrossRef]

- Moriguchi, H.; Shibata, A.; Watanabe, J. Tribological Properties of New Type DLC Film “Geniuscoat HAM”. Nissin Electr. 2017, 62, 1–6. Available online: https://nippon-itf.co.jp/technology/pdf/NEGIHO.pdf (accessed on 27 April 2021).

- Okubo, H.; Watanabe, S.; Tadokoro, C.; Sasaki, S.; Sumi, T.; Tanaka, N. Wear acceleration mechanism of diamond-like carbon (DLC) films lubricated with MoDTC solution: Roles of tribofilm formation and structural transformation in wear acceleration of DLC films lubricated with MoDTC solution. Tribol. Int. 2019, 133, 271–287. [Google Scholar] [CrossRef]

- Okubo, H.; Yonehara, M.; Sasaki, S. In-situ raman observations of the formation of MoDTC-derived tribofilms at steel/steel contact under boundary lubrication. Tribol. Trans. 2018, 61, 1040–1047. [Google Scholar] [CrossRef]

- Díaz, J.; Paolicelli, G.; Ferrer, S.; Comin, F. Separation of the sp3 and sp2 components in the C 1s photoemission spectra of amorphous carbon films. Phys. Rev. B 1996, 54, 8064. [Google Scholar] [CrossRef]

- Khaemba, D.N.; Neville, A.; Morina, S. New insights on the decomposition mechanism of molybdenum DialkyldiThioCarbamate (MoDTC): A raman spectroscopic study. RSC Adv. 2016, 45, 38637–38646. [Google Scholar] [CrossRef]

- Dieterle, M.; Weinberg, G.; Mestl, G. Raman spectroscopy of molybdenum oxides. Phys. Chem. 2002, 4, 812–821. [Google Scholar] [CrossRef]

- Zhang, L.; Brow, R.K. A Raman study of iron–phosphate crystalline compounds and glasses. J. Am. Ceram. Soc. 2011, 94, 3123–3130. [Google Scholar] [CrossRef]

- Vedeanu, N.; Cozar, O.; Ardelean, I.; Lendl, B. IR and raman investigation of x(CuO·V2O5)(1-x) [P2O5·CaF2] glass system. J. Optoelectron. Adv. Mater. 2006, 8, 78–81. [Google Scholar]

- De Barros’Bouchet, M.I.; Martin, J.M.; Le-Mogne, T.; Vacher, B.; Yamada, Y. Mechanisms of MoS2 formation by MoDTC in presence of ZnDTP: Effect of oxidative degradation. Wear 2005, 258, 1643–1650. [Google Scholar] [CrossRef]

- Morina, A.; Neville, A.; Priest, M.; Green, J.H. ZDDP and MoDTC interactions in boundary lubrication-the effect of temperature and ZDDP/MoDTC ratio. Tribol. Int. 2006, 39, 1545–1557. [Google Scholar] [CrossRef]

- De Feo, M.; De Barros Bouchet, M.I.; Minfray, C.; Esnouf, C.; Le Mognea, T.; Meunier, F.; Yang, L.; Thiebaut, B.; Pavan, S.; Martin, J.M. Formation of interfacial molybdenum carbide for DLC lubricated by MoDTC: Origin of wear mechanism. Wear 2017, 370–371, 17–28. [Google Scholar] [CrossRef]

- Sugioka, M.; Kimura, F. Oxidation and reduction of molybdenum disulfide catalyst and their effects on the decomposition of 2-propanol. Sekiyu Gakkai Shi 1985, 28, 306–311. [Google Scholar] [CrossRef][Green Version]

- Travert, A.; Nakamura, H.; van Santen, R.A.; Cristol, S.; Paul, J.F. Hydrogen activation on mo-based sulfide catalysts, a periodic DFT study. J. Am. Chem. Soc. 2002, 7084–7095, 17–28. [Google Scholar] [CrossRef] [PubMed]

- Kosarieh, S.; Morina, A.; Laine, E.; Flemming, J.; Neville, A. Wear mechanisms of hydrogenated DLC in oils containing MoDTC. Tribol. Int. 2016, 64, 4. [Google Scholar] [CrossRef]

- Xiao, T.-C.; York, A.P.E.; Williams, V.C.; Al-Megren, H.; Hanif, A.; Zhuo, X.-Y.; Green, M.L.H. Preparation of molybdenum carbides using butane and their catalytic performance. Chem. Mater. 2000, 12, 3896–3905. [Google Scholar] [CrossRef]

- Shi, Y.; Zhou, W.; Lu, A.-Y.; Fang, W.; Lee, Y.-H.; Hsu, A.L.; Kim, S.M.; Kim, K.K.; Yang, H.Y.; Li, L.-J.; et al. van der Waals epitaxy of MoS2 layers usingg as growth templates. Nano Lett. 2012, 12, 2784–2791. [Google Scholar] [CrossRef]

| Band | Position [cm−1] | FWHM [cm−1] | Area | sp3/(sp2 + sp3) [%] | |

|---|---|---|---|---|---|

| NM-a-C | sp2 | 284.5 | 1.63 | 47,821 | 48.5 |

| sp3 | 285.3 | 3.11 | 45,089 | ||

| a-C:H | sp2 | 284.5 | 1.38 | 50,248 | 50 |

| sp3 | 285.3 | 2 | 51,199 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Okubo, H.; Watanabe, S.; Sasaki, S.; Tokuta, Y.; Moriguchi, H.; Iba, D.; Moriwaki, I. Tribological Properties of a Mesh-Like Nanostructured Diamond-Like Carbon (DLC) Lubricated with a Fully Formulated Oil at DLC/Steel Contacts under Boundary Lubrication. Coatings 2021, 11, 746. https://doi.org/10.3390/coatings11070746

Okubo H, Watanabe S, Sasaki S, Tokuta Y, Moriguchi H, Iba D, Moriwaki I. Tribological Properties of a Mesh-Like Nanostructured Diamond-Like Carbon (DLC) Lubricated with a Fully Formulated Oil at DLC/Steel Contacts under Boundary Lubrication. Coatings. 2021; 11(7):746. https://doi.org/10.3390/coatings11070746

Chicago/Turabian StyleOkubo, Hikaru, Seiya Watanabe, Shinya Sasaki, Yuuki Tokuta, Hideki Moriguchi, Daisuke Iba, and Ichiro Moriwaki. 2021. "Tribological Properties of a Mesh-Like Nanostructured Diamond-Like Carbon (DLC) Lubricated with a Fully Formulated Oil at DLC/Steel Contacts under Boundary Lubrication" Coatings 11, no. 7: 746. https://doi.org/10.3390/coatings11070746

APA StyleOkubo, H., Watanabe, S., Sasaki, S., Tokuta, Y., Moriguchi, H., Iba, D., & Moriwaki, I. (2021). Tribological Properties of a Mesh-Like Nanostructured Diamond-Like Carbon (DLC) Lubricated with a Fully Formulated Oil at DLC/Steel Contacts under Boundary Lubrication. Coatings, 11(7), 746. https://doi.org/10.3390/coatings11070746