Structure and Characterization of TiC/GLC Multilayered Films with Various Bilayers Periods

Abstract

1. Introduction

2. Experimental Section

2.1. Samples Preparation

2.2. Sample Characterization

2.3. Mechanical and Tribological Properties of the Multilayered Films

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Robertson, J. Diamond-like amorphous carbon. Mater. Sci. Eng. R Rep. 2002, 37, 129–281. [Google Scholar] [CrossRef]

- Erdemir, A.; Donnet, C. Tribology of diamond-like carbon films: Recent progress and future prospects. J. Phys. D Appl. Phys. 2006, 39, R311–R327. [Google Scholar] [CrossRef]

- Liu, X.; Hao, J.; Lv, Y.; Cui, X. The Effects of Precursor C2H2 Fraction on Microstructure and Properties of Amorphous Carbon Composite Films Containing Si and Ag Prepared by Magnetron Sputtering Deposition. Nanomaterials 2019, 9, 528. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Wang, L.; Zhang, G.; Wang, S.C.; Wood, R.J.K.; Xue, Q. Effect of bias voltage on microstructure and properties of Ti-doped graphite-like carbon films synthesized by magnetron sputtering. Surf. Coat. Technol. 2010, 205, 793–800. [Google Scholar] [CrossRef]

- Huang, J.; Wang, L.; Liu, B.; Wan, S.; Xue, Q. In Vitro Evaluation of the Tribological Response of Mo-Doped Graphite-like Carbon Film in Different Biological Media. ACS Appl. Mater. Interfaces 2015, 7, 2772–2783. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Li, H.; Ji, L.; Liu, X.; Wu, Y.; Lv, Y.; Fu, Y.; Zhou, H.; Chen, J. Synthesis and characterization of titanium-containing graphite-like carbon films with low internal stress and superior tribological properties. J. Phys. D Appl. Phys. 2012, 45, 556–563. [Google Scholar] [CrossRef]

- Zhang, S.; Bui, X.L.; Fu, Y. Magnetron-sputtered nc-TiC/a-C(Al) tough nanocomposite coatings. Thin Solid Film. 2004, 467, 261–266. [Google Scholar] [CrossRef]

- Voevodin, A.A.; Zabinski, J.S. Nanocomposite and nanostructured tribological materials for space applications. Compos. Sci. Technol. 2005, 65, 741–748. [Google Scholar] [CrossRef]

- Wang, Y.; Pu, J.; Wang, J.; Li, J.; Chen, J.; Xue, Q. Interlayer design for the graphite-like carbon film with high load-bearing capacity under sliding-friction condition in water. Appl. Surf. Sci. 2014, 311, 816–824. [Google Scholar] [CrossRef]

- Li, L.; Guo, P.; Liu, L.-L.; Li, X.; Ke, P.; Wang, A. Structural design of Cr/GLC films for high tribological performance in artificial seawater: Cr/GLC ratio and multilayer structure. J. Mater. Sci. Technol. 2018, 34, 1273–1280. [Google Scholar] [CrossRef]

- Strondl, C.; Carvalho, N.M.; De Hosson, J.T.M.; van der Kolk, G.J. Investigation on the formation of tungsten carbide in tungsten-containing diamond like carbon coatings. Surf. Coat. Technol. 2003, 162, 288–293. [Google Scholar] [CrossRef]

- Dwivedi, N.; Kumar, S.; Malik, H.K. Nanostructured Titanium/Diamond-Like Carbon Multilayer Films: Deposition, Characterization, and Applications. ACS Appl. Mater. Interfaces 2011, 3, 4268–4278. [Google Scholar] [CrossRef]

- Wang, J.; Pu, J.; Zhang, G.; Wang, L. Interface Architecture for Superthick Carbon-Based Films toward Low Internal Stress and Ultrahigh Load-Bearing Capacity. ACS Appl. Mater. Interfaces 2013, 5, 5015–5024. [Google Scholar] [CrossRef] [PubMed]

- Gong, D.; Xu, F. Study on the microstructure and mechanical properties of graphite like carbon films incorporated with Cu. Diam. Relat. Mater. 2019, 100, 107549. [Google Scholar] [CrossRef]

- Wang, W.; Ji, L.; Li, H.; Liu, X.; Zhou, H.; Chen, J. Influence of rotational speed on structure, mechanical and electrical properties of TiC/GLC composite films. Diam. Relat. Mater. 2019, 92, 65–73. [Google Scholar] [CrossRef]

- Stueber, M.; Albers, U.; Leiste, H.; Ulrich, S.; Holleck, H.; Barna, P.B.; Gee, I. Multifunctional nanolaminated PVD coatings in the system Ti–Al–N–C by combination of metastable fcc phases and nanocomposite microstructures. Surf. Coat. Technol. 2006, 200, 6162–6171. [Google Scholar] [CrossRef]

- Chen, R.; Tu, J.P.; Liu, D.G.; Yu, Y.L.; Qu, S.X.; Gu, C.D. Structural and mechanical properties of TaN/aCNx multilayer films. Surf. Coat. Technol. 2011, 206, 2242–2248. [Google Scholar] [CrossRef]

- Liu, D.G.; Tu, J.P.; Zhang, H.; Chen, R.; Gu, C.D. Microstructure and mechanical properties of carbon nitride multilayer films deposited by DC magnetron sputtering. Surf. Coat. Technol. 2011, 205, 3080–3086. [Google Scholar] [CrossRef]

- Wang, W.; Ji, L.; Li, H.; Zhou, H.; Chen, J. Self-organized formation of nano-multilayer structure in the carbon-copper thin film during reactive magnetron sputtering deposition process. J. Alloys Compd. 2017, 722, 242–249. [Google Scholar] [CrossRef]

- Wu, W.-Y.; Ting, J.-M. Growth and characteristics of metal-containing diamond-like carbon using a self-assembled process. Carbon 2006, 44, 1210–1217. [Google Scholar] [CrossRef]

- Wu, Y.; Li, H.; Ji, L.; Ye, Y.; Chen, J.; Zhou, H. A long-lifetime MoS2/a-C:H nanoscale multilayer film with extremely low internal stress. Surf. Coat. Technol. 2013, 236, 438–443. [Google Scholar] [CrossRef]

- Scandurra, R.; Scotto d’Abusco, A.; Longo, G. A Review of the Effect of a Nanostructured Thin Film Formed by Titanium Carbide and Titanium Oxides Clustered around Carbon in Graphitic Form on Osseointegration. Nanomaterials 2020, 10, 1233. [Google Scholar] [CrossRef]

- Tsai, P.-C.; Hwang, Y.-F.; Chiang, J.-Y.; Chen, W.-J. The effects of deposition parameters on the structure and properties of titanium-containing DLC films synthesized by cathodic arc plasma evaporation. Surf. Coat. Technol. 2008, 202, 5350–5355. [Google Scholar] [CrossRef]

- Sridhar, N.; Rickman, J.M.; Srolovitz, D.J. Multilayer film stability. J. Appl. Phys. 1997, 82, 4852–4859. [Google Scholar] [CrossRef][Green Version]

- Li, F.; Zhang, S.; Kong, J.; Zhang, Y.; Zhang, W. Multilayer DLC coatings via alternating bias during magnetron sputtering. Thin Solid Film. 2011, 519, 4910–4916. [Google Scholar] [CrossRef]

- Choy, K.-L.; Felix, E. Functionally graded diamond-like carbon coatings on metallic substrates. Mater. Sci. Eng. A 2000, 278, 162–169. [Google Scholar] [CrossRef]

- Alawajji, R.A.; Kannarpady, G.K.; Nima, Z.A.; Kelly, N.; Watanabe, F.; Biris, A.S. Electrical properties of multilayer (DLC-TiC) films produced by pulsed laser deposition. Appl. Surf. Sci. 2018, 437, 429–440. [Google Scholar] [CrossRef]

- Rose, F.; Wang, N.; Smith, R.; Xiao, Q.-F.; Inaba, H.; Matsumura, T.; Saito, Y.; Matsumoto, H.; Dai, Q.; Marchon, B.; et al. Complete characterization by Raman spectroscopy of the structural properties of thin hydrogenated diamond-like carbon films exposed to rapid thermal annealing. J. Appl. Phys. 2014, 116, 123516. [Google Scholar] [CrossRef]

- Fogarassy, Z.; Oláh, N.; Cora, I.; Horváth, Z.; Csanádi, T.; Sulyok, A.; Balázsi, K. The structural and mechanical characterization of TiC and TiC/Ti thin films grown by DC magnetron sputtering. J. Eur. Ceram. Soc. 2018, 38, 2886–2892. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, L.; Wang, S.C.; Zhang, G.; Wood, R.; Xue, Q. Nanocomposite Microstructure and Environment Self-Adapted Tribological Properties of Highly Hard Graphite-Like Film. Tribol. Lett. 2010, 40, 301–310. [Google Scholar] [CrossRef]

- Song, H.; Ji, L.; Li, H.; Liu, X.; Wang, W.; Zhou, H.; Chen, J. External-Field-Induced Growth Effect of an a-C:H Film for Manipulating Its Medium-Range Nanostructures and Properties. ACS Appl. Mater. Interfaces 2016, 8, 6639–6645. [Google Scholar] [CrossRef] [PubMed]

- Bai, W.Q.; Li, L.L.; Wang, X.L.; He, F.F.; Liu, D.G.; Jin, G.; Tu, J.P. Effects of Ti content on microstructure, mechanical and tribological properties of Ti-doped amorphous carbon multilayer films. Surf. Coat. Technol. 2015, 266, 70–78. [Google Scholar] [CrossRef]

- Leyland, A.; Matthews, A. On the significance of the H/E ratio in wear control: A nanocomposite coating approach to optimised tribological behaviour. Wear 2000, 246, 1–11. [Google Scholar] [CrossRef]

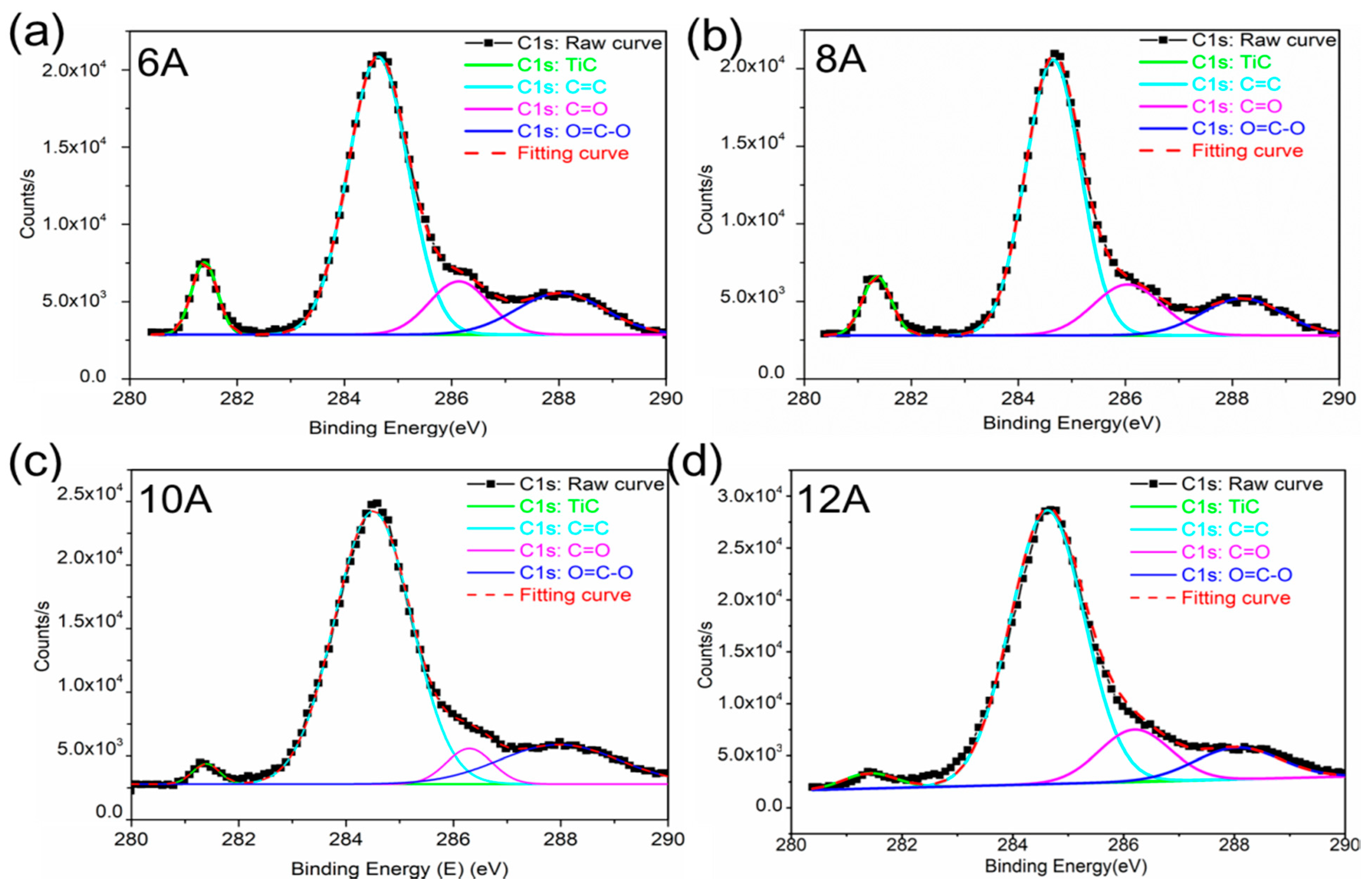

| Sputtering Current of Graphite | 6 A | 8 A | 10 A | 12 A | |

|---|---|---|---|---|---|

| Area ratio | AC=C/A | 0.611 | 0.659 | 0.752 | 0.772 |

| ATi-C/A | 0.078 | 0.061 | 0.038 | 0.023 | |

| Sputtering Current of Graphite | 6 A | 8 A | 10 A | 12 A |

|---|---|---|---|---|

| ID/IG | 1.16 | 4.61 | 4.69 | 4.57 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, W.; Ling, X.; Wang, R.; Nie, W.; Ji, L.; Li, H. Structure and Characterization of TiC/GLC Multilayered Films with Various Bilayers Periods. Coatings 2021, 11, 787. https://doi.org/10.3390/coatings11070787

Wang W, Ling X, Wang R, Nie W, Ji L, Li H. Structure and Characterization of TiC/GLC Multilayered Films with Various Bilayers Periods. Coatings. 2021; 11(7):787. https://doi.org/10.3390/coatings11070787

Chicago/Turabian StyleWang, Weiqi, Xiaoming Ling, Rui Wang, Wenhao Nie, Li Ji, and Hongxuan Li. 2021. "Structure and Characterization of TiC/GLC Multilayered Films with Various Bilayers Periods" Coatings 11, no. 7: 787. https://doi.org/10.3390/coatings11070787

APA StyleWang, W., Ling, X., Wang, R., Nie, W., Ji, L., & Li, H. (2021). Structure and Characterization of TiC/GLC Multilayered Films with Various Bilayers Periods. Coatings, 11(7), 787. https://doi.org/10.3390/coatings11070787